Page 1

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

Shop online at

User’s Guide

OMB-DBK Option Cards and Modules

Part 1 of 2, Through OMB-DBK-34A

OMB-457-0911 rev 8.1

Page 2

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

Warnings, Cautions, Notes, and Tips

Refer all service to qualified personnel. This symbol warns of possible personal injury or equipment damage under

noted conditions. Follow all safety standards of professional practice and the recommendations in this manual. Using

this equipment in ways other than described in this manual can present serious safety hazards or cause equipment

damage.

This warning symbol is used in this manual or on the equipment to warn of possible injury or death from electrical

shock under noted conditions.

This ESD caution symbol urges proper handling of equipment or components sensitive to damage from electrostatic

discharge. Proper handling guidelines include the use of grounded anti-static mats and wrist straps, ESD-protective

bags and cartons, and related procedures.

This symbol indicates the message is important, but is not of a Warning or Caution category. These notes can be of

great benefit to the user, and should be read.

In this manual, the book symbol always precedes the words “Reference Note.” This type of note identifies the location

of additional information that may prove helpful. References may be made to other chapters or other documentation.

Tips provide advice that may save time during a procedure, or help to clarify an issue. Tips may include additional

reference.

Specifications and Calibration

Specifications are subject to change without notice. Significant changes will be addressed in an addendum or revision to

the manual. As applicable, we calibrate our hardware to published specifications. Periodic hardware calibration is not

covered under the warranty and must be performed by qualified personnel as specified in this manual. Improper

calibration procedures may void the warranty.

iii

Page 4

Your order was carefully inspected prior to shipment. When you receive your order, carefully

unpack all items from the shipping carton and check for physical signs of damage that may have

occurred during shipment. Promptly report any damage to the shipping agent and your sales

representative. Retain all shipping materials in case the unit needs returned to th e factory.

CAUTION

Using this equipment in ways other than described in this manual can cause

personal injury or equipment damage. Before setting up and using your

equipment, you should read all documentation that covers your system.

Pay special attention to Warnings and Cautions.

Note:

During software installation, Adobe

®

PDF versions of user manuals will automatically

install onto your hard drive as a part of product support. The default location is in the

Programs group, which can be accessed from the Windows Desktop. Initial

navigation is as follows:

Start [Desktop “Start” pull-down menu]

⇒ Programs

⇒ Omega DaqX Software

You can also access the PDF documents directly from the data acquisition CD by using

the <View PDFs> button located on the opening screen.

Refer to the PDF documentation for details regarding both hardware and software.

®

A copy of the Adobe Acrobat Reader

is included on your CD. The Reader provides

a means of reading and printing the PDF documents. Note that hardcopy versions of

the manuals can be ordered from the factory.

iv

Page 5

Part 1 of 2

DBK Options

General Information through DBK34A

© 1998 through 2005 917594 Part 1 of 2 Printed in the United States of America

Page 6

ii

Page 7

Manual Layout

This user’s manual includes several chapters and independent DBK sections. It also includes DBK

Basics, which is a stand alone document.

DBK Basics

– Explains what DBKs are and uses tables to identify the various types of DBKs. The

document module includes: tips for setting up a data acquisition system, how to determine system power

requirements, and various power options.

Chapters*

1 – Signal Management. Discusses signal management and signal conditioning, and CE compliance

information.

2 – System Connections and Pinouts. Provides instructions for connecting a DBK option to a Daq

or LogBook device. Pinouts are included for the P1, P2, and P3 DB37 connectors, as well as the

100-pin P4 connector used by /2000 Series Devices.

3 – DBK Set Up in DaqView. Provides instruction for setting up analog and digital DBKs in

DaqView’s Hardware Configuration screen.

4 – DBK Set Up in LogView. Provides instruction for setting up analog and digital DBKs in

LogView’s Hardware Configuration window.

5 – Troubleshooting. Explains solutions to common noise, wiring, and configuration problems.

Dimensional Drawings

DBK Cards and Modules**

DBK by DBK basis. Refer to the Table of Contents for a complete list.

Documentation for discontinued DBKs [listed at the end of the Table of Contents] is not included in the

DBK Options Manual, but can be downloaded or read from our website.

Note: During software installation, Adobe

hard drive as a part of product support. The default location is in the Programs group, which can be

accessed from the Windows Desktop. Refer to the PDF documentation for details regarding both

hardware and software.

A copy of the Adobe Acrobat Reader

reading and printing the PDF documents. Note that hardcopy versions of the manuals can be ordered

from the factory.

Note that you can access PDF documents directly from the data acquisition CD via the <View PDFs>

button located on the CD’s opening screen.

* The chapters are included in Part 1 of the DBK Options Manual. DBKs up to and including DBK34A are also

included in Part 1.

** Part 2 of the manual begins with DBK41.

– Independent DBK documentation is provided in alphanumeric order on a

®

PDF versions of user manuals will automatically install onto your

®

is included on your CD. The Reader provides a means of

DBK Option Cards & Modules User’s Manual 917094 v

Page 8

Table of Contents

DBK Basics

Introduction…… DBK Basics-1

How Do DBKs Connect? ……

DBK Identification Tables …..

DBK Basics- 2

DBK Basics-9

Tips on Setting up a Data Acquisition

System ……

Power Supplies & Connectors ……

DBK Basics-12

DBK Basics-14

An Introduction to Power-Related

DBKs ……

Power Requirements......

DBK Basics-15

DBK Basics-16

Calculating Your System’s Power

Needs ……

Additional Reading …..

DBK Basics-18

DBK Basics-21

1 - Signal Management

Signal Modes ...... 1-1

System Noise ...... 1-5

Using DBK Cards and Modules for Signal

Conditioning ...... 1-6

Channel Control and Expansion ...... 1-7

Signal Acquisition ...... 1-9

Sequencer ...... 1-9

Scan Rate ...... 1-10

Triggering ...... 1-10

Counter/Timer Functions ...... 1-11

Simultaneous Sample and Hold (SSH) ...... 1-11

Two-Point Calibration of a Temperature

Measurement System ...... 1-12

Overview ...... 1-12

An Example of Two-Point Calibration ...... 1-13

Calculation of Scale and Offset ...... 1-14

Implementing the Scale and Offset Constants in

DaqView ...... 1-14

Converting Degrees from Celsius to

Fahrenheit ...... 1-14

One Known Temperature Environment ...... 1-15

Use of a Temperature Calibrator ...... 1-15

CE Compliance ...... 1-15

CE Standards and Directives ...... 1-16

Safety Conditions ...... 1-16

Emissions/Immunity Conditions ...... 1-17

CE Enhancements for Existing Products ...... 1-17

2 – System Connections and Pinouts

Overview …… 2-1

P1 – DB37 for Analog I/O …… 2-3

P2 – DB37 for Digital I/O …… 2-4

P3 – DB37 for Pulse/Frequency/High-Speed

Digital I/O …… 2-5

P4 to P1, P2, P3 Correlation …… 2-6

Ground Tables – P4 to P1, P2, P3 …… 2-9

3 – DBK Set Up in DaqView

Overview …… 3-1

Setting Up Analog DBKs …… 3-5

Setting Up Digital DBKs …… 3-7

Setting Internal Clock Speed to 100 kHz …3-9

4 – DBK Set Up in LogView

Overview …… 4-1

Setting Up Analog DBKs …… 4-4

Setting Up Digital DBKs …… 4-7

5 – Troubleshooting

ESD Handling Notice …… 5-1

Troubleshooting Checklist……5-1

Frequently Asked Questions ……5-3

Customer Assistance……5-6

Dimensional Drawings

DBK Documents

DBK1, 16-Connector BNC Adapter Module

DBK2, 4-Channel Voltage Output Card

DBK4, 2-Channel Dynamic Signal Input Card

DBK5, 4-Channel Current Output Card

DBK7, 4-Ch. Frequency-To-Voltage Input Card

DBK8, 8-Channel High-Voltage Input Card

DBK9, 8-Channel RTD Card

DBK10, 3-Slot Expansion Chassis

DBK11A, Screw-Terminal & BNC Option Card

DBK15, Universal Current, Voltage Input Card

DBK16, 2-Channel Strain-Gage Card

DBK17, 4-Channel Simultaneous Sample and

Hold Card

DBK18, 4-Channel, Low-Pass Filter Card

DBK20 and DBK21, Digital I/O Cards

DBK23, Isolated Digital Input Chassis

DBK24, Isolated Digital Output Chassis

DBK25, 8-Channel Relay Output Card

DBK30A, Rechargeable Battery Module

DBK32A, Auxiliary Power Supply Card

DBK34A, UPS / Battery Module

vi 917094 DBK Option Cards & Modules User’s Manual

Page 9

Part 2

DBK41, 10-Slot Expansion Module

DBK42, 16-Slot 5B Signal Conditioning Module

DBK43A, 8-Channel Strain-Gage Module

DBK44, 2-Ch. 5B Signal-Conditioning Card

DBK45, 4-Ch. SSH and Low-Pass Filter Card

DBK46, 4-Channel Analog Output Card

DBK48, Multipurpose Isolated Signal-

Conditioning Module (supports up to 16 8B

Modules)

DBK50 and DBK51, Voltage Input Modules

DBK55, 8-Channel Frequency-to-Voltage Input

Module

DBK60, 3-Slot Expansion Chassis

DBK65, 8-Channel Transducer Interface Module

DBK70, Vehicle Network Interface, Analog

Multiplexer Module (see p/n 1056-0901)

