Page 1

August 2002

OMB-CHARTSCAN-1400

Portable Data Recorder

OMB-483-0901

p/n

3.1

Rev

Page 2

OMEGAnetSM On-Line Service

http://www.omega.com

Servicing North America:

Internet e-mail

info@omega.com

USA:

Canada:

One Omega Drive, Box 4047

Stamford, CT 06907-0047

Tel: (203) 359-1660

e-mail: info@omega.com

976 Berger

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928

e-mail: canada@omega.com

FAX: (203) 359-7700

FAX: (514) 856-6886

For immediate technical or application assistance:

USA and Canada:

Mexico and

Latin America:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Tel: (95) 800-TC-OMEGA

En Espanol: (95) 203-359-7803

SM

FAX: (95) 203-359-7807

e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux:

Czech Republic:

France:

Germany/Austria:

United Kingdom:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING:

These products are not designed for use in, and should not be used for, patient-connected applications.

Postbus 8034, 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

ul. Rude armady 1868

733 01 Karvina-Hranice

Tel: 420 (69) 6311899

e-mail:czech@omega.com

9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

25 Swannington Road,

Broughton Astley, Leicestershire,

LE9 6TU, England

Tel: 44 (1455) 285520

FAX: 44 (1455) 283912

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

FAX: (31) 20 6434643

FAX: 420 (69) 6311114

FAX: (33) 130-699-120

FAX: 49 (07056) 8540

P.O. Box 7, Omega Drive,

Irlam, Manchester,

M44 5EX, England

Tel: 44 (161) 777-6611

FAX: 44 (161) 777-6622

Page 3

How To Use This Manual

Chapter 1: ChartScan

up and running. The chapter includes installation steps, basic concepts regarding the ChartView software

program, and a ChartView tutorial to quickly familiarize you with the software.

Chapter 2: General Information gives a general description of ChartScan and related hardware including

ChartScan’s expansion module and available signal conditioning cards.

Chapter 3: Hardware provides detailed information pertaining to ChartScan’s front and rear panels, voltage selector

switch, memory expansion, communication interfaces, digital I/O lines, external TTL connectors, signal

conditioning modules, CSN/Exp expansion chassis (option), and high current CSN/relay card (option).

Chapter 4: ChartView Software Reference explains the ready-to-use ChartView software that comes with every

ChartScan unit. Topics include detailed explanations of the program’s pull-down menus, toolbar icons, and

keypad control options. Additional features available through ChartView Plus are included.

Chapter 5: eZ-PostView and ViewXL - eZ-PostView is a time-domain post-acquisition data viewing application.

ViewXL is a Microsoft Excel Add-In. This chapter provides a brief overview of both applications and

references the actual user documentation that is included on your installation CD.

Chapter 6: Calibration explains how to use ScanCal, a software-automated method of calibration, as well as how to

manually calibrate the master chassis and option cards.

Unit Startup and ChartView Tutorial provides information to get your ChartScan system

Appendices

The Appendices provide programming-related information that is not necessary for ChartView users. Appendices

are as follows:

Appendix A: API Commands describes the entire command set for ChartScan. Syntax, parameters, interpretation,

and error codes are explained. Sections on the individual commands include their parameters, types, typical use,

related information, and a sample program excerpt.

Appendix B: Configuration Aspects for Programmers provides information on memory allocation, channel and

scan configuration, triggers, alarms, and digital I/O operation.

Appendix C: Registers, Data Formats, & Queries provides information regarding registers, data formats, status and

event reporting, and other operation-related factors.

Appendix D: ChartScan Program Examples explains the program examples which are supplied on the release disk.

Typical tasks are covered including various kinds of data acquisition and alarm control.

Appendix E: Bus States, Bus Lines, and Data Transfer Aspects provides reference material regarding bus states,

bus lines and data transfer (DIO) lines in relation to IEEE 488 and Serial Interfaces.

Appendix F: ASCII Code Summary summarizes ASCCII control codes and character codes.

Appendix G: ChartScan Error Messages lists and describes error codes pertaining to ChartScan.

Appendix H: Abbreviations

CAUTION

CAUTION

CAUTIONCAUTION

If equipment is used in any manner not specified in this manual, or if specification limits are

exceeded, the function of the equipment, as well as the protection provided by it, may be

impaired.

