Page 1

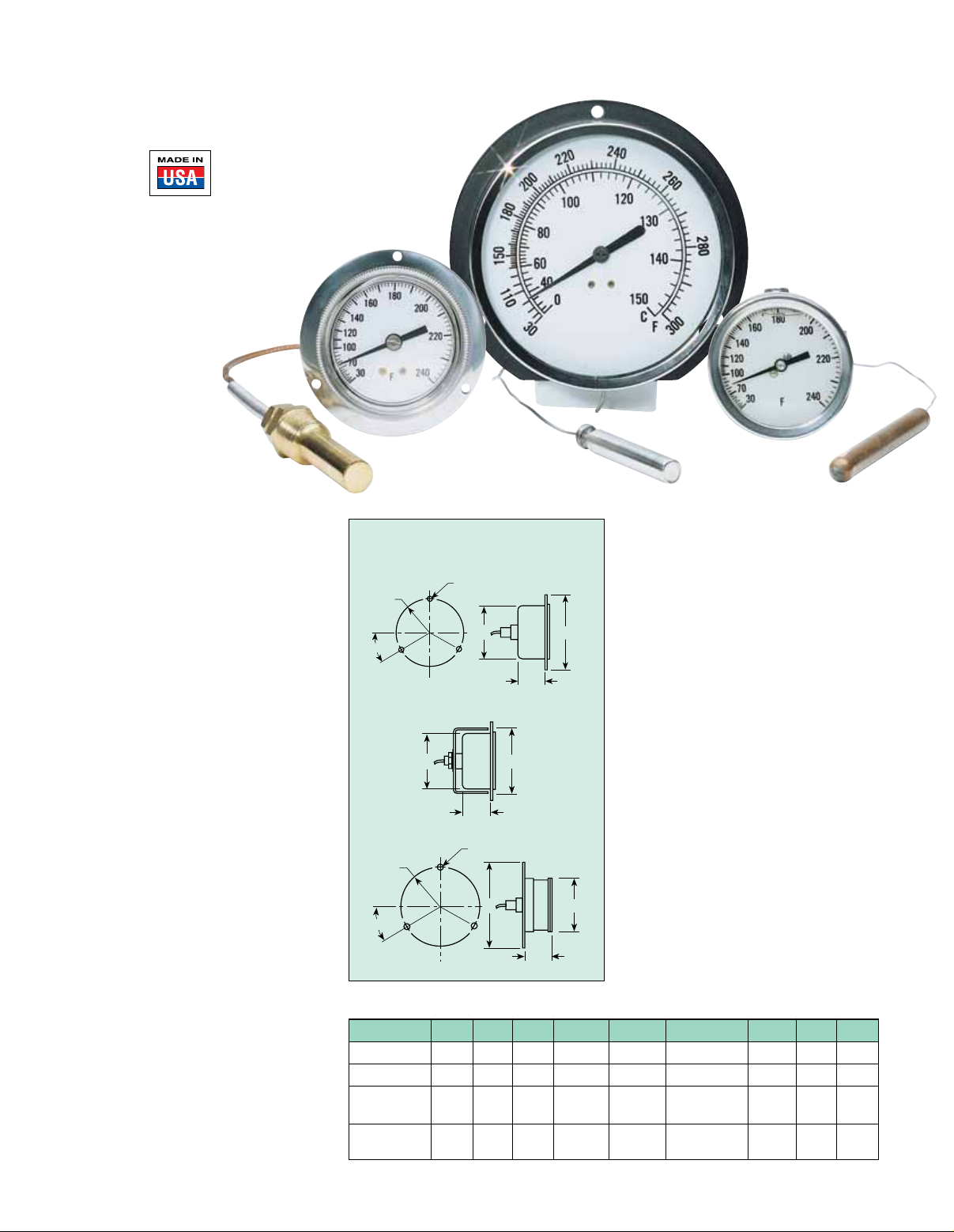

Vapor- and Gas-Actuated

T-VA/Line Dwg

CH

F

G

I

30ϒ

EA

EB

F

REAR FLANGE

CASE AND MOUNTING DIMENSIONS

U-CLAMP

CH

T-VA/Line Dwg

CH

F

G

I

30ϒ

CASE AND MOUNTING DIMENSIONS

Thermometers

U Accuracy ±1 Scale

Division or 1% Scale

for Gas

U Brass Movement with

Precision Gearing

U White Dial

with Black

Graduations

U Phosphor

Bronze

Bourdon Tube

OMEGA

®

remote vapor- and

gas-actuated thermometers are

manufactured to the highest standards

for a wide range of uses and can be

fitted into almost any temperatureindicating application. These

instruments are ideal for remote

reading, such as panel installations,

with capillary lengths of 1 to 100'.

