Page 1

T

-260L

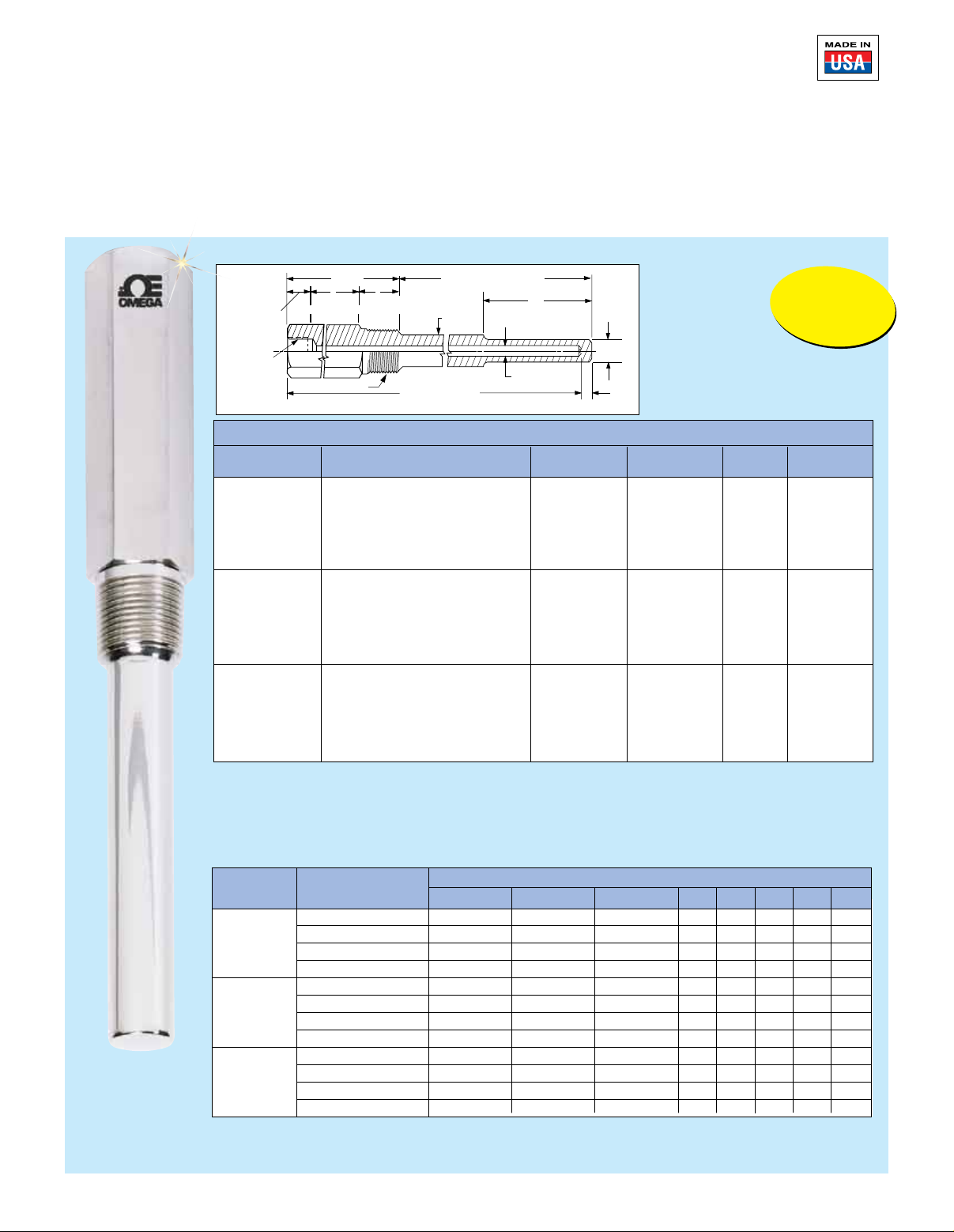

Series 260L Standard Threaded Well for

Application:

Standard length, 1⁄4" stem, bimetal thermometers;

#20-gage thermocouple elements; unarmored

liquid-in-glass test thermometers. Other temperaturesensing elements having 0.252" maximum diameter.

Connection Size:

1

⁄2, 3⁄4 and 1 NPT are standard. Other thread sizes are

available upon request.

Materials:

Brass (ASTM B-16), Carbon Steel (C-1018), Stainless

Steel A.I.S.I. 304 & A.I.S.I. 316, Monel®. Wells are also

available in special materials; prices on request.

Cap and Chain Options:

For Brass cap, add suffix “-CC-Brass” to the end of the

model number when ordering for additional cost.

For 304 SS cap, add suffix “-CC” to the end of the model

number for additional cost.

1

⁄4" Diameter Elements

Series 260L—Lagging Extension Type

†

NPSM internal

pipe thread

will accept

both NPT and

NPS male threads.

