Page 1

User’s Guide

®

®

wiSeries

Main Menu

CHART

(2 Seconds/Div)

1 Minute

1 Minute

1 Day

1 Week

1 Month

1 Year

0

5

C/Div

50

1200

300

100%

0%

10

%/Div90hPa/Div

C hPa

Tue Feb 5 10:19:10 PDT2008Tue Feb 5 10:18:10 PDT2008

http://192.168.1.200

Min/Max Temperature

48.0/41.0

P1 Process

P2 Sensor 2

P3 Process

P4 Process

P5 Process

P6 Process

P7 Process

P8 Sensor 8

A1 Ambient

A2 Sensor 2

A3 Ambient

A4 Ambient

A5 Ambient

A6 Ambient

A7 Ambient

A8 Sensor 8

Save Current Graph

Shop on line at

omega.com

e-mail: info@omega.com

For Latest Product Manuals

omegamanual.info

Wireless Meter Scanner & Controller

wi8xx-U

Page 2

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark

to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or

commissioning this device as the guide contains important information relating to safety and EMC.

Page 3

TABLE OF CONTENTS

Part 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Part 2 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Physical Characteristics and Mounting . . . . . . . . . . . . . . . . .5

2.1.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.4 Assembly and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.4.1 Panel Mounting Instruction . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.4.2 Antenna Mounting Instruction . . . . . . . . . . . . . . . . . . . . . . . .9

2.1.4.3 Disassembly Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.1.5 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.1.5.1 Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.1.5.2 Wiring Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.1.5.3 Jumper Settings for Display Color Setup . . . . . . . . . . . . . . .14

2.1.5.4 DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

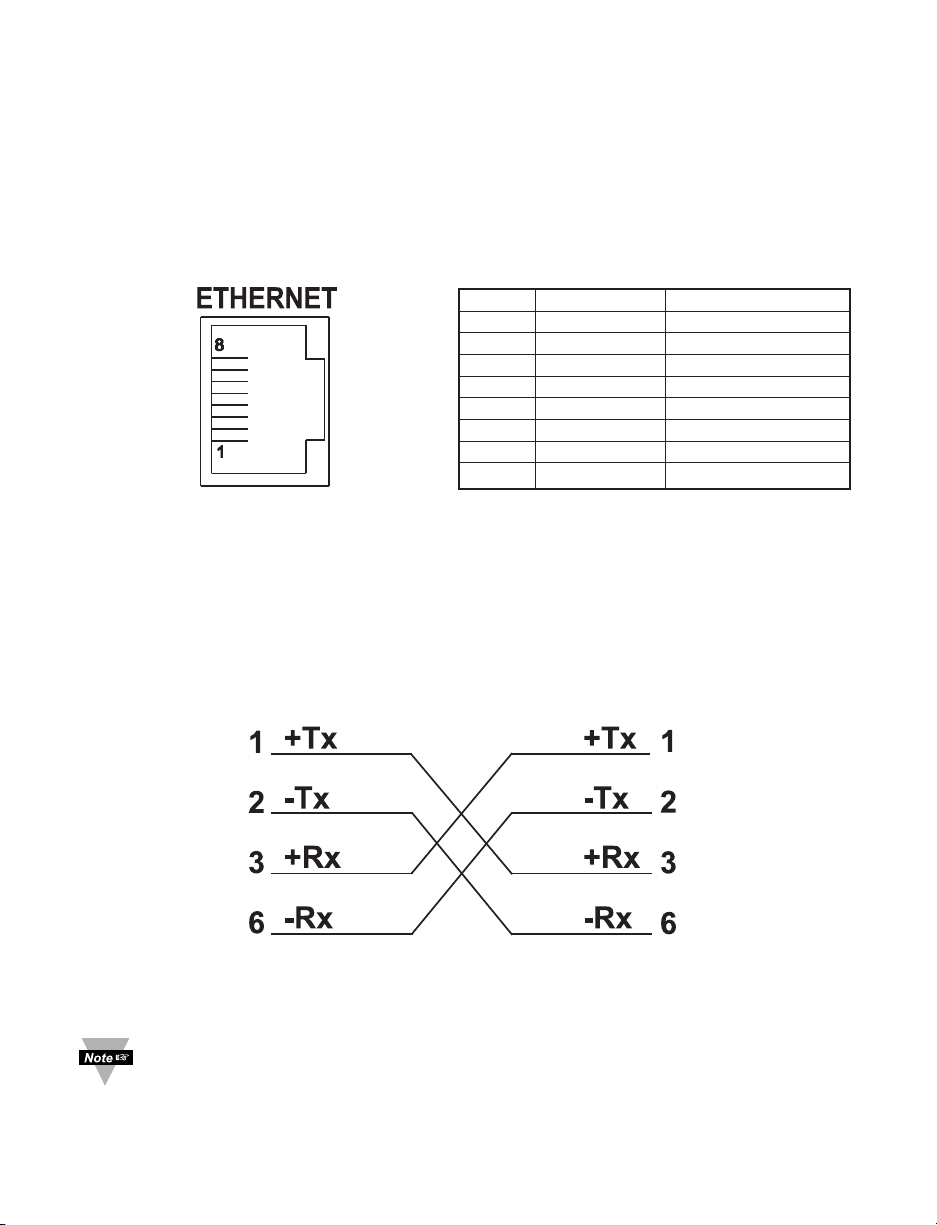

2.2 Network Communications . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.2.1 10Base-T RJ45 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.2.2 10Base-T Crossover Wiring . . . . . . . . . . . . . . . . . . . . . . . . .16

Part 3 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.1 Ethernet (MAC) Address . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.2 Network Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3 DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.4 DNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.5 IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.5.1 Default IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.5.2 Changing TCP/IP Properties on your Computer . . . . . . . . .20

Part 4 Network Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.0 Testing the Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.1 iConnect Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

4.2 Setting a New IP Address over the Network . . . . . . . . . . . .24

4.3 Meter’s Configurations and Operations . . . . . . . . . . . . . . . .25

4.3.1 Power Up Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.3.2 Get Readings from the End Device . . . . . . . . . . . . . . . . . . .27

4.3.3 Java Runtime Environment Setup . . . . . . . . . . . . . . . . . . . .29

4.3.3.1 Java Runtime Environment 1.5 (5.0) Setup Instructions . . .29

4.3.3.2 Java Runtime Environment 1.4 Setup Instructions . . . . . . .30

4.3.3.3 Browser Proxy Selection . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.3.4 Java Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.3.5 Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.3.6 Controller Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

i

Page 4

4.3.7 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.3.7.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.3.7.2 Setpoints & On/Off Control . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.3.7.3 Alarms 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.3.7.4 Analog Output Retransmission . . . . . . . . . . . . . . . . . . . . . .43

4.3.7.5 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.3.7.5.1 Display Color Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.3.7.6 Passcode ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4.3.8 Network Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.3.9 End Device Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.3.9.1 End Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.3.10 Access Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.4 Telnet Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.5 HTTPget Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.5.1 HTTPget using Port 2000 . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.5.2 HTTPget and ARP to Setup Device IP Address . . . . . . . . . .59

4.6 ARP Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.7 iLog Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.8 Mail Notifier Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.8.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.8.2 Program Options Setup and Configuration . . . . . . . . . . . . .64

4.8.3 Device Settings and Configuration . . . . . . . . . . . . . . . . . . . .65

Part 5 Environment/Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . .67

5.1 General Deployment Guidelines . . . . . . . . . . . . . . . . . . . . .67

5.2 With Line-of-Sight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

5.3 Without Line-of-Sight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

5.4 Casing and Closure Around the Antenna . . . . . . . . . . . . . . .70

Part 6 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Part 7 Factory Preset Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Appendix A Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Appendix B IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Appendix C IP Netmask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Appendix D ASCII Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Appendix E iLog Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Appendix F Warning and Regulatory Information . . . . . . . . . . . . . . . . . .83

LIST OF FIGURES:

Figure 1.1 Temperature Wireless Monitor and Control System

on the Ethernet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 2.1 Front Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ii

Page 5

Figure 2.2 Rear Panel Power and Output Connections . . . . . . . . . . . . . . .6

Figure 2.3 Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 2.4 Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 2.5 Antenna Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 2.6 Accessing the Main Board Assembly . . . . . . . . . . . . . . . . . . . .10

Figure 2.7 Main Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

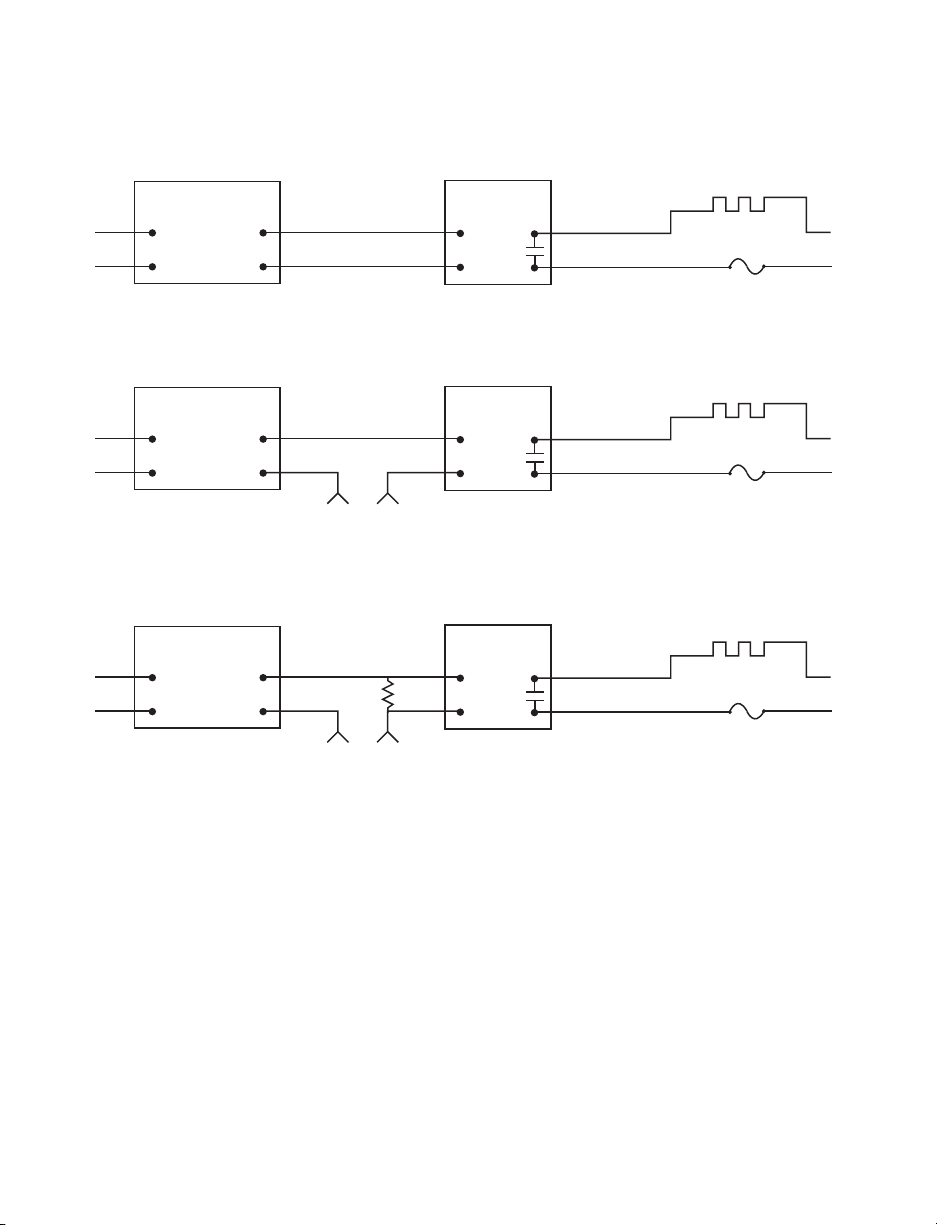

Figure 2.8a Mechanical Relay and SSR Output Wiring Hookup . . . . . . . . .12

Figure 2.8b Pulse and Analog Output Wiring Hookup . . . . . . . . . . . . . . . . .12

