Omega Flex FLEXIBLE GAS PIPING Installation Manual

FLEXIBLE GAS PIPING

FLEXIBLE GAS PIPING

DESIGN GUIDE

DESIGN GUIDE

and

and

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

December 2007

December 2007

®

RESIDENTIAL

RESIDENTIAL • COMMERCIAL • INDUSTRIAL

• COMMERCIAL • INDUSTRIAL

FGP-001, Rev. 12-07

TABLE OF CONTENTS

Chapter 1 Introduction

1.0 User Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Listing of applicable codes and standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

TracPipe Specification Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 Description of System and Components

2.0 Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Shut-off valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Material Use and Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TracPipe Flexible Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

AutoFlare Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TracPipe Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 3 System configurations and Sizing

3.1 System configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1A Series and parallel low-pressure systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1B Dual Pressure Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1C System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1D System Pressure Choices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Sizing Methods and Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2A Use of Sizing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2B Sizing Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Low-pressure Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Elevated Pressure Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Medium Pressure Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2C Sizing Hybrid Systems (Combination Steel/TracPipe Systems) . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2D Alternate Sizing Method (Sum of Pressure Loss Calculations) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

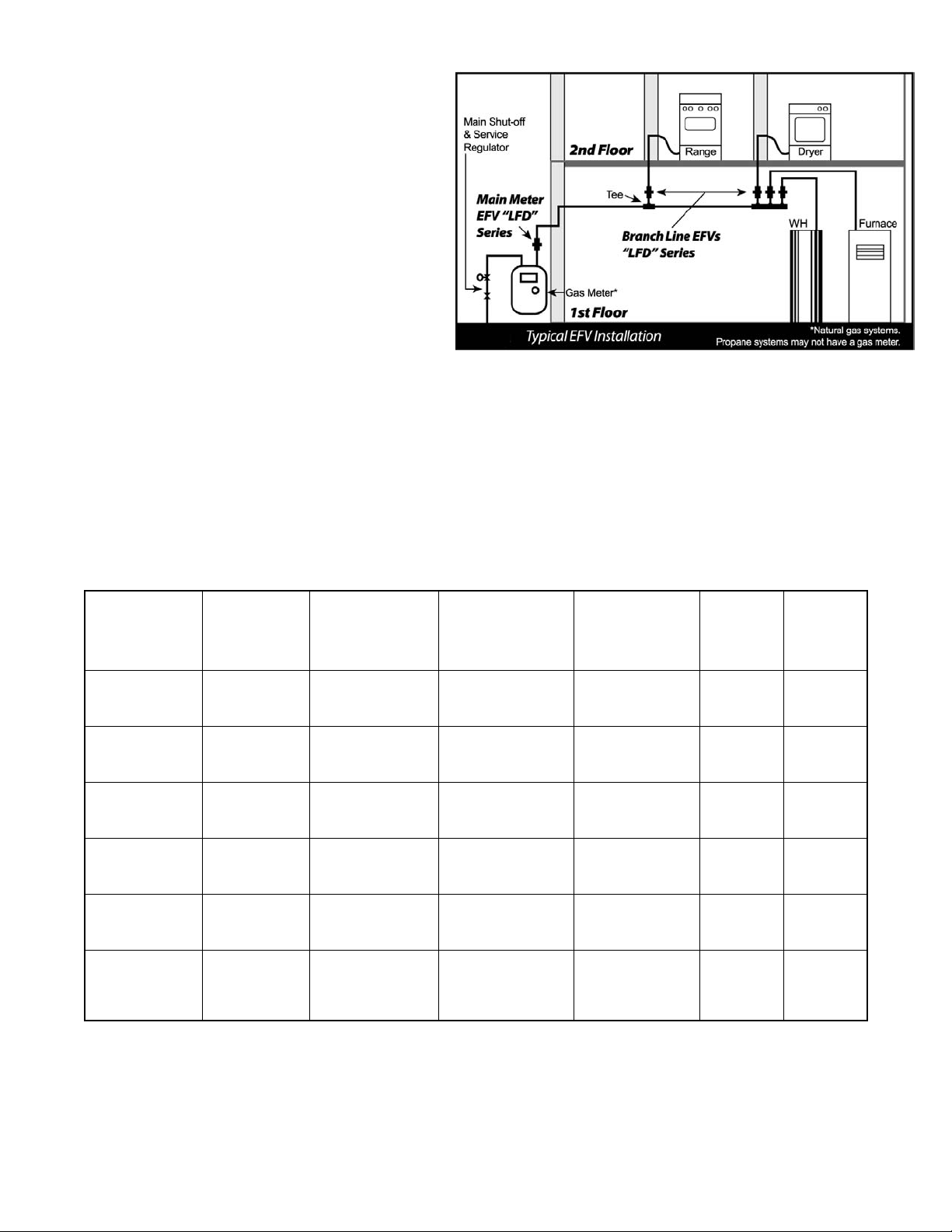

3.3 AUTOTRIP™ Low Pressure Excess Flow Valves for Natural Gas and Propane Service . . . . . . . 25

3.4 AUTOTRIP™ LFD SERIES Excess Flow Valves for Meter and

Branch Line/Manifold Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.4.1 Application, and Selection of AUTOTRIP LFD SERIES Excess Flow Valves . . . . . . . . . . . . . . . . . .27

3.4.2 Gas Piping System Sizing with LFD Series Excess Flow Valves . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.4.3 Methods of Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.4.4 Sizing Instructions For AUTOTRIP LFD SERIES EFVs Used With TracPipe CSST Systems . . . . .28

3.4.5 Sizing Instructions For AUTOTRIP LFD SERIES EFVs Used With

Low Pressure Steel Pipe Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.4.6 LFD Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.5 AUTOTRIP AFD SERIES Excess Flow Valves for Appliance Connector Inlet Applications . . . . . .30

3.5.1 Application and Selection of AUTOTRIP AFD SERIES Excess Flow Valves . . . . . . . . . . . . . . . . .31

3.5.2 AFD Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.6 GASBREAKER® EXCESS Flow Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

AutoTrip “LFD” Series Capacity Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table N-1AT AutoTrip-TracPipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table N-3AT AutoTrip-TracPipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table N-5AT AutoTrip –TracPipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table SP-1AT AutoTrip - Steel Pipe Low Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Table 3.3 AutoTrip “LFD” Series Excess Flow Valves- Propane Conversions . . . . . . . . . . . . . . . . .36

Table P-1AT AutoTrip (Propane Low Pressure System 11 in w.c.) -TracPipe . . . . . . . . . . . . . . . . .36

Table 3.4 AutoTrip - GasBreaker Equivalency Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 3.12 Pressure Drop across AutoTrip “LFD” Series EFV at given Flow Rates . . . . . . . . . . . .38

Chapter 4 Installation Practices

4.1 General Installation Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Minimum Bend Radius . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Debris Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Support- Vertical Runs/ Horizontal Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2 Fitting Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Tubing Cutting/End Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11

Assembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Minimum Tightening Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Re-assembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.2A Trouble Shooting Fitting Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3 Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Clearance Holes and Notching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3A Concealed Locations for Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3B Outdoor Installation Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.4 Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4A Striker Plate Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Spiral Metal Hose Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Thru-penetration Fire Stop UL Classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.5 Meter Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Termination Mounts/Meter Mounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6 Appliance Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6.1 Moveable Appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Termination Fittings with Appliance Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6.2 Fixed Appliance Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Direct Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6A Pad Mounted, Roof Top Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6B Outdoor Appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6C Fireplace Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.7 Manifold Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Allowable Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.8 Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Vent Limiter Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Vent Line and Sizing Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.8A Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.8B Regulator Capacity and Pressure Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.8C Over-Pressurization Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.9 Underground installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.9A Guidelines for underground installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.9B TracPipe PS fitting attachment instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.9C Underground ps with Flexible Poly Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.9D TracPipe PS-II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.9E TracPipe PS-II fitting attachment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.10 Electrical Bonding/Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.10A TracPipe CounterStrike CSST Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Chapter 5 Inspection Repair and Replacement

5.1 Minimum Inspection Requirements (Checklist) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

5.2 Repair/Replacement of Damaged Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 6 Pressure/Leakage Testing

6.0 Pressure Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1 Pressure Test for Elevated Pressure Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1A Appliance Connection Leakage Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.1B Regulator Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Chapter 7 Capacity Tables

7 in / 0.5 in WC Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8 in / 2 in WC Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

11 in / 5 in WC Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2 PSI / 1 PSI Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5 PSI / 3.5 PSI Drop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11 in / 0.5 in WC Drop (LP only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12-14 in / 2.5 in Drop (LP only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2 PSI / 1.5 PSI Drop (LP only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.1 Table PD.1 Pressure Drop per foot for TracPipe (Natural Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.2 Steel Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.2A Pressure Drop per 100 foot of Steel Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 8

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Appendix A UL Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Appendix B Manufactured Housing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

22

CHAPTER 1

INTRODUCTION

!

WARNINGS

SECTION 1.0 — USER WARNINGS

The TracPipe®gas piping material (CSST-

Corrugated Stainless Steel Tubing ) must

only be installed by a qualified person who

has been trained or otherwise qualified

through the TracPipe Gas Piping

Installation Program. Any installer must also

meet qualifications in accordance with state

and/or local requirements as established by

the administrative authority which enforces

the plumbing or mechanical code where the

gas piping is installed.

This document provides general instructions for the

design and installation of fuel gas piping systems

using gas piping material CSST. The guide must be

used in conjunction with state and local building

codes. Local codes will take precedence in

the event of a conflict between this guide

and the local code. In the absence of local

codes, installation must be in accordance with the

current edition of National Fuel Gas Code, ANSI

Sound engineering principles and practices

must be exercised for the proper design of

fuel gas piping systems, in addition to compliance with local codes. The installation

instructions and procedures contained in this

Design Guide must be strictly followed in

order to provide a safe and effective fuel gas

piping system or system modification. All

installations

must pass

customary inspections

by the local official having authority prior to

having the gas service turned on. All requirements of the local natural gas utility or

propane supplier must also be met.

Only the components provided or specified

by OMEGAFLEX as part of the approved

piping system are to be used in the installation.

The use of

TracPipe tubing or fittings

with tubing or fittings from other flexible gas piping manufacturers is strictly prohibited and may result in serious

bodily injury or property damage.

Z223.1/NFPA 54, the National Standard of Canada,

Natural Gas and Propane Installation Code, CSA

B149.1, the International Fuel Gas Code, the

Federal Manufactured Home Construction

and Safety Standards, ICC/ANSI 2.0 or the

Standard on Manufactured Housing, NFPA

501, as applicable

OMEGAFLEX

®

451 Creamery Way

Exton, PA 19341-2509

610-524-7272 Fax: 610-524-7282

WARNING !

If this system is used or installed improperly,

fire, explosion or asphyxiation may result.

The installation instructions and applicable

local codes must be strictly followed.

S

I

F

S

I

E

A

D

L

C

U

L

1-800-671-8622 www.omegaflex.com

© Copyright Omega Flex Inc. 1997, 1998, 2001, 2002,

OmegaFlex, TracPipe, AutoFlare, and CounterStrike are registered

trademarks of Omega Flex, Inc.

AutoTrip is a trademark of Omega Flex, Inc. registration pending.

3

2003, 2004, 2005, 2007

SECTION 1.1 — APPLICABLE

CODES AND STANDARDS

REGIONAL /MODEL CODES LISTING CSST

AS AN ACCEPTABLE GAS PIPING

MATERIAL AS OF JULY 2005:

a. ANSI/IAS LC-1

b. CANADA-CSA B149.1 Natural Gas

and Propane Installation Code

c. NFPA 54/ANSI Z 223.1 National Fuel

Gas Code

d. ICBO-Uniform Mechanical Code

e. BOCA-National Mechanical Code

f. CABO-1 and 2 Family Dwelling Code

g. SBCCI-Standard Gas Code

h. ICC-International Mechanical Code

i. IAPMO Listing FILE 3682

j. IAPMO Listing FILE 4665 TracPipe

PS-II

• CSA 6.26 Standard

k. ICBO Evaluation Services ER-5412.

l. Factory Mutual “Flexible Piping

Systems for Flammable Gases.”

m. California Mechanical and Plumbing

Codes

n. ICC-International Fuel Gas Code

o. NFPA 58 LP-Gas Code

p. UPC-Uniform Plumbing Code 2003

q. UL Through Penetration Firestop

Systems Classified (see Appendix A)

r. Tested to Code Requirements per

ASTM E84 (UL 723)

This Design and Installation Guide has been

written in accordance with the most current

edition of ANSI LC1 CSA 6.26, Fuel Gas

Piping Systems using Corrugated Stainless

Steel Tubing (CSST).

WHILE EVERY EFFORT HAS BEEN MADE TO PREPARE THIS DOCUMENT

IN ACCORDANCE WITH THE REGIONAL MODEL CODES IN EFFECT AT

ITS PRINTING, OMEGAFLEX CANNOT GUARANTEE THAT THE LOCAL ADMINISTRATIVE AUTHORITY WILL ACCEPT THE MOST RECENT VERSION OF

THESE CODES.

THE INSTALLER IS ULTIMATELY RESPONSIBLE TO DETERMINE SUITABILITY

AND ACCEPTANCE OF ANY BUILDING COMPONENT, INCLUDING GAS

PIPING. OMEGAFLEX ASSUMES NO RESPONSIBILITY FOR MATERIALS OR

LABOR FOR INSTALLATIONS MADE WITHOUT PRIOR DETERMINATION OF

LOCAL CODE AUTHORITY ACCEPTANCE.

