Page 1

User's Guide

http://www.omega.com

e-mail: info@omega.com

PCI-DAS1001

PCI-DAS1002

Page 2

Table of Contents

1.0 INTRODUCTION ....................................................

1

22.0 INSTALLATION .....................................................

2 2.1 HARDWARE INSTALLATION .........................................

2 2.2 SOFTWARE INSTALLATION, WINDOWS 95, 98 & NT ....................

22.2.1 INTRODUCTION ...........................................

22.2.2 INSTALLATION OPTIONS ....................................

22.2.3 FILE DEFAULT LOCATION ....................................

22.2.4 INSTALLATION QUESTIONS ................................

22.2.5 INSTALLATION COMPLETION ................................

3 2.3 RUN InstaCal .......................................................

32.3.1 LAUNCHING InstaCAL ........................................

32.3.2 TESTING THE INSTALLATION .................................

3 2.4 DOS AND/OR WINDOWS 3.1 ..........................................

43.0 HARDWARE CONNECTIONS .........................................

4 3.1 CONNECTOR PIN DIAGRAM .........................................

4 3.2 CONNECTING SIGNALS TO THE PCI-DAS1000 ..........................

54.0 ANALOG CONNECTIONS ............................................

5 4.1 ANALOG INPUTS ....................................................

54.1.1 SINGLE-ENDED AND DIFFERENTIAL INPUTS ....................

74.1.2 SYSTEM GROUNDS AND ISOLATION ...........................

9 4.2 WIRING CONFIGURATIONS ..........................................

104.2.1 COMMON GROUND / SINGLE-ENDED INPUTS ..................

104.2.2 COMMON GROUND / DIFFERENTIAL INPUTS ...................

104.2.3 COMMON MODE VOLTAGE < +/-10V / SINGLE-ENDED INPUTS ....

114.2.4 COMMON MODE VOLTAGE < +/-10V / DIFFERENTIAL INPUTS ....

114.2.5 COMMON MODE VOLTAGE > +/-10V .........................

124.2.6 ISOLATED GROUNDS / SINGLE-ENDED INPUTS .................

124.2.7 ISOLATED GROUNDS / DIFFERENTIAL INPUTS .................

145.0 PROGRAMMING & SOFTWARE APPLICATIONS ......................

14 5.1 PROGRAMMING LANGUAGES ......................................

14 5.2 PACKAGED APPLICATION PROGRAMS ..............................

156.0 SELF-CALIBRATION OF THE PCI-DAS1000 ...........................

15 6.1 CALIBRATION CONFIGURATION ....................................

156.1.1 ANALOG INPUTS ............................................

166.1.2 ANALOG OUTPUTS ..........................................

Page 3

177.0 PCI-DAS1000 REGISTER DESCRIPTION ..............................

17 7.1 REGISTER OVERVIEW ..............................................

17 7.2 BADR0 ............................................................

17 7.3 BADR1 ...........................................................

177.3.1 INTERRUPT / ADC FIFO REGISTER ............................

197.3.2 ADC CHANNEL MUX AND CONTROL REGISTER ................

217.3.3 TRIGGER CONTROL/STATUS REGISTER .......................

237.3.4 CALIBRATION REGISTER ....................................

247.3.5 DAC CONTROL/STATUS REGISTER ............................

25 7.4 BADR2 ............................................................

257.4.1 ADC DATA REGISTER .......................................

257.4.2 ADC FIFO CLEAR REGISTER ..................................

26 7.5 BADR3 ............................................................

267.5.1 ADC PACER CLOCK DATA AND CONTROL REGISTERS .........

277.5.2 DIGITAL I/O DATA AND CONTROL REGISTERS ................

297.5.3 INDEX AND USER COUNTER 4 DATA AND CONTROL REGISTERS .

31 7.6 BADR4 ............................................................

317.6.1 DAC0 DATA REGISTER ......................................

317.6.2 DAC1 DATA REGISTER ......................................

328.0 ELECTRICAL SPECIFICATIONS .....................................

32 8.1 ANALOG INPUT SECTION ...........................................

33 8.2 ANALOG OUTPUT ..................................................

33 8.3 PARAELLEL DIGITAL INPUT/OUTPUT ................................

34 8.4 COUNTER SECTION ................................................

34 8.5 OTHER SPECIFICATIONS ............................................

Page 4

1.0 INTRODUCTION

The PCI-DAS1002 and PCI-DAS1001 are multifunction analog and digital I/O boards designed to o perate in computers

with PCI bus accessory slots. The boards provide 16 single-ended/8 differential analog inputs with sample rates as high as

150 KHz. The boards also provide two analog output channels, 24-bits of parallel digital I/O and three counters. The only

difference between the boards are the analog input ranges. These are shown below.

PCI-DAS1002 Bipolar: +/- 10V, 5V, 2.5V and 1.25V

Unipolar: 0-10V, 0-5V, 0-2.5V and 0-1.25V

PCI-DAS1001 Bipolar: +/- 10V, 1.0V, 0.1V and 0.01V

Unipolar: 0-10V, 0-1.0V, 0-0.1V and 0-0.01V

The boards are fully plug-and-play, with no switches or jumpers to set. The boards are fully auto- and self-calibrating with

no potentiometers to adjust. All calibration is performed via software and on-board trim D/A converters.

The PCI-DAS1000 boards are fully supported by the powerful Universal Library software driver library as well as a wide

variety of application software packages including DAS Wizard and HP VEE.

1

Page 5

2.0 INSTALLATION

2.1 HARDWARE INSTALLATION

The PCI-DAS1001 and PCI-DAS1002 products are completely plug and play. Simply follow the steps shown below to

install your PCI hardware.

1.

Turn your computer off, unplug it, open it up and insert the PCI board into any available PCI slot.

2.

Close your computer up, plug it back in and turn it on.

3.

Windows will automatically detect the board as it starts up. If the board's configuration file is already on the

system, it will load without user interaction. If the configuration file is not detected, you will be prompted to insert

the disk containing it. The required file is on the InstaCal or Universal Library disk you received with your board.

Simply insert the CD (or Disk 1 if your software is on floppy disk) into an appropriate drive and click on

CONTINUE

Manager under DAS Component.

If the file is not found on the first attempt, use the browse function to select the drive that contains the InstaCAL

or Univesal Library disk, select the CBxx.INF file and then click on

. The appropriate file should then be automatically loaded and the PCI board will appear in the Device

CONTINUE.

2.2 SOFTWARE INSTALLATION

2.2.1 INTRODUCTION

Insta

Cal is the installation, calibration and test software supplied with your data acquisition hardware. The complete

Cal package is also included with the Universal Library. If you have ordered the Universal Library, the Universal Library

CD/disks install both the library and

compressed software. To install

contained on your CD, (or Disk 1 of the floppy disk set) and follow the on-screen instructions.

2.2.2 INSTALLATION OPTIONS

The Universal Librar y provides example pro grams for a wide variety of pro gramming languages. If you are installing the

Universal Library, an "Installation Options" dialog box will allow you to select which languages' example programs are

loaded onto your computer. Select the desired example programs by checking the appropriate box(s).

2.2.3 FILE DEFAULT LOCATION

Insta

Cal will place all appropriate files in "C:CB" If you change this default location remember where the installed files are

placed as you may need to access them later.

2.2.4 INSTALLATION QUESTIONS

At the end of the installation process the installation wizard will ask a series of questions updating your startup files. Unless

you have knowledge to the contrary, simply accept the default (YES) when prompted. You will also be asked if you would

like to read an updated README file. If possible, please choose yes and take a look at the information in the file. It will

include the latest information regarding the software you are installing.

2.2.5 INSTALLATION COMPLETION

After the installation of

system.

Insta

Insta

Cal. The installation will create all required files and unpack the various pieces of

Insta

Cal (and the Universal Library if applicable), simply run the SETUP.EXE file

Cal is complete you should restart your computer to take advantage of changes made to the

, WINDOWS

95, 98 & NT

Insta-

2

Page 6

2.3 RUN InstaCal

Run the InstaCal program in ord er to test your boar d and configur e it for run-ti me use. By configuring the board , you add

information to the configuration file, cb.cfg, that is used by the Universal Library and other third-party data acquisition

packages that use the Universal Library to access the board.

2.3.1 LAUNCHING InstaCAL

Launch InstaCal by going to your Start Menu then to Programs, then to ComputerBoards, and finally choosing InstaCal.

You may also launch the program by going to START>RUN and typing INSCAL32, or by finding the file named

"inscal32.exe" in your installation directory and double clicking it.

InstaCal will display a dialog box indicating the boards that have been detected in the system. If there are no other boards

currently installed by InstaCal, then the PCI-DAS1000 board will be assigned board number 0. Otherwise it will be

assigned the next available board number.

You can now view and change the board configuration by clicking the prope rties icon or selecting the Install\Configure

menu.

2.3.2 TESTING THE INSTALLATION

After you have run the install program, it is time to test the installation. The following section describes the InstaCal procedure to test that your board is properly installed.

With InstaCal running:

1. Select the board you just installed.

2. Select the "Test" function.

Follow the instructions provided to test for proper board operation.

2.4 DOS and/or WINDOWS 3.1

Most users are now installing PCI Bus board s in systems with 32-bit operating systems (e.g., Windows 95, 98 or NT). T he

PCI-CTR05 is not currently supported by the 16-bit library required to run under DOS or Windows 3.x.

Please contact us if your application is running under DOS or Windows 3.x.