DIA.

1

/

4

Metric Models

Available!

Visit omega.com

3

/

4

WRENCH

ALLOWANCE

1

/

NPSM

2

†

T + 1

T

LAGGING

EXTENSION

P NPT

3

/

4

1

THREAD

ALLOWANCE

Dimensions: inches

U INSERTION LENGTH

Q DIA.

A STEM LENGTH

1

/

2

2

0.002

0.260 BORE

1

/

2

To Order Visit omega.com/series_260l for Pricing and Details

Ext Stem Insert Lag Shank

Thread P Model Number Length A Length U Ext T Dia. Q

1⁄2 NPT 1/2-260L-U21/2-(*) 6 21⁄2 2 —

1/2-260L-U41/2-(*) 9 41⁄2 3 5⁄8

1/2-260L-U71/2-(*) 12 71⁄2 3 5⁄8

1/2-260L-U101/2-(*) 15 101⁄2 3 5⁄8

1/2-260L-U131/2-(*) 18 131⁄2 3 5⁄8

1/2-260L-U191/2- (*) 24 191⁄2 3 5⁄8

3⁄4 NPT 3/4-260L-U21/2-(*) 6 21⁄2 2 —

3/4-260L-U41/2-(*) 9 41⁄2 3 3⁄4

3/4-260L-U71/2- (*) 12 71⁄2 3 3⁄4

3/4-260L-U101/2-(*) 15 101⁄2 3 3⁄4

3/4-260L-U131/2-(*) 18 131⁄2 3 3⁄4

3/4-260L-U191/2- (*) 24 191⁄2 3 3⁄4

1 NPT 1-260L-U21/2-(*) 6 21⁄2 2 —

1-260L-U41/2-(*) 9 41⁄2 3 7⁄8

1-260L-U71/2- (*) 12 71⁄2 3 7⁄8

1-260L-U101/2-(*) 15 101⁄2 3 7⁄8

1-260L-U131/2-(*) 18 131⁄2 3 7⁄8

1-260L-U191/2-(*) 24 191⁄2 3 7⁄8

* Specify material type “304SS” for 304 stainless steel, “316SS” for 316 stainless steel, “CS” for carbon steel or

“BRASS” for brass. PFA coating available.

Ordering Example: 3/4-260L-U71/2-304SS, 304 stainless steel thermowell with

0.260" internal Dia., 3" lagging extension, 71⁄2" insertion length and a 12" stem length.

For Assistance in Choosing Head and Well Assemblies, visit omega.com/head_and_well

3

⁄4 NPT external thread,

Shown close

to actual size.

Visit omega.com

for pressuretemperature

ratings.

Maximum Fluid Velocity—Feet Per Second

Insertion Length – “U”

Well Type Material 21⁄2 41⁄2 71⁄2 101⁄2 131⁄2 161⁄2 191⁄2 221⁄2

1

⁄2

" - 260S

1

⁄2

" - 260L

Monel 261 (118) 95 (65.5) 34.4 17.5 10.5 7.1 5.2 3.8

3

⁄4

" - 260S

3

⁄4

" - 260L

Monel 261 (118) 112 (79.8) 40.6 20.7 12.4 8.3 6.1 4.5

1" - 260S

1" - 260L

Monel 261 (118) 128 (93.3) 46.7 23.7 14.4 9.5 6.9 5.1

Where single values appear in the velocity tables, these may be considered safe for water, steam, air or gas. In the

shorter insertion lengths, consideration is given to the velocity pressure effect of water flowing at higher velocities. The

values in parentheses, therefore, represent safe values for water flow, while the unbracketed values may be used for

steam, air, gas and similar density fluids.

Brass 207 (59.3) 75.5 (32.2) 27.3 (19.7) 13.9 8.4 5.6 4.1 3.0

Carbon steel 290 (106) 105 (59) 38.2 (36.3) 19.4 11.8 7.8 5.7 4.2

and

A.I.S.I. 304 and 316 300 (148) 109 (82.2) 39.5 20.1 12.2 8.1 5.9 4.4

Brass 207 (59.3) 89.1 (39.8) 32.2 (23.9) 16.4 9.9 6.6 4.8 3.6

Carbon steel 290 (106) 123 (71.2) 44.9 (42.7) 22.8 13.8 9.3 6.7 4.9

and

A.I.S.I. 304 and 316 300 (148) 128 (99.3) 46.4 23.6 14.3 9.6 6.9 5.1

Brass 207 (59.3) 102 (47.6) 37.0 (28) 18.8 11.4 7.6 5.5 4.1

Carbon steel 290 (106) 143 (84.3) 51.6 (50.6) 26.2 15.9 10.6 7.6 5.7

and

A.I.S.I. 304 and 316 300 (148) 148 (117) 53.5 27.2 16.5 11.0 7.9 5.9

B-19

Loading...

Loading...