Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

OME-A822PG

ISA-Bus

Multi-Functional Board

Hardware Manual

Shop online at

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

OME-A-822PGH/PGL

Enhanced Multi-Function Card

Hardware Manual

OME-A-822PGL/PGH Hardware Manual ---- 1

Page 4

Tables of Contents

1. Introduction_________________________________________________________ 4

1.1 General Description __________________________________________________ 4

1.2 Features _____________________________________________________________ 4

1.3 Specifications _________________________________________________________ 5

1.3.1 Power Consumption : ________________________________________________________ 5

1.3.2 Analog Inputs ______________________________________________________________ 5

1.3.3 A/D Converter _____________________________________________________________ 5

1.3.4 DA Converter ______________________________________________________________ 6

1.3.5 Digital I/O_________________________________________________________________6

1.3.6 Interrupt Channel ___________________________________________________________ 6

1.3.7 Programmable Timer/Counter _________________________________________________ 7

1.3.8 Direct Memory Access Channel (DMA) _________________________________________ 7

1.4 Applications __________________________________________________________ 8

1.5 Product Check List ____________________________________________________ 8

2. Hardware Configuration ______________________________________________9

2.1 Board Layout_________________________________________________________ 9

2.2 I/O Base Address Setting ______________________________________________ 10

2.3 Jumper Settings______________________________________________________ 11

2.3.1 JP1 : D/A Internal Reference Voltage Selection___________________________________ 11

2.3.2 JP2 : D/A Int/Ext Ref Voltage Selection ________________________________________ 12

2.3.3 JP3 : Single-ended/Differential Selection________________________________________ 12

2.3.4 JP4 : A/D Trigger Source Selection ____________________________________________ 13

2.3.5 JP5 : Interrupt Level Selection ________________________________________________ 13

2.3.6 JP6 : User Timer/Counter Clock Input Selection __________________________________ 14

2.3.7 JP7 : DMA DACK Selection, JP8 : DMA DRQ Selection _____________________ 15

2.4 I/O Register Address__________________________________________________ 16

2.4.1 8254 Counter _____________________________________________________________ 17

2.4.2 A/D Input Buffer Register ___________________________________________________ 17

2.4.3 D/A Output Latch Register___________________________________________________ 18

2.4.4 D/I Input Buffer Register ____________________________________________________ 19

2.4.5 Clear Interrupt Request______________________________________________________ 19

2.4.6 A/D Gain Control Register ___________________________________________________ 20

2.4.7 A/D Multiplex Control Register _______________________________________________21

2.4.8 A/D Mode Control Register __________________________________________________ 22

OME-A-822PGL/PGH Hardware Manual ---- 2

Page 5

2.4.9 A/D Software Trigger Control Register _________________________________________ 23

2.4.10 D/O Output Latch Register __________________________________________________ 24

2.5 Digital I/O __________________________________________________________ 25

2.6 8254 Timer/Counter __________________________________________________ 26

2.7 A/D Conversion ______________________________________________________ 27

2.7.1 A/D conversion flow________________________________________________________ 28

2.7.2 A/D Conversion Trigger Modes _______________________________________________ 29

2.7.3 A/D Transfer Modes ________________________________________________________ 29

2.7.4 Using software trigger and polling transfer ______________________________________ 30

2.8 D/A Conversion ______________________________________________________ 31

2.9 Analog Input Signal Connection _________________________________________ 32

2.10 Using OME-DB-8225 CJC Output ______________________________________ 36

3. Connector _________________________________________________________ 37

3.1 CN1/CN2/CN3 Pin Assignment _________________________________________ 37

3.2 Daughter Board ________________________________________________________ 40

3.2.1 OME-DB-8225 ____________________________________________________________ 40

3.2.2 OME-DB-37 ______________________________________________________________ 40

3.2.3 OME-DB-16P_____________________________________________________________ 40

3.2.4 OME-DB-16R_____________________________________________________________ 40

4. Calibration___________________________________________________________ 41

4.1 Description of Variable Resistors ________________________________________ 41

4.2 D/A Calibration ______________________________________________________ 42

4.3 A/D Calibration ______________________________________________________ 43

5. Diagnostic Utility____________________________________________________ 44

5.1 Introduction _________________________________________________________ 44

5.2 Running The Diagnostic Utility _________________________________________ 46

5.2.1 Setup ____________________________________________________________________ 47

5.2.2 CALIBRATION ___________________________________________________________ 49

5.2.3 FUNCTION TEST _________________________________________________________ 50

5.2.4 SPECIAL TEST ___________________________________________________________ 58

5.2.5 Help ____________________________________________________________________ 59

OME-A-822PGL/PGH Hardware Manual ---- 3

Page 6

1. Introduction

1.1 General Description

The OME-A-822PGL/PGH is a high performance, multifunction analog, digital I/O

board for PC AT compatible computers. The OME-A-822PGL provides low gain (0.5,1, 2, 4,

8). The OME-A-822PGH provides high gain (0.5,1,5,10,50,100,500,1000). The

OME-A-822PGL/PGH contains a 12-bit ADC with up to 16 single-ended or 8 differential

analog inputs. The maximum sample rate of the A/D converter is 100Ksample/sec. There are

two 12-bit DACs with voltage output, 16 channels of TTL-compatible digital input, 16

channels of TTL-compatible digital output and one 16-bit counter/timer channel for timing

input and output.

The following A/D performance bench marks were achieved on a 33MHz 486

computer:

z Polling mode : about 100Ksample/sec (with single-task OS)

z Interrupt mode : about 60Ksample/sec (with single-task OS)

z DMA mode : about 100Ksample/sec (with single-task OS)

1.2 Features

z The maximum sample rate of the A/D converter is 100 K samples/sec

z Software selectable input ranges

z PC AT compatible ISA bus

z A/D trigger mode : software trigger , pacer trigger, external trigger

z 16 single-ended or 8 differential analog input signals

z Programmable high gain : 0.5,1,5,10,50,100,500,1000 (OME-A-822PGH)

z Programmable low gain : 0.5,1,2,4,8 (OME-A-822PGL)

z 2 channel 12-bit D/A voltage output

z 16 digital input /16 digital output (TTL compatible)

z Interrupt handling

z Bipolar/Unipolar operation

z 1 channel general purpose programmable 16 bit timer/counter

OME-A-822PGL/PGH Hardware Manual ---- 4

Page 7

1.3 Specifications

1.3.1 Power Consumption :

z +5V @960 mA maximum, OME-A-822PGL/PGH

z Operating temperature : -20°C to 60°C

1.3.2 Analog Inputs

z Channels : 16 single-ended or 8 differential

z Input range : (software programmable)

OME-A-822PGL:bipolar : ±10V,±5V, ±2.5V, ±1.25V, ±0.0625V

unipolar : 0 to 10V, 0 to 5V, 0 to 0.2.5V, 0 to 1.25.V

OME-A-822PGH:bipolar : ±10,±5V,±1V, ±0.5V, ±0.1V, ±0.05V, ±0.01V, ± 0.005V

unipolar : 0 to 10V, 0 to 1V, 0 to 0.1V, 0 to 0.01V

z Input current : 250 nA max (125 nA typical ) at 25 deg. C

z On chip sample and hold

z Over voltage : continuous single channel to

z Input impedance : 10 Ω // 6pF

10

70Vp-p

Caution: refer to

Sec. 2.9 first

1.3.3 A/D Converter

z Type : successive approximation , Burr Brown ADS 774 or SIPEX-SP774B

( equivalent)

z Conversion time : 8 microsec.

z Accuracy : +/- 1 bit

z Resolution : 12 bits

OME-A-822PGL/PGH Hardware Manual ---- 5

Page 8

1.3.4 DA Converter

z Channels : 2 independent

z type : 12 bit multiplying , Analog device AD-7541

z Linearity : +/- 1/2 bit

z Output range : 0 to 5V or 0 to 10V jumper selected , may be used with other

AC or DC reference input. Maximum output limit +/- 10V

z Output drive : +/- 5mA

z settling time : 0.6 microseconds to 0.01% for full scale step

1.3.5 Digital I/O

z Output port : 16 bits, TTL compatible

Output Low: VOL=05.Vmax @IOL = 8 mA max

Output High: VOH = 2.7Vmin @IOH = -400µA max

z Input port : 16 bits, TTL compatible

Input Low: VIL=0.8V max; IIL = -0.4mA max

Input High: VIH=2.0V min; IIL = 20µA max

1.3.6 Interrupt Channel

z Level : 3,4,5,6,7,10,11,12,14,15, jumper selectable

z Enable : Via control register

OME-A-822PGL/PGH Hardware Manual ---- 6

Page 9

1.3.7 Programmable Timer/Counter

z Type : 82C54 -8 programmable timer/counter

z Counters : Counter1 and counter2 are cascaded as a 32 bit pacer timer.

