Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

OME-PIO-D56/D24

PCI-Bus

Digital I/O Board

Hardware Manual

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

OME-PIO-D56/D24

User Manual

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 1

Page 4

Table of Contents

1. INTRODUCTION...........................................................................................................................3

1.1 FEATURES .................................................................................................................................... 3

1.2 SPECIFICATIONS ...........................................................................................................................4

1.3 ORDER DESCRIPTION....................................................................................................................4

1.4 PCI DATA ACQUISITION FAMILY ................................................................................................. 5

1.5 PRODUCT CHECKLIST ...................................................................................................................5

2. HARDWARE CONFIGURATION...............................................................................................6

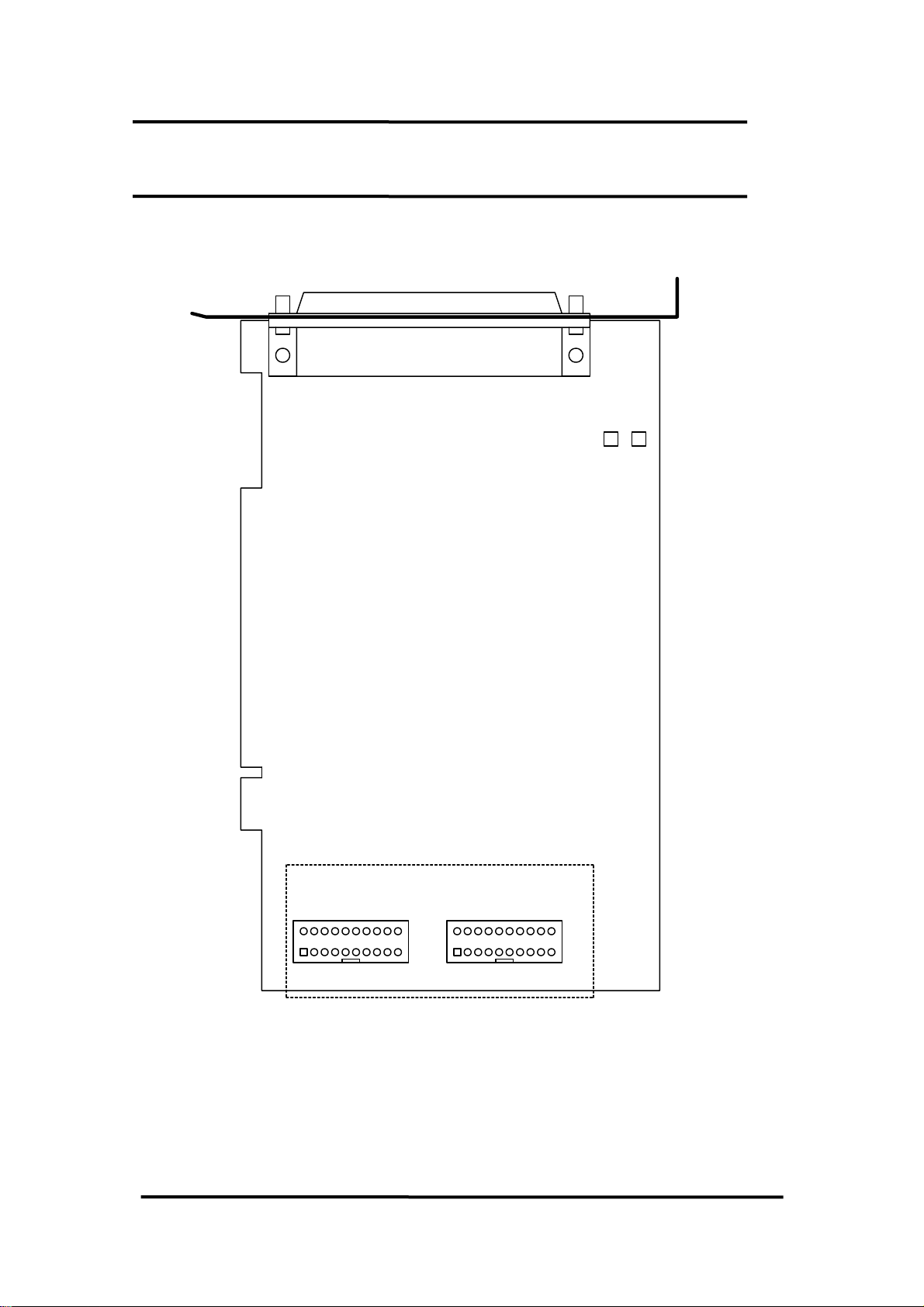

2.1 BOARD LAYOUT ........................................................................................................................... 6

2.2 I/O PORT LOCATION.....................................................................................................................7

2.3 ENABLING I/O OPERATION...........................................................................................................7

2.4 INTERRUPT OPERATION ..............................................................................................................11

2.5 DAUGHTER BOARDS................................................................................................................... 18

2.6 PIN ASSIGNMENT........................................................................................................................24

3. I/O CONTROL REGISTER ........................................................................................................26

3.1 HOW TO FIND THE I/O ADDRESS ................................................................................................26

3.2 THE ASSIGNMENT OF I/O ADDRESS.............................................................................................32

3.3 THE I/O ADDRESS MAP .............................................................................................................. 33

4. DEMO PROGRAM ......................................................................................................................38

4.1 PIO_PISO..................................................................................................................................39

4.2 DEMO1 .....................................................................................................................................41

4.3 DEMO2 .....................................................................................................................................42

4.4 DEMO3 .....................................................................................................................................43

4.5 DEMO4 .....................................................................................................................................45

4.6 DEMO5 .....................................................................................................................................47

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 2

Page 5

1. Introduction

The OME-PIO-D56/OME-OME-PIO-D24 provides 56/24 TTL digital I/O lines.

The OME-PIO-D56/OME-OME-PIO-D24 consists of one 24-bit bi-directional port,

one 16-bit input port and one 16-bit output port (only for OME-PIO-D56). The 24-bit

port supports three 8-bit groups PA, PB & PC. Each 8-bit group can be individually

configured to function as either an input or an output. All groups using 24-bit bi-

directional ports are configured as inputs upon power-up or reset.

Use the OME-DB-24PD to connect the input port for either isolation purposes,

or to interface to the output port for relay control. The OME-PIO-D56/OME-PIO-D24

has one D-sub connector and two 20-pin flat-cable connectors (only for OME-PIO-

D56). The flat cable can be connected to an OME-ADP-20/PCI adapter. The adapter

can be fixed on the chassis. It can be installed in a 5V PCI bus and supports “Plug &

Play”.

1.1 Features

• PCI bus

• Up to 56/24(OME-PIO-D56/OME-PIO-D24) channels of digital I/O

• All I/O lines buffered on the board

• Eight-bit groups independently selectable for I/O on 24-bit port

• Input / Output programmable I/O ports under software control

• Double side SMD, short card.

• Connects directly to OME-DB-24PR, OME-DB-24PD, OME-DB-24RD,

OME-DB-24PRD, OME-DB-16P8R, OME-DB-24POR, OME-DB-24SSR or

OME-DB-24C

• 4 interrupt sources: PC0, PC1, PC2, PC3

• One DB37 connector, two 20-pin flat-cable connectors (only for OME-PIO-D56)

• High drive capability

• Automatically detected by Windows 95/98/2000/XP

• No base address or IRQ switches to set

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 3

Page 6

1.2 Specifications

• All inputs are TTL compatible

Logic high voltage : 2.4V (Min.)

Logic low voltage : 0.8V (Max.)

• All outputs are TTL compatible

OPTO-22 output (CON3)

Sink current : 64mA (Max.)

Source current : 32mA(Max.)

16-channel output (CON1)

Sink current : 8mA (Max.)

Source current : 0.4mA(Max.)

• Environmental :

Operating Temperature: 0°C to 60°C

Storage Temperature: -20°C to 80°C

Humidity: 0 to 90% non-condensing

• Dimensions: 143mm X 105mm

• Power Consumption: +5V @ 530mA/420mA(OME-PIO-D56/OME-PIO-D24)

1.3 Order Description

• OME-PIO-D56 : PCI bus 56-bit DI/O board

• OME-PIO-D24 : PCI bus 24-bit DI/O board

1.3.1 Options

• OME-DB-24PD : 24 channel isolated D/I board

• OME-DB-24RD : 24 channel relay board

• OME-DB-24PRD : 24 channel power relay board

• OME-DB-16P8R : 16 channel isolated D/I and 8 channels relay output board

• OME-DB-24POR : 24 channel Photo MOS output board

• OME-DB-24C : 24 channel open-collector output board

• OME-ADP-20/PCI : extender, 20-pin header to 20-pin header for PCI bus I/O

boards

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 4

Page 7

1.4 PCI Data Acquisition Family

We provide a family of PCI bus data acquisition cards. These cards can be

divided into three groups as follows:

1. OME-PCI-series: first generation, isolated or non-isolated cards

OME-PCI-1002/1202/1800/1802/1602: multi-function family, non-isolated

OME-PCI-P16R16/P16C16/P16POR16/P8R8: D/I/O family, isolated

OME-PCI-TMC12: timer/counter card, non-isolated

2. OME-PIO-series: cost-effective generation, non-isolated cards

OME-PIO-823/821: multi-function family

OME-PIO-D144/D96/D64/D56/D48/D24: D/I/O family

OME-PIO-DA16/DA8/DA4: D/A family

3. OME-PISO-series: cost-effective generation, isolated cards

OME-PISO-813: A/D card

OME-PISO-P32C32/P64/C64: D/I/O family

OME-PISO-P8R8/P8SSR8AC/P8SSR8DC: D/I/O family

OME-PISO-730: D/I/O card

OME-PISO-DA2: D/A card

1.5 Product Checklist

In addition to this manual, the package includes the following items:

• One OME-PIO-D56(or OME-PIO-D24) card

• One software floppy diskette or CD

• One release note

Please read the release note first. Important information that could be given in release

note such as:

1. Where you can find the software driver & utility?

2. How to install software & utility?

3. The location of the diagnostic program?

4. FAQ

Attention!

If any one of these items is missing or damaged, please contact

Omega Engineering immediately. Save the shipping materials

and carton in case you want to ship or store the product in the

future.

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 5

Page 8

2. Hardware configuration

2.1 Board Layout

CON3

DI/O

Port0

Port1

Port2

PIO-D24

PIO-D56

PCI BUS

only for PIO-D56

D/O

CON1

12

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 6

1920

D/I

CON2

12

1920

Page 9

2.2 I/O Port Location

The OME-PIO-D56/OME-PIO-D24 consists of one 24-bit bi-directional port, one

16 bit input port and one 16 bit output port (only for OME-PIO-D56). The 24-bit port

supports three 8-bit groups: PA, PB & PC. Each 8-bit group can be individually

configured to function as either inputs or outputs. All groups using 24-bit bi-

directional ports are configured as inputs upon power-up or reset. The I/O port

locations are as follows:

Connector of

OME-PIO-D56/D24

CON3 (DI/O) Port0 Port1 Port2

Connector of OME-PIO-D56 Description

CON1 D/O

CON2 D/I

Refer to Sec. 2.1 for board layout & I/O port location.

Note: PC0, PC1, PC2 and PC3 can be used as interrupt signal source. Refer to Sec.

2.4 for more information.