Figure 2.9 Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

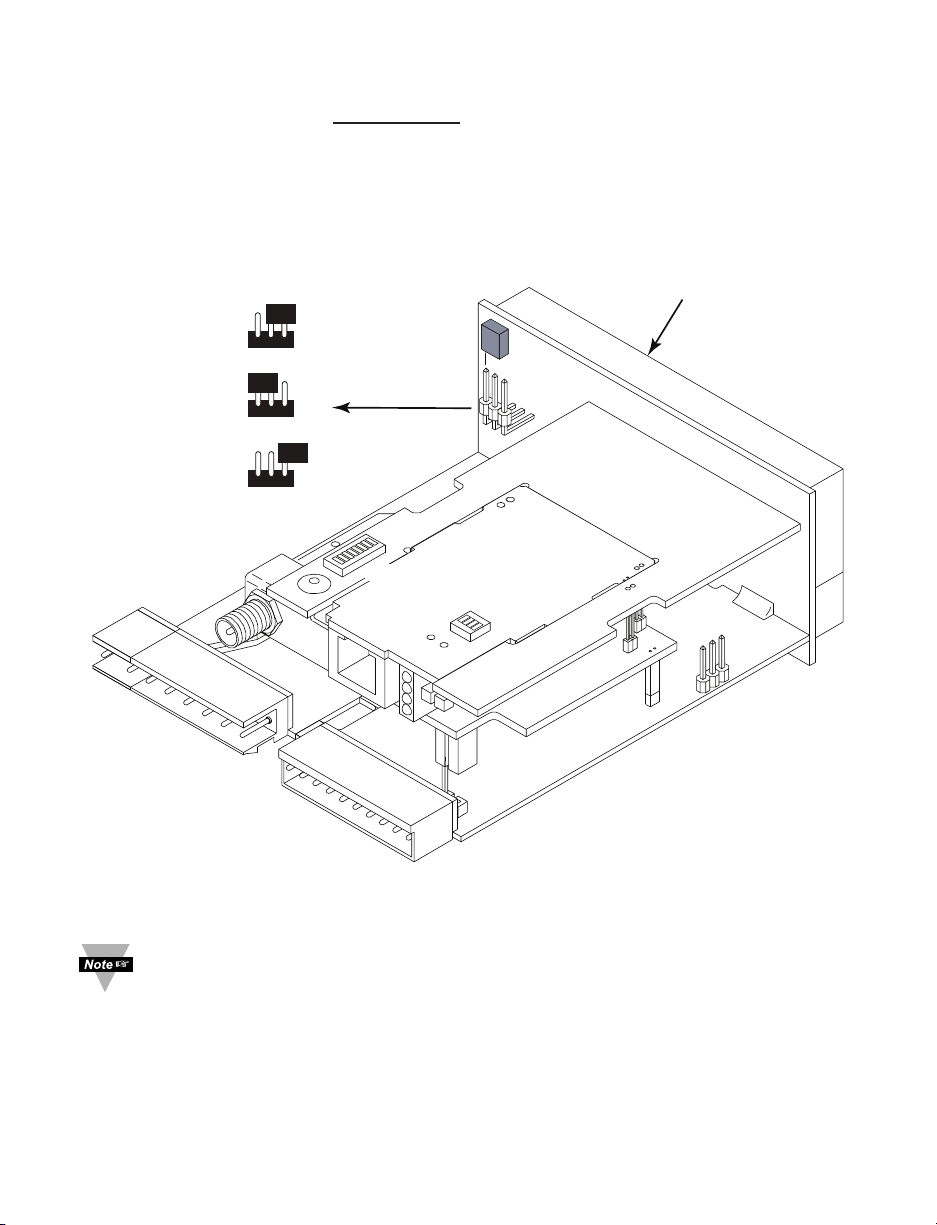

Figure 2.10 Location of S1 Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

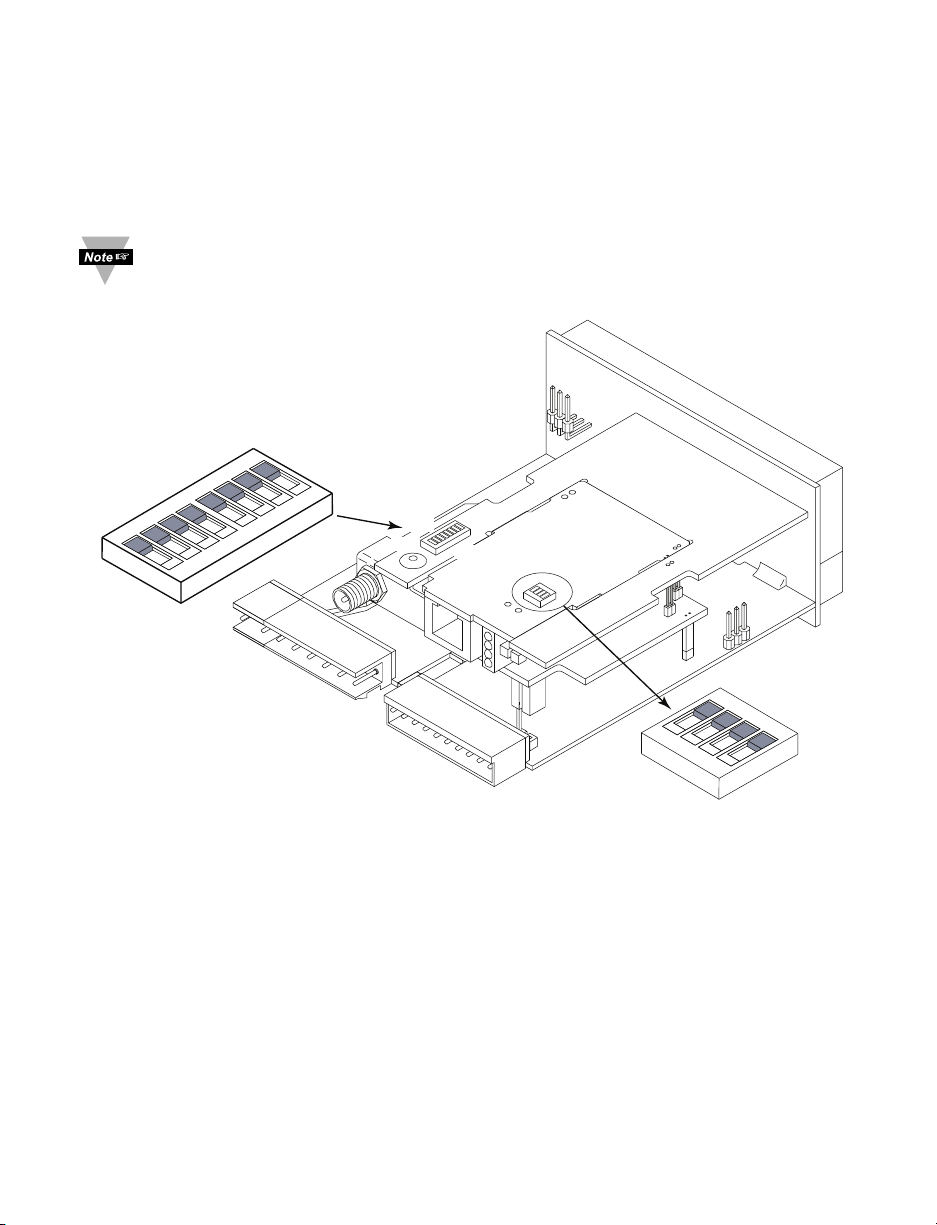

Figure 2.11 Location of DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 2.12 RJ45 Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Figure 2.13 10Base-T Crossover Cable Wiring . . . . . . . . . . . . . . . . . . . . .16

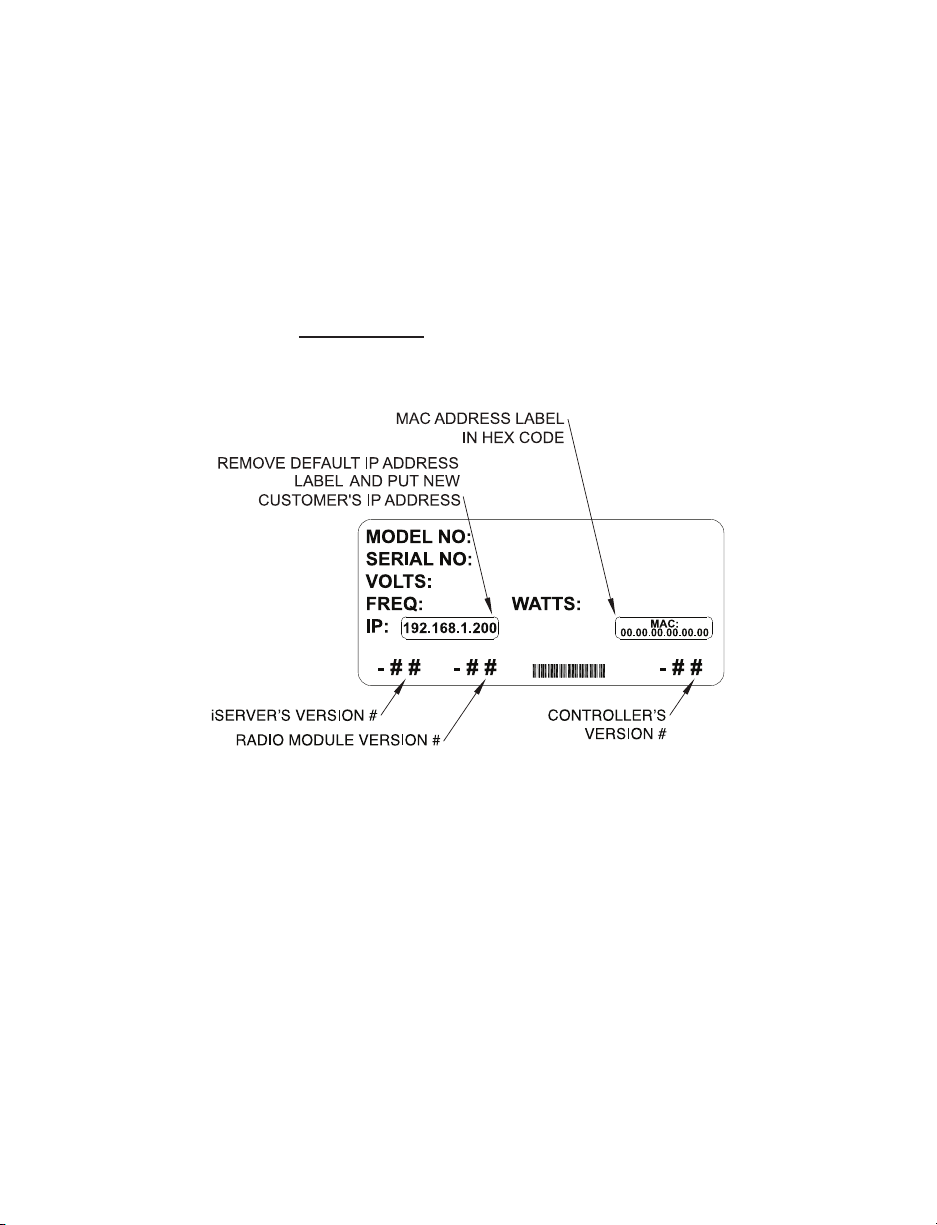

Figure 3.1 Label Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

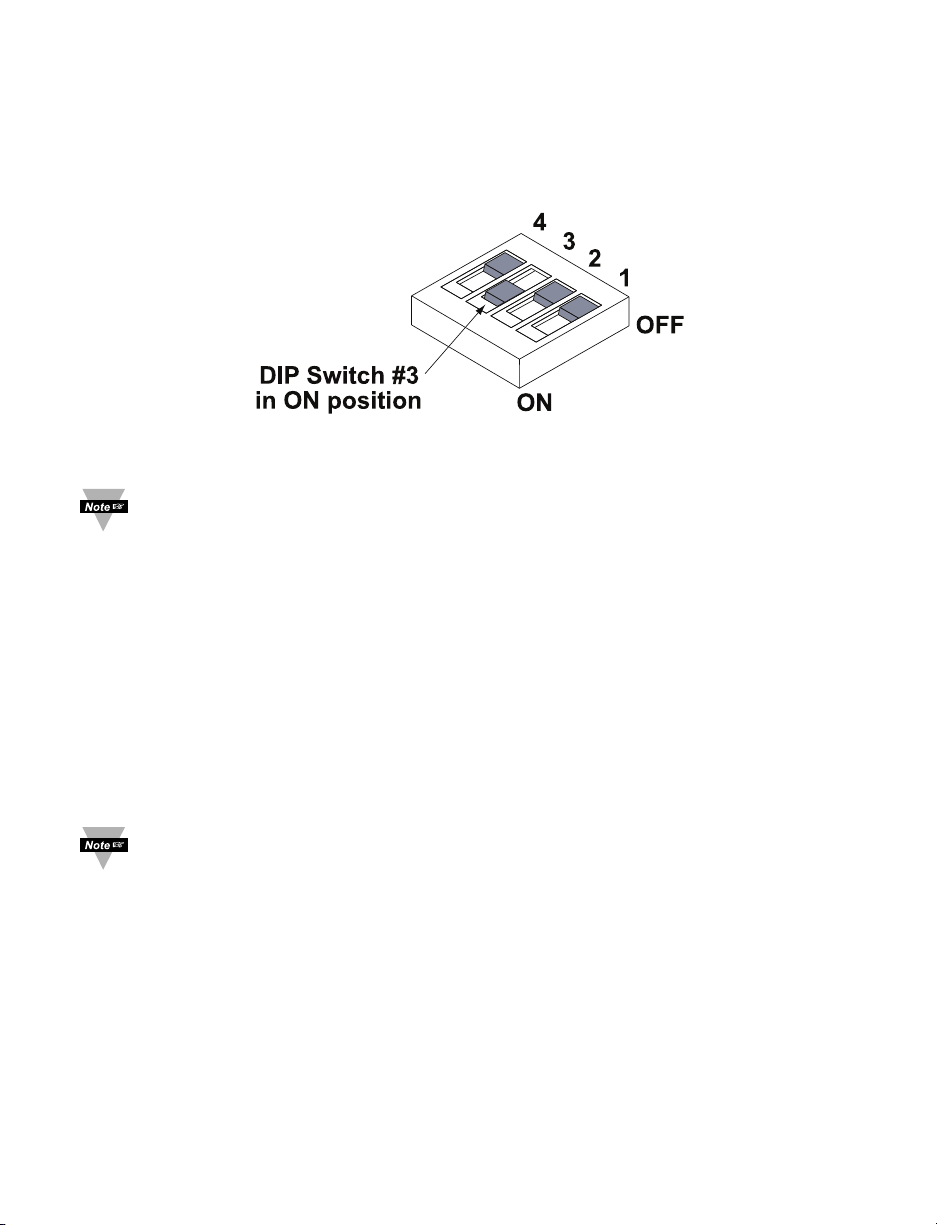

Figure 3.2 4 Position DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Figure 3.3 Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20.

Figure 3.4 Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Figure 4.1 Pinging the Meter from MS-DOS Prompt . . . . . . . . . . . . . . . . .21

Figure 4.2 Assigning an IP Address using iConnect . . . . . . . . . . . . . . . . .22

Figure 4.3 Accessing the Wireless System for Configuration . . . . . . . . . .23

Figure 4.4 Access Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Figure 4.5 Wireless System Home Page Menu . . . . . . . . . . . . . . . . . . . . .25

Figure 4.6 LOGIN and ADMINISTRATOR Passwords . . . . . . . . . . . . . . .26

Figure 4.7 Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 4.8 Comma Separated Value Format . . . . . . . . . . . . . . . . . . . . . . .28

Figure 4.9 Java 1.5.x.x Screen Shots . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 4.10 Java 1.4 Screen Shots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 4.11 Java Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 4.12 Java Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Figure 4.13 Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 4.14 Controller Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 4.15 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Figure 4.16 Setpoints & On/Off Control . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 4.17 Alarms 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 4.18 Analog Output Retransmission . . . . . . . . . . . . . . . . . . . . . . . . .43

Figure 4.19a Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 4.19b Display Menu (if Analog Output Option) . . . . . . . . . . . . . . . . . .45

Figure 4.20 ID Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Figure 4.21 Network Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Figure 4.22 End Device Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Figure 4.23 End Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Figure 4.24 Remote End Char . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Figure 4.25 Access Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Figure 4.26 HTTPget Example of Polling End Device . . . . . . . . . . . . . . . . .59

iii

Page 6

Figure 4.27 ARP Commands and Responses . . . . . . . . . . . . . . . . . . . . . . .60

Figure 4.28 iLog Software Logging Data for End Device . . . . . . . . . . . . . . .61

Figure 4.29 Mail Notifier Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Figure 4.30 Mail Notifier Profile Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Figure 4.31 Mail Notifier Device Settings . . . . . . . . . . . . . . . . . . . . . . . . . .66

Figure 5.1 Operation in Buildings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure 5.2 Fresnel Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Figure 5.3 Materials in Buildings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

LIST OF TABLES:

Table 2.1 Front Panel Enunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table 2.2 Rear Panel Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 2.3 Fuse Requirements (See Specifications) . . . . . . . . . . . . . . . . .11

Table 4.1 List of Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Table 4.2 Connector/Transmitter Types . . . . . . . . . . . . . . . . . . . . . . . . .59

Table 4.3 iLog Excel Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Table 4.4 Mail Notifier Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Table 7.1 Factory Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

iv

Page 7

PART 1

INTRODUCTION

1.1 Safety Considerations

This device is marked with the international caution symbol. It is important

to read this manual before installing or commissioning this device as it

contains important information relating to Safety and EMC (Electromagnetic

Compatibility).

