HIGH TEMPERATURE

L

B

C

M

D

A

H

E

4"

Airflow

Direction

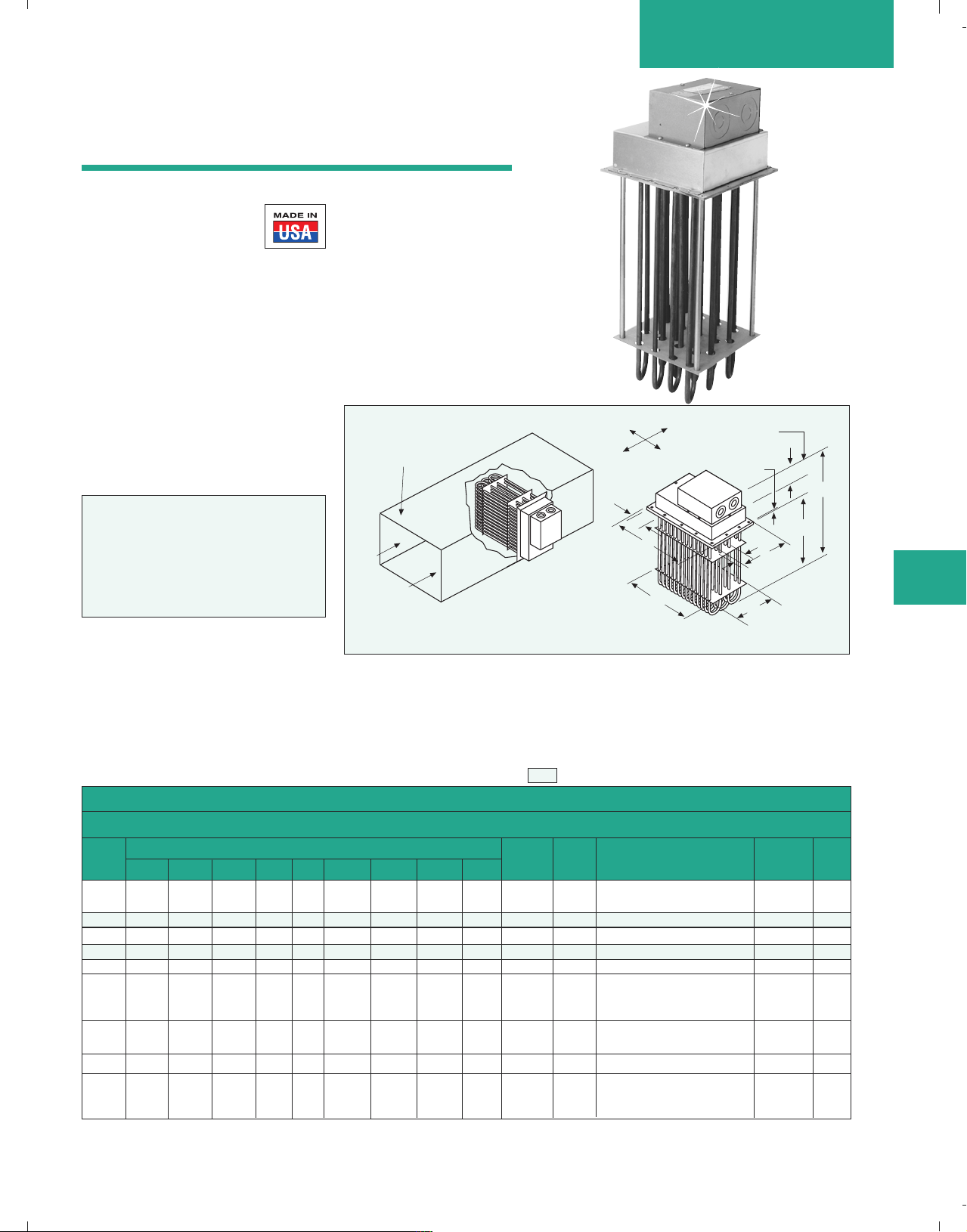

DimensionsTypical Installation

Air

Air

Duct opening is

Hairpin elements

K

III

II

I

IV

AIR DUCT HEATERS

ADH and ADHT Series

Starts at

$

1050

⻬ Series ADH Outlet

Air Temperatures

to 426°C (800°F)

⻬ Series ADHT Outlet

Air Temperatures

to 648°C (1200°F)

⻬ 5 to 270 kW

⻬ 480V, 3 Phase

⻬ 0.475" Dia. Tubular

Elements

APPLICATIONS

Heating air for various drying/

curing operations up to 648°C

(1200°F) air temperature, heat

treating, re-heating or

dehumidification, and other

similar air heating applications.