PA0 ~ PA7 PB0 ~ PB7 PC0 ~ PC7

2.3 Enabling I/O Operation

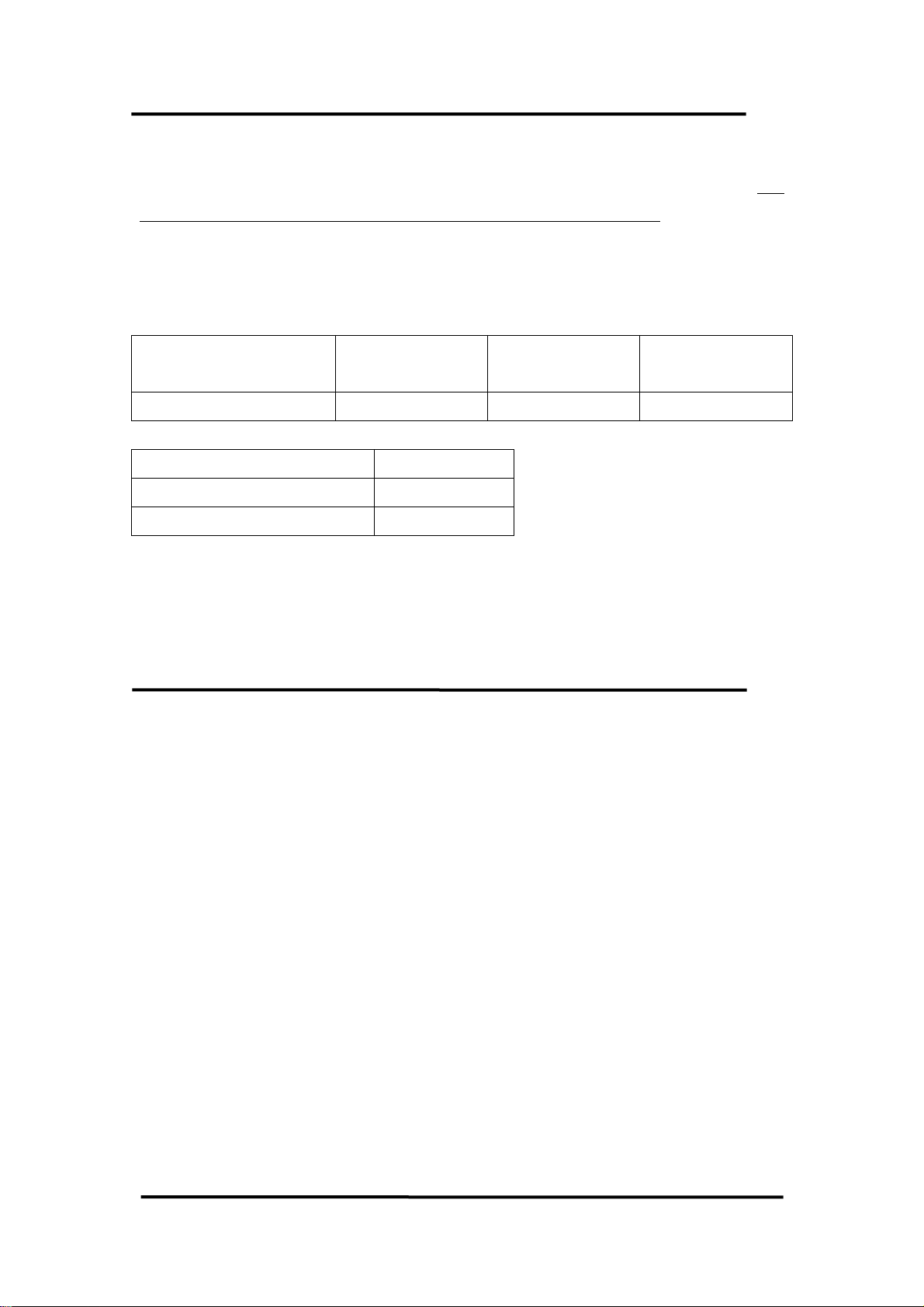

2.3.1 DI/DO Port Architecture (CON3)

Upon power-up, all D/I/O port (CON3) operations are disabled. The RESET\

signal controls the enable/disable state of D/I/O port. Refer to Sec. 3.3.1 for more

information about RESET\ signal. The power-up states are as follows:

• All D/I/O operations are disabled

• All three D/I/O ports are configured as D/I port

• All D/O latch register are undefined.(refer to Sec. 2.3.2)

Initialization must be performed before using these D/I/Os. The recommended

steps are as follows:

Step 1: Find address-mapping of OME-PIO/PISO cards (refer to Sec. 3.1)

Step 2: Enable all D/I/O operations (refer to Sec. 3.3.1)

Step 3: Configure the three ports (in CON3) to their expected D/I/O state &

send the initial value to all D/O ports (refer to Sec. 3.3.8)

Refer to DEMO1.C for demo program.

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 7

Page 10

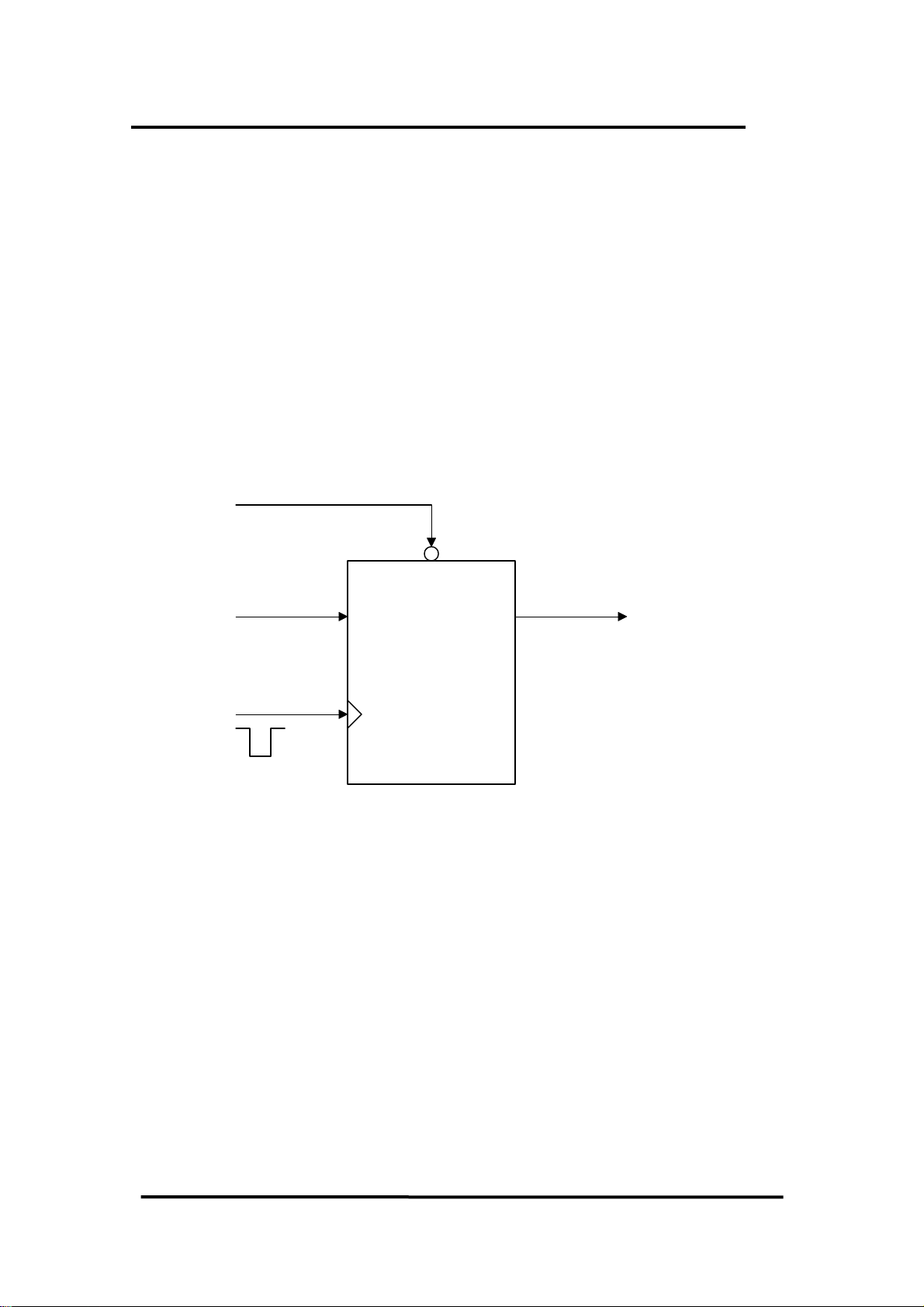

I/O select (Sec. 3.3.7)

RESET\ (Sec. 3.3.1)

Data

(Sec. 3.3.8)

Data

(Sec. 3.3.8)

disable\

input Latch

Clock input

D/O latch CKT

disable

Buffer input

Clock input

D/I buffer CKT

D/I/O

• When the RESET\ is in Low-state Æ all D/I/O operations are disabled

• When the RESET\ is in High-state Æ all D/I/O operation are enabled.

• If D/I/O is configured as D/I port Æ D/I= external input signal

• If D/I/O is configured as D/O port Æ D/I = read back of D/O

• If D/I/O is configured as D/I port Æ send to D/O will change the D/O latch

register only. The D/I & external input signals will not change.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 8

Page 11

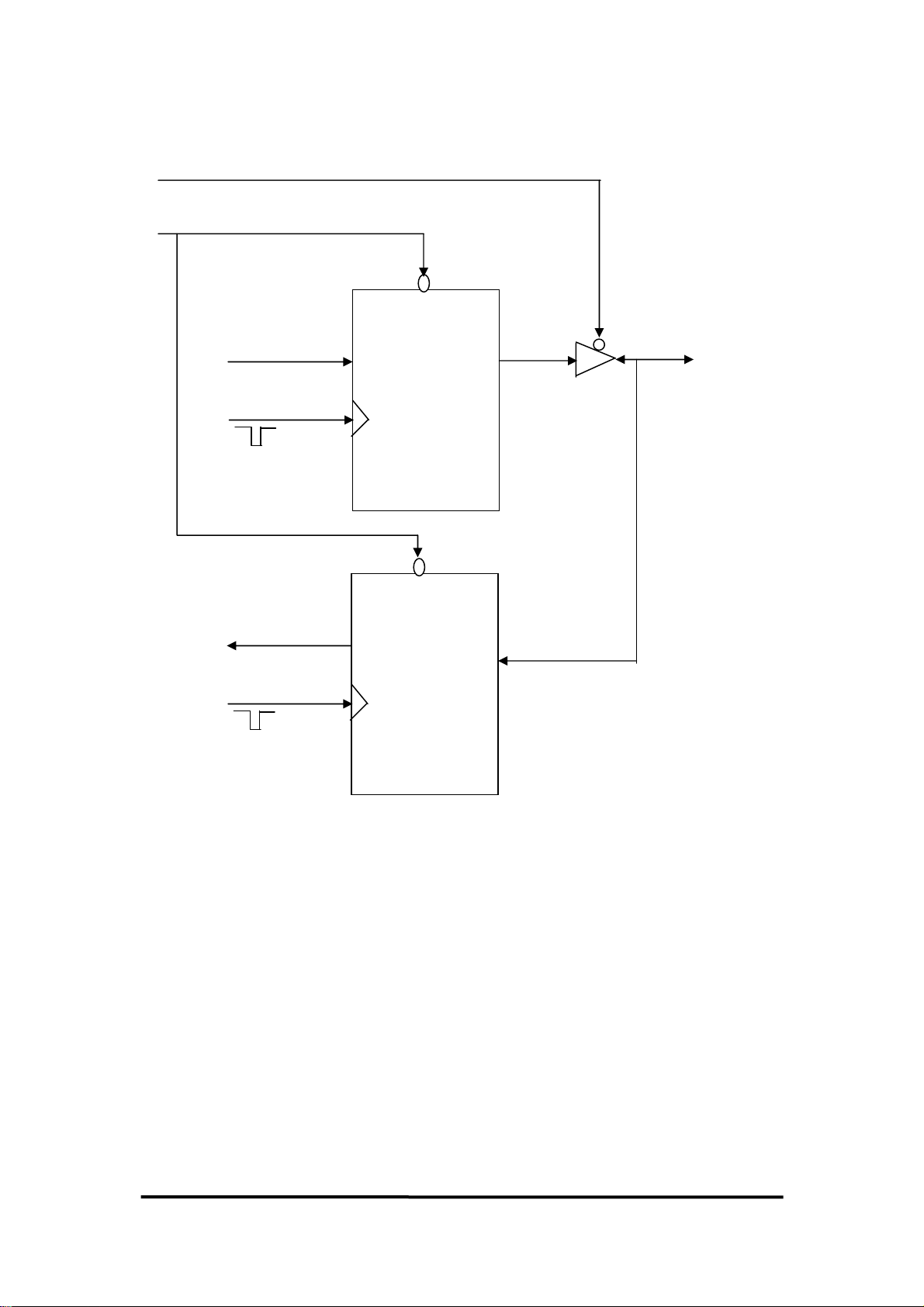

2.3.2 DI Port Architecture (CON2)

When the PC is powered up, all DI (CON2) port operations are disabled. The

RESET\ signal controls the enable/disable signal for the DI port. Refer to Sec. 3.3.1

for more information about the RESET\ signal.

