Page 1

DIAPHRAGM PRESSURE SEALS

TO ENSURE PROTECTION AND MEDIA COMPATIBILITY

Seals

Start at

$

Diaphragm seals, shown

with PGH-45L-200, process

gauge, $185, see page G-56.

450

⻬ Protects Pressure

Instrumentation from

Corrosive or Viscous

Fluids, Clogging, and

In-Line Freezing of the

Process Media

⻬ Glycerine Fill Fluid is

Standard, with Optional

Fill Fluids Available

⻬ Displacement of the

Liquid Fill in the

Pressure Seal Through

Movement of the

Diaphragm Transmits

Process Pressure

Directly to the Pressure

Instrumentation

OMEGA®diaphragm pressure

seals protect sensitive pressure

instrumentation from the damaging

effects of corrosives, slurries, or

viscous fluids. A variety of designs

and styles is available to suit

individual application requirements.

100 Series

Distinguished by its 3-part design,

the 100 Series includes a PTFE

coated diaphragm capsule that

threads into the top housing,

ensuring positive sealing at all

surfaces and minimizing fluid

leakage. The diaphragm capsule

can be replaced without replacing

the top housing. Continuous duty is

assured; should the sensor be

removed from the diaphragm seal,

the process fluid is prevented from

escaping. Easy cleaning and

inspection of the diaphragm can be

done during shutdown by detaching

the top and bottom housings.

This design eliminates the need to

refill the seal or recalibrate the

instrument when the top and bottom

housings are separated. A FKM

O-ring, compatible with all standard

fill fluids, and a PTFE backup ring,

make a seal between the diaphragm

capsule and the top housing. The

diaphragm is PTFE coated to

provide an integral gasket, thus

ensuring a leakproof connection

between the diaphragm and bottom

housing. The 100 Series consists

of a diaphragm capsule with a

corrugated, metallic diaphragm

edge welded to a sturdy backup

plate that threads into the top

housing. Once secured, the top

housing can be bolted to the bottom

housing. The bottom housing has a

standard 1⁄2 NPT fitting that easily

threads to the process piping.

102 Series

Virtually identical to the 100 Series

in both performance and design,

the 102 Series includes a standard

#150 raised face flange in place

of a threaded female NPT

process fitting. For more rugged

applications, an optional #300

raised face flange is also available.

202 Series

The 202 Series diaphragm

seal features a bonded PTFE

diaphragm and a PTFE #150 raised

face flange. This all-PTFE wetted

construction provides ruggedness

and maximum corrosion resistance

to acids, caustics, alkalis, ketones,

hydrocarbons, and alcohols. In

the new 202 design, the PTFE

diaphragm is bonded to the top

housing, allowing the top housing

and instrument to be removed

without losing the fill fluid.

OMEGA diaphragm pressure

seals are available for use with

OMEGA pressure instrumentation:

• Pressure Transducers

PX602 (p. B-38), PX603 (p. B-101),

PX605 (p. B-160), PX673

(p. B-113), PX675 (p. B-186)

• Dial Pressure Gauges

PGH (p. G-58), PGJ (p. G-58),

PGT Series (p. G-60)

• Pressure Switches

PSW-300 (p. H-22), PSW-370 (p. H-23),

PSW-400 (p. H-31)