This instrument is a panel mount device protected in accordance with EN

61010-1:2001, electrical safety requirements for electrical equipment for

measurement, control and laboratory. Installation of this instrument should

be done by qualified personnel. In order to ensure safe operation, the

following instructions should be followed.

This instrument has no power-on switch. An external switch or circuitbreaker shall be included in the building installation as a disconnecting

device. It shall be marked to indicate this function, and it shall be in close

proximity to the equipment within easy reach of the operator. The switch or

circuit-breaker shall meet the relevant requirements of IEC 947–1 and IEC

947-3 (International Electrotechnical Commission). The switch shall not be

incorporated in the main supply cord.

Furthermore, to provide protection against excessive energy being drawn

from the main supply in case of a fault in the equipment, an overcurrent

protection device shall be installed.

• Do not exceed voltage rating on the label located on the top of the

instrument housing.

• Always disconnect power before changing signal and power

connections.

• Do not use this instrument on a work bench without its case for safety

reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Unit mounting should allow for adequate ventilation to ensure

instrument does not exceed operating temperature rating.

• Use electrical wires with adequate size to handle mechanical strain and

power requirements. Install without exposing bare wire outside the

connector to minimize electrical shock hazards.

EMC Considerations

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wires close to the instrument if EMC

problems persist.

Failure to follow all instructions and warnings may result in injury!

This is a Class A ITE product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

1

Page 8

1.2 Before You Begin

Inspecting Your Shipment:

Remove the packing slip and verify that you have received everything

listed. Inspect the container and equipment for signs of damage as soon

as you receive the shipment. Note any evidence of rough handling in

transit. Immediately report any damage to the shipping agent. The carrier

will not honor damage claims unless all shipping material is saved for

inspection. After examining and removing the contents, save the packing

material and carton in the event reshipment is necessary.

Customer Service:

If you need assistance, please call the nearest Customer Service

Department, listed in this manual.

Manuals, Software:

The latest Operation Manual as well as free configuration software

(iConnect) are available from the website listed on the cover pages

of this manual, or on the CD-ROM enclosed with your shipment.

NOTES, WARNINGS and CAUTIONS

Information that is especially important to note is identified by following labels:

NOTE: Provides you with information that is important to successfully

setup and use the Programmable Digital Meter.

CAUTION or WARNING: Tells you about the risk of electrical shock.

CAUTION, WARNING or IMPORTANT: Tells you of circumstances

or practices that can effect the instrument’s functionality and must

refer to accompanying documents.

TIP: Provides you helpful hints.

1.3 Description

The wi®Series wireless monitoring and control system features meters compatible

with a large and growing number of wireless sensors: UWTC “Universal Wireless

Thermocouple” Type J, K, T, E, R, S, B, N, and C, UWRTD “Universal Wireless

RTD” , and UWIR “Universal Wireless Infrared Temperature Sensor”. For more

information about the UWTC, UWRTD, and UWIR, refer to the separate manual for

these products.

2

Page 9

1.3 Description (continued)

The wireless sensors transmit up to four hundred feet 400’ (approx. 120 meters-without obstructions or interference) to a wiSeries meter connected directly to an

Ethernet network and the Internet. The wireless system complies with IEEE 802.15.4

operating at 2.4 GHz. The wiSeries Meter Scanner & Controller can monitor up to

eight (8) wireless sensors.

The Meter also provides error detection mechanism for inactive communication

and diagnostic information including signal strength and data transmission

success rate to help troubleshooting potential wireless system installation issues.

The Meter connects directly to an Ethernet network and the Internet and features

award-winning embedded Web Server. It is easily configured and monitored with a

Web browser over the Ethernet network or the Internet.

CONTROL, MONITOR, AND ALARM: The Meter comes standard with dual outputs

of either Form C relays, SSR’s (solid state relays) or dc Pulses that can be used for

ON/OFF control functions or alarms.

The meter can monitor alarm conditions for any or all of the wireless sensors. For

example, the meter can be set up to trip an alarm if any one of the sensors indicated

that it was above or below a pre-set alarm point.

Analog output is fully scalable and may be configured as an ON/OFF controller or retransmission to follow your readings.

MONITOR AND CONTROL LOCALLY AND OVER THE INTERNET: The wiSeries

wireless monitoring and control system provides local monitoring and control, along

with remote Web-based monitoring of temperature from thermocouples, RTD’s, and

infrared temperature sensors.

The wiSeries system let’s you monitor and record temperature over an Ethernet

network or the Internet without any special software--just your Web Browser.

ETHERNET: The wiSeries meter-controller-scanner is an independent node on the

network sending and receiving data in standard TCP/IP packets. It is easily

configured from a Web Browser and can be password protected. From within an

Ethernet LAN or over the Internet, the user simply types the IP address (such as

192.168.1.200) or an easy to remember name (such as "Oven5" or "Fixture") and

the wiSeries meter serves a Web Page with the current readings.

EMAIL ALARM: The wiSeries meter can trigger an alarm if variables go above or

below a Setpoint that you determine. Your alarm can be sent by email to a single

user or to a group distribution list, including text messages to cell phones and PDA’s.

The "Mail Notifier" software is a free and easy program for this application.

CHARTS AND GRAPHS: The wiSeries system serves Active Web Pages to display

real time readings and charts of temperature. You can also log data in standard data

formats for use in a spreadsheet or data acquisition program such as Excel or Visual

Basic. We offer a free and easy to use program iLog for logging data to Excel.

The virtual chart viewed on the web page is a JAVA™ Applet that records a chart

over the LAN or Internet in real time. With the wiSeries system there is no need to

invest time and money learning a proprietary software program to log or chart the

data. Chart scales are fully adjustable on the fly. For example, the chart can display

one minute, one hour, one day, one week, one month or one year.

be charted across the full span or within any narrow range such as (20 to 30°C).

Temperature can

3

Page 10

1.3 Description (continued)

TC

RTD TC

WIRELESS METER

(Receiver)

END DEVICES

(Transmitters)

COMPUTER

(Datalogging

Software)

COMPUTER

(Standard

Web Browser)

ETHERNET

iLD Large Display Meter

Temperature

wi8xx-U

iR

DATALOGGING: The OPC Server software makes it easy to integrate the wiSeries

wireless sensor system with many popular Data Acquisition and Automation

programs offered by NEWPORT, OMEGA, Wonderware, iConics, Intellution,

Rockwell Automation, and National Instruments, among others.

PROGRAMMABLE COLOR DISPLAY: The wiSeries features patented

programmable color displays. The display can be programmed to change color at

any Setpoint or Alarm point. For example, the meter can be programmed to display

the process value in GREEN during warm-up, switching to AMBER to signal the

normal operating range, and in RED to signal an alarm condition. The changes in

color are quickly seen from a distance, and machine operators can intuitively react to

changing conditions. The colors can be programmed to change back when the value

drops back below the alarm point or to "latch" on until being reset by the operator.

The meter can also be programmed to display only one unchanging color: GREEN,

AMBER, or RED. This is a useful way to let an operator identify, at a glance,

temperature values in three separate locations, or to display three different

measurements.

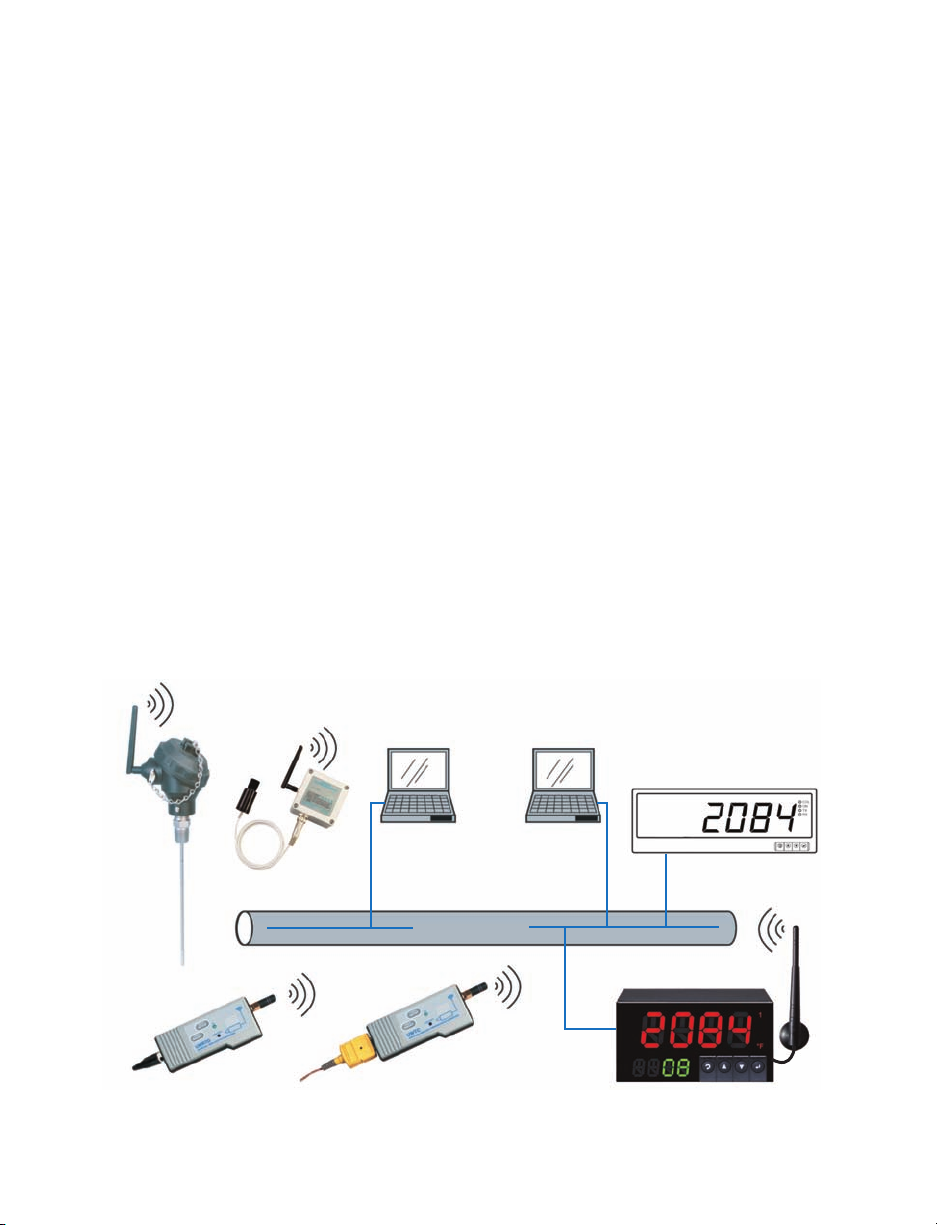

The following example Figure 1.1 illustrates how you can hookup the Temperature

Wireless System to your network:

The wireless system consists of a single Meter and one or more End Devices /

Transmitters. The End Devices will send data periodically to the Meter where it serves

as a gateway between the users and the End Devices. The users can access the data

through the Meter’s Web Server and provided data acquisition software.

A standard web browser can be used to monitor and chart temperature. The browser

can also be used to configure the meter’s IP address, passwords for access and

overall configuration parameters.

Figure 1.1 Temperature Wireless Monitor and

Control System on the Ethernet Network

4

Page 11

PART 2

1

2

C

F

1

2

%RH

D

1

2

C

F

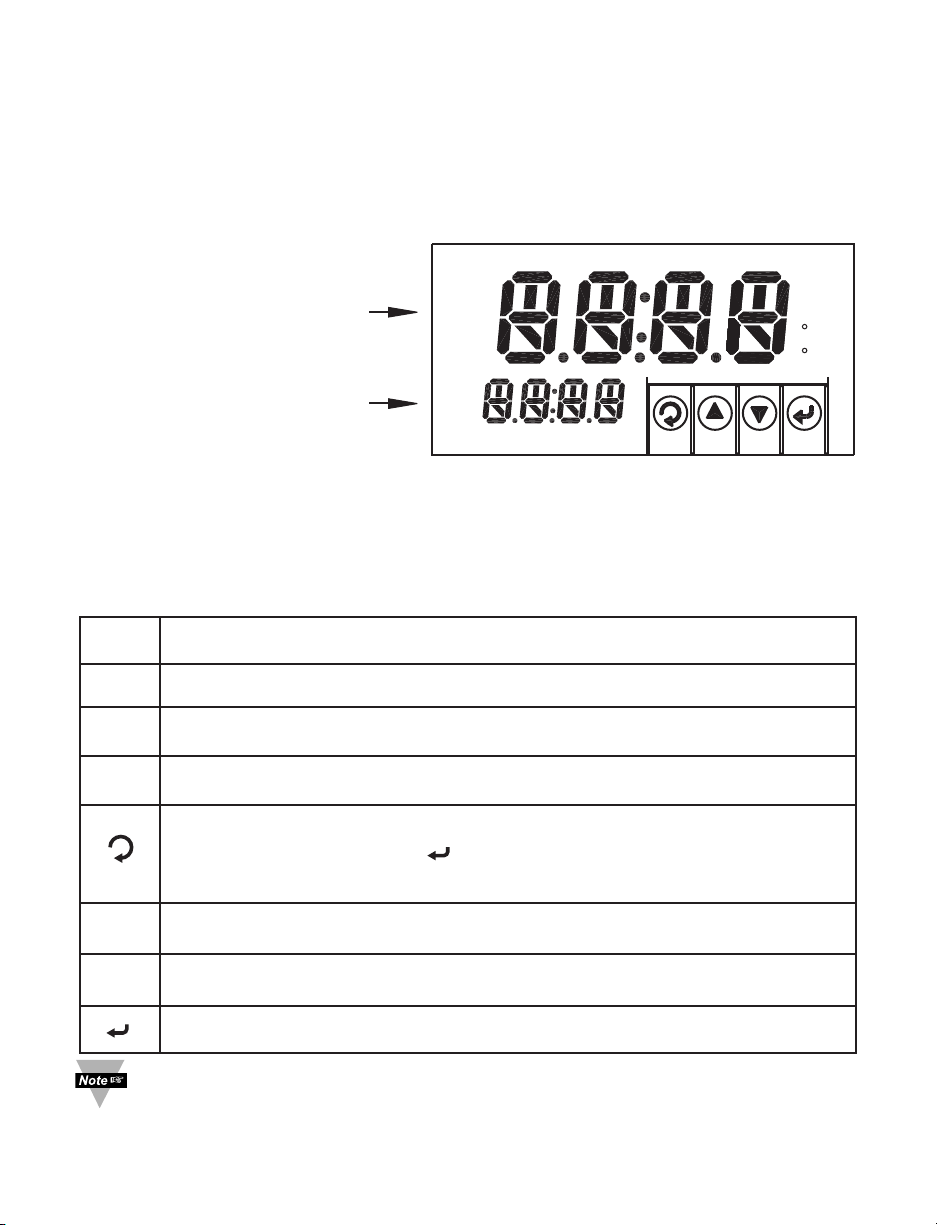

Upper Display:

Temperature Values

Lower Display:

Wireless Transmitter ID#

01 thru 08

HARDWARE

2.1 Physical Characteristics and Mounting

2.1.1 Front Panel

Figure 2.1 Front Panel Display

Table 2.1 Front Panel Enunciators

1

Output 1 / Setpoint 1 / Alarm 1 indicator

2

Output 2 / Setpoint 2 / Alarm 2 indicator

°C

°F

°C unit indicator for Temperature

°F unit indicator for Temperature

Changes display to Configuration Mode and advances through menu

items. Make sure to press twice (Stand-by) followed by pressing

(stop communication) before entering the Configuration mode.