• The RESET\ is in Low-state Æ all DI operations are disabled

• The RESET\ is in High-state Æ all DI operations are enabled

RESET\

disable

Data

Buffer input

Clock input

CON2

D/I buffer CKT

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 9

Page 12

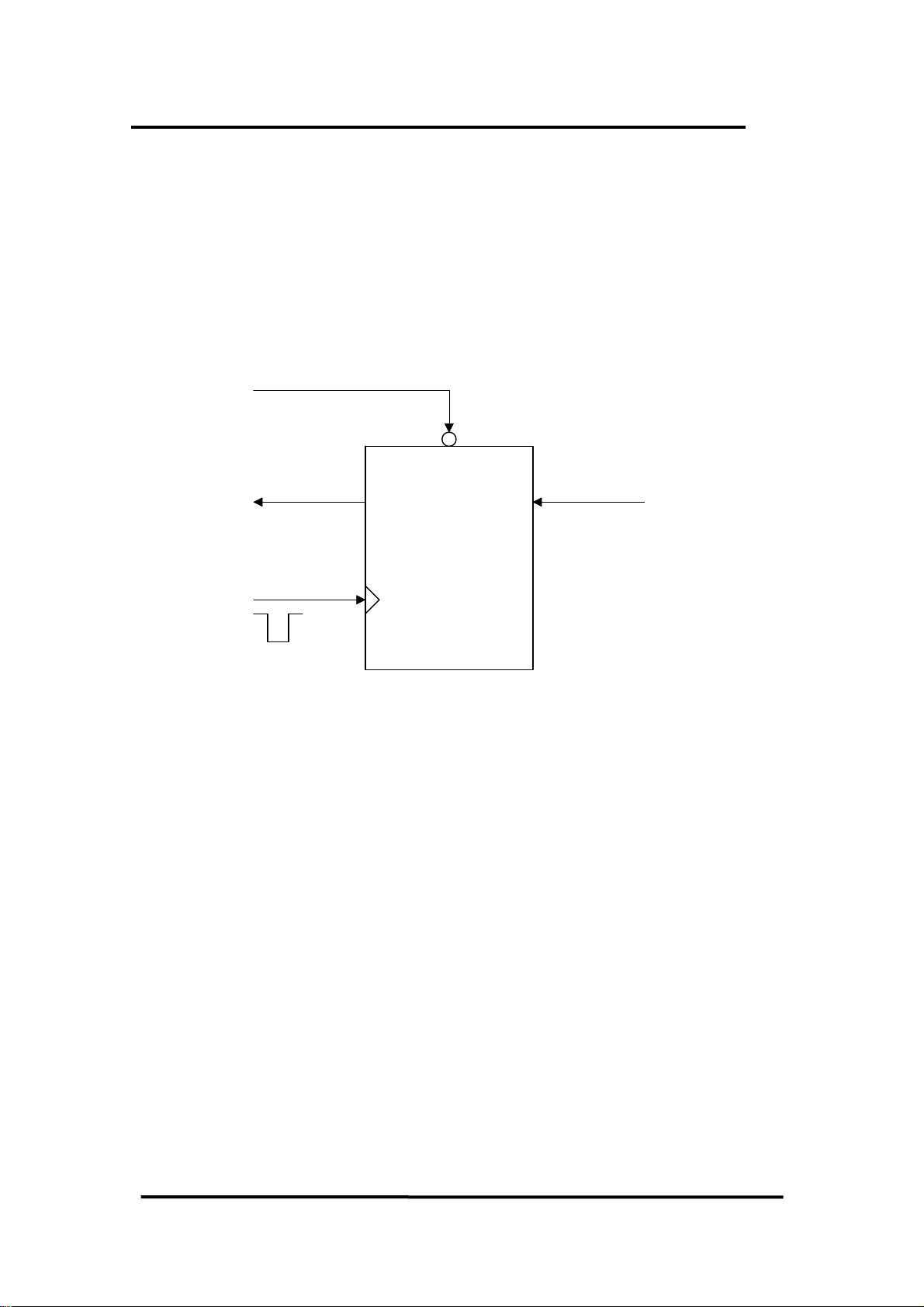

2.3.3 DO Port Architecture (CON1)

When the PC is powered up, all DO port (CON1) operations are disabled. The

RESET\ signal controls the enable/disable signal for the DI port. Refer to Sec. 3.3.1

for more information about the RESET\ signal.

• The RESET\ is in Low-state Æ all DO operations are disabled

• The RESET\ is in High-state Æ all DO operations are enabled

The power-up states are as follows:

• All DO operations are disabled

• All output latches are cleared to Low-Level

RESET\

clear

Data

input Latch

CON1

Clock input

D/O buffer CKT

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 10

Page 13

2.4 Interrupt Operation

All PC0, PC1, PC2 and PC3 can be used as an interrupt signal sources. Refer to

Sec. 2.1 for PC0/PC1/PC2/PC3 location. The interrupt of OME-PIO-D56/OME-

PIO-D24 is level-trigger & Active_High. The interrupt signal can be programmed to

inverted or non-inverted state. The programming procedure is given as follows:

1. Make sure the initial level is High or Low

2. If the initial state is High Æ select the inverted signal (Sec. 3.3.6)

3. If the initial state is Low Æ select the

4. Enable the INT function (Sec. 3.3.4)

5. If the interrupt signal is active Æ program will transfer into the interrupt

service routine Æ if INT signal is High now Æ select the inverted input

Æ if INT signal is Low now Æ select the non-inverted input

Refer to DEMO3.C & DEMO4.C for single interrupt source. Refer to

DEMO5.C for four interrupt sources.

If only one interrupt signal source is used, the interrupt service routine does not

have to identify the interrupt source. (Refer to DEMO3.C & DEMO4.C)

If there is more than one interrupt source, the interrupt service routine has to

identify the active signals via the following steps: (Refer to DEMO5.C)

1. Reads the new status of the interrupt signal source

2. Compares the new status with the old status to identify the active signals

3. If PC0 is active, service PC0 & non-inverter/inverted the PC0 signal

4. If PC1 is active, service PC1 & non-inverted/inverted the PC1 signal

non-inverted signal (Sec. 3.3.6)

5. If PC2 is active, service PC2 & non-inverted/inverted the PC2 signal

6. If PC3 is active, service PC3 & non-inverted/inverted the PC3 signal

7. Saves the new status to old status

Note: If the interrupt signal is too short, the new status may be the same as old

status. So the interrupt signal must be held active until the interrupt service

routine is executed. This hold time is different for different operating systems. It

can be as a short as micro-second or as a long as second. In general, 20ms is

enough for most operating systems.

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 11

Page 14

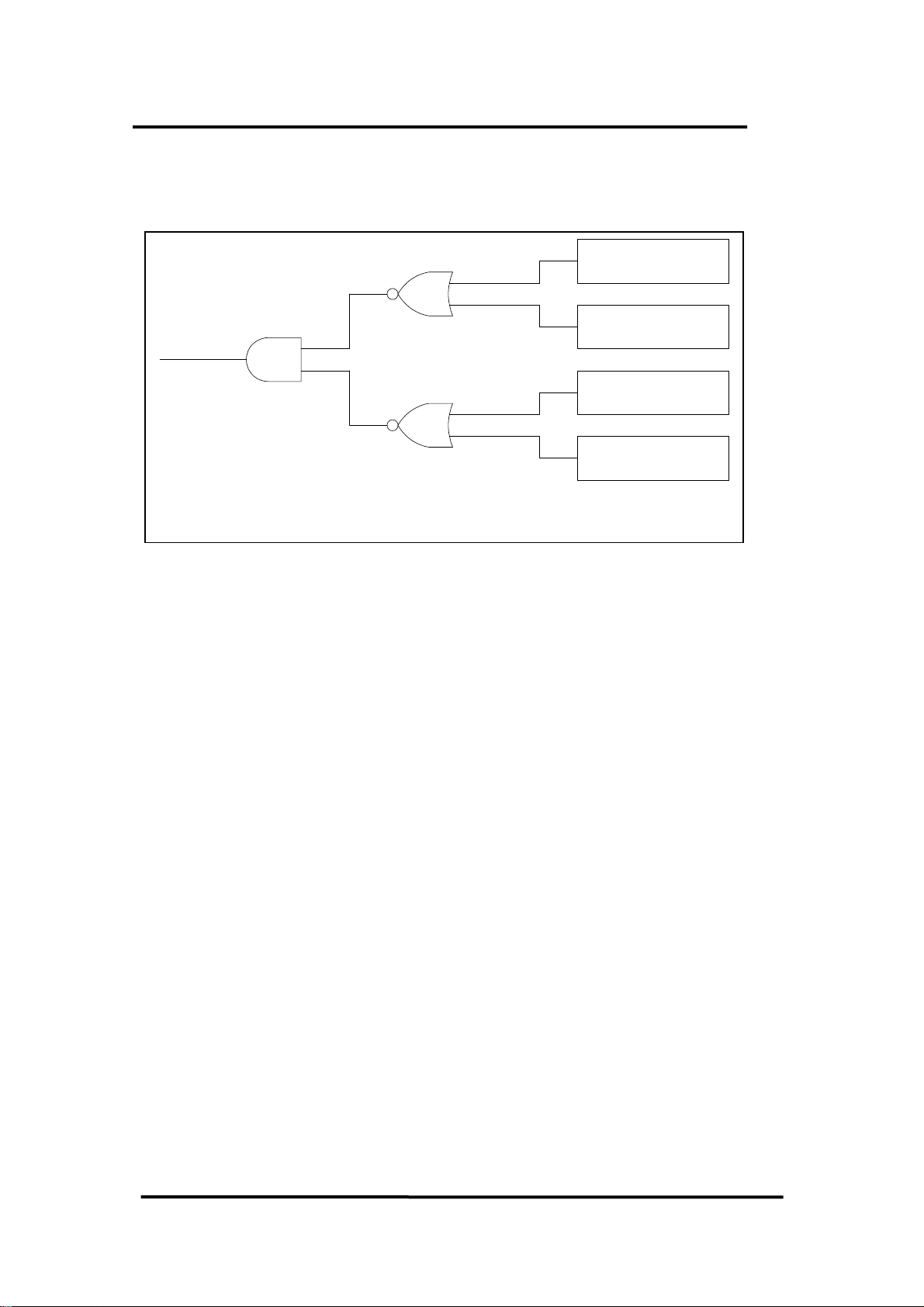

2.4.1 Interrupt Block Diagram of OME-PIO-

D56/D24

INT_CHAN_0

INT\

Level_trigger

The interrupt output signal of OME-PIO-D56/OME-PIO-D24, INT\ is

Level_trigger & Active_Low. If the INT\ generates a low pulse, the OME-PIO-

D56/OME-PIO-D24 will interrupt the PC only once. If the INT\ is fixed in low level,

the OME-PIO-D56/OME-PIO-D24 will interrupt the PC continuously.

INT_CHAN_0/1/2/3 must be controlled in a pulse type signals. It must be fixed in

low level state normally and generate a high pulse to interrupt the PC.

The priority of INT_CHAN_0/1/2/3 is the same. If all these four signals are active

at the same time, then INT\ will be active only one time. So the interrupt service

INT_CHAN_1

INT_CHAN_2

INT_CHAN_3

initial_low

active_high

routine has to read the status of all interrupt channels for a multi-channel interrupt.

Refer to Sec. 2.4 for mare information.