Counter0 is a user available timer/counter. The software driver also uses

counter0 to implement a machine independent timer.

z Clock input frequency : DC to 10 MHz

z Pacer output : 0.00047Hz to 0.5MHz

z Input ,gate : TTL compatible

z Internal Clock : 2 MHz

1.3.8 Direct Memory Access Channel (DMA)

z Level : CH1 or CH3, jumper selectable

z Enable : via DMA bit of control register

z Termination : by interrupt on T/C

z Transfer rate : 100K conversions/sec.

OME-A-822PGL/PGH Hardware Manual ---- 7

Page 10

1.4 Applications

z Signal analysis

z FFT & frequency analysis

z Transient analysis

z Production testing

z Process control

z Vibration analysis

z Energy management

z Industrial and laboratory. measurement and control

1.5 Product Check List

The OME-A-8322PGL/PGH includes the following items:

z OME-A-822PGL/PGH multifunction card

z OME-A-822PGL/PGH CD ROM

Attention !

If any of these items are missing or damaged, please contact our

customer service department. Save the shipping materials and carton

in case you want to ship or store the product in the future.

OME-A-822PGL/PGH Hardware Manual ---- 8

Page 11

2. Hardware Configuration

2.1 Board Layout

ISA BUS ISA BUS

JP5

SW1

CN2

JP4

CN1

JP1

OME-A-822PGL/PGH

VR1/2/3/4/5/6/7

JP8 JP7

OME-A-822PGL/PGH Hardware Manual ---- 9

JP6

CN3

JP3

JP2

Page 12

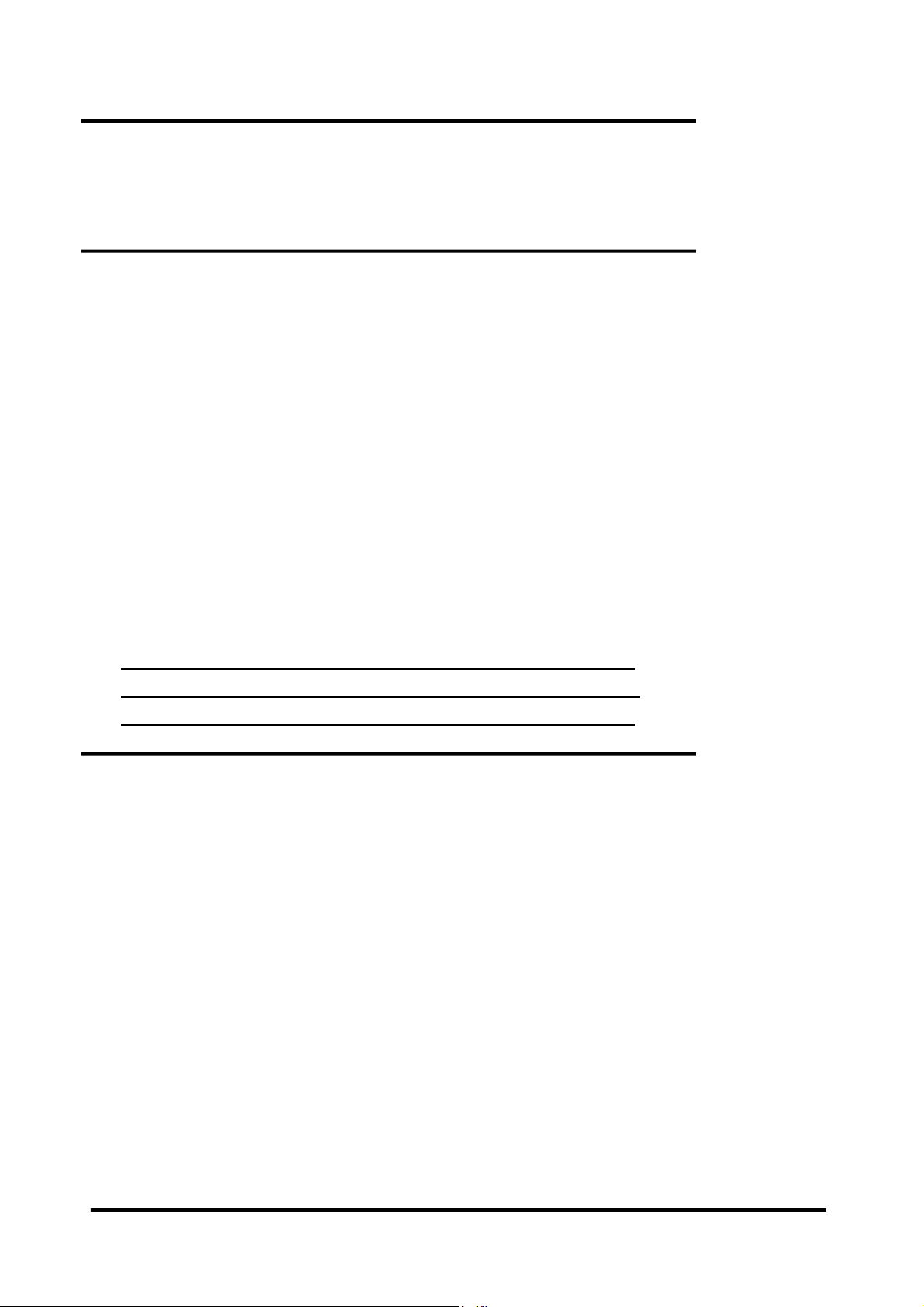

2.2 I/O Base Address Setting

The OME-A-822PGL/PGH occupies 16 consecutive locations in I/O address

space. The base address is set by DIP switch SW1. The default address is

0x220.

BASE

ADDR

200-20F OFF ON ON ON ON ON

210-21F OFF ON ON ON ON OFF

220-22F(;) OFF ON ON ON OFF ON

230-23F OFF ON ON ON OFF OFF

A9 A8 A7 A6 A5 A4

ON

6 5 4 3 2 1

SW1 : BASE ADDRESS

A9 A8 A7 A6 A5 A4

: : : : : : :

300-30F OFF OFF ON ON ON ON

: : : : : : :

3F0-3FF OFF OFF OFF OFF OFF

(;) : default base address is 0x220

OME-A-822PGL/PGH Hardware Manual ---- 10

Page 13

The PC I/O port map is given below.

(

(

)