Used in Configuration Mode to change values. In Run Mode, it’s used

to lock the display to the next sensor reading.

Used in Configuration Mode to change values. It’s also used to

resume scrolling sensors.

Accesses submenus in Configuration Mode

For complete Front Panel Pushbutton procedures, refer to the

Supplemental Guide.

and stores selected values

5

Page 12

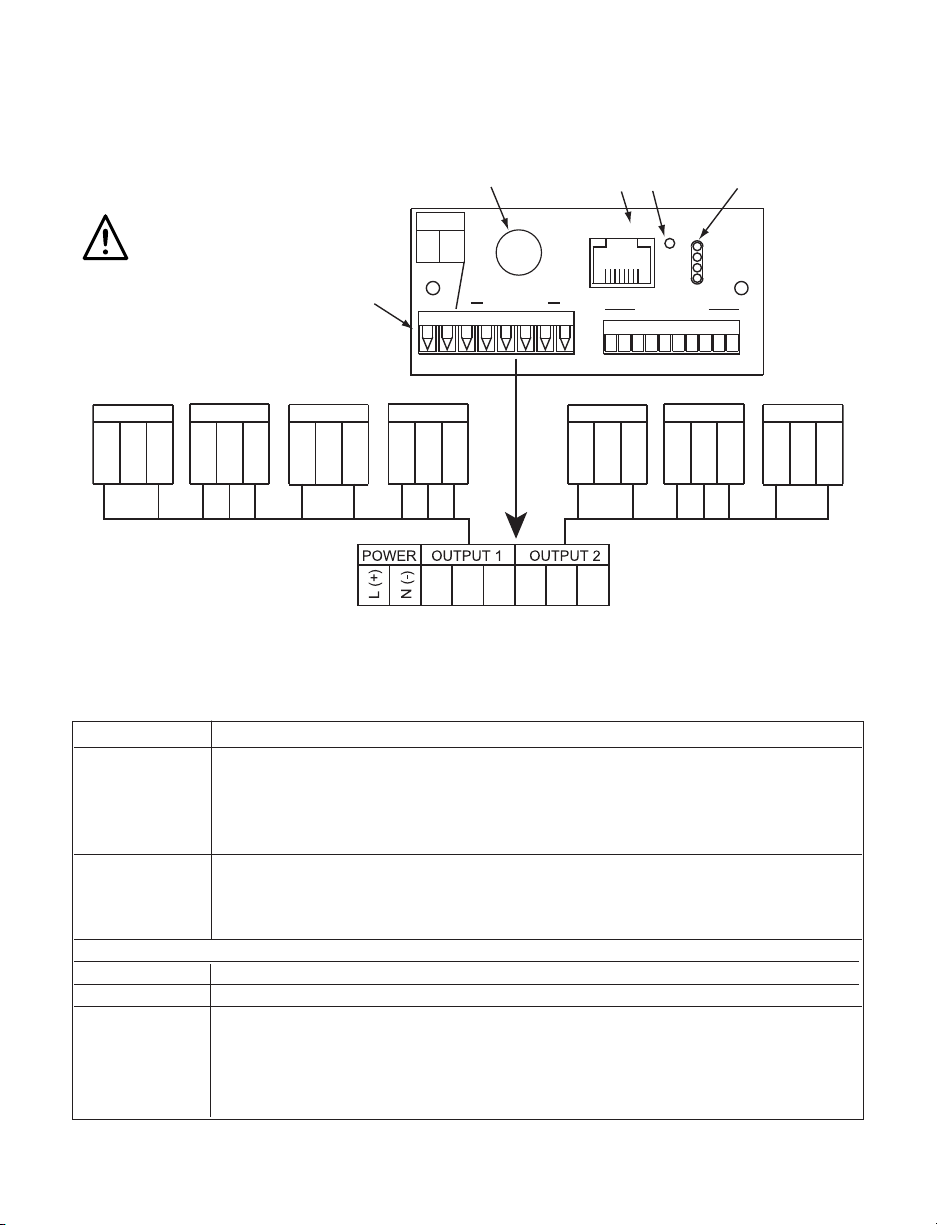

2.1.2 Rear Panel

ACTIVITY

NET LINK

TX

RX

81

ETHERNET

RST

RJ45 10BASE-T

CONNECTION

RESET

BUTTON

LED

INDICATORS

ANTENNA

LOCATION

POWER

L(+)

N(-)

16 OUTPUTS78

78

NOT USED

SSR RELAY PULSE SSR RELAY PULSEANALOG

8 7 6 5 4 3 2 1

OUTPUT 1OUTPUT 1OUTPUT 1OUTPUT 1 OUTPUT 2OUTPUT 2OUTPUT 2

POWER / OUTPUT

CONNECTOR

6 5 4 3 2 1 3 2 1 3 2 16 5 4 6 5 4 6 5 4

NO

NC

C

CUR

V

RTN

PUL

RTN

NO

C

NO

NC

C

PUL

RTN

NO

C

The rear panel connections are shown in Figure 2.2.

Use copper conductors

only for power connections

Figure 2.2 Rear Panel Power and Output Connections

Table 2.2 Rear Panel Connector

POWER AC/DC Power Connector: All models

OUTPUT 1 Based on one of the following models:

Relay SPDT

Solid State Relay (SSR)

Pulse

Analog Output (Voltage and Current)

OUTPUT 2 Based on one of the following models:

Relay SPDT

Solid State Relay (SSR)

Pulse

Network Communication Interface Section:

ETHERNET RJ45 interface for 10BASE-T connection.

RESET Button: Used for power reseting the Ethernet board.

ACTIVITY LED (Red) Blinking: Indicates network activities (receiving or

sending packets).

NET LINK LED (Green) Solid: Indicates good network link.

TX LED (Yellow) Blinking: Indicates transmitting data to the serial port.

RX LED (Green) Blinking: Indicates receiving data on the serial port.

6

Page 13

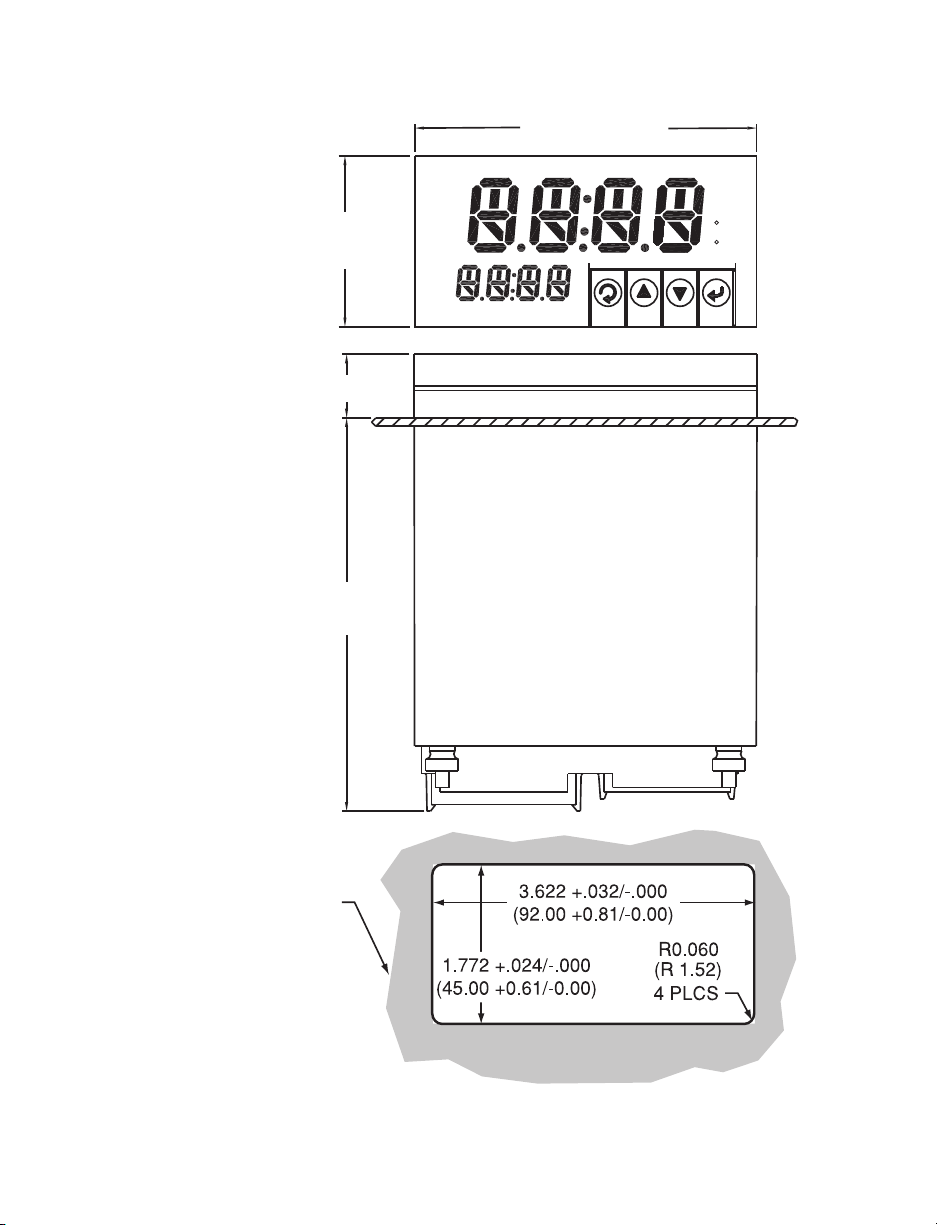

2.1.3 Dimensions

3.780 [96.00]

1.890

[48.00]

0.700 [17.78]

4.325

[109.85]

1

2

C

F

1

2

%RH

D

1

2

C

F

PANEL THICKNESS

0.25 (6.4) MAX

0.03 (0.6) MIN

PANEL CUTOUT

1/8 DIN

Figure 2.3 Mounting Dimensions

7

Page 14

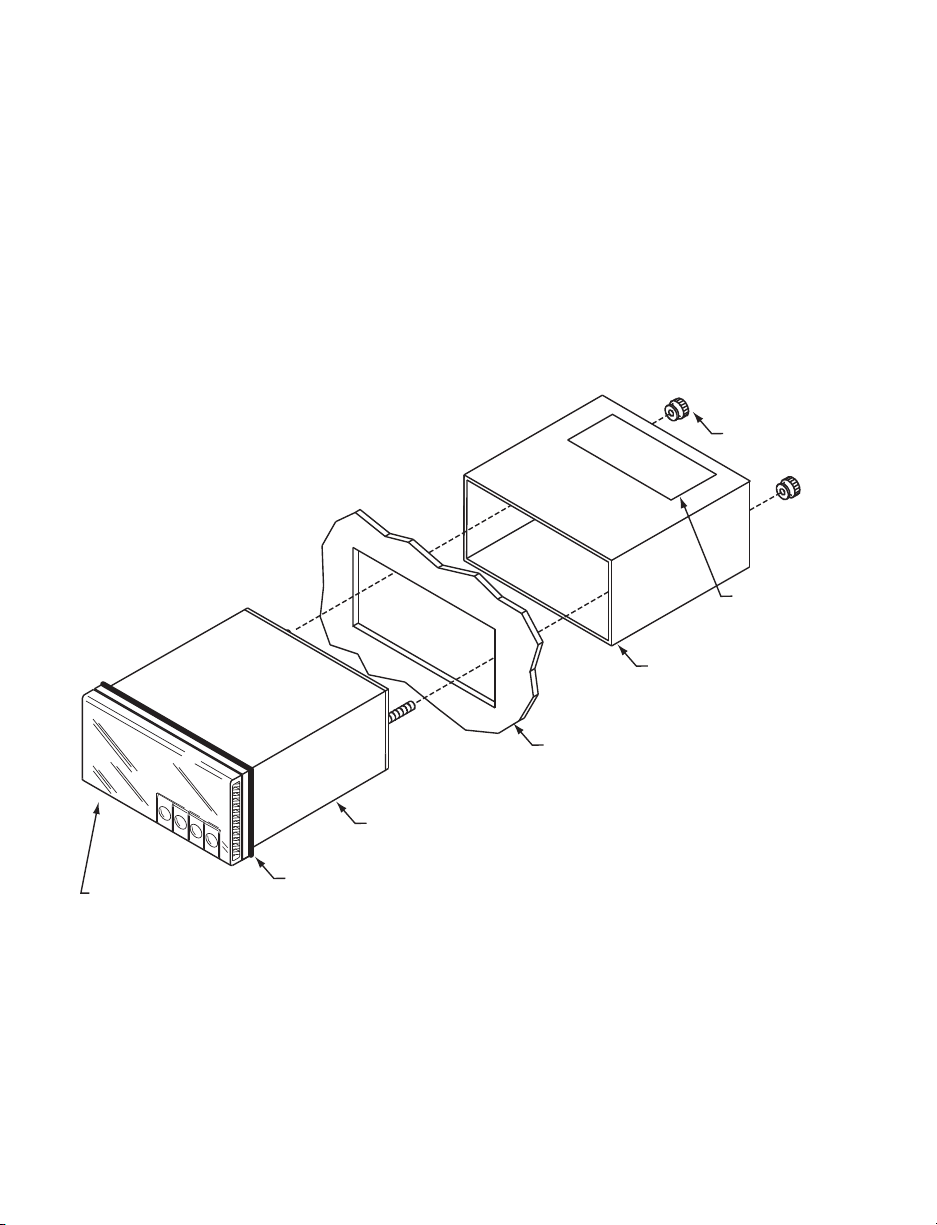

2.1.4 Assembly and Mounting

Front Bezel

Gasket

Case

Panel

Thumbnuts

Sleeve

Model No.