DEMO5.C → for multi-channel interrupt source

If only one interrupt source is used, the interrupt service routine does not have to read

the status of interrupt source. The demo programs DEMO3.C and DEMO4.C are

designed for single-channel interrupt demo, as follows:

DEMO3.C → for INT_CHAN_0 only (PC0 initial low)

DEMO4.C → for INT_CHAN_0 only (PC0 initial high)

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 12

Page 15

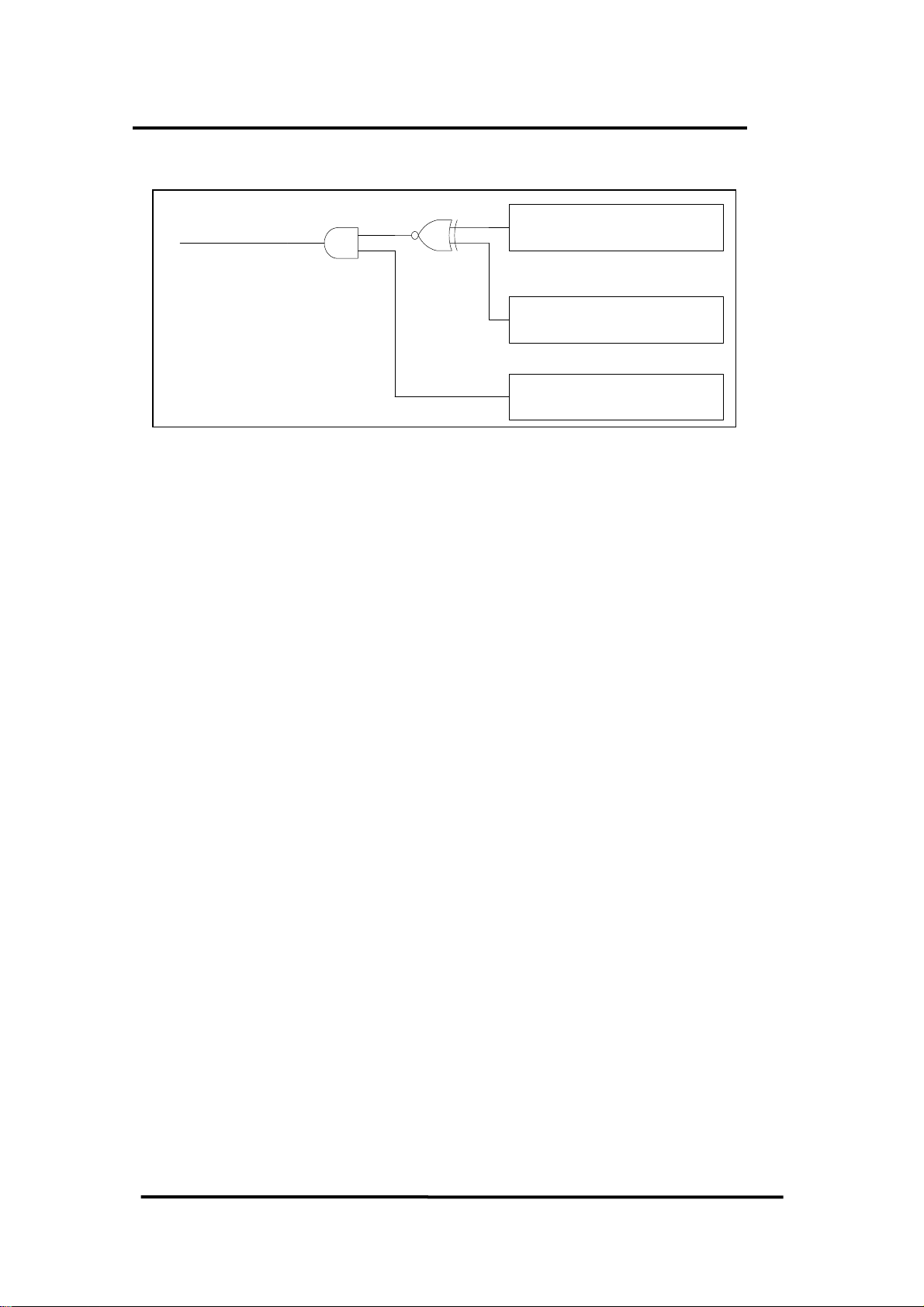

2.4.2 INT_CHAN_0/1/2/3

INT_CHAN_0 (1/2/3)

PC0(PC1/PC2/PC3)

Inverted/Noninverted select

INV0(1/2/3)

Enable/Disable select

EN0(1/2/3)

The INT_CHAN_0 must normally be fixed in low level state and generate a

high pulse to interrupt the PC.

The EN0 (EN1/EN2/EN3) can be used to enable/disable the INT_CHAN_0(1/2/3)

as follows : (Refer to Sec. 3.3.4)

EN0 (1/2/3) = 0 → INT_CHAN_0(1/2/3) = disable

EN0 (1/2/3) = 1 → INT_CHAN_0(1/2/3) = enable

The INV0 can be used to invert/non-invert the PC0 (1/2/3) as follows: (Refer to

Sec.3.3.6)

INV0 (1/2/3) = 0 → INT_CHAN_0(1/2/3) = inverted state of PC0 (1/2/3)

INV0 (1/2/3) = 1 → INT_CHAN_0(1/2/3) = non-inverted state of PC0 (1/2/3)

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 13

Page 16

2.4.3 Initial_high, active_low Interrupt source

If the PC0 is a initial_high, active_low signal, the interrupt service routine

should use INV0 to invert/non-invert the PC0 for high_pulse generation as follows:

(Refer to DEMO4.C)

Initial setting:

now_int_state=1; /* initial state for PC0 */

outportb(wBase+0x2a,0); /* select the inverted PC0 */

void interrupt irq_service()

{

if (now_int_state==1) /* now PC0 is changed to LOW */(a)

{ /* --> INT_CHAN_0=!PC0=HIGH now */

COUNT_L++; /* find a LOW_pulse (PC0) */

If((inport(wBase+7)&1)==0)/* the PC0 is still fixed in LOW */

{ /* Æ need to generate a high_pulse */

outportb(wBase+0x2a,1);/* INV0 select the non-inverted input */(b)

/* INT_CHAN_0=PC0=LOW --> */

/* INT_CHAN_0 generate a high_pulse */

now_int_state=0; /* now PC0=LOW */

}

else now_int_state=1; /* now PC0=HIGH */

/* don’t have to generate high_pulse */

}

else /* now PC0 is changed to HIGH */(c)

{ /* --> INT_CHAN_0=PC0=HIGH now */

COUNT_H++; /* find a HIGH_pulse (PC0) */

If((inport(wBase+7)&1)==1)/* the PC0 is still fixed in HIGH */

{ /* need to generate a high_pulse */

outportb(wBase+0x2a,0);/* INV0 select the inverted input */(d)

/* INT_CHAN_0=!PC0=LOW --> */

/* INT_CHAN_0 generate a high_pulse */

now_int_state=1; /* now PC0=HIGH */

}

else now_int_state=0; /* now PC0=LOW */

/* don’t have to generate high_pulse */

}

if (wIrq>=8) outportb(A2_8259,0x20);

outportb(A1_8259,0x20);

}

PC0

(a) (b) (c) (d)

INV0

INT_CHAN_0

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 14

Page 17

2.4.4 Initial_low, active_high Interrupt source

If the PC0 is a initial_low, active_high signal, the interrupt service routine

should use INV0 to inverted/non-inverted the PC0 for high_pulse generation as

follows: (Refer to DEMO3.C)

Initial setting:

now_int_state=0; /* initial state for PC0 */

outportb(wBase+0x2a,1); /* select the non-inverted PC0 */

void interrupt irq_service()

{

if (now_int_state==1) /* now PC0 is changed to LOW */(c)

{ /* --> INT_CHAN_0=!PC0=HIGH now */

COUNT_L++; /* find a LOW_pulse (PC0) */

If((inport(wBase+7)&1)==0)/* the PC0 is still fixed in LOW */

{ /* Æ need to generate a high_pulse */

outportb(wBase+0x2a,1);/* INV0 select the non-inverted input */(d)

/* INT_CHAN_0=PC0=LOW --> */

/* INT_CHAN_0 generate a high_pulse */

now_int_state=0; /* now PC0=LOW */

}

else now_int_state=1; /* now PC0=HIGH */

/* don’t have to generate high_pulse */

}

else /* now PC0 is changed to HIGH */(a)

{ /* --> INT_CHAN_0=PC0=HIGH now */

COUNT_H++; /* find a High_pulse (PC0) */

If((inport(wBase+7)&1)==1)/* the PC0 is still fixed in HIGH */

{ /* need to generate a high_pulse */

outportb(wBase+0x2a,0);/* INV0 select the inverted input */(b)

/* INT_CHAN_0=!PC0=LOW --> */

/* INT_CHAN_0 generate a high_pulse */

now_int_state=1; /* now PC0=HIGH */

}

else now_int_state=0; /* now PC0=LOW */

/* don’t have to generate high_pulse */

}

if (wIrq>=8) outportb(A2_8259,0x20);

outportb(A1_8259,0x20);

}

PC0

(a) (b) (c) (d)

INV0

INT_CHAN_0

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 15

Page 18

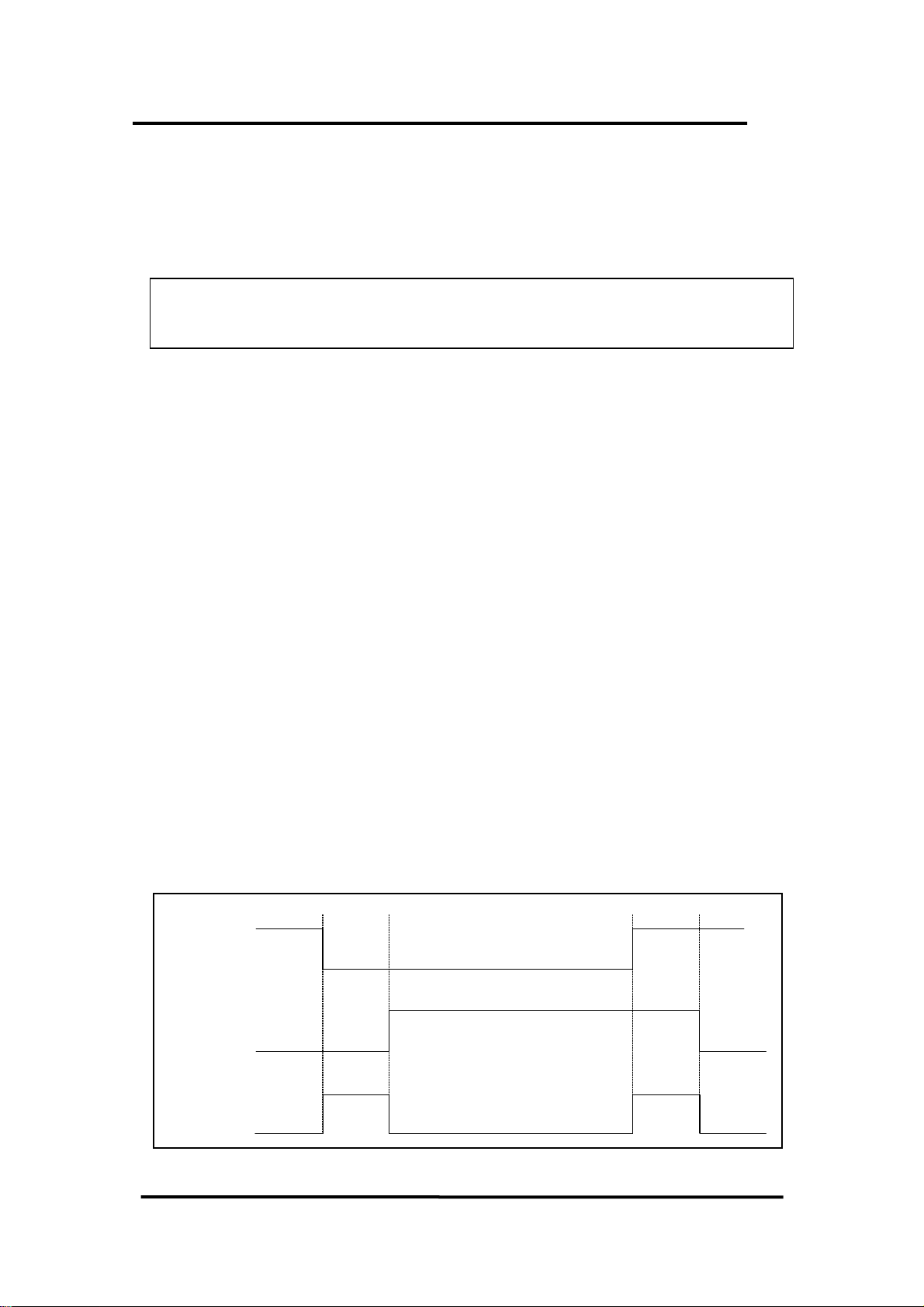

2.4.5 Muliti-Interrupt Source

Assume: PC0 is initial Low, active High,

PC1 is initial High, active Low

PC2 is initial Low, active High

PC3 is initial High, active Low

as follows :

PC0

PC1

PC2

PC3

PC0 & PC1 are

active at the same

time.

