Page 1

OM-MODL

Page 2

OMEGAnetSM On-Line Service

http://www.omega.com

Servicing North America:

Internet e-mail

info@omega.com

USA:

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Berger

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: canada@omega.com

FAX: (203) 359-7700

FAX: (514) 856-6886

For immediate technical or application assistance:

USA and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

En Espanol: (95) 203-359-7803

SM

FAX: (95) 203-359-7807

e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

ul. Rude armady 1868

733 01 Karvina-Hranice

Tel: 420 (69) 6311899

e-mail:czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

25 Swannington Road,

Broughton Astley, Leicestershire,

LE9 6TU, England

Tel: 44 (1455) 285520

FAX: 44 (1455) 283912

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

P.O. Box 7, Omega Drive,

Irlam, Manchester,

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Page 3

1... INTRODUCTION

1... INTRODUCTION

MANUAL OVERVIEW

This User’s manual provides information relative to the use of the OMP-MODL

Portable Data Logging Systems manufactured by Omega Engineering. The manual

is organized into sections describing the main components of a OMP-MODL system,

from the System Base through the various features within the provided software.

The last section of the manual consists of the Appendices which give detailed

specifications and information for general reference and advanced applications.

After following the instructions for the installation of the HyperWare software, much

can be learned by exploring this manual, the software and the hardware in any

order... without concern for damaging results. However, it is HIGHLY

RECOMMENDED that this User’s manual be read in its entirety before deploying the

OMP-MODL in a real application.

A note on the keyboard / mouse convention used within this manual... Throughout

the manual, instructions on PC keyboard entry or menu selections via mouse are

specified by using italic print such as ENTER which refers to the `Enter’ Key on the

keyboard or FILE which refers to the menu item titled `FILE’.

OMP-MODL SYSTEM: `THE BIG PICTURE’

The OMP-MODL is a battery powered portable data logging and control system. It

can be left at a site to collect data from various analog and digital signal or sensor

inputs. This data is mathematically processed by the OMP-MODL and stored in its

internal memory while simultaneously performing basic onsite alarm functions. The

collected data is then transferred to a PC running the supplied HyperWare software

for data plotting, real-time trending and analysis.

OMP-MNL VS OMP-MODL

The OMP-MNL is a special fixed functionality model of the OMP-MODL family. The

OMP-MNL offers the same functionality as the basic OMP-MODL with the exception

that it cannot be expanded with the addition of Interface Modules.

Throughout this manual, references made to the OMP-MODL generally refer to the

OMP-MNL and the OMP-MODL except where noted.

OMP-MODL SYSTEM COMPONENTS

A OMP-MODL portable data logging system consists of a number of components...

both hardware and software.

The main components are listed below and details follow:

♦ OMP-MODL System Base

♦ Interface Modules

♦ HyperWare™ , Windows based software

♦ Options such as modems, PCMCIA, etc

USING THE OMP-MODL

1-1

Page 4

1... INTRODUCTION

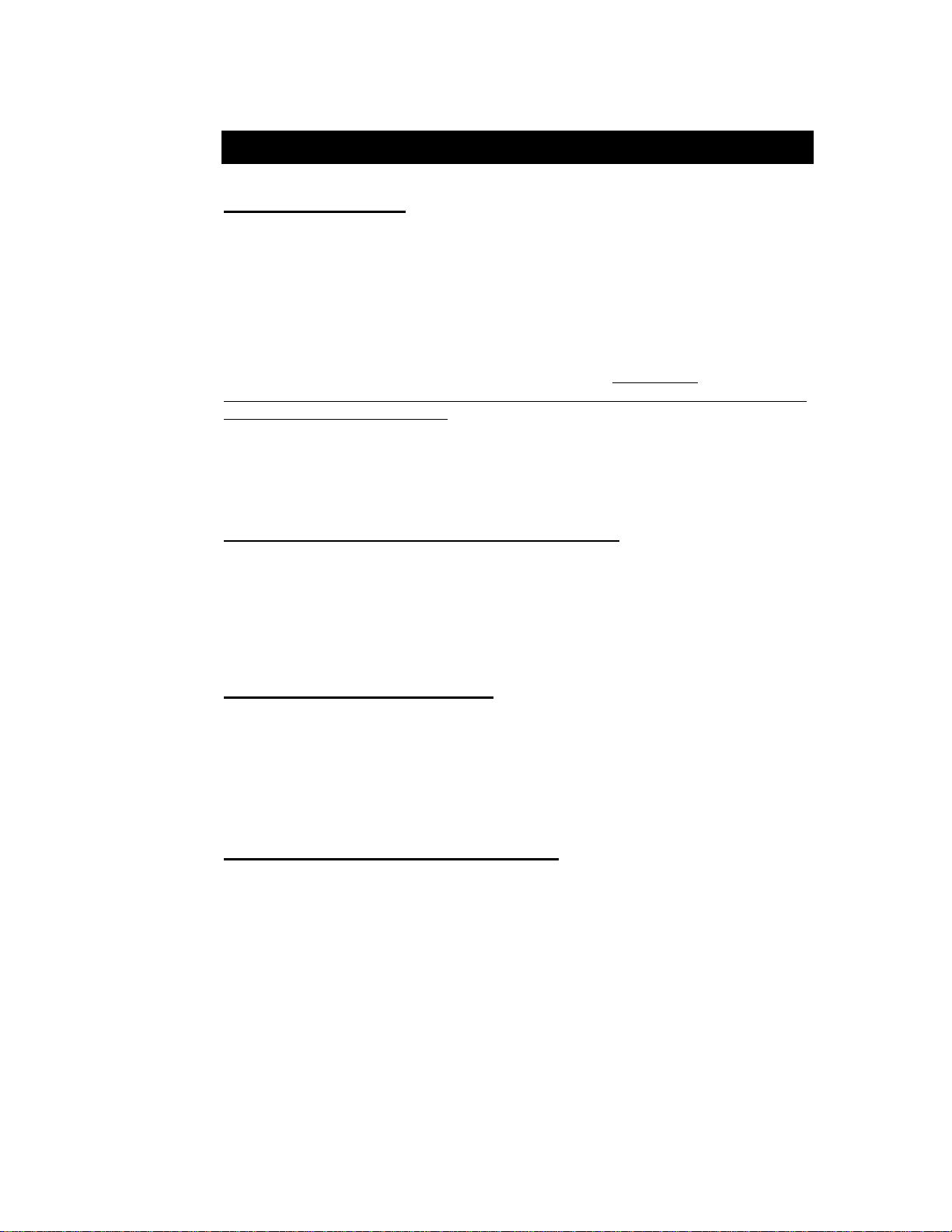

BOTTOM PLATE/HANGER

OMP-MODL System Base

The OMP-MODL System Base refers to the main data logger unit composed

of a stack of two interconnected modules... the MLCPU-1 module and the

MLAD-1 module. These two modules combined house the main

microprocessor and support circuitry, memory, power supplies, A to D

converter as well as 6 inputs (4 analog, 1 Cold Junction Compensation

ML-TOP

TOP PLATE

MLADC-1

MLCPU-1

ML-BACK

ML001

Figure 1... -1: OMP-MODL System Base w/ top and bottom

temperature and 1 digital) and 4 outputs. The System Base can be used

stand-alone as a 6 input / 4 output data logger (OMP-MNL) or expanded with

the addition of Interface Modules, battery packs, and/or display modules.

The System Base includes a connector bus that provides signal connections

to the added Interface Modules.

Interface Modules

Interface Modules (See Figure 1... -2) are add-on layers that provide the

interface to various types of inputs and output signals. The Interface

Modules can be User installed onto the System Base then configured for the

specific type of signal or sensor to be connected to the OMP-MODL.

Interface Modules are configured via software and/or switch settings on the

modules.

1-2

USING THE OMP-MODL

Page 5

1... INTRODUCTION

A family of Interface Modules is available for interface to various input signal

types such as thermocouples, RTD’s, voltage, current, frequency, event, etc.

Additionally, Interface Modules are available with outputs for digital alarm

and basic ON/OFF control functions.

Note that the OMP-MNL model does not support installation of additional

Interface Modules.