G-65

Page 2

DIAPHRAGM PRESSURE SEALS

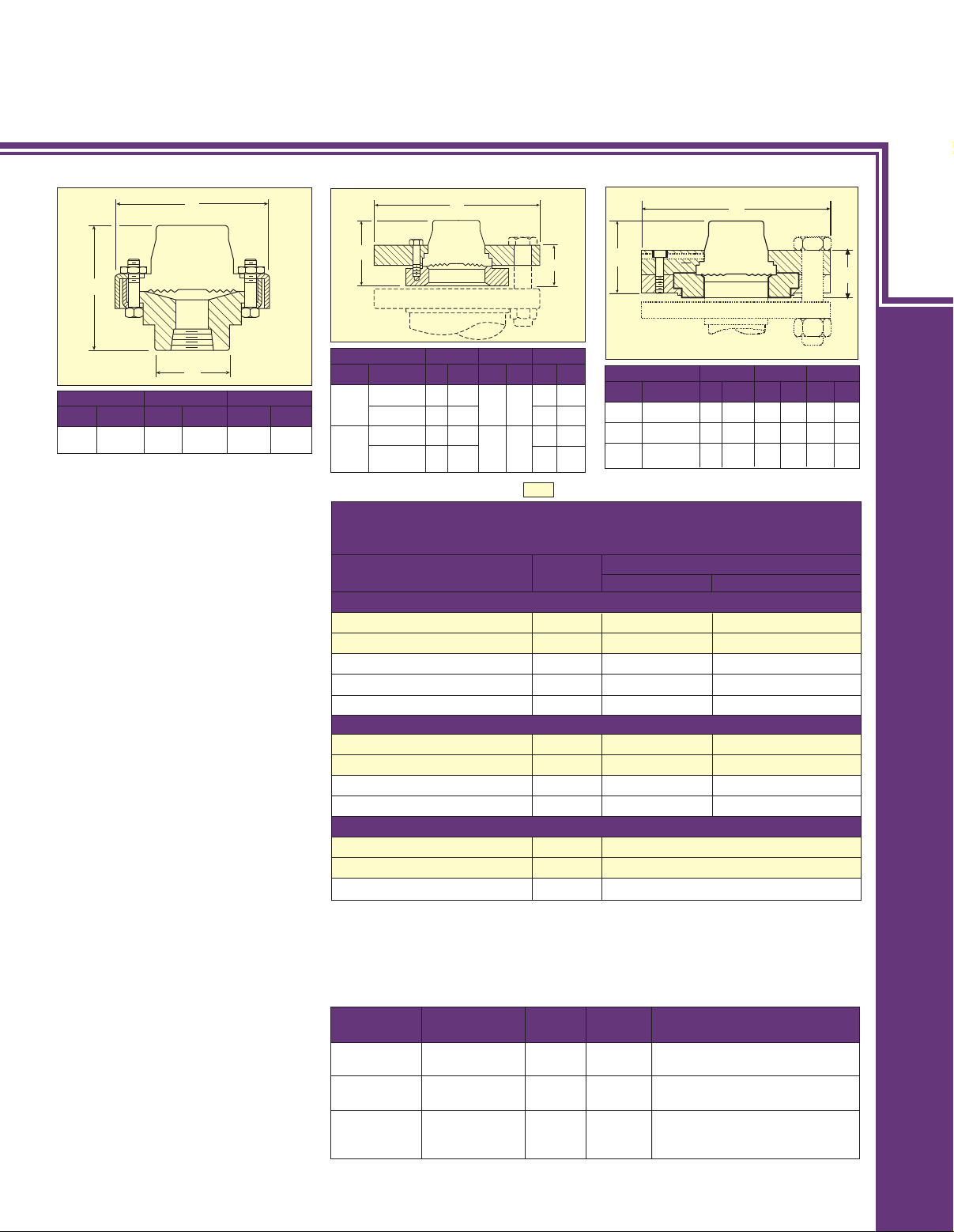

A

C

B

NUTS, BOLTS & FLANGE BY USER

A

B

C

TO ENSURE PROTECTION AND MEDIA COMPATIBILITY

AB C

in mm in mm in mm

33⁄4 95 27⁄8 73 113⁄16 46

102 Series100 Series

FLANGE ABC

SIZE

RATING #

150 41⁄4 127 11⁄2 38

1

⁄2"

1

300 6

150 6 152 13⁄8 35

2"

300 6

in mm in mm in mm

3

2

1

⁄8 61

15

⁄16 49

1

1

1

1

⁄2 38

⁄2 38

1

⁄4 159

1

⁄2 165

202 Series

B

FLANGE ABC

SIZE

RATING #

in mm in mm in mm

1" 150 41⁄4 100 23⁄16 56 13⁄8 35

11⁄2" 150 5 127 25⁄16 59 113⁄32 39

2" 150 6 152 21⁄8 54 19⁄16 40

PRESSURE

GAUGES

A

C

G

SPECIFICATIONS

Pressure: 15 to 2500 psig and

vacuums greater than 30 inHg;

#150 flanges to 150 psi, #300

flanges to 300 psi

Temperature: See fill solution

temperature range

Please Note: When diaphragm

seals are connected to pressure

instrumentation, slight shifts in

calibration will result. OMEGA

recalibrates the instrument with the

seal attached to negate calibration

shifts. Please allow additional lead

time when ordering.

Ordering Examples:

1)PGT-45L-100, 1-100-PM-1/2-CG

OMEGA test gauge and diaphragm

seal with 1 FNPT process connection.

All Monel

fill solution.

PGT-45L-100 $390

1-100-PM-1/2-CG 595

2)PGT-45L-100, 2-102-PM-1/2-CK-300-RF

OMEGA test gauge with 51 mm (2")

#300 raised face flange diaphragm

seal. All Monel wetted parts and

silicone solution.

PGT-45L-100 $390

2-102-PM-1/2-CK-300-RF

($570 + 65 + 95 + 195) 925

Notes: 1 PVC maximum 200 psi @ 23°C

(74°F), 125 psi @ 52°C (125°F), 80 psi @ 66°C

(150°F). 2 #150-RF PTFE flange maximum

150 psi @ 66°C (150°F). 3 PVC,

no thread; use solvent cement to install.

®

wetted parts and glycerine

®

_______

Total $985

_______

Total $1315

MOST POPULAR MODELS HIGHLIGHTED!