DBK80, 16-Ch. Differential Voltage Input Card

with Excitation Output

DBK81, 7-Ch. T/C Card

DBK82, 14-Ch. T/C Card

DBK83, 14-Ch. T/C Card, uses external

connection pod

DBK84, 14-Ch. T/C Module

DBK85, 16-Ch. Differential Voltage Module

DBK90, 56-Ch. T/C Module

DBK100 Series, (DBK100/D, 100/T,101)

In-Vehicle Thermocouple Measurement System

DBK200 Series Matrix

DBK200, P4-to-P1 Adapter Board

DBK202, DBK203, DBK204 Series

P4-to-P1/P2/P3 Adapters

DBK206, P4-to-P1/P2/P3 Adapter Board with

Screw Terminals

DBK207 and DBK207/CJC, 16-Channel,

5B Carrier Boards

DBK208, Relay Carrier Board,

Opto-22 Compatible

DBK209, P4 to P1/P2/P3 Mini-Adapter Board

DBK210, 32-Ch. Digital I/O Carrier Board

DBK213, Screw-Terminal & Expansion Module

3-Card Slot, P1/P2/P3/P4 Compatibility

DBK214, 16-Connector BNC Interface Module

P1/P2/P3/P4 Compatibility

DBK215, 16-Connector BNC Connection Module

with 68-Pin SCSI Adaptability

DBK601 thru DBK609, Termination Panels

Discontinued DBKs

The following DBKs have been discontinued.

However, you may contact the factory if you

need documentation for these devices.

DBK12 and DBK13, A/I Multiplexer Cards

DBK19, 14-Channel Thermocouple Card

DBK33, Triple-Output Power Supply Card

DBK34, Vehicle UPS Module

DBK40, 18-Connector BNC Analog Interface

DBK52, 14-Ch. Thermocouple Input Module

DBK53 and DBK54, Analog Multiplexing

Modules

DBK201, P4-to-P1/P2/P3 Adapter Board

DBK603, Termination Panel, Safety Jacks, SE

DBK605-B, Termination Panel, T/C, B Type, DE

DBK605-R, Termination Panel, T/C, R Type, DE

DBK605-S, Termination Panel, T/C, S Type, DE

DBK605-U, Termination Panel, T/C, U Type, DE

DBK609, Termination Panel, 5-Pin DIN

DBK Option Cards and Modules User’s Manual 917094 vii

Page 10

This page is intentionally blank.

viii 917594 DBK Option Cards & Modules User’s Manual

Page 11

DBK Basics

This “DBK Basics” section of the manual does not apply to DaqBoard/500 Series or DaqBoard/1000

Series boards. Those boards are not intended for use with DBK options; nor will they support such

options.

Introduction…… 1

How Do DBKs Connect to the Data Acquisition Device? …… 2

Connecting DBKs to DaqBook/100/200 Series Devices, ISA-Type DaqBoards, & LogBooks … 2

Connecting DBKs to Daq PC-Cards ……3

Connecting DBKs to DaqBoard/2000 Series Boards …… 4

Connecting DBKs to DaqBook/2000 Series Devices …… 5

DBK Identification Tables ….. 9

Analog Output DBKs …… 9

Digital I/O Control DBKs …… 9

Analog Signal Conditioning DBKs …… 9

Expansion and Terminal Panel Connection DBKs …… 10

Power Supply DBKs …… 12

Tips on Setting up a Data Acquisition System …… 12

Power Supplies and Power Connectors ……14

An Introduction to Power-Related DBKs ….. 15

Power Requirements …… 16

Calculating Your System’s Power Needs …… 18

Additional Reading ….. 21

Turn off power to all devices connected to the system before connecting cables or

setting configuration jumpers and switches. Electrical shock or damage to

equipment can result even under low-voltage conditions.

CAUTION

CAUTION

The discharge of static electricity can damage some electronic components.

Semiconductor devices are especially susceptible to ESD damage. You should

always handle components carefully, and you should never touch connector pins or

circuit components unless you are following ESD guidelines in an appropriate ESD

controlled area. Such guidelines include the use of properly grounded mats and

wrist straps, ESD bags and cartons, and related procedures.

Introduction

The term “DBK” typically refers to a card or module that is used to expand or enhance a primary data

acquisition device, such as a DaqBook, DaqBoard, or LogBook. As will be seen in the upcoming DBK

identification tables, DBKs provide a wide variety of data acquisition functions. Depending on the DBKs

used, one or more of the following can be realized:

• signal conditioning

• analog output

• digital I/O

• channel expansion

• supplying powering to another acquisition device

• providing an interface for different connectivity; for example, in a DaqBoard/2000 Series board,

converting a P4, 100-pin connector to P1, P2, and P3 37-pin, DB37 connectors.

Daq Systems 886995 DBK Basics, pg. 1

Page 12

Reference Notes: During software installation, Adobe

®

PDF versions of user manuals will

automatically install onto your hard drive as a part of product support. The default location

is in the Programs group, which can be accessed from the Windows Desktop. Refer to the

PDF documentation, especially the DBK Option Cards and Modules User’s Manual

(p/n 457-0905) for details regarding both hardware and software in relevant to DBKs.

®

A copy of the Adobe Acrobat Reader

is included on your CD. The Acrobat Reader

provides a means of reading and printing the PDF documents. Note that hardcopy versions

of the manuals can be ordered from the factory.

How Do DBKs Connect to the Data Acquisition Device?

Each DBK connects to the primary data acquisition device; e.g., a DaqBook, DaqBoard, or LogBook,

through one of three 37-pin ports, which are designated as follows:

• P1 – Analog I/O

• P2 – Digital I/O

• P3 – Pulse/Frequency/High-Speed Digital I/O

Depending on the primary data acquisition device, connectivity issues differ slightly. This will be made

clear by the figures and accompanying text that follow.

Connecting DBKs to DaqBook/100/200 Series Devices, ISA-Type DaqBoards, & LogBooks

Reference Notes:

o DaqBoard/2000 Series and /2000c Series users, refer to page 4.

o DaqBook/2000 Series users, refer to page 5.

For DaqBook/100 Series and DaqBook/200 Series devices, ISA-Type DaqBoards, and LogBooks, DBK

connections are not made directly to the port, but through a CA-37-x ribbon cable, where “x” indicates the

number of expansion devices that can be connected. For example, in addition to providing a DB37

connector to interface with the primary data acquisition device, a CA-37-3 cable includes three additional

DB37 connectors. These provide a means of adding three DBKs to one por t. Use of a CA-37-16 cable will

allow up to 16 DBKs to be added. The CA-37-x cable system is excellent for DaqBooks, LogBooks, and

ISA-type DaqBoards.

/100 /200 Series

Connecting DBKs to a DaqBook/100 Series or /200 Series Device

pg. 2, DBK Basics 967794 Daq Systems

Page 13

The previous figure applies to LogBooks, DaqBook/100/200 Series devices, and ISA-type DaqBoards. As

will be seen elsewhere in this document, some devices do not include all three connectors, i.e., P1, P2, and

P3.

Connecting DBKs to Daq PC-Cards

The Daq PC-Card is only intended for connections to a P1 connector of a single “passive” DBK card or

module. A passive DBK card or module is one that provides a desired connectivity (such as BNCs or screw

terminals), but performs no signal conditioning.

A CA-134 Interface Cable and a CN-86-F (dual DB37 female adapter) are used to provide the DB37,

P1 connector.

Daq PC-Card Cabling

The CA-134 cable connects to a CN-86-F adapter, which then connects to a single “passive” card or module.

The passive DBKs are:

• DBK1 – 16 Connector BNC Module

• DBK11A – Screw Terminal Option Card

• DBK40 – BNC Analog Interface

Reference Note:

For information regarding the passive DBKs (DBK1, DBK11A, and DBK40), refer to

the DBK Option Cards and Modules User’s Manual (p/n 457-0905).

Daq Systems 967794 DBK Basics, pg. 3

Page 14

Connecting DBKs to DaqBoard/2000 Series Boards

DaqBoard/2000 Series and cPCI DaqBoard/2000 Series boards have 100-pin connectors designated as P4.

The 100 pins correlate to various pins on P1, P2, and P3 DB37 connectors.* Connectivity in the system is as

follows (see figure).

• Both the DaqBoard/2000 and /2000c Series board connect to a CA-195 cable.

The cable has two, 100-pin, P4 connectors.

• The CA-195 connects to a DBK200 Series adapter board or adapter module for 100-pin to

37-pin adaptations, e.g., P4-to-P1, P2, P3; but not necessarily all three.*

• The DBK200 Series adapter connects to a CA-37-x ribbon cable, where “x” indicates the

number of expansion devices that can be connected. For example, in addition to providing a

DB37 connector to interface with the primary data acquisition device, a CA-37-3 cable

includes three additional DB37 connectors. These provide a means of adding three DBKs to

one port. Use of a CA-37-16 cable will allow up to 16 DBKs to be ad ded.

• The CA-37-x cable connects to expansion DBKs, in accordance with port type. For example,

Analog DBKs to port P1, Digital DBKs to port P2, and passive DBKs to port P3.