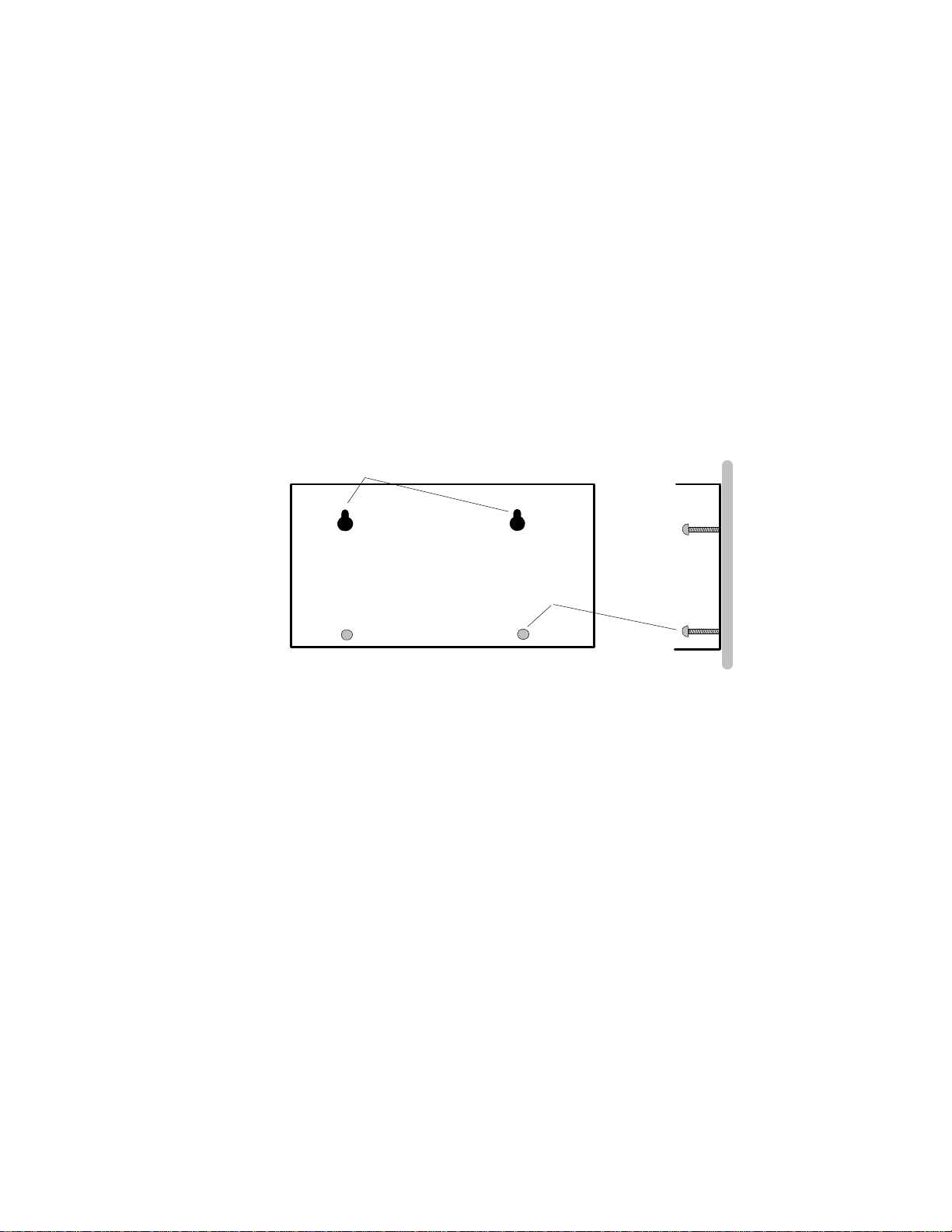

Configuration Switches

Inter-Module Connection bus

Side Retaining Screw holes

Figure 1... -2; Interface Module

I/O Wiring Terminal

Strip

HyperWare™ Software

Utilized with the OMP-MODL is a powerful Windows based software

package called HyperWare. HyperWare, running on an IBM compatible PC

under the Microsoft Windows environment provides a multitude of functions

for setup of the OMP-MODL as well as analysis of collected data including:

♦ Serial Communications support between the PC and the

OMP-MODL for RS-232 and telephone modem links

(OMP-MNL does not support modem comm)

♦ Programming of the OMP-MODL using the powerful

HyperNet™ visual icon based programming method

♦ Multi-channel, graphic data display of previously

collected data using HyperPlot™

♦ Screen captures of HyperPlot graphs for seamless

integration into other Windows based software

applications such as wordprocessors, spreadsheets, or

desk-top publishing packages

♦ Conversion of collected data files to ASCII text or

Microsoft Excel file formats

USING THE OMP-MODL

1-3

Page 6

1... INTRODUCTION

Additional Components

Special function modules are also available to provide:

♦ Powerful mathematical data manipulation of collected

data during conversion to HyperPlot graphs, ASCII text

files and Excel files

♦ HyperTrack™ real-time graphic and numeric data

display of OMP-MODL inputs and HyperNet nodes

Telephone Modem Interface - plug-in modules that contain integral

low power 2400 Baud or 14.4 Kbaud telephone modems. These

modules allow for direct connection to standard telephone lines for

data transfer, reprogramming, and control...all from a remote PC

running HyperWare (not supported by OMP-MNL model) .

PCMCIA Memory Card Interface - plug-in module provides a

socket and interface circuitry for removable PCMCIA memory card

support. When utilized, the OMP-MODL stores data to the credit

card sized PCMCIA card. At any time, the card can be unplugged

from its socket and carried or shipped to a another site where the

data can be downloaded to a PC. Advantages of the PCMCIA card

include massive data storage capability, easily transportable data,

field data collection by non-technical staff, and reprogramming of

field units via card.

Battery Pack - add-on module containing 6 alkaline D-Cell batteries

for installations without power.

Front Panel Display and User Switch module - plug-on module

provides a faceplate with 2-line LCD, full set of User switches and

Status indicators.

Special Serial Communications Interface - a variety of special

serial communication types and protocols are available for serial

signal interface. Contact Omega Engineering about your specific

application requirement.

1-4

USING THE OMP-MODL

Page 7

1... INTRODUCTION

FEATURES

Designed with the User in mind, the OMP-MODL portable data logging system has a

multitude of integral features ranging from special hardware considerations to

unlimited software programmability and data review. Capabilities include:

♦ Up to 24 channels of analog input or 40+ digital input/outputs.

♦ Configurable Interface Modules accept a multitude of signal types and ranges all

on a single module.

♦ Low power design allows for field logging up to 3 weeks from a set of commonly

available D-Cells.

♦ Pluggable I/O wiring Terminal Strips facilitate quick connect and disconnect of

the sensor and signal wiring harness.

♦ Four integral alarm outputs including two relays

♦ True Microsoft Windows based HyperWare software.

♦ Powerful HyperPlot graphic data display software with seamless integration of

plotted data into other Windows applications.

♦ HyperNet visual icon based programming provides unlimited flexibility in

programming, yet maintains simplicity with drag and drop icon configuration. Set

the OMP-MODL up without writing cryptic lines of code nor experiencing the

rigors of excruciating two button menu tree nightmares.

♦ Intelligent logging methodologies include logging only upon change of an input

(Delta-Logging), Conditional logging based on input levels, Conditional logging

based on time of day or elapsed time, dual speed logging initiated by User

programmed conditions, and more.

♦ Real-Time data display (on optional liquid crystal display) of User defined node

points... ranging from raw input signals to intermediate processed data to data

logged to memory.

♦ User defined alarm messages

♦ Pager call-out upon User defined alarm conditions

(Note: OMP-MNL has limited capabilities from above listing)

USING THE OMP-MODL

1-5

Page 8

1... INTRODUCTION

SUMMARY OF STEPS IN UTILIZING THE OMP-MODL

In a typical application of the OMP-MODL portable data logging system, the

following sequence of steps would be involved. Details of each step are presented

in later sections of this manual.

1. Install the required Interface Modules into the OMP-MODL

System Base. Configure Interface Module hardware switches if

applicable (eg enabling a front end divider for the +/-30VDC

range on the HLIM-1)

2. Connect a serial cable link between the OMP-MODL and your

PC. Launch HyperWare and establish the connection.

HyperWare will automatically configure for the detected logger

model (OMP-MNL, OMP-MODL, or HyperLogger). Then change

to the HyperNet Development Screen.

3. Query the OMP-MODL for its current hardware configuration by

clicking the NEW button.

4. Construct a Program Net for this logging session by dragging

and dropping icons onto the HyperNet screen, then connecting

signals between the icons. Save the Program Net to disk and

print out a Terminal Strip Adapter wiring diagram for field

reference.

5. Transfer the Program Net to OMP-MODL memory via the serial

link and disconnect the serial link.

6. Install the OMP-MODL at the site and make the appropriate

wiring connections to the I/O Terminal Strips and modem (if

used).

7. Enable the OMP-MODL, then as a quick pre-departure check,

check readings at various pre-programmed Program Net nodes

using the Next and Select buttons while viewing the OMP-MODL

display.

8. Leave the OMP-MODL to collect data.

9. Later, connect up to the OMP-MODL via a serial link (RS-232 or

modem) or retrieve the PCMCIA memory card and from within

HyperWare, download the OMP-MODL memory to a file on the

PC.

10. For a fast and immediate review of the collected data, doubleclick on the data icon and HyperPlot will automatically load and

graphically display the collected data.

11. Save the desired HyperPlot graphic view as a Windows Bitmap

file , then switch to your Windows based wordprocessor and

seamlessly insert the saved graphic into your test report.

12. Optionally, use the HyperWare Post-Processing capability to

configure a special data reduction/ conversion icon network.

Then run the collected data file through the post processor and

generate a text file, Excel Spreadsheet file or another HyperPlot

file.

1-6

USING THE OMP-MODL

Page 9

13.

1... INTRODUCTION

USING THE MODULOGGER

1-7

Page 10

2... OMP-MODL System Base

BOTTOM PLATE/HANGER

2... OMP-MODL SYSTEM BASE

SYSTEM BASE OVERVIEW

System Base refers to the main data logger unit composed of a stack of two

interconnected modules... the MLCPU-1 module and the MLAD-1 module. These

two modules combined house the main microprocessor and support circuitry,

memory, power supplies, A to D converter as well as 6 inputs (4 analog, 1 Cold

Junction Compensation temperature and 1 digital) and 4 outputs. The System Base

can be used stand-alone as a 6 input / 4 output data logger (i.e. the OMP-MNL) or

expanded with the addition of Interface Modules, battery packs, and/or display

modules in the case of the OMP-MODL model. Additional modules are covered in

the following chapter.

The System Base includes a connector bus that provides signal connections to any

added Interface Modules.

ML-TOP

TOP PLATE

MLADC-1

MLCPU-1

ML-BACK

ML001

Figure 2... -1: System Base Assembly

ENCLOSURE / MOUNTING

The OMP-MODL (Figure 2... -1) is built up by plugging together a combination of

modular layers. A top plate (or display module ML-DISP) is then fastened to the top

and a bottom plate/hanger is fastened to the bottom of the stack to complete the

Using the OMP-MODL

2-1

Page 11

2... OMP-MODL System Base

unit. As modules are added to the stack, the connectors must be aligned and

plugged together as the modules slide together. Four side retaining screws are then

installed into the sides to securely hold the assembly together.

Top Plate

A flat metal plate is provided to cover the top end of the module stack in

units not equipped with the ML-DISP Display and User button module (Refer

to the ML-DISP module in Chapter 3). The top plate fits into a recess at the

top of the unit and is fastened in place with 4 screws.

Bottom Plate / Mounting

A bottom plate is provided to cover the bottom end of the module stack as

well as provide means to mount the logger to a surface. Additionally, in

systems utilizing the Battery Pack (P/N: ML-BATT) the bottom plate is an

integral part of the Battery Pack and holds the batteries as well. The MLBATT is described in Chapter 3.

KEYHOLE SLOTS

ANCHOR

SCREWS

ML003

Figure 2... -2: Bottom Plate / Hanger

Mounting is done by fastening the unit to a surface with round head screws

through the keyhole slots and optionally locking the unit in place with the

addition of another anchor screw (Figure 2... -2)

To mount the unit, remove the bottom plate from the logger by removing the

4 side retaining screws in the side of the plate, then use the plate as a

template to mark the screw hole locations. The bottom plate can then be

mounted on the screws. If desired, 2 locking screws can be added in the

bottom holes to securely hold the logger and prevent it from being slid up

and off of the keyhole screws.