ADDRESS Device ADDRESS DEVICE

000-1FF PC reserved 320-32F XT Hard Disk

200-20F Game/control 378-37F Parallel Printer

210-21F XT Expansion Unit 380-38F SDLC

238-23F Bus Mouse/Alt. Bus Mouse 3A0-3AF SDLC

278-27F Parallel Printer 3B0-3BF MDA/Parallel Printer

2B0-2DF EGA 3C0-3CF EGA

2E0-2E7 AT GPIB 3D0-3DF CGA

2E8-2EF Serial Port 3E8-3EF Serial Port

2F8-2FF Serial Port 3F0-3F7 Floppy Disk

300-31F Prototype Card 3F8-3FF Serial Port

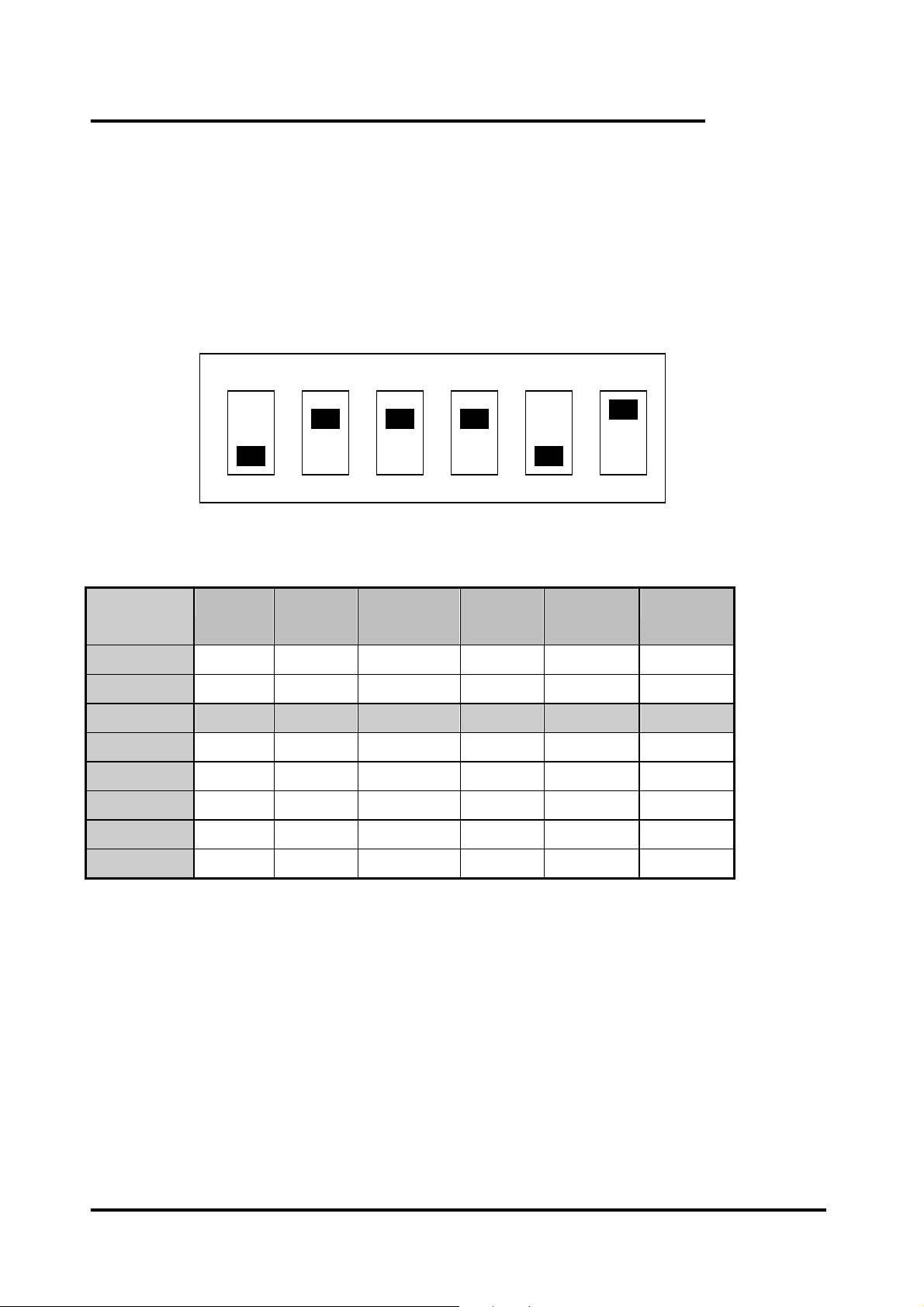

2.3 Jumper Settings

2.3.1 JP1 : D/A Internal Reference Voltage

Selection

1

2

3

-10V)

(-5V)

Reference

Voltage

-10V

Select (-5V) : D/A voltage output = 0 to 5V (both channel)

Reference

Voltage

-5V

(default)

-10V

1

2

3

(-5V)

Select (-10V) : D/A voltage output = 0 to 10V (both channel)

JP1 is valid only if JP2 is set to D/A internal reference voltage

OME-A-822PGL/PGH Hardware Manual ---- 11

Page 14

2.3.2 JP2 : D/A Int/Ext Ref Voltage Selection

If JP2 is set to internal reference, then JP1 should be set to -5V or -10V internal reference

Ch 1 = INT

Ch 2 = INT

(default)

Ch 1 = INT

Ch 2 =EXT

(ExtRef2)

JP2(vref)

JP2(vref)

Ch 1 =EXT

(ExtRef1)

Ch 2 =EXT

(ExtRef2)

Ch 1 =EXT

(ExtRef1)

Ch 2 = INT

JP2(vref)

JP2(vref)

voltage.

If JP2 is set to external reference, then ExtRef1, CN3 pin 31, is the external reference

voltage for D/A channel 1. and ExtRef2, CN3 pin 12, is the external reference voltage for

D/A Channel 2.

2.3.3 JP3 : Single-ended/Differential Selection

The OME-A-822PGL/PGH offers 16 single-ended or 8 differential analog input channels.

Single-ended

(default)

SINGLE

DIFF

Differential

SINGLE

DIFF

The JP3 jumper sets the inputs to single-ended or differential mode. You can not select

single-ended and differential simultaneously.

Refer to Sec. 2.9 first.

OME-A-822PGL/PGH Hardware Manual ---- 12

Page 15

2.3.4 JP4 : A/D Trigger Source Selection

The OME-A-822PGL/PGH supports two trigger types, internal trigger and

external trigger. The external trigger comes from ExtTrg, CN3 pin 17.

There are two types of internal triggers, software trigger and pacer trigger.

More detailed information is given in section 2.4.8.

Internal

Trigger

(default)

INTTRG

EXTTRG

External

Trigger

INTTRG

EXTTRG

2.3.5 JP5 : Interrupt Level Selection

NO Interrupt

Interrupt 15

(default)

The interrupt channel can not be shared. The OME-A-822 software driver can support

8 different cards in one system but only 2 of these cards can use the interrupt transfer

IRQ 3 4 5 6 7 9 10 11 12 14 15 NC

IRQ 3 4 5 6 7 9 10 11 12 14 15 NC

function.

OME-A-822PGL/PGH Hardware Manual ---- 13

Page 16

K

2.3.6 JP6 : User Timer/Counter Clock Input

Selection

The cascaded counter1 and counter2 are used as a pacer timer. Counter0 can

be used as a user programmable timer/counter. The user programmable

timer/counter can be set to 2M internal clock or external clock ExtCLK,

Internal 2M

Clock

(default)

The OME-A-822PGL/PGH has 3 independent 16 bit timer/counters.

INTCLK

EXTCLK

External

Clock

INTCL

EXTCLK

CN3 pin 37. The block diagram is given in section 2.6. The clock source must

be very stable. Using the 2M internal clock is strongly suggested.

The OME-A-822PGL/PGH software driver uses counter0 as a machine

independent timer. If users program calls the A-822_Delay() subroutine,

counter0 will be programmed as a machine independent timer. More detailed

information is provided in section 2.6.

NOTE : if you use A-822_Delay(), the JP6 jumper must

be set to internal 2M clock.

OME-A-822PGL/PGH Hardware Manual ---- 14

Page 17

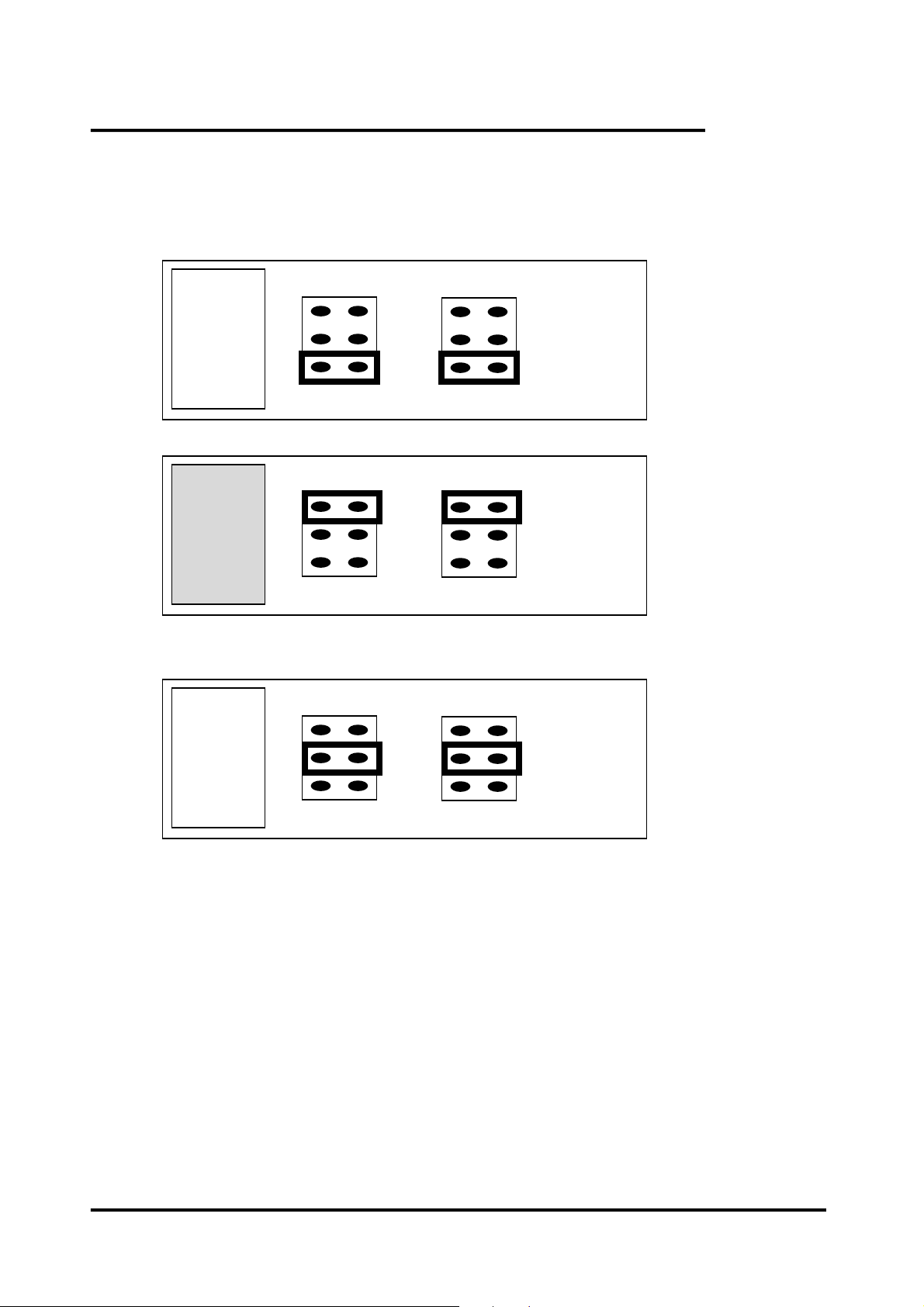

2.3.7 JP7 : DMA DACK Selection,

K

K

K

JP8 : DMA DRQ Selection

NO DMA

DMA 1

(default)

DRQ

1

5

JP7

DRQ

1

5

JP7

2

6

2

6

DAC

1

5

JP8

DAC

1

5

JP8

2

6

2

6

The DMA channel can not shared. The OME-A-822 software driver can support 8

different boards in one PC based system, but only two of these boards can use the DMA

transfer function.