Label

2.1.4.1 Panel Mounting Instruction

1. Using the dimensions from the panel cutout in Figure 2.3, cut an opening in

the panel.

2. Remove sleeve from the rear of the case by removing thumbnuts.

3. Insert the case into the opening from the front of the panel, so the gasket seals

between the bezel and the front of the panel.

4. Slip the sleeve over the rear of the case.

5. Tighten the thumbnuts to hold the unit firmly in the panel.

Figure 2.4 Panel Mounting

8

Page 15

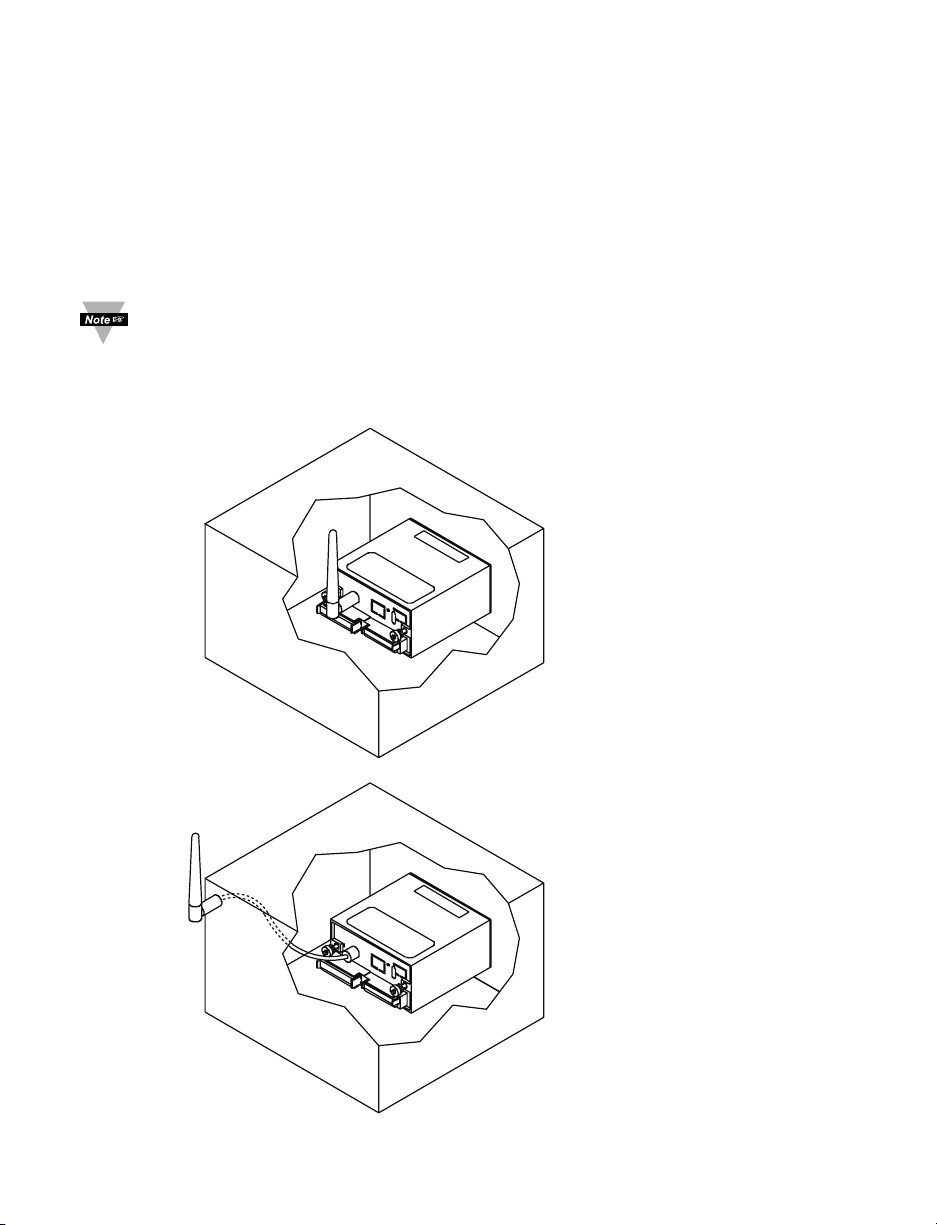

2.1.4.2 Antenna Mounting Instruction

METER MOUNTED

IN NON-METALIC

ENCLOSURE.

METER MOUNTED

IN A METALIC

ENCLOSURE.

For best reception: connect the antenna directly to the rear of the meter, if the

meter is not installed in a metal panel or enclosure.

If the rear of the meter is behind a metal panel or in a cabinet, use a coaxial

cable to position the antenna outside of the enclosure in the open air.

Use the shortest cable that can reach a suitable location. The antenna on this

Meter and any End Devices should be installed in a vertical position, pointing

towards the sky.

Metallic structure should be kept at least 0.8" (2 cm), although 2.4" (6 cm)

is recommended away from the antenna.

Any casing that encloses the antenna should be plastic. In addition, it is

also wise to avoid plastic case with dark fillers or colorants.

Refer to Section 5 for more Environmental / Operating Conditions.

Figure 2.5 Antenna Mounting

9

Page 16

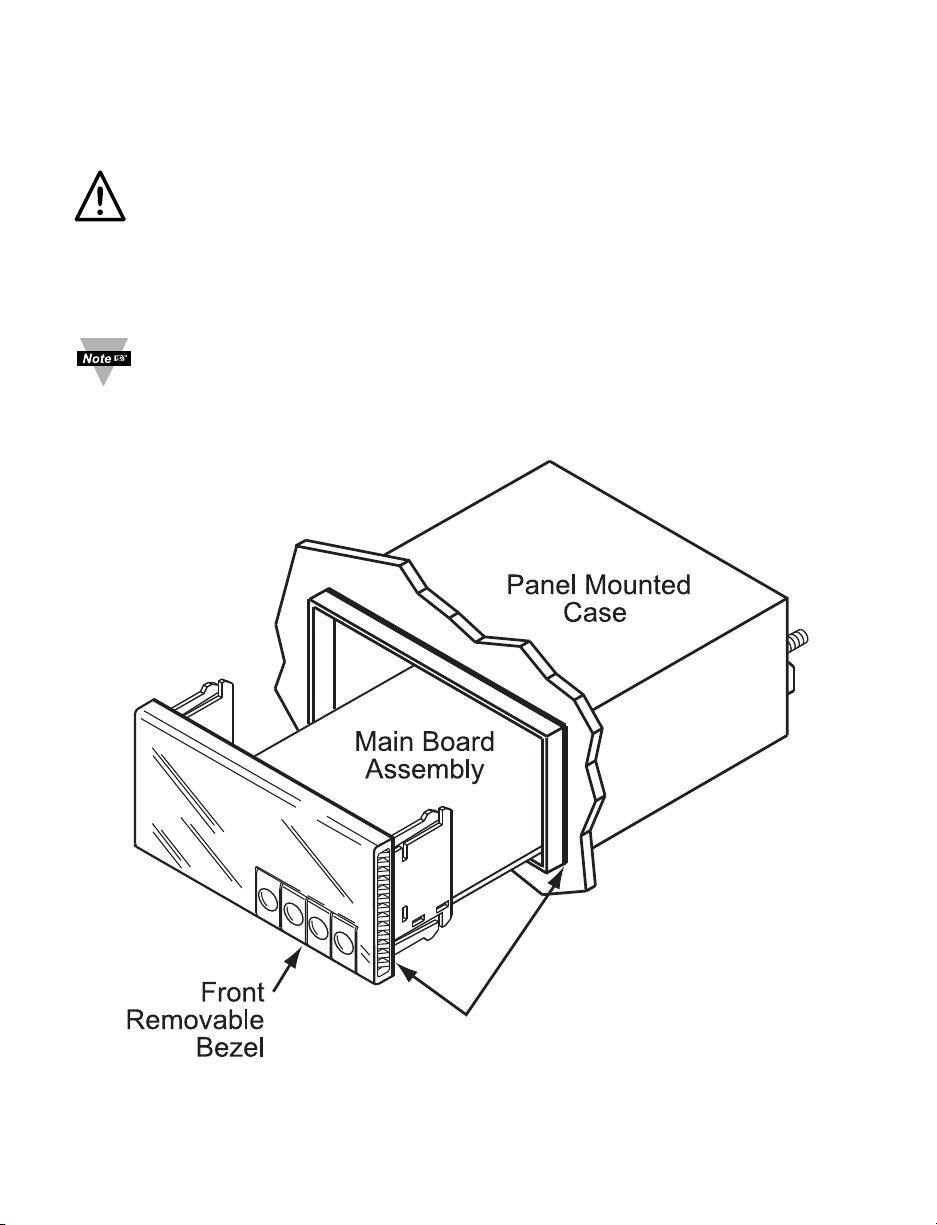

2.1.4.3 Disassembly Instruction

Gasket

If necessary, the board assembly may be removed from the front of the case

housing.

Warning: Disconnect ac power from the unit before proceeding.

1. Remove the board assembly from the case by pulling at the sides of the bezel.

2. The bezel, along with the board assembly will unlatch from the case housing.

•

Depending on the size of your Ethernet connector, you may need to

disconnect it from the RJ45 jack on the rear of the meter.

•

Depending on the length of your antenna cable, you may need to

disconnect it from the rear of the meter.

Figure 2.6 Accessing the Main Board Assembly

10

Page 17

2.1.5 Electrical Installation

24 Vac or

20 to 36 Vdc

90 to 240 Vac 110 to 375 Vdc

OR

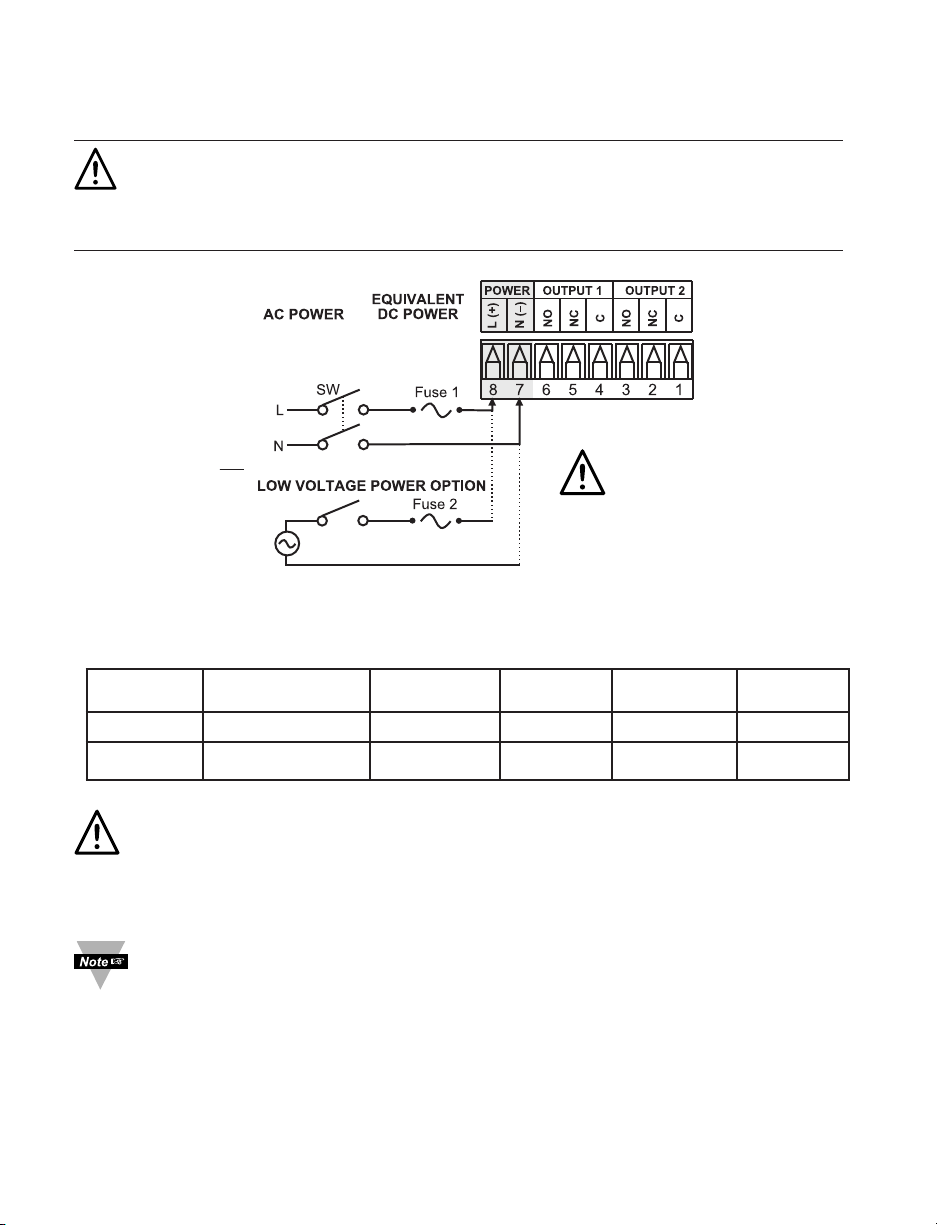

2.1.5.1 Power Connections

Warning: Do not connect ac power to your meter until you have

completed all output connections. This meter must only be installed by a

specially trained electrician with corresponding qualifications. Failure to

follow all instructions and warnings may result in injury!

Connect the main power connections as shown below.

Use copper

conductors only for

power connections

Figure 2.7 Main Power Connections

Table 2.3 Fuse Requirement (See Specifications Section)

FUSE Connector Output Type For 115Vac For 230Vac DC

FUSE 1

FUSE 2

For the low voltage power option, in order to maintain the same degree of

protection as the standard high voltage input power units (90 - 240 Vac),

always use a Safety Agency Approved DC or AC source with the same

Overvoltage Category and pollution degree as the standard AC unit (90 240 Vac).

The Safety European Standard EN61010-1 for measurement, control,

and laboratory equipment requires that fuses must be specified based on

IEC127. This standard specifies for a Time-lag fuse, the letter code “T”.

The above recommended fuses are of the type IEC127-2-sheet III. Be

aware that there are significant differences between the requirements

listed in the UL 248-14/CSA 248.14 and the IEC 127 fuse standards. As a

result, no single fuse can carry all approval listings. A 1.0 Amp IEC fuse is

approximately equivalent to a 1.4 Amp UL/CSA fuse. It is advised to

consult the manufacturer’s data sheets for a cross-reference.