Vapor, or more precisely vaporized

liquid, thermometers will give

excellent readings, provided the

temperature being measured is

above or below ambient temperature.

Vapor instruments also have

progressive graduations and are

best read in the upper 2⁄3 of the dial

range. Many ranges are available

between -40 to 232°C (-40 to 450°F),

and care should be taken to select

a range that will locate the operating

temperatures within the upper 2⁄3 of

the dial range.

OMEGA® gas-actuated thermometers

combine advanced gas coil technology

with a state-of-the-art gas absorbent

(Class IV) thermal system, producing

a superior temperature measurement

instrument that can be fitted to a wide

variety of applications. Gas-actuated

thermometers have an advantage

over vapor-actuated thermometers

in that they are more accurate over the

full range. They also operate at higher

and lower ranges than vapor-actuated

thermometers.

The linear dial on all OMEGA® gas

thermometers provides a consistent

1% accuracy across the full span of

each range. This, combined with

over 20 Fahrenheit and dual ranges,

from -196 to 649°C (-320 to 1200°F),

provides complete coverage of all

normal temperature requirements.

CASE AND MOUNTING DIMENSIONS

FRONT FLANGE

D

30ϒ

G

30ϒ

Dial Size A B C D E F G H I

2" 2.94 2.25 — 1.28R 2.05 0.98 — — 0.14

1

⁄2" 3.69 2.81 — 1.56R 2.56 1.0 — — 0.17

2

1

⁄2" 4.75 3.97 4.75 2.16R 3.59 1.41RF 2.16R 3.69 0.16

3

0.75 UC, FF

1

⁄2" 5.88 — 5.88 2.69R 4.59FF 1.41RF 2.69R 4.69 0.22

4

4.87RF 0.75 UC, FF

U-CLAMP

EB

REAR FLANGE

I

F

I

E-17

F

F

Specifications

Dial Sizes: 2, 21⁄2, 31⁄2, 41⁄2"

Dial: Aluminum with white finish and

black markings

Pointer: Furnished standard adjustable

Movement:

Brass with precision gearing

Bourdon Tube:

Vapor-phosphor bronze

Gas: Nitrogen in nispan coil

Accuracy:

Vapor: ±1 scale division

Gas: ±1% of scale

Process Connection: Plain bulb,

1

⁄2 NPT union; or thermowell

Note: thermowells must be used

whenever the bulb would be

exposed to pressure, fluid velocity,

or corrosive media

Window: Polycarbonate STD;

glass available on all models

Bulb: Stainless steel or copper;

bulb OD

threads. Bulb lengths from 2

7

7

Capillary: Copper, copper with bronze

braid armor; stainless steel with stainless

steel armor; capillary lengths 1 to 100'

(standard length, 5')