ChartScan User’s Manual

Page 4

Table of Contents

1 ChartScan-

Unit Startup & ChartView Tutorial

Overview…… 1-1

Unit Startup……1-2

Inspect Your System……1-2

Install Software……1-2

Check and Install Hardware……1-3

Verify Voltage Setting……1-3

Verify DIP Switch Setting……1-3

Install Signal Conditioning Card(s)……1-3

Install Interface Communications Card (option)… 1-4

Connect Expansion Chassis (option)……1-4

Connect ChartScan to your computer……1-4

Apply power to ChartScan…… 1-5

Connect Channel Signal Inputs……1-5

Start ChartView, Configure System, and Collect

Data……1-7

ChartView, Basic Concepts……1-10

Configuration Files……1-10

Understanding Groups, Charts, and

Channels……1-10

Three Ways of Using ChartView……1-11

ChartView Tutorial……1-11

2 General Information

General Description……2-1

Operational Aspects……2-2

Data Handling and Triggering……2-2

Software and Hardware……2-3

ChartScan Specifications……2-3

3 Hardware

Overview ……3-1

Front Panel ……3-1

Rear Panel ……3-2

Power Aspects ……3-3

Changing the Voltage Setting ……3-3

Replacing the AC Power Supply Fuse ……3-4

Memory Configuration ……3-4

Expanded Memory Options ……3-4

Calibration Memory Write Enable/Disable ……3-6

RS-232/422 Interface Configuration ……3-6

Configuring RS-322/422 Parameters …… 3-6

Serial Port Pin Connectors ……3-8

Ethernet Interface Configuration ……3-9

IEEE 488 Configuration (Option) ……3-11

Digital I/O Lines ……3-13

Logic Levels ……3-13

Digital I/O Port Pinout ……3-13

External TTL BNC Connectors ……3-14

Signal Conditioning Cards ……3-14

CSN14/TC/P Thermocouple and Low Volts Card

with Subminiature Plugs ……3-15

CSN14/LV/ (T, B, & S) Low Voltage Cards …3-17

CSN14/HV/S High Voltage Card with Safety Jack

Connectors ……3-18

CSN/Relay Card

(for High-Current Digital-Output) ……3-19

CSN/Relay Card Specifications……3-20

Expansion Chassis, CSN/Exp (Option) ……3-20

Connecting the Expansion Chassis ……3-20

Automatic Channel Assignment ……3-22

4 ChartView Software Reference

Overview ……4-1

Groups, Charts, & Channels ……4-2

Three Ways of Using ChartView ……4-2

What ChartView and ChartView Plus Provide …4-3

Main Window ……4-4

Channel Information Region ……4-6

Status Indicator Region ……4-7

Main Window Toolbar ……4-8

Group Select ……4-8

Start, Pause, and Stop Charts ……4-8

Scroll Faster & Scroll Slower ……4-8

Display Configuration ……4-9

Channel Configuration ……4-15

PostView post-acq data viewer ……4-15

Arm Acquisition ……4-15

Disarm ……4-15

Print Charts ……4-16

Main Window Pull-Down Menus ……4-16

Bar Graph, Analog, and Digital Meters ……4-27

Overview ……4-27

Bar Graph Meters ……4-28

Analog Meters ……4-29

Digital Meters ……4-30

Meter Toolbars ……4-31

Meter Pull-Down Menus ……4-31

Meters Configuration Menu ……4-32

Setup Window ……4-33

Channel & Alarm Setup Dialog Box ……4-33

Channel Configuration Columns ……4-35

Alarm Configuration Columns ……4-36

Acquisition Setup Dialog Box ……4-36

Burst Mode, Operational Issues ……4-39

Measuring AC Voltage, or AC RMS Voltage……4-40

Data Destination Dialog Box ……4-42

Data Destination ……4-42

Auto Re-arm (ChartView Plus only) ……4-42

Why use Auto Re-arm? ……4-43

Disabling Auto Re-arm ……4-43

Chart Setup Wizard ……4-44

Introduction ……4-44

Automatic Chart Setup with Wizard ……4-45

Bypassing Automatic Chart Setup ……4-46

ii ChartScan User’s Manual

Page 5

5 eZ-PostView and ViewXL

6 Calibration

Introduction ……6-1

Calibration Setup ……6-1

Non-Volatile Storage of

Calibration Constants ……6-1

Hardware Protected RAM ……6-2

ScanCal Software Application ……6-3

ScanCal’s Main Window ……6-3

Using ScanCal ……6-3

Interface Parameters

System Inventory

Calibration

Calibration Without ScanCal ……6-5

Password ……6-5

Calibration Mode Indicator ……6-5

Command Active Indicators ……6-5

Manual Calibration of Main Unit ……6-6

Offset Calibration of Main Unit ……6-6

Gain Calibration of Main Unit ……6-8

Manual Calibration of

Signal Conditioning Cards ……6-10

Offset Calibration of Cards ……6-10

Gain Calibration of Low Volts Cards ……6-12

Gain Calibration of High Volts Card ……6-15

Cold Junction Calibration ……6-17

Appendices

Appendix A

Appendix B

Appendix C

Appendix D

Appendix E

Appendix F

Appendix G

Appendix H

API Commands

Configuration Aspects for

Programmers

Registers, Data Formats, & Queries

ChartScan Program Examples

Bus States, Bus Lines, and Data

Transfer Aspects

ASCII Code Summary

ChartScan Error Messages

Abbreviations

ChartScan User’s Manual

08-09-02

iii

Page 6

iv ChartScan User’s Manual

Page 7

ChartScan Unit Startup and ChartView Tutorial 1

Overview…… 1-1

Unit Startup……1-2

Inspect Your System……1-2

Install Software……1-2

Check and Install Hardware……1-3

Verify Voltage Setting……1-3

Verify DIP Switch Setting……1-3

Install Signal Conditioning Card(s)……1-3

Install Interface Communications Card (option)…… 1-4

Connect Expansion Chassis (option)……1-4

!

