Page 1

em

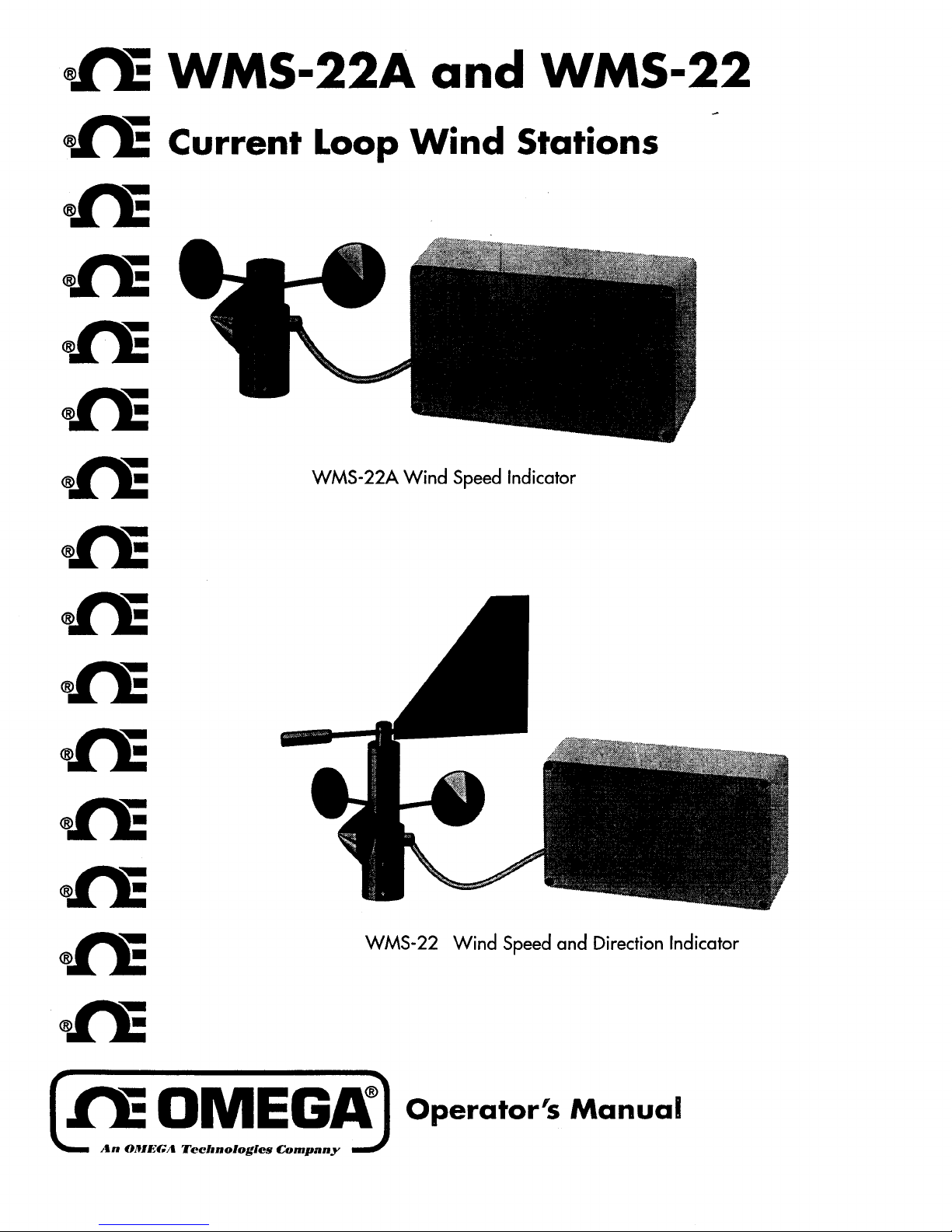

WMS-22A

and

WMS-22

@

fl

Current Loop Wind Stations

WMS-22A Wind Speed indicator

*

WMS-22 Wind Speed and Direction Indicator

Operator ’s

Manual

Page 2

Unpacking Instructions

Remove the Packing List and verify that you have received all equipment, including the following

(quantities in parentheses):

0

WMS-22A or WMS-22”. Wind Sensor

0

Transmitter Housing Assembly, with I/O connection terminal strips

-

_-_

l

Operator’s Manual

If you have any questions about the shipment, please call the OMEGA Customer Service Department.

When you receive the shipment, inspect the container and equipment for signs of damage. Note any

evidence of rough handling in transit. Immediately report any damage to the shipping agent.

The carrier will not honor damage claims unless all shipping material is saved for

inspection. After examining and removing contents, save packing material and

carton in the event reshipment is necessary.