FEATURES

Rugged construction. Sturdy 0.475"

diameter tubular elements mounted

to a heavy

Terminal housing made of 18 gage

aluminized steel. Element support

plates of 16 gage aluminized steel are

held in place by stainless steel support

rods. High temperature units have the

To Order

1

⁄4 or 3⁄8" thick steel flange.

(Specify Model Number)

ADH-005/480V/3P, $1050

shown smaller than actual size

additional feature of stainless steel

material for the 3" insulation housing

and element support plate—all of which

provides superior rigidity, strength and

reliability.

MOST POPULAR MODELS HIGHLIGHTED!

3-1⁄2"

J

Long life metal sheath tubular

elements—Corrosion/oxidation

resistant sheath. High grade

Incoloy sheath material for excellent

corrosion/oxidation resistance at high

operating temperatures.

ADH-Low-Medium Temperature (30 W/in2)

kW ABCDEHKLMElem. Circ. Model No. Price lbs

100 435⁄8 203⁄8 281⁄4 423⁄8 53⁄8 31⁄2 111⁄8 91⁄2 60 5 ADH-100/480V/3P 6350 175

162 395⁄8 35 427⁄8 383⁄8 47⁄8 31⁄2 111⁄8 91⁄2 54 6 ADH-162/480V/3P 9800 185

216 275⁄8 35 427⁄8 263⁄8 41⁄2 37⁄8 20 183⁄8 72 6 ADH-216F/480V/3P 15,950 240

270 335⁄8 35 427⁄8 323⁄8 51⁄2 37⁄8 20 183⁄8 90 8 ADH-270F/480V/3P 19,200 300

Ordering Example: ADH-035/480V/3P, 21-element, 3-phase, 480V high temperature air duct heater, $3250.

Refer to J-5 for application data.

Dimensions - Inches

555⁄8 201⁄8 281⁄8 4

10 75⁄8 203⁄8 281⁄8 6

15 9

20 115⁄8 203⁄8 281⁄8 101⁄4 23⁄4 31⁄2 111⁄8 91⁄2 12 1 ADH-020/480V/3P 1900 35

25 135⁄8 203⁄8 281⁄8 121⁄4 31⁄4 31⁄2 111⁄8 91⁄2 15 1 ADH-025/480V/3P 2300 40

30 15

35 175⁄8 203⁄8 281⁄4 163⁄8 41⁄4 31⁄2 111⁄8 91⁄2 21 1 ADH-035/480V/3P 3250 65

40 195⁄8 203⁄8 281⁄4 183⁄8 43⁄4 31⁄2 111⁄8 91⁄2 24 2 ADH-040/480V/3P 3700 70

45 215⁄8 203⁄8 281⁄4 203⁄8 51⁄4 31⁄2 111⁄8 91⁄2 27 2 ADH-045/480V/3P 4158 80

50 235⁄8 203⁄8 281⁄4 203⁄8 53⁄4 31⁄2 111⁄8 91⁄2 30 2 ADH-050/480V/3P 4550 90

60 275⁄8 203⁄8 281⁄4 263⁄8 41⁄2 31⁄2 111⁄8 91⁄2 36 2 ADH-060/480V/3P 5100 105

5

⁄8 203⁄8 281⁄8 8

5

⁄8 203⁄8 281⁄4 143⁄8 33⁄4 31⁄2 111⁄8 91⁄2 18 1 ADH-030/480V/3P 2750 55

1

⁄4 21⁄2 31⁄2 111⁄8 91⁄2 31ADH-005/480V/3P $1050 8

1

⁄4 31⁄2 31⁄2 111⁄8 91⁄2 61ADH-010/480V/3P 1250 15

1

⁄4 33

1

⁄2 111⁄8 91⁄2 91ADH-015/480V/3P 1450 25

No. No. Wt.