Connecting DBKs to a DaqBoard/2000 Series Board

* DaqBoard/2003 and cPCI DaqBoard/2003c are exceptions to the above connectivity method. The /2003

board typically connects directly to a DBK205 (P4-to-Screw Terminal Adapter), as discussed in the DBK

Option Cards and Modules User’s Manual (p/n 457-0905).

Note: DaqBook/2000 Series Devices, which are discussed in the following section, can also connect to DBKs via

a P4 connector, as indicated in the above figure.

pg. 4, DBK Basics 967794 Daq Systems

Page 15

Connecting DBKs to DaqBook/2000 Series Devices

Several products make use of the DaqBook/2000 nomenclature. However, they do not all offer the same

connection options. Refer to pinouts for the specific devices, as needed.

Product Connects to DBK Expansions via …

DaqBook/2001 and /2005 37-pin connectors P1, P2, and P3. There is no P4.

DaqBook/2020 37-pin connectors P1 and P2. There is no P3 or P4.

DaqOEM/2001 and /2005 40-pin headers (JP1, JP2, and JP3). There is no P4.

DaqBook/2000A 37-pin connectors P1, P2, P3, and a 100-pin P4 connector.

DaqBook/2000E 37-pin connectors P1, P2, P3, and a 100-pin P4 connector.

DaqBook/2000X 37-pin connectors P1, P2, P3, and a 100-pin P4 connector.

For DaqBook/2000 Series devices, DBK connections can be made to Ports P1, P2, and/or P3 (when

applicable). For the “AEX” models a 100-pin P4 connector can be used. A discussion of both methods,

follows.

The P4 connector on a DaqBook/2000 “AEX” device shares signal connections with the

P1, P2, and P3 connectors. P4 offers no additional I/O. Connecting a DBK200 Series

Option to P4 via a CA-195 cable distances the P1, P2, P3 connection from the

DaqBook/2000 Series device. It does not provide any new signal I/O. See the following

Caution.

CAUTION

Signal conflicts between a DaqBook/2000 “AEX” device’s P1, P2, P3 connectors and its

P4 connector can result in erroneous readings and possible equipment damage.

Therefore, when connections have been made to P1, P2, and/or P3, use caution when

making connections through P4, and visa versa.

Refer to P1, P2, P3, and P4 pinouts to avoid making duplicate signal connections.

There are two ways to connect a DBK option to a DaqBook/2000 “AEX” device. The first

method is preferable, as it introduces less noise.

Preferred Method – (a) Connect a CA-37-x cable to the appropriate DB37 connector

[P1, P2, or P3] on the DaqBook/2000 Series device. (b) Connect the

free end of the cable to the DBK card or module.

Optional Method – (a) Connect a CA-195-x cable to the P4 connector on the

DaqBook/2000 Series device. (b) Connect the free end of the cable

to a DBK200 Series device. (c) Connect the DBK option to the

DBK200 Series device, as applicable.

The primary reason that less noise is seen in the “preferred” method is that a

DaqBook/2000 Series device’s P1 connector pertains only to analog acquisition signals

and the P2 connector pertains only to digital I/O. This provides a strong degree of

isolation between the two signal types. However, in the case of a CA-195-x cable

connected to P4, digital and analog signals co-exist in one cable.

If you need to use the P4 connection method, use of the 8-inch ribbon cable (CA-195-1)

will result in the lowest level of crosstalk [for that method].

Daq Systems 967794 DBK Basics, pg. 5

Page 16

Connecting DBKs to a DaqBook/2000 Series Device via P1, P2, and/or P3

The DBKs do not connect directly to the port, but through a CA-37-x ribbon cable, where “x” indicates the

number of expansion devices that can be connected. For example, a CA-37-3 cable includes a 37-pin mating

connector to interface with the DaqBook/2000 Series DB37 connector (P1, P2, P3); it also includes three

additional DB37 connectors. These provide a means of adding three DBKs to one port. Use of a

CA-37-16 cable will allow up to 16 DBKs to be added to one DaqBook/2000 Series device DB37-type port.

DaqBook/2000

Series Device

Connecting DBKs to a DaqBook/2000 Series Device via P1, P2, and P3

The P4 connector on a DaqBook/2000 “AEX” device shares signal connections with the

P1, P2, and P3 connectors. P4 offers no additional I/O. Connecting a DBK200 Series

Option to P4 via a CA-195 cable distances the P1, P2, P3 connection from the

DaqBook/2000 Series device. It does not provide any new signal I/O. See the following

Caution.

CAUTION

Signal conflicts between a DaqBook/2000 “AEX” device’s P1, P2, P3 connectors and its

P4 connector can result in erroneous readings and possible equipment damage.

Therefore, when connections have been made to P1, P2, and/or P3, use caution when

making connections through P4, and visa versa.

The following pinouts indicate the P1, P2, and P3 pins, and their P4 equivalents.

Use the pinouts to avoid making duplicate signal connections.

pg. 6, DBK Basics 967794 Daq Systems

Page 17

Connecting DBKs to a DaqBook/2000 “AEX” Device via P4

Every DaqBook/2000 “AEX” device has a 100-pin connector designated as P4. The P4 pins correlate to

various pins on P1, P2, and P3.

The P4 connector on a DaqBook/2000 “AEX” device shares signal connections with the

P1, P2, and P3 connectors. P4 offers no additional I/O. Connecting a DBK200 Series

Option to P4 via a CA-195 cable distances the P1, P2, P3 connection from the

DaqBook/2000 “AEX” device. It does not provide any new signal I/O. See the following

Caution.

CAUTION

Signal conflicts between a DaqBook/2000 AEX device’s P1, P2, P3 connectors and its

P4 connector can result in erroneous readings and possible equipment damage.

Therefore, when connections have been made to P1, P2, and/or P3, use caution when

making connections through P4, and visa versa.

Refer to P1, P2, P3, and P4 pinouts to avoid making duplicate signal connections.

A brief explanation of P4 connectivity for DaqBook/2000 AEX devices follows the illustration.

DaqBook/2000

Series Device

P4

Connecting DBKs to a DaqBook/2000 AEX Device via P4

DaqBook/2001, DaqBook/2005, DaqOEM/2001, DaqOEM/2005, and DaqBook/2020 do

not have a P4 connector. The P4 connection option applies to “AEX” models only.

Daq Systems 967794 DBK Basics, pg. 7

Page 18

P4 connectivity for DaqBook/2000 “AEX” devices is as follows:

• One end of a CA-195 cable connects to the DaqBook/2000 “AEX” device’s 100-pin P4

connector. Note that the CA-195 cable has two P4 connectors.

• The other end of the CA-195 cable connects to a DBK200 Series adapter board [or adapter

module] for 100-pin to 37-pin adaptations, e.g., P4-to-P1, P2, P3; but not necessarily all three.

• The DBK200 Series adapter connects to one or more CA-37-x ribbon cables, where “x”

indicates the number of expansion devices that can be connected. For example, in addition to

providing a DB37 connector to interface with the primary data acquisition device, a CA-37-3

cable includes three additional DB37 connectors. These provide a means of adding three

DBKs to one port. Use of a CA-37-16 cable will allow up to 16 DBKs to be added.

• The CA-37-x cable connects to expansion DBKs, in accordance with port type. For example,

Analog DBKs to port P1, Digital DBKs to port P2, and passive DBKs to port P3.

There are two ways to connect a DBK option to a DaqBook/2000 “AEX” device. The first

method is preferable, as it introduces less noise.

Preferred Method – (a) Connect a CA-37-x cable to the appropriate DB37 connector

[P1, P2, or P3] on the DaqBook/2000 Series device. (b) Connect the

free end of the cable to the DBK card or module.

Optional Method – (a) Connect a CA-195-x cable to the P4 connector on the

DaqBook/2000 Series device. (b) Connect the free end of the cable

to a DBK200 Series device. (c) Connect the DBK option to the

DBK200 Series device, as applicable.

The primary reason that less noise is seen in the “preferred” method is that a

DaqBook/2000 “AEX” device’s P1 connector pertains only to analog acquisition signals

and the P2 connector pertains only to digital I/O. This provides a strong degree of

isolation between the two signal types. However, in the case of a CA-195-x cable

connected to P4, digital and analog signals co-exist in one cable.

If you need to use the P4 connection method, use of the 8-inch ribbon cable (CA-195-1)

will result in the lowest level of crosstalk [for that method].

The CE Cable Kit, p/n CA-209D, may be required for systems that require a P4 cable

length of 3 feet. The CA-209D kit includes a shielded version of the CA-195 cable, two

grounding pigtails, and associated cable clamps. When properly connected, the shielded

cable provides greater immunity to noise. The CE Compliance chapter includes details.

pg. 8, DBK Basics 967794 Daq Systems

Page 19

DBK Identification Tables

Analog Output DBKs

Analog Output

Product Name/Description I/O

DBK2 Voltage Output Card 4 channels P1

DBK5 Current Output Card 4 channels P1

DBK46 Analog Output Card option for designated devices 4 channels Internal

Digital I/O Control DBKs

Digital I/O / Control

Product Name/Description I/O

DBK20 General-Purpose Digital I/O Card (Screw Terminals) 48 channels P2

DBK21 General-Purpose Digital I/O Card (DB37 Connectors) 48 channels P2

DBK23 Optically Isolated Digital-Input Module 24 channels P2

DBK24 Optically Isolated Digital-Output Module 24 channels P2

DBK25 Relay Output Card 8 channels P2

DBK208 Carrier board for Opto-22 Compatible SSR Digital Modules. 16 Channels P2 or P4

DBK210 Carrier Board for Grayhill 70M-Series Mini-Modules 32 Channels P2 or P4, P1 exp.