Page 3

Servicing USA and Canada: Call OMEGA

Toll

Free

USA

One Omega

Stamford, CT 06907-0047

Telephone: (203) 359-1660

FAX: (203) 359-7700

Sales Service: l-800-826-6342

Customer Service: l-800-622-2378

Engineering Service: l-800-872-9436

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Drive, Box 4047

Canada

976 Bergar

Lava1

(Quebec)

Telephone: (514) 856-6928

FAX: (514) 856-6886

l-SOO-TC-OMEGASM

/

l-SOO-622-BESTSM

/

l-SOO-USA-WHENSM

/

H7L

5Al

Servicing Europe: United Kingdom Sales and Distribution Center

25 Swannington Road, Broughton Astley, Leicestershire

6TU,

England

FAX: 44 (1455) 283912

LE9

Telephone: 44 (1455) 285520

The OMEGA Complete Measurement and

Control Handbooks

V

Temperature

&

V

Pressure, Strain

r/

Flow and Level

DH

I/

and

Conductivitv

Force

&

Encyclopedias

V

Data

V

Electric Heaters

V

Environmental Monitoring

Acquistion Systems

and Control

Call for Your FREE Handbook Request

MHDOS95HABA

Form Today:

(203)

359-RUSH

Page 4

OMEGA Engineering

Model WMS-22 and WMS-22A Current Loop

WindStations

Instruction Manual

1.0 INTRODUCTION

The WMS-22 Current Loop

paramenter into 4-20

external power is required since the encoding electronics for wind speed and for wind direction are

isolated and powered from their respective 2-wire current loops.

The WMS-22 wind sensor includes a three-cup anemometer and wind vane. The sensor is ruggedly

constructed of UV-resistant ABS plastic and anodized aluminum parts. The cable that connects the

pole-mounted wind sensor to the encoder electronics package may be extended up to a total of 250

feet. The encoded current loops signals may be transmitted over distances of up to several miles.

The electronics package, which is typically mounted in an indoor locations, is supplied in a gasketed,

wall-mounted

The measurement time base for the wind speed-to-current conversion in the encoder is crystal

controlled for stable long-term accuracy.

direction measurement circuitry to minimize drift and non-linerity.

NEMA-4X

mA

WindStation

output signals for use by process control or monitoring systems.

enclosure.

measures wind speed and direction and converts each

No

Likewise, ratiometric signal conditioning is used to the

Two versions are offered; the WMS-22A measures wind speed only, while the WMS-22 measures

both wind speed and direction. The WMS-22 systems consist of two subassemblies: a wind sensor

and a signal conditioning electronics assembly.

2.0 PHYSICAL DESCRIPTION

2.1 The Wind Sensor

The rotating assembly containing the three-cup anemometer and wind vane for sensing wind speed

and directional information is called the wind sensor. The wind vane is mounted on a common axis

with the anemometer and includes a tail fin with a nose weight that provides balance.

is coupled to an angular encoder which is housed within the cylindrical weather skirt.

2.2 The Encoder

The encoder electronics package is housed in a sealed NEMA enclosure and contains two independent

4-20

mA

data channels, one for wind speed and the second for wind direction.

its respective 2-wire measurement loop.

Each- is powered from

The wind vane

Page 5

2.3 Specifications

Wind Speed

Measurement Range

Averaging Interval

Resolution

Threshold

Measurement Accuracy

O-100 mph

2.1 Seconds

1 mph

<l

mph

f3%

F.S.

I

~

Wind Direction

Range O-360” Mechanical 350” Electrical

Resolution

Accuracy

Threshold

2 Degrees

+5

Degrees

51

Mph

Current Loop

ou t pu t

span

Supply Voltage Range

4

10 to 48 Vdc

InA

t o

20

2-Wire Loop Interface Screw Terminal Block

3.0

GENERAL DESCRIPTION

3.1 Wind Speed Measurement

1”

The WMS-22 wind sensor is designed to be mounted on the end of a

supplied with 40 feet of cable for connection to the electronics housing.

ball bearing is protected from the weather and has lifetime lubrication.

of the wind vane balances the weight of the moving mass over its supporting bearing.

outside diameter pole. It is

The anemometer’s precision

The counterweight at the end

It is important

that the wind sensor be installed in a location free from any obstructions that would distort the natural

flow of air across the sensor.

mA)

The full-scale (20

The full-scale span of the direction channel represents a full 360 degree swing of the wind vane.

output of the wind speed channel represents a measured 100 mph wind speed.

The

potentiometer used as a direction sensor for wind direction has a small arc of resistance discontinuity

(typically

straddling the North direction (indicated by the set screw in the mounting base).

5-10”)

When the wind vane is pointing in this region, the loop current will be encoded as an underscale

value of approximately 3.6

4.0

INSTALLATION

mA.