3

Page 7

3.0 HARDWARE CONNECTIONS

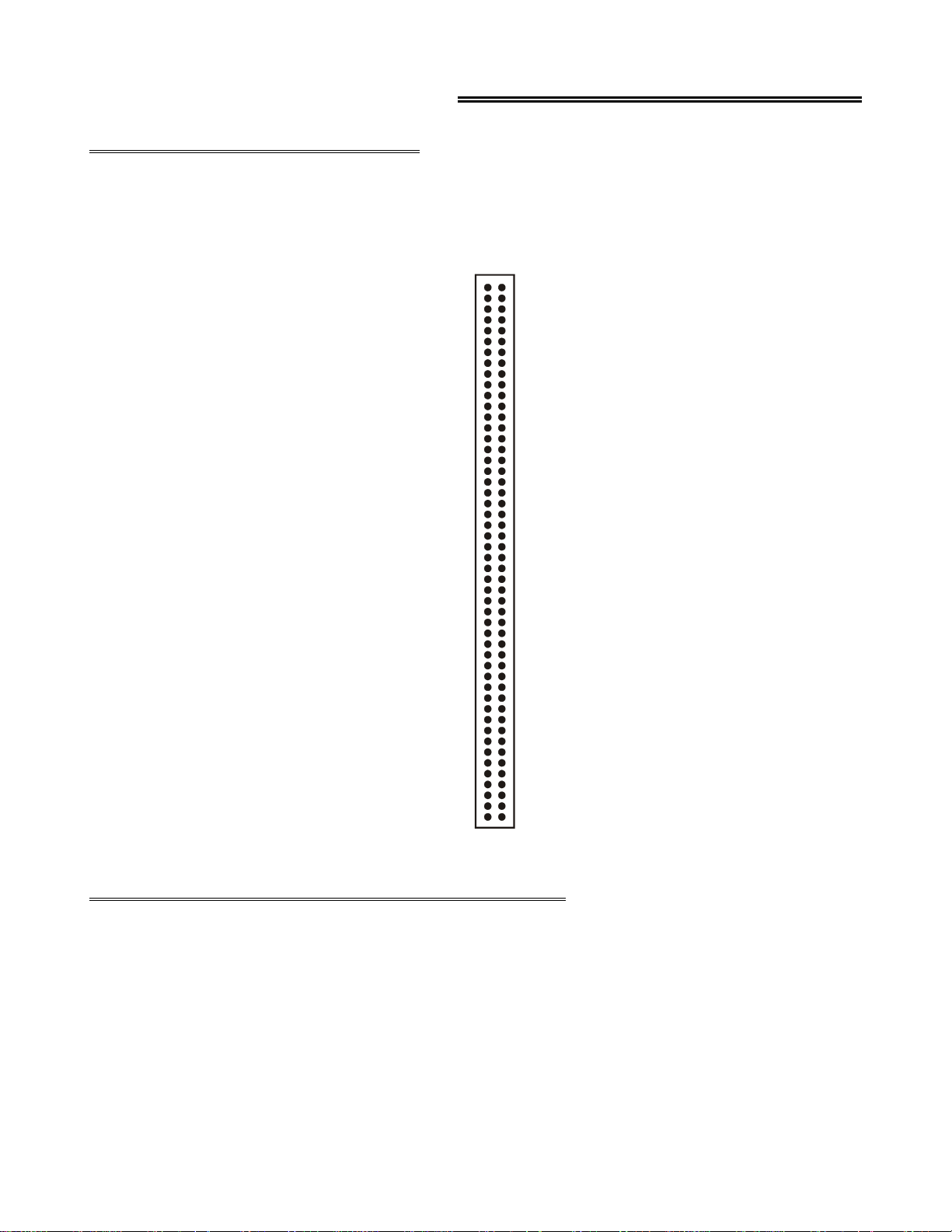

3.1 CONNECTOR PIN DIAGRAM

The PCI-DAS1000 series employ a 100 pin I/O connector. Please make accurate notes and pay careful attention to wire

connections. In a large system a misplaced wire may create hours of work ‘fixing’ problems that do not exist before the

wiring error is found.

Analog Ground 1

Analog Input Ch 0 High 2

Analog Input Ch 0 Low / 8 High 3

Analog Input Ch 1 High

Analog Input Ch 1 Low / 9 High

Analog Input Ch 2 High

Analog Input Ch 2 Low / 10 High

Analog Input Ch 3 High

Analog Input Ch 3 Low / 11 High

Analog Input Ch 4 High

Analog Input Ch 4 Low / 12 High

Analog Input Ch 5 High

Analog Input Ch 5 Low / 13 High

Analog Input Ch 6 Low / 14 High

Analog Input Ch 7 Low / 15 High

Analog Input Ch 6High

Analog Input Ch 7 High

Analog Ground 18

A/D External Pacer 42

A/D External Trigger 45

NC 19

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

D/A GN D 0 35

D/A OUT 0 36

D/A GND 1 37

D/A OUT 1 38

CLK 4 39

GATE 4 40

OU T 4 41

NC 43

NC 44

NC

NC

PC +5V 48

NC 49

PC Ground 50

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

46

47

51 Digital A0

52

D ig ita l A1

53

4

5

6

7

8

9

D ig ita l A2

54

D ig ita l A3

55

D ig ita l A4

56

D ig ita l A5

57

D ig ita l A6

58

D ig ita l A7

59

D ig ita l B0

60

D ig ita l B1

61

D ig ita l B2

62

D ig ita l B3

63

D ig ita l B4

64

D ig ita l B5

65

D ig ita l B6

66

D ig ita l B7

67

D ig ita l C0

68

D ig ita l C1

69

D ig ita l C2

70

D ig ita l C3

71

D ig ita l C4

72

D ig ita l C5

73

D ig ita l C6

74

D ig ita l C7

75 NC

76

N C

77

N C

78

N C

79

N C

80

C L K 6

81

G ATE 6

82

O UT 6

83

N C

84

N C

85

C L K 5

86

G ATE 5

87

O UT 5

88

N C

89

P C Gr o u n d

90 PC +12V

91 PC Ground

92 P C -1 2 V

93

N C

94

N C

95 A /D Inte r n a l Pa c e r Ou tpu t

96

N C

97

N C

98

N C

99 N C

100 PC Ground

PCI-DAS 100 0 C onnector Diagram

3.2 CONNECTING SIGNALS TO THE PCI-DAS1000

The 100 pin connector provides a far greater signal density than the traditional 37 pin D type connector. In exchange for

that density comes a far more complex cable and mating connector. The C100-FF-2 cable is a pair of 50 pin ribbon cables.

At one end they are joined together with a 100 pin connector. From the 100 pin connector designed to mate with the

PCI-DAS1000 connector, the two 50 pin ribbon cables diverge and are terminated at the other end with standard 50 pin

header connectors. A CIO-MINI50 screw terminal board is the ideal way to terminate real word signals and route them into

the PCI-DAS1000. The BNC16/8 series provides convenient BNC connections to each of the analog inputs.

.

4

Page 8

4.0 ANALOG CONNECTIONS

4.1 ANALOG INPUTS

Analog signal connection is one of the most challenging aspects of applying a data acquisition board. If you are an Analog

Electrical Engineer then this section is not for you, but if you are like most PC data acquisition users, the best way to

connect your anal og inputs may not be ob vious. Though comple te coverage o f this topic is well beyond the scope of this

manual, the following section provides some explanations and helpful hints regarding these analog input connections. This

section is designed to help you achieve the optimum performance from your PCI-DAS1000 series board.

Prior to j umping into a ctual conne ction schemes, you sho uld have at le ast a ba sic underst anding of Single-E nded/Di fferential inputs and system grounding/isolation. If you are already comfortable with these concepts you may wish to skip to the

next section (on wiring configurations).

4.1.1 Single-Ended and Differential Inputs

The PCI-DAS1000 provides either 8 differential or 16 single-ended input channels. The concepts of single-ended and

differential inputs are discussed in the following section.

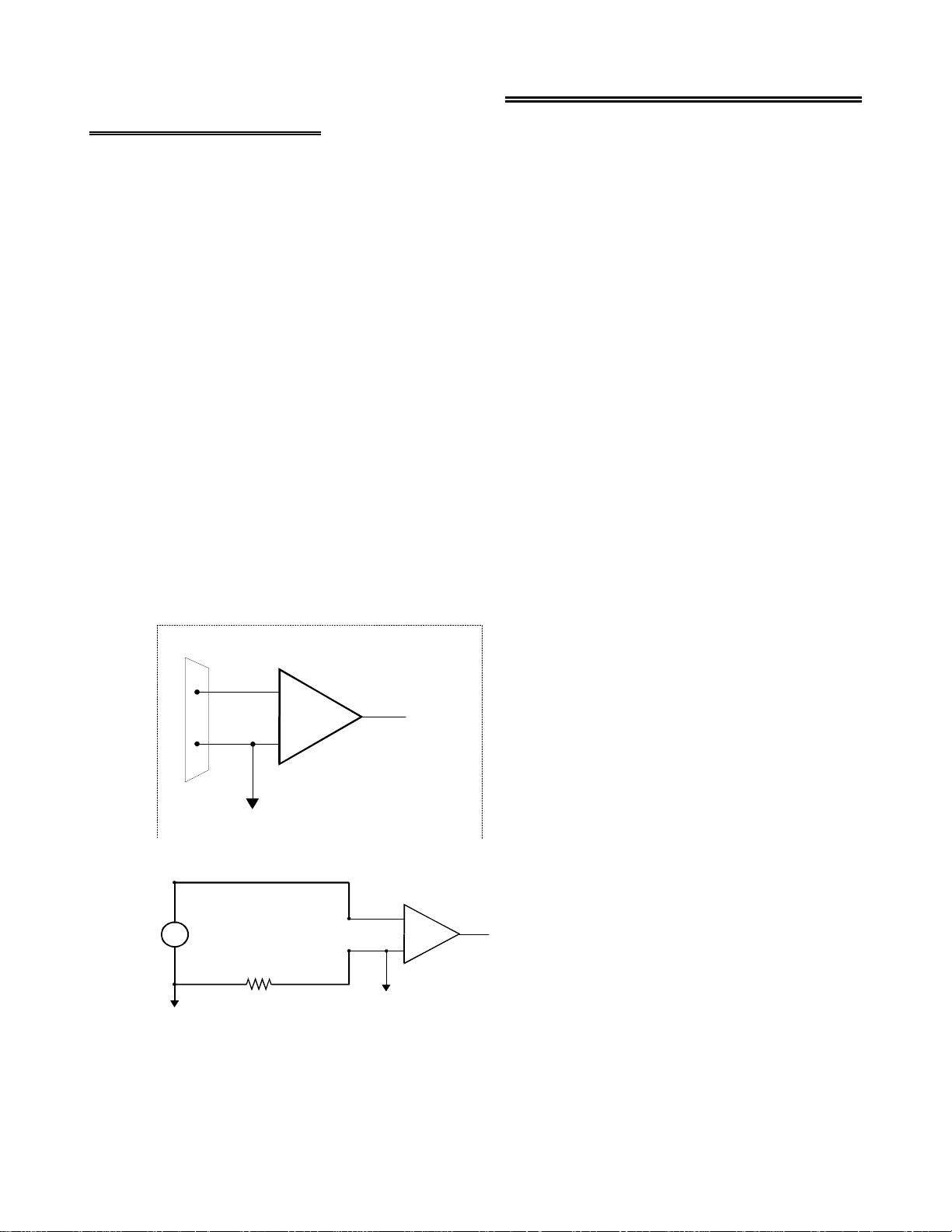

Single-Ended Inputs

A single-ended input measures the voltage between the input signal and ground. In this case, in single-ended mode the

PCI-DAS1000 measures the voltage between the input channel and LLGND. The single-ended input configuration requires

only one physical connection (wire) per channel and allows the PCI-DAS1000 to monitor more channels than the (2-wire)

differential configuration using the same connector and onboard multiplexor. However, since the PCI-DAS1000 is measuring the input voltage relative to its own low level ground, single-ended inputs are more susceptible to both EMI (Electro

Magnetic Interference) and any ground noise at the signal source. The following diagrams show the single-ended input

configuration.