4

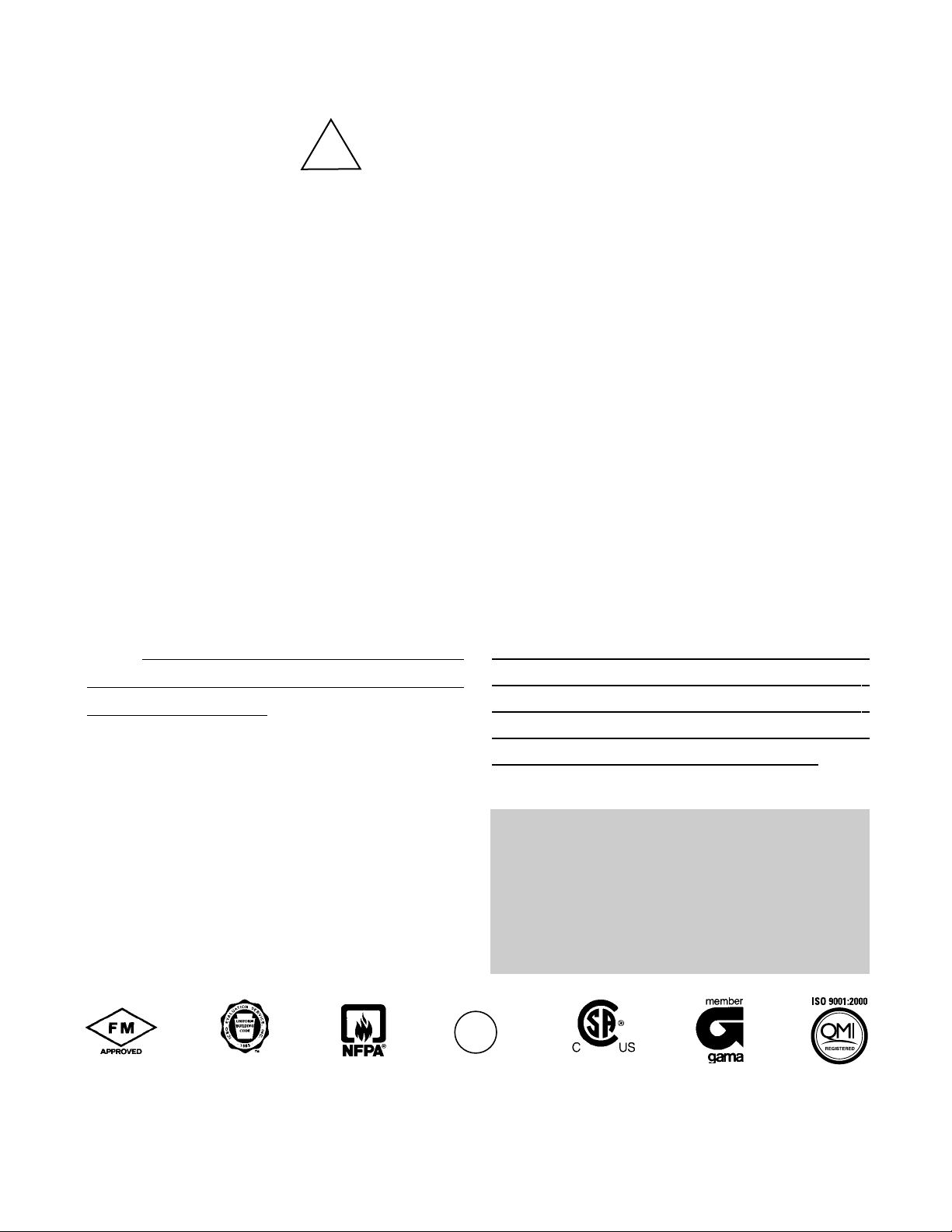

TracPipe

®

SPECIFICATION DATA SHEET

FGP-SS4-CHART

TracPipe®part no.

FGP-SS4-375 FGP-SS4-500 FGP-SS4-750 FGP-SS4-1000 FGP-SS4-1250 FGP-SS4-1500 FGP-SS4-2000

Size (inch) 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

EHD (AGA size) 15 19 25 31 37 46 62

Jacket O.D. (max.) .668 .868 1.108 1.383 1.665 1.920 2.590

Inside Diameter (nom) .440 .597 .820 1.040 1.290 1.525 2.060

Wall Thickness (in.) .01 .01 .01 .01 .012 .012 .012

*EHD (Effective Hydraulic Diameter) A relative measure of Flow Capacity; This number is used to compare individual sizes between different manufacturers. The

higher the EHD number the greater flow capacity of the piping.

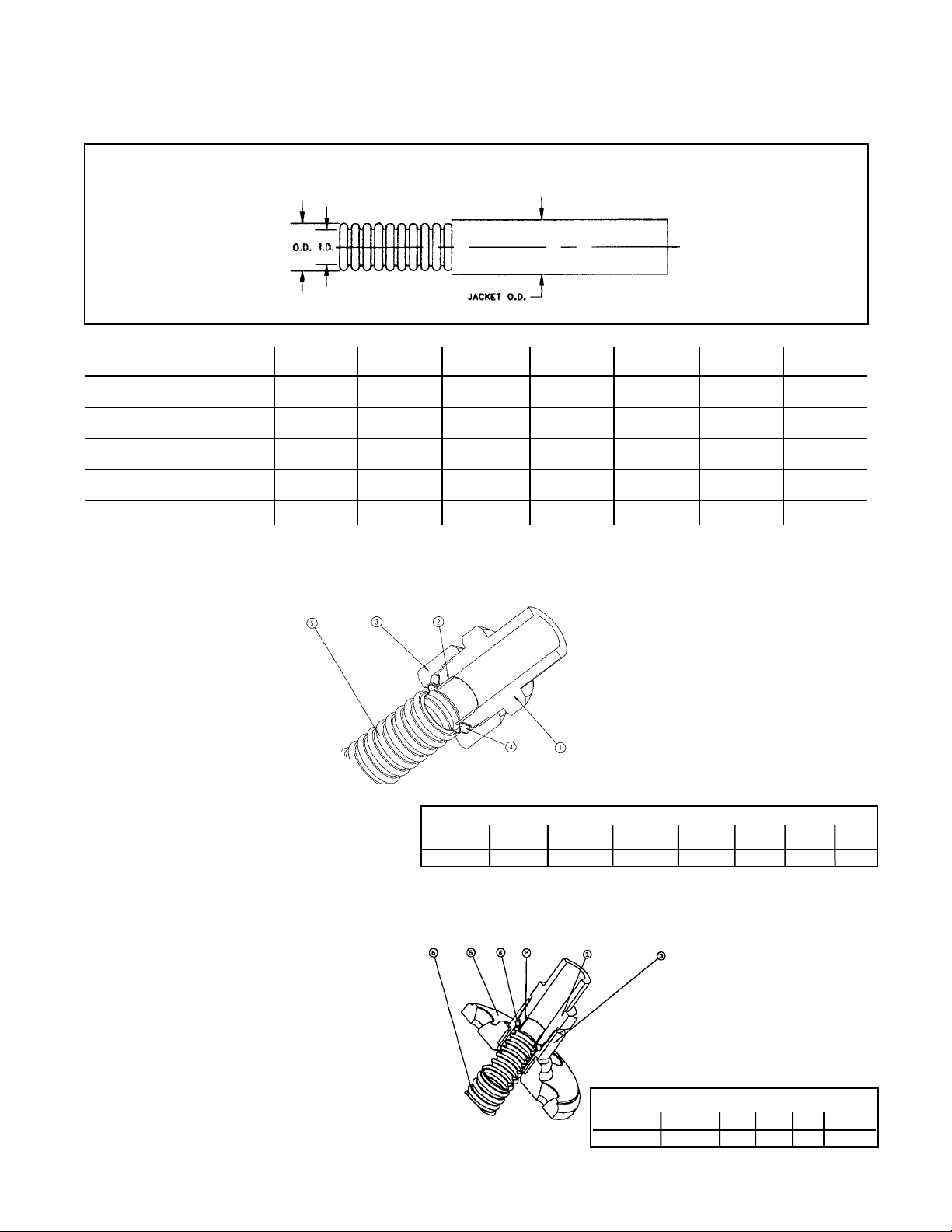

STRAIGHT AUTO-FLARE FITTINGS

1. ADAPTER – Brass

2. INSERT – Stainless Steel

3. NUT—Brass

4. SPLIT-RINGS – Brass or

Stainless Steel

5. FLEXIBLE PIPE – Stainless Steel

Tube size 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

NPT Thread 1/2"or 3/8" 1/2"or 3/4" 3/4"or 1/2" 1"or 3/4" 1-1/4" 1-1/2" 2"

AVAILABLE IN SIZES

FLANGE MOUNT AUTO-FLARE FITTINGS

1. ADAPTER – Brass

2. INSERT – Stainless Steel

3. FLANGE NUT – Brass

4. SPLIT-RINGS – Brass or

Stainless Steel

5. FLANGE – Malleable Iron/Brass

6. FLEXIBLE PIPE – Stainless Steel

CONSULT FACTORY FOR OTHER TERMINATION METHODS

5

AVAILABLE IN SIZES

Tube Size 3/8" 1/2" 3/4" 1" 1-1/4"

NPT Thread 1/2"or 3/8" 1/2" 3/4" 1" 1-1/4"

CHAPTER 2

DESCRIPTION of SYSTEM and COMPONENTS

SECTION 2.0 — TracPipe

FLEXIBLE GAS PIPING MATERIAL

DESCRIPTION

1. TUBING

The TracPipe fuel gas piping system con-

sists of corrugated, semi-rigid stainless

steel tubing with brass mechanical attachment fittings terminating in NPT pipe fittings for easy attachment to traditional

black iron pipe systems and direct connections to gas appliances.

Tubing is available in sizes 3/8 inch, 1/2 inch

3/4 inch, 1 inch, 1-1/4 inch, 1-1/2 inch,and 2

inch.

The 300 series stainless steel tubing is

jacketed, with a non-metallic cover which

provides ease of running through joists,

studs, and other building components. The

jacket is

marked at

intervals

with the

amount of

tubing left

on the reel,

for quick

measurement.

2. FITTINGS

Straight NPT pipe fittings are standard and are

available in sizes shown above to fit all tubing.

Additional fittings include termination mount

and flange-mount straight and 90 degree

elbow fittings for termination of gas lines near

movable appliances; and meter termination

accessories for support of TracPipe at utility

meter sets on building exteriors and roof penetrations. Tee fittings are available for addition of branch lines into tubing runs; reducer

tees are available in popular sizes and pipe

outlet tees terminate in pipe threads on the

outlet leg for size changes utilizing available

black iron reducer fittings.

3. ACCESSORIES

Accessories are available for expansion of

the flexible piping material and additions to

existing fuel gas piping systems. These

accessories include:

A. Manifolds — allow parallel installations

with “home runs” to each appliance.

1/2 inch female NPT outlets and 3/4 inch

and

1/2 inch

female

NPT

inlets.

Large size

manifolds

are also

available

for use with commercial size TracPipe.

B. Pressure Regulators: pounds to inches -

for use in elevated pressure system

installations (over 14 inches water column

- one half

psi) to

reduce

pressure

to standard low

pressure

for appliances.

Regulators are available for use on

natural and propane gas. Regulators

are equipped with approved vent

limiters except for the REG-7 size.

C. Protection Devices-for use where flexible

piping passes through studs, joists and

other building

materials and

is restricted

from moving

to avoid nails,

screws and

other puncture threats.

6

There are four striker plate configurations made from stamped steel and

specially hardened to resist penetration

from screws and pneumatic nail guns.

These are quarter-striker, half striker fullstriker and 6" X 17" flat plate striker. Spiral

wound galvanized steel “floppy” conduit is

available for use as additional protection.

D. Shut-off Valves-for use in elevated pres-

sure installations: 2 psi up to 5 psi.

(Standard

gas-cocks

should be

used at appliance stub

outs and other

low pressure

areas of the

piping system.) Brass

lever-handle ball valves supplied by

OmegaFlex are rated for 5 psi use and

are available in 1/2 inch and 3/4 inch sizes.

SECTION 2.1 — MATERIAL USE

AND LIMITATIONS

Some of the special usage features of

TracPipe gas piping are outlined below:

1. Flexible gas piping is used to provide safe,

efficient, timely installation of fuel gas piping within buildings, residential, commercial, and industrial, or for outdoor connections to appliances that are attached or in

close proximity to the building.

2. Flexible gas piping can be routed in most

locations where traditional gas piping

materials are installed: inside hollow wall

cavities, along or through floor joists in

basements, on top of the joists in attics,

on roof tops or along soffits or in chases

outside of buildings. TracPipe gas piping

has been tested and is listed by CSA

International for both outdoor and indoor

use.

3. TracPipe is listed by CSA International

for fuel gas use in the USA and Canada

for pressures up to 25 psi. For local gas

utility approved use only, TracPipe has

been tested for use up to 125 PSI for sizes

3/8" up to 1-1/4", and for use up to 25 psi

for sizes 1-1/2" and 2".

This Design and Installation Guide has

been written in accordance with the most

current edition of ANSI LC 1 CSA 6.26,

FUEL GAS PIPING SYSTEMS USING CORRUGATED STAINLESS STEEL TUBING

(CSST).

This Design Guide is intended to aid the professional gas pipe installer in the design,

installation and testing of flexible fuel gas piping systems for residential, commercial and

industrial buildings. It is not possible for this

guide to anticipate every variation in construction style, building configuration, appliance requirement, or local restriction. This

document will not therefore cover every application. The user should either exercise his

own engineering judgment on system design

and installation, or seek technical input from

other qualified sources. Additional information pertaining to gas piping systems is available from your local gas utility or propane

supplier.

4. In North America, the most common pressure for Natural Gas is 6-7 inches water

column, standard low pressure. Elevated

pressures of either 2 psi or one half psi are

also available from utilities in most areas

for new residential construction. 5 PSI

systems are commonly installed in commercial or industrial buildings. Elevated

pressures allow the use of smaller diameter piping, while providing for increased

loads and longer length runs.

5. Flexible gas piping can be used for

Natural gas and propane (Liquefied

Petroleum gas) and other fuel gases recognized in NFPA 54 National Fuel Gas

Code.

6. TracPipe CSST with the yellow polyethyl-

ene jacket and CounterStrike with black

jacket have been tested by Underwriters

Laboratory to UL723 (ASTM E84) Surface

Burning Characteristics with flame spread

7

and smoke density ratings meeting the

requirements of ANSI/CSA LC-1 for use in

air ducts and plenums. It is mandatory,

however, to follow fire and building code

requirements in all installations.

7. For underground or under slab burial the

flexible gas piping run must be encased in

a sleeve of polyethylene, or other

approved water resistant material. See

Section 4.9, Underground Installations.

Sleeved runs under concrete slabs

beneath buildings must be installed as

required by local codes. Most codes

require venting of the sleeves under buildings to the outdoors. This can be accomplished using Pre-sleeved TracPipe PS

or PS-II with available accessories.

8. Flexible gas piping can be used in con-

junction with steel pipe (black iron or galvanized) in either new construction or renovation and replacement piping installations. All TracPipe fittings terminate in

standard NPT male or female pipe threads

to interface with appliances, valves,

unions and couplings.