DMA 3

DRQ

1

5

JP7

2

6

DAC

1

5

JP8

2

6

OME-A-822PGL/PGH Hardware Manual ---- 15

Page 18

2.4 I/O Register Address

The OME-A-822PGL/PGH occupies 16 consecutive PC I/O addresses. The

following table lists the registers and their locations.

Address Read Write

Base+0 8254 Counter 0 8254 Counter 0

Base+1 8254 Counter 1 8254 Counter 1

Base+2 8254 Counter 2 8254 Counter 2

Base+3 Reserved 8254 Counter Control

Base+4 A/D Low Byte D/A Channel 0 Low Byte

Base+5 A/D High Byte D/A Channel 0 High Byte

Base+6 DI Low Byte D/A Channel 1 Low Byte

Base+7 DI High Byte D/A Channel 1 High Byte

Base+8 Reserved A/D Clear Interrupt Request

Base+9 Reserved A/D Gain Control

Base+A Reserved A/D Multiplexer Control

Base+B Reserved A/D Mode Control

Base+C Reserved A/D Software Trigger Control

Base+D Reserved DO Low Byte

Base+E Reserved DO High Byte

Base+F Reserved Reserved

OME-A-822PGL/PGH Hardware Manual ---- 16

Page 19

2.4.1 8254 Counter

The 8254 Programmable timer/counter has 4 registers from Base+0 through

Base+3. For detailed programming information on the 8254 , please refer to

Intel‘s “Microsystem Components Handbook”.

Address Read Write

Base+0 8254 Counter 0 8254 Counter 0

Base+1 8254 Counter 1 8254 Counter 1

Base+2 8254 Counter 2 8254 Counter 2

Base+3 Reserved 8254 Counter Control

2.4.2 A/D Input Buffer Register

(READ) Base+4 : A/D Low Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

(READ) Base+5 : A/D High Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 READY D11 D10 D9 D8

A/D 12 bit data : D11…..D0, D11=MSB, D0=LSB

READY =1 : A/D 12 bit data not ready

=0 : A/D 12 bit data is ready

The low 8 bit A/D data is stored in address BASE+4 and the high 4 bit data is stored in

address BASE+5. The READY bit is used as an indicator for the A/D conversion. When an

A/D conversion is completed, the READY bit will clear to zero.

OME-A-822PGL/PGH Hardware Manual ---- 17

Page 20

2.4.3 D/A Output Latch Register

(WRITE) Base+4 : Channel 1 D/A Low Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

(WRITE) Base+5 :Channel 1 D/A High Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X D11 D10 D9 D8

(WRITE) Base+6 : Channel 2 D/A Low Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

(WRITE) Base+7 :Channel 2 D/A High Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X D11 D10 D9 D8

D/A 12 bit output data: D11..D0, D11=MSB, D0=LSB, X=don‘t care

The D/A converter will convert the 12 bit digital data to an analog output. The lower 8 bits

of D/A channel 1 are stored in the address BASE+4 and the high 4 bits are stored in the

address BASE+5. The address BASE+6 and BASE+7 store the 12 bit data for D/A channel

2. The D/A output latch registers are designed with a “double buffered” structure, so the

analog output latch registers will not update until the high 4 bit digital data are written. If the

user sends the high 4 bit data first, the D/A 12 bit output latch registers will update at once.

So the lower 8 bits will be the previous data latched in the register. This action will cause

an error on the D/A output voltage. The user must send the low 8 bits first and then

send the high 4 bits to update the 12 bit D/A output latch register.

NOTE : Send the low 8 bits first, then send the high 4 bits.

OME-A-822PGL/PGH Hardware Manual ---- 18

Page 21

2.4.4 D/I Input Buffer Register

(READ) Base+6 : D/I Input Buffer Low Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

(READ) Base+7 : D/I Input Buffer High Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D15 D14 D13 D12 D11 D10 D9 D8

D/I 16 bits input data : D15..D0, D15=MSB, D0=LSB

The OME-A-822PGL/PGH provides 16 TTL compatible digital inputs. The low 8 bits are

stored in the address BASE+6. The high 8 bits are stored in address BASE+7.

2.4.5 Clear Interrupt Request

(WRITE) Base+8 : Clear Interrupt Request Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X X X X X

X=don‘t care, XXXXXXXX=any 8 bits data is validate

If the OME-A-822PGL/PGH is used in the interrupt transfer mode, an on-board hardware

status bit will be set after each A/D conversion. This bit must be cleared by software before

the next hardware interrupt. Writing any value to address BASE+8 will clear this hardware

bit and the hardware will generate another interrupt when next A/D conversion is completed.

OME-A-822PGL/PGH Hardware Manual ---- 19

Page 22

2.4.6 A/D Gain Control Register

(WRITE) Base+9 : A/D Gain Control Register Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X GAIN3 GAIN2 GAIN1 GAIN0

The only difference between the OME-A-822PGL and OME-A-822PGH is the GAIN

control function. The OME-A-822PGL provides gains of 1/2/4/8 and the

OME-A-822PGH provides gains of 1/10/100/1000. The gain control register control the

gain of the A/D input signal. Bipolar/Unipolar will affect the gain factor.

It is important to select the correct gain-control-code according to Bipolar/Unipolar input.

NOTE : If the gain control code is changed, the hardware needs an extra delay for

the gain settling time. The gain settling time is different for the different gain control codes.

The software driver does not take care the gain settling time, so the user needs to add

the delay . If the application program will run on different machines, the user needs to

implement a machine independent timer. The software driver, A-822_delay(), is designed for

this purpose. If this subroutine is used, then counter2 as described in sec 2.6 is reserved by

the software driver to implement the machine independent timer.

OME-A-822PGL GAIN CONTROL CODE TABLE

BI/UNI Settling Time GAIN Input Range GAIN3 GAIN2 GAIN1 GAIN0

BI 23 us 1 +/- 5V 0 0 0 0

BI 23 us 2 +/- 2.5V 0 0 0 1

BI 25 us 4 +/- 1.25V 0 0 1 0

BI 28 us 8 +/- 0.0625V 0 0 1 1

UNI 23 us 1 0V to 10V 0 1 0 0

UNI 23 us 2 0V to 5V 0 1 0 1

UNI 25 us 4 0V to 2.5V 0 1 1 0

UNI 28 us 8 0V to 1.25V 0 1 1 1

BI 23 us 0.5 +/- 10V 1 0 0 0

BI=Bipolar, UNI=Unipolar, X=don‘t care, N/A=not available

OME-A-822PGL/PGH Hardware Manual ---- 20

Page 23

OME-A-822PGH GAIN CONTROL CODE TABLE

BI/UN Settling Time GAIN Input Range GAIN3 GAIN2 GAIN1 GAIN0

BI 23 us 1 +/- 5V 0 0 0 0

BI 28 us 10 +/- 0.5V 0 0 0 1

BI 140 us 100 +/- 0.05V 0 0 1 0

BI 1300 us 1000 +/- 0.005V 0 0 1 1

UNI 23 us 1 0 to 10V 0 1 0 0

UNI 28 us 10 0 to 1V 0 1 0 1

UNI 140 us 100 0 to 0.1V 0 1 1 0

UNI 1300 us 1000 0 to 0.01V 0 1 1 1

BI 23 us 0.5 +/- 10V 1 0 0 0

BI 28 us 5 +/- 1V 1 0 0 1

BI 140 us 50 +/- 0.1V 1 0 1 0

BI 1300 us 500 +/- 0.01V 1 0 1 1

BI=Bipolar, UNI=Unipolar, X=don‘t care, N/A=not available

2.4.7 A/D Multiplex Control Register

(WRITE) Base+A : A/D Multilexer Control Register Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X D3 D2 D1 D0

A/D input channel selection data = 4 bits : D3..D0, D3=MSB, D0=LSB, X=don‘t care

Single-ended mode : D3..D0

Differential mode : D2..D0, D3=don’t care

The OME-A-822PGL/PGH provides 16 single-ended or 8 differential analog input signals.