Connect ChartScan to your computer……1-4

Apply power to ChartScan…… 1-5

Connect Channel Signal Inputs……1-5

Start ChartView, Configure System, and Collect Data……1-7

ChartView, Basic Concepts……1-10

Configuration Files……1-10

Understanding Groups, Charts, and Channels……1-10

Three Ways of Using ChartView……1-11

ChartView Tutorial……1-11

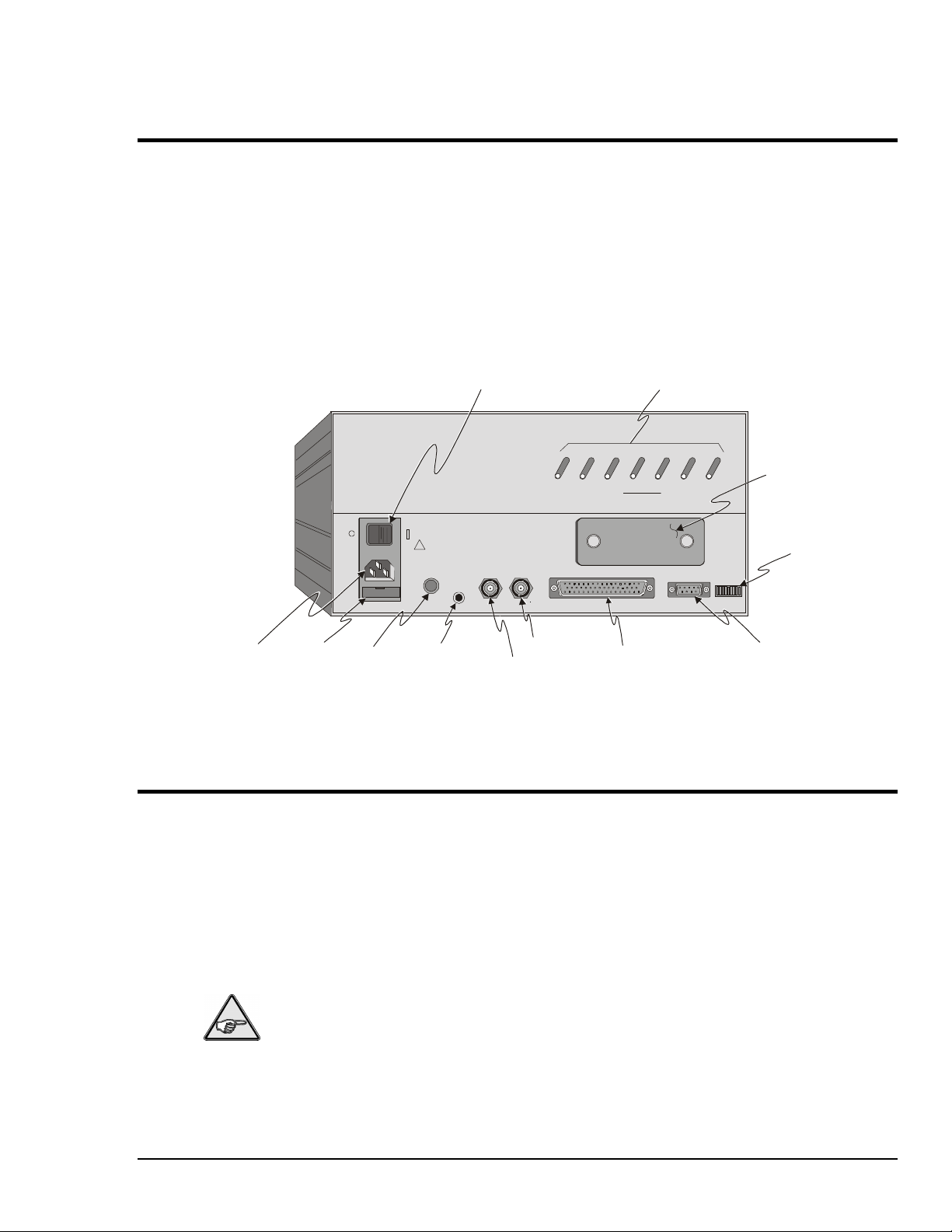

Power Switch

TRIGGER

OUTPUT

IN

TRIGGER SCAN

ALARM

TTL

ALARMS AND DIG ITAL I/O

LED Indicators

SERIAL

Interface

ERROR POWERSEND RECEIVE

RS-232

Card Slot

DIP Switch

Overview

Note: If you used the ChartScan Quick Start document (483-0940) to startup your unit, you may choose to

Note: Chapter 3, Hardware Setup, contains detailed information pertaining to hardware issues.

This chapter provides the steps to connect, power up, and run ChartScan. Although there are many ways to

configure ChartScan, this Startup is intended for a simple setup. In addition to the following steps, this chapter

includes a section on basic concepts and a ChartView tutorial. These are provided to help you gain a better

understanding of the ChartView program.

Power

Connector

Fuse

Holder

Chassis

Ground

Calibration

Enable/Disable*

TTL Output

Trigger In

Alarms & Digital I/O

(DB50) Connector

RS-232 (DB9)

Connector

ChartScan Rear Panel

*Note: Early production ChartScan units do not have a Calibration Enable/Disable Pushbutton; but

make use of a micro switch as discussed elsewhere in this manual.

skip this chapter; or you may wish to run through the ChartView tutorial which begins on page 1-11.

Reference Note: If you plan to connect your ChartScan to a network through a Net232

Ethernet/RS-232 converter, refer to the Net232 User’s Guide, part no. 1037-0901.

