Page 1

8

1.5

8

1.5

15

1.0

8

1.5

15

1.0

25

1.5

8

1.5

15

1.0

25

1.5

25

1.0

8

1.5

15

1.0

25

1.5

25

1.0

30

2.6

8

1.5

15

1.0

25

1.5

25

1.0

30

2.6

15

1.5

8

1.5

15

1.0

25

1.5

25

1.0

30

2.6

30

4.5

15

1.5

8

1.5

15

1.0

25

1.5

25

1.0

30

2.6

30

4.5

15

1.5

25

1.5

8

1.5

15

1.0

25

1.5

25

1.0

30

2.6

30

4.5

15

1.5

25

1.5

25

1.7

8

1.5

15

1.0

25

1.5

25

1.0

30

2.6

30

4.5

15

1.5

25

1.5

30

4.5

25

1.7

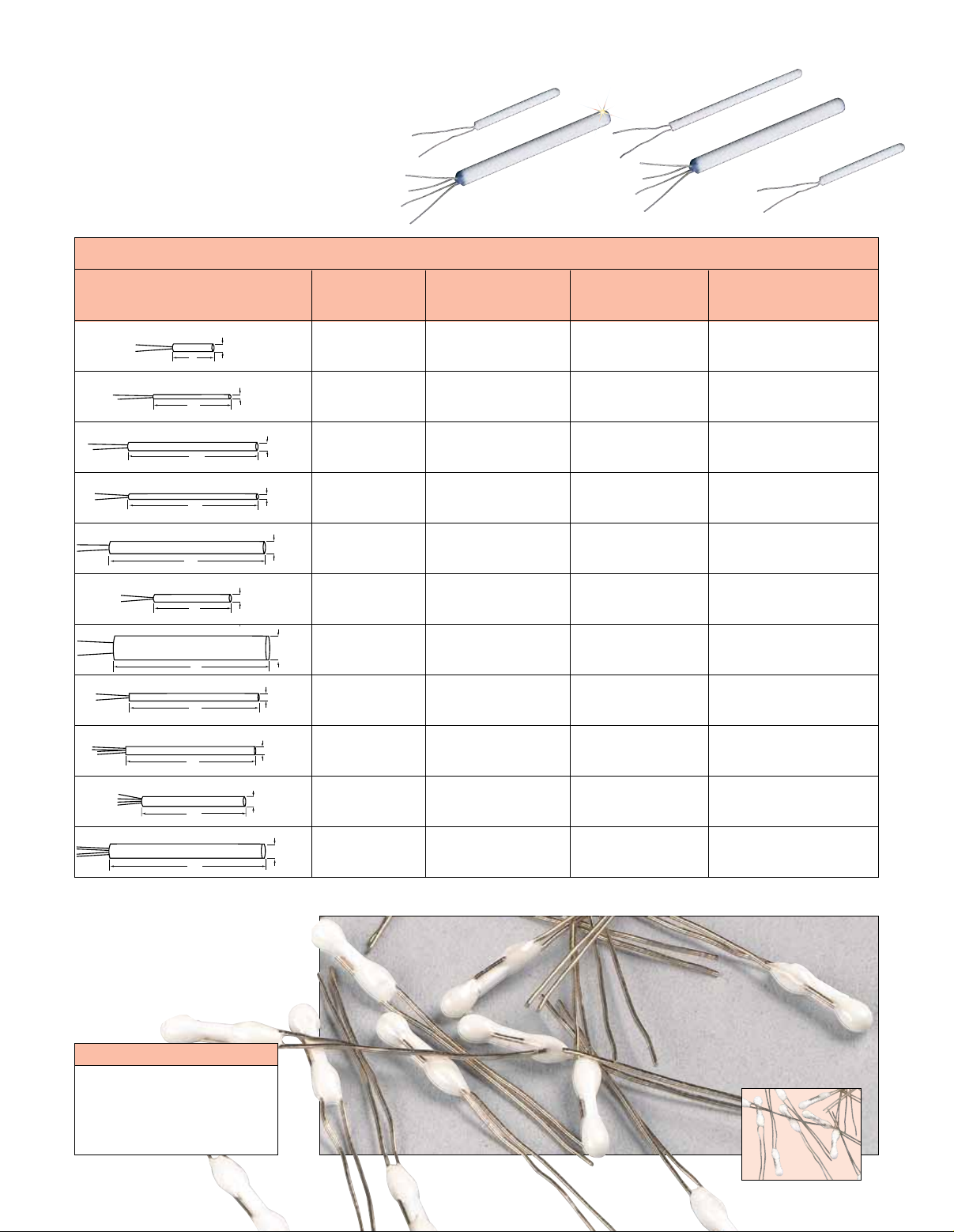

Ceramic Wire-Wound Platinum

RTD Elements

“KN” Series

To Order Visit omega.com/1pt100k_rtd_elements for Pricing and Details

Nominal Self-Heating Error in

Dimensions in millimeters Resistance Temperature °C/mW Flowing Air

(1 mm = 0.03937") (ohms) Range, °C (°F) Model No. V = 1m/sec

1 x 100

1.5

8

1 x 100

15

1.0

1 x 100

25

1.5

1 x 100

25

1.0

1 x 100

30

2.6

1 x 100

15

1.5

1 x 100

30

1 x 100

25

4.5

1.5

2 x 100

25

1.7

2 x 100

2 x 100

Dual elements. All RTD elements come standard with 10 mm bare leads. Welded insulated extension leads available.