Notes

o P1, P2, and P3 DB37 connectors do not exist on the DaqBoard/2000 Series boards or /2000c

Series boards, but are obtained by using P4 adapters (DBK200 series boards).

o For DaqBoard/2000 Series devices, unless otherwise noted, the internal clocks should be set to

100 kHz when used with any of the following DBK options: DBK12, DBK13, DBK15, DBK19,

DBK52, DBK53, and DBK54. See specific DBK section for details.

o DaqBoard/500 Series boards do not support DBK options.

o DaqBoard/1000 Series boards do not support DBK options.

o DaqBook/2000 “AEX” devices have P1, P2, and P3 connectors and, in addition a P4 connector.

Connects To:

PC Board

Connects To:

Daq Systems 967794 DBK Basics, pg. 9

Page 20

Analog Signal Conditioning DBKs

The DBKs that are used for analog signal conditioning attach to transducers and condition their outputs into

analog voltages. An A/D converter, located in the primary acquisition device, measures the analog voltages.

There are many signal-conditioning solutions available (and more are in development). Note that DBK

high-capacity modules require more circuitry than can fit on a compact card.

Analog Signal Conditioning

Product Name/Description I/O

DBK4 Dynamic Signal Input Card 2 channels P1

DBK7 Frequency-to-Voltage Input Card 4 channels P1

DBK8 High-Voltage Input Card 8 channels P1

DBK9 RTD Measurement Card 8 channels P1

DBK12 Low-Gain Analog Multiplexing Card See note 2 16 channels P1

DBK13 High-Gain Analog Multiplexing Card See note 2 16 channels P1

DBK15 Universal Current/Voltage Input Card See note 2 16 channels P1

DBK16 Strain-Gage Measurement Card 2 channels P1

DBK17 Simultaneous Sample & Hold Card 4 channels P1

DBK18 Low-Pass Filter Card 4 channels P1

DBK19 Thermocouple Card See note 2 14 channels P1

DBK42 5B Isolated Signal-Conditioning Module 16 channels P1

DBK43A Strain-Gage Measurement Module 8 channels P1

DBK44 5B Isolated Signal-Conditioning Card 2 channels P1

DBK45 SSH and Low-Pass Filter Card 4 channels P1

DBK48 8B Isolated Signal-Conditioning Module 16 channels P1

DBK50 Isolated High-Voltage Input Module 8 channels P1

DBK51 Isolated Low-Voltage Input Module 8 channels P1

DBK52 Thermocouple Input Module See note 2 14 channels P1

DBK53 Low-Gain Analog Multiplexing Module See note 2 16 channels P1

DBK54 High-Gain Analog Multiplexing Module See note 2 16 channels P1

DBK55 Frequency to Voltage Module 8 channels P1

DBK65 Channel Transducer Interface Module 8 channels P1

DBK70 Vehicle Network Interface, Analog Multiplexer Module 16 channels P1

DBK80 Differential Voltage Input Card with Excitation Output 16 channels P1

DBK81 Thermocouple Card, High-Accuracy 7 channels P1

DBK82 Thermocouple Card, High-Accuracy 14 channels P1

DBK83 Thermal Couple Card, High-Accuracy; uses Connection Pod 14 channels P1

DBK84 Thermocouple Module, High-Accuracy 14 channels P1

DBK85 Differential Voltage Module 16 channels P1

DBK90 Thermocouple Module, High-Accuracy 56 channels P1

DBK207 Carrier Board for 5B Compatible Analog Input Modules 16 channels P1 or P4

DBK207/CJC Carrier Board for 5B Compatible Analog Input Modules.

Notes

DBK207/CJC includes cold junction compensation (CJC)

o P1, P2, and P3 DB37 connectors do not exist on the DaqBoard/2000 Series boards or /2000c

Series boards, but are obtained by using P4 adapters (DBK200 series boards).

o For DaqBoard/2000 Series devices, unless otherwise noted, the internal clocks should be set to

100 kHz when used with any of the following DBK options: DBK12, DBK13, DBK15, DBK19,

DBK52, DBK53, and DBK54. See specific DBK section for details.

o DaqBoard/500 Series boards do not support DBK options.

o DaqBoard/1000 Series boards do not support DBK options.

o DaqBook/2000 “AEX” devices have P1, P2, and P3 connectors and, in addition a P4 connector.

Connects To:

16 channels P1 or P4

pg. 10, DBK Basics 967794 Daq Systems

Page 21

Expansion and Terminal Panel Connection DBKs

The following DBKs offer provide various expansion and connection options. The stackable 3-slot DBK10

low-profile enclosure can be used for up to three DBKs. If a system has more than 3 DBKs, the 10-slot

DBK41 can be used. Several DBK41s can be daisy-chained to accommodate many DBKs in one system.

Expansion and Connection, General

Product Name/Description I/O

DBK1 16-Connector BNC Adapter Module 16 connectors P1

DBK10 3-Slot Expansion Chassis 3 cards P1, P2, or P3

DBK11A Screw-Terminal Option Card (DB37-Screw Terminal Block) Component

DBK40 BNC Interface 18 connectors P1

DBK41 Analog Expansion Enclosure 10 cards P1

DBK60 Expansion Chassis with Termination Panels 3 cards P1 or P2

Termination Panels, Connectivity for DaqBoard/260

Product Name/Description I/O

DBK601 Termination Panel - Blank rear panel none N/A

DBK602 Termination Panel - BNC rear panel 16 connectors DBK Card

DBK603 Termination Panel - Safety Jacks, single ended 16 connectors DBK Card

DBK604 Termination Panel - Safety Jacks, differential 8 differential (16) DBK Card

DBK605 Termination Panels - Thermocouple, differential panels;

specify type: B, J, K, R, S, or T

DBK606 Termination Panel – 3 Terminal Blocks; 16 connections per TB 48 connectors DBK Card

DBK607 Termination Panel – strain relief clamp none N/A

DBK608 Termination Panel – 3 female DB37 connectors three DB37 DBK Card

Connects To:

P1, P2, or P3

sockets

Connects To:

16 differential DBK Card

Several signal connection options were developed primarily for use with DaqBoard/2000 Series and

cPCI DaqBoard/2000c Series Boards. The DBK200 Series P4-Adapter documentation provides the basic

connection concepts. That information, along with the related DBK subsections should enable you to set up

your desired configuration.

Connection Interface Boards and Modules

Product Description I/O

DBK200 P4-to-P1 Adapter Board P1 P4

DBK201 P4-to-P1/P2/P3 Adapter Board P1, P2, P3 P4

DBK202 P4-to-P1/P2/P3 Adapter Board with Screw-Terminals P1, P2, P3 * P4

DBK203 A module version of DBK202 P1, P2, P3 * P4

DBK204 A module version of DBK202 with an included CE cable kit. P1, P2, P3 * P4

DBK205 P4-to-TB1 12-slot Screw Terminal Block for DaqBoard/2003. TB1, 12-slot P4

DBK206 P4-to-P1/P2/P3 Adapter Board with Screw-Terminals P1, P2, P3 * P4

DBK209 P4-to-P1/P2/P3 Mini-Adapter Board P1, P2, P3 * P4

DBK213 3 card slots, Screw Terminal & Expansion Module P1, P2, P3 * P1, P2, P3, P4

DBK214 16-Connector BNC Interface Module, with Screw-Terminals P1, P2, P3, BNC * P1, P2, P3, P4

DBK215 16-Connector BNC Connection Module with Screw-Terminals;

Note 1:

Note 2:

for use withDaqBoard/500 Series and DaqBoard/1000 Series

P1, P2, and P3 DB37 connectors do not exist on the DaqBoard/2000 Series or /2000c Series boards,

but are obtained by using P4 adapters (DBK200 series). These adapters typically connect to the

DaqBoard/2000 Series [/2000c Series] 100-pin P4 connector via cable.

DBK215 is only for use with DaqBoard/500 Series and DaqBoard/1000 Series. It cannot be used with

DaqBoard/2000 Series devices.

An asterisk in the I/O column indicates that the associated device includes screw-terminal blocks.

*

BNC * SCSI 68

Connects To:

Daq Systems 967794 DBK Basics, pg. 11

Page 22

Power Supply DBKs

Power supply type DBKs are typically used in laboratory, automotive, and field applications. Input power

can come from any +10 to +20 VDC source, or from an AC source by using an appropriately rated AC-toDC adapter. The DBK30A rechargeable power supply can power DBK modules where AC mains are not

available (the DBK30A outputs 28 V for powering transducers). For a large number of DBK cards, the

DBK32A or DBK33 can be installed into an expansion slot. The DBK33 is used when +5 V is required in

addition to ±15 VDC. The DBK34 provides a steady 12 or 24 VDC while working with vehicle electrical

systems that may be turned on or off during testing.