J-3

L

B

C

M

D

A

H

E

4"

3-1/2"

3-5/8"

Airflow

Direction

DimensionsTypical Installation

Air

Air

Sheet Metal

Duct

Thermocouple

Terminal Box

Insulated

Standoff

Collar

Insulation

(3" max.)

K

III

II

I

IV

Low watt density resistor wire. Watt

density on the heating coil is designed

for low watt density operation by

increasing the coil diameter, gage

and length of resistance wire to give

maximum surface area and low

operating coil surface temperature—

providing longer coil life.

Easy element replacement. Individual

elements are mechanically fastened to

the flange permitting convenient, easy

replacement.

Low wiring compartment

temperatures. Made possible by the

addition of a one-inch thick blanket of

insulation in the terminal box—allows

use of low temperature field wiring

instead of expensive high temperature

busbars and wire. High temperature

units include additional three inches

of insulation to help reduce duct heat

losses.

Easy access to simplified field

wiring terminals. Terminal housing

is completely removable for maximum

access to field wiring terminals.

Individual terminal blocks with threaded

stud type terminals are provided for

each circuit to permit quick positive

attachment of circuit wiring conductors.

Dirt/dust resistant terminal housing.

Terminal housing made of solid heavy

gauge aluminized steel rather than

perforated metal to resist dirt and

dust accumulation on the electrical

connections and thus provide longer

service life.

Flange mounting gasket. Packed

separately with each duct heater to

ADHT-005/480V/3P, $1463

shown smaller than actual size

minimize leakage between the

flange and air duct.

MOST POPULAR MODELS HIGHLIGHTED!

To Order

ADHT-High Temperature (20 W/in2)

kW ABCDEHKLMElem. Circ. Model No. Price lbs

555⁄8 201⁄8 281⁄8 4

10 75⁄8 203⁄8 281⁄8 6

15 95⁄8 203⁄8 281⁄8 8

20 115⁄8 203⁄8 281⁄8 101⁄4 23⁄4 31⁄2 111⁄8 91⁄2 12 1 ADHT-020/480V/3P 2350 40

25 135⁄8 203⁄8 281⁄8 121⁄4 31⁄4 31⁄2 111⁄8 91⁄2 15 1 ADHT-025/480V/3P 2650 50

30 155⁄8 203⁄8 281⁄4 143⁄8 33⁄4 31⁄2 111⁄8 91⁄2 18 1 ADHT-030/480V/3P 3150 65

35 175⁄8 203⁄8 281⁄4 163⁄8 41⁄4 31⁄2 111⁄8 91⁄2 21 1 ADHT-035/480V/3P 3800 80

40 195⁄8 203⁄8 281⁄4 183⁄8 43⁄4 31⁄2 111⁄8 91⁄2 24 2 ADHT-040/480V/3P 4300 90

45 215⁄8 203⁄8 281⁄4 203⁄8 51⁄4 31⁄2 111⁄8 91⁄2 27 2 ADHT-045/480V/3P 4850 100

50 235⁄8 203⁄8 281⁄4 223⁄8 53⁄4 31⁄2 111⁄8 91⁄2 30 2 ADHT-050/480V/3P 5300 110

60 275⁄8 203⁄8 281⁄4 263⁄8 41⁄2 31⁄2 111⁄8 91⁄2 36 2 ADHT-060/480V/3P 5900 130

80 355⁄8 203⁄8 281⁄4 343⁄8 43⁄8 31⁄2 111⁄8 91⁄2 48 4 ADHT-080/480V/3P 6700 175

90 395⁄8 203⁄8 281⁄4 383⁄8 47⁄8 31⁄2 111⁄8 91⁄2 54 5 ADHT-090/480V/3P 7050 200

100 435⁄8 203⁄8 281⁄4 423⁄8 53⁄8 31⁄2 111⁄8 91⁄2 60 5 ADHT-100/480V/3P 7400 220

120 275⁄8 35 427⁄8 263⁄8 41⁄2 31⁄2 111⁄8 91⁄2 36 4 ADHT-120/480V/3P 9350 205

160 355⁄8 35 427⁄8 343⁄8 43⁄8 31⁄2 111⁄8 91⁄2 48 8 ADHT-160/480V/3P 11250 270

180 395⁄8 35 427⁄8 383⁄8 47⁄8 31⁄2 111⁄8 91⁄2 54 6 ADHT-180/480V/3P 12300 305

240 275⁄8 35 427⁄8 263⁄8 41⁄2 37⁄8 20 183⁄8 72 8 ADHT-240F/480V/3P 20000 400

Ordering Example: ADHT-020/480V/3P is a 12-element, 3-phase, 480V high temperature air duct heater, $2350.