®

11. TracPipe AutoFlare

fittings have been

tested by CSA International (formerly the

American Gas Association Laboratories )

and are listed for use in concealed locations as defined in NFPA 54 National Fuel

Gas Code, The Uniform Plumbing Code,

and The International Fuel Gas Code.

This facilitates installation of the key

valves required for gas fireplaces in many

jurisdictions. Concealed fittings are also

desirable when adding tees for branch

runs in series configurations and in other

installation situations where locating a

TracPipe fitting in an accessible location

is not practical.

9. For retrofit installations, TracPipe can be

snaked through hollow wall cavities without major restoration as is typical when

running rigid pipe through existing construction. The replacement or addition of

gas appliances, fireplaces, and gas logs is

greatly facilitated with flexible piping on

reels requiring no special tooling or oily

threading equipment.

10. TracPipe gas piping can be run directly

to the shut off valves of most fixed appliances without installing an appliance

connector. For moveable appliances

such as ranges or dryers, the use of an

approved flexible appliance connector is

required in most jurisdictions. TracPipe

cannot be substituted as a connector for

this use when the appliance is free to

move for cleaning, etc.

8

SECTION 2.2 — SYSTEM COMPONENTS

®

®

TracPipe Flexible Gas Piping

Component Material Description/Dimensions

Corrugated

TracPipe

Flexible

Gas

Piping

Stainless

Steel

(300 Series)

with

Polyethylene

Jacket

part no.

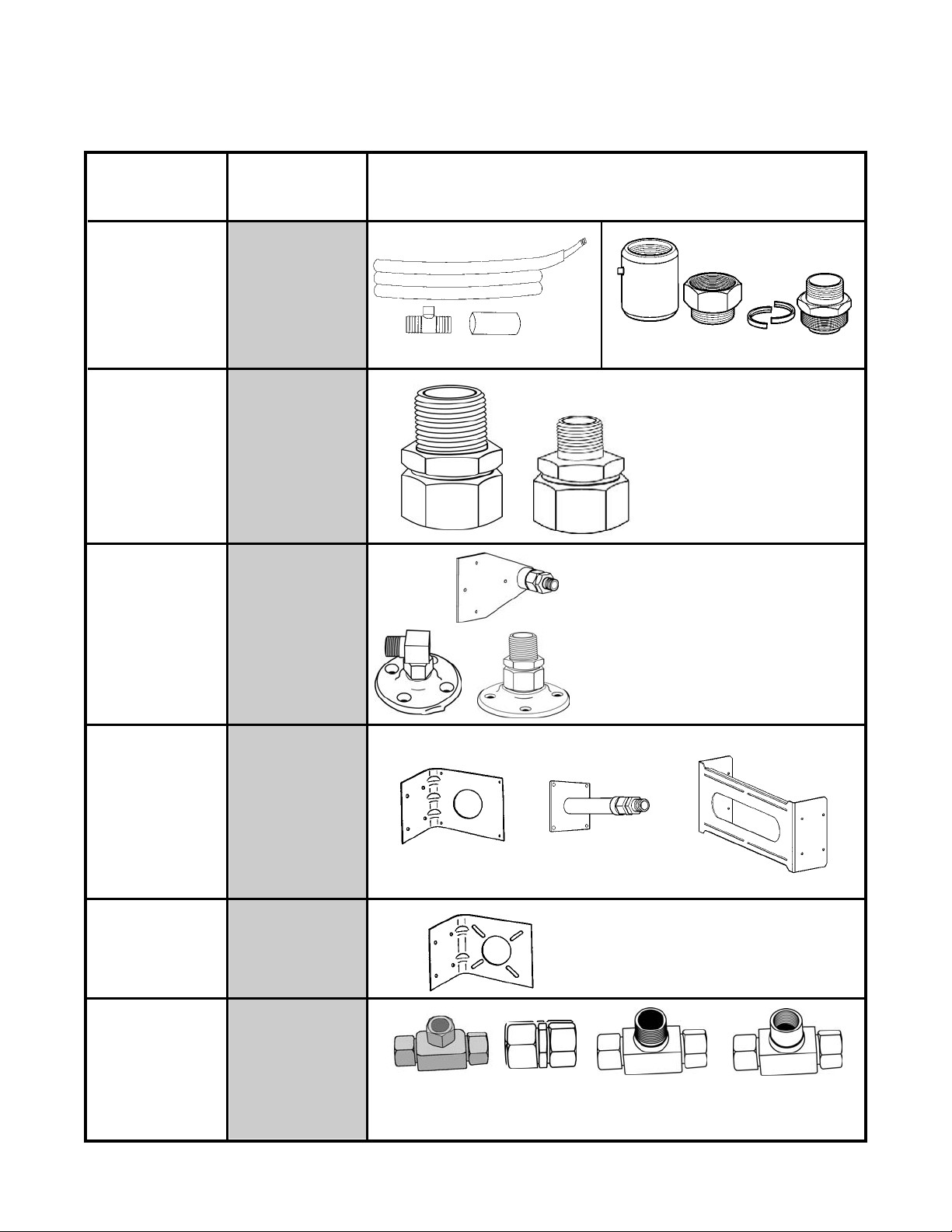

Size (inch) 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

EHD (AGA size) 15 19 25 31 37 46 62

Jacket O.D. (max.) .668 .868 1.108 1.38 1.665 1.920 2.590

Inside Dia. (nom) .440 .597 .820 1.040 1.290 1.525 2.060

*EHD (Effective Hydraulic Diameter) A relative measure of Flow Capacity; This number is used to compare individual sizes between different manufacturers. The higher the EHD number the greater flow

capacity of the piping.

FGP-SS4-375 FGP-SS4-500 FGP-SS4-750 FGP-SS4-1000 FGP-SS4-1250 FGP-SS4-1500 FGP-SS4-2000

TracPipe

on

Reels

Plywood

Reels

for

packaging

Note: other reel lengths available upon request.

Weight

Pipe Size Standard Reel Length

3/8 inch 250 feet 100 feet 29 pounds

1/2 inch 87 pounds

3/4 inch 55 pounds

1 inch 180 feet 60 pounds

1-1/4 inch 115 pounds

1-1/2 inch 125 pounds

2 inch 150 feet 92 pounds

500 feet 250 feet

100 feet 50 feet

250 feet

100 feet

180 feet

100 feet

250 feet

150 feet

250 feet

150 feet

Long Reel

9

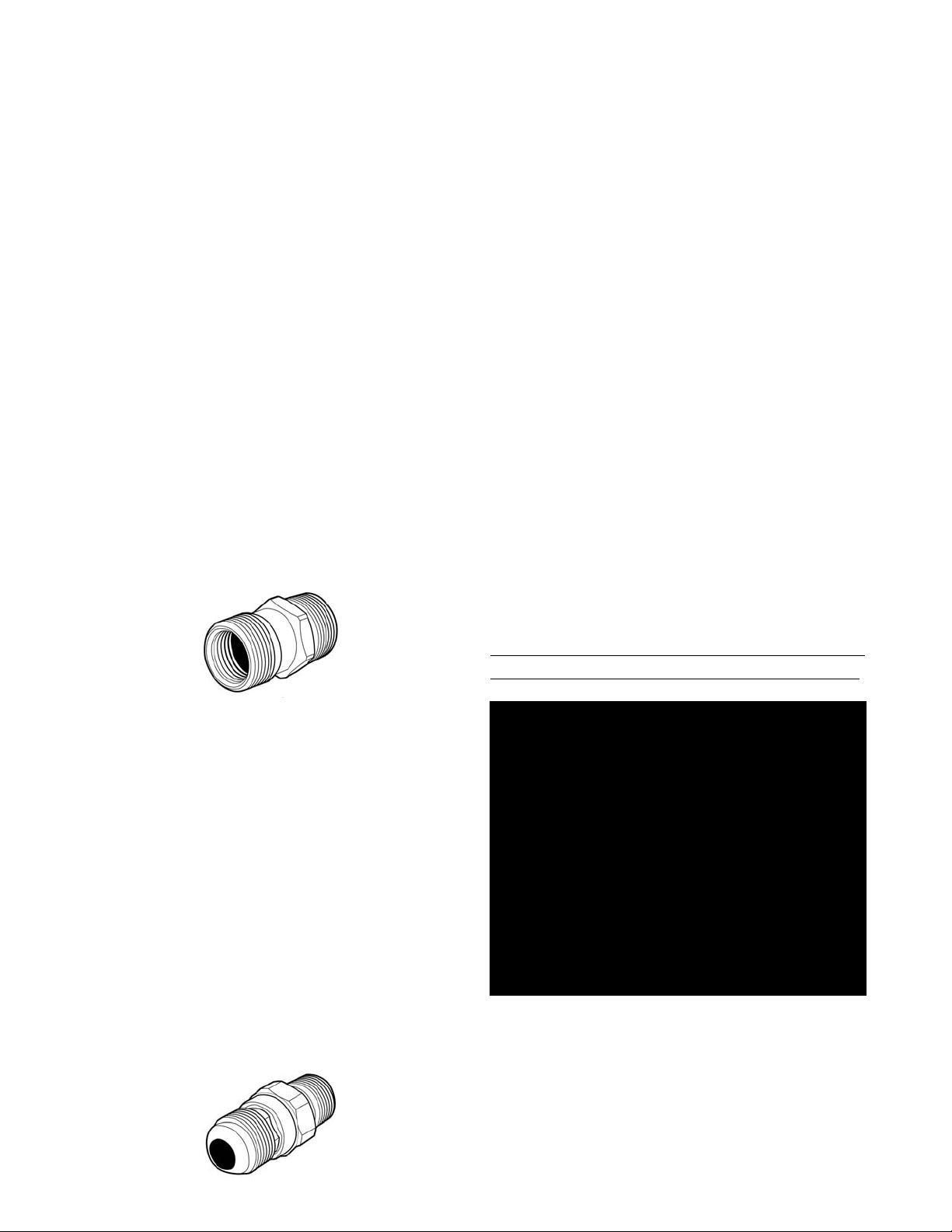

AutoFlare®Fittings

The fittings and accessories pictured on the following pages are representative of the range of products available

from TracPipe. Refer to the latest TracPipe Price Sheet for a complete listing of part numbers.

Component Material Description/Dimensions

PS PS-II

TracPipe PS

&

PS-II

Accessories

Black

Polyethylene

Sleeved

TracPipe

Vent Tee

Heat Shrink Cuff

Vent Nut Split Adapter

Coupling Rings

Straight

Mechanical

Fitting

Reducer

Fitting

Termination

and Flange

Mount

Fittings

Straight

and 90 Elbow

Meter

Termination

Fitting

Stud

Bracket

Brass

Fitting

Autoflare

Insert

Brass

Fitting

Autoflare

Insert

Brass

Flange

Brass Fitting

Autoflare

Insert

Galv. steel

Mounting

Bracket

Sizes: 3/8, 1/2, 3/4, 1, 1-1/4, 1-1/2

and 2 inch

Note size 3/8 fitting has

either 1/2" NPT or 3/8"

NPT Thread

Sizes: 3/8, 1/2, 3/4, 1 inch

and 1-1/4 inches

Note size 3/8 fitting has either

1/2" NPT or 3/8" NPT Thread

Elbow Sizes: 3/8 in. and 1/2 in.

Flange

Mounting

Bracket

Tee

Fitting

&

Coupling

Galv. Steel

Brass Tee

Fitting

& Coupling

Autoflare

Insert

One size fits all:

Size 3/8 through 1-1/4 inches

Sizes: 3/8, 1/2, 3/4, 1, 1-1/4, 1-1/2, and 2 inch

Reducer tees available for 1/2, 3/4, 1, 1-1/4, 1-1/2, and 2 inch sizes

10

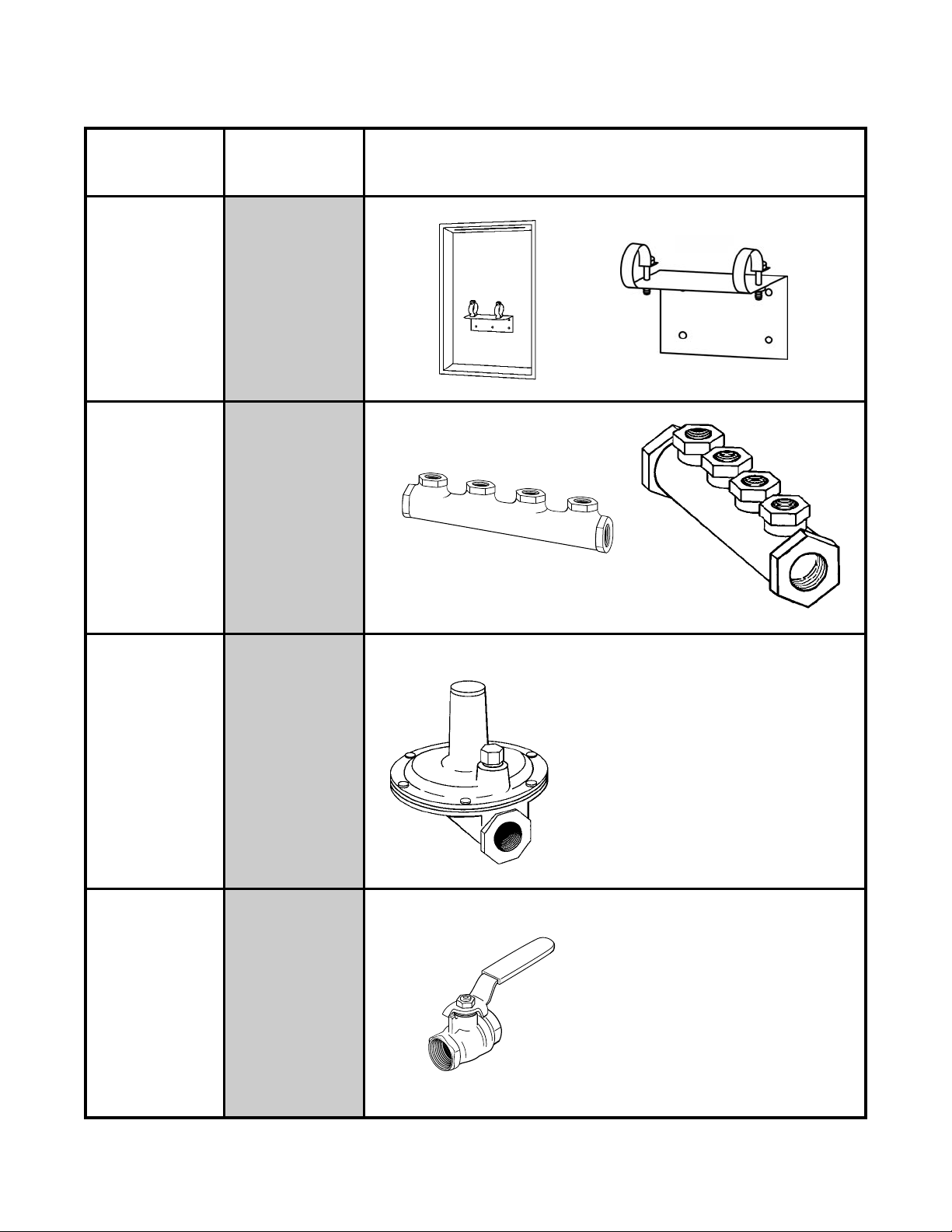

TracPipe Accessories

Component Material Description/Dimensions

Load

Center

Manifold

Bracket

Multi-

Port

Manifolds

Painted Steel

Galvanized

Steel

Malleable

Iron

Poly Coated

Pressure

Regulators

Shut

Off

Valves

Cast

Housing

Suitable

for

Outdoor

Use

Brass

Housing

with

Stainless

Steel

Ball

Sizes: 1/2 inch & 3/4 inch & 1-1/4 inch

Regulator includes approved vent lim-

iting device for REG 3 (1/2 in.) and

REG 5A (3/4 in.).