PC2 & PC3 are

active at the same

time.

Refer to DEMO5.C for source program. All these four falling-edge & rising-edge

can be detected by DEMO5.C.

PC0 & PC1 are

return to normal

at the same time.

PC2 & PC3 are

return to normal at

the same time.

Note: When the interrupt is active, the user program has to identify the active

signals. These signals may be active at the same time. The interrupt service

routine has to service all active signals at the same time.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 16

Page 19

void interrupt irq_service()

{

new_int_state=inportb(wBase+7)&0x0f; /* read all interrupt state */

int_c=new_int_state^now_int_state; /* compare which interrupt */

/* signal be change */

if ((int_c&0x1)!=0) /* INT_CHAN_0 is active */

{

if ((new_int_state&0x01)!=0) /* now PC0 change to high */

{

CNT_H1++;

}

else /* now PC0 change to low */

{

CNT_L1++;

}

invert=invert^1; /* to generate a high pulse */

}

if ((int_c&0x2)!=0)

{

if ((new_int_state&0x02)!=0) /* now PC1 change to high */

{

CNT_H2++;

}

else /* now PC1 change to low */

{

CNT_L2++;

{

invert=invert^2; /* to generate a high pulse */

}

if ((int_c&0x4)!=0)

{

If ((new_int_state&0x04)!=0) /* now PC2 change to high */

{

CNT_H3++;

}

else /* now PC2 change to low */

{

CNT_L3++;

}

invert=invert^4; /* to generate a high pulse */

}

if ((int_c&0x8)!=0)

{

if ((new_int_state&0x08)!=0) /* now PC3 change to high */

{

CNT_H4++;

{

else /* now PC3 change to low */

{

CNT_L4++;

}

invert=invert^8; /* to generate a high pulse */

}

now_int_state=new_int_state;

outportb(wBase+0x2a,invert);

if (wIrq>=8) outportb(A2_8259,0x20);

outportb(A1_8259,0x20);

}

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 17

Page 20

2.5 Daughter Boards

2.5.1 OME-DB-37

The OME-DB-37 is a general purpose daughter board for D-sub 37 pins,

designed for an easy-wiring connection.

2.5.2 OME-DN-37

The OME-DN-37 is a general purpose daughter board for OME-DB-37 with DIN-

Rail Mounting. It is designed for easy-wiring connection..

37pin cable

OME-DN-37

2.5.3 OME-DB-8125

The OME-DB-8125 is a general purpose screw terminal board. It is designed for

easy wire connection. There is one D-Sub37 & two 20-pin flat-cable headers on the

OME-DB-8125.

37pin cable

OME-DB-8125

(D-Sub 37 or

20-pin flat-cable header)

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 18

Page 21

2.5.4 OME-ADP-20/PCI

The OME-ADP-20/PCI is an extender for 20-pin header. One side of OME-

ADP-20/PCI connects to a 20-pin header. The other side mounts on the PC chassis as

follows:

NOTE: Please choose the suitable extender for your application

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 19

Page 22

2.5.5 OME-DB-24PD Isolated Input Board

The OME-DB-24PD is a 24 channel isolated digital input daughter board. The

optically isolated inputs of the OME-DB-24PD consist of a bi-directional opto-

coupler with a resistor for current sensing. Use the OME-DB-24PD to sense DC

signals from TTL levels up to 24V or use the OME-DB-24PD to sense a wide range

of AC signals. Use this board to isolate the computer from large common-mode

voltages, ground loops and transient voltage spikes that often occur in industrial

environments.

OME-PIO-D56/D24

Opto-Isolated

OME-PIO-D56/D24

OME-DB-24PD

AC or DC Signal

0V to 24V

+

-

OME-DB-24PD

50-pin flat-cable header Yes

D-sub 37-pin header Yes

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 20

Page 23

2.5.6 OME-DB-24RD Relay Board

The OME-DB-24RD, a 24 channel relay output board, consists of 24 form C

relays for efficient, programmable load switching. The relays are energized by

applying a 12V/24V signal to the appropriate relay channel on the 50-pin flat

connector. There are 24 enunciator LEDs for each relay which light when their

associated relay is activated.

Form C Relay

Normal Open

Normal Close

Com

OME-PIO-

OME-DB-24RD

D56/PIO-D24

Note:

Channel : 24 Form C Relay

Relay: Switch up to 0.5A at 110ACV

or 1A at 24DCV

OME-DB-24RD

50-pin flat-cable header Yes

D-sub 37-pin header Yes

OME-DB-24R, OME-DB-24RD 24*Relay (120V, 0.5A)

OME-DB-24PR,OME-DB-24PRD 24* Power Relay (250V, 5A)

OME-DB-24POR 24*photo MOS Relay (350V, 01.A)

OME-DB-24SSR 24*SSR (250VAC, 4A)

OME-DB-24C 24*O.C. (30V, 100 mA)

OME-DB-16P8R 16*Relay (120V, 0.5A) + 8*isolated input

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 21

Page 24

2.5.7 OME-DB-24PRD, OME-DB-24POR, OME-

DB-24C

OME-DB-24PRD 24*power relay, 5A/250V

OME-DB-24POR 24*photo MOS relay, 0.1A/350VAC

OME-DB-24C 24*open collector, 100mA per channel, 30V max.

The OME-DB-24PRD, a 24-channel power relay output board, consists of 8

form C and 16 form A electromechanical relays for efficient, programmable load

control. The contact of each relay can control a 5A load at 250ACV/30VDCV. The

relay is energized by applying a 5 volt signal to the appropriate relay channel on the

20-pin flat cable connector(using only 16 relays) or 50-pin flat cable

connector(OPTO-22 compatible for DIO-24 series). Twenty four enunciator LEDs

(one for each relay) light when their associated relay is activated. To avoid

overloading your PC’s power supply, this board needs a +12VDC or +24VDC

external power supply.

OME-PIO-

D56/PIO-D24

Normal Open

Form A Relay

Com

OME-DB-24PRD

D-Sub37

50-pin header

Note:

50-Pin connector (OPTO-22 compatible), for OME-DIO-24/48/44,

OME-PIO-D144/D96/D56/D48/D24

Channel: 16 Form A Relay, 8 Form C Relay

Relay: switches up to 5A at 110ACV / 5A at 30DCV

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 22

Page 25

2.5.8 Daughter Board Comparison Table

20-pin flat-cable 50-pin flat-cable D-sub 37-pin

OME-DB-37 No No Yes

OME-DN-37 No No Yes

OME-ADP-37/PCI No Yes Yes

OME-ADP-50/PCI No Yes No

OME-DB-24P No Yes No

OME-DB-24PD No Yes Yes

OME-DB-16P8R No Yes Yes

OME-DB-24R No Yes No

OME-DB-24RD No Yes Yes

OME-DB-24C Yes Yes Yes

OME-DB-24PR Yes Yes No

OME-DB-24PRD No Yes Yes

OME-DB-24POR Yes Yes Yes

OME-DB-24SSR No Yes Yes

Note: There is no 50-pin flat cable header on OME-PIO-D56/OME-PIO-D24. The

OME-PIO-D56/OME-PIO-D24 has one D-Sub 37 connector and two 20 pin flat-cable

headers (only for OME-PIO-D56).

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 23

Page 26

2.6 Pin Assignment

CON3: 37 pin of D-type female connector.

Pin Number Description Pin Number Description

1 N.C. 20 VCC

2 N.C. 21 GND

3 P1B7 22 P2C7

4 P1B6 23 P2C6

5 P1B5 24 P2C5

6 P1B4 25 P2C4

7 P1B3 26 P2C3

8 P1B2 27 P2C2

9 P1B1 28 P2C1

10 P1B0 29 P2C0

11 GND 30 P0A7

12 N.C. 31 P0A6

13 GND 32 P0A5

14 N.C. 33 P0A4

15 GND 34 P0A3

16 N.C. 35 P0A2

17 GND 36 P0A1

18 VCC 37 P0A0

19 GND XXXXXXX This pin not available

All signals are TTL compatible.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 24

Page 27

CON2 : 20-pin header (only for OME-PIO-D56)

Pin Number Description Pin Number Description

1 DI0 2 DI1

3 DI2 4 DI3

5 DI4 6 DI5

7 DI6 8 DI7

9 DI8 10 DI9

11 DI10 12 DI11

13 DI12 14 DI13

15 DI14 16 DI15

17 GND 18 GND

19 Vcc 20 +12V

CON1 : 20-pin header (only for OME-PIO-D56)

Pin Number Description Pin Number Description

1 DO0 2 DO1

3 DO2 4 DO3

5 DO4 6 DO5

7 DO6 8 DO7

9 DO8 10 DO9

11 DO10 12 DO11

13 DO12 14 DO13

15 DO14 16 DO15

17 GND 18 GND

19 Vcc 20 +12V

All signals are TTL compatible.

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 25

Page 28

3. I/O Control Register

OME-PIO-D24

< REV 1.0 ~ REV 5.0 > : < REV 6.0 or above > :

• Vendor ID = 0xE159 • Vendor ID = 0xE159

• Device ID = 0x0002 • Device ID = 0x0001

• Sub-vendor ID = 0x80 • Sub-vendor ID = 0xC080

• Sub-device ID = 0x01 • Sub-device ID = 0x01

• Sub-aux ID = 0x40 • Sub-aux ID = 0x40

OME-PIO-D56

< REV 1.0 ~ REV 4.0 > : < REV 5.0 or above > :

• Vendor ID = 0xE159 • Vendor ID = 0xE159

• Device ID = 0x0002 • Device ID = 0x0001

• Sub-vendor ID = 0x80 • Sub-vendor ID = 0xC080

• Sub-device ID = 0x01 • Sub-device ID = 0x01

• Sub-aux ID = 0x40 • Sub-aux ID = 0x40

3.1 How to Find the I/O Address

The plug & play BIOS will assign a proper I/O address to every OME-PIO/PISO

series card in the power-up stage. The IDs of the cards are given below:

• Vendor ID = 0xE159 (0xE159 for Rev 6.0 or above)

• Device ID = 0x0002 (0x0001 for Rev 6.0 or above)

The sub IDs of OME-PIO-D56/OME-PIO-D24 are given as follows:

• Sub-vendor ID= 0x80 (0xC080 for Rev 6.0 or above)

• Sub-device ID = 0x01

• Sub-aux ID = 0x40

We provide all the following necessary functions:

1. PIO_DriverInit(&wBoard, wSubVendor, wSubDevice, wSubAux)

2. PIO_GetConfigAddressSpace(wBoardNo,*wBase,*wIrq, *wSubVendor,

*wSubDevice, *wSubAux, *wSlotBus, *wSlotDevice)

3. Show_PIO_PISO(wSubVendor, wSubDevice, wSubAux)

All functions are defined in PIO.H. Refer to Chapter 4 for more information. The

important driver information is given as follows:

1. Resource-allocated information:

• wBase : BASE address mapping in this PC

• wIrq: IRQ channel number allocated in this PC

2. PIO/PISO identification information:

• wSubVendor: subVendor ID of this board

• wSubDevice: subDevice ID of this board

• wSubAux: subAux ID of this board

3. PC’s physical slot information:

• wSlotBus: hardware slot ID1 in this PC’s slot position

• wSlotDevice: hardware slot ID2 in this PC’s slot position

The utility program, PIO_PISO.EXE, will detect & show all OME-

PIO/PISO cards installed in this PC. Refer to Sec. 4.1 for more information.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 26

Page 29

3.1.1 PIO_DriverInit

PIO_DriverInit(&wBoards, wSubVendor,wSubDevice,wSubAux)

• wBoards=0 to N Æ number of boards found in this PC

• wSubVendor Æ subVendor ID of board to find

• wSubDevice Æ subDevice ID of board to find

• wSubAux Æ subAux ID of board to find

This function can detect all OME-PIO/PISO series card in the system. It is

implemented based on the PCI plug & play mechanism. It will find all OME-

PIO/PISO series cards installed in this system & save all their resource information in

the library.