In single-ended mode, D3..D0 selects the active channel. In differential mode, D2..D0 selects

the active channel and (D3 has no affect).

NOTE: The settling time of the multiplexer depends on the resistance.of the input

sources.

source resistance = about 0.1K ohm Æ settling time = about 3 us.

source resistance = about 1K ohm Æ settling time = about 5 us.

source resistance = about 10K ohm Æ settling time = about 10 us.

source resistance = about 100K ohm Æ settling time = about 100 us.

OME-A-822PGL/PGH Hardware Manual ---- 21

Page 24

2.4.8 A/D Mode Control Register

(WRITE) Base+B : A/D Mode Control Register Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X X D2 D1 D0

X=don‘t care

JP4 Select Internal Trigger

Mode Select Trigger Type Transfer Type

D2 D1 D0 Software Trig Pacer Trig Software Interrupt DMA

0 0 0 X X X X X

0 0 1 Select X Select X X

0 1 0 X Select X X Select

1 1 0 X Select Select Select X

X=disable

JP4 Select External Trigger

Mode Select Trigger Type Transfer Type

D2 D1 D0 External Trigger Software Interrupt DMA

0 0 0 X X X X

0 0 1 X X X X

0 1 0 Select X X Select

1 1 0 Select Select Select X

The A/D conversion can be divided into 2 stages, trigger stage and transfer stage

trigger stage will generate a trigger signal to the A/D converter and the transfer stage will

transfer the result to the CPU.

The trigger method may be internal trigger or external trigger. The internal trigger can

be software trigger or pacer trigger. The software trigger is simple to use but does not

control the sampling rate very precisely. In the software trigger mode, the program issues

a software trigger command (sec 2.4.9) to initiate the A/D conversion. The program then

must poll the A/D status bit until the ready bit is 0(sec 2.4.2).

. The

The pacer trigger can control the sample rate very precisely. In the pacer trigger

mode, the pacer timer (sec 2.6) will generate periodic trigger signals to the A/D converter.

The converted data can be transferred to the CPU by polling or interrupt or by DMA transfer.

OME-A-822PGL/PGH Hardware Manual ---- 22

Page 25

The software driver provides three data transfer methods, polling, interrupt and DMA.

The polling subroutine, A-822_AD_PollingVar() or A-822_AD_PollingArray(), set the A/D

mode control register to 0x01. This control word enables software trigger and polling

transfer. The interrupt subroutine, A-822_AD_INT_START(…), sets the A/D mode control

mode register to ox06. This control word enables pacer trigger and interrupt transfer. The

DMA subroutine, A-822_AD_DMA_START(…), sets the A/D mode control register to

0x02. This control word means pacer trigger and DMA transfer.

Please refer to sec. 2.7 for detailed information.

2.4.9 A/D Software Trigger Control Register

(WRITE) Base+C : A/D Software Trigger Control Register

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

X X X X X X X X

X=don‘t care, XXXXXXXX=any 8 bits data is validate

The A/D converter can be triggered by software trigger or pacer trigger. The details

are given in sec. 2.4.8 and sec. 2.7. Writing any value to address BASE+C will generate a

trigger pulse to the A/D converter and initiate an A/D conversion. The address BASE+5

offers a ready bit to indicate an A/D conversion is completed.

The software driver uses this control word to detect the OME-A-822PGL/PGH

hardware board. The software initiates a software trigger and checks the ready bit . If the

ready bit can not cleared to zero in a fixed time, the software driver will return a error

message. If there is an I/O BASE address error, the ready bit will not be cleared to zero. The

software driver, A-822_CheckAddress(), uses this method to detect the I/O BASE address

setting

OME-A-822PGL/PGH Hardware Manual ---- 23

Page 26

2.4.10 D/O Output Latch Register

(WRITE) Base+D : D/O Output Latch Low Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

(WRITE) Base+E : D/O Output Latch High Byte Data Format

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D15 D14 D13 D12 D11 D10 D9 D8

D/O 16 bits output data : D15..D0, D15=MSB, D0=LSB

The OME-A-822PGL/PGH provides 16 TTL compatible digital outputs. The lower 8 bits are

stored in address BASE+D. The high 8 bits are stored in address BASE+E

OME-A-822PGL/PGH Hardware Manual ---- 24

Page 27

2.5 Digital I/O

The OME-A-822PGL/PGH provides 16 digital input channels and 16

digital output channels. All levels are TTL compatible. The connection

diagram and block diagram are given below:

Base+D

D0..D7

Power on

reset

Base+E

Base+6

D0..D7

Output Latch Register

Latch

D0..D7

Reset

Reset

D8..D15

Latch

Output Latch Register

OME-A-822PGL/PGH

Input Buffer Register

Read

D0..D7

CN2

1..8

17..18

DGND

9..16

OME-A-822PGL/PGH

CN1

1..8

TTL

TTL

DI

DGND

External

Device

DO

Base+7

D8..D15

Read

Input Buffer Register

OME-A-822PGL/PGH Hardware Manual ---- 25

17..18

DGND

9..16

DGND

External

Device

Page 28

2.6 8254 Timer/Counter

The 8254 Programmable timer/counter has 4 registers from Base+0 through Base+3. For

detailed programming information about the 8254 , please refer to Intel‘s “Microsystem

Components Handbook”.The block diagram is shown below.

CN3.33

VCC

10K

CN3.37

Cin : clock input

Cout : clock output

INTCLK : internal clock

CN3 : connector CN3

4M 2M

INTCLK

JP6

2M

Gate

Cin

Counter 0

PACER CLK

Counter 1

Cin

Cin

Gate

Counter 2

Gate

Cout

Cout

Cout

CN3.16

CN3.35

VCC

10K

CN3.34

The counter0, counter1 and counter2 are all 16 bit counters. Counter 1 and counter 2 are

cascaded as a 32 bit timer. This 32 bit timer is used as a pacer timer. The software driver,

A-822_Delay(), uses counter 0 to implement a machine independent timer for settling

time delay (sec. 2.4.6 and sec. 2.4.7). If A-822_Delay() is not used, counter0 can be used as

a general purpose timer/counter.

NOTE : When using A-822_Delay() to implement a machine

independent timer, the JP6 jumper must be set to internal 2M

clock.

OME-A-822PGL/PGH Hardware Manual ---- 26

Page 29

2.7 A/D Conversion

This section explains how to perform A/D conversions. The A/D conversion

can be triggered 3 ways, by software trigger, by pacer trigger or by

external trigger to the A/D converter. At the end of A/D conversion, it is

possible to transfer data by 3 ways, those are polling , interrupt and DMA.

Before using the A/D conversion functions, the user should be aware of the

following issues:

z A/D data register BASE+4/BASE+5 stores the A/D conversion data (sec. 2.4.2)

z A/D gain control register BASE+9 selects the gain (sec. 2.4.6)

z A/D multiplexer control register BASE+A selects the analog input

channel (sec. 2.4.7)

z A/D mode control register BASE+B selects the trigger type and transfer

type (sec. 2.4.8)

z A/D software trigger control register is BASE+C (sec. 2.4.9)

z JP3 selects single-ended or differential input (sec. 2.3.3)

z JP4 selects internal/external trigger (sec. 2.3.4)

z JP5 selects the IRQ level (sec. 2.3.5)

z JP6 selects the internal/external clock for counter0 (sec. 2.3.6)

z JP7 and JP8 selects the DMA channel (sec. 2.3.7)

z There are 3 trigger types : software, pacer, external trigger (sec.

2.4.8)

z There are 3 transfer types : polling, interrupt, DMA (sec. 2.4.8)

The block diagram is given below:

CN3

16/8 to 1

Multi-

plexer

Base+A Base+9 Trigger

Gain

control

12 bits

A/D

Logic

Buffer

Logic

Memory

CPU Transfer

OME-A-822PGL/PGH

JP3 Base+C

OME-A-822PGL/PGH Hardware Manual ---- 27

Base+B JP4 JP5

JP7

JP8

Page 30

2.7.1 A/D conversion flow

Before using the A/D converter, the user should configure the following hardware settings:

1. select single-ended or differential input (JP3) (refer to Sec. 2.9 first)

2. select internal trigger or external trigger (JP4)

3. select IRQ level if needed (JP5)

4. select DMA channel if needed (JP7,JP8)

5. select internal clock or external clock for counter0 if needed (JP6)

The user must decide which A/D conversion mode will be used. The software driver

supports three different modes: polling, interrupt and DMA. The polling mode (sec. 2.4.9)

is the simplest but most limited. The software driver should be used for interrupt or DMA

mode.