Note: Stainless steel High Pressure tags

are available for use where required by

code

Sizes: 1/2 inch & 3/4 inch

11

TracPipe Accessories

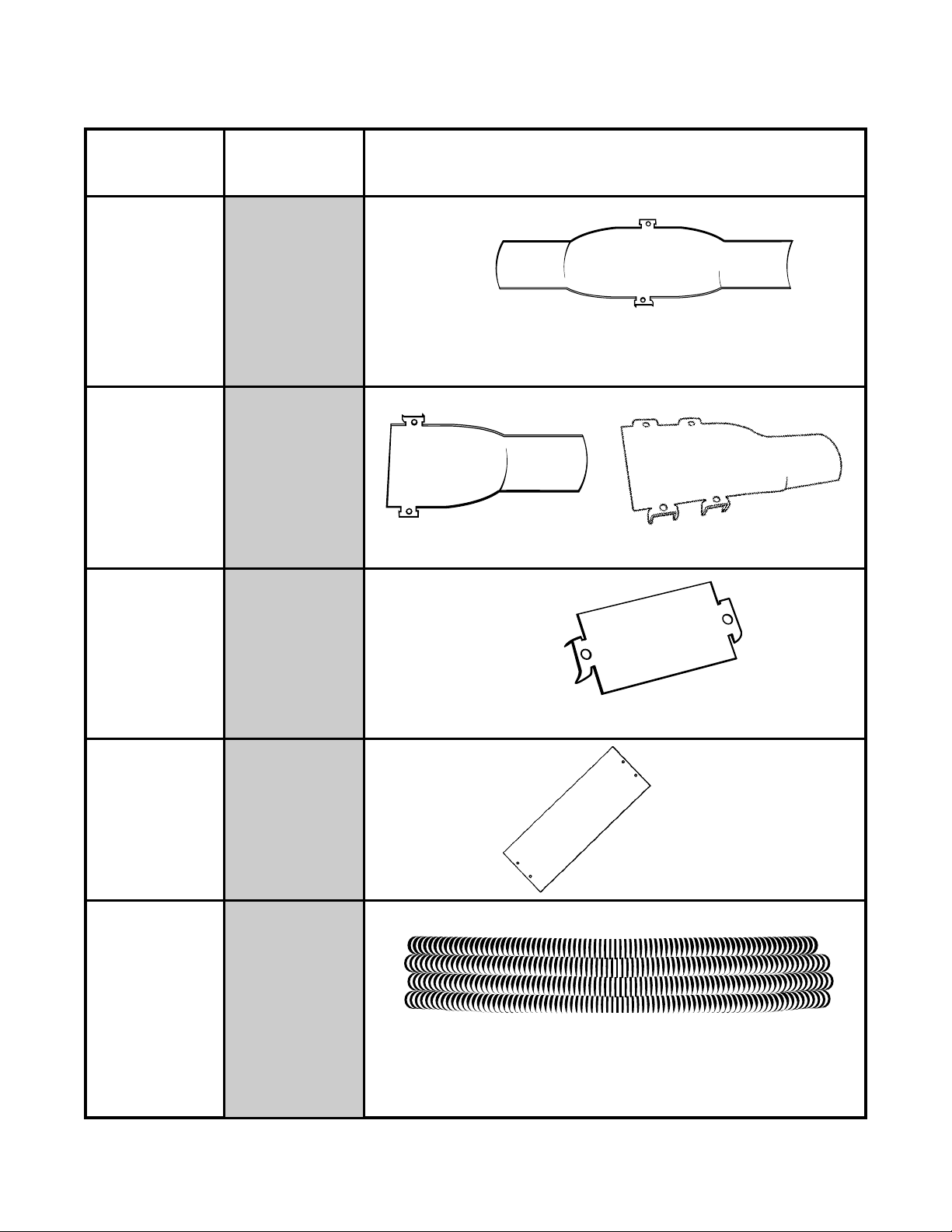

Component Material Description/Dimensions

Full

Striker

Plate

Half

Striker

Plate &

Three Quarter

Striker

Plate

Quarter

Striker

Plate

Carbon

Steel

Hardened

size: 3" x 12"

Carbon

Steel

Hardened

size: 3" x 7" size: 3" x 8"

Carbon

Steel

Hardened

size: 3" x 2"

6 x 17

Striker

Plate

Floppy

Strip

Wound

Conduit

Carbon

Steel

Hardened

size: 6" x 17"

Type RW

Galvanized

Steel

sizes: Fits 3/8", 1/2", 3/4", 1", 1-1/4", 1-1/2"

and 2" TracPipe

12

r

CHAPTER 3

SYSTEM CONFIGURATIONS AND SIZING

SECTION 3.1 — SYSTEM

CONFIGURATIONS

There are several piping system options

available to the installer using TracPipe gas

piping material. This flexibility of design is

one of the major benefits of CSST.

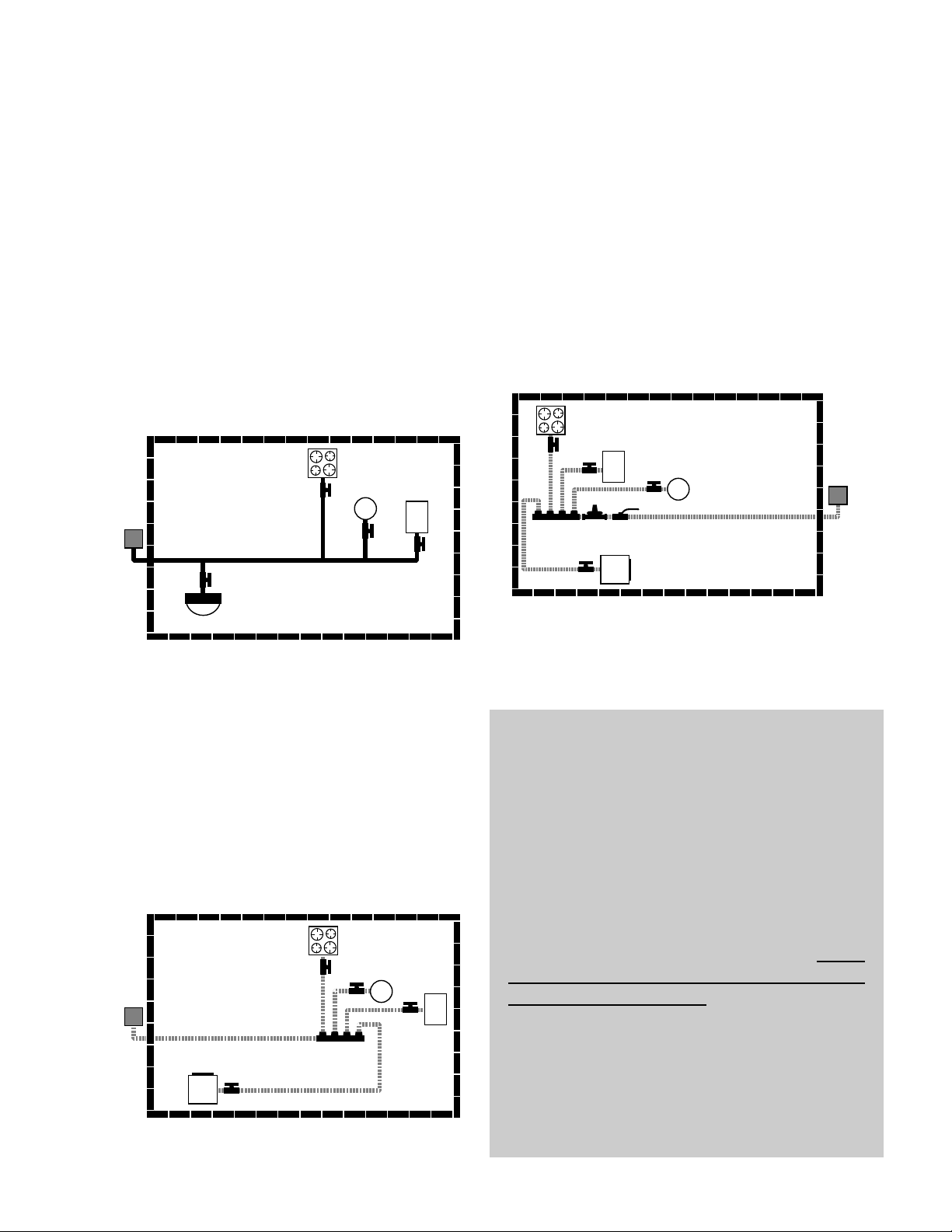

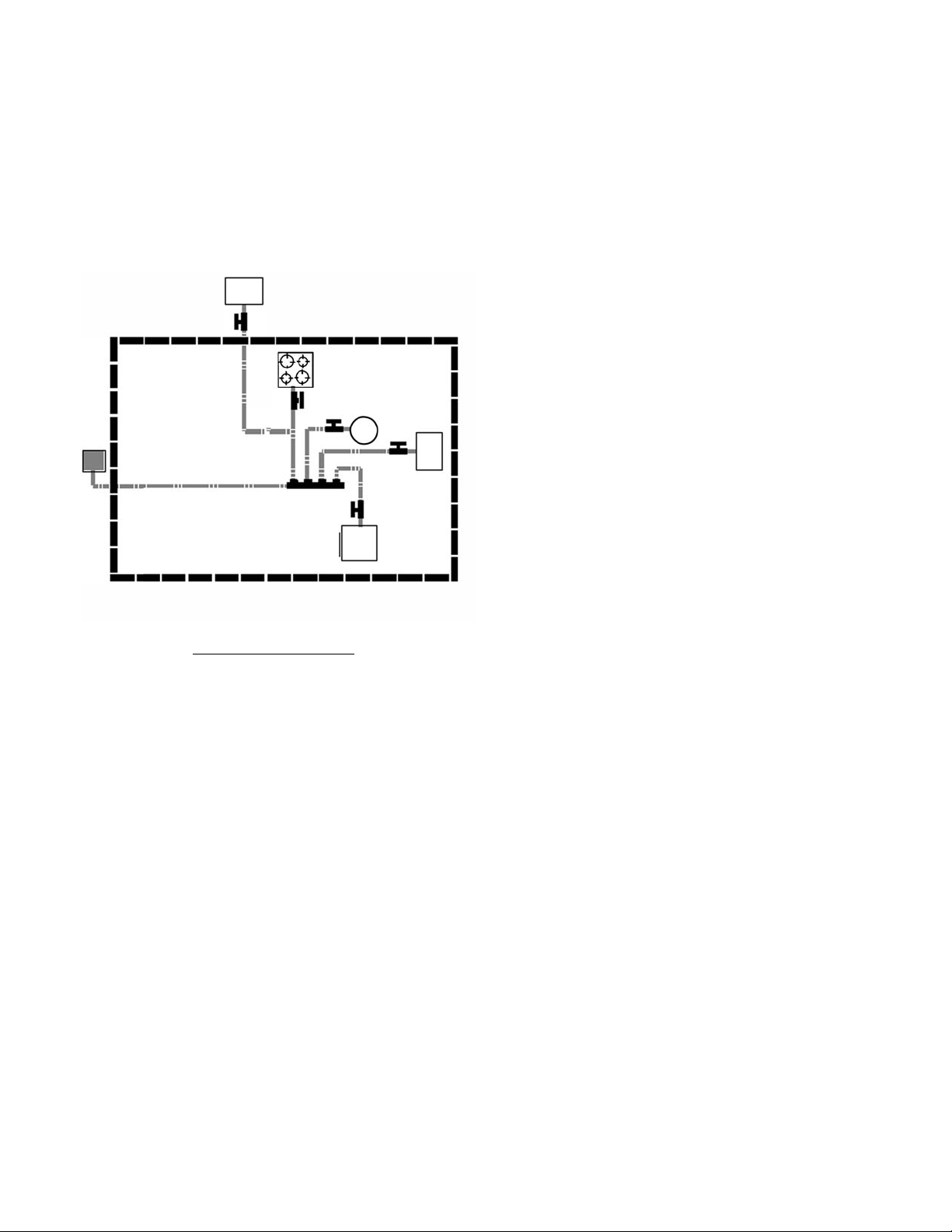

3.1A — LOW PRESSURE SYSTEMS

1. SERIES: A series layout is the most common arrangement utilized for black iron

pipe. This consists of a main run with tees

branching off to each appliance.

range

50 CFH

gas meter

163 CFH

water heater

30 CFH

furnace

60 CFH

3.1B — DUAL PRESSURE SYSTEMS

Elevated pressure systems (2 psi for residential and up to 5 psi for commercial installations) are usually piped with one or more

house line regulators (pounds-to-inches) followed by a manifold and runs to each of the

appliances. It is possible that these runs to

appliances may contain tees branching off to

an additional appliance where gas loads permit.

range

55 CFH

furnace

80 CFH

E

C

dryer

D

30 CFH

B

water heater

40 CFH

gas mete

A

205 CFH

2 PSI

fireplace

18 CFH

Series Layout

2. PARALLEL: A parallel system consists of a

central distribution manifold with branch

runs to the appliances. This is usually

accomplished by providing a main supply

line to a manifold and installing “home

runs” to each appliance location. In the

parallel system shown below the pressure

is not elevated above 1/2 pound and no

regulator is required.

range

55 CFH

water heater

1/2 PSI

gas meter

205 CFH

A

dryer

30 CFH

Parallel Layout

40 CFH

C

B

D

furnace

H

80 CF

E

Dual Pressure System Layout

NOTE:

HYBRID SYSTEMS – FLEXIBLE GAS

PIPE and RIGID BLACK PIPE COMBINATIONS.