Power Supply

Product Name/Description Power

DBK30A Rechargeable Battery/Excitation Module +12-14, 24-28 VDC (3.4 A-hr @ 14 VDC)

DBK32A Auxiliary Power Supply Card ±15 V @ 500 mA

DBK33 Triple-Output Power Supply Card ±15 V @ 250 mA; +5 V @ 1 A

DBK34 Vehicle UPS Module 12/24 VDC (5 A-hr @12 VDC)

DBK34A UPS Battery Module 12/24 VDC (5 A-hr @12 VDC)

Tips on Setting up a Data Acquisition System

A successful installation involves setting up equipment and setting software parameters. In addition to this

manual, you may need to consult your Daq device or LogBook user’s manual.

DBKs should be configured before connections are made and power is applied. This sequence can prevent

equipment damage and will help ensure proper operation on startup. Many DBKs have on-board jumpers

and/or DIP switches that are used for setting channels and other variables. You will need to refer to the

individual DBK document modules to ensure that the DBKs are properly configured for you application.

Prior to designing or setting up a custom data acquisition system, you should review the following tips.

After reviewing the material you can write out the steps to setup a system that will best meet your specific

application needs.

1. The end use of the acquisition data should be used to determine how you set up and program your

acquisition system. Prior to creating the system you should understand its layout and know how you are

going to assign the channels. If you can answer the following questions you are off to a good start. If

not, you need to find the answers.

• What engineering units, ranges, sampling rates, etc. are best for your data?

• Will the data be charted graphically, statistically processed, or exported to other programs?

• How will the data be used?

• How will the data be saved?

• What are the system power requirements? Using several DBKs or transducers that require

excitation current may require an extra power supply, e.g., a DBK32A.

2. Assign channel numbers.

3. Plan the location of transducers, cable runs, DBKs, the acquisition device [LogBook or Daq device],

and the computer. Label your transducers, cables, and connectors to prevent later confusion.

pg. 12, DBK Basics 967794 Daq Systems

Page 23

4. When configuring your LogBook or Daq device(s) consider the following:

• LogBook calibration is typically performed automatically through LogView software;

however, some DBKs may require manual calibration.

• The DaqBook/100 Series and DaqBook/200 Series devices, and DaqBoards (ISA type)

have internal jumpers and switches that you must set manually to match your

application.

• Some DaqBook/100 Series and DaqBook/200 Series models are partially configured in

software.

• DaqBook/2000 Series devices have no jumpers or internal switches and are configured

entirely through software.

• Daq PC-Cards are configured entirely in software.

• DaqBoard/2000 Series boards are PCI type boards. They have no jumpers or switches and

are configured entirely through software.

• cPCI DaqBoard/2000c Series boards are compact PCI (cPCI) type boards. They have no

jumpers or switches and are configured entirely through software.

• You may need to refer to other documentation, such as Quick Starts, Installation Guides,

User’s Manuals, and pertinent DBK document modules.

5. Perform all hardware configurations before connecting signal and power. Remember to

configure all the DBK cards and modules for your application. Several jumpers and DIP switches

may need to be set (channel, gain, filters, signal mode, etc).

6. Setting up channel parameters often requires both hardware and software setup.

7. Route and connect all signal and power cables while all power is turned OFF.

8. To minimize electrical noise, route all signal lines away from any RF or high-voltage devices.

9. Follow your device’s specific installation instructions. For certain devices software should be installed

first; for others, hardware should be installed prior to software installation.

10. After software is loaded, remember to set the software parameters as needed for your application.

The software must recognize all the hardware in the system. Measurement units and ranges

should be checked to verify that they meet your application requirements.

11. Remember to set all channels to the proper mode for your DBK or other signal source.

12. After your system is up and running, verify proper data acquisition and data storage.

13. Verify system accuracy; adjust ranges or calibrate as needed.

14. Device specific information regarding system setup and expansion can be found in the Daq and

LogBook User’s manuals; and in the applicable DBK document modules of this manual.

15. If you are considering system expansion, review the DBK10, DBK41, and DBK60 document modules.

The best option depends on the number of DBK cards in your system. For just a few cards, use the

stackable 3-slot DBK10 low-profile expansion enclosure. For more than six cards, use the 10-slot

DBK41. DBK41s can be daisy-chained to one-another to handle a large number of DBKs.

In regard to power management, you should review the DBK30A, DBK32A, and DBK33 document

16.

modules. For portable applications, the compact DBK30A rechargeable power supply can provide

power to the DBK10 or DBK41. The DBK30A also includes a 28 V output for powering 4 to 20 mA

transducers. For applications with many DBK cards (initially or in future expansion), the DBK32A or

DBK33 can be installed into any expansion slot. The DBK32A provides ±15 VDC and the DBK33

provides ±15 VDC and +5 VDC.

Daq Systems 967794 DBK Basics, pg. 13

Page 24

Power Supplies and Power Connectors

Power supplies convert the raw power they receive into a lower DC voltage and/or current for use by

devices with various power demands. Many of the power supplies that are used to power data acquisition

equipment are of the switching-mode type. These devices provide a regulated output whether the power

supply’s input is, for example, 60 Hz, 120 VAC as in the United States or, 50 Hz, 220 VAC as found in

European countries. Small power supplies, that do not switch, consist of simple transformer/rectifiers and

filtered capacitors; and operate over a smaller voltage range.

Some manufacturers improve the power output of their units over time, without changing the model

number. For example, one very popular power supply was previously rated at 15 VDC @ 2.7 amps, yet

more recent versions of the same model number are rated 15 VDC @ 3.3 amps. Read the manufacturer’s

information pertaining to your power supplies so you don’t accidentally overload the supply.

DBKs – The following table indicates the type of power supply that is typically used with certain DBKs.

These DBKs can be powered from a

Switching-Mode Type Power Supply

The switching-mode power supply typically

receives power from a 100 to 240 VAC source at 50

Hz to

60 Hz and converts it to the 15 VDC required by the

DBK.

DBK Description DBK Description

DBK32A Auxiliary Power Supply Card DBK23 Optically Isolated Digital-Input Module

DBK33 Triple-Output Power Supply Card DBK24 Optically Isolated Digital-Output Module

DBK42 5B Isolated Signal Conditioning Module DBK43A Strain Gage Measurement Module

DBK70 Vehicle Network Interface DBK50 Isolated High-Voltage Input Module

DBK51 Isolated Low-Voltage Input Module

The DIN5 is the system’s basic power connector (see the following figure). The CA-115 is a 6-in. cable

with a plug (male) DIN5 connector on both ends. The CA-115 is used to connect DBK32As [or DBK33s]

in parallel when they are to be powered by the same power supply.

Power Output Connector

Male connector located on the

power supply cable and on both

ends of the CA-115 cable.

Power Input Connector

Female connector located on

the device being powered

(DaqBook, DBK32A, DBK33).

DIN5 Power Connectors

Note 1:

DIN5 connectors for LogBook, DBK34, and DBK34A have threaded retaining rings.

These DBKs can be powered from a

Transformer/Rectifier Type, Unregulated Power Supply

The DBKs in this column use up to15 VDC @

900 mA. This transformer/rectifier type power

supply receives power from a 110 to 125 VAC

source, at 60 Hz, and converts it to the 15 VDC

required.

(see Notes 1 and 2)

DIN5 Power Out

On a DBK34 and DBK34A

Note 2:

In regard to the above pinout for the DBK34 and DBK34A Power Out DIN5 connector, the 28 V

pin is only active when the device is in the 28 VDC mode; however, the 14 V pin is active

regardless of the mode selected.

pg. 14, DBK Basics 967794 Daq Systems

Page 25

An Introduction to Power-Related DBKs

The power-related DBK options are the DBK30A, DBK32A, DBK33, DBK34, and DBK34A. From the

standpoint of providing reliable power, these DBKs have proven convenient in laboratory, automotive, and

field applications.

Input power for these devices can come from any 10 to 20 VDC source, or from an AC source via an

appropriate AC-to-DC adapter.

A brief synopsis of the DBK power options follows. Refer to the respective document modules for complete

information.

DBK30A module - provides power at 14 and 28 VDC with a rated capacity of 3.4 A-hr @ 14 VDC.

The DBK30A’s 28 V output will power 4 to 20 mA transducers.

power DBK modules in situations where AC mains are not available.

Note: Some transducers (e.g., 2-wire 4-20 mA transmitters, bridge-configured sensors, etc) require an

excitation voltage in order to work properly. The DBK30A supplies 14 and 28 VDC. Consult

transducer documentation before applying power.

The module’s rechargeable power supply can

DBK32A - provides ±15 VDC @ 500 mA.

DBK33 - provides ±15 VDC @ 250 mA and +5 VDC @ 1000 mA.

The DBK32A and DBK33 power cards attach directly to the P1 analog expansion bus where they supply

power to DBK analog expansion cards. The DBK32A and the DBK33 can be powered from an included AC

adapter, an optional DBK30A battery module, or from a +10 to +20 VDC source such as a car battery.

When installed in a DBK10 three-slot expansion chassis, the DBK32A or DBK33 supplies power

to the analog DBK [that is to receive power] via a CA-37-x cable.

If used with the DBK41 ten-slot expansion enclosure, the DBK32A or DBK33 installs into one of the analog

expansion slots on the DBK41’s backplane. A power card in any DBK41slot (other than the leftmost, when

viewed from the rear) will power the other cards that are connected to the DBK41’s backplane.

CAUTION

If using a DBK32A or a DBK33 with a DaqBook/100 Series, DaqBook/200 Series, or a

DaqBoard [ISA type] device, you must entirely remove the shunt jumpers from JP1.