3

⁄8" on plain bulbs, 7⁄16" with

⁄8" depending on capillary length

1

⁄2 to

Page 2

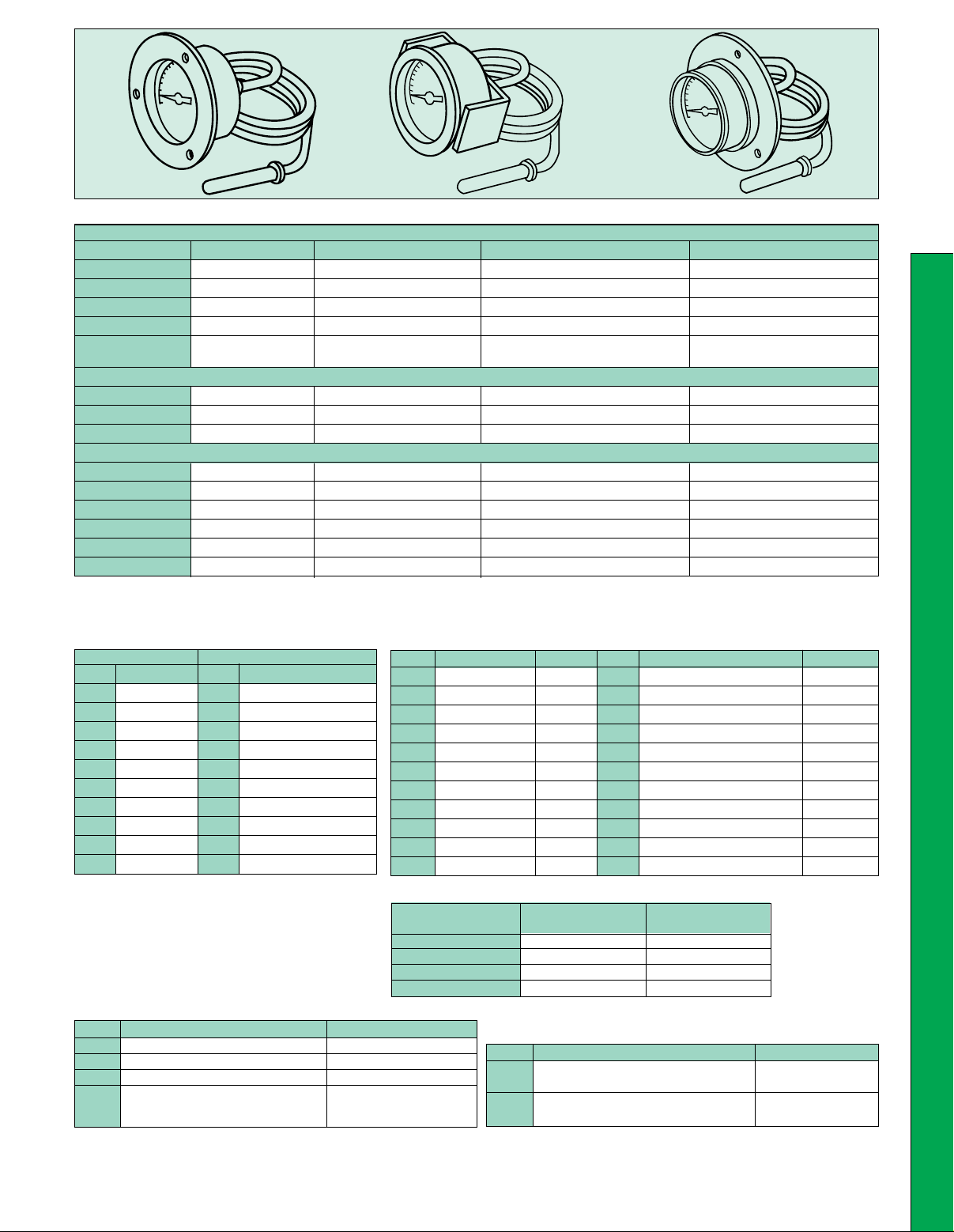

Front flange

(panel mount)

U-clamp Rear flange

(surface mount)

Table 1: Case Style

Front Flange (Panel Mount)

Code Dial Case Lens* Connection Location

20FR 2" Stainless steel Polycarbonate* Rear

25FR 2

35FR 3

45FR 4

45FL 4

(hinge ring type)

U-Clamp (Panel Mount)

20UR 2" Stainless steel Polycarbonate* Rear

25UR 2

35UR 3

Rear flange (Surface Mount)

20RR 2" Stainless steel Polycarbonate* Rear

35RR 3

35RB 3

45RR 4

45RB 4

45TB 4

Glass lens available; specify “Glass” lens, for an additional cost. ** Polycarbonate lens available; specify “Poly” lens, for an additional cost.