CH IN

LL GND

I/O

Connector

+

-

Inp u t

Amp

To A/D

Single-Ended Input

CH IN

~

Vs

1

g

Any voltage differential between grounds

g1 and g2 shows up as an error signal

at the input amplifier

Vs + Vg2 - Vg1

LL GND

Single-ended input with Comm on M ode Voltage

+

Input

Amp

-

2

g

To A /D

5

Page 9

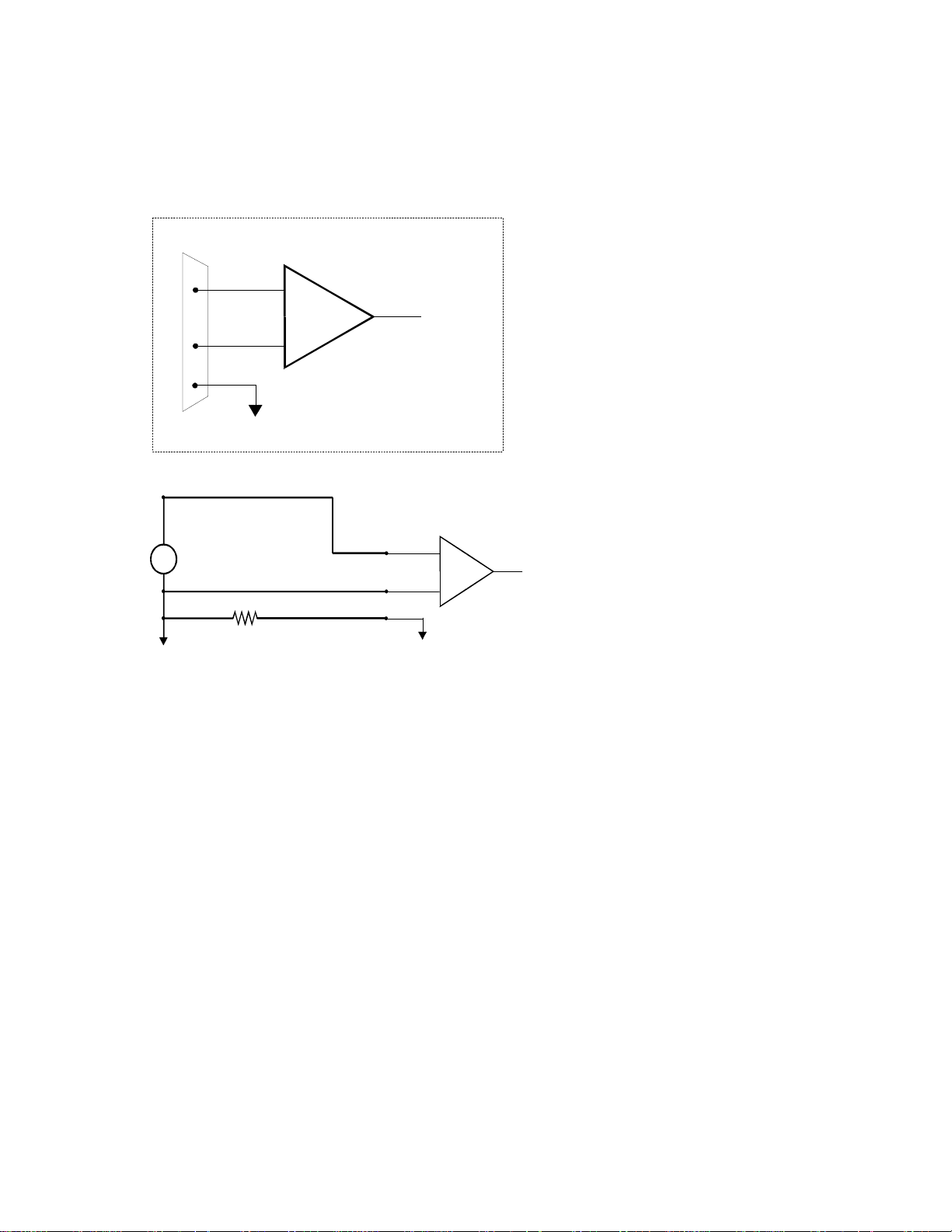

Differential Inputs

g

y

g

g

g

g

Differential inputs measure the voltage between two distinct input signals. Within a certain range (referred to as the common

mode range), the measurement is almost independent of signal source to PCI-DAS1000 ground variations. A differential

input is also much more immune to EMI than a single-ended one. Most EMI noise induced in one lead is also induced in the

other, the input only measures the difference between the two leads, and the EMI common to both is ignored. This effect is a

major reason there is twisted pair wire as the twisting assures that both wires are subject to virtually identical external influence. The diagram below shows a typical differential input configuration.

CH High

CH Low

LL GN D

I/O

Connector

Vs

~

Vcm = V

12

Common Mode Volta

b

differential input configuration. Ho w ever,

no te th a t V cm + V s mus t rema in w ithin

the amplifier’s co m mon m ode ran

+

Inp ut

Amp

-

Differential In put

Vs

Vcm

2 - Vg1

e (Vcm) is ignored

e of ±10V

CH High

CH Low

LL GND

To A/ D

+

Inp u t

Amp

-

Differential

Inp ut

To A/ D

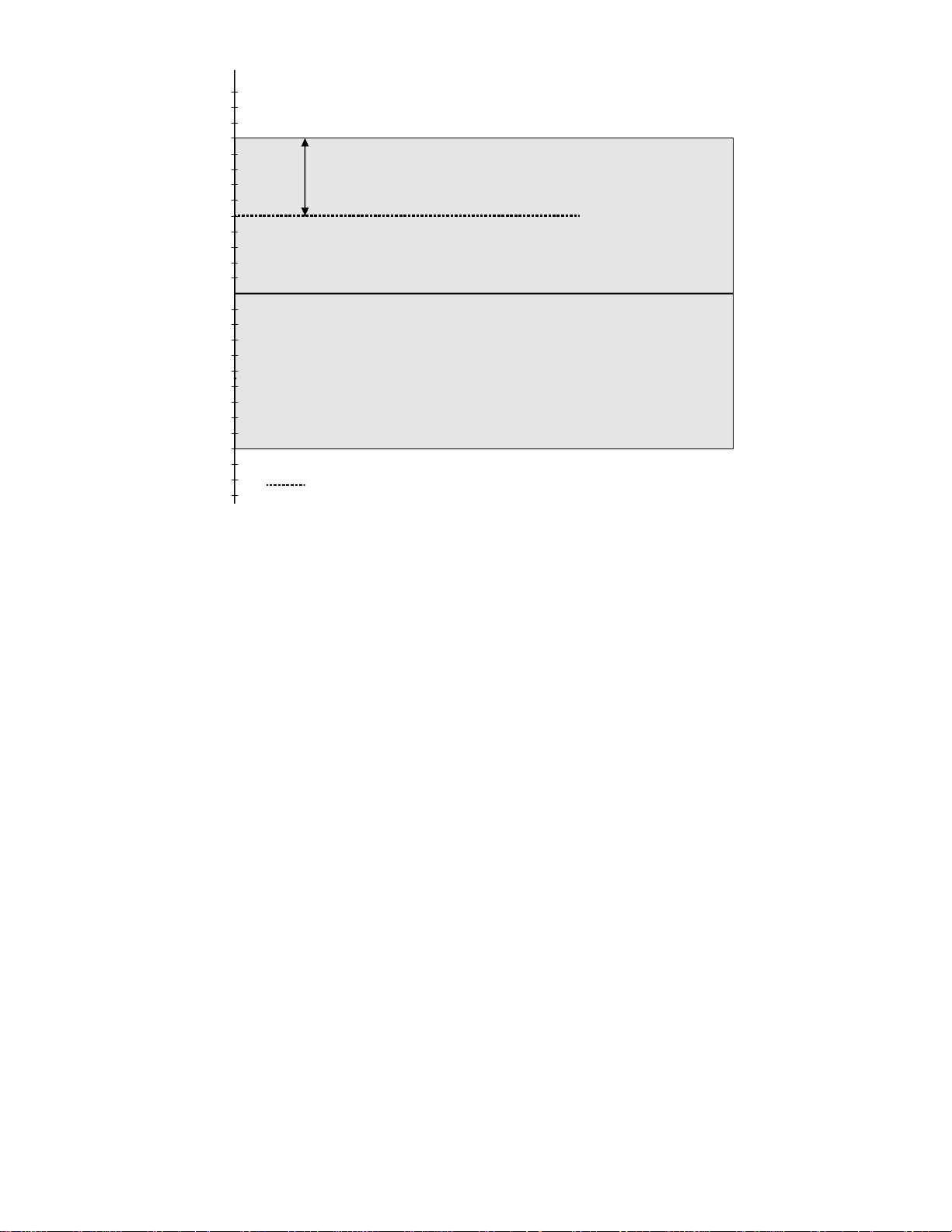

Before moving on to the discussion of grounding and isolation, it is important to explain the concepts of common mode, and

common mode range ( CM Range). Common mode voltage is dep icted in the diagram above a s Vcm. Though differ ential

inputs measure the voltage between two signals, without (almost) respect to the either signal’s voltages relative to ground,

there is a li mit to how far away from ground ei ther signa l can go. Though the PCI-DAS1000 has differential inputs, it will

not measure the difference between 100V and 101V as 1 Volt (in fact the 100V would destroy the board!). This limitation

or common mode range is depicted graphically in the following diagram. The PCI-DAS1000 common mode range is +/- 10

Volts. Even in differential mode, no input signal can be measured if it is more than 10V from the board’s low level ground

(LLGND).