Sample program 1: find all OME-PIO-D56/OME-PIO-D24 in the PC

wSubVendor=0x80; wSubDevice=1; wSubAux=0x40; /* for OME-PIO-

D56/D24 */

wRetVal=PIO_DriverInit(&wBoards, wSubVendor,wSubDevice,wSubAux);

printf("Threr are %d OME-PIO-D56/OME-PIO-D24 Cards in this PC\n",wBoards);

/* step2: save resources of all OME-PIO-D56/OME-PIO-D24 cards installed in

this PC */

for (i=0; i<wBoards; i++)

{

PIO_GetConfigAddressSpace(i,&wBase,&wIrq,&wID1,&wID2,&wID3,

&wID4,&wID5);

printf("\nCard_%d: wBase=%x, wIrq=%x", i,wBase,wIrq);

wConfigSpace[i][0]=wBaseAddress; /* save all resource of this card */

wConfigSpace[i][1]=wIrq; /* save all resource of this card */

}

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 27

Page 30

Sample program 2: find all OME-PIO/PISO in this PC (refer to Sec. 4.1 for more

information)

wRetVal=PIO_DriverInit(&wBoards,0xff,0xff,0xff); /*find all PIO_PISO*/

printf("\nThrer are %d PIO_PISO Cards in this PC",wBoards);

if (wBoards==0 ) exit(0);

printf("\n-----------------------------------------------------");

for(i=0; i<wBoards; i++)

{

PIO_GetConfigAddressSpace(i,&wBase,&wIrq,&wSubVendor,

&wSubDevice,&wSubAux,&wSlotBus,&wSlotDevice);

printf("\nCard_%d:wBase=%x,wIrq=%x,subID=[%x,%x,%x],

SlotID=[%x,%x]",i,wBase,wIrq,wSubVendor,wSubDevice,

wSubAux,wSlotBus,wSlotDevice);

printf(" --> ");

ShowPioPiso(wSubVendor,wSubDevice,wSubAux);

}

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 28

Page 31

The sub-IDs of OME-PIO/PISO series card are given as following:

OME-PIO/PISO series card Description Sub_vendor Sub_device Sub_AUX

OME-PIO-D144 (Rev 4.0) 144 * D/I/O 5C80 01 00

OME-PIO-D96 (Rev 4.0) 96 * D/I/O 5880 01 10

OME-PIO-D64 (Rev 2.0) 64 * D/I/O 4080 01 20

OME-PIO-D56 (Rev 6.0) 24* D/I/O +

C080 01 40

16*D/I + 16*D/O

OME-PIO-D48 (Rev 2.0) 48*D/I/O 0080 01 30

OME-PIO-D24 (Rev 6.0) 24*D/I/O C080 01 40

OME-PIO-821 Multi-function 80 03 10

OME-PIO-DA16 (Rev 4.0) 16*D/A 4180 00 00

OME-PIO-DA8 (Rev 4.0) 8*D/A 4180 00 00

OME-PIO-DA4 (Rev 4.0) 4*D/A 4180 00 00

OME-PISO-C64 (Rev 4.0) 64 * isolated D/O

0280 00 00

(Current Sinking)

OME-PISO-A64 (Rev 3.0) 64 * isolated D/O

0280 00 50

(Current Sourcing)

OME-PISO-P64 (Rev 4.0) 64 * isolated D/I 0280 00 10

OME-PISO-P32C32

(Rev 5.0)

32 * isolated D/O

(Current Sinking)

80 08 20

+32 * isolated D/I

OME-PISO-P32A32

(Rev 3.0)

32 * isolated D/O

(Current Sourcing)

8280 00 70

+32 * isolated D/I

OME-PISO-P8R8

(Rev 2.0)

OME-PISO-P8SSR8AC

(Rev 2.0)

OME-PISO-P8SSR8DC

(Rev 2.0)

OME-PISO-730 (Rev 2.0) 16*DI + 16*D/O +

8* isolated D/I +

8 * 220V relay

8* isolated D/I +

8 * SSR /AC

8* isolated D/I +

8 * SSR /DC

4200 00 30

4200 00 30

4200 00 30

C2FF 00 40

16* isolated D/I +

16* isolated D/O

(Current Sinking)

OME-PISO-730A

(Rev 3.0)

16*DI + 16*D/O +

16* isolated D/I +

62FF 00 80

16* isolated D/O

(Current Sourcing)

OME-PISO-813 (Rev 2.0) 32 * isolated A/D 4280 02 00

OME-PISO-DA2 (Rev 5.0) 2 * isolated D/A 4280 03 00

Note: If your board is a different version, it may also have different sub IDs. We

offer the same function calls irrespective of the board version.

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 29

Page 32

3.1.2 PIO_GetConfigAddressSpace

PIO_GetConfigAddressSpace(wBoardNo,*wBase,*wIrq, *wSubVendor,

*wSubDevice,*wSubAux,*wSlotBus, *wSlotDevice)

• wBoardNo=0 to N Æ totally N+1 boards found by PIO_DriveInit(….)

• wBase Æ base address of the board control word

• wIrq Æ allocated IRQ channel number of this board

• wSubVendor Æ subVendor ID of this board

• wSubDevice Æ subDevice ID of this board

• wSubAux Æ subAux ID of this board

• wSlotBus Æ hardware slot ID1 of this board

• wSlotDevice Æ hardware slot ID2 of this board

The user can use this function to save resource of all OME-PIO/PISO cards

installed in this system. Then the application program can control all functions of

OME-PIO/PISO series card directly. The sample program is given as follows:

/* step1: detect all OME-PIO-D56/OME-PIO-D24 cards first */

wSubVendor=0x80; wSubDevice=1; wSubAux=0x40; /* for OME-PIO-

D56/D24 */

wRetVal=PIO_DriverInit(&wBoards, wSubVendor,wSubDevice,wSubAux);

printf("There are %d OME-PIO-D56/OME-PIO-D24 Cards in this PC\n",wBoards);

/* step2: save resource of all OME-PIO-D56/OME-PIO-D24 cards installed in this

PC */

for (i=0; i<wBoards; i++)

{

PIO_GetConfigAddressSpace(i,&wBase,&wIrq,&t1,&t2,&t3,&t4,&t5);

printf("\nCard_%d: wBase=%x, wIrq=%x", i,wBase,wIrq);

wConfigSpace[i][0]=wBaseAddress; /* save all resource of this card */

wConfigSpace[i][1]=wIrq; /* save all resource of this card */

}

/* step3: control the OME-PIO-D56/OME-PIO-D24 directly */

wBase=wConfigSpace[0][0];/* get base address the card_0 */

outport(wBase,1); /* enable all D/I/O operations of card_0 */

wBase=wConfigSpace[1][0];/* get base address the card_1 */

outport(wBase,1); /* enable all D/I/O operations of card_1 */

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 30

Page 33

3.1.3 Show_PIO_PISO

Show_PIO_PISO(wSubVendor,wSubDevice,wSubAux)

• wSubVendor Æ subVendor ID of board to find

• wSubDevice Æ subDevice ID of board to find

• wSubAux Æ subAux ID of board to find

This function will output a text string for this special subIDs. This text string is the

same as that defined in PIO.H

The demo program is given as follows:

wRetVal=PIO_DriverInit(&wBoards,0xff,0xff,0xff); /*find all PIO_PISO*/

printf("\nThrer are %d PIO_PISO Cards in this PC",wBoards);

if (wBoards==0 ) exit(0);

printf("\n-----------------------------------------------------");

for(i=0; i<wBoards; i++)

{

PIO_GetConfigAddressSpace(i,&wBase,&wIrq,&wSubVendor,

&wSubDevice,&wSubAux,&wSlotBus,&wSlotDevice);

printf("\nCard_%d:wBase=%x,wIrq=%x,subID=[%x,%x,%x],

SlotID=[%x,%x]",i,wBase,wIrq,wSubVendor,wSubDevice,

wSubAux,wSlotBus,wSlotDevice);

printf(" --> ");

ShowPioPiso(wSubVendor,wSubDevice,wSubAux);

}

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 31

Page 34

3.2 The Assignment of I/O Address

The plug & play BIOS will assign the proper I/O address to the OME-

PIO/PISO series card. If there is only one OME-PIO/PISO board, the user can

identify the board as card_0. If there are two PIO/PISO boards in the system, the

user will be very difficult to identify which board is card_0? The software driver can

support 16 boards max. Therefore the user can install 16 boards of PIO/PSIO series

in one PC system. How to find the card_0 & card_1?

The simplest way to identify which card is card_0 is to use wSlotBus &

wSlotDevice as follows :

1. Remove all OME-PIO-D56/OME-PIO-D24 from this PC

2. Install one OME-PIO-D56/OME-PIO-D24 into the PC’s PCI_slot1, run

PIO_PISO.EXE & record the wSlotBus1 & wSlotDevice1

3. Remove all OME-PIO-D56/OME-PIO-D24 from this PC

4. Install one OME-PIO-D56/D24 into the PC’s PCI_slot2, run PIO_PISO.EXE &

record the wSlotBus2 & wSlotDevice2

5. Repeat (3) & (4) for all PCI_slot?, record all wSlotBus? & wSlotDevice?

The records may be as follows:

PC’s PCI slot wSlotBus wSlotDevice

Slot_1 0 0x07

Slot_2 0 0x08

Slot_3 0 0x09

Slot_4 0 0x0A

PCI-BRIDGE

Slot_5 1 0x0A

Slot_6 1 0x08

Slot_7 1 0x09

Slot_8 1 0x07

The above procedure will record all wSlotBus? & wSlotDevice? in this PC. These

values will be mapped to this PC’s physical slot. This mapping will not be changed

for any PIO/PISO cards. So it can be used to identify the specified OME-PIO/PISO

card as follows:

Step 1: Record all wSlotBus? & wSlotDevice?

Step2: Use PIO_GetConfigAddressSpace(…) to get the specified card’s wSlotBus

& wSlotDevice

Step3: The user can identify the specified OME-PIO/PISO card if the compare

the wSlotBus & wSlotDevice in step2 to step1.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 32

Page 35

3.3 The I/O Address Map

The I/O address of OME-PIO/PISO series card is automatically

assigned by the main board ROM BIOS. The I/O address can also be re-

assigned by user. Users are strongly recommended to change the auto-

assigned I/O address. The plug & play BIOS will assign proper I/O

address to each OME-PIO/PISO series card very well. The I/O addresses

of OME-PIO-D56/OME-PIO-D24 are given as follows:

Address Read Write

Wbase+0 RESET\ control register Same

Wbase+2 Aux control register Same

Wbase+3 Aux data register Same

Wbase+5 INT mask control register Same

Wbase+7 Aux pin status register Same

Wbase+0x2a INT polarity control register Same

Wbase+0xc0 read Port0 write Port0

Wbase+0xc4 read Port1 write Port1

Wbase+0xc8 read Port2 write Port2

Wbase+0xcc read configuration Port0~Port2 configuration

Wbase+0xd0 read CON2 Low byte

(only for OME-PIO-D56)

Wbase+0xd4 read CON2 high byte

(only for OME-PIO-D56)

Note. Refer to Sec. 3.1 for more information about wBase.

write CON1 Low byte

(only for OME-PIO-D56)

write CON1 high byte

(only for OME-PIO-D56)

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 33

Page 36

3.3.1 RESET\ Control Register

(Read/Write): wBase+0

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reserved Reserved Reserved Reserved Reserved Reserved Reserved RESET\

Note. Refer to Sec. 3.1 for more information about wBase.

When the PC is first powered up, the RESET\ signal is in Low-state. This will

disable all D/I/O operations. The user has to set the RESET\ signal to High-state

before any D/I/O command.

outportb(wBase,1); /* RESET\=High Æ all D/I/O are enable now */

outportb(wBase,0); /* RESET\=Low Æ all D/I/O are disable now */

3.3.2 AUX Control Register

(Read/Write): wBase+2

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Aux7 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1 Aux0

Note. Refer to Sec. 3.1 for more information about wBase.