*

Pricing is dependent on lead style; see page C-110.

Ordering Examples: 1PT100KN815,

1 x 100 Ω self-heating error

of 0.28 ceramic wire-wound

platinum RTD elements.

1PT100KN1515, 100 Ω, 1.5 D x 15 mm L,

ceramic wire wound RTD.

1 to 4 units ........................Net

5 to 10 units ...................... 4%

11 to 24 units .................... 6%

25 to 49 units .................. 10%

50 to 99 units .................. 11%

100 units and up ............. 13%

Discount Schedule

30

30

4.5

2.6

-200 to 600

(-330 to 1110)

-200 to 600

(-330 to 1110)

-200 to 850

(-330 to 1560)

-200 to 600

(-330 to 1110)

-200 to 600

(-330 to 1110)

-200 to 600

(-330 to 1110)

-200 to 600

(-330 to 1110)

-200 to 600

(-330 to 1110)

-200 to 850

(-330 to 1560)

-200 to 600

(-330 to 1110)

-200 to 600

(-330 to 1110)

C-127

1PT100KN815 0.28

1PT100KN1510 0.14

1PT100K2515 0.08

1PT100KN2510 0.07

1PT100KN3026 0.04

1PT100KN1515 0.08

1PT100KN3045 0.01

1PT100KN2515 0.07

*2PT100K2517 0.06

*2PT100KN3045 0.01

*2PT100KN3026 0.04

H2104, shown

larger than actual

size.

Actual size.