6

Page 10

+13V

g

+12V

+11V

+10V

+9V

+8V

+7V

+6V

+5V

+4V

+3V

+2V

+1V

-1V

-2V

-3V

-4V

-5V

-6V

-7V

-8V

-9V

-10V

-11V

-12V

-13V

Gray area represents com m on m ode range

Both V+ and V- must always remain within

the co mmo n mo d e ra n

W ith V cm= + 5 V D C,

+Vs must be less than +5V, or the common m ode range will b e e x cee d e d (> + 10 V )

Vcm

Vcm (Comm on M o de Voltage) = +5 Volts

e relative to LL G nd

4.1.2 System Grounds and Isolation

There are three scenarios possible when connecting your signal source to your PCI-DAS1000 board.

1. The PCI-DAS1000 and the signal source may have the same (or common)

ground. This signal source may be connected directly to the PCI-DAS1000.

2. The PCI-DAS1000 and the signal source may have an offset voltage

between their grounds (AC and/or DC). This offset it commonly

referred to a common mode voltage. Depending on the magnitude of

this voltage, it may or may not be possible to connect the PCI-DAS1000

directly to your signal source. We will discuss this topic further in a later

section.

3. The PCI-DAS1000 and the signal source may already have isolated

grounds. This signal source may be connected directly to the

PCI-DAS1000.

Which system do you have?

Try the following experiment. Using a battery powered voltmeter*, measure the voltage (difference) between the ground

signal at your signal source and at your PC. Place one voltmeter probe on the PC ground and the other on the signal source

ground. Measure both the AC and DC Voltages.

*If you do not have access to a voltmeter, skip the experiment and take a look a the following three sections. You may be able to identify

your system type from the descriptions provided.

If both AC and DC r eadings ar e 0.00 volts, you may have a system with common ground s. However, sinc e voltmeters will

average out high frequency signals, there is no guarantee. Please refer to the section below titled

Common Grounds

.

If you measure reasonably stable AC and DC voltages, your system has an offset voltage between the grounds category.

This offset is referred to as a Common Mode Voltage. Please be careful to read the following warning and then proceed to

the section describing

Common Mode

systems.

7

Page 11

WARNING

If either the AC or DC voltage is greater than 10 volts, do not connect the PCI-DAS1000 to this signal

source. You are beyond the boards usable common mode range and will need to either adjust your

grounding system or add special Isolation signal conditioning to take useful measurements. A ground

offset voltage of more than 30 volts will likely damage the PCI-DAS1000 board and possibly your

computer. Note that an offset voltage much greater than 30 volts will not only damage your

electronics, but it may also be hazardous to your health.

This is such an important point, that we will state it again. If the voltage between the ground of your

signal source and your PC is greater than 10 volts, your board will not take useful measurements. If

this voltage is greater than 30 volts, it will likely cause damage, and may represent a serious shock

hazard! In this case you will need to either reconfigure your system to red uce the ground differentials,

or purchase and install special electrical isolation signal conditioning.

If you cannot obtain a reasonably stable DC voltage measurement between the grounds, or the voltage drifts around considerably, the two grounds are most likely isolated. The easiest way to check for isolation is to change your voltmeter to it’s

ohm scale and measure the resistance between the two grounds. It is recommended that you turn both systems off prior to

taking this resistance measurement. If the measured resistance is more than 100 Kohm, it’s a fairly safe bet that your system

has electrically isolated grounds.

Systems with Common Grounds

In the simplest (but perhaps least likely) case, your signal source will have the same ground as the PCI-DAS1000. This

would typically occur when providing power or excitation to your signal source directly from the PCI-DAS1000. There may

be other common ground configurations, but it is important to note that any voltage between the PCI-DAS1000 ground and

your signal ground is a potential error voltage if you set up your system based on a common ground assumption.

As a safe rule of thumb, if your signal source or sensor is not connected directly to an LLGND pin on your PCI-DAS1000,

it’s best to assume that you do not have a common ground even if your voltmeter measured 0.0 Volts. Configure your

system as if there is ground offset voltage between the source and the PCI-DAS1000. This is especially true if you are using

high gains, since ground potentials in the sub millivolt range will be large enough to c ause A/D erro rs, yet will not likely be

measured by your handheld voltmeter.

Systems with Common Mode (ground offset) Voltages

The most frequently encountered grounding scenario involves grounds that are somehow connected, but have AC and/or DC

offset voltages between the PCI-DAS1000 and signal source grounds. This offset voltage my be AC, DC or both and may

be caused by a wide array of phenomena including EMI pickup, resistive voltage drops in ground wiring and connections,

etc. Ground offset voltage is a more appropriate term to describe this type of system, but since our goal is to keep things

simple, and help you make appropriate connections, we’ll stick with our somewhat loose usage of the phrase Common

Mode.

Small Common Mode Voltages

If the voltage between the signal source ground and PCI-DAS1000 ground is small, the combination of the ground voltage

and input signal will not exceed the PCI-DAS1000’s +/-10V common mode range, (i.e. the voltage between grounds, added

to the maximum input voltage, stays within +/-10V), This input is compatible with the PCI-DAS1000 and the system may be

connected without additional signal conditioning. Fortunately, most systems will fall in this category and have a small

voltage differential between grounds.

Large Common Mode Voltages

If the ground differential is large enough, the PCI-DAS1000’s +/- 10V common mode range will be exceeded (i.e. the

voltage between PCI-DAS1000 and signal source grounds, added to the maximum input voltage you’re trying to measure

exceeds +/-10V). In this case the PCI-DAS1000 cannot be directly connected to the signal source. You will need to change

your system grounding configuration or add isolation signal conditioning. (Please look at our ISO-RACK and ISO-5Bseries products to add electrical isolation, or give our technical support group a call to discuss other options.)

NOTE

8

Page 12

Relying on the earth prong of a 120VAC for signal ground connections is not advised.. Different

ground plugs may have large and potentially even dangerous voltage differentials. Remem ber that the

ground pins on 120VAC outlets on different sides of the room may only be connected in the basement.

This leaves the possibility that the “ground ” pins may have a significant vo ltag e dif ferential ( especia lly

if the two 120 VAC outlets happen to be on different phases!)

PCI-DAS1000 and signal source already have isolated grounds

Some signal sources will already be electrically isolated from the PCI-DAS1000. The diagram below shows a typical

isolated ground system. These signal sources are often battery powered, or are fairly expensive pieces of equipment (since

isolation is not an inexpensive proposition), isolated ground systems provide excellent performance, but require some extra

effort during connections to assure optimum performance is obtained. Please refer to the following sections for further

details.

4.2 WIRING CONFIGURATIONS

Combining all the grounding and input type possibilities provides us with the following potential connection configurations.

The combinations along with our recommendations on usage are shown in the chart below.

Ground Category Input Configuration Our view

RecommendedSingle-Ended InputsCommon Ground

AcceptableDifferential InputsCommon Ground

Common Mode

Voltage < +/-10V

Common Mode

Voltage < +/-10V

Common Mode

Voltage > +/- 10V

Common Mode

Voltage > +/-10V

Already Isolated

Grounds

The following sections depicts recommended input wiring schemes for each of the 8 possible input configuration/grounding

combinations.

Single-Ended Inputs

Differential Inputs

Not RecommendedSingle-Ended Inputs

RecommendedDifferential Inputs

Unacceptable without

adding Isolation

Unacceptable without

adding Isolation

AcceptableSingle-ended InputsAlready Isolated Grounds

RecommendedDifferential Inputs

9

Page 13

4.2.1 Common Ground / Single-Ended Inputs

g

Single-ended is the recommended configuration for common ground connections. However, if some of your inputs are

common ground and some are not, we recommend you use the differential mode. There is no performance penalty (other

than loss of channels) fo r using a differ ential input to measure a common ground signal source . However the re verse is not

true. The diagram below shows a recommended connection diagram for a common ground / single-ended input system

Signal

So u rc e with

C omm o n Gnd

Optional wire

since signal source

and A/D board share

comm on g round

CH IN

LL GND

I/O

Connector

+

-

Input

Amp

To A /D

A/D Board

Signal source and A/D board

sharing comm on ground connected

to sin gle- e nde d in put.

4.2.2 Common Ground / Differential Inputs

The use of differential inputs to monitor a signal source with a common ground is a acceptable configuration tho ugh it

requires more wiring and offers fewer channels than selecting a single-ended configuration. The diagram below shows the

recommended connections in this configuration.

Signal

S ou rc e w ith

Common Gnd

Optional wire

since signal source

and A/D board share

common g round

Required connection

of LL GND to CH Low

CH High

CH Low

LL GND

I/O

Conn ec tor

+

Inp u t

Amp

-

A/D Board

To A / D

Signal source and A/D board

sharin

comm on ground connected

to differential input.

4.2.3 Common Mode Voltage < +/-10V / Single-Ended Inputs

This is not a recommended configuration. In fact, the phrase common mode has no meaning in a single-ended system and

this case would be better described as a system with offset grounds. Anyway, you are welcome to try this configuration, no

system damage should occur and depending on the overall accuracy you require, you may receive acceptable results.

10

Page 14

4.2.4 Common Mode Voltage < +/-10V / Differential Inputs

Systems with varying ground potentials should always be monitored in the differential mode. Care is required to assure that

the sum of the input signal and the ground differential (referred to as the common mode voltage) does not exceed the

common mode range of the A/D board (+/-10V on the PCI-DAS1000). The diagram below show recommended connections

in this configuration.