Slip the logger back into the bottom plate and install the 4 side screws.

2-2

Using the OMP-MODL

Page 12

TIP: For applications utilizing loggers equipped with a large number of

Interface Modules, the stack can become rather tall. In these

applications, side plate mounting may be desired. Contact LBI for

details on the side mounting bracket..

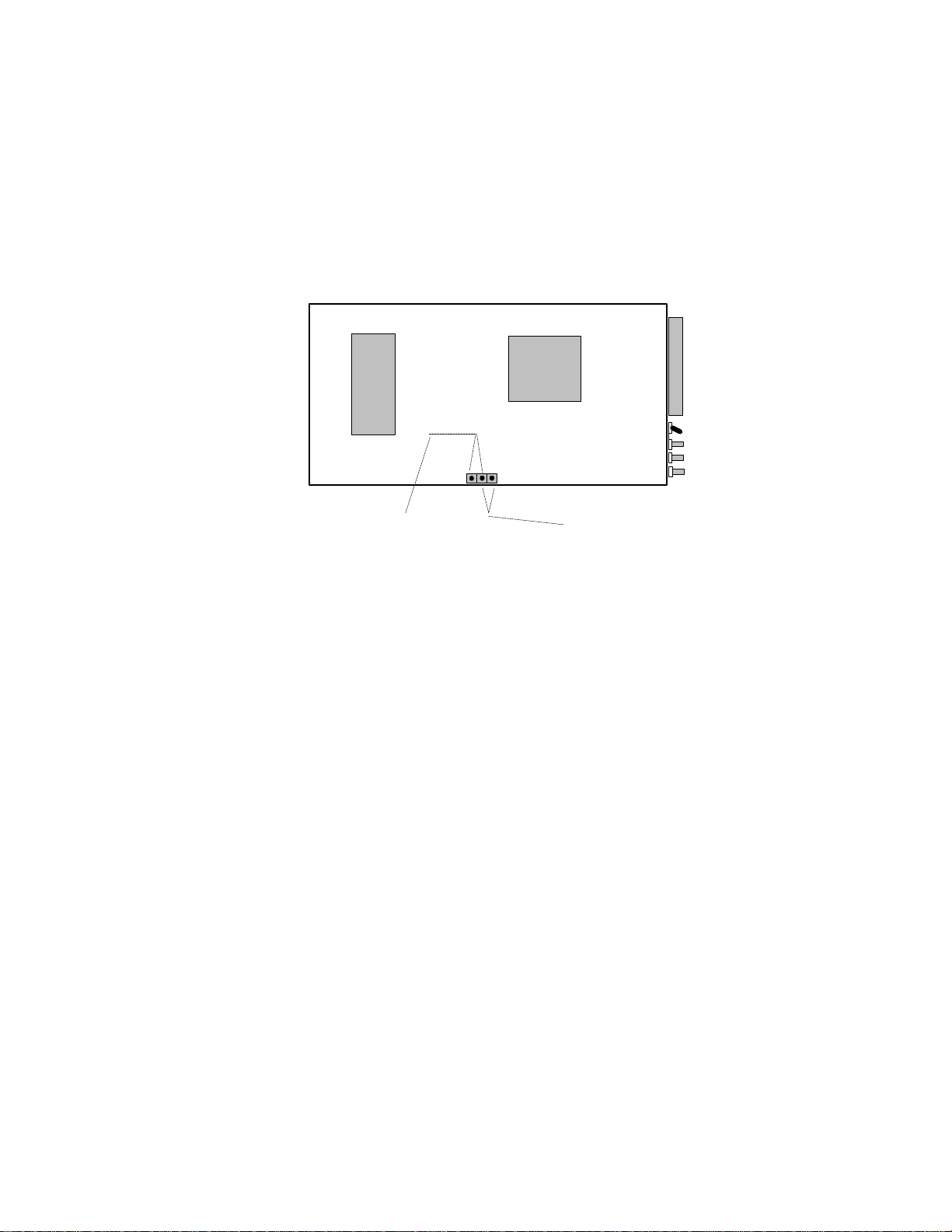

MLCPU-1 MODULE

Overview

RELAY 2

RELAY 1

STATUS

FEEDBACK

2... OMP-MODL System Base

EXTERNAL POWER

RELAY R1

RELAY R2

+5V

TTL

GND

1 2 3 4 5 6 7 8 9

STOP

RESET

ENABLE

POWER

SERIAL PORT

Figure 2... -3: MLCPU-1 Module (end view)

The MLCPU-1 module contains the microprocessor, memory, power

supplies, GPDI input circuitry, alarm output circuitry, User push buttons and

status indicators. Various components in this module are identified in Figure

2... -3. This module is required in all OMP-MODL systems.

User Interface Indicators and Buttons

An array of LED indicators and buttons are available at one end of the

MLCPU-1. Identification and function follows:

Main Power Switch:

A small recessed toggle switch controls the power to the logger.

Using a pencil or other small object, flip the switch side to side to

turn power ON/OFF. Upon turning power ON, after a short delay,

the Feedback LED (see following) will blink 5 times indicating that

the unit has sequenced through a power-up reset and is operative,

ready to accept commands.

Using the OMP-MODL

2-3

Page 13

2... OMP-MODL System Base

Feedback LED Indicator:

The green Feedback LED is used to provide feedback to the User as

buttons are pressed and the logger performs various commands.

These responses include:

Command Feedback LED Response

Enable Unit 2 blinks

Stop Unit 2 blinks

Power-Up Reset 5 blinks

Two Button Reset 5 blinks

System Initialization (3 button) 10 blinks

Memory Clear ON continuously for 10

Executing Program Net 1 blink every 10 seconds

Status LED Indicator:

The green STATUS LED is merely a visual indicator provided for

User specified application from within a Program Net. This LED can

be programmed by the User to indicate Alarms and other operational

feedback.

seconds then OFF

Alarm LED Indicators (2):

The ALARM LED’s labeled R1 and R2, provide visual indication of

the state of the two programmable operation output relays included

in the MLCPU-1. When an ALARM LED is ON, the relay contacts

are closed.

ENABLE Button:

Pressing the ENABLE button initiates the execution of the current

Program Net residing in OMP-MODL memory. Upon press of the

ENABLE button, the Feedback LED (see following) will blink 2 times

indicating acknowledgement of the command. If the logger is

equipped with the ML-DISP module, the the LCD will change to

display ENABLED on the second line.

If the Feedback LED does not blink twice in response to a press, the

unit may already be Enabled or may have been previously running

in the Rotary Memory Mode.

Note that operation of the ENABLE button may be inhibited if the

logger is programmed with in the Rotary Memory Logging mode.

In this mode, only one logging session can be logged. To initiate

another, the first session must be cleared from memory. This

parameter is set within the Global icon during construction of a

Program Net. Refer to the Master Icon Reference Appendix for

details on the Global icon.

While enabled and executing a Program Net, the Feedback LED will

blink every 10 seconds indicating operation.

2-4

Using the OMP-MODL

Page 14

2... OMP-MODL System Base

FYI: The label ENABLE was chosen rather than START for a subtle but

important reason. When the ENABLE button is pressed, execution of the

Program Net commences... but that does not necessarily mean that data

logging to memory has started.

For example, a Program Net is developed and uploaded to the OMPMODL that includes a setpoint function that controls logging to memory.

For example log only when the kiln temperature exceeds 150F. Pressing

the ENABLE button merely causes the OMP-MODL to take readings of the

kiln temperature... but logging to memory STARTS when the temperature

rises above the 150F threshold.

STOP Button:

Pressing STOP at any time causes the OMP-MODL to finish

sequencing through the currently executing Program Net, then stop

executing. The Feedback LED will blink twice to indicate

acknowledgement of the command. If the logger is equipped with

the ML-DISP module, the LCD will change to display STOPPED on

the second line.

The STOP button can also be used to clear data that has been

logged to memory.

CLEARING MEMORY WITH THE STOP BUTTON:

To Clear data memory with the STOP button, press and hold the

STOP button. The Feedback LED will light continually for

approximately 10 seconds, then turn off. When the LED turns

off, memory has been cleared and the button can be released.

RESET Button:

A hardware reset of the OMP-MODL microprocessor can be

performed by depressing and releasing both the STOP and RESET

buttons at the same time. This normally should not be required but

in the event that a noise glitch or some other malfunction occurs,

this manual Reset capability is provided for a User to force a reset of

the microprocessor from the front panel.

After a Reset, the Feedback LED will blink 5 times indicating that a

the system has been reset. This Reset does not clear data memory

nor the Program Net currently residing in logger memory.

WATCH-DOG TIMER RESET

A special automatic reset circuit is incorporated into the System

Base to add additional reliability to the OMP-MODL system. This

circuitry, called a Watch-Dog Timer will force the OMP-MODL

microprocessor to reset and continue operation where it left off

(within 2 seconds) in the event that an unforseen hiccup or noise

glitch (for example, from a nearby lightning strike) causes the

microprocessor to lose its place or lock-up.

Although this circuit normally should not operate, it adds one

more level of robustness to the OMP-MODL for handling

unforeseen events.

Using the OMP-MODL

2-5

Page 15

2... OMP-MODL System Base

3-Button System Initialization:

A complete initialization of the logger that will clear data memory

and program memory can be performed using the ENABLE, STOP

and RESET buttons. This sequence is normally only used when a

unit is upgraded in the field with a new EPROM or in the event that

the Program memory has become corrupted due to unforeseen

events such as disassembly while powered up, improper insertion of

a PCMCIA card, exposure to an extreme noise noise glitch (for

example, from a nearby lightning strike) that has caused the

microprocessor to lose its place or lock-up or other malfunction.

To perform this 3-Button Initialization,

1. Depress and hold the ENABLE button

2. Momentarily, depress the STOP and RESET buttons

simultaneously.

3. After a second or so, release the ENABLE button.

4. Observe the Feedback LED. After a few seconds, the

Feedback LED should blink 10 times in succession. This

indicates that a complete system initialization has been

performed.

If the logger is equipped with a ML-DISP modules, after a

short sequence of display messages on the LCD, a

SYSTEM INITIALIZED message should display

momentarily indicating that the logger was properly

initialized. If this message does not display, repeat the

procedure.