4.1 Unpacking

Empty the loose packing material from the corrugated shipping container and carefully lift out the

wind sensor assembly.

List of Enclosed Materials

1.

2.

3.

Wind Speed, Wind Direction sensor, with 40 feet of cable

Transmitter Housing Assembly with I/O connection terminal strips input receptacle.

Instruction Manual.

Page 6

4.2 Wind Sensor Installation

Choose the mounting location for the wind sensor and temperature sensor unit which is free from

obstructions.

A typical installation will position the wind sensor approximately 10 meters above the highest obstacle

within a 300 meter radius of the mounting locations.

diameter TV mast tubing or a

electrically to minimize the probability of any lightning damage.

that the setscrew on the anemometer base is facing True North.

directional orientation.

4.3 Transmitter Installation

Mount the transmitter assembly in a covered location where it can be conveniently connected to its

exterior wind sensor.

length without degrading the accuracy of its measurements.

its base is pointing to North.

staples are used to secure it. The standard wind sensor is supplied with 40 feet of cable. In the event

that the interconnecting cable needs to be extended, use good splicing techniques and waterproof the

splice if it will be exposed to the weather.

Use extreme care to prevent contact with electrical power lines while erecting the unit.

Position the WMS-22 sensor on the end of a

314”

Schedule 40 pipe.

The six-wire cable to the wind sensor may be extended to up to 250 feet in

Use care not to puncture the jacket of the interconnecting cable if

If the pole is metal it should be well grounded

Turn the anemometer on the pole so

Tighten the setscrew to fix the

Orient the sensor so that the setscrew in

1”

I/O connection terminal strips are located at the top edge of the printed circuit board.

functions with the corresponding colors of the wind sensor interconnecting cable are as follows:

1

Speed Input + (White)

Jl

1 1

0

0

1

-

Speed Input

2 lo l

l

5 lo l

l

06

01

a2

01

a2 0

5.0 OPERATIONAL CHECKOUT

Connect the speed and wind direction process control loops to the appropriate locations of the

terminal strip of the printed circuit board as shown on the earlier chart. For test purposes, you may

wish to use an unregulated but filtered source of

resistor (preferably

encoding circuits requires the proper polarity of loop current; however, diodes are included to protect

the circuitry against the case of a reversed polarity connection.

0

0

0

0

I

Direction Return

I

Unused (Blue)

52

Wind Speed plc Loop

Wind

Wind Direction plc Loop +

53

Wind Direction plc Loop

f

Sneed

1% accuracy) connected in a series with the supply. The loop powered

(Black)

LOOD

~lc

-

(Yellow)

+

-

-

lo- to 24-volt DC power having a precision 100 ohm

Terminal

Page 7

lo.9

Connect the test leads of a digital voltmeter across the resistor to measure the plc

measured wind speed and direction at several cardinal calibration points should correspond to the

following:

current.

The

Wind Direction Wind Speed (mph) Loop Current

N+

NE = 45 ”

E = 90 ”

SE = 135 ”

S = 180 ”

II

SW =

NW

II

5.1 Circuit Board Adjustments

Multiple turn potentiometers on the printed circuit board are provided for independent gain and offset

adjustment of both the speed and direction channels

225”

W=270”

315” 87.5 18.0

=

N -

I

I

0.0 4.0

12.5

25

37.5

50

62.5

75 16.0

100

I

I

as follows:

20 . 0

6.0

8.0

10.0

12.0

14.0

(mA)

V

1000

(Volts)

0.4

0.6

0.8

1.0

1.2

I

I

1.4

1.6

1.8

2.0

::: ““ .

The WMS-22 normally should not require adjustment of these controls. An exception occurs if for

any reason the wind sensor is changed or if the cabling to the wind sensor exceeds 200 feet in length.

In these cases the span control of the direction channel may require a slight adjustment.

jumper is included on the PC board direction channel to facilitate checking its offset and span

adjustments. To use this feature, remove the jumper normally in place at the

move it to the “JO” position.

mA

level. If necessary, adjust R-25 to obtain this value, noting that counterclockwise rotation of its

adjustment screw will cause the offset value to increase. Moving the jumper position to the “JF”

location will cause the loop current to its full scale value of 20

obtain this value noting that counterclockwise rotation of its adjustment screw will cause an increase

in the span.

since there is some slight interaction between the two adjustments. Be sure to return the jumper to

the JW position at the conclusion of this adjustment procedure.

The Wind Speed channel should not normally require adjustment in the field.

If either the span or offset trim are changed, it is suggested that both values be checked,

This should force the wind direction loop current to its zero scale or 4

mA.