Power N/A 100 mA(T) 100 mA(T) 100 mA(T)

Power

N/A N/A N/A 400 mA(T)

11

Page 18

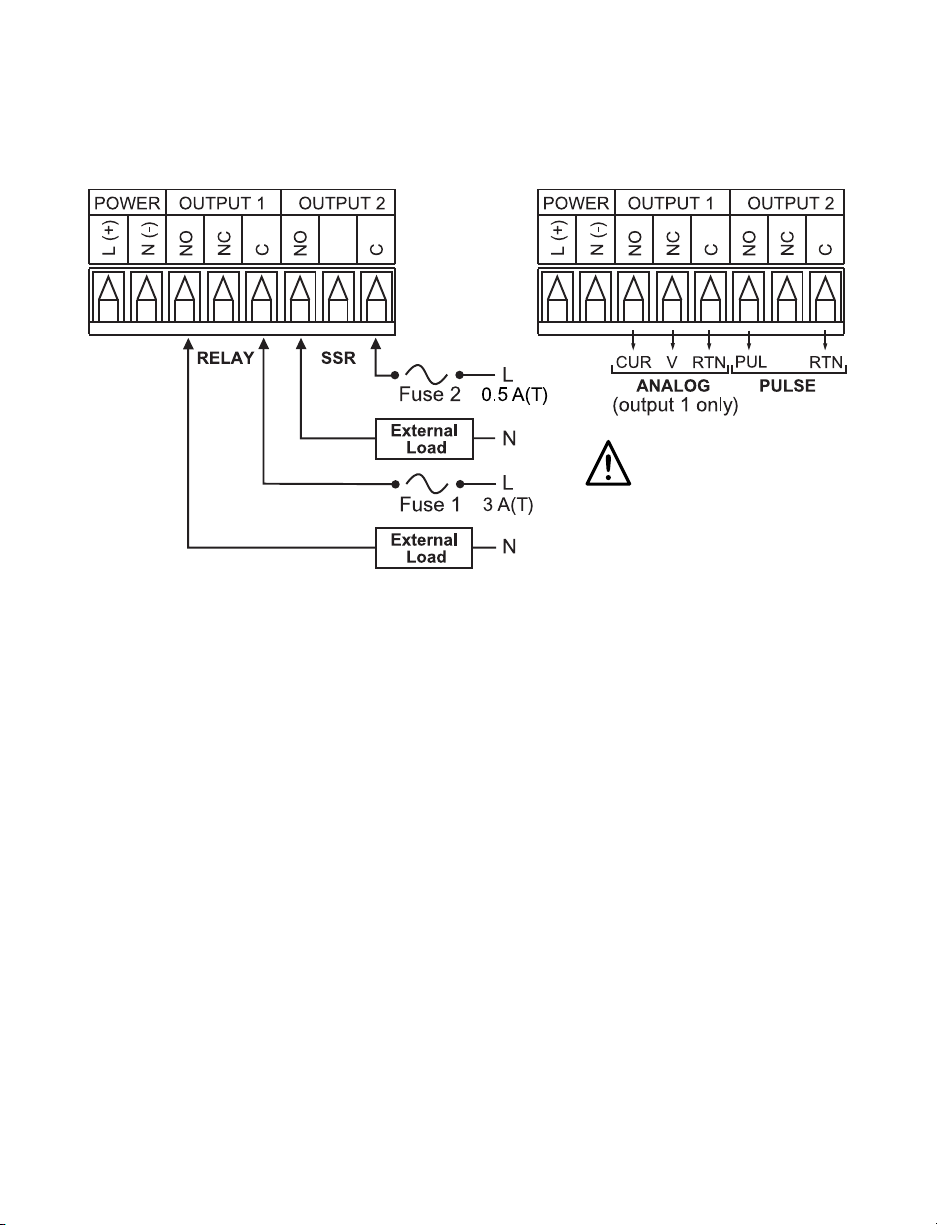

2.1.5.2 Wiring Outputs

This meter has two factory installed outputs. The SPDT Mechanical Relay, SPST

Solid State Relay, Pulse and Analog Output Connection are shown below.

Use copper

conductors only for

power connections

Figure 2.8

a) Mechanical Relay and SSR b) Pulse and Analog

Outputs Wiring Hookup Outputs Wiring Hookup

12

Page 19

2.1.5.2 Wiring Outputs (continued)

TEMPERATURE

CONTROLLER

CONTROL

SIDE

dc INPUT

SSR

ac INPUT

SSR

ac INPUT

SSR

LOAD

SIDE

HEATER

Vac

Vac

dc CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH dc VOLTAGE SSR DRIVER OUTPUT

FAST BLOW

FUSE

0 or 5 Vdc,

TYPICALLY

4

3

1

2

TEMPERATURE

CONTROLLER

CONTROL

SIDE

LOAD

SIDE

HEATER

Vac

Vac

ac CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH MECHANICAL RELAY OUTPUT

FAST BLOW

FUSE

Vac

DRIVING

SSR

4

3

1

2

TEMPERATURE

CONTROLLER

CONTROL SIDE

LOAD

RESISTOR

LOAD

SIDE

HEATER

Vac

Vac

ac CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH TRIAC OUTPUT

FAST BLOW

FUSE

Vac

DRIVING

SSR

4

3

1

2

Figure 2.9 Typical Applications

13

Page 20

2.1.5.3 Jumper Settings for Display Color Setup

1

4

3

2

ON

1

ON

RED

GREEN

S1

8

GREEN

RED

S1

AMBER

S1 (Open)

S1

Display Board

To change the color of the lower display follow the instructions below:

1.

The unit should be removed from the panel and opened.

Refer to Section 2.1.4.3 for assembly and disassembly instructions.

2.

Locate S1 jumper, on the back side of the display board. Select the

position for your color choice of Red, Green or Amber.

Figure 2.10 Location of S1 Jumper

To change the color of the upper Display, see Section 4.3.7.5.

14

Page 21

2.1.5.4 Dip Switches

1

4

3

2

OFF

ON

1

4

3

2

OFF

ON

1

ON

OFF

S1

8

4 Position

DIP Switch on

Ethernet Board

8 Position

DIP Switch on

Wireless Board

OFF

ON

1

8

To change the DIP switches, follow the instructions below:

1.

The unit should be removed from the panel and opened.

Refer to Section 2.1.4.3 for assembly and disassembly instructions.

2.

Locate the 4 and 8 position DIP switches, on the top board.

The Meter is shipped with all DIP switches in "OFF" position

To set the Wireless and Ethernet settings to Factory Default, Refer to

Section 7.

1 To change the

2-8 N/A

Wireless settings to

Factory Default

Figure 2.11 Location of DIP Switches

1 N/A

2 To change the Ethernet settings to

Factory Default

3 To enable/disable DHCP

4 N/A

15

Page 22

2.2 Network Communication Interfaces

2.2.1 10Base-T RJ-45 Pinout

The 10BASE-T Ethernet network (RJ-45) system is used in the Meter for

network connectivity. The 10 Mbps twisted-pair Ethernet system operates over

two pairs of wires. One pair is used for receiving data signals and the other pair

is used for transmitting data signals. This means that four pins of the eight-pin

connector are used.

Pin Name Description

1 +Tx + Transmit Data

2 -Tx - Transmit Data

3 +RX + Receive Data

4 N/C Not Connected

5 N/C Not Connected

6 -Rx - Receive Data

7 N/C Not Connected

8 N/C Not Connected

Figure 2.12 RJ45 Pinout

2.2.2 10Base-T Crossover Wiring

When connecting the iServer directly to the computer, the transmit data pins of

the computer should be wired to the receive data pins of the Meter, and vice

versa. The 10Base-T crossover cable with pin connection assignments are

shown below.

Figure 2.13 10Base-T Crossover Cable Wiring

Use straight through cable for connecting the Meter to an Ethernet hub.

The ports on the hub are already crossed.

16

Page 23

PART 3

NETWORK CONFIGURATION

3.1 Ethernet (MAC) Address

MAC (Media Access Control) address is your computer's unique hardware

number. When you're connected to the LAN from your computer, a

correspondence table relates your IP address to your computer's physical (MAC)

address. The MAC address can be found on the label of your meter (see Figure

2.4 and 3.1) and contains 6 bytes (12 characters) of hexadecimal numbers

XX:XX:XX:XX:XX:XX For Example

Remove the small label with the default IP address and there will be room to put

your IP address.

: 0A:0C:3D:0B:0A:0B

Figure 3.1 Label Detail

3.2 Network Protocols

The Meter can be connected to the network using standard TCP/IP protocols. It

also supports ARP, HTTP (Web Server), DHCP, DNS and Telnet protocols.

3.3 DHCP

DHCP, Dynamic Host Configuration Protocol enables individual computers or

devices to extract their IP configurations from a server (DHCP server).

If the DHCP is enabled on your Meter, as soon as the Meter is connected to the

network, there is an exchange of information between DHCP server and the

Meter. During this process the IP address, the Gateway address, and the Subnet

Mask will be assigned to the Meter by the DHCP server. Note that the DHCP

server must be configured correctly to do such assignment.

17

Page 24

3.3 DHCP (continued)

The Meter is shipped with DHCP disabled (factory default).

If fixed or static IP address is desired, the DHCP must be disabled.

The DHCP can be enabled by setting the DIP switch # 3 to the "ON" position

Figure 3.2 4 Position DIP Switch

Setting the Meter’s IP address to 0.0.0.0 will also enable DHCP.

3.4 DNS

DNS, Domain Name System enables individual computers and devices to be

recognized over a network based on a specific name instead of an IP address.

For example, instead of having to use http://192.168.1.200 (IP address), you

would use only http://wis03ec or any eight character name stored as Host

Name under "Access Control" page from the Wireless System Home Page.

The default DNS name for the Meter is "wis" followed by the last four digits of

the MAC address of that particular Meter.

1. It is very important to communicate with the network administrator in

order to understand the DHCP and its existing configurations on the

host server, before enabling the DHCP on the Meter.

2. The Meters are shipped with a default static IP address of

192.168.1.200 and Subnet Mask of 255.255.255.0.

3. On Windows servers where the DCHP and DNS are separate

functions it is very important to configure the DHCP server to

communicate with the DNS in order for the iServer’s Host Name to

correctly respond. If you cannot access the iServer using its Host

Name, please contact your network administrator to make sure the

DHCP and DNS servers are linked together.

18

Page 25

3.5 IP Address

Every active device connected to the TCP/IP network must have a unique IP

address. This IP address is used to establish a connection to the Meter. Every

computer using TCP/IP should have a unique 32-bit address which is divided

into two portions, the network ID and the host ID. For instance, every computer

on the same network uses the same network ID. At the same time, all of them

have a different host ID. For more details about the IP address see Appendix B.

3.5.1 Default IP Address

The Meter is shipped with a default IP address of 192.168.1.200 and Subnet

Mask of 255.255.255.0. If you are going to use a Web browser or Telnet

program to access the Meter using its default IP address, make sure that the PC

from which you’re establishing the connection has an IP address that is in the

same range as the Meter’s IP address (192.168.1.x, where x can be any number

from 1 to 254). See Section 3.5.2.

Your PC’s IP address cannot

You also need to make sure that your PC’s Subnet Mask is 255.255.255.0. This

is a good way to access the Meter over the network and make any configuration

changes needed. If 192.168.1.200 is already in use on your network, use an

Ethernet crossover cable between your computer and the Meter to change the IP

address or any other settings within the Meter.

be the same as the Meter’s IP address.

19

Page 26

3.5.2 Changing TCP/IP Properties on Your Computer

Go to your computer’s Control Panel then Network Connections.

Pick the network with the proper Ethernet card. Right click and choose

Properties

Look for Internet Protocol, click on it

and press Properties

Figure 3.3 Network Connections

Setup the IP address (in this case, 192.168.1.1) as shown below and press OK

You can access the Meter’s Web

Server via any internet browser

using IP address of 192.168.1.200.

Once you log into the Meter’s Web

Server, you will be able to change its

IP configuration according to

Section 4.2.

After you configure the

Meter’s IP configurations,

you should go back and set

your PC’s previous IP

settings.

.

Figure 3.4 Network Connections

20

Page 27

PART 4

NETWORK OPERATIONS

This Meter can be used and configured in several ways, depending on user’s

preference and network setup. It can be configured using a Web browser, like

Internet Explorer. It can also be configured using the iConnect Configuration

Software.

If DHCP and DNS servers are configured to exchange information, the

connection will be very simple. All you need to do is to enable DHCP on the

Meter (see Section 3.3) and use a straight through network cable to connect the

Meter to an Ethernet hub or switch and power it up. Now, you can use the

Meter’s default Host (Domain) Name, which is wisxxxx (where xxxx are the last

four characters of its MAC address) to access the Meter’s Web Server.

If DHCP is not the preferred method, you can configure your PC’s network

connection with an IP address of 192.168.1.x that is in the same range as the

Meter’s default IP address (192.168.1.200) and connect to the Meter using a

cross-over network cable between your PC’s network port and the Meter. After

you’re done with configuring the Meter, you can always set your PC back to its

original settings. See Section 3.5.2 for more details.

On your computer, from the MS-DOS Prompt window type "ping 192.168.1.200

and press Enter. If DHCP and DNS servers are used type "ping wisxxxx", where

xxxx are the last four digits of the Meter’s MAC address, located on the meter. You

should get a reply as shown in Figure 4.1.

You can use the host name (wisxxxx) instead of the IP address only if your

DHCP server is configured to communicate with your DNS. Please consult

with your IT department for details.

4.0 Testing the Connection

"

Figure 4.1 Pinging the Meter from MS-DOS Prompt

This proves that the connection is proper and you can get into configuration or

run mode using the Telnet or Web browser.