After initialization, reprogram the logger with a new Net Program

and the unit is ready to operate.

RS-232 Serial Communications Port

A female 6/6 RJ-12 modular phone type jack is provided on the MLCPU-1

for RS-232 communications. A mating 6 conductor cable (CAR-4) plugs into

this port. The other end of the cable plugs into the 9-pin or 25 pin serial port

on a PC via a modular plug to DB-9F (P/N: RJDB-9H) or DB-25F (P/N:

RJDB-25H) adapter. Note that this port is not for direct connection of a

telephone line.

2-6

Using the OMP-MODL

Page 16

2... OMP-MODL System Base

CAUTION

The RS-232 jack is only for connection of RS-232

type signals (via the supplied cable and adapters)

and is not for direct connection of a telephone line.

For telephone modem communication with the OMP-

MODL, utilize the OMP-MODL Modem Interface

Module.

Direct connection of a telephone line to the RS-232

jack may result in permanent damage to the OMP-

MODL.

For longer communication distances, a longer cable can be used. Longer

cables can be purchased from Omega Engineering or from stores handling

standard phone supplies. If a cable is procured from a source other than

Omega Engineering, insure that the cable is 6 conductor and has the plugs

installed correctly. Refer to Appendix I for wiring details.

Although the RS-232 specification is only for communication distances up to

50’, communication with the OMP-MODL via RS-232 at Baud rates up to

19.2 Kbaud has been successfully achieved with 100’ of cable.

The OMP-MODL RS-232 communication circuitry powers up when a cable is

plugged into the port and a connection is established from within the

HyperWare Software. When the communication circuitry is powered up, an

additional load of approximately 30 mA is put on the logger power supply.

For this reason, when not communicating with the OMP-MODL and

operating from battery power, disconnect the connection from within

HyperWare and/or unplug the RS-232 cable. For extended communication

sessions battery life can be preserved by powering the OMP-MODL from an

external power supply.

TIP: For relative reference, with the communication

circuitry powered up, a new set of batteries will discharge

in approximately 3 days.

Using the OMP-MODL

2-7

Page 17

2... OMP-MODL System Base

TTL ALARM OUTPUT

Terminal Strip Connections

The MLCPU-1 is provided with a terminal strip connector for connection of

power, input and output wiring (Figure 2... -4). The terminal strip connector

can be unplugged from the module allowing for quick disconnect and

reconnection of wiring. Connection details follow:

RELAY R2

RELAY R1

STATUS

FEEDBACK

EXTERNAL POWER

RELAY R1

RELAY R2

+5V

GND

1 2 3 4 5 6 7 8 9

STOP

RESET

ENABLE

POWER

SERIAL PORT

ML004

Figure 2... -4: MLCPU-1 Terminal Strip Connections (end view)

External Power (Terminals 1 & 2)

An external power source may be used to power the OMP-MODL .

If an external power supply is connected to the OMP-MODL and its

supply voltage is greater than approximately 10.7 VDC, the OMPMODL will operate from the external supply and the batteries will not

be used. In the event that the external power fails or drops below

10.7V, the OMP-MODL will automatically transfer to battery power

and continue operation.

The External Power Supply terminals will accept either AC or DC

input and polarity is not relevant.

EXTERNAL SUPPLY VOLTAGE RANGE:

A field selectable dual input range feature allows the logger to

accomodate a very wide range of input voltage applied to the

External terminals. A jumper provided on the MLCPU-1

programs the input range for HI or LO range:

2-8

LO Range: (8 to 24 Vdc / 10 to 23 Vac) (factory default)

HI Range: (11 to 32 Vdc / 12 to 23 Vac)

Using the OMP-MODL

Page 18

2... OMP-MODL System Base

To change the setting, access must be gained to the jumper on

the top of the MLCPU-1 module (Figure 2... -5). Per the

assembly / disassembly instructions in Chapter 3, open the

logger to gain access to the top of the MLCPU-1. The Hi/Lo

jumper is installed on two pins of a 3 pin header. To program a

new range, remove and reinstall the jumper on the desired pair of

pins.

CPU

EPROM

LOW RANGE

Figure 2... -5: MLCPU-1 External Power Voltage Range Jumper

OVERVOLTAGE PROTECTION:

The MLCPU-1 incorporates circuitry to protect the logger from

over-voltage, transient voltage spikes, and over-current

conditions encountered on the External Power Terminals. In the

event that extended out of spec voltages are impressed on the

External Power terminals, protective circuitry will activate and

blow the 1.5A input fuse. Replacement fuses (P/N: Littelfuse

27301.5) are available from Omega Engineering Incorporated or

electronic distributors.

BATTERY CONNECTION PIGTAIL:

The MLCPU-1 is equipped with a pigtail and connector for

connection to the ML-BATT battery pack module. This connector

dangles from the bottom side of the MLCPU-1 circuit board. If

batteries are not utilized, this pigtail should be left unconnected.

Details on connection and use are provided in the section on the

ML-BATT battery module in Chapter 3.

HIGH RANGE

ML005

Relay R1 (Terminals 3 & 4)

Wiring connections for Output Relay 1. The relay is a normally open

device with contacts rated for 500 ma MAX at 32VDC MAX .

Operation is dependent on logic associated with the Relay Alarm #1

icon within the Program Net executing in the logger.

Using the OMP-MODL

2-9

Page 19

2... OMP-MODL System Base

Relay R2 (Terminals 5 & 6)

Wiring connections for Output Relay 2. The relay is a normally open

device with contacts rated for 500 ma MAX at 32VDC MAX.

Operation is dependent on logic associated with the Relay Alarm #2

icon within the Program Net executing in the logger.

+5V (Terminal 7)

This terminal provides a current limited, voltage regulated +5 VDC

supply for alarm and sensor excitation applications. The supply is

current limited to approximately 100mA and is short-circuit

protected. ON/OFF control of the output is dependent on logic

associated with the +5 Volt Out icon within the Program Net

executing in the logger.

Loads should be connected between Terminal 7 ( + ) and GND at

Terminal 9 ( - ).

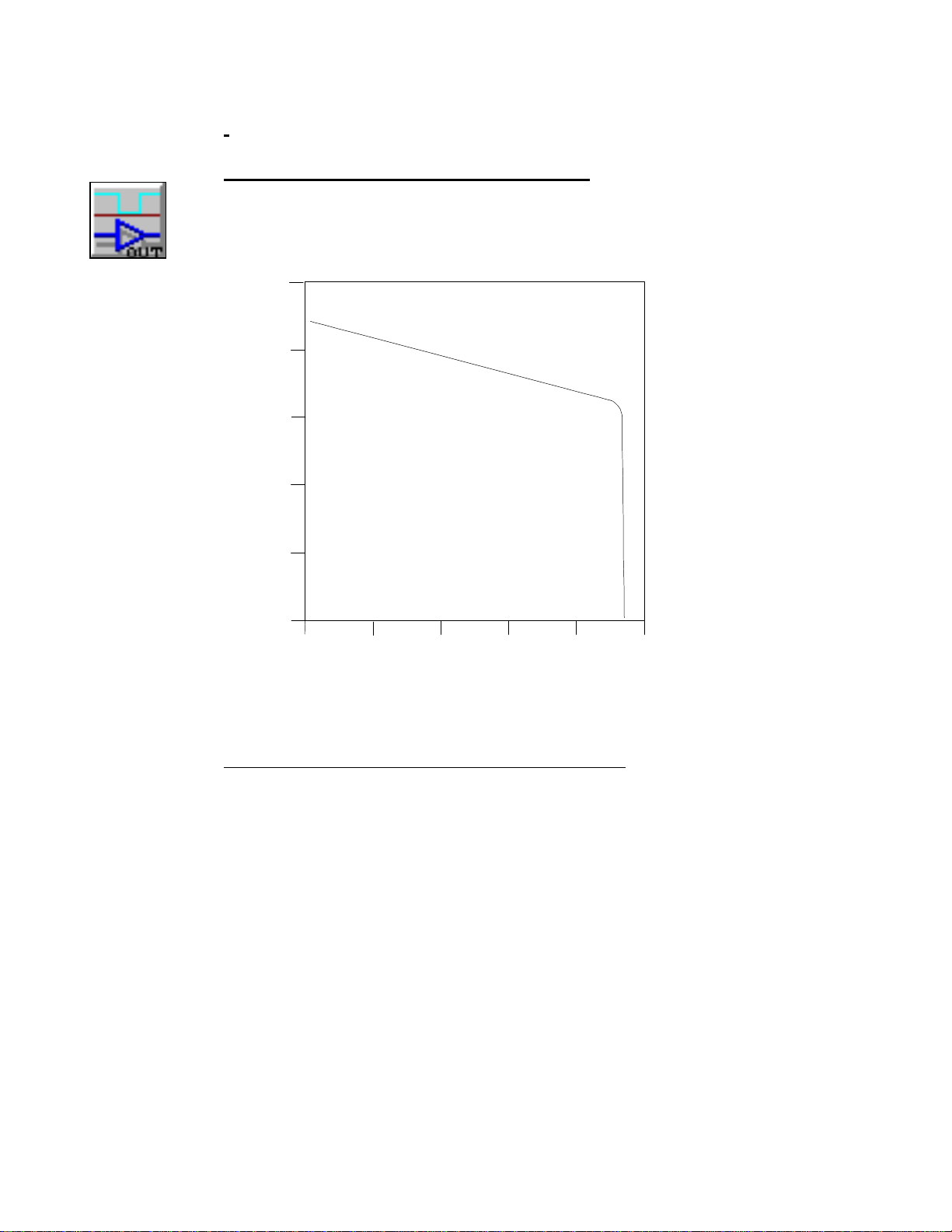

TTL Alarm Output (Terminal 8)

A low current 5Vdc rated digital output is available from this terminal

under control from the Digital Alarm #1 icon within HyperNet. The

output swings from 0 to 5VDC relative to the GND terminal (terminal

9) and is intended for sourcing and sinking signal level loads only.

The output is current limited with an internal 4.3Kohm series resistor

2-10

Figure 2... -6: System Base Digital Output

(TTL) Current Sourcing Characteristics

which results in varying output voltage levels as a function of load or

sourced current as shown in Figure 2... -5. This Digital Output

provides sufficient current for control of the Omega Engineering

RPS-1, Rechargable Power Supply which can be used for powering/

exciting higher current sensors such as 4-20mA transmitters (see

Accessories in Appendix H).