The analog input signals come from CN3. These signals may be single-ended or

differential and must match the setting of JP3.

The multiplexer can select 16 single-ended or 8 differential signals into the gain control

module. The settling time of multiplexer depends on the source resistance. Because the

software doesn’t account for the settling time, the user should provide sufficient delay

when switching channels. (sec. 2.4.7)

The gain control module also requires settling time if the gain control code is changed.

Since the software doesn’t account for settling time, the user should provide sufficient

delay if the gain control code is changed. (sec. 2.4.6)

The software driver provides a machine independent timer, A-822_Delay(), for settling

time delay. This subroutine assumes that the JP6 jumper is set to the internal 2M clock and

uses counter0 to implement a machine independent timer. If A-822_Delay() is used,

counter0 will be reserved and can not be used as a user programmable timer/counter.

The A/D converter needs a trigger signal to start an A/D conversion cycle. The

OME-A-822PGL/PGH supports three trigger modes, software, pacer and external trigger.

The result of the A/D conversion can be transferred into the PC memory by three modes:

polling, interrupt and DMA..

OME-A-822PGL/PGH Hardware Manual ---- 28

Page 31

2.7.2 A/D Conversion Trigger Modes

OME-A-822PGL/PGH supports three trigger modes.

1 : Software Trigger :

Write any value to the A/D software trigger control register, BASE+A, to initiate an

A/D conversion cycle. This mode is very simple but it is very difficult to achieve a

precise sample rate.

2 : Pacer Trigger Mode :

The block diagram of the pacer timer is shown in section 2.6. The pacer timer can

provide a very precise sample rate.

3 : External Trigger Mode :

When a rising edge of an external trigger signal is applied, an A/D conversion will be

performed. The external trigger source comes from pin 17 of CN3.

2.7.3 A/D Transfer Modes

OME-A-822PGL/PGH supports three transfer modes.

1 : polling transfer :

This mode can be used with all trigger modes. More detailed information is given in

section 2.4.8. The software scans the A/D high byte data register, BASE+5, until

READY_BIT=0.The low byte data is available in BASE+4.

2 : interrupt transfer :

This mode can be used with the pacer trigger or external trigger. More detailed

information is given in section 2.4.8.The user can set the IRQ level by adjusting jumper

JP5. A hardware interrupt signal is sent to the PC when an A/D conversion is

completed.

DMA trans3 : fer :

This mode can

information is given in section 2.4.8. The user can set the DMA channel by adjusting

jumpers JP7 and JP8. Two hardware DMA requests signals are sent sequentially to the

PC when an A/D conversion is completed. The single mode transfer of the 8237 is

suggested.

be used with the pacer trigger or external trigger. More detailed

OME-A-822PGL/PGH Hardware Manual ---- 29

Page 32

2.7.4 Using software trigger and polling transfer

If the user needs to control the A/D converter without the A-822 software driver, software

trigger and polling transfer is suggested. The program steps are listed below:

1. send 0x01 to the A/D mode control register (software trigger + polling transfer)

(refer to Sec. 2.4.8)

2. send channel number to the multiplexer control register (refer to Sec.

3. send the gain control code value to the gain control register (refer to Sec 2.4.6)

4. delay the settling time (refer to Sec. 2.4.6 and Sec. 2.4.7)

5. send any value to the software trigger control register to generate a software trigger

signal

(refer to Sec. 2.4.9)

6. scan the READY bit of the A/D high byte data until READY=0 (refer to Sec. 2.4.2)

7. read the 12 bit A/D data (refer to Sec. 2.4.2)

8. convert the 12 bit binary data to a floating point value

2.4.7)

OME-A-822PGL/PGH Hardware Manual ---- 30

Page 33

2.8 D/A Conversion

The OME-A-822PGL/PGH provides two 12 bit D/A converters. Before

using the D/A converter function, you should address the following items:

z D/A output register, BASE+4/BASE+5/BASE+6/BASE+7, (sec. 2.4.3)

z JP1 jumper set to internal reference voltage -5V or -10V (sec. 2.3.1)

z JP2 jumper set to internal or external reference voltage (sec. 2.3.2)

z If JP2 is set to internal and JP1 is set to -5V, the D/A output range is 0 to 5V

z If JP2 is set to internal and JP1 is set to -10V, the D/A output range is 0 to 10V

z If JP2 is set to external, the external reference voltage can be AC/DC +/- 10V

The block diagram is given below:

D0..D7

OME-A-822PGL/PGH

-5/-10 V

Internal

Reference

D/A channel 0

Base+4/+5

Ref

JP1

JP2

Base+6/+7

D/A channel 1

Analog

Gnd

Ref

CN3

V0+ V0-

30

9,10,14,28,29

31

Vref0+ Vref0-

Vref1+ 12Vref1-

V1+ V1-

32

NOTE : The D/A output latch registers use a “double buffer” structure. The user must

send the low byte data first, then send the high byte data. If the user

only sends the high byte, the low byte data will be the previous value.

OME-A-822PGL/PGH Hardware Manual ---- 31

Page 34

2.9 Analog Input Signal Connection

The OME-A-822 can measure signals in the single-ended or differential mode. In the

differential mode each channel has a unique signal HIGH and signal LOW connection. In the

single-ended mode all channels have a unique signal HIGH connection but share a common

LOW or ground connection. Differential connections are very useful for low level signals

(millivolt), since they better reject electrical noise that can affect the quality of the

measurement. A differential connection is also necessary when a common ground is

unacceptable. The benefit of using a single-ended connection is that twice the number of

channels is available. In general, a single-ended connection is often a good choice when

working with higher level signals (5V or 10V for example), especially if the signal is coming

from an isolated device such as a signal conditioner. Several different types of wiring

diagrams are discussed below.

Figure 1-A shows a differential connection to a grounded source. If the source is

grounded, making a second connection to the card’s ground could cause a ground loop

resulting in erroneous data. It is important to note that the maximum common mode

voltage between the input source and AGND is 70Vp-p. If the card is connected to a

source with a common mode voltage greater than 70Vp-p, the input multiplexer will be

permanently damaged! When measuring common mode voltage, it is best to use an

oscilloscope rather than a multi-meter.

Figure 1-B shows a differential connection to a floating source. In such cases a

connection should be made between the low channel input and analog ground.

Figure 2 shows connection of multiple sources in single-ended mode. This connection

assumes creating one common ground will not cause a problem. This is normally the case

when connecting to devices that are isolated or floating.

Figure 3 demonstrates how to connect bridge transducers. Bridge transducers include

strain gauges, load cells and certain type of pressure transducers. The diagram assumes that

there is a single external power supply providing power to the bridge. Each bridge is

connected to a differential channel. No connection is made between channel low and

analog ground. A connection should be made between analog ground and the negative of

the power supply. An isolated power supply is strongly suggested.

Figure 4 demonstrates how to connect a 4-20mA current loop. Since the card reads

voltages, the current is converted to voltage by passing it through a shunt resistor. By Ohms

law (V=IR), when using a 250Ω resistor, 4 mA will be converted to 1V and 20mA to 5V.

If the source is linear, the output voltage range will also be linear.

OME-A-822PGL/PGH Hardware Manual ---- 32

Page 35

Figure 1-A

If the source is grounded, a second ground connection

on the card could result in a ground loop.

Figure 1-B

OME-A-822PGL/PGH Hardware Manual ---- 33

Page 36

Figure 2

Figure 3

OME-A-822PGL/PGH Hardware Manual ---- 34

Page 37

Figure 4

R is a shunt resistor. A 250Ω shunt resistor converts 4-20mA to 1-5Vdc.

Signal Shielding

z The signal shielding is the same for the connections shown in Figure 1 to Figure 4

z Use a single connection to frame ground (not A.GND or D.GND)

Vin

OME-A-822PGL/PGH

A.GND

D.GND

Frame Ground

OME-A-822PGL/PGH Hardware Manual ---- 35

Page 38

2.10 Using OME-DB-8225 CJC Output

The OME-DB-8225 daughter board contains built-in cold junction

compensation (CJC) circuitry that provides a 10mV per Deg C output. With 0.0

Volts @ -273 Deg C. The OME-A-822 should be protected from drafts and

direct sunlight in order to accurately reflect room temperature.

CJC Calibration:

1. Connect the OME-A-822PGL/PGH to the OME-DB-8225 CN1

2. Set the OME-A-822PGL/PGH to single-ended Mode

3. Set the JP1 jumper to 1-2 and the JP2 jumper to 2-3 ( single-ended mode)

4.Read the temperature from a digital thermometer placed near D1/D2(See the

OME-DB-8225 Layout) .