Signal Source

with C omm on

M od e V o lta g e

The voltage differential

between these grounds,

added to the maximum

input signal must stay

w ith in + /- 1 0 V

GND

CH High

CH Low

LL GND

I/O

Conn ec tor

+

Inp u t

Amp

-

A/D Board

To A /D

Signal source and A/D board

with com m on m ode voltage

connected to a differential input.

4.2.5 Common Mode Voltage > +/-10V

The PCI-DAS1000 will not directly monitor signals with common mode voltages greater than +/-10V. You will either need

to alter the system ground configuration to reduce the overall common mode voltage, or add isolated signal conditioning

between the source and your board.

Isolation

Barrier

arge comm on

L

mode voltage

between signal

source & A/D b oard

When the voltage difference

between signal source and

A/D board ground is large

enough so the A/D board’s

common mode range is

exceeded, isolated signal

conditioning must be added.

System with a Large Comm on Mode Voltage,

GND

Connector

Connected to a Single-Ended Input

I/O

CH IN

LL GND

+

Inpu t

Amp

-

A/D Board

To A / D

11

Page 15

on

g

m

arge com

L

mode voltage

betwee n signal

s o urce & A/D b o ard

GND

Isolation

Barrier

10 K

CH High

CH Low

LL GN D

+

Inpu t

Amp

To A /D

-

When the voltage difference

between signal source and

A/D board ground is large

enough so the A/D board’s

common mode range is

exceeded, isolated signal

conditioning must be add ed.

10K is a recommended value. You may short LL GND to CH Low

ins tea d , b u t th is w ill r e d u c e y o u r s y s te m ’s n o is e imm un ity.

I/O

Connector

A/D Board

System with a Large Com m on M ode Voltage,

Connected to a Differential Input

4.2.6 Isolated Grounds / Single-Ended Inputs

Single-ended inputs can be used to monitor isolated inputs, though the use of the differential mode will increase your

system’s noise immunity. The diagram below shows the recommended connections is this configuration.

Iso late d

s ign al

so u r ce

CH IN

LL GND

I/O

Connector

+

-

Inpu t

Amp

To A / D

A/D Board

Isolated Signal Source

Connected to a Sin

le-Ended Input

4.2.7 Isolated Grounds / Differential Inputs

Optimum performance with isolated signal sources is assured with the use of the differential input setting. The diagram

below shows the recommend connections is this configuration.

12

Page 16

Signal Source

a n d A/ D Boa rd

Alr ead y Is ola te d .

GND

10 K

CH High

CH Low

LL GND

+

-

Inp u t

Amp

To A/D

These grounds are

electrically isolated.

I/O

Conn ec tor

10K is a recommended value. You m ay short LL GND to CH Low

instead, but this will re d u c e y o ur system’s noise immu nity.

Already isolated signal source

and A/D board connected to

a differential input.

A/D Board

13

Page 17

5.0 PROGRAMMING & SOFTWARE APPLICATIONS

Your PCI-DAS1000 is supported by the powerful Universal Library. We strongly recommend that you take advantage of

the Universal Library as you software interface. The complexity of the the registers required for automatic calibration

combined with the PCI BIOS's dynamic allocation of addresses and internal resources makes the PCI-DAS1000 series very

challenging to program via direct register I/O operations. Direct I/O programming should be attempted only by very experienced programmers.

Although the PCI-DAS1000 is part of the larger DAS family, there is no correspondence between register locations of the

PCI-DAS1000 and boards in the CIO-DAS16 family. Software written at the register level for the other DAS boards will

not work with the PCI-DAS1000. However, software written based on the Universal Library should work with the

PCI-DAS1000 with few or no changes.

5.1 PROGRAMMING LANGUAGES

The Universal Library provides complete access to the PCI-DAS1000 functions from the full range of Windows programming languages. If you are planning to write pro grams, or would like to run the example p rograms for Visual B asic or any

other language, please turn now to the UniversalLibrary manual.

The opitional VIX Components package may greatly simplify your programming effort. VIX Components is a set of

programming tools based on a DLL interface to Windo ws languages. A set of VBX, OCX or ActiveX interfaces allows

point and click construction of graphical displays, analysis and control structures. Please see the catalog for a complete

description of the package.

5.2 PACKAGED APPLICATION PROGRAMS

Many packaged application programs, such as DAS Wizard and HP-VEE now have drivers for the PCI-DAS1000. If the

package you own does not appear to have drivers for the PCI-DAS1000 please fax or e-mail the package name and the

revision number from the install disks. We will research the package for you and advise how to obtain PCI-DAS1000

drivers.

Some application drivers are included with the Universal Library package, but not with the Application package. If you

have purchased an application package directly from the software vendor, you may need to purchase our Universal Library

and drivers. Please contact us for more information on this topic.

14

Page 18

6.0 SELF-CALIBRATION OF THE PCI-DAS1000

The PCI-DAS1000 is shipped fully-calibrated from the factory with cal coefficients stored in nvRAM. At run time, these

calibration factors are loaded into system memory and are automatically retrieved each time a different DAC/ADC range is

specified. The user has the option to recalibrate with respect to the factory-measured voltage standards at any time by

simply selecting the "Calibrate" option in InstaCal. Full calibration typically requires less than two minutes and requires no

user intervention.

6.1 CALIBRATION CONFIGURATION

6.1.1 Analog Inputs

The PCI-DAS1000 provides self-calibration of the analog source and measure systems thereby eliminating the need for

external equipment and user adjustments. All adjustments are made via 8-bit calibration DACs or 7-bit digital potentiometers referenced to an on-board factory calibrated standard. Calibration factors are stored on the serial nvRAM..

A variety of methods are used to calibrate the different elements on the board. The analog front-end has several knobs to

turn. Offset calibration is performed in the instrumentation amplifier gain stage. Front-end gain adjustment is performed

via a variable attenuator/gain stage.

The analog output circuits are calibrated for both gain and offset. Offset adjustments for the analog output are made in the

output buffer section. The tuning range of this adjustment allows for max DAC and output buffer offsets. Gain calibration

of the analog outputs are performed via DAC reference adjustments.

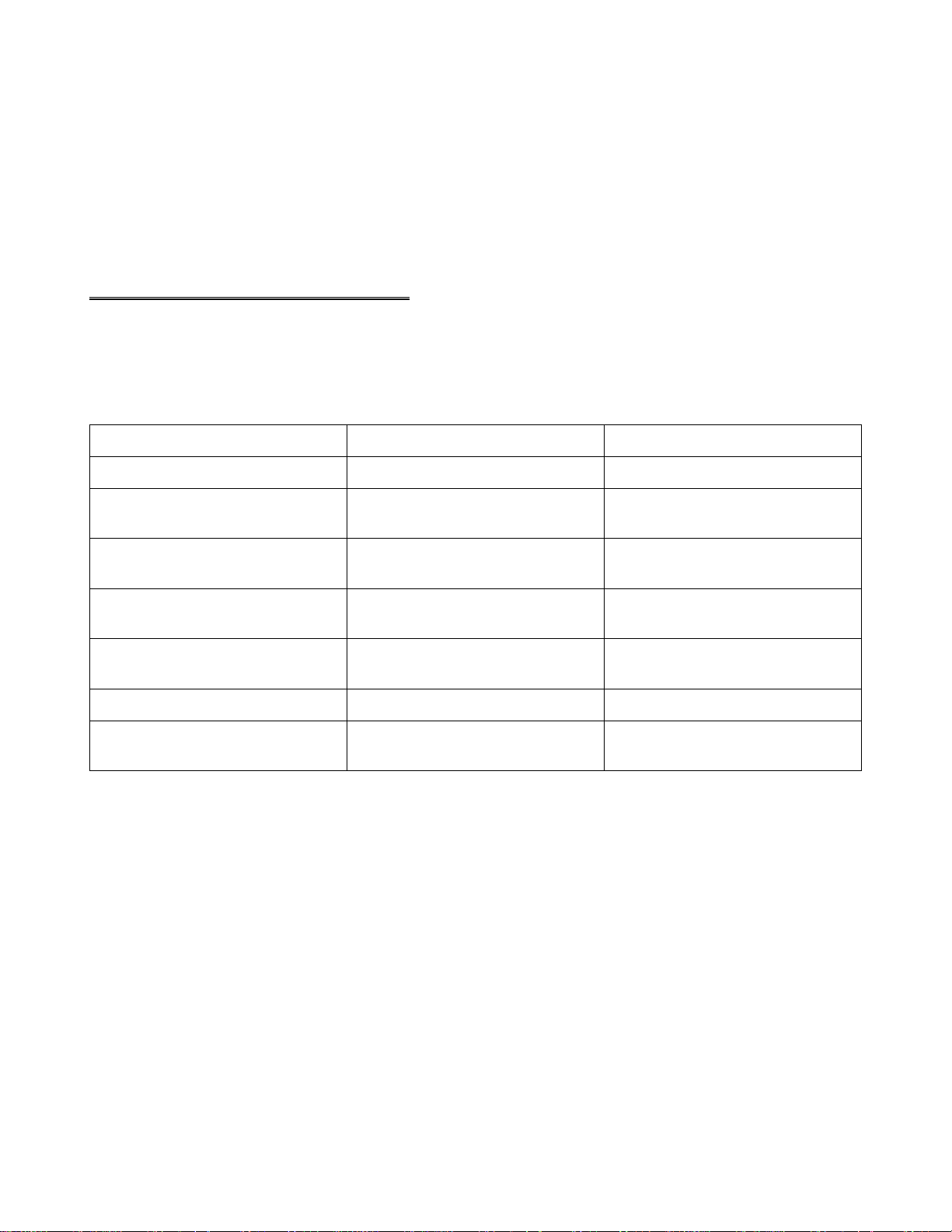

Figure 1 below is a block diagram of the analog front-end calibration system:

Cal

Ref

8

Trim Dac

(Coarse)

Trim Dac

(Fine)

PGA

Offset Adj

Offset

Variable Gain

Digital Offset Pot

Figure 1

ADC

7

15

Page 19

6.1.2 Analog Outputs

The calibration scheme for the Analog Out section is shown in Figure 2 below. This circuit is duplicated for both DAC0

and DAC1

Analog-Out

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

(Coarse)

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

Trim Dac

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

(Fine)

12

Gain Adj

Gain Adj

Gain Adj

Ref

Trim Dac

DAC

Analog Out

Offset Adj

Figure 2

16

Page 20

7.1 REGISTER OVERVIEW

7.0 PCI-DAS1000 REGISTER DESCRIPTION

PCI-DAS1000 operation registers are mapped into I/O address space. Unlike ISA bus designs, this board has

addresses each corresponding to a reserved block of addresses in I/O space. As we mention in our programming chapter,

we highly recommend customers use the Universal Library package. Direct register level programming should be attempted

only by extremely experienced register level programmers.