In low or medium pressure systems,

it is often advantageous to use both corrugated stainless steel tubing and rigid pipe in

the same system. This is the case when a

larger diameter main branch is required to

provide for the total appliance load in a parallel system.

TracPipe

is certified for use in

combination with black iron pipe and copper

tube gas piping systems. For additional information on Hybrid Systems see examples

showing the method for sizing hybrid systems

using both

TracPipe

and black iron pipe

These are included in the SIZING EXAMPLES

section of this manual. Refer to Section 3.2C

13

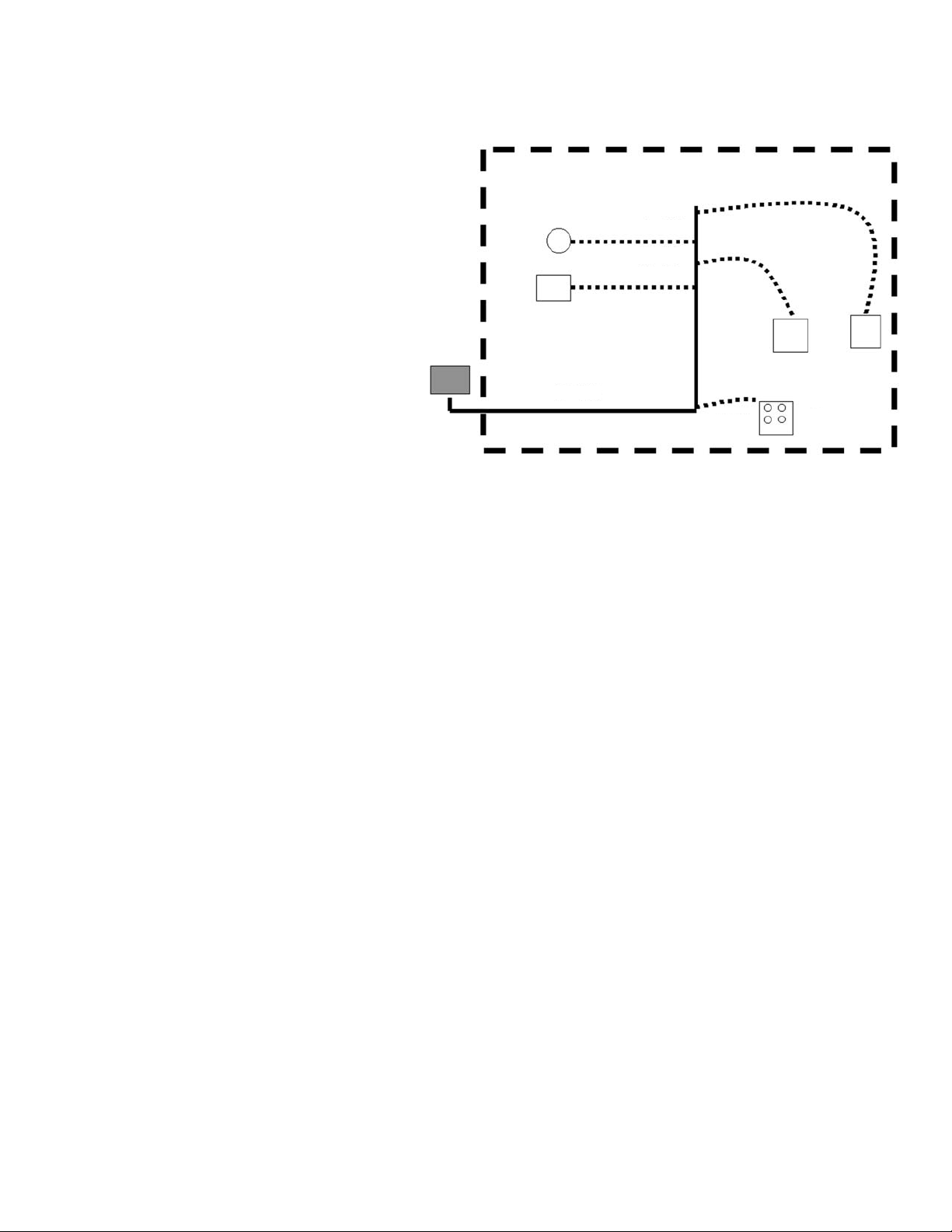

SECTION 3.1C — SYSTEM DESIGN

1. Prepare a sketch or layout of the gas piping system you are about to install. The

information you will need is the location of

each appliance, the point of delivery

(location of utility meter or second stage

LP regulator), appliance load demands,

and possible pipe routing locations. The

load demand data is usually available on

the appliance manufacturer’s nameplate,

or can be provided by the builder.

2. Determine local piping restrictions prior to

installing flexible gas piping. The major

code bodies in North America have written

Corrugated Stainless Steel Tubing into the

latest revisions of their mechanical codes,

but local and state adoption of these

codes often lags behind. CONFIRM THA

THE LOCAL CODE AUTHORITY HAS

ACCEPTED THE USE OF FLEXIBLE GAS

PIPING. Your TracPipe distributor should

be able to provide that information but

confirmation by the installer should be

made where there is a question.

SECTION 3.1D — SYSTEM

PRESSURE CHOICES

1. NATURAL GAS-Determine the delivery

pressure provided by the Local

Distribution Utility where the piping will be

installed.

appliances manufactured for use in the

US and Canada are designed to operate up to a maximum of 14 inches

water column.

c. ELEVATED PRESSURE-2 PSI -Is the

highest natural gas pressure usually

supplied within residential buildings in

North America. This pressure always

requires the installation of a poundsto-inches house line regulator between

the utility meter set and the appliances.

2. PROPANE (LP GAS)-Is typically supplied

within residential buildings at 11 inches

water column, set at the second stage reg-

T

ulator mounted outside the building.

Propane can also be utilized at medium

pressure, with the use of a 13-14 inch setting. For 2 PSI Propane elevated pressure

the Maxitrol regulator used is FGP-REG3P.(which is factory set at 11 inches water

column.) A second stage regulator which

reduces 10 psi from the tank to 2 psi must

be used. (e.g. Fisher model R312E).

NOTE:

International (formerly AGA Laboratories) for a

working pressure of 125 PSI for sizes 3/8" through

1-1/4" and 25 PSI for sizes 1-1/2 & 2".

TracPipe

has been tested by CSA

a. LOW PRESSURE-6 to 7 inches water

column-equivalent to 4 ounces or 1/4

pound is the standard pressure supplied by natural gas utilities in the USA

and Canada.

b. MEDIUM PRESSURE-1/2 POUND-12

to 14 inches water column-Is available

from many natural gas utilities as an

enhanced pressure supply. The increase

in pressure provides for reductions in

pipe size and does not require a

pressure regulator. Most natural gas

PRESSURE CONVERSION CHART

1/4 PSI = 7" w.c. = 4 oz.

1/2 PSI = 14" w.c. = 8 oz.

1 PSI = 28" w.c. = 16 oz.

2 PSI = 56" w.c. = 32 oz.

14

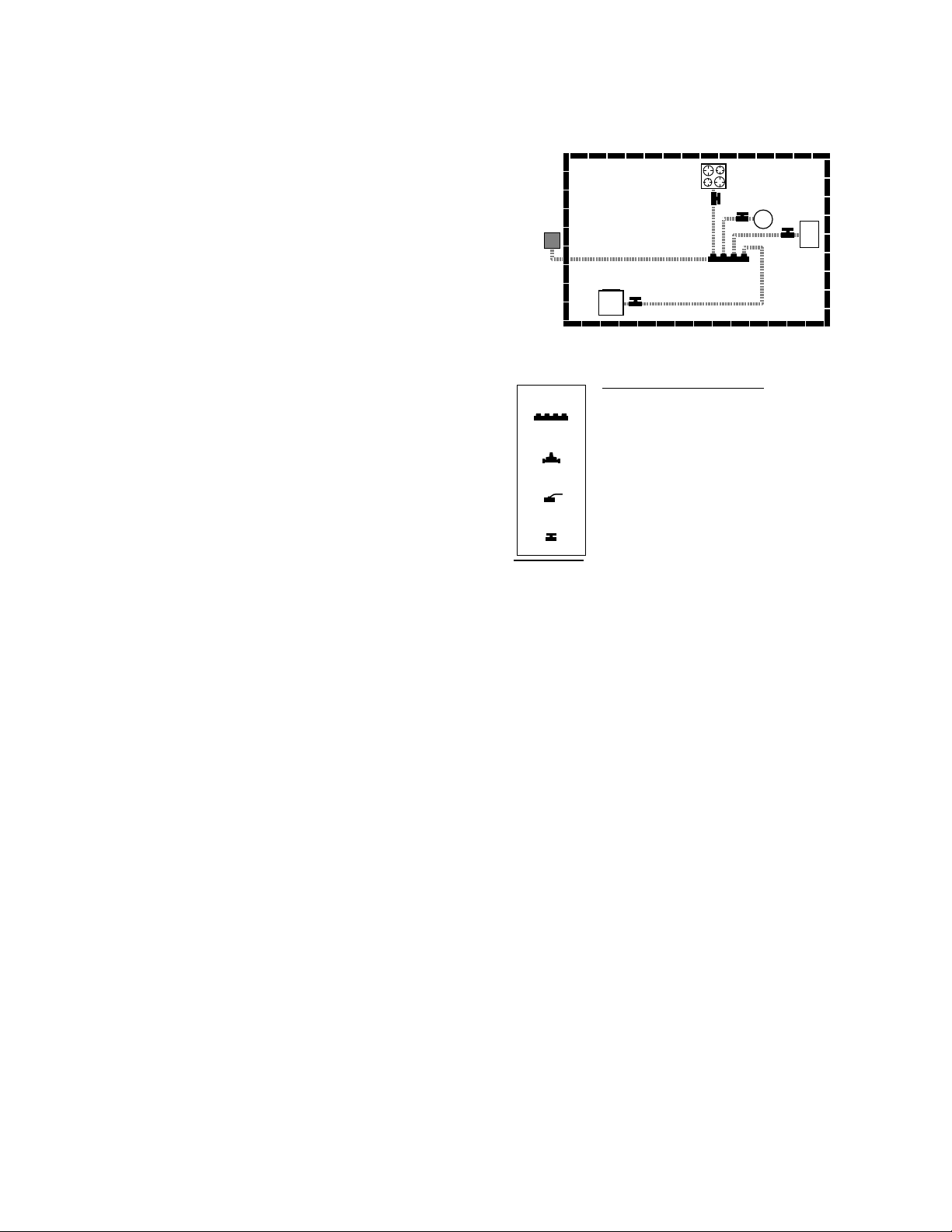

SECTION 3.2 SIZING METHODS and EXAMPLES

low pressure

gas meter

100 CFH

water heater

35 CFH

furnace

65 CFH

B

A

C

SECTION 3.2A — USE OF SIZING

TABLES

This Chapter includes flexible gas piping sizing procedures for both low pressure and elevated pressure systems. Every piping system

introduces pressure loss to the fluid flowing

within. The amount of loss depends on the

piping size and the gas flow, expressed in

cubic feet per hour (and converted to BTU’s).

The object of the sizing exercise is to determine the smallest size piping which will introduce the allowed pressure loss or drop within the length of piping required. Sizing Tables

(Capacity Charts) provide the maximum flow

capacity for a given length of run for each

pipe size. A different sizing table is used for

each system pressure and pressure drop

combination.

1. The low pressure series system (standard

arrangement) is sized in the same way as a

conventional low pressure black iron pipe

system using TracPipe sizing tables or

tables found in National Fuel Gas Code

NFPA 54. This method is known as the

“Branch Length Method”. Pressure drop in

a low pressure system is usually limited to

1/2 inch water column over the system.

This part of the system is sized the same

as a low pressure system, except that a

special table N-3 is used allowing 3 inches

of water column drop. These lines are typically sized for only one appliance load

installed as a “home run” from the manifold.

SECTION 3.2B — SIZING EXAMPLES

BRANCH LENGTH METHOD

To size each of the following systems, determine the required size for each section and

outlet. To size each section of the system,

determine both the total gas load for all appliances and the maximum distance (longest

length) in which a particular section delivers

gas.