Failure to do so will result in damage to the 8254 timer chip. Refer to the power card

document modules and to the Daq device Hardware sections of the DaqBook/100 Series

and DaqBook/200 Series, and DaqBoard [ISA] user’s manuals for JP1 locations and

configurations.

DBK34A module – provides 12 or 24 VDC with a 5.0 or 2.5 A-hr capacity (respectively).

The DBK34A is classified as a UPS / Battery module. The module can be used for in-vehicle testing

in scenarios where the vehicle’s electrical system does not affect acquisition device power during

starter-current surge, or power-off.

Daq Systems 967794 DBK Basics, pg. 15

Page 26

Power Requirements

The improper use of power can cause system damage. The following terms are important in regard to

understanding your system’s power needs.

• Supply power for signal conditioning type DBKs comes from a primary acquisition device,

such as a DaqBook/2000 Series device or LogBook, or from a power card or module. If

needed, the DBK32A or DBK33 can provide additional power to meet DBK power demands.

The DBK power supplies work off of low-voltage DC that can come from an AC adapter or

from a DC source, such as a car battery.

• Demand for power comes from DBK cards and modules [and in some systems, from

transducers]. You should use the DBK Power Requirement Worktable to calculate your

system’s power needs. After completing the table, compare the total power demand to the

supply power.

• Distribution of power to most DBKs is via the P1 interface. The DBK41 expansion chassis

has a jumper to isolate +5 VDC power from P1. The P1 Pin designations are as follows:

Pin 1: +5 VDC

Pin 2: -15 VDC

Pin 21: +15 VDC

Pin 7: digital ground

Pin 28: analog ground

Pin 29: analog ground

Note: Certain DBK modules have their own internal power supplies and require only 10 VDC to 20 VDC.

LogBook

The LogBook [with no DBKs attached] uses approximately 12 Watts of power. If using battery-power, you

can compute operational endurance from your battery’s watt×hr rating and the following calculation tables.

DaqBoard/2000 Series Boards

DaqBoard/2000 Series and cPCI DaqBoard/2000c Series Boards use 3.5 watts of power

(700 mA @ 5 VDC) from their host computer. Power consumption can be up to 10 W with external

accessories.

Avoid power cycling the host PC. Wait 10 seconds after powering down the host PC before powering it

back on. This will allow any residual voltages to decay enabling the DaqBoard/2000 Series or /2000c Series

board to start up in a known good state.

DaqBook/100 Series & /200 Series, DaqBoard [ISA], and Daq PC-Card

If using power from AC mains (through adapter), you need not worry about Daq device power use. If using

battery-power, you can compute operational endurance from the battery’s watt×hr rating and power tables.

Daq PC-Card and DaqBoard use power from their host PC.

DaqBook/100 and DaqBook/200 Series devices use no power from the PC, but do require DC voltage from

an AC-to-DC adapter, or another suitable source. Voltage needs are as follows:

• +7 to +20 VDC for DaqBook/100, DaqBook/112, and DaqBook/120

• +10 to +24 VDC for DaqBook/216

• 9 to +18 VDC for DaqBook/200 and DaqBook/260.

Various AC adapter models support power grids of USA, Europe, Japan, and Asia.

pg. 16, DBK Basics 967794 Daq Systems

Page 27

DaqBook/2000 Series Devices

If using power from AC mains (through adapter), you need not worry about Daq device power use. If using

battery-power, you can compute operational endurance from the battery’s watt×hr rating and power tables.

DaqBook/2000 Series devices use no power from the PC, but do require DC voltage from an AC-to-DC

adapter with a supply range of +10 VDC to +30 VDC, or another suitable DC source.

Various AC adapter models support power grids of USA, Europe, Japan, and Asia.

Power Requirements Table

DaqBook/100 510 mA @ 12 VDC = 6.12 W

DaqBook/112 360 mA @ 12 VDC = 4.32 W

DaqBook/120 510 mA @ 12 VDC = 6.12 W

DaqBook/200 620 mA @ 12 VDC = 7.44 W

DaqBook/216 600 mA @ 12 VDC = 7.2 W

DaqBook/260 620 mA @ 12 VDC = 7.44 W

DaqBook/2001, /2005 1000 mA @ 15 VDC = 15.0 W

DaqBook/2020 1000 mA @ 15 VDC = 15.0 W

Device Power Required (Watts)

DaqOEM/2001, /2005 1000 mA @ 15 VDC = 15.0 W

DaqLab 1000 mA @ 15 VDC = 15.0 W

DaqScan 1000 mA @ 15 VDC = 15.0 W

DaqBoard/100A 1330 mA @ 5 VDC = 6.65 W

DaqBoard/112A 970 mA @ 5 VDC = 4.85 W

DaqBoard/200A 1700 mA @ 5 VDC = 8.5 W

DaqBoard/216A 1340 mA @ 5 VDC = 6.7 W

DaqBoard/2000 Series board 700 mA @ 5 VDC = 3.5 W

(Note 1)

cPCI DaqBoard/2000c Series board 700 mA @ 5 VDC = 3.5 W

(Note 1)

DaqBook/2000A

DaqBook/2000X

DaqBook/2000E Under No External Load (0W):

Under No External Load (0W):

467mA @ 15VDC = 7 W

Under Full External Load (15W):

1533mA @ 15VDC = 23 W

1133mA @ 15VDC = 17 W

Under Full External Load (15W):

2200mA @ 15VDC = 33 W

Daq PC-Card/112B

Daq PC-Card/216B

Note 1: For DaqBoard/2000 Series and /2000c Series boards, consumption can be

up to 10 W with external accessories.

Daq Systems 967794 DBK Basics, pg. 17

Normal Operation:

160 mA @ 5 VDC = 0.8W

Power Down Mode:

40 mA @ 5 VDC = 0.2 W

Page 28

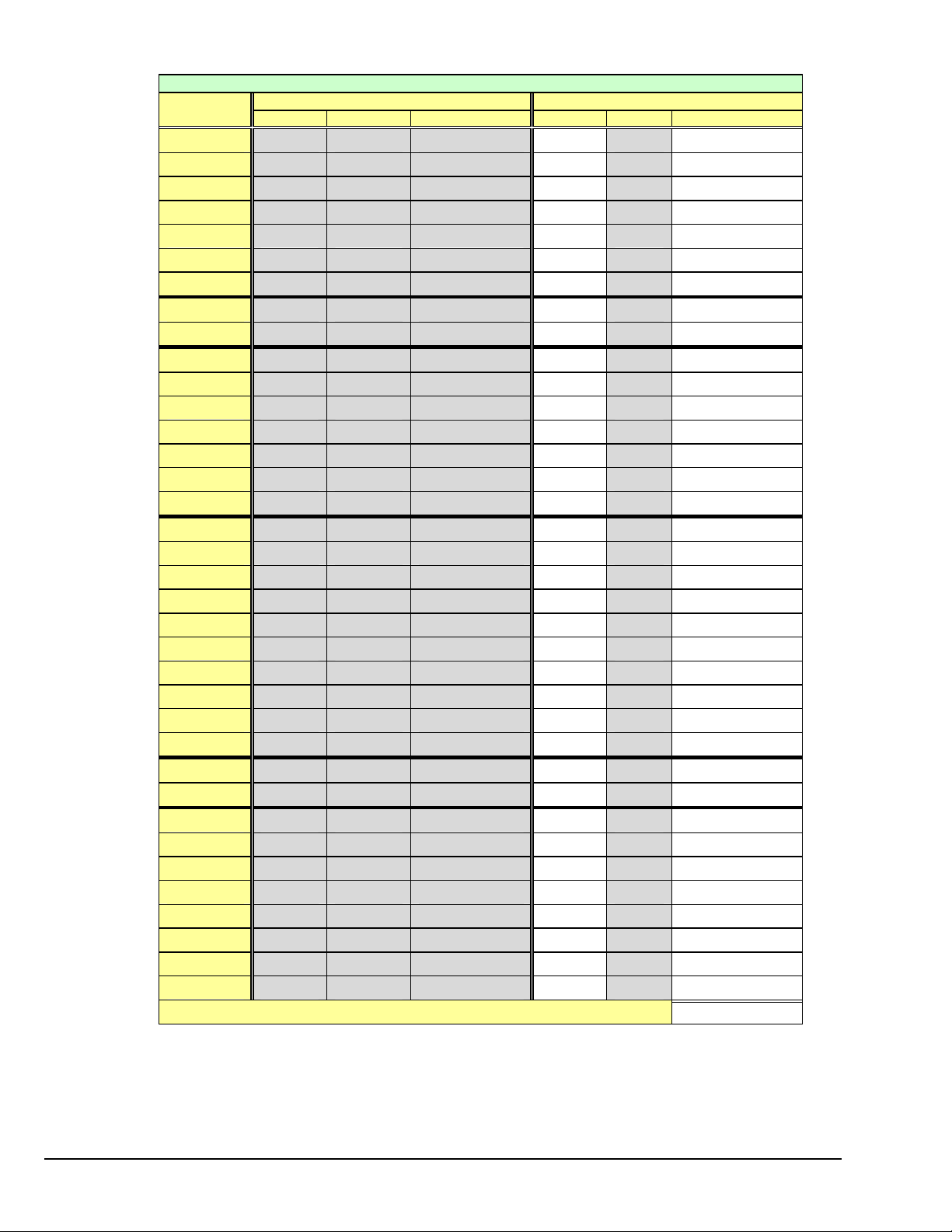

Calculating Your System’s Power Needs

Use the chart below and the worktable on the next page to ensure your system will have sufficient power.