Of six Base Address Regions (BADR) available in the PCI 2.1 specification, five are implemented in this design and are

summarized as follows:

OperationsFunctionI/O Region

32-Bit DWORDPCI Controller Operation RegistersBADR0

16-Bit WORDGeneral Control/Status RegistersBADR1

16-Bit WORDADC Data, FIFO Clear RegistersBADR2

8-Bit BYTEPacer, Counter/Timer and DIO RegistersBADR3

16-Bit WORDDAC Data RegistersBADR4

BADRn will likely be different on different machines. Assigned by the PCI BIOS, these Base Address values cannot be

guaranteed to be the same even on subsequent power-on cycles of the same machine. All software must interrogate BADR0

at run-time with a READ_CONFIGURATION_WORD instruction to determine the BADRn values. Please see the "

AMCC S5933 PCI Controller Data Book"

for more information.

several

base

1997

7.2 BADR0

BADR0 is reserved for the AMCC S5933 PCI Controller operations. There is no reason to access this region of I/O space

for most PCI-DAS1000 users. The installation procedures and Universal Library access all required information in this

area. Unless you are writing direct register level software for the PCI-DAS1000, you will not need to be concerned with

BADR0 address.

7.3 BADR1

The I/O region defined by BADR1 contains 5 control and status registers for ADC, DAC, interrupt and Autocal operations.

This region supports 16-bit WORD operations.

7.3.1 INTERRUPT / ADC FIFO REGISTER

BADR1+ 0: Interrupt Control, ADC status. A read/write register.

WRITE

0123456789101112131415

-

-

Write operations to this register allow the user to select interrupt sources, enable interrupts, clear interrupts as well as ADC

FIFO flags. The following is a description of the Interrupt/ADC FIFO Register:

INT0INT1INTE-EOAIE-EOACLINTCL-----ADFLCL

17

Page 21

INT[1:0]

INTE

General Interrupt Source selection bits.

SourceINT0 INT1

Not Defined 00

End of Channel Scan10

AD FIFO Half Full01

AD FIFO Not Empty11

Enables interrupt source selected via the INT[1:0] bits.

1 = Selected interrupt Enabled

0 = Selected interrupt Disabled

EOAIE

sample size has been gathered.

EOACL

INTCL

ADFLCL

READ

Enables End-of-Acquisition interrupt. Used during FIFO'd ADC operations to indicate that the desired

1= Enable EOA interrupt

0 = Disable EOA interrupt

A write-clear to reset EOA interrupt status.

1 = Clear EOA interrupt.

0 = No effect.

A write-clear to reset

1 = Clear

0 = No effect.

A write-clear to reset latched ADC FIFO Full status.

1 = Clear ADC FIFO Full latch.

0 = No Effect.

NOTE: It is not necessary to reset any write-clear bits after they are set.

INT[1:0]

INT[1:0]

interrupt

selected interrupt status.

0123456789101112131415

------EOAIINT-EOBIADHFIADNEIADNELADFUL--

Read operations to this register allow the user to check status of the selected interrupts and ADC FIFO flags. The following

is a description of Interrupt / ADC FIFO Register Read bits:

EOAI

INT

EOBI

Status bit of ADC FIFO End-of-Acquisition interrupt

1 = Indicates an EOA interrupt has been latched.

0 = Indicates an EOA interrupt has not occurred.

Status bit of General interrupt selected via

these interrupts has occurred.

1 = Indicates a General interrupt has been latched.

0 = Indicates a General interrupt has not occurred.

Status bit ADC End-of-Burst interrupt. Only valid for ADC Burst Mode enabled.

1 = Indicates an EOB interrupt has been latched.

0 = Indicates an EOB interrupt has not occurred.

INT[1:0]

bits. This bit indicates that any one of

18

Page 22

ADHFI

Status bit of ADC FIFO Half-Full interrupt. Used during REP INSW operations.

1 = Indicates an ADC Half-Full interrupt has been latched. FIFO has been filled

with more than 255 samples.

0 = Indicates an ADC Half-Full interrupt has not occurred. FIFO has not yet

exceeded 1/2 of its total capacity.

ADNEI

complete in single conversion applications.

ADNE

Real-time status bit of ADC FIFO Not-Empty status signal.

LADFUL

Status bit of ADC FIFO Not-Empty interrupt. Used to indicate ADC conversion

1 = Indicates an ADC FIFO Not-Empty interrupt has been latched and that

one data word may be read from the FIFO.

0 = Indicates an ADC FIFO Not-Empty interrupt has not occurred. FIFO has

been cleared, read until empty or ADC conversion still in progress.

1 = Indicates ADC FIFO has at least one word to be read.

0 = Indicates ADC FIFO is empty.

Status bit of ADC FIFO FULL status. This bit is latched.

1 = Indicates the ADC FIFO has exceeded full state. Data may have been lost.

0 = Indicates non-overflow condition of ADC FIFO.

7.3.2 ADC CHANNEL MUX AND CONTROL REGISTER

BADR1 + 2

This register sets channel mux HI/LO limits, ADC gain, offset and pacer source.

A Read/Write register.

WRITE

0123456789101112131415

CHL1CHL2CHL4CHL8CHH1CHH2CHH4CHH8GS0GS1SEDIFFUNIBIPADPS0ADPS1--

CHL8-CHL1,

When these bits are written, the analog input multiplexers are set to the channel specified by CHL8-CHL1. After each

conversion, the input multiplexers increment to the next channel, reloading to the "CHL" start channel after the "CHH"

stop channel is reached. LO and HI channels are the decode of the 4-bit binary patterns.

GS[1:0]

These bits determine the ADC range as indicated below.

SEDIFF

UNIBIP

CHH8-CHH1

Selects measurement configuration for the Analog Front-End.

1 = Analog Front-End in Single-Ended Mode. This mode supports

up to 16 channels.

0 = Analog Front-End in Differential Mode. This mode supports

up to 8 channels.

Selects offset configuration for the Analog Front-End.

1 = Analog Front-End Unipolar for selected range

0 = Analog Front-End Bipolar for selected range.

RangeGS0GS1

10V00

5V10

2.5V01

1.25V11

19

Page 23

The following tables summarizes all possible Offset/Range configurations

PCI-DAS1002

Input GainInput RangeGS0GS1UNIBIP

000

100

010

110

001

101

011

111

±10V

± 5V

±2.5V

±1.25V

0-10V

0-5V

0-2.5V

0-1.25V

PCI-DAS1001

Input GainInput RangeGS0GS1UNIBIP

000

100

010

110

001

101

011

111

±10V

± 1V

±0.1V

±0.01V

0-10V

0-1V

0-0.1V

0-0.01V

:

Measurement

Resolution

4.88 mV1

2.44 mV2

1.22 mV4

610 uV8

2.44 mV1

1.22 mV2

610 uV4

305 uV8

Measurement

Resolution

4.88 mV1

488 uV10

48.8 uV100

4.88 uV1,000

2.44 mV1

244 uV10

24.4 uV100

2.44 uV1,000

ADPS[1:0]

These bits select the ADC Pacer Source. Maximum Internal/External Pacer

frequency is 330KHz.

Note: For ADPS[1:0] = 00 case, SW conversions are initiated

via a word write to BADR2 + 0. Data is 'don't care.'

READ

EOC

Real-time, non-latched status of ADC End-of-Conversion signal.

1 = ADC DONE

0 = ADC BUSY

Pacer SourceADPS0ADPS1

SW Convert00

82C54 Counter/Timer10

External Falling01

External Rising11

0123456789101112131415

--------------EOC-

20

Page 24

7.3.3 TRIGGER CONTROL/STATUS REGISTER

BADR1 + 4

This register provides control bits for all ADC trigger modes. A Read/Write register.

WRITE

0123456789101112131415

TS0TS1--TGENBURSTEPRTRGXTRCL---ARMFFM0C0SRC--

TS[1:0]

TGEN

This bit is used to enable External Trigger function

BURSTE

These bits select one-of-two possible ADC Trigger Sources:

SourceTS0TS1

Disabled00

SW Trigger10

External (Digital)01

Not Defined11

Note

: TS[1:0] should be set to 0 while setting up Pacer source and count values.

1 = External rising-edge Digital Trigger enabled.

0 = External Digital Trigger has no effect.

Note that the external trigger requires proper setting of the

bits. Once these bits are set, the next rising edge will start a Paced ADC conversion.

Subsequent triggers will have no effect until external trigger flop is cleared (

This bit enables 330KHz ADC Burst mode. Start/Stop channels are selected via

the CHLx, CHHx bits in ADC CTRL/STAT register at BADR1 + 2.

1 = Burst Mode enabled

0 = Burst Mode disabled

TS[1:0]

and

TGEN

XTRCL

).

PRTRG

XTRCL

ARM,

FFM0

This bit enables ADC Pre-trigger Mode. This bit works with the ARM and FFM0

bits when using Pre-trigger mode. See document "PCI-DAS1000 ADC Modes"

for programming guidelines.

1 = Enable Pre-trigger Mode

0 = Disable Pre-trigger Mode

A write-clear to reset the

1 = Clear

0 = No Effect.

These bits works in conjunction with

See document "PCI-DAS1000 ADC Modes" for programming guidelines.

XTRIG

XTRIG

status.

flip-flop.

PRTRG

during FIFO'd ADC operations.

21

Page 25

The table below provides a summary of bit settings and operation.