GND (Terminal 9)

This terminal serves as a common or ground connection for the

Digital Outputs and for the +5V supply. It is connected directly to

the OMP-MODL circuit ground.

Using the OMP-MODL

Page 20

2... OMP-MODL System Base

RTC / Memory Backup Battery

The OMP-MODL utilizes static ram for internal data storage which requires a

constant power supply to maintain its memory. Similarly, the Real Time

Clock (RTC) that keeps track of the date and time within the OMP-MODL

runs continually whether the main power switch is ON or OFF.

When the main power is ON, the memory and RTC draw their power from

the D-Cell batteries (or a connected external power supply). When the main

power is switched OFF, power for memory and the RTC automatically

switches to a small coin type lithium cell that is mounted on the main OMPMODL circuit board (Figure 2... -7).

EXTERNAL POWER FUSE

LITHIUM CELL

EPROM

BATTERY PIGTAIL & CONNECTOR

ML006

Figure 2... -7: Memory and RTC lithium battery location (bottom of

MLCPU-1)

This cell will provide power for the RTC and memory for approximately one

year. Any time that the OMP-MODL main power is ON extends this lifetime.

At any time, the approximate state of charge of the lithium cell can be

displayed on the LCD under the SYSTEM STATUS / SUPPLY VOLTAGES

menu or from a serially connected PC running HyperWare and a Status

Query command. For lithium cell replacement procedure, refer to Appendix

D.

MLAD-1 MODULE

Overview

The MLAD-1 module contains the Analog to Digital converter, General

Purpose Digital Input channel circuitry, Cold Junction Compensation

circuitry, and four channels of analog input. This module plugs into the top

of the MLCPU-1 module (or MLIM-5 if so equipped) and is required in all

OMP-MODL systems.

Using the OMP-MODL

2-11

Page 21

2... OMP-MODL System Base

A terminal strip is provided at one end of the module for the connection of

sensor and signal wiring. The terminal strip can be unplugged for mass

connect/disconnect of the field wiring. Connections are defined in Figure 2...

-8 and details on each of the functions follow.

CHGND

GPDI

-

+

17 18

EARTH GROUND

ML007

GND

A B C

-

+

1 2 3 4 5 6 7 8 9

SHIELD

GND

- +

+

+

INTERNAL CJC

EXTERNAL CJC

-

GND

GND

D

-

1110 12 13 14 15 16

CJC

Figure 2... -8: Terminal Strip connections (MLAD-1 Module, end view)

2-12

Four Channel Analog Input (terminals 1 through 12)

The MLAD-1 module provides four channels of analog input signal

conditioning identical to that provided by the MLIM-1 Module (Chapter 3).

Each of the four channels can be individually programmed for thermocouple,

DC Voltage and DC Current inputs. Hardware configuration switches are

provided on the MLAD-1 circuit board to configure the input channels for DC

current and medium or high level DC voltage inputs.

Refer to the MLIM-1 Module section in Chapter 3 for details on the input

configuration switches, wiring connections and applications of these inputs.

Cold Junction Compensation (terminals 13, 14, & 15)

Integral to the MLAD-1 is a cold junction compensation (CJC) sensor. This

sensor is a 10 Kohm @25C (Fenwall curve 16) thermistor which is located

by terminal strip header on the inside of the MLAD-1. The CJC sensor

senses the temperature of the terminal strips (Internal Mode) which in turn,

is used in the mV to temperature conversion equation required in

thermocouple measurements. Additionally, the CJC sensor can be used

within a Program Net to monitor the temperature inside the OMP-MODL

enclosure.

Using the OMP-MODL

Page 22

2... OMP-MODL System Base

INTERNAL CJC SENSING APPLICATIONS:

For OMP-MODL applications with thermocouple inputs

connected directly to the MLAD-1 or any installed MLIM-1 Analog

Input modules, a wire jumper must be installed across terminals

13 and 14 (marked INT for internal). The OMP-MODL is shipped

from the factory with this jumper installed.

NOTE: If thermocouples are connected to the OMPMODL on any channel, a wire jumper must be installed

across the CJC terminal strip terminals marked INT or

erroneous readings will occur..

EXTERNAL CJC SENSING APPLICATIONS:

If thermocouples are not being directly connected to the TSA (ie

CJC is not required), this CJC sensor channel can be used to

measure temperatures (or limited range resistance) outside of

the enclosure. A 10 Kohm thermistor (with the specified

resistance curve) or a resistance type sensor can be connected

across the terminals marked EXT on the CJC terminal strip.

Refer to the CJC Icon in Appendix A for additional details.

For external sensing applications, copper lug potted thermistors

with 10’ leads are available from Omega Engineering.

Chassis Ground (terminals 16)

A single terminal is provided on the MLAD-1 which connects to the internal

Chassis Ground circuit within the logger. In installations where sensor wiring

utilizes a Shield conductor connection to I/O module terminal strips (eg in

many MLIM-1 applications) a single conductor should be connected from

this terminal to a good earth ground to complete the shielding circuit.

General Purpose Digital Input (terminals 17 & 18)

Integral to the MLAD-1 is a single digital input channel that can be

configured under HyperNet as an Event or Counter input. The GPDI input

signal (either a contact closure or 0 to 15VDC max driven signal) is applied

across the two terminals observing polarity.

The operation of the GPDI is configured during construction of the Program

Net within HyperNet. Programming details and applications are described in

the Master Icon Reference in Appendix A.

Using the OMP-MODL

2-13

Page 23

2... OMP-MODL System Base

NOTES:

2-14

Using the OMP-MODL

Page 24

2... ModuLogger System Base

Using the ModuLogger

2-1

Page 25

3... INTERFACE MODULES

3... INTERFACE MODULES

By adding Interface Modules (Figure 3... -1), the OMP-MODL System Base can be

expanded for additional I/O channels, modem, display, PCMCIA memory, and

battery operation. A full family of modules is available to meet most signal interface

and/or feature requirements.

This section covers the installation, wiring, hardware configuration, and application

considerations of the basic OMP-MODL family of Interface Modules. As additional

modules are added, the instruction sheets should be added to this section for

reference.

Programming and use of added Interface Module channels is done with the

HyperNet Program Net and is covered within Chapter 7 and the Master Icon

Reference in Appendix A.

I/O Wiring Terminal

Strip

Inter-Module Connection bus

Side Retaining Screw holes

Figure 3... -1: Interface Module

HANDLING

As with all electronic systems, static electricity discharge can weaken or cause

permanent damage to circuitry. Protective circuitry is integral to the OMP-MODL

system including the Interface Modules, however when the Interface Modules are not

installed in the System Base, the protective circuitry is not effective. Therefore,

when handling Interface Modules, it is recommended that reasonable static control

procedures be followed.

♦ Before touching the Interface Module, discharge static electricity

built up in your body be touching a grounded point such as a

water faucet, cover plate screw on a receptacle, metal surface

of a grounded appliance or other earth ground.

♦ Do not wrap or store the Interface Module in static generating

materials such as untreated styrofoam packing `peanuts’ or

USING THE OMP-MODL 3-1

Page 26

3... INTERFACE MODULES

plastic bags. Anti-Static bags are available for storage of static

sensitive components.

INSTALLATION

When shipped, Interface Modules are provided with side screws and any necessary

accessories. If ordered with a logger, the Interface Modules are typically factory

installed in the System Base before shipment.

The Interface Modules stack onto the System Base building a `layered’ logger to

meet the User’s needs. All modules (except the ML-BATT Battery Pack) have an

inter-module connection bus that connects signals and power between the

modules(Figure 3... -1).

To add a module, perform the following steps and any special Installation

Instructions detailed in the following Interface Module specific sections.

1. Review the Interface Module instructions and observe any

special installation instructions. These may include setting

Module Address Switches and Input Configuration Switches.

2. Turn the OMP-MODL System Power switch OFF.

3. Determine the Port (layer) at which the new Interface Module is

to be installed. Refer to Figure 3... -4. Note that some modules

must be installed at a particular position (eg the MLIM-5 must be

installed between the MLCPU-1 and the MLAD-1 modules).

Also note that many modules require a Module address to

be programmed through the setting of one or more Module

Address Switches. This is covered in detail in the module

specific sections that follow.

4. Remove the four side retaining screws (Figure 3... -1) from the

enclosure nearest the joint into which the new module is to

added.

1. Carefully separate the layers while keeping them parallel (Figure

3... -2). Minimize the amount of twisting or rocking as this will

result in bent connector bus pins.

CORRECT MODULE SEPERATION

Figure 3... -2: Separating Modules without bending connector pins...

INCORRECT

2. After separation, examing the gold connector bus pins on the

Interface Module. These pins must be straight to insure proper

USING THE OMP-MODL3-2

ML011

Page 27

3... INTERFACE MODULES

TTL ALARM OUTPUT

alignment and connection with the mating module. If any pins

are bent, straighten them with a small pliers.

3. Orient the Interface Module to be added so that the similar

length connector bus’s align and the terminal strips or other User

controls are all at the same end.

4. While peering into the gap between the modules, carefully

match up the connector pins on one module and the mating

socket on the other module and slide the two together. Examine

the connectors from different views as the modules come

together to insure that all of the pins are properly aligned.

5. Press the modules firmly together and reinstall the side access

screws to hold the modules together.

1. Turn the logger power ON and observe the Feedback LED

(Figure 3... -3) on the MLCPU-1 module. Within a few seconds,

the LED should blink 5 times indicating that a system reset has

been performed. This is also a fairly good indication that the

unit has been reassembled correctly.

EXTERNAL POWER

RELAY R2

RELAY R1

STATUS

FEEDBACK

1 2 3 4 5 6 7 8 9

RELAY R1

RELAY R2

+5V

GND

STOP

RESET

ENABLE

POWER

SERIAL PORT

ML004

Figure 3... -3: Feedback LED on MLCPU-1

Alternatively, if the logger is equipped with the ML-DISP

module, observe the LCD for normal operation and any error

messages afer switching the power ON.

If an indication of proper operation is not seen, repeat the

installation procedure, examining connector pins closely for bent

or misaligned pins.