To Order

(Specify as Ordering Suffix to Pressure Instrument Model Number)

ORDERING SUFFIX PRICE WETTED MATERIALS

DIAPHRAGM BOTTOM HOUSING

100 Series

[†]-100-SS-1/2-CG* $450 316L SS 316 SS

[†]-100-PM-1/2-CG* 595 K-Monel Monel 400

[†]-100-GG-1/2-CG* 975 Hastelloy®B Hastelloy B

[†]-100-HH-1/2-CG* 975 Hastelloy®C Hastelloy C

[†]-100-SV-1/2-CG* 325 316L SS PVC

102 Series with #150-RF Flange**

[††]-102-SS-1/2-CG-150-RF $465 316L SS 316 SSF

[††]-102-PM-1/2-CG-150-RF 570 K-Monel Monel 400

[††]-102-GG-1/2-CG-150-RF 830 Hastelloy B Hastelloy B

[††]-102-HH-1/2-CG-150-RF 830 Hastelloy C Hastelloy C

202 Series with PTFE Seals with #150-RF Flange

1-202-TT-1/2-CG-150-RF $460 PTFE with 1" process conn.

1

11/2-202-TT-1/2-CG-150-RF 540 PTFE with 1

⁄

2" process conn.

2-202-TT-1/2-CG-150-RF 580 PTFE with 2" process conn.

To order seals separately, remove “CG” suffix from model number and subtract $45 from price.

*

T

o order 102 series seals with #300-RF flange, change “150” in model number to “300”

**

and add $195 to price.

[†] Specify process fitting:

[††] Specify process fitting: 1

1

⁄4, 1⁄2, 3⁄4 or 1" (all standard)

1

⁄2, (standard) or 2" ($65 additional)

Fill Solutions

TEMP

TYPE RANGE CODE PRICE USAGE

Glycerine -18 to 204°C CG STD Gauge pressure

(0 to 400°F)

Silicone -40 to 315°C CK $95 Gauge/vacuum pressure

(-40 to 600°F)

Halocarbon -57 to 150°C CF

Quote at

Gauge/vacuum pressure in

(-70 to 300°F) time of presence of strong oxidizing

order

agents (oxygen, chlorine, etc.)

G-66

(1)(3)

(2)

(2)

(2)

Page 3

One Omega Drive | Stamford, CT 06907 | 1-888-TC-OMEGA (1-888-826-6342) | info@omega.com

EPG05

www.omega.com

UNITED KINGDOM

www. omega.co.uk

Manchester, England

0800-488-488

UNITED STATES

www.omega.com

1-800-TC-OMEGA

Stamford, CT.

CANADA

www.omega.ca

Laval(Quebec)

1-800-TC-OMEGA

GERMANY

www.omega.de

Deckenpfronn, Germany

0800-8266342

Karviná, Czech Republic

FRANCE

www.omega.fr

Guyancourt, France

088-466-342

CZECH REPUBLIC

www.omegaeng.cz

596-311-899

BENELUX

www.omega.nl

Amstelveen, NL

0800-099-33-44

More than 100,000 Products Available!

Temperature

Calibrators, Connectors, General Test and Measurement

Instruments, Glass Bulb Thermometers, Handheld Instruments

for Temperature Measurement, Ice Point References,

Indicating Labels, Crayons, Cements and Lacquers, Infrared

Temperature Measurement Instruments, Recorders Relative

Humidity Measurement Instruments, RTD Probes, Elements

and Assemblies, Temperature & Process Meters, Timers and

Counters, Temperature and Process Controllers and Power

Switching Devices, Thermistor Elements, Probes and

Assemblies,Thermocouples Thermowells and Head and Well

Assemblies, Transmitters, Wire

Flow and Level

Air Velocity Indicators, Doppler Flowmeters, Level

Measurement, Magnetic Flowmeters, Mass Flowmeters,

Pitot Tubes, Pumps, Rotameters, Turbine and Paddle Wheel

Flowmeters, Ultrasonic Flowmeters, Valves, Variable Area

Flowmeters, Vortex Shedding Flowmeters

pH and Conductivity

Conductivity Instrumentation, Dissolved Oxygen

Instrumentation, Environmental Instrumentation, pH

Electrodes and Instruments, Water and Soil Analysis

Instrumentation

Data Acquisition

Auto-Dialers and Alarm Monitoring Systems,

Communication Products and Converters, Data

Acquisition and Analysis Software, Data Loggers

Plug-in Cards, Signal Conditioners, USB, RS232, RS485

and Parallel Port Data Acquisition Systems, Wireless

Transmitters and Receivers

Pressure, Strain and Force

Displacement Transducers, Dynamic Measurement

Force Sensors, Instrumentation for Pressure and Strain

Measurements, Load Cells, Pressure Gauges, Pressure

Reference Section, Pressure Switches, Pressure Transducers,

Proximity Transducers, Regulators,

Strain Gages, Torque Transducers, Valves

Heaters

Band Heaters, Cartridge Heaters, Circulation Heaters,

Comfort Heaters, Controllers, Meters and Switching

Devices, Flexible Heaters, General Test and Measurement

Instruments, Heater Hook-up Wire, Heating Cable

Systems, Immersion Heaters, Process Air and Duct,

Heaters, Radiant Heaters, Strip Heaters, Tubular Heaters

click here to go to the omega.com home page

Loading...

Loading...