C0SRC

FIFO ModeARM is set...FFM0PRTRG

00

10

01

11

This bit allows the user to select the clock source for user Counter 0.

1 = Internal 10MHz oscillator

0 = External clock source input via CTR0CLK pin on 100p connector.

Via SW when

remaining count <1024

------------------------

Via SW immediately

Via SW immediately

Via SW when

remaining count <1024

------------------------

Via SW immediately

Via SW immediately

# Samples >1 FIFO

Normal Mode

----------------------------------

1/2 FIFO < # Samples < 1 FIFO

Normal Mode

# Samples <1/2 FIFO

Normal Mode

# Samples >1 FIFO

Pre-Trigger Mode

----------------------------------

1/2 FIFO < # Samples < 1 FIFO

Pre-Trigger Mode

# Samples <1/2 FIFO,

Pre-Trigger Mode

Sample CTR

Starts on...

ADHF

ADC Pacer

ADHF

XTRIG

READ

XTRIG

INDX_GT

1 = External Trigger flip-flop has been set. This bit is write-cleared.

0 = External Trigger flip-flop reset. No trigger has been received.

1 = Pre-trigger index counter has completed its count.

0 = Pre-trigger index counter has not been gated on or has not yet completed its count

0123456789101112131415

-------XTRIG----INDX_GT---

.

22

Page 26

7.3.4 CALIBRATION REGISTER

See "Calibrating The PCI-DAS1000" document for additional programming details.

BADR1 + 6

This register controls all autocal operations. This is a Write-only register.

WRITE

SEL8800SEL7376-CSRC0CSRC1CSRC2CALENSDI

0123456789101112131415

--------

SEL8800

SEL7376

CSRC[2:0]

This bit enables the 8-bit trim DACs for the following circuits:

Cal Function DAC Channel

0

1

2

3

4

5

6

7

This bit latches the 7-bit serial data stream into the AD7376 digital potentiometer

(10KOhm). The AD7376 is used for analog front-end gain calibration.

These bits select the different calibration sources available to the ADC front end.

DAC0

DAC0

DAC0

DAC1

DAC1

DAC1

ADC

ADC

Fine Gain

Coarse Gain

Offset

Offset

Fine Gain

Coarse Gain

Coarse Offset

Fine Offset

Cal SourceCSRC0CSRC1CSRC2

AGND000

7.0V100

3.5V010

1.75V110

0.875V001

8.6mV101

VDAC0011

VDAC1111

CALEN

SDI

This bit is used to enable Cal Mode.

1 = Selected Cal Source,

0 = Analog Channel 0 functions as normal input.

Serial Data In. This bit is used to set serial address/data stream for the

DAC8800 TrimDac and 7376 digital potentiometer. Used in conjunction

with

SEL8800

and

SEL7376

CSRC[2:0]

bits.

, is fed into Analog Channel 0.

23

Page 27

7.3.5 DAC CONTROL/STATUS REGISTER

BADR1 + 8

This register selects the DAC gain/range and update modes. This is a Write-only register.

WRITE

0123456789101112131415

DACEN-----MODEDAC0R0DAC0R1DAC1R0DAC1R1----

-

DACEN

MODE

DACnR[1:0]

This bit enables the Analog Out features of the board.

1 = DAC0/1 enabled.

0 = DAC0/1 disabled.

The power-on state of this bit is 0.

This bit determines the analog output mode of operation.

1 = Both DAC0 and DAC1 updated with data written to DAC0 data register.

0 = DACn updated with data written to DACn data register.

The power-on state of this bit is 0.

These bits select the independent gains/ranges for either DAC0 or DAC1.

n=0 for DAC0 and n=1 for DAC1.

LSB SizeRangeDACnR0DACnR1

2.44mVBipolar 5V00

4.88mVBipolar 10V10

610uVUnipolar 5V01

1.22mVUnipolar 10V11

24

Page 28

7.4 BADR2

The I/O Region defined by BADR2 contains the ADC Data register and the ADC FIFO clear

register.

7.4.1 ADC DATA REGISTER

BADR2 + 0

ADC Data register.

WRITE

Writing to this register is only valid for SW initiated conversions. The ADC Pacer source must

be set to 00 via the ADPS[1:0] bits. A null write to BADR2 + 0 will begin a single conversion.

Conversion status may be determined in two ways. The

until true or

conversion is complete and the data word is present in the FIFO.

READ

ADNEI

(the AD FIFO not-empty interrupt) may be used to signal that the ADC

MSB LSB

bit in BADR1 + 0 may be polled

EOC

0123456789101112131415

AD0AD1AD2AD3AD4AD5AD6AD7AD8AD9AD10AD110000

AD[11:0]

Bipolar Mode

Unipolar

Mode

This register contains the current ADC data word. Data format is dependent upon

offset mode:

Offset Binary Coding

:

000 h = -FS

7FFh = Mid-scale

FFFh = +FS - 1LSB

Straight Binary Coding

:

000 h = -FS (0V)

7FFh = Mid-scale (+FS/2)

FFFh = +FS - 1LSB

(0V)

7.4.2 ADC FIFO CLEAR REGISTER

BADR2 + 2

ADC FIFO Clear register. A Write-only register. A write to this address location clears

the ADC FIFO. Data is don't care. The ADC FIFO should be cleared before all new

ADC operations.

25

Page 29

7.5 BADR3

The I/O Region defined by BADR3 contains data and control registers for the ADC Pacer, Pre/Post-Trigger Counters, User

Counters and Digital I/O bytes. The PCI-DAS1000 has two 8254 counter/timer devices. These are referred to as 8254A

and 8254B and are assigned as shown below:

FunctionCounter #Device

ADC Post-Trigger Sample Counter08254A

ADC Pacer Lower Divider18254A

ADC Pacer Upper Divider28254A

08254B

All reads/writes to BADR3 are byte operations.

User Counter #3 & ADC Pre-Trigger Index

Counter

User Counter #418254B

User Counter #528254B

7.5.1 ADC PACER CLOCK DATA AND CONTROL REGISTERS

8254A COUNTER 0 DATA -

ADC POST TRIGGER CONVERSION COUNTER

BADR3 + 0

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

Counter 0 is used to stop the acquisition when the desired number of samples have been gathered. It essentially is gated on

when a 'residual' number of conversions remain. The main counting of samples is done by the Interrupt Service Routine,

which will increment each time by 'packets' equal to 1/2 FIFO. Generally the value loaded into Counter 0 is N mod 1024,

where N is the total count, or the post trigger count, since Total count is not known when pre-trigger is active. Counter 0

will be enabled by use of the

operated in Mode 0.

8254A COUNTER 1 DATA

bit (BADR1 + 4) when the next-to-last 1/2-full interrupt is processed. Counter 0 is to

ARM

- ADC PACER DIVIDER LOWER

BADR3 + 1

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

26

Page 30

8254A COUNTER 2 DATA - ADC PACER DIVIDER UPPER

BADR3 + 2

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

Counter 1 provides the lower 16 bits of the 32-bit pacer clock divider. Its output is fed to the clock input of Counter 2

which provides the upper 16-bits of the pacer clock divider. The clock input to Counter 1 is a precision 10MHz oscillator

source.

Counter 2 output is called the 'Internal Pacer' and can be selected by software to the be the ADC Pacer source. Counters 1

& 2 should be configured to operate in 8254 Mode 2.

ADC 8254 CONTROL REGISTER

BADR3 + 3

WRITE ONLY

01324567

D0D1D2D3D4D5D6D7

The control register is used to set the operating Modes of 8254 Counters 0,1 & 2. A counter is configured by writing the

correct Mode information to the Control Register followed by count written to the specific Counter Register.

The Counters on the 8254 are 16-bit devices. Since the interface to the 8254 is only 8-bits wide, Count data is written to the

Counter Register as two successive bytes. First the low byte is written, then the high byte. The Control Register is 8-bits

wide. Further information can be obtained on the 8254 data sheet, available from Intel or Harris.

7.5.2 DIGITAL I/O DATA AND CONTROL REGISTERS

he 24 DIO lines on the PCI-DAS1000 are grouped as three byte-wide I/O ports. Port assignment and functionality is identical to that of the industry standard 8255 Peripheral Interface. Please see the Intel or Harris data sheets for more

information.

DIO PORT A DATA

BADR3 + 4

PORT A may be configured as an 8-bit I/O channel.

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

DIO PORT B DATA

BADR3 + 5

PORT B may be configured as an 8-bit I/O channel. Its functionality is identical to that of

PORT A.

READ/WRITE

27

01324567

D0D1D2D3D4D5D6D7

Page 31

DIO PORT C DATA

BADR3 + 6

PORT C may be configured as an 8-bit port of either input or output, or it may be split into two independent 4-bit ports of

input or output. When split into two 4-bit I/O ports,

make up the lower nibble,

write to Port C is a byte operation. Unwanted information must be ANDed out during reads

and writes must be ORd with current value of the other 4-bit port.

READ/WRITE

comprise the upper nibble. Although it may be split, every

D[7:4]

D[3:0]

01324567

D0D1D2D3D4D5D6D7

DIO CONTROL REGISTER

BADR3 + 7

The DIO Control register is used configure Ports A,B and C as inputs or outputs. Operation is identical to that of the 8255

in Mode 0.

WRITE

01324567

D0D1D2D3D4D5D6D7

The following table summarizes the possible I/O Port configurations for the PCI-DAS1000

DIO operatin in MODE 0:

PORT AD0D1D3D4

UPPER

PORT BPORT C

PORT C

LOWER

OUTOUTOUTOUT0000

INOUTOUTOUT1000

OUTINOUTOUT0100

ININOUTOUT1100

OUTOUTINOUT 0010

INOUTINOUT1010

OUTININOUT0110

INININOUT1110

OUTOUTOUTIN0001

INOUTOUTIN1001

OUTINOUTIN0101

ININOUTIN1101

OUTOUTININ0011

INOUTININ1011

OUTINININ0111

ININININ1111

28

Page 32

7.5.3 INDEX and USER COUNTER 4 DATA AND CONTROL REGISTERS

8254B COUNTER 0 DATA - ADC PRE-TRIGGER INDEX COUNTER(or user counter 4)

BADR3 + 8

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

Counter 0 of the 8254B device is a shared resource on the PCI-DAS1000. When not in ADC pre-trigger mode, the clock,

gate and output lines of Counter 0 are available to the user at the 100 pin connector as user counter 4. The 8254's Counter 0

clock source is SW selectable via the

When in ADC Pre-trigger mode, this counter is used as the ADC Pre-Trigger index counter. This counter serves to mark the

boundary between pre- and post-trigger samples when the ADC is operating in Pre-Trigger Mode. The External ADC

Trigger flip flop gates Counter 0 on; the ADC FIFO Half-Full signal gates it off. Knowing the desired number of posttrigger samples, software can then calculate how may 1/2 FIFO data packets need to be collected and what corresponding

residual sample count needs to be written to BADR3 + 0.