If the load (calculated in the worktable) exceeds available power (from the chart at the right), you must

add a power card or a module such as a DBK32A or DBK33.

Available Power Chart — Supply to Expansion Devices

Product Available Power

LogBook +5 VDC @ 0.10 A from P1-1, P2-18, P2-20, P3-20

+15 VDC @ 0.15 A from P1-21

+15 VDC @ 0.05 A from P3-19

-15 VDC @ 0.15 A from P1-2

-15 VDC @ 0.05 A from P3-37

DaqBook/100 2100 mW

DaqBook/112 2400 mW

DaqBook/120 2100 mW

DaqBook/200 4000 mW

DaqBook/216 4000 mW

DaqBook/260 4000 mW

DaqBook/2000 AEX 15000 mW; 5V at 1 A; ± 15 V at 500 mA each

DaqBook/2001, /2005 10,000 mW

DaqBook/2020 7,000 mW

DaqOEM/2001, /2005 10,000 mW

DaqLab 10,000 mW

DaqScan 10,000 mW

DaqBoard/100A 3300 mW

DaqBoard/112A 3300 mW

DaqBoard/200A 3000 mW

DaqBoard/216A 3000 mW

DaqBoard/260A 3000 mW

DaqBoard/2000 Series

& /2000c Series

Daq PC-Card/112B 0 mW

Daq PC-Card/216B 0 mW

5000 mW; 5 V at 1 A; ±15 V at 75 mA each (with

exception of DaqBoard/2002 and /2002c)

pg. 18, DBK Basics 967794 Daq Systems

Page 29

Available Power Chart — Supply to Expansion Devices

Product Available Power

DBK32 7500 mW

DBK32A 15000 mW

DBK33 7500 mW

DBK34 5 A-hr in 12 V mode; fused at 8 A

DBK34A 5 A-hr in 12 V mode; fused at 8 A

Use the following procedure and table to calculate the required system power.

1. In the Quantity column (5th), list the number of DBKs of that type in your system.

2. In the Sub Total column (7th), enter the product of column 5 and column 6 (mW).

3. Add the Sub Total column, and enter the sum at the bottom right of the table.

This result is your power requirement in mW.

DBK32, DBK32A, and DBK34 cannot supply +5 VDC. In cases that require +5 VDC, if

the +5 VDC requirement exceeds 500 mW from a LogBook or Daq device, then a DBK33

must be used. Note that DBK33 can supply 1000 mW at +5 VDC.

Note:

The DBK34 has an 8 amp fuse, and has a capacity of 5 A-hr when in the 12V mode,

and a capacity of 2.5 A-hr when in the 24V mode.

Daq Systems 967794 DBK Basics, pg. 19

Page 30

DBK Power Requirement Worktable—Demand

DBK Voltage Reference Calculation

Options +15 VDC -15 VDC +5 VDC Quantity × mW = Sub Total

DBK1

DBK2

DBK4

DBK5

DBK7

DBK8

DBK9

DBK10

DBK11A

DBK12

DBK13

DBK15

DBK16

DBK17

DBK18

DBK19

DBK20

DBK21

DBK23***

DBK24***

DBK25

DBK40

DBK41

DBK42

DBK43A***

DBK44

DBK45

DBK46

DBK48

DBK50***

DBK51***

DBK52

DBK53

DBK54

DBK55

DBK60

0 0 0 0

18 mA 18 mA 5 mA 565

95 mA 80 mA 25 mA 2750

2 mA 2 mA 15 mA 135

14 mA 8 mA 18 mA 420

15 mA 15 mA <1 mA 455

21 mA 16 mA <1 mA 560

0 0 0 0

0 0 0 0

15 mA 15 mA <1 mA 455

15 mA 15 mA <1 mA 455

16 mA 16 mA <1 mA 485

37 mA 32 mA <1 mA 1040

30 mA 30 mA <1 mA 905

36 mA 36 mA <1 mA 1085

6 mA 7 mA <1 mA 200

0 0 <10 mA 50

0 0 <10 mA 50

0 0 <2 mA 10

0 0 <2 mA 10

0 0 <2 mA 10

0 0 0 0

0 0 0 0

<1 mA <1 mA <1 mA 35

<1 mA <1 mA <1 mA 35

<1 mA <1 mA 60 mA (Note 1) 330

52 mA 52 mA <1 mA 1565

20 mA 20 mA 400 mA 2600

<1 mA <1 mA <1 mA 35

<1 mA <1 mA <1 mA 35

<1 mA <1 mA <1 mA 35

6 mA 7 mA <1 mA 200

15 mA 15 mA <1 mA 455

15 mA 15 mA <1 mA 455

30 mA 20 mA 40 mA 950

0 0 0 0

Total Power Requirement in mW

Note 1: DBK44’s 60 mA value is based on 30 mA for each of two 5B modules. This value will be higher if using

Note 2: DBK2 and DBK5 are not used with LogBook.

*** Three asterisks indicate that the DBK is a module with internal power supply; powered separately.

5B module 5B38 (200 mA for each 5B38), or if using 5B39 (170 mA for each 5B39). Refer to the DBK44

document module for more information.

This table is continued.

pg. 20, DBK Basics 967794 Daq Systems

Page 31

DBK Power Requirement Worktable—Demand

DBK Voltage Reference Calculation

Options +15 VDC -15 VDC +5 VDC Quantity × mW = Sub Total

DBK65

DBK70***

DBK80

DBK81

DBK82

DBK83

DBK84

DBK85

DBK90

DBK200

DBK201

DBK202

DBK203

DBK204

DBK205

DBK206

DBK207

DBK207/CJC

DBK208

DBK209

DBK210

DBK213

DBK214

DBK215

25 mA 25 mA 1 mA 755

<1 mA <1 mA <1 mA 35

25 mA 25 mA <1 mA 755

35 mA 35 mA <2 mA 1060

60 mA 60 mA <2 mA 1810

60 mA 60 mA <2 mA 1810

60 mA 60 mA <2 mA 1810

25 mA 25 mA 1 mA 755

40 mA 40 mA 40 mA 1400

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

<1 mA <1 mA <1 mA 35

<1 mA <1 mA <1 mA 35

0 0 6 mA 30

0 0 0 0

0 0 90 mA 450

0 0 0 0

0 0 10 mA 50

0 0 10 mA 50

Total Power Requirement in mW

Note 2: DBK207, DBK207/CJC, DBK208, and DBK210 are not used with LogBook.

*** Three asterisks indicate that the DBK is a module with internal power supply; powered separately.

Additional Reading

During software installation, Adobe® PDF versions of user manuals will automatically install onto your hard drive

as a part of product support. The default location is in the Programs group, which can be accessed from the

Windows Desktop. Refer to the PDF documentation for details regarding both hardware and software.

A copy of the Adobe Acrobat Reader

printing the PDF documents. Note that hardcopy versions of the manuals can be ordered from the factory.

Daq Systems 967794 DBK Basics, pg. 21

®

is included on your CD. The Reader provides a means of reading and

Page 32

pg. 22, DBK Basics 967794 Daq Systems

Page 33

Signal Management 1

Signal Modes ...... 1-1

System Noise ...... 1-5

Using DBK Cards and Modules for Signal Conditioning ...... 1-6

Channel Control and Expansion ...... 1-7

Signal Acquisition ...... 1-9

Sequencer ...... 1-9

Scan Rate ...... 1-10

Triggering ...... 1-10

Counter/Timer Functions ...... 1-11

Simultaneous Sample and Hold (SSH) ...... 1-11

Two-Point Calibration of a Temperature Measurement System ...... 1-12

Overview ...... 1-12

An Example of Two-Point Calibration ...... 1-13

Calculation of Scale and Offset ...... 1-14

Implementing the Scale and Offset Constants in DaqView ...... 1-14

Converting Degrees from Celsius to Fahrenheit ...... 1-14

One Known Temperature Environment ...... 1-15

Use of a Temperature Calibrator ...... 1-15

CE Compliance ...... 1-15

CE Standards and Directives ...... 1-16

Safety Conditions ...... 1-16

Emissions/Immunity Conditions ...... 1-17

CE Enhancements for Existing Products ...... 1-17

Signal Modes

Input signals come in one of two modes, single-ended or differential. Expansion modules, LogBook, and

Daq device default setting use the single-ended mode. Some DBKs use differential inputs for certain kinds

of transducers; but DBK output is always single-ended. The following text briefly describes the two signal

modes.

Note: For DaqBook/100, /112, /120, jumper settings determine the signal mode. Single-ended is the

Single-ended mode refers to a mode, or circuit set-up, in which a voltage is measured between 1 signal line

and common ground voltage (Vcm). The measured voltage may be shared with other channels. The

advantage of a single-ended non-differential mode [over differential mode] is that it provides for a higher

channel count (16 vs 8 channels).

Differential-mode refers to a mode, or circuit set-up, in which a voltage is measured between 2 signal

lines. The resulting measured differential voltage is used for a single channel. Differential inputs reduce

signal errors and the induction of noise from ground current. The following illustration is an example of

how noise is reduced, or canceled-out, when using the differential mode.