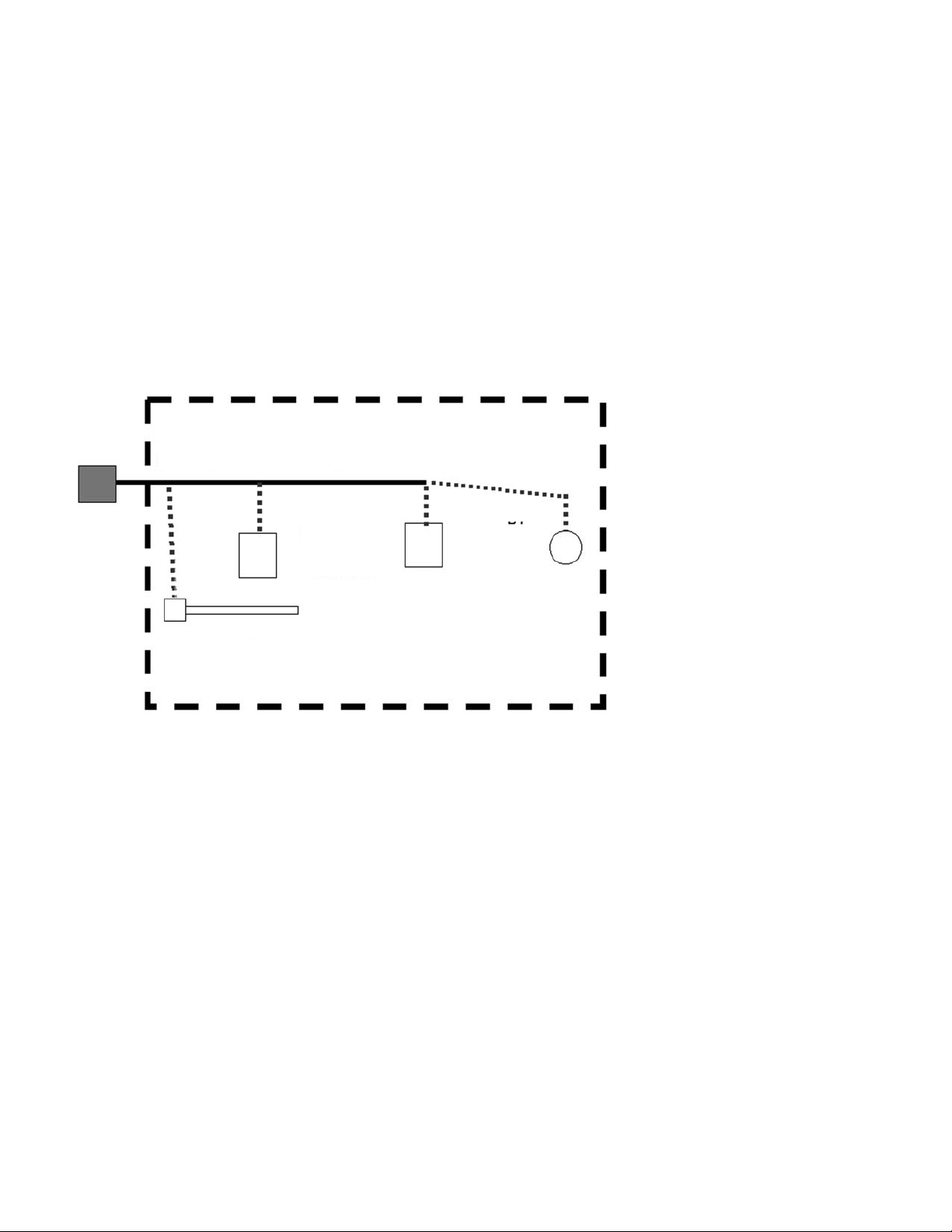

EXAMPLE 1 LOW PRESSURE SYSTEM

SERIES ARRANGEMENT

2. Elevated pressure systems incorporate two

operating pressures downstream of the utility meter set. The first pressure, set by the

service regulator at the meter, is usually 2

PSI. This part of the system is sized separately and ends at the pounds-to-inches regulator. The allowable pressure loss for this

part of the system must be added to the

effect of the regulator to determine the available pressure at the regulator outlet. The

chart in Section 4.8B shows pressure losses

for maximum loads through the regulator.

3. For a 2 PSI system, the proper drop is usu-

ally 1 PSI for this part of the system; this

allows for the approximate 3/4 PSI regulator drop downstream and provides the 1/4

PSI (6-7 inches w.c.) necessary for appliances. The regulator reduces the pressure

from pounds to 8 inches water column.

Figure 3-1

manifold

LENGTH OF RUNS

A = 10 Feet

pressure regulator

B = 10 Feet

C = 15 Feet

line shut-off

appliance shut-off

Supply pressure 6 inches w.c.

Allowable drop 0.5 inches w.c.

1. The system presented in figure 3-1 is typical of a single family installation in which

there are a limited number of appliances

located in one general area. The supply

pressure is 6 inches water column and the

allowable drop is 1/2 inch.

15

2. To size section A, determine the longest

run from the meter that includes section A

and the total gas load it must deliver:

• Meter to Furnace is 20 ft. (A+B)

parallel. The MEDIUM PRESSURE SYSTEM

(1/2 PSI ) allows a higher pressure drop

(6 inches Water column) than is available

with low pressure systems.

• Meter to Water Heater is 25 ft. (A+C).

This is the longest run.

• Determine the maximum load transported by Section A

• Furnace plus Water Heater = 100 cfh

(100,000 BTU)

• Select Table N-1 “Low Pressure 6

inches- 1/2 inch w.c. drop”

• Using the longest run method, select

the column showing the measured

length, or the next longest length if the

table does not give the exact length.

Referring to table N-1 the column for 25

feet of piping shows that sizes 3/8 and

1/2 are too small and the next available

size is 3/4 supplying 132 cfh.

• The correct size is 3/4".

3. To size Section B, determine the length of

run from the meter to the Furnace and the

load delivered:

• Length is 20 ft (A+B) and load is 65 cfh

(65,000 BTU)

• Table N-1 shows that size 1/2" supplies

67 cfh

• The correct size is 1/2".

4. To size Section C, determine the length of

run from the meter to the Water Heater and

the load delivered:

• Length is 25 ft (A+C) and load is 35 cfh

(35,000 BTU)

• Table N-1 shows that size 1/2" is

required, because size 3/8" only supplies 27 cfh (27,000 BTU)

• The correct size is 1/2"

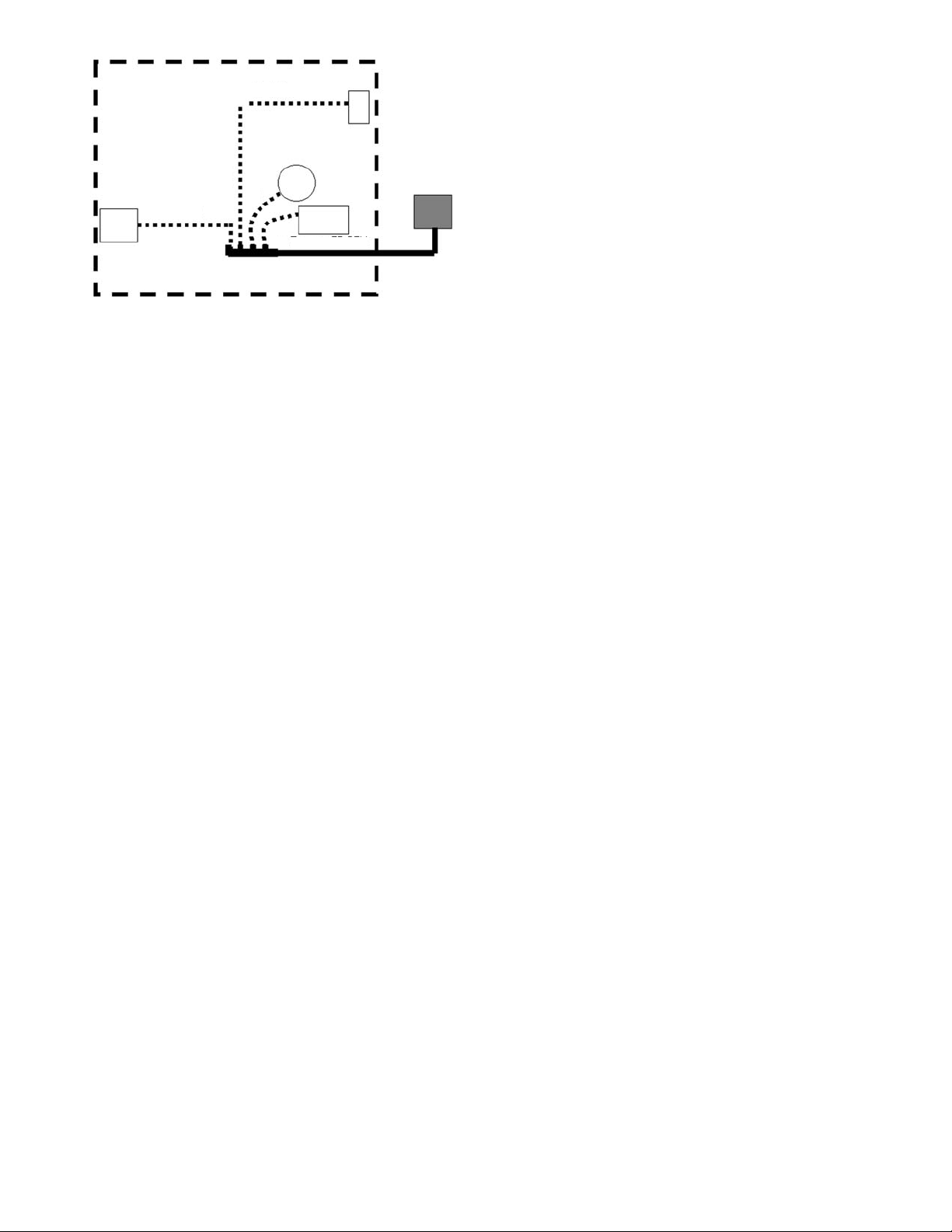

EXAMPLE 2 MEDIUM

PRESSURE 12-14 INCHES W.C. (1/2 PSI)

1. The system shown in Figure 3-2 is typical

of a single family installation with several

appliances. The arrangement chosen is

range

55 CFH

water heater

1/2 PSI

gas meter

205 CFH

dryer

30 CFH

40 CFH

C

B

A

D

furnace

H

80 CF

E

Figure 3-2

LENGTH OF RUNS

manifold

A = 10 Feet

B = 20 Feet

pressure regulator

C = 10 Feet

D = 40 Feet

line shut-off

appliance shut-off

E = 10 Feet

Supply pressure 1/2 PSI (12"-14"

w.c.)

Allowable drop: 6" w.c.

2. To size SECTION A, determine the

LONGEST RUN from the meter to the furthest appliance.

• Meter to dryer is 50 feet (10+40) A+D

• Determine maximum load transported by section A

• Dryer + Range + Water heater +

Furnace = 205 cfh ( 205,000 BTU)

• Select table N-4 “Medium Pressure

1/2 PSI with 6 inch drop”.

Table N-4 shows that 1/2" size is too

small for 205 cfh at 50 ft. but 3/4"

can handle 315 cfh.

• The correct size is 3/4"

3. To size SECTION B, the distance from the

meter to the range is 30 ft (10+20) A+B

• Load is 55 cfh ( 55,000 BTU )

• Table N-4 shows that 3/8" size can

handle 90cfh

• The correct size for section B is 3/8"

4. To size SECTION C, the distance from the

meter to the water heater is 20 ft (10+10) A+C

• Load is 40 cfh ( 40,000 BTU )

• Table N-4 shows that that 3/8" size

16

can handle 112cfh

r

• The correct size for section C is 3/8"

5. To size SECTION D, the distance from the

meter to the dryer is 50 ft (10+40) A+D

• Load is 30 cfh ( 30,000 BTU )

• Table N-4 shows that that 3/8" size

can handle 69cfh at 50 feet

• The correct size for section D is 3/8"

6. To size SECTION E, the distance from the

meter to the furnace is 20 ft (10+10) A+E

• Load is 80 cfh ( 80,000 BTU )

• Table N-4 shows that that 3/8" size

can handle 112cfh at 20 feet

• The correct size for section E is 3/8"

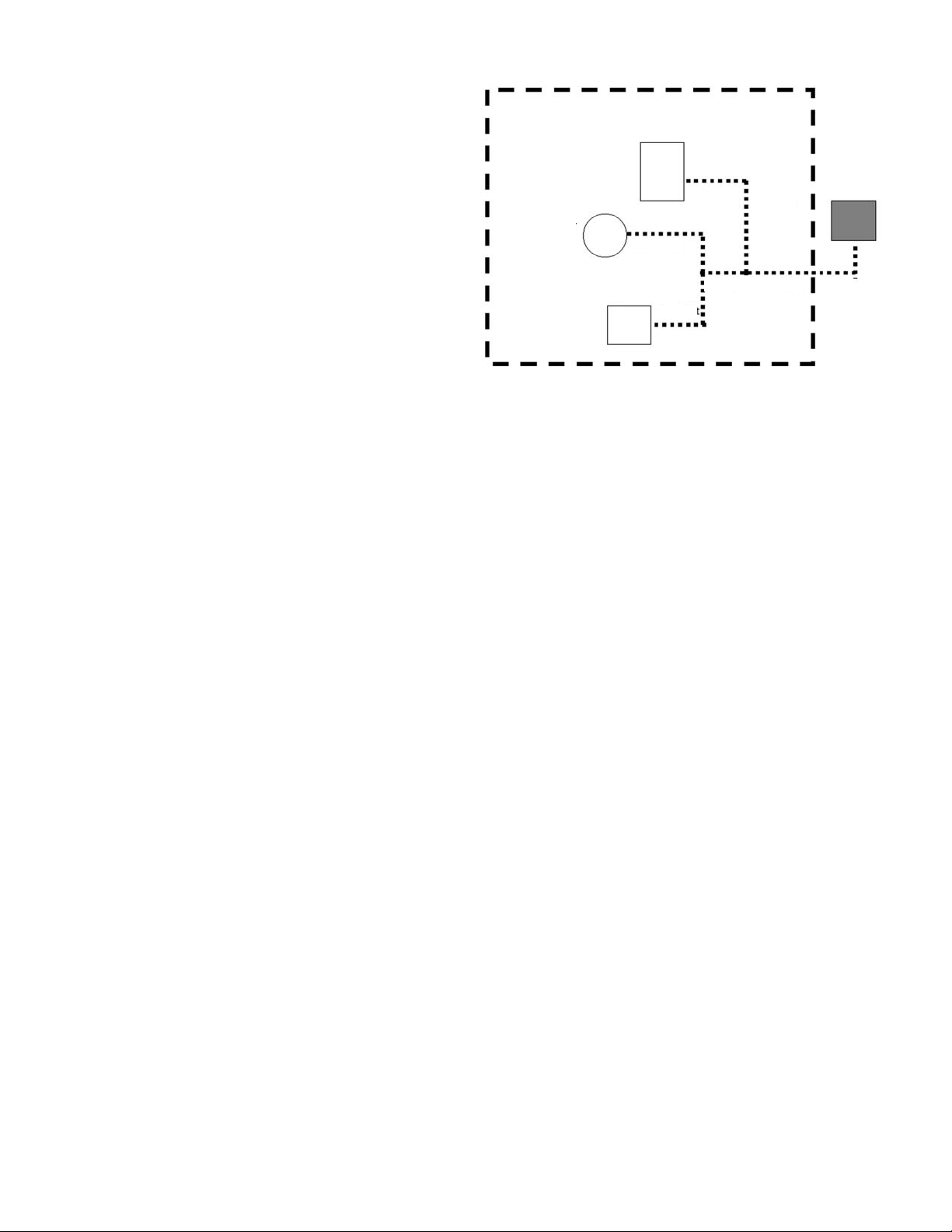

EXAMPLE 3 ELEVATED

PRESSURE 2 PSI SYSTEM

PARALLEL ARRANGEMENT

1. The system shown in figure 3-3 is adapted

for multifamily or single family application

with an extended (100 feet) tubing run from

the meter to the regulator The 2 PSI system

is well adapted to handle the long runs

required in multifamily buildings with centralized meter banks.