5.Read OME-A-822PGL/PGH analog input channel 0 (single-ended Channel 0)

6.Adjust VR1 until a stable reading of 10mV per deg C is attained .

For example, when the ambient temperature is 24 deg C. the reading value

of CJC will be 2.97V

(273 deg c +24 deg c ) X 10 mV/deg c = 2.97V

You will need an A/D channel for the CJC calibration. AI0 is reserved for CJC

calibration when used in single-ended mode and CH0-HI & CH0-LO is reserved for the

differential mode. differential mode is recommended when working with thermocouples.

OME-A-822PGL/PGH Hardware Manual ---- 36

Page 39

3. Connector

The OME-A-822PGL/PGH provides three connectors. Connector 1, CN1

contains the 16 digital inputs. Connector 2, CN2, contains the 16 digital

outputs. Connector 3, CN3, contains the analog inputs, analog outputs and

timer/counter I/O.

3.1 CN1/CN2/CN3 Pin Assignment

CN1 : Digital Input Pin Assignment.

Pin Number Description Pin Number Description

1 Digital Input 0/TTL 2 Digital Input 1/TTL

3 Digital Input 2/TTL 4 Digital Input 3/TTL

5 Digital Input 4/TTL 6 Digital Input 5/TTL

7 Digital Input 6/TTL 8 Digital Input 7/TTL

9 Digital Input 8/TTL 10 Digital Input 9/TTL

11 Digital Input 10/TTL 12 Digital Input 11/TTL

13 Digital Input 12/TTL 14 Digital Input 13/TTL

15 Digital Input 14/TTL 16 Digital Input 15/TTL

17 GND 18 GND

19 +5V Output 20 +12V Output

CN2 : Digital Output Pin Assignment.

Pin Number Description Pin Number Description

1 Digital Output 0/TTL 2 Digital Output 1/TTL

3 Digital Output 2/TTL 4 Digital Output 3/TTL

5 Digital Output 4/TTL 6 Digital Output 5/TTL

7 Digital Output 6/TTL 8 Digital Output 7/TTL

9 Digital Output 8/TTL 10 Digital Output 9/TTL

11 Digital Output 10/TTL 12 Digital Output 11/TTL

13 Digital Output 12/TTL 14 Digital Output 13TTL

15 Digital Output 14/TTL 16 Digital Output 15/TTL

17 GND 18 GND

19 +5V Output 20 +12 OutputV

OME-A-822PGL/PGH Hardware Manual ---- 37

Page 40

SINGLE-ENDED SIGNAL MODE

CN3 : Analog input, Analog output and Timer/Counter Pin Assignment.

Pin Number Description Pin Number Description

1 Analog Input 0/+ 20 Analog Input 8/+

2 Analog Input 1/+ 21 Analog Input 9/+

3 Analog Input 2/+ 22 Analog Input 10/+

4 Analog Input 3/+ 23 Analog Input 11/+

5 Analog Input 4/+ 24 Analog Input 12/+

6 Analog Input 5/+ 25 Analog Input 13/+

7 Analog Input 6/+ 26 Analog Input 14/+

8 Analog Input 7/+ 27 Analog Input 15/+

9 Analog GND 28 Analog GND

10 Analog GND 29 Analog GND

11 D/A internal -5V/-10V

voltage reference

12 D/A channel 1 external

voltage reference input

13 +12V Output 32 D/A channel 1 analog

14 PCB analog GND 33 User timer/counter‘s

15 PCB digital GND 34 Timer/counter 1&2 GATE

16 User timer/counter output 35 Timer/counter 1 output

17 External trigger source

input/TTL

18 Reserved 37 User timer/counter external

19 +5V Output XXXXXXX This pin not available

30 D/A channel 0 analog

voltage output

31 D/A channel 0 external

voltage reference input

voltage output

GATE control input

control input

36 Reserved

clock input (internal=2M)

OME-A-822PGL/PGH Hardware Manual ---- 38

Page 41

DIFFERENTIAL SIGNALS

CN3 : Analog input, Analog output and Timer/Counter Pin Assignment.

Pin Number Description Pin Number Description

1 Analog Input 0/+ 20 Analog Input 0/-

2 Analog Input 1/+ 21 Analog Input 1/-

3 Analog Input 2/+ 22 Analog Input 2/-

4 Analog Input 3/+ 23 Analog Input 3/-

5 Analog Input 4/+ 24 Analog Input 4/-

6 Analog Input 5/+ 25 Analog Input 5/-

7 Analog Input 6/+ 26 Analog Input 6/-

8 Analog Input 7/+ 27 Analog Input 7/-

9 Analog GND 28 Analog GND

10 Analog GND 29 Analog GND

11 D/A internal -5V/-10V

voltage reference output

12 D/A channel 1 external

voltage reference input

13 +12V Output 32 D/A channel 1 analog

14 Analog GND 33 User timer/counter GATE

15 Digital GND output 34 Timer/counter 1&2 GATE

16 User timer/counter output 35 Timer/counter 1 output

17 External trigger source

input/TTL

18 Reserved 37 User timer/counter external

19 +5V output XXXXXXX This pin not available

30 D/A channel 0 analog

voltage output

31 D/A channel 0 external

voltage reference input

voltage output

control input

control input

36 Reserved

clock input (internal=2M)

OME-A-822PGL/PGH Hardware Manual ---- 39

Page 42

3.2 Daughter Board

The OME-A-822PGL/PGH can be connected with many different daughter boards. The

daughter boards are described below:

3.2.1 OME-DB-8225

The OME-DB-8225 provides an on-board CJC(Cold Junction Compensation) circuit

for thermocouple measurement and a terminal block for easy signal connection. The CJC

is connected to A/D channel_0. The OME-A-822PGL/PGH can connect to an

OME-DB-8225 through a 37-pin D-sub connector on CN3.

3.2.2 OME-DB-37

The OME-DB-37 is a general purpose 37-pin screw terminal board. It connects to a

37-pin D-sub connector.

3.2.3 OME-DB-16P

The OME-DB-16P is a 16 channel isolated digital input board. The

OME-A-822PGL/PGH provides 16 channels of non-isolated TTL-compatible digital inputs

via the CN1 connector. If used with the OME-DB-16P, the OME-A-822PGL/PGH can

provide 16 channels of isolated digital input. Isolation can protect the computer if abnormal

or excessive input signals are received.

3.2.4 OME-DB-16R

The OME-DB-16R provides 16 SPDT relay outputs. The OME-A-822PGL/PGH

provides 16 TTL-compatible digital outputs via CN2. If connecting to the OME-DB-16R,

the OME-A-822PGL/PGH can provide 16 relay outputs to control external devices.

OME-A-822PGL/PGH Hardware Manual ---- 40

Page 43

4. Calibration

The OME-A-822PGL/PGH is factory calibrated for optimum performance. Recalibration is

suggested for high vibration environments. The following items are required for

calibrating the OME-A-822PGL/PGH.

z One 6 digit multimeter

z One stable voltage source (4.9988V)

z Diagnostic program : this program included with the

OME-A822PGL/PGH.

4.1 Description of Variable Resistors

There are seven variable resistors(VRs) on the OME-A-822PGL/PGH used for calibration,

they are described below.