In the schematic, voltage signal S

spikes with the same polarity, phase, and magnitude in each input signal cancel out—resulting in a clean

differential signal (S

In the schematic, signals S

however, even if these signals were out of phase, the noise in

each (indicated by jagged lines) would still have the same

magnitude, phase, and polarity. For that reason, they would

still cancel out.

factory-set default. For DaqBoard and Daq PC-Card, choosing between differential and singleended inputs is made by software command.

is subtracted from signal S1, resulting in the output signal shown. Noise

2

- S2).

1

and S2 are shown in-phase;

1

DBK Option Cards and Modules 886995 Signal Management 1-1

Page 34

Input Isolation

Three benefits of input isolation are circuit protection, noise reduction, and the rejection of high common

mode voltage.

• Circuit protection. Input isolation separates the signal source from circuits that may be damaged by

the signal. (Voltages higher than about 10 V can distort data or damage chips used in data

acquisition.) High-voltage signals or signals with high-voltage spikes should therefore be isolated.

The protection can also work the other way—to safeguard a sensitive signal conditioner from a

failing device elsewhere in the system.

• Noise reduction. Isolation eliminates ground loops for high-gain systems and multi-unit systems that

are grounded together. The chassis for each device can rest at a ground potential slightly different

from the other devices. These irrelevant currents and the spikes they may have picked up by

induction can thus be kept out of the measurement circuit.

• Rejection of high common-mode voltage. There is a limit to the voltage applied to a differential

amplifier between ground and the amplifier inputs. Fortunately, the differential amplifier rejects high

common-mode voltage signals. High common-mode voltage and noise spikes are rejected (canceled

out) in in-phase signals (same amplitude and frequency) that are present in both the high and low

inputs at the same time.

References for Differential Modes

There are three basic types of measurement configuration related to differential mode; these are groundreferenced, shunt-referenced, and floating.

Differential Mode, Ground-Referenced

In ground-referenced configurations, the signal voltage is

referenced to a local common ground. In most cases, the local

ground will be at a different voltage potential from the PC’s

ground.

Differential inputs provide attenuation of the common-mode

noise. When in this mode, the amplifier sees the voltage

differential between the high and low inputs (see figure).

Common-mode noise reduction occurs because noise in the

high input signal is typically the same as the noise in the low

input signal. Because of this phenomena, the voltage

difference between the 2 signals remains essentially unaffected

by noise spikes, since these spikes appear at the same instant

and at the same magnitude in both the high and low input

signals. In other words, the noise spikes cancel each other out.

As noted earlier, even if these signals were out-of-phase, the

noise would still cancel out since the spikes in both signals

would be of the same magnitude and polarity.

Note: In the simple example (shown in the figure), the

differential between the high and low signals would result in a straight line because the signals are

equal in frequency, phase, and magnitude.

Differential Mode, Shunt-Referenced

There are situations in which small voltages need to be measured and the currents flowing in the power

supply common will cause measurement errors. As shown in the figure, using the analog common as the

reference point will result in errors. These errors are the result of variations in current flow along the

common line [(I3 * Z3) + (I3 & I2) * Z2].

1-2 Signal Management 886995 DBK Option Cards and Modules

Page 35

Differential Circuit with Shunt-reference

A way around this problem is to use a differential measurement for each shunt, with the instrument

common connected to the supply common. Each input channel will measure the shunt voltage and will

reject any voltage in the common wire (common-mode rejection).

Differential Mode, Floating (Isolated from Ground)

Floating-differential measurements are made when low-level signals must

be measured in the presence of high levels of common-mode noise (e.g., a

T/C

(+)

(-)

CH0H

CH0L

non-grounded thermocouple). When the signal source has no direct

connection to the system analog common, one must be provided. This can

be done by connecting a resistor between one of the two signal lines;

usually the lower in potential and common. A resistor of 10 to 100 kΩ is

satisfactory (less noise with the lower values).

CAUTION

10 k

Ω

Analog

Com.

MUX

BOARD

DBK12/13/15

Floating Diffe rential Circuit

Do not use differential signal hookups with the intent of achieving isolation or circuit

protection. Differential signal hookups do not provide isolation, or any other kind of

circuit protection.

Connecting Differential Amplifiers

Wire connections must be solid. Loose wires will add noise to the circuit. Low grade unshielded cables

will act as antennas, inducing more noise into the system. For this reason, all applications using a

differential amplifier require the use of quality signal cables and connectors. The signal cable used should

be constructed with:

• Insulated outer jacket

• Twisted signal pairs

• Foil shield

Insulated Out er Jacket

Foil Shield

Drain Wir e

Twisted Signal Pair

• Drain wire (copper stranded)

The twisted signal pairs should make use of

low impedance, stranded copper conductors;

and the foil shield should be of the type using

Stranded Copper

Conductors

Twisted Signal Pair

Shielded Signal Cable

multiple folds.

The copper-stranded drain wire should be considered as part of the shield, and should be connected as

described later in this section. Proper use of a quality signal cable will result in a dramatic reduction of

noise.

The signal circuit must be connected with only one ground from the shield, as indicated in the left side of

the figure below. A mistake, which is often made, is having two grounds (one at each end of the signal

shield). Having two grounds, as shown in the right side of the figure, creates a “ground loop.” The ground

loop provides a path for current to circulate, causing the induction of noise that can affect the signal.

DBK Option Cards and Modules 886995 Signal Management 1-3

Page 36

CORRECT

Shield

Grounding Wire

Potential difference and no path

for current flow.

High Input Signal

Differential

Amplifier

Low Input Signal

WRONG

Ground loop caused by

current flow.

High Input Signal

Shield

Grounding Wire

Differential

Amplifier

Low Input Signal

No Noise-Inducing Ground Loop Noise-Inducing Gro und Loop

Aside from eliminating noise-inducing ground loops, the use of bias resistors should also be considered

with isolated signal sources. Bias resistors can be used to provide bias current for the positive and negative

(high and low) input signals to the differential amplifier. The impedance value of the bias resistors

depends on the output impedance of the signal source.

Low Input SignalHigh Input Signal

Shield

Differential

Amplifier

Ground in g Wire

Locate bi as resistors (R and R ) as close

as possible to the different ia l amplifier.

12

R

R

1

2

A basic rule of thumb is: The value of the bias resistor should be at least 10 times the output impedance of

the signal source, but less than 1 M

Ω

.. Bias resistors should be located as close as possible to the

differential amplifier. Ground only one end of the signal shield.

Unipolar and Bipolar Measurement

Unipolar signals are always zero or positive. Bipolar signals can be negative or positive and typically

range from -5 to +5 V (-10 to +10 V for the /2000 Series Devices). Using one or the other depends on the

signal from the transducer and its signal conditioning. If the DBK (or other signal conditioner) outputs a

bipolar signal, then the LogBook or Daq device should be set to bipolar. If the LogBook or Daq device

sequencer is using the wrong mode for a channel, that channel’s reading may be clipped or in error.

Reading a bipolar signal in unipolar mode misses half the signal, and the half received is not converted

with optimal resolution.

Note: The different DBKs can use either or both signal modes. Refer to the DBK documentation, and

verify that the DBK and the LogBook or Daq device are set to the proper mode for each channel.

12-Bit vs 16-Bit Resolution

An analog-to-digital converter (ADC) converts an analog voltage to a digital number. The digital number

represents the input voltage in discrete steps with finite resolution. The number of bits that represent the

digital number determines ADC resolution. An n-bit ADC has a resolution of 1 part in 2

• 12-bit resolution is 1 part in 4096 (in binary powers, 2

range.

• 16-bit resolution is 1 part in 65,536 (in binary powers, 2

12

) and corresponds to 2.44 mV for a 10 V

16

) and corresponds to 0.153 mV in a 10 V

n

.

range.

1-4 Signal Management 886995 DBK Option Cards and Modules

Page 37

System Noise

Electrical noise can present problems even with good equipment; thus, controlling noise is imperative.

Some techniques avoid or prevent noise sources from entering the system; other techniques remove noise

from the signal.

Laboratory and industrial environments often have multiple sources of electrical noise. An AC power line

is a source of 50/60 Hz noise. Heavy equipment (air conditioners, elevators, pumps, etc.) can be a source

of noise, particularly when turned on and off. Local radio stations are a source of high-frequency noise,

and computers and other electronic equipment can create noise in a multitude of frequency ranges. Thus,

an absolute noise-free environment for data acquisition is not realistic. Fortunately, noise-reduction

techniques such as averaging, filtering, differential voltage measurement, and shielding are available to

reduce noise to an acceptable level.

Note: Additional noise-reduction information is contained in the section, “Signal Modes,” especially in the

Averaging

Averaging is done in software after several samples have been collected. Depending on the nature of the

noise, averaging can reduce noise by the square root of the number of averaged samples. Although

averaging can be effective, it suffers from several drawbacks. Noise in measurements only decreases as

the square root of the number of measurements—reducing RMS noise significantly may require many

samples. Thus, averaging is suited to low-speed applications that can provide many samples.

Note: Only random noise is reduced or eliminated by averaging. Averaging will not reduce or eliminate

paragraphs pertaining to connections, signal cables, and ground loops.

any signal that is periodic.

Analog Filtering

A filter is an analog circuit element that attenuates an incoming signal according to its frequency. A lowpass filter attenuates frequencies above the cutoff frequency. Conversely, a high-pass filter attenuates