• furnace + water heater + dryer + range =

80 cfh + 40 cfh + 30 cfh + 55cfh = 205

cfh (205,000 BTUH) Select Table N-5

“Elevated Pressure 2 PSI with 1 PSI

drop’’ This is the standard table chosen

to stay within the Maxitrol 325-3 regulator capacity. See note below.

• Length is 100 ft.

• Table N-5 shows that 3/8" size is too

small for 205 cfh but 1/2" can handle

222cfh.

• The correct size is 1/2"

3. To size each of the other sections:

Select Table N-3 “Regulator Outlet 8.0

inches w.c with a drop of 3.0 inches w.c

• Section B is 15 feet with a 40 cfh load

3/8" has a capacity of 90 cfh

• Section C is 10 feet with a 80 cfh load

3/8" has a capacity of 112 cfh

• Section D is 25 feet with a 30 cfh load

3/8" has a capacity of 69 cfh

• Section E is 20 feet with a 55 cfh load

3/8" has a capacity of 78 cfh

• The correct size for all these runs is 3/8"

2. To size section A determine the entire gas

load it will deliver

range

55 CFH

furnace

80 CFH

E

C

dryer

D

30 CFH

B

water heater

40 CFH

2 PSI

gas mete

A

205 CFH

Figure 3-3

LENGTH OF RUNS

manifold

A = 100 Feet

B = 15 Feet

pressure regulator

line shut-off

appliance shut-off

C = 10 Feet

D = 25 Feet

E = 20 Feet

Supply pressure 2 PSI

Allowable drop: 1 PSI up to reg.

3 inches w.c.-reg. to appliance

NOTE: at 250 cfh gas flow the

FGP-REG-3 regulator contributes

3/4 PSI drop to the system. (see

chart below). The low pressure

part of the system downstream of

the regulator requires the standard

1/4 PSI to power appliances.

Deducting the 3/4 psi drop and the

1/4 psi load the maximum allowable drop for the meter run is 1

psi. Start with 2 PSI - 3/4 drop for

regulator - 1/4 left for Appliance =

1 PSI drop for section A.

Capacities and Pressure Drop

Pressure Drop through Regulator

Based on flow in cubic feet per hour

P/N 7" w.c. 1/2 psi 3/4 psi 1 psi

FGP-REG-3

FGP-REG-5A

FGP-REG-7L

145 204 250 289

338 476 583 673

690 972 1191 1375

17

EXAMPLE 4 MEDIUM

PRESSURE 12-14 INCHES W.C. 1/2 PSI)

PARALLEL SYSTEM WITH A SERIES BRANCH

1. The system shown in Figure 3-4 has a barbeque installed nearby the range. A parallel arrangement was chosen for the medium pressure system (12 inch W.C. with 6

inches W.C. drop) with a single run feeding

both range and barbeque in series.

D

1/2 PSI

gas meter

260 CFH

C

A

E

F

B

G

3. To size SECTION B, the line from the manifold serves both the range and the barbeque.

• Total load is 105 CFH (105,000 BTUH)

• Longest length is 75 feet (A+B+C) from

the meter to the barbeque

• Table N-4 shows that size 1/2" can

handle 116 CFH at 80 ft

• The correct size is 1/2"

4. To size SECTION C, the distance from the

meter to the barbeque is 75 ft (A+B+C)

• Load is 55 CFH (55,000 BTUH).

• Table N-4 shows that size 3/8" can only

handle 54 CFH at 80 ft

• The correct size is 1/2"

5. To size SECTION D, the distance from the

meter to the range is 65 ft (A+B+D)

• Load is 50 CFH (50,000 BTUH).

• Table N-4 shows that size 3/8" can

handle 58 CFH at 70 ft

• The correct size is 3/8"

Figure 3-4

LENGTH OF RUNS

A = 20 Feet

B = 35 Feet

C = 20 Feet

D = 10 Feet

E = 10 Feet

F = 10 Feet

G = 15 Feet

2. To size SECTION A, determine the length

of the longest run from the meter and the

entire gas load it must deliver:

• Range + Barbeque + Water heater +

Furnace +Dryer = 260 CFH (260,000

BTUH).

• Meter to barbeque is 75 ft (A+B+C) This

is the longest length

• Select Table N-4 Medium Pressure.

Table N-4 shows that 1" is required for

260 CFH at 75 ft (using next longer distance 80 ft column)

• The correct size is 1"

6. To size SECTION E, the distance from the

meter to the water heater is 30 ft (A+F)

• Load is 40 CFH (40,000 BTUH).

• Table N-4 shows that size 3/8" can

handle 81 CFH at 70 ft

• The correct size is 3/8"

7. To size SECTION F, the distance from the

meter to the furnace is 30 ft (A+E)

• Load is 80 CFH (80,000 BTUH).

• Table N-4 shows that size 3/8" can

handle 81 CFH at 30 ft

• The correct size is 3/8"

8. To size SECTION G, the distance from the

meter to the dryer is 35 ft (A+G)

• Load is 35 CFH (35,000 BTUH).

• Table N-4 shows that size 3/8" can

handle 78 CFH at 40 ft

• The correct size is 3/8"

18

SECTION 3.2C — SIZING HYBRID

SYSTEMS

(Black Iron and TracPipe Combination)

To size a commercial or a residential system

with a rigid black iron trunk line and flexible

TracPipe branches feeding the appliances,

you will need both the standard gas piping

capacity tables for black iron printed in many

plumbing and mechanical codes (and contained in both National and International Fuel

Gas Code) and the TracPipe Capacity Tables

printed later in this manual.

NOTE: Black Iron pipe Capacity Table is provided in this Design Guide Section 7.2

A

B

C

Total Load is 715 CFH (715,000 BTU)

Section A correct size is 11/2 inch black pipe

3. To determine rigid pipe size (section B)

reduce load by the load carried in section A1

to Radiant Heater (175 CFH). Use same

number for length: 70 ft. is longest run.

Load for this section is 540 CFH

Section B correct size is 1 1/2 inch black pipe

4. To determine rigid pipe size (section C)

reduce load further by the load carried in

section B1 to first unit

heater (250 CFH). Use

same number for length:

70 ft. is longest run.

Load for this section is

290 CFH

Section C correct size is 1

1/4 inch black pipe

C1

2 x each

250 CFH

Low-pressure

gas meter

715 CFH

B1

Unit heaters

A1

Radiant Heater

175 CFH

Figure 3-5

LENGTH OF RUNS

A = 15 Feet C = 20 Feet

A1 = 45 Feet C1 = 5 Feet

B = 15 Feet D1 = 20 Feet

B1 = 10 Feet

EXAMPLE 5 LOW PRESSURE HYBRID SYSTEM (Black Iron and TracPipe Combination)

SERIES ARRANGEMENT

1. The system shown in figure 3-5 is a typical

commercial building with 4 appliances. The

gas pressure for this example is standard low

pressure with 6-inch supply pressure and 0.5inch pressure drop.

2. To determine rigid pipe size (section A)

determine the longest run from the meter

to the furthest appliance:

Meter to Water Heater Add A + B + C + D1

= 70 ft.

D1

5. To determine TracPipe

sizing for the branch runs

the length to be used is

Water heater

40 CFH

the total length of black

pipe plus TracPipe from

the meter to that appliance. The load used is the

load of the individual

piece of equipment.

6. To determine the size of

TracPipe (section D1) the

length is 70 ft and the load

is 40 CFH. Using Table N-1:

Section D correct size is 3/4 inch

7. To determine the size of TracPipe (section

C1) the length is 55 ft and the load is 250

CFH. Using Table N-1:

Section C1 correct size is 11/2 inch

8. To determine the size of TracPipe (section

B1) the length is 40 ft and the load is 250

CFH. Using Table N-1:

Section B1 correct size is 11/4 inch

9. To determine the size of TracPipe (section

A1) the length is 60 ft and the load is 175

CFH. Using Table N-1:

Section A1 correct size is 11/4 inch

19

EXAMPLE 6 LOW PRESSURE HYBRID SYSTEM (Black Iron and TracPipe Combination)

SERIES ARRANGEMENT

Water heater

Low

pressure

meter

230 CFH

40 CFH

Furnace

70 CFH

A=40 ft

G=25 ft

D=10 ft

C2=6 ft

C1=6 ft

F=30 ft

35 CFH

B=20 ft

E=20 ft

H=40 ft

I=30 ft

Dryer

Figure 3-6

Fireplace

30 CFH

Range

55 CFH

5. Section C1, the longest run is 120 ft and

load is reduced to 105. Correct size is 1".

6. Section C2, the longest run is 120 ft and

load is reduced to 70. Correct size is 3/4".

7. Section D, the longest run is 120 ft and

load is reduced to 30. Correct size is 1/2".

8. Section E, length is 60 ft and the load is

55 CFH. From Table N-1 the correct size

is 3/4".

9. Section F, length is 90 ft and the load is 70

CFH. From Table N-1 the correct size is

3/ 4 " .

1. The system presented in figure 3-6 is a

typical residence with 5 appliances. The

supply pressure is 7 inches w.c. The

allowable drop is 1-inch w.c. total. (black

iron drop is 0.5 in. w.c. and TracPipe

drop is 0.5 in. w.c.) Note: Check with your

local inspection department and/or gas

utility before sizing any low-pressure system with a total drop of more than 0.5 in.

w.c.

2. The black iron trunk line (A+B+C1+C2+D)

will first be sized for a drop of 0.5 in., w.c.

in accordance with the standard method

(longest total run) and each TracPipe

branch run to an appliance will then be

sized for 1.0 in w.c. drop based on the

length from that appliance back to the

meter. The maximum pressure drop to

each appliance will be 1.0-inch w.c.

3. The longest total run is 120 ft. (total length

of all black iron sections and TracPipe

section to the furthest appliance). The

total load is 70+40+55+35+30=230 CFH.

Correct size for A is 1-1/4"

10.Section G, length is 95 ft and the load is

40 CFH. From Table N-1 the correct size

is 3/4".

11.Section H, length is 120 ft and the load is

30 CFH. From Table N-1 the correct size

is 3/4".

12.Section I, length is 95 ft and the load is 35

CFH. From Table N-1 the correct size is

3/ 4 " .

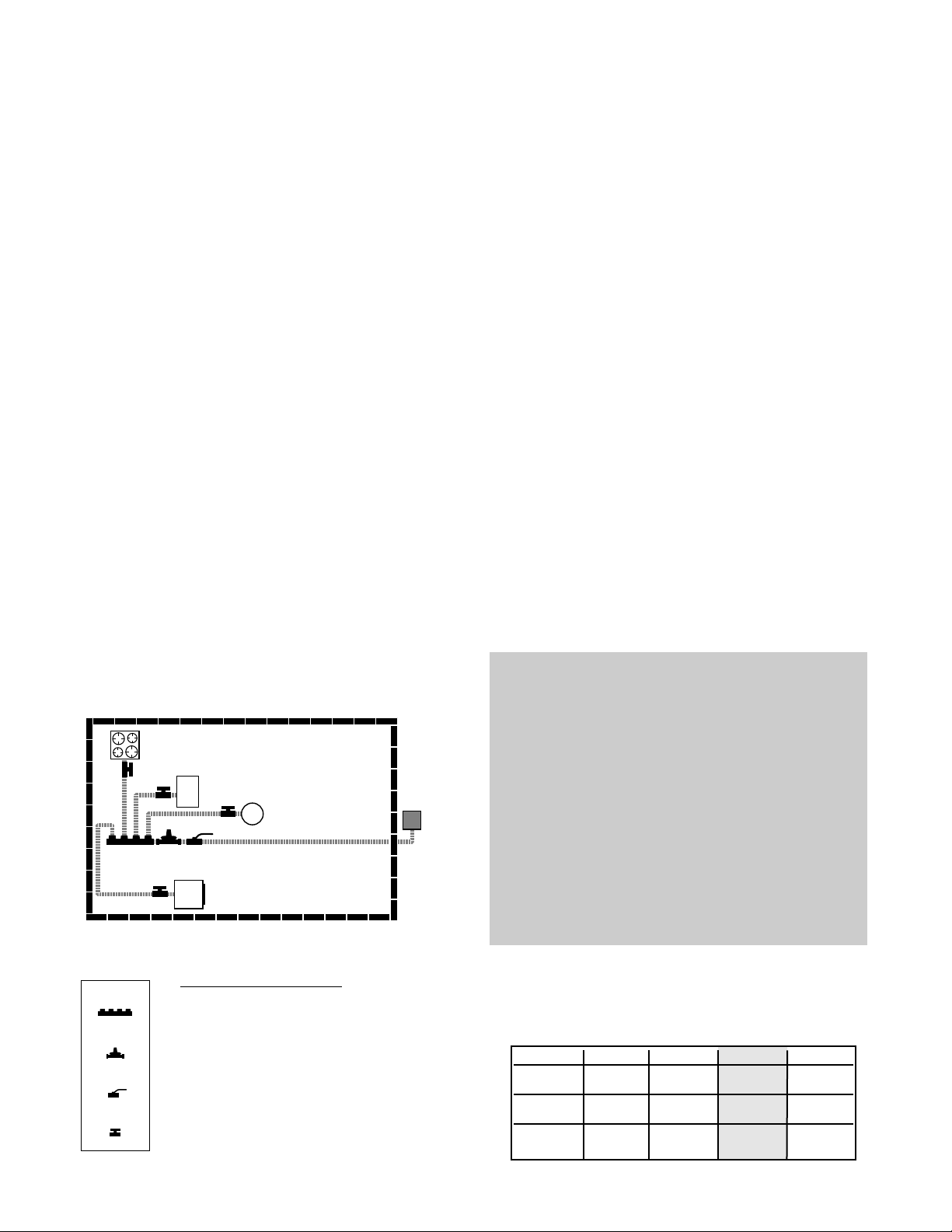

EXAMPLE 7 LOW PRESSURE HYBRID STEEL

PIPE AND TRACPIPE-PARALLEL ARRANGEMENT-MANIFOLD-USING THE LONGEST RUN

METHOD

1. The system presented in figure 3-7 is typ-

ical of a residential installation with four

appliances. The supply pressure is 7-8

inches water column. The system will be

sized with 0.5 inches w. c. drop for the

steel pipe trunk line and 1 inch w.c. drop

for the TracPipe branches. (Note: con-

firm that pressure drops larger than 0.5

inches water column are permitted in your

jurisdiction)

4. Section B, the longest run remains 120 ft

but the load is reduced to 175 CFH.