Aux?=0Æ this Aux is used as a D/I

Aux?=1Æ this Aux is used as a D/O

When the PC is first powered up, All Aux? signals are in Low-state. All Aux? are

designed as D/I for all OME-PIO/PISO series. Please set all Aux? in D/I state.

3.3.3 AUX data Register

(Read/Write): wBase+3

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Aux7 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1 Aux0

Note. Refer to Sec. 3.1 for more information about wBase.

When the Aux? is used as D/O, the output state is controlled by this register.

This register is designed and reserved for feature extension, so do not control this

register now.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 34

Page 37

3.3.4 INT Mask Control Register

(Read/Write): wBase+5

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 0 EN3 EN2 EN1 EN0

Note. Refer to Sec. 3.1 for more information about wBase.

EN0=0Æ disable PC0 as a interrupt signal (default)

EN0=1Æ enable PC0 as a interrupt signal

outportb(wBase+5,0); /* disable interrupt */

outportb(wBase+5,1); /* enable interrupt PC0 */

outportb(wBase+5,0x0f); /* enable interrupt PC0, PC1,PC2,PC3 */

3.3.5 Aux Status Register

(Read/Write): wBase+7

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Aux7 Aux6 Aux5 Aux4 Aux3 Aux2 Aux1 Aux0

Note. Refer to Sec. 3.1 for more information about wBase.

Aux0=PC0, Aux1=PC1, Aux2=PC2, Aux3=PC3, Aux7~4=Aux-ID. Refer to

DEMO5.C for more information. The Aux 0~3 are used as interrupt source. The

interrupt service routine has to read this register for interrupt source identification.

Refer to Sec. 2.5 for more information.

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 35

Page 38

3.3.6 Interrupt Polarity Control Register

(Read/Write): wBase+0x2A

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 0 INV3 INV2 INV1 INV0

Note. Refer to Sec. 3.1 for more information about wBase.

INV0=1Æ select the non-inverted signal from PC0

INV0=0Æ select the inverted signal from PC0

outportb(wBase+0x2a,0x0f); /* select the non-inverted input PC0/1/2/3 */

outportb(wBase+0x2a,0x00); /* select the inverted input of PC0/1/2/3 */

outportb(wBase+0x2a,0x0e); /* select the inverted input of PC0 */

/* select the non-inverted input PC1/2/3 */

outportb(wBase+0x2a,0x0c); /* select the inverted input of PC0/1 */

/* select the non-inverted input PC2/3 */

Refer to Sec. 2.4 for more information.

Refer to DEMO5.C for more information.

3.3.7 I/O Selection Control Register

(Write): wBase+0xcc

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 0 0 Port2 Port1 Port0

Note. Refer to Sec. 3.1 for more information about wBase.

Port? = 1Æ this port is used as a D/O port

Port? = 0Æ this port is used as a D/I port

outportb(wBase+0xcc,0x00); /* configure Port0/1/2 as D/I port */

outportb(wBase+0xcc,0x04); /* configure Port0/1 as D/I port */

/* configure Port2 as D/O port */

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 36

Page 39

3.3.8 Read/Write 8-bit data Register

(Read/Write):wBase+0xc0/0xc4/0xc8/0xd0/0xd4

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

Note. Refer to Sec. 3.1 for more information about wBase.

There are five/three 8-bit I/O ports in the OME-PIO-D56/OME-PIO-D24. Each

port is easy to read/write to by access to their own data registers.

outportb(wBase+0xc0,Val); /* write to D/O port */

Val=inportb(wBase+0xc0); /* read from D/I port */

outportb(wBase+0xcc,0x07); /* configure Port0~Port2 as DO port */

outportb(wBase+0xc0,i1); /* write to Port0 */

outportb(wBase+0xc0,i2); /* write to Port1 */

outportb(wBase+0xc0,i3); /* write to Port2 */

outportb(wBase+0xcc,0x01); /* configure Port0 as DO port */

/* Port1~Port2 as DI port */

outportb(wBase+0xc0,i1); /* write to Port0 */

j2=inportb(wBase+0xc4); /* read Port1 */

j3=inportb(wBase+0xc8); /* read Port2 */

l=inportb(wBase+0xd0); /* read CON2 Low byte */

h=inportb(wBase+0xd4); /* read CON2 High byte */

Val=(h<<8)+l; /* Val is 16 bit data */

outportb(wBase+0xd0,Val); /* write to CON1 Low byte */

outportb(wBase+0xd4,(Val>>8)); /* write to CON1 high byte */

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 37

Page 40

4. Demo program

It is recommended to read the release notes first. Important information will be given

in release note as follows:

1. Where you can find the software driver & utility?

2. How to install software & utility?

3. Where is the diagnostic program?

4. FAQs

There are many demo programs available on the software floppy disk or CD.

After the software installation, the driver will be installed into disk as follows:

• \TC\*.* Æ for Turbo C 2.xx or above

• \MSC\*.* Æ for MSC 5.xx or above

• \BC\*.* Æ for BC 3.xx or above

• \TC\LIB\*.* Æ for TC library

• \TC\DEMO\*.* Æ for TC demo program

• \TC\LIB\Large\*.* Æ TC large model library

• \TC\LIB\Huge\*.* Æ TC huge model library

• \TC\LIB\Large\PIO.H Æ TC declaration file

• \TC\\LIB\Large\TCPIO_L.LIB Æ TC large model library file

• \TC\LIB\Huge\PIO.H Æ TC declaration file

• \TC\\LIB\Huge\TCPIO_H.LIB Æ TC huge model library file

• \MSC\LIB\Large\PIO.H Æ MSC declaration file

• \MSC\LIB\Large\MSCPIO_L.LIB Æ MSC large model library file

• \MSC\LIB\Huge\PIO.H Æ MSC declaration file

• \MSC\\LIB\Huge\MSCPIO_H.LIB Æ MSC huge model library file

• \BC\LIB\Large\PIO.H Æ BC declaration file

• \BC\LIB\Large\BCPIO_L.LIB Æ BC large model library file

• \BC\LIB\Huge\PIO.H Æ BC declaration file

• \BC\\LIB\Huge\BCPIO_H.LIB Æ BC huge model library file

NOTE: The library is validated for all OME-PIO/PISO series cards.

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 38

Page 41

4.1 PIO_PISO

/* ------------------------------------------------------------ */

/* Find all PIO_PISO series cards in this PC system */

/* step 1 : plug all PIO_PISO cards into PC */

/* step 2 : run PIO_PISO.EXE */

/* ------------------------------------------------------------ */

#include "PIO.H"

WORD wBase,wIrq;

WORD wBase2,wIrq2;

int main()

{

int i,j,j1,j2,j3,j4,k,jj,dd,j11,j22,j33,j44;

WORD wBoards,wRetVal;

WORD wSubVendor,wSubDevice,wSubAux,wSlotBus,wSlotDevice;

char c;

float ok,err;

clrscr();

wRetVal=PIO_DriverInit(&wBoards,0xff,0xff,0xff); /*for PIO-PISO*/

printf("\nThrer are %d PIO_PISO Cards in this PC",wBoards);

if (wBoards==0 ) exit(0);

printf("\n-----------------------------------------------------");

for(i=0; i<wBoards; i++)

{

PIO_GetConfigAddressSpace(i,&wBase,&wIrq,&wSubVendor,

&wSubDevice,&wSubAux,&wSlotBus,&wSlotDevice);

printf("\nCard_%d:wBase=%x,wIrq=%x,subID=[%x,%x,%x],

SlotID=[%x,%x]",i,wBase,wIrq,wSubVendor,wSubDevice,

wSubAux,wSlotBus,wSlotDevice);

printf(" --> ");

ShowPioPiso(wSubVendor,wSubDevice,wSubAux);

}

PIO_DriverClose();

}

NOTE: the PIO_PISO.EXE is valid for all PIO/PISO cards. The user can execute

the PIO_PISO.EXE to get the following information:

• List all PIO/PISO cards installed in this PC

• List all resources allocated to every PIO/PISO cards

• List the wSlotBus & wSlotDevice for specified PIO/PISO card identification.

(Refer to Sec. 3.2 for more information)

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 39

Page 42

4.1.1 PIO_PISO.EXE for Windows

User can find this utility in the company CD or floppy disk. It is useful for all

OME-PIO/PISO series card.

After executing the utility, detailed information for all OME-PIO/PISO cards that

installed in the PC will be show as follows:

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 40

Page 43

4.2 DEMO1

/* demo 1 : D/O demo of CON3 */

/* step 1 : connect a OME-DB-24C to CON3 of OME-PIO-D56/D24 */

/* step 2 : run DEMO1.EXE */

/* step 3 : LEDs of OME-DB-24C will turn on sequentially */

/* -------------------------------------------------------------- */

#include "PIO.H"

WORD wBase,wIrq;

int main()

{

int i1,i2,i3;

long i;

WORD wBoards,wRetVal,t1,t2,t3,t4,t5,t6;

WORD wSubVendor,wSubDevice,wSubAux,wSlotBus,wSlotDevice;

char c;

clrscr();

/* step1 : find address-mapping of PIO/PISO cards */

wRetVal=PIO_DriverInit(&wBoards,0x80,0x01,0x40);/* for OME-PIOD56/D24*/

printf("\n(1) Threr are %d OME-PIO-D56/D24 Cards in this PC",wBoards);

if ( wBoards==0 ) exit(0);

printf("\n\n-------------- The Configuration Space --------------");

for(i=0;i<wBoards;i++)

{

PIO_GetConfigAddressSpace(i,&wBase,&wIrq,&wSubVendor,

&wSubDevice,&wSubAux,&wSlotBus,&wSlotDevice);

printf("\nCard_%d:wBase=%x,wIrq=%x,subID=[%x,%x,%x],SlotID=

[%x,%x]",i,wBase,wIrq,wSubVendor,wSubDevice,

wSubAux,wSlotBus,wSlotDevice);

printf(" --> ");

ShowPioPiso(wSubVendor,wSubDevice,wSubAux);

}

PIO_GetConfigAddressSpace(0,&wBase,&wIrq,&t1,&t2,&t3,&t4,&t5);

/* select card_0 */

/* step2 : enable all D/I/O port */

outportb(wBase,1); /* /RESET -> 1 */

/* step3 : configure I/O direction */

outportb(wBase+0xcc,0x07); /* set CON3 as D/O ports */

i=1;

for (;;)

{

i1=i&0xff;

i2=(i>>8)&0xff;

i3=(i>>16)&0xff;

outportb(wBase+0xc0,i1);

outportb(wBase+0xc4,i2);

outportb(wBase+0xc8,i3);

delay(10000);

i=i<<1;

i=i&0x0ffffff;

if (i==0) i=1;

if (kbhit()!=0) break;

}

PIO_DriverClose();

}

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 41

Page 44

4.3 DEMO2

/* demo 2 : DI/O demo of CON1, CON2 & CON3 */

/* step 1 : connect OME-DB-24P to CON3 of OME-PIO-D56/D24 */

/* : connect CON1 t0 CON2 of OME-PIO-D56 */

/* step 2 : run DEMO2.EXE */

/* step 3 : check the information on screen D/I will same as D/O */

/* : check the result on screen will same as CON3 input */

/* -------------------------------------------------------------- */

#include "PIO.H"

WORD wBase,wIrq;

int main()

{

int i1,i2,i3,j1,j2,j3;

WORD wBoards,wRetVal,t1,t2,t3,t4,t5,t6;

WORD wSubVendor,wSubDevice,wSubAux,wSlotBus,wSlotDevice;

char c;

long i;

clrscr();

/* step1 : find address-mapping of PIO/PISO cards */

.

.