USING THE OMP-MODL 3-3

Page 28

3... INTERFACE MODULES

ML-DISP (Display and User Interface Module)

Must be mounted as Top Layer

Input / Output Module Layer

Module Position # 6

6

Input / Output Module Layer

5

Module Position # 5

Input / Output Module Layer

4

Module Position # 4

Input / Output Module Layer

3

Module Position # 3

Input / Output Module Layer

2

Module Position # 2

ML012

MLAD-1 Layer. Analog Inputs

fixed at Module Position # 1

1

MLIM-5 Layer (if installed)

Must layer between MLAD-1 and MLCPU-1

MLCPU-1 Layer. Fixed Position

ML-BATT Battery Pack. Connects

to bottom of MLCPU-1 module

Figure 3... -4: Layer / Module Address Reference

USING THE OMP-MODL3-4

Page 29

3... INTERFACE MODULES

INTERFACE MODULE OPERATIONAL INSTRUCTIONS:

Each Interface Module has specific characteristics and instructions for set-up and

use that are unique to that particular module. These instructions are included in

following sections or provided with the Interface Module at the time of purchase. As

Interface Modules are added to a User’s OMP-MODL, the instruction sheets

provided should be added to this section of the manual.

The instructions for most Interface Modules include both hardware and software

details. Software instructions will commonly be referenced from other sections of

this manual such as in the chapter on HyperComm for the modem modules and the

chapter on HyperNet programming for analog and digital Interface Modules.

Instruction sheets for the following Interface Modules are currently included in this

section:

♦ ML-BATT; Battery Pack Module

♦ ML-DISP; Display and User Interface Module

♦ MLIM-1; Analog (thermocouple, Vdc and Adc Interface

Module (Configuration shared with MLAD-1 Module)

♦ MLIM-2; Event, Frequency, Count Interface Module

♦ MLIM-4; RTD, Thermistor, and Resistance Module

♦ MLIM-8; Digital Interface Module (8 channel digital I/O)

♦ MLIM-5 PCMCIA Memory Card Interface Module

♦ MLIM-5 PCMCIA Memory Card Interface Module with

2400B modem

♦ MLIM-5 PCMCIA Memory Card Interface Module with

14,400B modem

USING THE OMP-MODL 3-5

Page 30

3... INTERFACE MODULES

NOTES:

USING THE OMP-MODL3-6

Page 31

3... INTERFACE MODULES

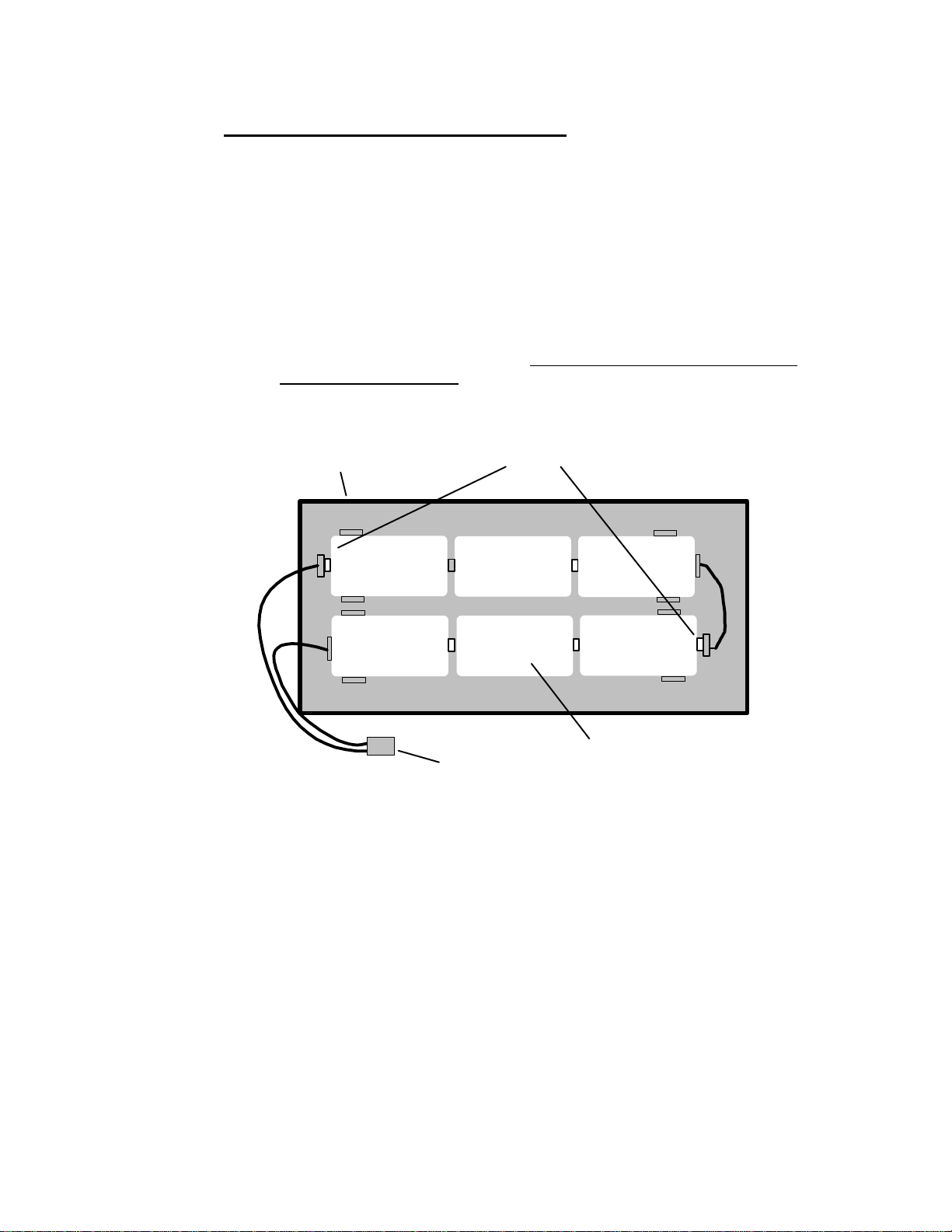

ML-BATT; BATTERY PACK MODULE

The OMP-MODL can be equipped with the ML-BATT module to provide battery

power for portable or remote site applications. The ML-BATT module includes two

holders, each of which contains 3 D-cells, resulting in a nominal 9Vdc supply to the

OMP-MODL. The ML-BATT module fastens to the bottom of the MLCPU-1 module

with 4 side screws. A pigtail and polarized connector facilitate quick connection to

the mating connector provided on the MLCPU-1 module (Figure 3... -6).

Field Installation of the ML-BATT Module

Upon receipt of the module, examine the unit and insure that the batteries

are firmly seated in their holders. The ML-BATT module fastens to the

bottom of the MLCPU-1 module with 4 machine screws. The batteries must

be installed (Figure 3... -5) with the positive terminal toward the holder end

marked with a red washer.

ML-BATT Module

+ + +

Figure 3... -5: ML-BATT Battery Pack Module

RED (+) POLARITY MARKERS

+++

Alkaline D-Cells ( 6 )

Battery Connection Pigtail

(retaining tubes not shown)

ML009

Remove the existing back plate installed on the OMP-MODL by removing

the 4 side screws and gently sliding the back plate off of the MLCPU-1

module. This back plate will be replaced by the ML-BATT module and is no

longer required.

A foam spacer is provided to help hold the batteries in their holders. A slot

is cut in the foam spacer. Route the wire pigtail extending from the MLCPU1 through this slot. Connect the polarized connector on the end of the wiring

pigtail in the ML-BATT module to the mating connector on the MLCPU-1

module.

USING THE OMP-MODL 3-7

Page 32

3... INTERFACE MODULES

ACCESS SCREW

SCREWS

Align and stack the ML-BATT and MLCPU-1 modules with the foam spacer

against the MLCPU-1 printed circuit board and the connector on the MLBATT side. Fasten the modules together with the four side retaining screws.

ML-CPU MODULE

FOAM RETAINER

6 ALKALINE D-CELLS

INITIAL INSTALLATION

BATTERY REPLACEMENT

Figure 3... -6: ML-BATT module details

POLARIZED CONNECTORS

BOTTOM PLATE

Field Replacement of Batteries

To access the batteries, remove the four retaining screws holding the bottom

plate to the OMP-MODL assembly. The battery connector can then be

unplugged and the batteries be replaced by popping them out of the holders

and reinstalling new batteries. Align the batteries with the positive terminal

toward the holder end marked with a red washer. Reconnect the battery

connector, adjust the position of the foam spacer and fasten the bottom

plate back onto the OMP-MODL assembly with the four side screws.

Note that the batteries can be accessed by removing any level of the 4 side

access screws on the ML-BATT module, however it is typically easiest to

remove the 4 on the metal bottom plate.

ML009

Alkaline D-cells are recommended for use in the OMPMODL as they contain significantly more energy than

standard or `heavy-duty’ cells and will provide

substantially longer recording capability. Depending on

the Program Net within the OMP-MODL, a fresh set of

alkaline D-cells can power the OMP-MODL for up to 4

weeks of logging.

USING THE OMP-MODL3-8

Page 33

3... INTERFACE MODULES

ML-DISP; DISPLAY AND USER INTERFACE MODULE

The OMP-MODL can be equipped with the ML-DISP module ( Figure 3... -7) to

provide a 2 line liquid crystal display (LCD), front panel Status/Alarm indicating LEDs

and a full complement of User buttons. With these features, system messages,

status, and more can be accessed in the field without a serial connection to a PC.

ModuLogger 2.27

Memory Full

Status

Alarm 1

Alarm 2

Next

Select

Enable

Stop

Reset

Figure 3... -7: ML-DISP Module

Module Installation:

Refer to the Installation Section earlier in this chapter for detailed installation

instructions of the Interface Module onto the System Base. No special

considerations are required for installation of this module.

I/O Module Layer Requirements / Limitations:

The ML-DISP module must be installed as the top layer in a OMP-MODL

system (obviously). The ML-DISP does not utilize any Module Address

switches.

Hardware Input Signal Configuration Switches:

The ML-DISP does not utilize any configuration switches and is

automatically detected.

Push Buttons

Located on the right side of the ML-DISP are five momentary push buttons

providing basic OMP-MODL operational control. These buttons provide the

following features:

USING THE OMP-MODL 3-9

Page 34

3... INTERFACE MODULES

NEXT and SELECT

The NEXT and SELECT buttons are for User control of the liquid

crystal display (LCD) information displays. Pressing NEXT will

advance the LCD to the next menu item at the current menu level.