Correct size is 1".

20

D=30 ft

Fireplace

Range

55 CFH

E=25 ft

B=10 ft

C=10 ft

Figure 3-7

B

30 CFH

Water

heater

35 CFH

C

Furnace 75 CFH

A=20 ft

Low pressure

gas meter

195 CFH

2. To size the steel pipe trunk line, determine

the longest run from the meter to any

appliance and the total load. The longest

run is to the fireplace.

• Meter to fireplace is 50 ft (A + D)

• Total load is 195 CFH (75 + 35 + 30 + 55)

Using steel pipe Table SP-1 (page 77) following the 50 ft column down, the correct

size for the steel pipe is 1".

3. To determine the size of the TracPipe run

“C” to the furnace use the load through

that branch (75 CFH) and calculate the

length from the meter to the furnace.

• Meter to furnace is 30 ft (A + B)

• Furnace load is 75 CFH

Using Table N-2A the 1.0-inch w.c. pressure drop chart for TracPipe. Follow the

30 ft column down, the correct size for the

furnace branch line “C” is 1/2".

4. To determine the size of the TracPipe run

“B” to the water heater use the load

through that branch (35 CFH) and calculate the length from the meter to the water

heater.

• Meter to water heater is 30 ft (A + C)

• Water heater load is 35 CFH

Using Table N-2A the 1.0-inch w.c. pressure drop chart for TracPipe. Follow the

30 ft column down, the correct size for the

water heater branch line “B” is 1/2".

5. To determine the size of the TracPipe run

“D” to the fireplace use the load through

that branch (30 CFH) and calculate the

length from the meter to the fireplace.

• Meter to fireplace is 50 ft (A + D)

• Fireplace load is 30 CFH

Using Table N-2A the 1.0-inch w.c. pressure drop chart for TracPipe. Follow the

50 ft column down, the correct size for the

fireplace branch line “D” is 1/2".

6. To determine the size of the TracPipe run

“E” to the range use the load through that

branch (30 CFH) and calculate the length

from the meter to the range.

• Meter to range is 45 ft (A + E)

• Range load is 55 CFH

Using Table N-2A the 1.0-inch w.c. pressure drop chart for TracPipe. Follow the

50 ft column down, the correct size for the

range branch line “D” is 1/2".

SECTION 3.2D — ALTERNATE

SIZING METHOD:

SUM OF PRESSURE LOSS

CALCULATIONS

1. In addition to the longest run sizing

method, there is another approach to pipe

sizing, which yields results closer to the

actual friction loss results (obtained from

testing) for each section of an installed

gas piping system. This engineered

approach “Sum of Pressure Loss

Calculations” avoids the simplified, conservative approximations of the longest

run method. Mechanical engineers who

design piping systems understand that

placing a building’s entire load (theoretically) at the farthest equipment outlet is

not only inaccurate but will often yield

pipe sizes which are larger than necessary. The longest run method was devised

at a time when gas utilities could not

always guarantee a constant pressure at

every meter during times of high

demands; it is a conservative approach

and, although it is the customary sizing

approach in North America, other engineered calculations are permitted by most

codes.

21

2. Pressure Loss Calculations which sum up

friction losses in each section of a gas

piping system can provide a system

design with more accurate and possibly

smaller piping diameters than the traditional longest run method. These calculations utilize pressure loss charts for each

size of CSST, which have been developed

from actual test results. The maximum

flow capacity is predicted with more precision than with the longest run method.

The Sum of Pressure Loss method is

described below with tables providing

pressure loss per foot based upon the

total load supplied by that length of pipe

with all appliances operating.

3. The system designer has simply to determine the load and the length for each run. A

tentative size is chosen and pressure loss in

that leg is determined by multiplying the

loss per foot (inches w.c. from the chart) by

the length. Starting at the meter and working outward the pressure loss for each leg

is then summed up until the farthest appliance is reached. The total calculated loss is

then compared with the allowable loss,

which must not be exceeded from the

meter to the farthest appliance. The allowable pressure loss for each system is the

responsibility of the system designer, based

on model codes and on the available pressure at the meter set (or second stage regulator) and the pressure required for each

appliance (usually found on the manufacturer's data plate.) Current language in

many model codes states: The allowable

loss under maximum probable flow conditions, from the point of delivery to the inlet

connection of the appliance, shall be such

that the supply pressure at the appliance is

greater that the “minimum inlet pressure”

as stated on the appliance manufacturers

data plate. If the initial proposed design calculation yields a total pressure loss, which

is higher than allowed, simply go back and

calculate again with larger sizes, starting

from the meter.

USING SUM OF PRESSURE LOSS METHOD

Furnace

65 CFH

B=10 ft

Water Heater

35 CFH

Dryer

35 CFH

EXAMPLE 8 LOW PRESSURE SYSTEM

SERIES ARRANGEMENT

C2=10 ft

C1=5 ft A=10 ft

D=15ft

Figure 3-8

1. The system presented in figure 3-8 is similar

to that in 3-1, a single-family installation with

the addition of one more appliance, a dryer.

The supply pressure is 6 inches water column and the allowable pressure drop is 1/2

inch.

2. To size section A, calculate the load carried by that section:

• Furnace plus Water Heater plus Dryer =

135 CFH (135,000 BTU)

Using Table PD-1 find pressure loss at 135

MBTU load through 3/4" TracPipe Average

of .019 and .022 is .021. Drop per foot is

0.021; multiply by length 10 feet = 0.21

drop

3. To size section B find the drop per foot for

the load carried by that section:

65 CFH (MBTU)

Using Table PD-1 find pressure loss at 65

MBTU through 1/2" TracPipe

Use the average of loss between 60 and

70 MBTU: Average of .019 and .027 is

.023 ; Drop per foot is 0.023 Multiply by

length 10 feet = 0.23 drop

Sum pressure loss meter to Furnace 0.21

+ 0.23 = .44 inches w.c

This leg is sized properly at 1/2" because

sum of loss is less than .5 in. w.c.

22

4. To size section C1 find the drop per foot

for the load carried by that section:

70 CFH (MBTU)

Using Table PD-1 find pressure

loss at 70 MBTU load through 1/2"

TracPipe

Drop per foot is .027; length is 5

ft; 5 X .027 is .135

5. To size section C2 find the drop

per foot for the load carried by

that section:

35 CFH (MBTU)

Low

Low

Pressure

Pressure

Meter

Meter

230 CFH

230 CFH

Using Table PD-1 find pressure

loss at 35 CFH load through 1/2"

TracPipe

Average of .008 and .004 is .006;

length is 10 ft; 10X .006 is .06

Sum pressure loss to water heater

0.21 + .135 + .06 = .405 inches

w.c

This leg is sized properly at 1/2" because

sum of loss is less than .5 in. w.c.

6. To size section D find the drop per foot for

the load carried by that section:

35 CFH (MBTU)

Using Table PD-1 find pressure loss at 35

MBTU through 1/2" TracPipe

Drop per foot is .006 (see number 4

above); Multiply by length 15 feet = .09

Sum pressure loss to dryer 0.21 + 0.135 +

.09 = .435 inches w.c.

This leg is sized properly at 1/2" because

sum of loss is less than .5 in. w.c.

The sum of pressure loss method allows the

addition of an appliance without increasing

trunk line size.

EXAMPLE 9 LOW PRESSURE HYBRID SYSTEM (Steel Pipe and TracPipe Combination)

SERIES ARRANGEMENT USING SUM OF

PRESSURE LOSS METHOD

1. The system presented in figure 3-9 is

identical to that in Figure 3-6: a singlefamily installation with 5 appliances. Low

pressure 6-7 inches and a pressure drop

of 0.5 inches water column. NOTE: in

Example 6 this system was sized using

the longest run method. Here we will use

the sum of pressure loss method discussed in section 3.2D.

Water Heater

40 CFH

G=25 ft

Furnace

70 CFH

A=40 ft

D=10 ft

C2=5 ft

C1=5 ft

F=30 ft

B=20 ft

Figure 3-9

H=40 ft

Dryer

35 CFH

E=30 ft

I=30 ft

Fireplace

30 CFH

Range

55 CFH

2. Begin by using pipe sizes determined in

Example 6 and determine if these are correct with this method. It is possible that

smaller pipe sizes may be sufficient; this

will be determined by calculating the sum

of pressure losses from the meter to each

appliance. To use this method a tentative

size will be assigned to each run and this

size will be confirmed or revised by the

calculation. The sum total loss of a run

from the meter to the appliance cannot

exceed the allowable pressure loss.

3. To determine pressure loss through section A (steel pipe trunk), use the load

through that section (230 CFH) and find

pressure loss per foot from the steel pipe

Schedule 40 Pressure Drop Curves Graph

Table SP-1. The 1 1/4 inch pipe diameter

line intersects the 230 CFH line at a pressure drop of .18 inches w.c. per 100 feet

of length. Multiply the length: 40 feet by

the loss per foot: 0.0018. The pressure

loss for this section is 0.072.

4. To determine pressure loss through section

B we use the load through that section

(175 CFH). Find pressure loss for 1" size

from the steel pipe graph in Table SP-1

- 0.6 per 100 feet. Multiply the length: 20

feet by the loss per foot: 0.006. The pressure loss for this section is 0.12.

23

5. To determine pressure loss through section C1 we use the load through that section (105 CFH). Find pressure loss for 1"

size from the steel pipe graph - 0.2 per

100 feet. Multiply the length: 5 feet by the

loss per foot: 0.002. The pressure loss for

this section is 0.01.

6. To determine pressure loss through section C2 we use the load through that section (70 CFH). Find pressure loss for 3/4"

size from the steel pipe graph - 0.38 per

100 feet. Multiply the length: 5 feet by the

loss per foot: 0.0038. The pressure loss for

this section is 0.019.

7. To determine pressure loss through section D we use the load through that section (30 CFH). Find pressure loss for 1/2"

size from the steel pipe graph - 0.31 per

100 feet. Multiply the length: 10 feet by the

loss per foot: 0.0031. The pressure loss for

this section is 0.031.

8. To determine pressure loss through section E (TracPipe drop to the range), use

the load through that section (55 CFH) and

find pressure loss from Table PD-1

Pressure Drop per Foot for TracPipe.

Trying the 3/4 inch column we find .004

inches per foot length (there is no 55 CFH

load listed, so we use 60 CFH). Multiply

the length: 30 feet by the loss per foot

.004. The pressure loss for this section is

0.12. Add the loss of section A to the loss

of section E for total loss from the meter to

range. 0.072 + 0.12 = 0.192. Since this is

less than the 0.5 allowable drop the correct size for section E is 3/4".

9. To determine pressure loss through section F (TracPipe drop to the furnace),

use the load (70 CFH) and find pressure

loss from Table PD-1. In the 3/4" column

we find 0.005. Multiply the length: 30 feet

by 0.005. The pressure loss for this section is 0.15.

Add the loss of sections A + B to the loss

of section F for total loss from meter to

furnace. 0.072 + 0.12 + 0.15 = 0.342. The

correct size for section F is 3/4".

10. To determine pressure loss through section G (TracPipe drop to the water

heater), use the load (40 CFH) and find

pressure loss from Table PD-1. In the 1/2"

column we find 0.008. Multiply the length:

25 feet by 0.008. The pressure loss for this

section is 0.20. Add the loss of sections A

+ B + C1 + C2 to the loss of section G for

total loss from meter to furnace. 0.072 +

0.12 + 0.01 + 0.019 + 0.20 = 0.421. The

correct size for section G is 1/2".

11. To determine pressure loss through section H (TracPipe drop to the fireplace),

use the load (30 CFH) and find pressure

loss from Table PD-1. In the 1/2" column

we find 0.004. Multiply the length: 40 feet

by 0.004. The pressure loss for this section is 0.16. Add the loss of sections A + B

+ C1 + C2 + D to the loss of section H for

total loss from meter to furnace. 0.072 +

0.12 + 0.01 + 0.019 + 0.031 + 0.16 =

0.412. The correct size for section H is

1/2".

1

2. To determine pressure loss through section I (TracPipe drop to the dryer), use the

load (35 CFH) and find pressure loss from

Table PD-1. In the

0.006. Multiply the length: 30 feet by

0.006. The pressure loss for this section is

0.18. Add the loss of sections A + B + C1

to the loss of section I for total loss from

meter to dryer. 0.072 + 0.12 + 0.01 + 0.18

= 0.382. The correct size for section I is

1/2"

. Using the Sum of Pressure Loss

Method we calculate that three of the five

TracPipe sections (when compared with

the longest length method) can utilize

reduced sizes to deliver the necessary

load with a pressure loss equal to or less

than the allowable 0.5 inches water column. This enables the installer to use

TracPipe on all but the furnace and range

drops, which remain

1/2"

column we find

3/4"

.

1/2"

24

SECTION 3.3 AUTOTRIP™ LOW

PRESSURE EXCESS FLOW

VALVES FOR NATURAL GAS AND

PROPANE SERVICE

An excess flow valve (EFV) is a protective

device to help control the discharge of fuel

gas in the event of a complete breakage of

pipe lines or flex connector rupture. Excess

flow valves have been of help in limiting gas

loss in many incidents involving breakage of

piping; thus they do provide a useful safety

function in gas systems. This section

explains what protection excess flow valves

can offer, points out conditions which can

interfere with that protection, and offers suggestions for effective excess flow valve

installation.

1. There are two types of AutoTrip EFVs:

LFD Series Line/Meter excess flow valves

and AFD Series Appliance Connector

excess flow valves.

AUTOTRIP Appliance Connector EFVs act to

restrict the flow of gas should the downstream appliance connector suffer a complete break or pull-out. The inlet side of the

AUTOTRIP Appliance Connector excess flow