ChartScan User’s Manual,

1-5-99

1-1

Page 8

The basic Startup Steps are:

1. Inspect Your System

2. Install Software

3. Check and Install Hardware

a. Verify Correct Voltage Setting

b. Verify Correct DIP Switch Setting

c. Install Signal Conditioning Card(s)

d. Install Interface Communications Card (option)

e. Connect Expansion Chassis (option)

4. Connect ChartScan to Your Computer

5. Apply power to ChartScan

6. Connect Channel Inputs

7. Start ChartView, Configure System, and Collect Data

Unit Startup

1. Inspect Your System

If you have not already done so, carefully unpack your shipping carton and check all contents for

damage that may have occurred during shipment. Immediately report all damage to the shipping agent

and your sales representative. Retain all shipping materials in case the unit must be returned to the

factory.

Each ChartScan is shipped with the following:

ChartScan Portable Data Recorder

-----------------483-0940

483-0901

483-0601 Disks (or CD-ROM) in IBM format, includes ChartView Software

CN-18-50 DB50 Digital I/O Mating Connector

CA-1 Power Cable

FU-1-.5 1/2A, 250V, Slo Blo, 3AG for 105 - 125V power line or

FU-1-.25 1/4A, 250V, Slo Blo, 3AG for 210 - 250V power line

Signal Conditioning Card(s) pre-installed per customer order

ChartScan Quick Start Sheet

ChartScan User’s Manual

2. Install Software

For successful operation your computer should conform to the following, as a minimum:

•

PC system with Pentium processor is required

• Windows 3.1+, Windows 95, or Windows 98

•

8 Mbytes of RAM for Windows 3.1+ (16 Mbytes recommended)

•

16 Mbytes of Ram for Win95/98 (32 Mbytes recommended)

• For Net232 users, the PC requires a 10BASE-T ethernet card.