*

1

⁄2" Stainless steel Polycarbonate* Rear

1

⁄2" Stainless steel Polycarbonate* Rear

1

⁄2" Stainless steel Polycarbonate* Rear

1

⁄2" Black aluminum Polycarbonate* Lower rear

1

⁄2" Stainless steel Polycarbonate* Rear

1

⁄2" Stainless steel Polycarbonate Rear

1

⁄2" Stainless steel Polycarbonate* Rear

1

⁄2" Stainless steel Polycarbonate* Bottom

1

⁄2" Stainless steel Polycarbonate* Rear

1

⁄2" Stainless steel Polycarbonate* Bottom

1

⁄2" Phenolic Glass** Bottom (turret)

E

Table 2: Temperature Ranges††

For Vapor (Model No. Starts with “VA”)

°F Ranges °F and °C Ranges

Code °F Range Code °F (°C) Range

-20 -40 to 60°F -21 -40 to 60 (-40 to 15)

-30 -40 to 110°F -31 -40 to 110 (-40 to 40)

-32 -20 to 120°F -33 -20 to 120 (-30 to 50)

-72 0 to 180°F -73 0 to 180 (-20 to 80)

-49 0 to 150°F -79 0 to 150 (-15 to 65)

-80 20 to 220°F -81 20 to 220 (0 to 105)

-50 40 to 240°F -51 40 to 240 (0 to 115)

-56 0 to 250°F -57 0 to 250 (-20 to 120)

-60 30 to 300°F -61 30 to 300 (0 to 150)

†

-68

100 to 350°F -66† 100 to 350 (40 to 175)

Table 2A for Gas (Model No. Starts with “GA”)

Code °F Ranges Div Code °F and (°C) Ranges Div

-FB -320 to 100°F 5° -DB -320 to 100 (-200 to 40) 5°/2°

-FE -120 to 120°F 2° -DE -120 to 120 (-85 to 50) 2°/1°

-FG -40 to 180°F 2° -DG -40 to 180 (-40 to 80) 2°/2°

-FH 0 to 120°F 1° -DH 0 to 120 (-15 to 50) 1°/1°

-FJ 60 to 120°F 1° -DJ 60 to 120 (15 to 50) 1°/

-FL 20 to 240°F 2° -DL 20 to 240 (-5 to 110) 2°/1°

-FN 0 to 300°F 5° -DN 0 to 300 (-10 to 150) 5°/1°

-FP 50 to 550°F 5° -DP 50 to 550 (10 to 29) 5°/5°

-FR 50 to 750°F 5° -DR 50 to 750 (0 to 400) 5°/5°

-FT 400 to 1200°F 10° -DT 400 to 1200 (200 to 650) 10°/5°

†,†††

-70

200 to 450°F — -71

†,†††

Table 3: Capillary and Bulbs

Capillary Capillary

Code†† and Bulb Material Protection

-A Copper None

-C Copper Bronze braid

-D† 316 SS None

-E† 316 SS SS armor

Table 4: Process Connection

Note: Capillary lengths over 5' effect bulb length. See Dimensions Table.

Code Connection Type Material

-J1 None (plain bulb) –

-K2

-L2†

-M2†

† Higher temp ranges are available with “-D” or “-E” and “-L2” or “-M2”. M2 only available with 316 SS capillary.

†† Ranges 300°F or above for vapor-actuate and all gas-actuated models only offered with stainless steel systems.

††† Stainless steel only.

1

⁄2 NPT union Brass

1

⁄2 NPT union 316 SS

1

⁄2 NPT sliding union, 316 SS

jam nut and

bendable extension

Code Connection Type Material

-J2 Jam nut only Brass

(required with thermowell)

-J3 Jam nut only 316 SS

(required with thermowell)