Page 2

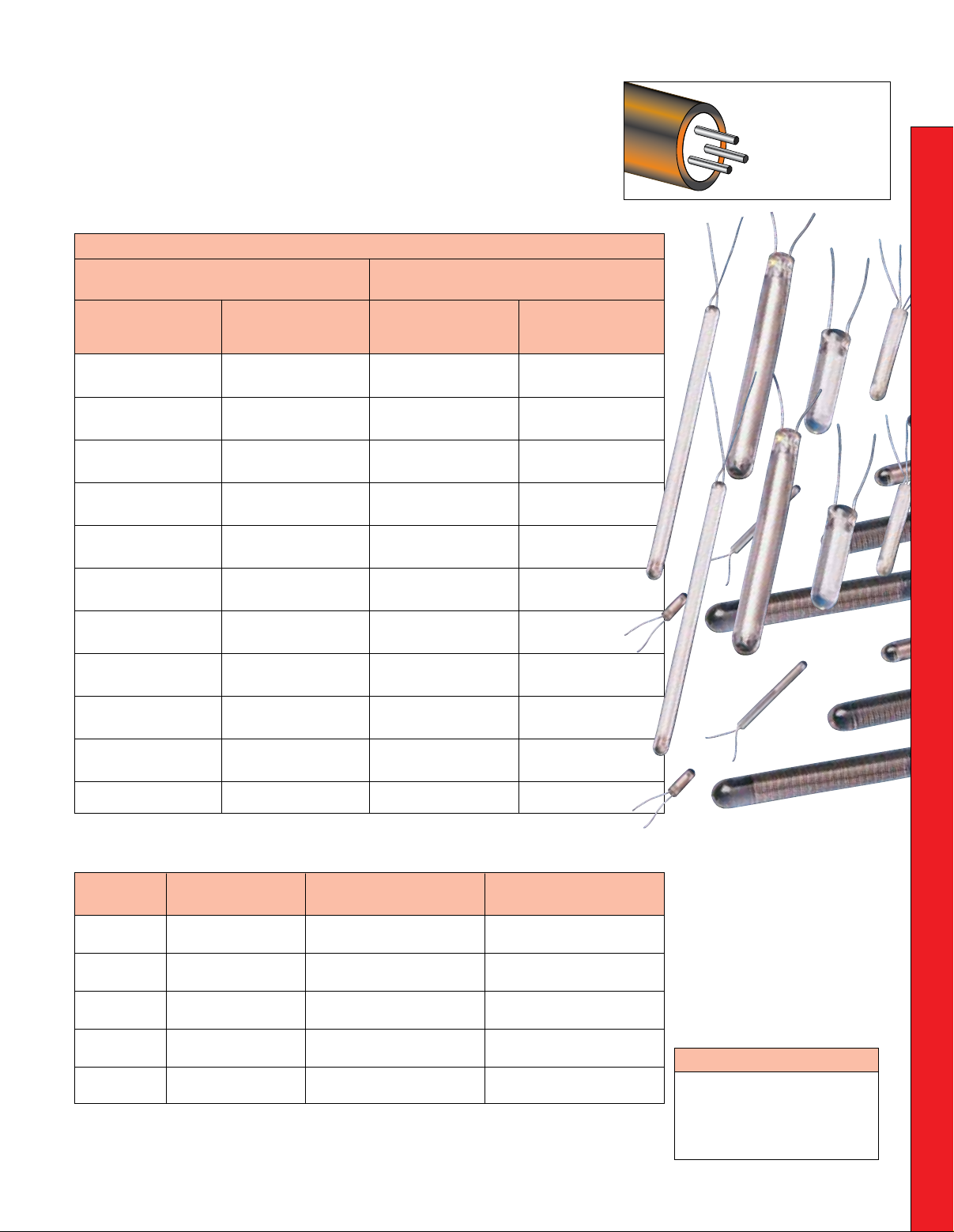

Class B Tolerance (Per IEC751)

Alpha = 0.00385

Ceramic wire-wound platinum RTD

elements are made by placing a

coiled platinum wire into a ceramic

core and sealing the ends off

with glass. They are suitable for

extremely low or high temperatures

Response Time in Seconds

Flowing Water Moving Air

V = 0.4 m/sec V = 1 m/sec

50% 90% 50% 90%

Response Response Response Response

0.2 0.5 6.7 21.8

0.2 0.3 3.0 9

0.2 0.4 5.7 17

0.2 0.4 3.0 8.8

and are tolerant of thermal shocks.

They offer limited vibration

resistance (depending on

mounting method) and should be

used in dry environments only.

Available!

OMEGA’s RTD MI Cable!

Available in a wide

selection of conductor

configurations and sheath

materials. Please visit

omega.com/316-rtd_clad

C

0.3 0.6 10.5 34.0

0.2 0.4 5.0 15.7

0.40 1.4 26.0 90.0

0.2 0.4 5.3 16.0

0.2 0.4 6.1 19.0

0.4 1.4 26.8 83.7

0.30 0.6 11 36.0

RTD Elements for Tight Spaces

Model Temperature Nominal Resistance

Number Range (Ω) Dimensions

A2102* -50 to 400°C 1 x 100 4 L x 5 W x 2 mm D

(-60 to 750°F) (0.16 x 0.20 x 0.08")

A2105* -50 to 400°C 1 x 100 2 L x 2.4 W x 2 mm D

(-60 to 750°F) (0.08 x 0.09 x 0.08")

A2132* -50 to 400°C 1 x 500 4 L x 5 W x 2 mm D

(-60 to 750°F) (0.16 x 0.20 x 0.08")

A2142* -50 to 400°C 1 x 1000 4 L x 5 W x 2 mm D

(-60 to 750°F) (0.16 x 0.20 x 0.08")

H2104 -50 to 600°C 1 x 100 1.5 Dia. x 4 mm L

(-60 to 1110°F) (0.06 x 0.20")

These elements have leads perpendicular to the body for surface measurements.

*

Curve is European } = 0.00385. All RTD elements available with welded PTFE insulated extension

Ordering Examples: A2102, 1 x 100 Ω, 4 mm L RTD elements.

A2142, 1000 Ω, 4 x 5 mm RTD element.

Enlarged to show construction.

See previous page for dimensions.

Discount Schedule

1 to 4 units ............Net

5 to 10 units ...........4%

11 to 24 units ..........6%

25 to 49 units .........10%

50 to 99 units .........11%

100 units and up ......13%

C-128

Loading...

Loading...