If necessary, adjust R-24 to

“JW”

A movable

position and

4

Page 8

5

II

-l-

DC PO W ER

SOURC E

10 lo 48

MOD E L Z OO - W S - 2 2

CURREN T L OO P W I NDS TAT I O N

VDC

+

+

-

TYPICAL LOAD OF

PRODUCES OUTPUTS OF

TYP I CA L W I R ING W I T H A S I NG L E PO W ER SOURC E

Page 9

L

=

Ei

I

-

I J I

I-

--II

Page 10

WARRANTY

ree of defects in mat

satisfactory service for a period of 13

months

additional one (1) month grace period to the normal

handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on

each product. If the unit should malfunction, it must be returned to the factory for evaluation.

OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately

upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective it

will be repaired or replaced at no charge. However, this WARRANTY is VOID, if the unit shows

evidence of having been tampered with or shows evidence of being damaged as a result of

excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication;

misuse or other operating conditions outside of OMEGA ’s control. Components which wear or

which are damaged by misuse are not warranted. These include contact points, fuses, and

OMEGA is glad to offer suggestions on the use of its various products. Nevertheless,

OMEGA only warrants that the parts manufactured by it will be as specified and free of

defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE AND ALL IMPLIED

WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive and

the total liability of OMEGA with respect to this order, whether based on contract,

warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the

purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

from date of purchase. OMEGA Warranty adds an

one (1) year product warranty

to cover

triacs.

Every precaution for accuracy has been taken in the preparation of this manual; however, OMEGA

ENGINEERING, INC. neither assumes responsibility for any omissions or errors that may appear

nor assumes liability for any damages that result from the use of the products in accordance with

the information contained in the manual.

SPECIAL CONDITION: Should this equipment be used in or with any nuclear installation or activity,

purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the equipment in such a manner.

/

RETURN REQUESTS

INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA ENGINEERING Customer Service

Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN

AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA ’S CUSTOMER SERVICE DEPARTMENT

(IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on

the outside of the return package and on any correspondence.

FOR

WARRANTY

RETURNS, please have the FOR

following information available BEFORE

contacting OMEGA:

1.

P.O. number under which the product was

PURCHASED,

Model and serial number of the product

2.

under warranty, and

Repair instructions and/or specific problems

3.

relative to the product.

NON-WARRANTY

TION,

Charges.

available-BEFORE contaction OMEGA:

1

1.

consult OMEGA for current

Have the following information

P-0.

number to cover the COST of the

REPAIRS OR

repair/calibration,

2.

Model and serial number of the product, and

Repair instructions and/or specific problems

3.

relative to the product.

CALIBRA-

repair/calibra-

OMEGA ’s

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

0

Copyright 1995 OMEGA ENGINEERING, INC. All rights reserved. This documentation

reproduced, translated, or reduced to any electronic medium or machine-readable form, in

written consent of OMEGA ENGINEERING, INC.

policy is to make running changes, not

model

changes, whenever an improvement is possible. This affords

not

m ay

be cop ied , pho t ocop ied ,

w ho le o r in pa rt, w it hou t P r io r

Page 11

I

I

Find Everything Where Do

Need for

Process Measurement and Control?

OMEGA...Of

TEMPERATURE

&

w

Thermocouple, RTD

w

Wire: Thermocouple, RTD & Thermistor

&

m

Calibrators

m

Recorders, Controllers

w

Infrared Pyrometers

Ice Point References

PRESSURE/STRAIN FORCE

&

m

Transducers

B

Load Cells

B

Displacement Transducers

w

Instrumentation

Strain Gages

&

Pressure Gauges

FLOW/LEVEL

m

Rotameters, Gas Mass Flowmeters

w

Air Velocity Indicators

@

Turbine/Paddlewheel Systems

&

m

Totalizers

Batch Controllers

H/CONDUCTIVITY

pH Electrodes, Testers & Accessories

g

l8

Benchtop/Laboratory Meters

B

Controllers, Calibrators, Simulators

@’

Industrial

pH & Conductivity Equipment

Thermistor Probes, Connectors, Panels &

&

Process Monitors

&

Accessories

&

Flow Computers

&

Pumps

Course!

Assemblies

DATA ACQUISITION

B

@t’

w

B

B

HEATERS

m

@’

w

B

@’

ENVIRONMENTAL MONITORING AND CONTROL

B

w

@’

B

m

B

M2312/0995

Data Acquisition and Engineering Software

Communications-Based Acquisition Systems

&

Plug-in Cards for Apple, IBM

Datalogging Systems

&

Recorders, Printers

Heating Cable

&

Cartridge

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

Metering

Refractometers

Pumps

Air, Soil

Industrial Water

pH,

Conductivity & Dissolved Oxygen Instruments

Strip Heaters

&

Control Instrumentation

&

Tubing

&

Water Monitors

Plotters

&

Wastewater Treatment

Compatibles

Page 12

Loading...

Loading...