Use Microsoft Windows Run dialog box to install ChartView. Direct Windows to run the

SETUP.EXE file found on Installation Diskette 1,or Installation CD, as applicable. Follow the onscreen dialog boxes to complete a successful installation.

If you ordered ChartViewNET or ChartViewPlus, have your registration ID sheets at

hand so you can enter your registration numbers when prompted by the installation

utility.

The ChartView program group includes the following:

PostView Readme ChartView

PostView Help ScanCal Uninstall ChartView Version x.x

Note: Once the software has been installed, you can run through the ChartView tutorial. The tutorial

makes use of a Simulated Instrument Mode and does not require any hardware hook-up.

1-2 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 9

3. Check and Install Hardware

Depending on your order, your ChartScan unit may not require all the steps under this heading. If a

step does not apply to your unit, simply go on to the next one.

a) Verify Voltage Setting

Based on your order, your ChartScan system was set at the voltage indicated on the sticker (located on

the rear of the unit, near the power switch). Verify that the voltage value indicated on the sticker

matches the voltage of your intended AC power supply. If you need to change the voltage selection for

any reason, refer to Chapter 3, Power Aspects, Changing the Voltage Setting.

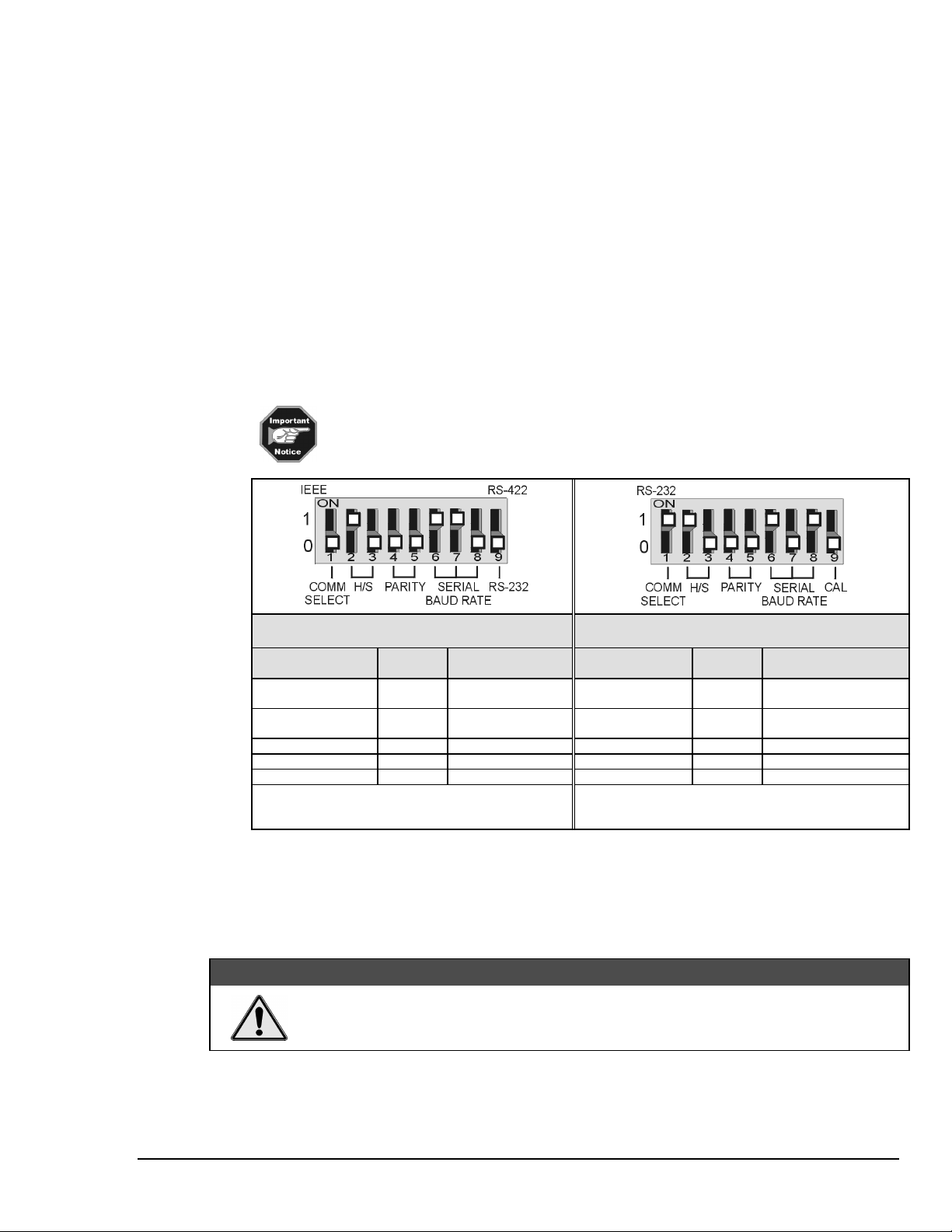

b) Verify DIP Switch Setting

The DIP switch is located on the lower right corner of ChartScan’s rear panel. Default settings are

indicated in the following figures and table. Refer to Chapter 3 if you desire to change the RS-232

parameters from their default values, or if you wish to use the IEEE 488 interface option. For ethernet

use of ChartScan, make sure the unit is configured for RS-232 serial communications, then refer to the

Net232 User’s Guide (p/n 1037-0901).

Early production ChartScan units do not have a Calibration Enable/Disable

Pushbutton. If you have an early production unit, refer to the right-hand DIP switch

illustration.

DIP Switch Default Settings

Selection Micro-

COMM SELECT 1 0 – Serial

HANDSHAKE

(H/S)

PARITY 4,5 0,0 - No Parity PARITY 4,5 0,0 - No Parity

BAUD RATE 6,7,8 1,1,0 – 19200 Baud BAUD RATE

RS-232 or RS-422 9 0 – RS-232 CALIBRATION 9 0 - Disabled

Switch #

2,3 1,0 - Hardware

c) Install Signal Conditioning Card(s)

Signal conditioning cards are pre-installed per customer order. However, if you need to install a signal