Pressing the SELECT button selects that menu item and a new level

of menus or results are displayed.

A detailed explanation of the operation of the NEXT and SELECT

buttons is covered in a later section on the Display.

ENABLE Button:

The ENABLE button duplicates the functions of the ENABLE button

located on the end of the MLCPU-1 module (discussed in prior

section MLCPU-1 Module).

STOP Button:

The STOP button duplicates the functions of the STOP button

located on the end of the MLCPU-1 module (discussed in prior

section MLCPU-1 Module).

As discussed in that section, memory can be cleared by holding this

button down for approximately 10 seconds. Memory can also be

cleared through a menu sequence utilizing the NEXT and SELECT

buttons on loggers equipped with the ML-DISP module. See Display

section following.

RESET Button:

The RESET button duplicates the functions of the RESET button

located on the end of the MLCPU-1 module (discussed in prior

section MLCPU-1 Module).

3-Button System Initialization:

A complete initialization of the logger that will clear data memory

and program memory can be performed using the ENABLE, STOP

and RESET buttons. This sequence (discussed in prior section

MLCPU-1 Module) can be performed using the buttons located on

the ML-DISP module as well.

Display

An extended temperature range 2-line by 16 character liquid crystal display

(LCD) is provided. Information ranging from Operational Mode to System

Status to Alarm Messages to signal readings can all be displayed on the

LCD. The LCD is continually ON. Information to be displayed is controlled

by a User via the SELECT and NEXT front panel buttons.

Additionally, alarm messages will be automatically displayed on the LCD

when User pre-programmed conditions are met. These messages and

USING THE OMP-MODL3-10

Page 35

3... INTERFACE MODULES

conditions are defined by the User in the Program Net developed within

HyperNet ( Chapter 7) and loaded into OMP-MODL memory.

Display Operation

Information that can be displayed on the LCD is arranged in a

hierarchical format and is accessed by a User via the NEXT and the

SELECT buttons on the front panel of the OMP-MODL. The menu

structure is diagrammed in Figure 3... -8.

Pressing the NEXT button advances the display to the next available

item in that menu level. Repetitive presses of the NEXT button will

result in a circular sequencing through all of the available menu

items on the current level and eventual repeat of the sequence.

USING THE OMP-MODL 3-11

Page 36

3... INTERFACE MODULES

SELECT

N

E

X

T

LOGGER X.XX

<MODE>

SYSTEM

STATUS

Shows the EPROM version number and the

current operating mode

SELECT

Display

Date and Time

N

E

Remaining Memory

X

T

Net Program Name

Display

Unit Name and ID

Net Program

Description

System Supply

Voltage

Shows the current date

and time in the Logger

Shows the % memory used

and # of samples recorded

Shows the Unit Name and

ID (set from HyperWare)

Name of the Net Program

(set from HyperWare with

Global Icon)

Desc. of Net (set from

HyperWare with Global Icon)

Voltage of the batteries or

external supply, whichever

is greater

DISPLAY PROBE

ICON VALUES

DISPLAY MEMORY

ICON VALUES

DISPLAY STATUS

MESSAGES

ERASE

MEMORY

(Loops to top of this menu)

Return to Top

Menu

(Loops to top of this menu)

Steps through all of the Probe Icons and Displays their

current values

Steps through all of the Memory Icons and displays their

current values

Steps through all of the active Message Icons

Erases data memory, leaving Net program intact

Figure 3... -8: LCD (display) Menu Structure

Jumps to the top of the

menu system

ML054

USING THE OMP-MODL3-12

Page 37

3... INTERFACE MODULES

Pressing the SELECT button selects that menu item and a new level

of menus or results are displayed. A detailed description of the

various menu items and levels follow.

TIP - a good comprehension of this LCD menu structure

can be achieved by close reading of this section... but

better results may be achieved by just `diving in’ and

poking around with the NEXT and SELECT buttons to

develop a feel for the structure. Then read through this

section for the details.

Display Menu Items

Following are descriptions of each of the display menu items

identified in Figure 3... -8. Further details may be found in later

sections detailing the functions described.

TOP MENU:

When the OMP-MODL is powered ON, the Top Menu is

displayed in the LCD. The Top Menu indicates the OMP-MODL

EPROM version on the top line of the LCD (software version

residing in an EPROM memory chip within the OMP-MODL) and

on the bottom line, the current operational mode of the OMPMODL. Displayed Modes include:

ENABLED

Indicates the OMP-MODL is currently executing a Program

Net that has been developed with HyperNet and transferred

to the OMP-MODL memory.

STOPPED

The OMP-MODL is not executing a Program Net. Since the

Net is not executing and updating the net, stepping through

various Probe Points will result in values and states that will

not be current.

MEMFULL STOPPED

Data memory within the OMP-MODL has filled and the

execution of the Program Net has stopped. This message

will also display if the Rotary Memory mode is utilized (See

Global icon in Appendix A) and a logging session has been

performed. In Rotary Memory mode, only one logging

session can be maintained in the OMP-MODL memory.

MEMFULL ENABLED

Memory within the OMP-MODL has filled, however

execution of the Program Net is continuing. This mode of

operation may be User selected when alarming/control

functions are to be monitored.... even after the OMP-MODL

memory has filled. This display will only occur if the User

has selected the memory utilization option Log to Full

USING THE OMP-MODL 3-13

Page 38

3... INTERFACE MODULES

Memory and Continue Processing during setup of the

Program Net within HyperNet (Global Icon option).

MEMFULL WRAPPING

Displays when the OMP-MODL Program Net is configured in

the Rotary Memory mode. When memory fills, the OMPMODL starts writing over the first collected data. Since the

Program Net is still executing, alarms and control functions

continue to be monitored. Rotary Memory mode is enabled

during setup of the Program Net under the Global Icon.

RCV’ING NET

Displays momentarily during the actual serial upload of of a

Program Net to the OMP-MODL.

NO PROGRAM NET

Displays upon first power up of the OMP-MODL after the

Program Net has been lost. This should only occur after

replacement (or initial installation) of the lithium cell used for

Data Memory backup. The display indicates that a search

for a valid Program Net stored within the OMP-MODL

memory has failed.

In the event that this message displays, check (and replace

if low) the Lithium Cell via the STATUS menu described

below. Then reprogram the OMP-MODL with a new

Program Net.

BAD PROGRAM NET

Displays if an illegal or corrupted Program Net is in memory.

This message should only occur if memory containing the

Program Net has been corrupted or the unit has undergone

a 3-button Initialization which has cleared out the OMPMODL Program Net. In the event that this message

displays, reprogram the logger with a new Program Net,

then check (and replace if low) the Lithium Cell via the

STATUS menu described below.

CARD ERROR: MISSING FILE

Displays upon power-up of the OMP-MODL with an

improperly prepared PCMCIA card inserted (MLIM-5

module). The card should be formatted and prepared for

use within the OMP-MODL as described in Chapter 6.

BAD CONFIG

Displays if User selectable switch settings on the MLAD-1 or

any other OMP-MODL Interface Modules do not match the

currently loaded Program Net. The message also identifies

which Interface Module and channel or incompatible. If this

message displays, modify the Program Net to match the

hardware or open the OMP-MODL and examine the switch

settings on the installed Interface Modules and correct the

invalid setting(s).

SYSTEM STATUS

From the Top Menu, pressing the Next button once will advance

the display to System Status. Pressing SELECT while System

USING THE OMP-MODL3-14

Page 39

3... INTERFACE MODULES

Status is displayed results in a new level of display. Menu

selections available on this level include:

DATE AND TIME

Press SELECT to display the current Date and Time in the

OMP-MODL Real Time Clock. This is the date and time to

which collected data is referenced. The OMP-MODL date

and time are set from within HyperComm (Chapter 5).

REMAINING MEMORY

Press SELECT to display the number of samples recorded

and the percentage of memory used.

TIP: Depending on the User defined format

for data storage and the actual time and

values being stored, samples will require

varying amounts of memory for storage. For

this reason, use caution when extrapolating

the remaining logging time.

UNIT NAME & ID

Press SELECT to display the programmed OMP-MODL

Name and ID. The OMP-MODL Unit name and ID can be

User assigned through HyperWare (Chapter 5). This ID can

be used for corporate tracking of multiple units, calibration

schedules, etc.

PROGRAM NET NAME

Press SELECT to display the currently loaded Program Net

name. This name is assigned during the development of a

Program Net (Chapter 7).

PROGRAM NET DESCRIPTION

Press SELECT to display a previously programmed

description of the Program Net (above).

SYSTEM SUPPLY VOLTAGE

Press SELECT to display the OMP-MODL supply voltage

and the approximate state of charge of the memory / clock

backup lithium cell. If internal batteries are installed in the

OMP-MODL and an external power supply is also

connected, the displayed Supply Voltage indicated refers to

the greater of the two.

FYI: The displayed Supply Voltage is

measured at an internal node on the power

supply circuitry. Displayed battery voltage is

the voltage of the internal batteries .

External supply voltage will be

approximately 2 volts higher than indicated.

If the Input Range Jumper (see MLCPU-1

section) is set to HI, the External supply

voltage will be approximately 3.5 volts

higher than indicated.

The state of charge display for the lithium cell (used for

memory and clock backup) will display GOOD or LOW. If

USING THE OMP-MODL 3-15

Page 40

3... INTERFACE MODULES

DISPLAY PROBE ICON VALUES

During the construction of a Program Net within HyperNet, the

User can opt to connect Probe Point icons to various nodes

throughout the net. These Probe Point icons allow the User to

view the current values on the nodes to which they are

connected. (Program Net development is described in Chapter 7

and details on the Probe Point icon are included in Appendix A.)

One of the ways that the Probe Point values can be viewed is via

the OMP-MODL front panel LCD, as follows:

From the Top Menu, pressing the NEXT button twice will

advance the LCD to Display Probe Icon Values. Pressing

SELECT while Display Probe icon Values is on the LCD will shift

the display to a level containing the actual Probe Point values.

The top line of this display is the Probe icon Name assigned to

the icon during construction of the net and the second line is the

value and units.

Repetitively pressing NEXT will step the display through all of the

Probe icons previously programmed into the Program Net. To

return to the Top Menu, press SELECT when Return to Top

Menu is displayed.