21

Page 28

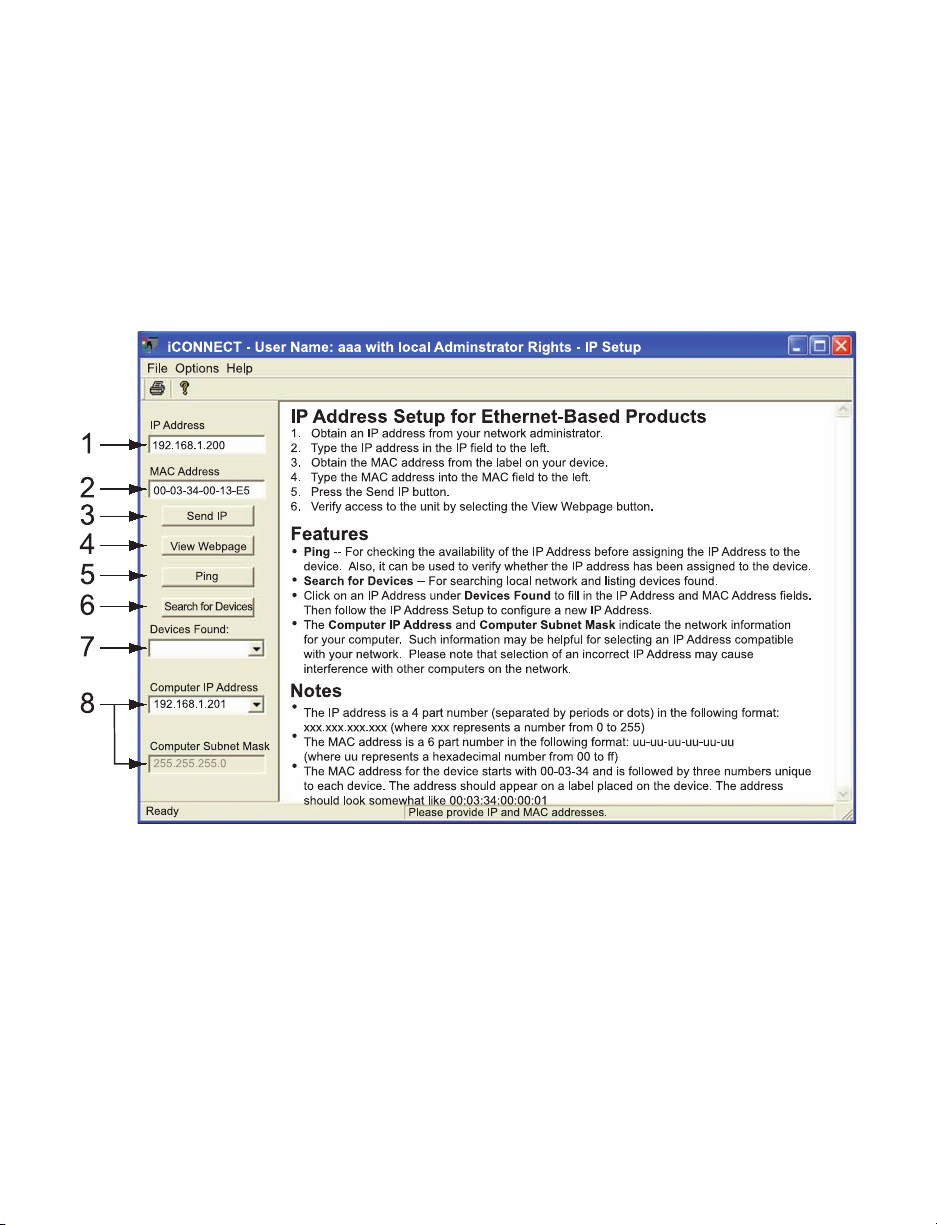

4.1 iConnect Software

The Meter may also be assigned an IP Address by using the iConnect software.

a) Download the iConnect software from the website listed in this manual.

b) Install iConnect software on a networked PC. This software is compatible

with Windows 95, 98, NT, 2000, and XP.

c) Use iConnect to assign an IP address to the Meter and access its web

pages for configuration. You can also use any standard web browser to

access the Wireless System’ web pages. Consult with your IT department

for obtaining an IP address.

Figure 4.2 Assigning an IP Address using iConnect

1) Place the IP address in this box.

2) Take the MAC address from the label attached to the bottom of the Meter

and place it in this box.

3) Click here to send the above IP address to the Meter.

4) After the IP address is assigned to the Meter, click here to access it’s web

pages.

5) Click here to Ping the Meter whose IP address is shown in the IP address box.

6) Click here to find all the Meters on your network .

7) The IP addresses for the Meters found by the iConnect will be listed here.

8) These fields indicate the IP address and the subnet mask of the PC on

which the iConnect is running.

22

Page 29

4.1 iConnect Software (continued)

WIRELESS SENSOR HOME PAGE

d) To access the Wireless System for Configuration:

Click on the "View Webpage" button, you will access the Wireless System’s

home page, refer to Section 4.3 for details.

Figure 4.3 Accessing the Wireless System for Configuration

23

Page 30

4.2 Setting a New IP Address over the Network

ACCESS CONTROL

ACCESS CONTROL

http://192.168.1.200

Address

Main Menu

Login Password 12345678

Admin Password

00000000

IP Address 192.168.1.200

Gateway Address

0.0.0.0

Subnet Mask

255.255.255.0

MAC Address 00:03:03:00:21:D9

Host Name wis21d9

Save Reset

Network Reset

Besides using the iConnect software, you may use the Meter’s default IP

address to access it and assign a new IP address to it.

The Meter is shipped with a default IP address of 192.168.1.200 and Subnet Mask

of 255.255.255.0. You can configure your PC’s Network connection with an IP

address that is in the same range as the Meter’s IP address (192.168.1.x) and

connect to the Meter using a crossover network cable between your PC and the

Meter.

With this completed, you can go to the DOS-Prompt and ping 192.168.1.200. If

you receive responses back (Figure 4.1), you can go to the Web browser and

type in http://192.168.1.200

Page.

Select button, you’ll be asked for the password. You should be

Access Control

on the Access Control page were you can simply type in the desired Static IP

address, and click Save.

For more details about the

and it will take you to the Wireless System’ Home

"

Access Control"page refer to Section 4.3.10.

For the IP address to take effect, the Meter needs to be turned OFF and ON

using the "Network Reset" button. Pressing the physical button marked "RESET"

on the Meter does the same thing.

You can now connect the Meter to an Ethernet hub using a straight through

cable, power it up, and follow the ping routine mentioned in the previous section.

Figure 4.4 Access Control

24

Page 31

4.3 Meter’s Configurations and Operations

Using a web browser, you should be able to view the Meter’s homepage.

• Start your web browser.

• From the browser you type http://wisxxxx

MAC address label located on the Meter (see Figure 3.1), if DHCP and DNS

are used. If a static IP address is used, then simply type http://x.x.x.x

x.x.x.x is the Meter’s IP address.

• The Home Page, will be displayed.

using the last four-digits from the

, where

Figure 4.5 Wireless System Home Page Menu

In order to access certain menu items of the Home Page, users may be

prompted for a password, as shown in the two following figures.

25

Page 32

4.3 Meter’s Configurations and Operations (continued)

ADMINISTRATOR

ADMINISTRATOR

LOGIN

LOGIN

http://192.168.1.200 http://192.168.1.200

Figure 4.6 LOGIN and ADMINISTRATOR Passwords

There are 2 different access levels:

1. ADMINISTRATOR Password

(administrator) allows certain groups and

individual users to access and modify parameters without any restrictions.

The default password is 00000000. This password can be up to 16

alphanumeric case-sensitive characters.

2. LOGIN Password

(operator) allows users to access and modify all of the

parameters, except "Access Control" which requires an Administrator

password.

The default password is 12345678. This password can be up to 16

alphanumeric case-sensitive characters.

4.3.1 Power Up Meter

For instructions on how to power the Meter, refer to Section 2.1.5.

To verify that an End Device is working before deploying remotely, install the

battery and power it on right next to the Meter. When the End Device is powered

on, the green LED (TX) will blink periodically. This indicates the End Device is

broadcasting its data to the Meter on channel 12 defined by IEEE 802.15.4.

The LED will blink only when the End Device sends data to the Meter. If the

Meter is not powered on, or it’s out of reach, the End Device will not receive the

acknowledgment packet from the Meter and therfore to save battery power it will

go to sleep.

The sleeping period can be defined by the users via the USB port (PC

Configuration software) on the End Device. The End Device sends new data for

a short period of time after every sleep period is over, until it can establish the

connection back with the Meter.

When there are two End Devices with the same Device ID/address, both

will be transmitting data every sampling period with their LEDs blinking.

The Meter will receive data from both End Devices and will display their

verify that the Meter is displaying the correct data.

data alternately. To avoid this, turn the End Device on one by one and

26

Page 33

4.3.2 Get Readings from the End Device

wiSeries

Lab 200

Lab 100

ID: 1 Strength: 100%Sequence: 10 Success: 100% Battery: 3.78V Update: 120sec Running

ID: 2 Strength: 94%Sequence: 24 Success: 100% Battery: 3.67V Update: 120sec Running

7073

6877

Lab 700

F

F

F

F

F

F

ID: 7 Strength: 21%Sequence: 28 Success: 100% Battery: 3.67V Update: 120sec Running

7578

Process Ambient

Data Logging: INACTIVE

Main Menu

Refresh seconds

5

Once you see the End Device’s LED blinking periodically, it means it is sending

data which will appear on the "Readings" page. To view the data in a chart

format, you can use the "Chart" page.

Click on from the Home Page, the following page will appear, showing

updates of the Process and Ambient Temperature.

Readings

Figure 4.7 Readings

While accessing the "Readings" page, If a blank screen appears without

any "java application running" or image of a "Java logo", please verify you

have the latest Java Runtime Environment installed and configured

according to the Section 4.3.3.1. If you do not have Java Runtime

Environment, you may download it from our website or contact the

Customer Service Department nearest you.

The "Readings" fields are defined as follows:

Title

: Meter’s name, assigned in Network Setup Menu.

Name

: End Device’s name, assigned in End Device Setup Menu.

Reading Values

: The order from left to right is Process Temperature, then Ambient.

First Reading: Process - process temperature reading with temperature unit.

Second Reading: Ambient - built-in sensor temperature reading with

temperature unit.

Reading "Open" indicates that no sensing device is detected.

27

Page 34

4.3.2 Get Readings from the End Device (continued)

ID: End Device ID/address

Sequence

The Sequence number is incremented for each newly received data. Therefore,

it indicates if the sensor is transmitting data successfully.

Strength

Success

battery lifetime and high network traffic.

Battery

gets to 3.0V, the batteries should be replaced.

Update

Running/Lost

Device. It displays "Lost" if the Meter has not received data from the End Device.

Data Logging

activate data logging, a file browser pops up to ask for which file data will be

saved. Data is in Comma Separated Value (csv) format, which can also be

opened in Excel. Please name file with .csv extension.

: Sequence number [0-255 ].

: It is the radio signal strength (0-100%), the higher the better.

: 0-100%, a low success rate indicates a longer data delay, shorter

: The total voltage of the battery in the End Device. Once the voltage

: The time interval the Meter received data from the End Device.

: It displays "Running" if the Meter is receiving packages from the End

: Press to activate/de-activate data logging. When it is pressed to

Figure 4.8 Comma Separated Value Format

Columns from left to right: Date and time, Device ID, Device name, Reading 1,

Unit 1, Reading 2, Unit 2, Sequence number, Signal strength, Success rate,

Battery voltage, Status, Update, Next Device ID, Next Device name (up to 8 End

Devices).

ACTIVE data is currently being logged in the specified file.

INACTIVE data logging is not executed.

Refresh

: How often the current applet asks for data from the embedded server.

See Section 4.3.4 before activating data logging.

28

Page 35

4.3.3 Java Runtime Environment Setup

If your computer does not have Java installed, please download from

java.sun.com. You can change the Java setting by clicking its icon in Control

Panel. To load the applet, you have to enable the web browser and disable

cache.

4.3.3.1 Java Runtime Environment 1.5 (5.0) Setup Instructions

1. Go to your computer's Control Panel. Open the Java Plug-in

2. Click on "Settings" & "View Applets" in the "General" tab.

3. Select the "Settings" button on the General Tab

Un-check the "Enable Caching" box. Then close dialog box to show the

General Tab again

4. Select the "Network Settings" button on the General Tab.

Proceed to the Browser tab. Follow the Browser Proxy Selection

instructions below.You should either select the "Use Browser Settings"

option or the "Direct Connection" option depending on the network

connections between your computer and the Meter. (Generally, select

"Direct Connection" if accessing the Meter on your local network and

select "Use Browser Settings" option for access from your internal

network to the internet.)

5. Refresh or restart the webpage.

For Java Version 1.5.x.x it is found under "General" > "Settings" > "View Applets"

and then at the bottom there is the Checkbox to REMOVE CACHE .

Figure 4.9 Java 1.5.x.x. Screen Shots

29

Page 36

For Java 1.6.x.x it is similar to Java 1.5.x.x but there is no need to

Java (TM) Plug-in Control Panel

AdvancedBasic ProxiesBrowser CertificatesCache About

Update

Enable Caching

Cache Settings

View Clear

Location

Size

Jar Compression

MB

Unlimited

C:\Documents and Settings\AppData\Sun\Java\Deploymentcache\java

None High

Apply Reset Help

Maximum

50

remove CACHE.

4.3.3.2 Java Runtime Environment 1.4 Setup Instructions

1. Go to your computer's Control Panel. Open the Java Plug-in

2. Select the "Cache" Tab

Un-check the "Enable Caching" box

3. Select the "Proxy" Tab. Follow these Browser Proxy Selection

instructions below. (Generally, un-check the box if accessing the Meter

on your local network and check the box for access from your internal

network to the internet.)

4. Refresh or restart the webpage.

To disable cache setting:

For Java Version 1.4.2.x it is found under the CACHE TAB.

Figure 4.10 Java 1.4.2.x Screen Shot

30

Page 37

4.3.3.3 Browser Proxy Selection

Accessing Meter units within your internal network

• Usually when the computer and Meters are on an internal network, you will

not use Proxy server access.

• You should un-check the "Use Browser Settings" option on the "Proxy" tab.

Accessing Meter units using the internet

• Often the web browser will use Proxy server access to the internet. In such

cases, the default Java runtime settings on the "Proxy" tab should suffice.

The default setting is the "Use Browser Settings" option.

• If the default proxy setting doesn't work, then you may have a situation where

the proxy settings of the web browser are incorrect.

Diagnostics:

If the web page of the Wireless System appears, then the HTTP Proxy is

working fine.

If the data isn't updated on the Wireless System upon selecting the "Readings"

page, there may be a problem with access through a winsock proxy server. In such

cases your network administrator will need to provide the winsock proxy server and

port #s. (The TCP ports the Meter uses for Java applets are 1000 and 2003).

These values should be entered into the Socks line on the "Proxy" tab (of the

Java Plugin control panel) or into the "connections" tab on the View,Internet

Options dialog and make sure that the Proxy tab shows that the "Use Browser

Settings" option is not selected (i.e. when you specify proxy connections in the

Java Plugin control panel).

Accessing Meter units over Peer-to-Peer network

A simple peer-to-peer network is setup by disconnecting from the main network

(as users will often do when trying to do initial setup of the Meter) and then

connecting the Meter to another computer using an ethernet hub, an ethernet

switch, or a Cross-over cable connection.

Often when using a peer-to-peer network, the Java plugin and the web browser

(such as Internet Explorer) have internet connections configured to connect

through proxy servers. In such case, you will need to simply assign the final IP

address on this peer to peer network and then view the Wireless System’s charts

after connecting the Meter into the regular network. Otherwise you can disable

the Java plug-in's "Use Browser Settings" temporarily and then reconfigure the

Java plug-in settings for regular network access after testing the Wireless

System’s chart access on your peer-to-peer network.

The "Use Browser Settings" should not be selected. And the HTTP and Socks

proxy entries should be blank. Also, setup the internet browser so that proxy

servers are disabled.