E-18

200 to 450 (100 to 230) —

1

⁄2°

Page 3

Dimensions: inch

Capillary

Plain Bulb Union Connection Thermowell Bendable Ext

Length L D U S D U S D L S D

1 to 5' (bulb #1) 21⁄2

6 to 10' (bulb #1) 3

11 to 25' (bulb #2) 3

26 to 50' (bulb #3) 4

51 to 75' (bulb #4) 7

76 to 100' (bulb #5) 10

7

⁄16

3

⁄16 3⁄8 21⁄2 31⁄4

7

⁄8 3⁄8 41⁄2 51⁄4

7

⁄8 3⁄8 61⁄2 71⁄4

7

⁄8 3⁄8 81⁄2 91⁄4

3

⁄8 13⁄16 23⁄8

3⁄8

3

23⁄8 7

1

⁄16

7

⁄16 115⁄16 21⁄2 9⁄16 21⁄2 3-13 3⁄8

15

⁄16

7

⁄16 25⁄8 33⁄8 9⁄16 37⁄16 4-14 3⁄8

7

⁄16 45⁄8 53⁄8 9⁄16 47⁄8 5-15 3⁄8

7

⁄16 65⁄8 73⁄8 9⁄16 77⁄8 8-18 3⁄8

7

⁄16 85⁄8 93⁄8 9⁄16 107⁄8 11-21 3⁄8

1

1⁄2 9

⁄16

2

⁄16

7

3

⁄16

4-14

3

⁄8

Thermowells for Vapor- and Gas-Actuated Bulbs (except M2)

1

Model No. Description Model No. Description

⁄2 NPT

3

⁄4 NPT

1/2-445S-U1 15/16-316SS-CB 3/4-445S-U1 15/16-316SS-CB

1/2-445S-U1 15/16-316SS-SB 1 to 10' Capillary 3/4-445S-U1 15/16-316SS-SB 1 to 10' Capillary

1/2-445S-U1 15/16-BRASS-CB (bulb #1) 3/4-445S-U1 15/16-BRASS-CB (bulb #1)

1/2-445S-U1 15/16-BRASS-SB 3/4-445S-U1 15/16-BRASS-SB

1/2-445S-U2 5/8-316SS-CB 3/4-445S-U2 5/8-316SS-CB

1/2-445S-U2 5/8-316SS-SB 11 to 25' Capillary 3/4-445S-U2 5/8-316SS-SB 11 to 25' Capillary

1/2-445S-U2 5/8-BRASS-CB (bulb #2) 3/4-445S-U2 5/8-BRASS-CB (bulb #2)

1/2-445S-U2 5/8-BRASS-SB 3/4-445S-U2 5/8-BRASS-SB

1/2-445S-U4 5/8-316SS-CB 3/4-445S-U4 5/8-316SS-CB

1/2-445S-U4 5/8-316SS-SB 26 to 50' Capillary 3/4-445S-U4 5/8-316SS-SB 26 to 50' Capillary

1/2-445S-U4 5/8-BRASS-CB (bulb #3) 3/4-445S-U4 5/8-BRASS-CB (bulb #3)

1/2-445S-U4 5/8-BRASS-SB 3/4-445S-U4 5/8-BRASS-SB

1/2-445S-U6 5/8-31SS-CB 3/4-445S-U6 5/8-316SS-CB

1/2-445S-U6 5/8-316SS-SB 51 to 75' Capillary 3/4-445S-U6 5/8-316SS-SB 51 to 75' Capillary

1/2-445S-U6 5/8-BRASS-CB (bulb #4) 3/4-445S-U6 5/8-BRASS-CB (bulb #4)

1/2-445S-U6 5/8-BRASS-SB 3/4-445S-U6 5/8-BRASS-SB

1/2-445S-U8 5/8-316SS-CB 3/4-445S-U8 5/8-316SS-CB

1/2-445S-U8 5/8-316SS-SB 76 to 100' Capillary 3/4-445S-U8 5/8-316SS-SB 76 to 100' Capillary

1/2-445S-U8 5/8-BRASS-CB (bulb #5) 3/4-445S-U8 5/8-BRASS-CB (bulb #5)

1/2-445S-U8 5/8-BRASS-SB 3/4-445S-U8 5/8-BRASS-SB

To Order Visit omega.com/va_ga_gas_thermom for Pricing and Details

Construct a Model Number as Follows - See 3 Examples Below:

Model No. Table 1 – Table 2 or 2A – Table 3 – Table 4 – Table 5 – Table 6

Case Style Temperature Capillary and Capillary Process Thermowell

VA or GA and Size Range Bulb Length (feet) Connection (Optional)

1) VA 25FR – 32 – D – 05 – J1

2) GA 45FL – DH – E – 12 – L2

3) VA 25FRGlass – 32 – D – 10 – J3 – 1/2-445S-U1

15/16-316SS-SB

E-19

Loading...

Loading...