Displayed Probe icon values will be updated whenever the net

node is updated. If the OMP-MODL is Stopped (ie not executing

the net), the last calculated node value will be displayed.

LOW is displayed, download any desired data memory, then

replace the lithium cell per the instructions in Appendix D.

RETURN TO TOP MENU

Press SELECT to return to the Top Menu display. Press

NEXT to cycle through this level’s menu selections again.

FYI: Probe Point is used for the icon name as

connecting these icons to a node on a Net is

somewhat analogous to putting a test meter probe

on the Net nodes and reading a value.

TIP: Displaying Probe icon Values while the OMP-MODL

is enabled will slow down the execution of the net. For

higher speed data logging applications (eg sub-second

sampling rates), faster performance can be achieved by

leaving the LCD in a mode where it is not displaying the

time/date, battery state of charge, remaining memory,

Probe icons, Memory Icons , or Net Values,

DISPLAY MEMORY ICON VALUES

In addition to display of Probe icon values (previously described),

the last value stored to any Memory icon within the executing

Program Net can also be displayed on the LCD.

From the Top Menu, pressing the NEXT button three times will

advance the LCD to Display Memory Icon Values. Pressing

SELECT while Display Memory Icon Values is on the LCD will

shift the display to a level containing the actual last logged

values. The top line of this display is the Memory Icon Name

USING THE OMP-MODL3-16

Page 41

3... INTERFACE MODULES

assigned to the icon during construction of the net and the

second line is the last logged value and units.

To return to the Top Menu, press SELECT when the Return to

Top Menu message is displayed.

DISPLAY STATUS MESSAGES

Messages can be sent to the LCD due to OMP-MODL

operational conditions or User programmed Program Net

conditions. To view the active messages; from the Top Menu,

press NEXT five times and then SELECT while the Display

Status Messages menu is displayed. Step through the messages

with the NEXT button and return to the Top Menu by pressing

SELECT when Return to Top Menu is displayed.

Depending on the inputs and programmed conditions within the

currently executing Program Net, User programmed messages

may come and go as the conditions for display are met then not

met over time.

During execution of a Program Net, if the conditions (either

OMP-MODL operational or User defined Program Net) are met

for a message display (eg an alarm conditon occurs), the

message will display on the LCD immediately... overwriting any

current displays. Messages displayed on the LCD will not be

cleared from the LCD when they become False, however they

will be cleared from the internal display queue. Messages will

only be cleared from the LCD if another message is displayed or

if the User changes the LCD (via the Select/Next buttons) in any

way. For additional information on message display capability

from within a Program Net,, refer to the Message icon in

Appendix A.

ERASE MEMORY (VIA DISPLAY SEQUENCE)

Data memory within the OMP-MODL and within an inserted

PCMCIA card can be cleared via the SELECT and NEXT

buttons. To clear memory, from the Top Menu, press NEXT six

times until the message Erase Memory appears on the LCD.

Then press SELECT a total of five times to clear the memory.

Successful erasure of the memory is confirmed with a Memory

has been Erased message.

Note that at any time during this sequence of SELECT button

presses, pressing the NEXT button will abort the Memory Clear

sequence and stored data will be preserved.

Internal OMP-MODL memory and PCMCIA card memory can

also be cleared via a serial communication link. Refer to the

Chapter 5 on HyperComm for details. Additionally, memory can

be cleared using the STOP button (see details in the STOP

button explanation in the MLCPU-1 section)

Status Lights

The Status lights on the ML-DISP duplicate the lights located on the end of

the MLCPU-1 module (discussed in prior section MLCPU-1 Module).

Three light emitting diode (LED) lights are provided on the front panel,

labeled STATUS, ALARM 1 and ALARM 2. The STATUS LED is merely a

USING THE OMP-MODL 3-17

Page 42

3... INTERFACE MODULES

visual indicator provided for User specified application from within a

Program Net. The ALARM LED’s provide visual indication of the state of the

two output relays contained on the MLCPU-1 module. When the ALARM

LED is ON, the relay contacts are closed.

USING THE OMP-MODL3-18

Page 43

3... INTERFACE MODULES

MLIM-1; FOUR CHANNEL ANALOG INTERFACE MODULE

Overview:

The MLIM-1 is a four channel add-on Interface Module for use in conjunction

with the OMP-MODL System Base.

NOTE: The MLAD-1 module of the System Base

includes the functionality of the MLIM-1 in additon to its

other functions. This section’s configuration and

operation instructions pertain to both the MLIM-1 add-on

module and the MLAD-1 component of the System Base.

Each of the four channels can be individually programmed for any

combination of the following signal types and input ranges with HyperWare

software (via HyperNet) and hardware Configuration Switches (located on

the Interface Module).

Thermocouple:

Type Color (USA) Range (F) Range (C)

J white/red -60 to 1400F -50 to 760C

K yellow/red 32 to 2500F 0 to 1370C

E purple/red -150 to 1830F -100 to 1000C

T blue/red -250 to 750F -160 to 400C

R black/red 32 to 1830F 0 to 1000C

S black/red 32 to 3182F 0 to 1750C

Table 3... -1: Thermocouple input types and ranges

DC Voltage:

Full Scale (FS) ranges:

Icon Full Scale Input Ranges

VDC-LO +/- 20mV +/-40mV +/-50mV +/-60mV +/-100mV

+/-200mV +/-1V +/-2V

VDC-MED +/-5 V +/- 10V

VDC-HI +/- 3V +/-15V +/-30V

Table 3... -2: DC Voltage input ranges

Input Impedance for the 5V, 10V, and 30V ranges is >2.5Megohm.

All other range’s input impedance is > 10 Megohm.

USING THE OMP-MODL 3-19

Page 44

3... INTERFACE MODULES

DC Current:

Full Scale (FS) ranges:

Icon Full Scale Input Ranges

mA-LO +/-200uA +/-400uA +/-500uA +/-1.0mA

+/-2.0mA +/-11 mA +/-22mA

Table 3... -3: DC Current input ranges

Input resistance for all current ranges is a 100 ohm precision shunt.

Module Installation:

Refer to the Installation Section earlier in this chapter for detailed installation

instructions of the Interface Module onto the System Base.

I/O Wiring Terminal

Strip

Module Address (Layer) Switches

Inter-Module Connection bus

OFF - ON OFF - ON OFF - ON

Module 2

Module 3

Module 4

Module 5

Module 6

ml051

Side Retaining Screw holes

Figure 3... -9: MLIM-1 Module Address Switches

I/O Module Layer Requirements / Limitations:

The MLIM-1 module can be installed in any of the five I/O Module positions

(Figure 3... -4). The module layer address must be set on the module to

correspond to the layer position into which the module is installed.

This address is programmed into the module through the use of the three

Module Address Switch banks (Figure 3... -9). Each switch bank contains 5

switches. Note the marking on the circuit board identifying address rows for

Module Layers 2 through 5. Set one switch in each of the 3 banks ON

corresponding to a module layer determined above. Each switch bank

should have only ONE switch ON and the other four switches OFF.

USING THE OMP-MODL3-20

Page 45

Module Address (Layer) Switch banks

3... INTERFACE MODULES

Module 2

Module 3

Module 4

Module 5

Module 6

OFF - ON OFF - ON OFF - ON

ml051

Figure 3... -10: Example Address setting for Module Layer Position 4

CAUTION: The switch banks may have different numbering than the circuit

board... insure that the marking on the circuit board is followed... not the

marking on the switch banks.

NOTE: The MLAD-1 module does not have Module Address Switches as

the MLAD-1 is always in Module Address Layer Position 1.

Ground Ref

ON

OFF

Configuration Switches

(one per channel)

ml013

Chan A Chan B Chan C Chan D

jumpers

Fuse (one per

channel)

I/O Wiring Terminal

Strip

Figure 3... -11: Channel configuration switches within the MLIM-1

Module

USING THE OMP-MODL 3-21

Page 46

3... INTERFACE MODULES

Hardware Input Signal Configuration Switches:

Four sets of Input Configuration Switches are provided for each of the four

channels (Figure 3... -11). Through the use of these switches, various types

of signals can be directly fed into the OMP-MODL eliminating the need for

User supplied external precision dividers, shunts and other circuitry.

Although for most applications, an in-depth understanding of the function of

these switches is not required, a simplified schematic of the input section of

the MLIM-1 is provided in Figure 3... -12. As can be seen in this schematic,

different combinations of the switches interject voltage dividers and shunts

into the input stage of the Interface Module.

2.49M

INPUT

SW2 SW3 SW4

Figure 3... -12: Simplified schematic of input section of MLIM-1

SW1

FUSE

0-30

Range

GROUND REFERENCE JUMPER

22K

0-10

Range

and MLAD-1 Modules

4-20mA

Range

AMP

ML014

The following reference chart provides the necessary information for

configuration of the input switches. The switch settings are read by the

OMP-MODL during a query of the hardware configuration (from within

HyperNet) so the User is not burdened with keeping notes of the current

Module configuration. Improper setting of the switches will result in a `Bad

Configuration’ message on the LCD upon power-up of the OMP-MODL. In

the event that this message displays, check the switch settings per Table 3...

-4 and correct the conflict.

USING THE OMP-MODL3-22

Page 47

3... INTERFACE MODULES

Input / Range SW 1 SW2 SW3 SW4

Thermocouples

OFF OFF OFF

ON

VDC up through +/-2 VDC

VDC up through +/-10 VDC OFF OFF

VDC up through +/-30 VDC OFF

All Current (mADC) Ranges

Table 3... -4: MLIM-1 configuration switch settings

ON

ON

OFF OFF

ON

OFF OFF

OFF

ON

MLIM-1 Channel Configuration via Software:

When a MLIM-1 channel is configured as a particular type of input via the

module configuration switches, the configuration will be automatically

detected during the development of a Program Net for the OMP-MODL.

Software input range configuration and utilization of the MLIM-1’s channels

in a Program Net is covered in Chapter 7 and within the Master Icon Listing

in Appendix A.

Ground Ref

ON

OFF

Chan A Chan B Chan C Chan D

Configuration Switches

(one per channel)

ml013

Figure 3... -13: Channel configuration switches within the MLIM-1

and MLAD-1 Modules

I/O Wiring Terminal

Strip

jumpers

Fuse (one per

channel)

Input Overcurrent Fuses:

Each channel is protected by a 125mA fuse as shown in Figure 3... -12