VR Num. Description

VR1 A/D offset adjustment

VR2 A/D gain adjustment

VR3 D/A channel 0 gain adjustment

VR4 D/A channel 1 gain adjustment

VR5 D/A reference voltage adjustment

VR6 A/D unipolar offset adjustment

VR7 A/D programmable amplifier offset adjustment

OME-A-822PGL/PGH Hardware Manual ---- 41

Page 44

4.2 D/A Calibration

1. Run the A82XDIAG.EXE program

2. Press the “Right Arrow Key” to select “CALIBRATION”.

3. Press the “Down Arrow Key” to select “G. D/A REFERENCE”.

4. Press the “Enter Key”

5. Connect VREF, pin 11 of CN3, to a DVM (Digital Volt Meter)

6. Adjust VR5 until the DVM=4.9988V

7. Press the “ESC Key”

8. Select and Execute “A. D/A REFERENCE 1” item

9. Connect D/A channel 0, pin 30 of CN3, to the DVM

10. Adjust VR3 until the DVM=4.9988V

11. Press the “ESC Key”

12. Select and Execute “B. D/A REFERENCE2” item

13. Connect D/A channel 1, pin 32 of CN3, to the DVM

14. Adjust VR4 until the DVM=4.9988V

OME-A-822PGL/PGH Hardware Manual ---- 42

Page 45

4.3 A/D Calibration

1. Run the A82XDIAG.EXE

2. Press “Right Arrow Key” to select “CALIBRATION”

3. Press the “Down Arrow Key” to select “C. A/D REFERENCE” item.

4. Press the “Enter Key”

5. Input a stable 4.9988V to A/D channel 0, pin 1 of CN3

6. Adjust VR2 until the A/D data shown on the screen is between 4094 to 4095

7. Press the “ESC Key”

8. Select and Execute the “D. A/D OFFSET” item

9. Input a stable 0V to A/D channel 0, pin1 of CN3

10. Adjust VR1 until the A/D data shown on the screen is between 2048 to 2049

11. Press the “ESC Key”

12. Repeat step_3 to step_11 until there is no need to adjust VR2,VR1

13. Select and Execute “E. PGA OFFSET” item

14. Input a stable 0V to A/D channel 0, pin 1 of CN3

15. Adjust VR7 until the A/D data shown in screen between 2048 to 2049

16. Press “ESC Key”

17. Select and Execute “F. PGA REFERENCE” item

18. Input a stable 0V to A/D channel 0 , pin1 of CN3

19. Adjust VR6 until the A/D data shown on screen is between 0 and 1

OME-A-822PGL/PGH Hardware Manual ---- 43

Page 46

5. Diagnostic Utility

5.1 Introduction

The A82XDIAG.EXE diagnostic utility is a menu-driven program which allows

complete testing of the OME-A-822PGL/PGH board. To run the diagnostic utility,

change to the subdirectory used in the installation process (C:\OME-A-822 for example).

Then type "A82XDIAG" <Enter> to start the application. These steps are shown

below:

C:\>CD A822<Enter>

C:\A822>CD DIAG <Enter>

C:\A822\DIAG>A82XDIAG <Enter>

A configuration file, named OME-A-82X.CFG is associated with the

A82XDIAG.EXE program. The configu ration of the OME-A-822PGL/PGH board

is stored in this file. The stored information includes the board's I/O base address, interrupt

number and DMA channel. Changes are not automatically saved to the configuration file,

the user must select the save function to save any changes. When the

A82XDIAG.EXE utility starts, it will automatically check if the jumper setting of

the I/O base address matches the value stored in the configuration file. If the addresses do

not match, an error message will appear as shown below.

OME-A-822PGL/PGH Hardware Manual ---- 44

Page 47

Although you can continue by pressing any key, it is recommended that the jumper

situation be corrected since many operations in the A82XDIA utility check the I/O

base address and report an error if the configuration file and the actual jumper settings do

not match.

OME-A-822PGL/PGH Hardware Manual ---- 45

Page 48

5.2 Running The Diagnostic Utility

The initial screen of A82XDIAG is shown below. There are five

main menus in the initial screen. They are Setup, Calibration, FunctionTest,

sPecialTest and Help. Use the Left or Right key to select the main menu.

Then use the Up or Down key to select the menu item. Alternately, the user

can press the command key to highlight the menu item. A command key in a

menu item is the character that is highlighted. To execute a function associated

with a highlighted menu item, just press <Enter> and press <Esc> to abort the

current function.

OME-A-822PGL/PGH Hardware Manual ---- 46

Page 49

5.2.1 Setup

The Setup menu allows the user to setup the board configuration. There are six functions in

this muen, Card type, Base Addresss, DMA no, IRQ no, Save option, eXit.

Card type : <Up/Down> key to select A-822PGL/PGH, <Enter> key to select

Base Address : <Up/Down> key to select base address, <Enter> key to select

DMA no : <Up/Down> key to select DMA no, <Enter> key to select

IRQ no : <Left/Right> key to select IRQ no, <Enter> key to select

Save option : <Left/Right> key to select yes/no, <Enter> key to select

eXit : <Left/Right> key to select yes/no, <Enter> key to select

Base address selection screen.

OME-A-822PGL/PGH Hardware Manual ---- 47

Page 50

DMA no and IRQ no selection screen

OME-A-822PGL/PGH Hardware Manual ---- 48

Page 51

5.2.2 CALIBRATION

The CALIBRATION menu contains ten submenu items: they are, D/A Reference voltage,

D/A Channel 0 gain, D/A channel 1 gain, A/D Gain, A/D Offset, A/D Bipolar Offset, A/D

Unipolar Offset. These items relate to the calibration of the OME-A-822PGL/PGH. The

CALIBRATION main menu, is a graphic representation of the OME-A-822PGL/PGH board

layout. In order to maintain the specified performance, it may be required to calibrate the

board after working with it for an extended period of time. There are seven variable resistors

(VRs) that need to be adjusted during the calibration process. When you highlight one of the

first seven menu items, the associated VR will begin to blink and a message window will

appear that will instruct you how to adjust the VR. The main menu screen is shown below.

OME-A-822PGL/PGH Hardware Manual ---- 49

Page 52

5.2.3 FUNCTION TEST

The FUNCTION TEST main menu contains seven submenus: they are D/A TEST, Digital

I/O, A/D MULTIPLEX, A/D use IRQ, A/D use DMA, A/D GAIN, Timer 0. The main menu

is shown below.

The “D/A TEST” menu, is shown below.

OME-A-822PGL/PGH Hardware Manual ---- 50

Page 53

<D/A TEST > Test Screen

z Assume D/A output range 0 to 5V

z Send D/A output to both channels simultaneously

z Press <p> pause screen, press <p> again release screen

z Press <Up> key to increase screen delay

z Press <Down > key to decrease screen delay

z Press <ESC> key to quit

OME-A-822PGL/PGH Hardware Manual ---- 51

Page 54

<Digital I/O> Test Screen

z Connect CN1 to CN2

z 16 bit up counter is sent to 16 channel DO

z 16 channel DO is connected to 16 channel DI

z 16 channel DI are readback and show on the screen

z If DO equals DI then OK shown on screen

z If DO does not equal DI then Error shown on screen

z Press <p> pause screen, press <p> again release screen

z Press <Up> key to increase the screen delay

z Press <Down > key to decrease the screen delay

z Press <ESC> key to quit

OME-A-822PGL/PGH Hardware Manual ---- 52

Page 55

<A/D Multiplexer> Test Screen

z Assume 16 channel single-ended, bipolar, gain=1, analog input signals

z Input range from -5V to +5V

z Continue to scan 16 channels

z Press <ESC> key to quit

OME-A-822PGL/PGH Hardware Manual ---- 53

Page 56

<A/D use IRQ> Test Screen

z Assume single-ended, bipolar, gain=1

z Use <PgUp> key to select the next channel

z Use <PgDn> key to select the previous channel

z Use <Up>/<Down> key to adjust C1

z Use <Left>/<Right> key to adjust C2

z The sample rate = The pacer timer rate = 2000/(C1*C2) K

z Use <p> key to pause screen, use next <p> key to release screen

z Use <ESC> to quit

z The A/D mode control register=0x06 Æ select pacer trigger and use interrupt transfer

z One cycle samples 1000 A/D data points

z Minimum, maximum and average values are shown on the screen

OME-A-822PGL/PGH Hardware Manual ---- 54

Page 57

<A/D use DMA> Test Screen

z Assume single-ended, bipolar, gain=1

z Use <PgUp> key to select the next channel

z Use <PgDn> key to select the previous channel

z Use <Up>/<Down> key to adjust C1

z Use <Left>/<Right> key to adjust C2

z Sample rate = pacer timer rate = 2000/(C1*C2) K

z Use <p> key to pause screen, use next <p> key to release screen

z Use <ESC> to quit

z A/D mode control register=0x02 Æ select pacer trigger and use DMA transfer

z One cycle samples 1000 A/D data points

z Minimum, Maximum and Average values are shown on the screen

OME-A-822PGL/PGH Hardware Manual ---- 55

Page 58

<DA GAIN> Test Screen

z Assume single-ended, bipolar, gain=1, A/D channel 0 connected to D/A channel 0

z Use <Up>/<Down> key to adjust gain control code

z Use <Left>/<Right> key to adjust D/A output value

z Use software trigger and polling transfer mode

z Press <ESC> key to quit

OME-A-822PGL/PGH Hardware Manual ---- 56

Page 59

<Timer 0> Test Screen

z Assume JP6 set to internal 2M clock

z If the counter0 is functioning normally, the value will increment automatically.

OME-A-822PGL/PGH Hardware Manual ---- 57

Page 60

5.2.4 SPECIAL TEST

The SPECIAL TEST menu contains four submenu items: they are D/A Volt Set, DIO Bit

Pattern, IRQ Clock Test and DMA Clock Test. These functions are reserved for factory

testing.

OME-A-822PGL/PGH Hardware Manual ---- 58

Page 61

5.2.5 Help

The Help menu will display the software version as shown below.

OME-A-822PGL/PGH Hardware Manual ---- 59

Page 62

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

ARRANTY

RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

FOR NON-W

ARRANTY

REPAIRS,

consult OMEGA

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

Page 63

M4031/0104

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...