Refer to J-5 for application data. All ADHT models come with K type overtemp thermocouple.

(Specify Model Number)

Dimensions - Inches

1

⁄4 21⁄2 31⁄2 111⁄8 91⁄2 31ADHT-005/480V/3P $1650 10

1

⁄4 31⁄2 31⁄2 111⁄8 91⁄2 61ADHT-010/480V/3P 1800 20

1

⁄4 33

No. No. Wt.

1

⁄2 111⁄8 91⁄2 91ADHT-015/480V/3P 1950 30

J-4

HIGH TEMPERATURE

170

150

130

110

90

70

50

30

10

0

KILOWATTS

HUNDRED CUBIC FEET OF AIR PER MINUTE

1 3 5 7 9 11

Heat Requirements for Air

Based on .08 lbs./cu. ft. Weight

and a specific Heat of .237 Btu./lb./°F

600°F RISE

550°F RISE

500°F RISE

450°F RISE

400°F RISE

350°F RISE

300°F RISE

250°F RISE

200°F RISE

150°F RISE

100°F RISE

75°F RISE

50°F RISE

AIR DUCT HEATERS

APPLICATION GUIDE

Selecting heater size. Refer to

Technical Section for examples on

determining kW requirements. For quick

estimating purposes, the following

formula may be used for standard

conditions (includes 1.2 safety factor):

kW = CFM x temp. diff/2500

Maximum work temperature. Types

ADH and ADHT process air heaters

can generally be used at the following

maximum temperature shown, provided

the minimum air velocity is maintained

uniformly through the heater:

Air Velocity

(ft/sec) ADH ADHT

4 800 1050

9 800 1100

16 800 1150

25 800 1200

36 800 1200

Application assistance. OMEGALUX

sales/application engineers are

available to assist you in the design

or selection of equipment.

Max. Outlet Air Temp. °F

Additional protection can be achieved

by installing an air flow or pressure

differential switch to protect the heater

against low air flow conditions.

Operation controls. Selection of

these controls, thermostat, SCR units,

contactors etc., depends on the degree

of accuracy required, reliability,

electrical rating of heater and economic

considerations. (Refer to Control

Section—P).

Field power & control circuit wiring.

Must be capable of carrying the

electrical load and be protected by

overcurrent protective devices, such

as fusing, circuit breakers or ground

fault detection in accordance with the

requirements of the NEC and local

codes as applicable.

Tandem mounting. Multiple heaters

may be mounted in tandem with

each other provided the maximum

recommended outlet air temperature

is not exceeded.

OPTIONS AVAILABLE

Gas tight design. Achieved by the

use of threaded compression fittings

with fiber washers to attach heating

elements to flange—prevents leakage

of ducted air into terminal housing.

Overtemperature protection.

Thermocouple welded to the element

sheath surface and wired to a terminal

block can be provided for accurate

overheat protection. Standard on high

temperature units.

Moisture or explosion-resistant

terminal housings are available for

those applications requiring special

terminal protection.

J

INSTALLATION

MOUNTING TIPS

Low temperature duct heaters can be

fastened directly to the sheet metal duct

work with bolts or sheet metal screws.

High temperature duct heaters are

generally mounted to a field fabricated

stand off collar from the ductwork to

position the heater such that the 3"

insulation housing is in the same plane

as the duct insulation.

All heaters can be mounted in any

position; top, side or bottom (preferred)

entry. Minimum duct size is A or L

dimension plus

5

plus 1

⁄8".

Provide adequate heater support.

Consideration should be given to

installing hangers or some other means

of heater support whenever there is

any question about the ability of the

ductwork to support the heater weight.

Overtemperature protection.

All heaters should include an

overtemperature (overheat) control

whose temperature sensing element

is located on the air discharge side of

the heater as close to the heater as is

practical. High temperature ADHT units

include an overtemperature (Type K)

thermocouple as standard.

3

⁄8" and B dimension

J-5

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...