C0SRC

bit in BADR1+4.

8254B COUNTER 1 DATA - USER COUNTER #5

BADR3 + 9

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

The clock, gate and output lines of Counter 1 are available to the user at the 100 pin connector as user counter 5. The

8254's Counter 1 clock source is always external and must be provided by the user. The buffered version of the internal

10MHz clock available at the user connector may be used as the

clock source.

8254B COUNTER 2 DATA - USER COUNTER #6

BADR3 + Ah

READ/WRITE

01324567

D0D1D2D3D4D5D6D7

The clock, gate and output lines of Counter 2 are available to the user at the 100 pin connector as user counter 6. The

8254's Counter 2 clock source is always external and must be provided by the user. The buffered version of the internal

10MHz clock available at the user connector may be used as the clock source.

29

Page 33

8254B CONTROL REGISTER

BADR3 + Bh

WRITE ONLY

01324567

D0D1D2D3D4D5D6D7

The control register is used to set the operating Modes of 8254B Counters 0,1 & 2. A counter is configured by writing the

correct Mode information to the Control Register, then the proper count data must be written to the specific Counter Register.

The Counters on the 8254 are 16-bit devices. Since the interface to the 8254 is only 8-bits wide, Count data is written to the

Counter Register as two successive bytes. First the low byte is written, then the high byte. The Control Register is 8-bits

wide. Further information can be obtained on the 8254 data sheet, available from Intel or Harris.

30

Page 34

7.6 BADR4

The I/O Region defined by BADR4 contains the DAC0 and DAC1 data registers.

7.6.1 DAC0 DATA REGISTER

BADR4 + 0

WRITE

0123456789101112131415

----

MSB LSB

DAC0(0)DAC0(1)DAC0(2)DAC0(3)DAC0(4)DAC0(5)DAC0(6)DAC0(7)DAC0(8)DAC0(9)DAC0(10)DAC0(11)

Writing to this register will initiate data conversion on DAC0. If the

is set, writes to this register will provide a simultaneous update of both DAC0 and DAC1 with the data written to this register.

The data format is dependent upon the offset mode described below:

Bipolar Mode

Unipolar

: Offset Binary Coding

000 h = -FS

7FFh = Mid-scale

FFFh = +FS - 1LSB

Mode

Straight Binary Coding

:

000 h = -FS (0V)

7FFh = Mid-scale (+FS/2)

FFFh = +FS - 1LSB

(0V)

MODE

bit in BADR1+8

7.6.2 DAC1 DATA REGISTER

BADR4 + 2

WRITE

0123456789101112131415

----

MSB LSB

DAC1(0)DAC1(1)DAC1(2)DAC1(3)DAC1(4)DAC1(5)DAC1(6)DAC1(7)DAC1(8)DAC1(9)DAC1(10)DAC1(11)

Writing to this register will initiate data conversion on DAC1. If the

is set, writes to this register will have no effect

31

MODE

bit in BADR1+8

Page 35

8.0 ELECTRICAL SPECIFICATIONS

(Typical specifications for 25 DegC unless otherwise specified.

)

8.1 ANALOG INPUT SECTION

A/D converter type 7800

Resolution 12 bits

Programmable ranges

PCI-DAS1001 ±10V, ±1V, ±0.1V, ±0.01V, 0 - 10V, 0 - 1V, 0 - 0.1V, 0 - 0.01V

PCI-DAS1002 ±10V, ±5V, ±2.5V, ±1.0V, 0 - 10V, 0 - 5V, 0 - 2.5V, 0 - 1.0

A/D pacing Programmable: internal counter or external source (A/D External Pacer)

or software polled

Burstmode Software selectable option, rate = 6.67µs

A/D Trigger sources External digital (A/D External Trigger)

A/D Triggering Modes

Digital: Software enabled, rising edge, hardware trigger

Pre-trigger: Unlimited pre- and post-trigger samples. Total # of samples must be >

512.

Data transfer From 1024 sample FIFO via REPINSW, interrupt or software polled

Polarity Unipolar/Bipolar, software selectable

Number of channels 8 differential or 16 single-ended, software selectable

A/D conversion time 3µs

Throughput 150KHz min

Relative Accuracy ±1.5LSB

Differential Linearity error ±0.75 LSB

Integral Linearity error ±0.5 LSB typ, ±1.5 LSB max

Gain Error (10V,1V and 0.1V Ranges) ± 0.02% of reading Max

Gain Error (0.01V Range) ± 0.4% of reading Max

No missing codes guaranteed 12 bits

Gain drift (A/D specs) ±6ppm/°C

Zero drift (A/D specs) ±1ppm/°C

Common Mode Range ±10V

CMRR @ 60Hz 70dB

Input leakage current 200nA

Input impedance 10Meg Ohms Min

Absolute maximum input voltage ±15V

32

Page 36

8.2 ANALOG OUTPUT

D/A type AD7847AR

Resolution 12 bits

Number of channels 2

Output Ranges ±10V, ±5V, 0-5V, 0-10V. Each channel independently programmable.

D/A pacing Software

Data transfer Programmed I/O.

Offset error ±600µV max, all ranges (calibrated)

Gain error ±0.02% FSR max (calibrated)

Differential nonlinearity ±1LSB max

Integral nonlinearity ±1LSB max

Monotonicity 12 bits

D/A Gain drift ±2 ppm/°C max

D/A Bipolar offset drift ±5 ppm/°C max

D/A Unipolar offset drift ±5 ppm/°C max

Throughput PC dependent

Settling time (to .01% of 10V step) 4µs typ

Slew Rate 7V/µS

Current Drive ±5 mA min

Output short-circuit duration 25 mA indefinite

Output Coupling DC

Amp Output Impedance 0.1 Ohms max

Miscellaneous Power up and reset, all DAC's cleared to 0 volts, ±200mV

8.3 PARAELLEL DIGITAL INPUT/OUTPUT

Digital Type 82C55A

Configuration 2 banks of 8, 2 banks of 4, programmable by bank as input or output

Number of channels 24 I/O

Output High 3.0 volts @ -2.5mA min

Output Low 0.4volts @ 2.5 mA max

Input High 2.0 volts min, Vcc+0.5 volts absolute max

Input Low 0.8 volts max, GND-0.5 volts absolute min

Power-up / reset state Input mode (high impedance)

Interrupts INTA# - mapped to IRQn via PCI BIOS at boot-time

Interrupt enable Programmable

Interrupt sources Residual counter, End-of-channel-scan, AD-FIFO-not-empty,

AD-FIFO-half-full

33

Page 37

8.4 COUNTER SECTION

Counter type 82C54

Configuration Two 82C54 devices. 3 down counters per 82C54, 16 bits each

82C54A:

Counter 0 - ADC residual sample counter.

Source: ADC Clock.

Gate: Internal programmable source.

Output: End-of-Acquisition interrupt.

Counter 1 - ADC Pacer Lower Divider

Source: 10 MHz oscillator

Gate: Tied to Counter 2 gate, programmable source.

Output: Chained to Counter 2 Clock.

Counter 2 - ADC Pacer Upper Divider

Source: Counter 1 Output.

Gate: Tied to Counter 1 gate, programmable source.

Output: ADC Pacer clock (if software selected), available at connector

82C54B:

Counter 0 - Pretrigger Mode

Source: ADC Clock.

Gate: External trigger

Output: End-of-Acquisition interrupt.

Counter 0 - User Counter 4 (when in non-Pretrigger Mode)

Source: User input at 100pin connector (CLK4) or internal 10MHz

(software selectable)

Gate: User input at 100pin connector (GATE4).

Output: Available at 100pin connector (OUT4).

Counter 1 - User Counter 5

Source: User input at 100pin connector (CLK5).

Gate: User input at 100pin connector (GATE5).

Output: Available at 100pin connector (OUT5).

Counter 2 - User Counter 6

Source: User input at 100pin connector (CLK6).

Gate: User input at 100pin connector (GATE6).

Output: Available at 100pin connector (OUT6).

Clock input frequency 10Mhz max

High pulse width (clock input) 30ns min

Low pulse width (clock input) 50ns min

Gate width high or low 50ns min

Input low voltage 0.8V max

Input high voltage 2.0V min

Output low voltage 0.4V max

Output high voltage 3.0V min

8.5 OTHER SPECIFICATIONS

Power consumption

+5V Operating (A/D converting to FIFO) 0.8A typical, 1.0A max

Environmental

Operating temperature range 0 to 70°C

Storage temperature range -40 to 100°C

Humidity 0 to 90% non-condensing

34

Page 38

EC Declaration of Conformity

High speed analog I/O board for the PCI busPCI-DAS1000

DescriptionPart Number

to which this declaration relates, meets the essential requirements, is in conformity with, and CE marking has been

applied according to the relevant EC Directives listed below using the relevant section of the following EC standards

and other normative documents:

EU EMC Directive 89/336/EEC

EU 55022 Class B

technology equipment.

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

Carl Haapaoja, Director of Quality Assurance

: Electrostatic discharge requirements for industrial process measurement and control equipment.

: Radiated electromagnetic field requirements for industrial process measurements and control equipment.

: Electrically fast transients for industrial process measurement and control equipment.

: Limits and methods of measurements of radio interference characteristics of information

: EC generic immunity requirements.

: Essential requirements relating to electromagnetic compatibility.

Page 39

Loading...

Loading...