/* step2 : enable all D/I/O port */

outportb(wBase,1); /* /RESET -> 1 */

/* step3 : configure I/O direction */

outportb(wBase+0xcc,0x00); /* set CON3 as D/I ports */

i=1;

for (;;)

{

gotoxy(1,7);

i1=i&0xff;

i2=(i>>8)&0xff;

outportb(wBase+0xd0,i1);

outportb(wBase+0xd4,i2);

j1=inportb(wBase+0xd0);

j2=inportb(wBase+0xd4);

printf("\nDO = [%2x,%2x], DI = [%2x,%2x]",i2,i1,j2,j1);

if ((j1!=i1)||(j2!=i2))

{

printf("\n\nError ......");

}

else printf("\nO.K. ......");

j1=inportb(wBase+0xc0);

j2=inportb(wBase+0xc4);

j3=inportb(wBase+0xc8);

printf("\n\nD/I of CON3 [PA, PB, PC] = [%2x,%2x,%2x] ",j1,j2,j3);

i=i<<1;

i=i&0x0ffff;

if (i==0) i=1;

if (kbhit()!=0) return;

}

PIO_DriverClose();

}

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 42

Page 45

4.4 DEMO3

/* demo 3 : Count high pulse of PC0 */

/* (initial Low & active High) */

/* step 1 : run DEMO3.EXE */

/* -------------------------------------------------------------- */

#include "PIO.H"

#define A1_8259 0x20

#define A2_8259 0xA0

#define EOI 0x20

WORD init_low();

WORD wBase,wIrq;

static void interrupt irq_service();

int COUNT,irqmask,now_int_state;

int main()

{

int i,j;

WORD wBoards,wRetVal,t1,t2,t3,t4,t5,t6;

WORD wSubVendor,wSubDevice,wSubAux,wSlotBus,wSlotDevice;

char c;

clrscr();

/* step1 : find address-mapping of PIO/PISO cards */

.

.

/* select card_0 */

/* step2 : enable all D/I/O port */

outportb(wBase,1); /* /RESET -> 1 */

/* step3 : configure I/O direction */

outportb(wBase+0xcc,0x00); /* set CON3 as D/I ports */

COUNT=0;

init_low();

printf("\n\n***** show the count of High_pulse *****\n");

for (;;)

{

gotoxy(1,8);

printf("\nCOUNT=%d",COUNT);

if (kbhit()!=0) break;

}

outportb(wBase+5,0); /* disable all interrupt */

PIO_DriverClose();

}

/* Use PC0 as external interrupt signal */

WORD init_low()

{

disable();

outportb(wBase+5,0); /* disable all interrupt */

if (wIrq<8)

{

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 43

Page 46

irqmask=inportb(A1_8259+1);

outportb(A1_8259+1,irqmask & 0xff ^ (1<<wIrq));

setvect(wIrq+8,irq_service);

}

else

{

irqmask=inportb(A1_8259+1);

outportb(A1_8259+1,irqmask & 0xfb); /* IRQ2 */

irqmask=inportb(A2_8259+1);

outportb(A2_8259+1,irqmask & 0xff ^ (1<<(wIrq-8)));

setvect(wIrq-8+0x70,irq_service);

}

outportb(wBase+5,1); /* enable interrupt (PC0) */

now_int_state=0; /* now ini_signal is low */

outportb(wBase+0x2a,1); /* select the non-inverte */

enable();

}

void interrupt irq_service()

{

if (now_int_state==1) /* now PC0 change to low */

{ /* INT_CHAN_0 = !PC0 */

if ((inportb(wBase+7)&1)==0) /* PC0 still fixed in low */

{ /* need to generate a high pulse */

outportb(wBase+0x2a,1); /* INV0 select noninverted input */

now_int_state=0; /* now PC0=low */

}

else now_int_state=1; /* now PC0=High */

}

else /* now PC0 change to high */

{ /* INT_CHAN_0 = PC0 */

COUNT++;

if ((inportb(wBase+7)&1)==1) /* PC0 still fixed in high */

{ /* need to generate a high pulse */

outportb(wBase+0x2a,0); /* INV0 select inverted input */

now_int_state=1; /* now PC0=high */

}

else now_int_state=0; /* now PC0=low */

}

if (wIrq>=8) outportb(A2_8259,0x20);

outportb(A1_8259,0x20);

}

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 44

Page 47

4.5 DEMO4

/* demo 4 : Count high pulse of PC0 */

/* (initial High & active Low) */

/* step 1 : run DEMO4.EXE */

/* -------------------------------------------------------------- */

#include "PIO.H"

#define A1_8259 0x20

#define A2_8259 0xA0

#define EOI 0x20

WORD init_high();

WORD wBase,wIrq;

static void interrupt irq_service();

int COUNT,irqmask,now_int_state;

int main()

{

int i,j;

WORD wBoards,wRetVal,t1,t2,t3,t4,t5,t6;

WORD wSubVendor,wSubDevice,wSubAux,wSlotBus,wSlotDevice;

char c;

clrscr();

/* step1 : find address-mapping of PIO/PISO cards */

.

.

/* select card_0 */

/* step2 : enable all D/I/O port */

outportb(wBase,1); /* /RESET -> 1 */

/* step3 : configure I/O direction */

outportb(wBase+0xcc,0x00); /* set CON3 as D/I ports */

COUNT=0;

init_high();

printf("\n\n***** show the count of Low_pulse *****\n");

for (;;)

{

gotoxy(1,7);

printf("\nCOUNT=%d",COUNT);

if (kbhit()!=0) break;

}

outportb(wBase+5,0); /* disable all interrupt */

PIO_DriverClose();

}

/* Use PC0 as external interrupt signal */

WORD init_high()

{

disable();

outportb(wBase+5,0); /* disable all interrupt */

if (wIrq<8)

{

irqmask=inportb(A1_8259+1);

outportb(A1_8259+1,irqmask & 0xff ^ (1<<wIrq));

setvect(wIrq+8,irq_service);

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 45

Page 48

}

else

{

irqmask=inportb(A1_8259+1);

outportb(A1_8259+1,irqmask & 0xfb); /* IRQ2 */

irqmask=inportb(A2_8259+1);

outportb(A2_8259+1,irqmask & 0xff ^ (1<<(wIrq-8)));

setvect(wIrq-8+0x70,irq_service);

}

outportb(wBase+5,1); /* enable interrupt (PC0) */

now_int_state=1; /* now ini_signal is high */

outportb(wBase+0x2a,0); /* select the inverte */

enable();

}

void interrupt irq_service()

{

if (now_int_state==1) /* now PC0 change to low */

{ /* INT_CHAN_0 = !PC0 */

COUNT++;

if ((inportb(wBase+7)&1)==0) /* PC0 still fixed in low */

{ /* need to generate a high pulse */

outportb(wBase+0x2a,1); /* INV0 select noninverted input */

now_int_state=0; /* now PC0=low */

}

else now_int_state=1; /* now PC0=High */

}

else /* now PC0 change to high */

{ /* INT_CHAN_0 = PC0 */

if ((inportb(wBase+7)&1)==1) /* PC0 still fixed in high */

{ /* need to generate a high pulse */

outportb(wBase+0x2a,0); /* INV0 select inverted input */

now_int_state=1; /* now PC0=high */

}

else now_int_state=0; /* now PC0=low */

}

if (wIrq>=8) outportb(A2_8259,0x20);

outportb(A1_8259,0x20);

}

OME-PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 46

Page 49

4.6 DEMO5

/* demo 5 : Four interrupt source */

/* PC0 : initial Low , active High */

/* PC1 : initial High , active Low */

/* PC2 : initial Low , active High */

/* PC3 : initial High , active Low */

/* step 1 : run DEMO5.EXE */

/* -------------------------------------------------------------- */

#include "PIO.H"

#define A1_8259 0x20

#define A2_8259 0xA0

#define EOI 0x20

WORD init();

WORD wBase,wIrq;

static void interrupt irq_service();

int irqmask,now_int_state,new_int_state,invert,int_c,int_num;

int CNT_L1,CNT_L2,CNT_L3,CNT_L4;

int CNT_H1,CNT_H2,CNT_H3,CNT_H4;

int main()

{

int i,j;

WORD wBoards,wRetVal,t1,t2,t3,t4,t5,t6;

WORD wSubVendor,wSubDevice,wSubAux,wSlotBus,wSlotDevice;

char c;

clrscr();

/* step1 : find address-mapping of PIO/PISO cards */

.

.

/* select card_0 */

/* step2 : enable all D/I/O port */

outportb(wBase,1); /* /RESET -> 1 */

/* step3 : configure I/O direction */

outportb(wBase+0xcc,0x00); /* set CON3 as D/I ports */

init();

printf("\n***** show the count of pulse *****\n");

for (;;)

{

gotoxy(1,7);

printf("\n(CNT_L,CNT_H)=(%d,%d) (%d,%d) (%d,%d) (%d,%d)

%x",CNT_L1,CNT_H1,CNT_L2,CNT_H2,CNT_L3,CNT_H3,CNT_L4,CNT_H4,int_num);

if (kbhit()!=0) break;

}

outportb(wBase+5,0); /* disable all interrupt */

PIO_DriverClose();

}

/* Use PC0, PC1, PC2 & PC3 as external interrupt signal */

WORD init()

{

disable();

outportb(wBase+5,0); /* disable all interrupt */

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 47

Page 50

if (wIrq<8)

{

irqmask=inportb(A1_8259+1);

outportb(A1_8259+1,irqmask & 0xff ^ (1<<wIrq));

setvect(wIrq+8,irq_service);

}

else

{

irqmask=inportb(A1_8259+1);

outportb(A1_8259+1,irqmask & 0xfb); /* IRQ2 */

irqmask=inportb(A2_8259+1);

outportb(A2_8259+1,irqmask & 0xff ^ (1<<(wIrq-8)));

setvect(wIrq-8+0x70,irq_service);

}

invert=0x05;

outportb(wBase+0x2a,invert); /* PC0 = non-inverte input */

/* PC1 = inverte input */

/* PC2 = non-inverte input */

/* PC3 = inverte input */

now_int_state=0x0a; /* PC0 = Low */

/* PC1 = High */

/* PC2 = Low */

/* PC3 = High */

CNT_L1=CNT_L2=CNT_L3=CNT_L4=0; /* Low_pulse counter */

CNT_H1=CNT_H2=CNT_H3=CNT_H4=0; /* High_pulse counter */

int_num=0;

outportb(wBase+5,0x0f); /* enable interrupt PC0,PC1 */

enable(); /* PC2,PC3 */

}

/* -------------------------------------------------------------- */

/* NOTE:1.The hold-time of INT_CHAN_0/1/2/3 must long enough */

/* 2.The ISR must read the interrupt status again to the */

/* active interrupt sources. */

/* 3.The INT_CHAN_0&INT_CHAN_1 can be active at the same time*/

/* -------------------------------------------------------------- */

void interrupt irq_service()

{

char c;

int_num++;

new_int_state=inportb(wBase+7)&0x0f; /* read all interrupt state */

int_c=new_int_state^now_int_state; /* compare which interrupt */

/* signal be change */

if ((int_c&0x1)!=0) /* INT_CHAN_0 is active */

{

if ((new_int_state&0x1)!=0)/* now PC0 is change to high */

{

CNT_H1++;

}

else /* now PC0 is change to low */

{

CNT_L1++;

}

invert=invert^1; /* to generate a high pulse */

}

if ((int_c&0x2)!=0) /* INT_CHAN_1 is active */

{

if ((new_int_state&0x2)!=0)/* now PC1 is change to high */

{

CNT_H2++;

}

PIO-D56/PIO-D24 User Manual (Ver.2.1, Oct/2003, PPH-005-21) ---- 48

Page 51

else /* now PC1 is change to low */

{

CNT_L2++;

}

invert=invert^2; /* to generate a high pulse */

}

if ((int_c&0x4)!=0) /* INT_CHAN_2 is active */

{

if ((new_int_state&0x4)!=0)/* now PC2 is change to high */

{

CNT_H3++;

}

else /* now PC2 is change to low */

{

CNT_L3++;

}

invert=invert^4; /* to generate a high pulse */

}

if ((int_c&0x8)!=0) /* INT_CHAN_3 is active */

{

if ((new_int_state&0x8)!=0)/* now PC3 is change to high */

{

CNT_H4++;

}

else /* now PC3 is change to low */

{

CNT_L4++;

}

invert=invert^8; /* to generate a high pulse */

}

now_int_state=new_int_state;

outportb(wBase+0x2a,invert);

if (wIrq>=8) outportb(A2_8259,0x20);

outportb(A1_8259,0x20);

}

OME-PIO-D56/OME-PIO-D24 User Manual (Ver.2.1, Oct/2003) ---- 49

Page 52

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY

RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-W

ARRANTY

REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 53

M4038/0104

Where Do I Find Everything I Need for

Process Measurement and Contr ol?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERA TURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DA TA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEA TERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENT AL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...