Java and the Java Coffee Cup Logo are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S. and

other countries."

31

Page 38

4.3.4 Java Policy

To activate data logging and save graphs from the Java applets, it is necessary

to create a Java Policy file and copy it onto a folder.

1) Open a Notepad file and using the IP address of the Meter type the

following:

grant codeBase "http://192.168.1.200/"

{

permission java.security.AllPermission "*", "*";

};

This file should have the IP address of the Meter; in this case the default

IP address is 192.168.1.200. If the IP address is changed, then the IP

address shown in the file needs to be changed; otherwise, it will not work.

If more than one Meter is being monitored from the same computer, it is

necessary to repeat the above for each of the Meters in the same

"java_policy.txt" file.

If DHCP/DNS is enabled, the unique Meter’s name using DNS should replace

the IP address. Example: "http:\\zSrvTEST". Make sure the DHCP server

updates the DNS table to keep track of the Meter’s name and IP addresses

(consult with your network administrator).

2) Save the file as java_policy.txt.

3) Create a folder in your C: drive called "0_JAVAPOLICY".

4) Place the java.policy.policy file into the "0_JAVAPOLICY" folder.

Figure 4.11 Java Policy

32

Page 39

4.3.4 Java Policy (continued)

Java Runtime Settings

Control Panel

Java Control Panel

Control Panel

Address

CommentsName

Java Java(TM) Control Panel

General Update Security AdvancedJava

Java Applet Runtime Settings

Runtime settings are used when an applet is executed in the browser.

Java Applet Runtime Settings

Product Name Version Location Java Runtime Parameters

JRE 1.5.0_06 C:\Program Files\java\jre1.5.0_06 -Djava.security.policy=C:\0_JAVAPOLICY\java_policy.txt

OK Cancel

OK Cancel Apply

View...

5)Change Java Applet’s Runtime Parameters found on the following path:

a. Control Panel --> Java --> Java Control Panel --> Java Tab --> View

b. Inside the box under the Java Runtime Parameters type the following:

-Djava.security.policy=C:\0_JAVAPOLICY\java_policy.txt

c. Click OK on the Java Runtime Settings window.

d. Click Apply on the Java Control Panel window and then OK.

6) Close all opened Web browser.

Figure 4.12 Java Policy

The "Data Logging" and "Save Current Graph" buttons in the "Readings"

and "Chart" pages will not be active if the instructions explained in the

above Section 4.3.4 are not followed.

33

Page 40

4.3.5 Chart

wiSeries

Main Menu

CHART

(2 Seconds/Div)

1 Minute

1 Minute

1 Day

1 Week

1 Month

1 Year

0

5

C/Div

50

1200

300

100%

0%

10

%/Div

90

hPa/Div

C hPa

Tue Feb 5 10:19:10 PDT 2008Tue Feb 5 10:18:10 PDT 2008

http://192.168.1.200

Min/Max Temperature

48.0/41.0

P1 Process

P2 Sensor 2

P3 Process

P4 Process

P5 Process

P6 Process

P7 Process

P8 Sensor 8

A1 Ambient

A2 Sensor 2

A3 Ambient

A4 Ambient

A5 Ambient

A6 Ambient

A7 Ambient

A8 Sensor 8

Save Current Graph

Click on from the Home Page, the following page will appear.

The Java™ Applet graph displays Process Temperature and Ambient

Temperature. It can be charted across the full span or within any narrow range

(such as 20 to 30ºC).

Chart

If a blank screen appears without any "java application running" or image

of a "Java logo", please verify you have the latest Java Runtime

Environment installed and configured according to the instructions (refer

to Section 4.3.3.1). If you do not have Java Runtime Environment, you

may download it from our website or contact the Customer Service

Department nearest you.

Figure 4.13 Chart

34

Page 41

4.3.5 Chart (continued)

Title: Meter’s name, assigned in "Network Setup" page.

Save Current Graph: Save the current graph in PNG (Portable Network

Graphics) format. The filename has the extension .png.

Max/Min Temperature: Maximum and minimum temperature of the current

graph.

If a sensor is selected (trend line and sensor name turns bold), its most current

temperature reading is shown here.

Reading "Open" indicates that no sensing device is detected.

Temperature Unit: Temperature unit to be used, either ºC or ºF.

P# button (Process): P# shows the sensor name (assigned in the End Device

Setup Menu) and controls the process sensor readings.

When clicked once, it turns bold, highlights the process sensor trend line and

displays current sensor readings.

When clicked twice, it turns white and the trend line will disappear.

When clicked again, it comes back to normal operation.

Chart Area: Display the trend lines of the sensors.

Range of temperature can be controlled by the upper and lower boxes on the

left.

A# button (Ambient): A# shows the sensor name (assigned in the End Device

Setup Menu), displays error messages [Lost] and controls the ambient sensor

readings.

When clicked once, it turns bold, highlights ambient sensor trend line and

displays current sensor readings.

When clicked twice, it turns white and the trend line will disappear.

When clicked again, it comes back to normal operation.

Applet Start Date and Time: Activates when the "Chart" page opens up.

X-axis Drop-down List: Time scale for the chart.

The chart area can be shown based on 1 min, 1 hour, 1 day, 1 week, 1 month, or

1 year time intervals.

Last Update Date and Time: The last date and time when data arrived.

35

Page 42

4.3.6 Controller Setup

Please refer to local regulations for the allowed maximum transmission power

Transmission Power

PID 13106 (version x.x)

iSeries Firmware Version x.x

Input

Setpoints & On/Off

Alarm 2

Alarm 1

Passcode ID

Display

Permanent Store

Enable Standby Mode Before Configuring Unit

Scrolling

Main Menu

CONTROLLER SETUP

Setup

Transmission Power

Misc.

Monitor

CONTROLLER SETUP

http://192.168.1.200Address

Update

Update

20dBm

End Device ID -

Reset Controller

Disable Standby

Enable Standby

Channel 12

Input

Setpoints & On/Off

Alarm 2

Analog Out

CONTROLLER SETUP

Setup

CONTROLLER SETUP

http://192.168.1.200Address

The Meter has two modes of operations. One is through the Front Panel Buttons

(please refer to Front Panel Supplement for more details), and the other is by

using the browser to configure the settings. Click on from the Home

Page. In a few seconds the following page will appear.

A

B

Controller

This portion of

the menu will

be different

only if you have the

Analog Output Option

installed in your Meter.

C

D

Figure 4.14 Controller Setup

Please refer to

local

regulations for

the maximum

allowed transmission

power.

36

Page 43

4.3.6 Controller Setup (continued)

Below are the definitions of terms used in the Controller Setup page.

A) Setup:

Clicking on the options shown, allows user to modify the different parameters

shown under this menu (see Section 4.3.7. Setup Page for more details)

B) Monitor:

Scrolling: If checked, the Meter will display data from all the End Devices.

Otherwise, it only displays data from the End Device specified on Device ID.

End Device ID: Address/ID of the End Device that will be display on the Meter.

C) Transmission Power:

Channel 12: The Meter communicates in a fixed channel. Operation channel

#12 defined in IEEE 802.15.4 for the sensor network.

Transmission Power: This determines the signal power transmitted by the

Meter. The options are 10 dBm and 20 dBm.

Please refer to local regulations for the allowed maximum transmission

power.

For additional details, please refer to Appendix F

D) Miscellaneous:

PID 13106 (version): The Personal Network ID is fixed to 13106. In parenthesis

is the firmware version of the radio module. The firmware version is also shown

on a label attached to the Meter (see Figure 3.1).

iSeries Version: The firmware version of the Meter. The firmware version is

also shown on a label attached to the Meter (see Figure 3.1)

37

Page 44

4.3.7 Setup

Temperature Unit

F

Filter

4

Control End Device ID:

for Retransmission and On/Off

5

Main Menu

SETUP

Input

SETUP

http://192.168.1.200Address

Cancel

Update

This section is used to configure the Meter online. Click on the specific settings

to change the parameters on that section

4.3.7.1 Input

Control End Device ID: Insert the End Device ID number that will be used as

input to control

Filter: This option allows the user to specify the number of readings stored in

the Digital Averaging Filter. Choice of: 1, 2, 4, 8, 16, 32, 64, 124.

Temperature Unit: Unit of temperature readings, [ ºC or ºF ].

Figure 4.15 Input

38

Page 45

4.3.7.2 Setpoints & On/Off Control

Auto Setpoint Deviation: If "enabled", allows changes to Setpoint 1 to be

made automatically to Setpoint 2. This mode is very helpful if the Temperature

changes often.

In Setpoint Deviation Mode, set SP2 a certain number of degrees or counts

away from SP1--this relation remains fixed when SP1 is changed.

For instance:

Setting SP1=200 and SP2=20 and enabling SP Deviation means that the

absolute value of SP2=220.

Moving SP1 to 300, the absolute value of SP2 becomes 320.

Setpoint 1: This setpoint controls Output 1

Setpoint 2: This setpoint controls Output 2

Permanent Store: Check to save Setpoints in the Meter’s permanent storage.

On/Off 1 and On/Off 2: To enable and disable On/Off Control. Enabling On/Off

Controls will disable the Alarms, and vice versa.

DeadBand: The Dead Band or neutral zone, is the number of degrees counts

around Setpoint 1 (or Setpoint 2 if On/Off 2) which the temperature value must

pass above or below the Setpoint before the output changes state.

Action: Choice of direct or reverse. The error that results from the

measurement of the Process Variable may be positive or negative since it may

be greater or smaller than the Setpoint.

If a positive error should cause the Meter output to increase (i.e. cooling), it

would be called Direct Acting.

If a negative error should cause the output to increase (i.e. heating), it would be

called Reverse Acting.

39

Page 46

4.3.7.2 Setpoints & On/Off Control (continued)

Setpoint 2

Permanent Store

100

DeadBand

DeadBand

On/Off 1

On/Off 2

Auto Setpoint Deviation

Disabled

Disabled

Disabled

Direct

0

Setpoint 1

0

Action

Action

Reverse

0

Main Menu

SETUP

Setpoints & On/Off Control

SETUP

http://192.168.1.200

Address

Cancel

Update

Figure 4.16 Setpoints & On/Off Control

40

Page 47

4.3.7.3 Alarms 1 & 2

Alarm 1 (or 2) Relay: to enable or disable (no alarm function) the alarms .

Alarm 1 (or 2) Low: editable box for the low alarm value.

Alarm 1 (or 2) High: editable box for the high alarm value.

Active: If Above, Alarm condition triggered when the process variable is greater

than the Alarm Hi Value (Low value ignored).

If Below, Alarm condition triggered when the process variable is less than the

Alarm Low Value (Hi value ignored).

If Hi/Low, Alarm condition triggered when the process variable is less than the

Alarm Low Value or above the Hi Value.

If Band, Alarm condition triggered when the process variable is above or below

the "band" set around the Setpoint. Band equals Hi Value (Low Value ignored).

A "band" is set around the Setpoint only in the "Deviation" Mode.

Normally: if Open, then the relay is "energized" only when an alarm condition

occurs.

If Closed, this is "Fail Safe" Mode. Relay is energized under "normal" conditions

and becomes de-energized during alarm or power failure.

Latch: if Latched, Alarm remains "latched" until reset.

If Unlatched, Alarm remains latched only as long as the alarm condition is true.

Absolute: if Absolute, this allows Alarms to function independently from their

respective Setpoints. If the process being monitored does not change often, then

"Absolute" Mode is recommended.

If Deviation, this allows changes to Setpoints to be made automatically to their

corresponding Alarms. Deviation Mode is typically the ideal mode if the process

temperature changes often. In Deviation Mode, set Alarm 1 a certain number of

degrees or counts away from Setpoints, this relation remains fixed even if

Setpoints are changed.

Alarm at Power On: If the alarm is enabled at Power On, the alarm will be

active right after reset for all the End Devices (given the conditions are met),

except the End Device designated in the "Input" menu of the Web Server.

If the alarm is disabled at Power On, the alarm will become enabled when the

process value enters the non alarm area. The alarm is not active while the

process value is approaching the Setpoints.

Errors indicating "lost" or "open" sensor condition can trigger the alarm if

the alarm is set for "active high" above 9000 degrees.

41

Page 48

4.3.7.3 Alarms 1 & 2 (continued)

Normally

Alarm at Power On:

Alarm could be

triggered immediately by non-controlling

end device at startup.

Absolute

Active

Alarm 1 Relay

Alarm 1 Low

Enabled

0

Above

Absolute

Enabled

Alarm 1 High

100

Latch

Unlatched

Open

Main Menu

SETUP

Alarm 1

SETUP

http://192.168.1.200

Address

Cancel

Update

Figure 4.17 Alarms 1 & 2

42

Page 49

Input High

Output Low

Retransmission

Voltage/Current

Enabled

Voltage

0.00

Input Low

0

Output High

10.00

Min. 0V

Max. 10V

1000

Main Menu

SETUP

Analog Output Retransmission

SETUP

http://192.168.1.200

Address

Cancel

Update

4.3.7.4 Analog Output Retransmission

This menu will appear only if you have the Analog Output Option installed

in your Meter.

Figure 4.18 Analog Output Retransmission

Retransmission: When enabled, the input data will be scaled based on Input

Low and Input High and will be outputted. If the input reaches high value the

output will be 10V or 20mA. If the input reaches low value, the output will be

0V or 0mA.

Voltage/Current: Select the output to be Voltage (0-10V) or Current (0-20mA).

Input Low: The minimum input value scaled for Output Low.

Output Low: Output Voltage or Current represented by Input Low.

Input High: The minimum input value scaled for Output High.

Output High: Output Voltage or Current represented by Input High.

43

Page 50

4.3.7.5 Display

Screen Update (seconds)

3

Normal

Green

Alarm 1

Red

Alarm 2

Amber

Main Menu

SETUP

Display

SETUP

http://192.168.1.200

Address

Cancel

Update

This submenu allows the user to select the color of the display--green, red,

amber.

Screen Update: Editable box to enter the display time in seconds between each

End Device.

Normal: Choose the display color of temperature when it is in the normal stage.

Alarm 1: Choose the display color of temperature when alarm 1 is true.

Alarm 2: Choose the display color of temperature when alarm 2 is true.

In order to display one color, set the same display color on all three

submenus.

If user wants the Display to change color every time when both Alarm 1

and Alarm 2 are triggered, the Alarm values should be set in such a way

that Alarm 1 value is always on the top of Alarm 2 value, otherwise value

of Alarm 1 will overwrite value of Alarm 2 and Display Color would not

change when Alarm 2 is triggered.

Figure 4.19a Display Menu

44

Page 51

4.3.7.5 Display (continued)

Screen Update (seconds)

3

Normal

Green

Alarm 2

Amber

Main Menu