conditioning card, or CSN/Relay card, perform the following steps. Repeat the steps for additional

cards, and for placing cards into the optional CSN/Exp expansion chassis, if applicable.

Ensure ChartScan is powered down and not connected to any power source prior to

installing or removing a card. Failure to do so could cause equipment damage.

Dip Switch Default Settings

(Early Production Units Only)

Setting Selection Micro-

Communication

Handshake

CAUTION

CAUTION

CAUTIONCAUTION

COMM SELECT 1 1- RS-232

HANDSHAKE

(H/S)

1

1

It is recommended that you do not exceed 9600 Baud

unless you have firmware version 1.3 or greater. The

firmware version can be read in ChartView’s title bar.

Switch #

2,3 1,0 - Hardware

6,7,8 1,0,1 - 9600 Baud

Setting

Handshake

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-3

Page 10

CAUTION

CAUTION

CAUTIONCAUTION

Use approved ESD precautions, including static-free work area and grounded wrist strap,

when handling circuit boards and electronic components. Failure to do so could cause

equipment damage due to electrostatic discharge.

CAUTION

CAUTION

CAUTIONCAUTION

Only one CSN/Relay card can be used in a ChartScan system. Attempts to install the

CSN/Relay card in a slot other than slot #1 of ChartScan’s main unit can cause equipment

damage.

The CSN/Relay card, if used, must be installed in the bottom slot of the main unit. Aside

from this requirement, cards may be installed in any slot.

1. Ensure ChartScan is powered down and not connected to any power source.

2. With channel labels oriented upright, carefully slide the card into the unit, and along the card

support grooves. Gently force the card to engage its edge connector with ChartScan’s internal

mating connector.

3. Tighten the external screws snug, at each end of the card.

d) Install IEEE 488 Interface Communications Card (option)

If you ordered an optional IEEE 488 Interface Card (CSN14/488), please refer to the

IEEE 488 Configuration (Option) section of Chapter 3 for installation instructions.

e) Connect Expansion Chassis (option)

If you ordered a expansion chassis (CSN/Exp), please refer to the Expansion Chassis, CSN/Exp

(Option) section of Chapter 3 for installation instructions.

4. Connect ChartScan to Your Computer

Reference Note: ChartScan is default configured for serial port connection to a PC. For

IEEE 488 connection, please refer to the Chapter 3 section, IEEE 488 Configuration (Option).

Reference Note: For ethernet operation refer to the Net232 User’s Guide, p/n 1037-0901.

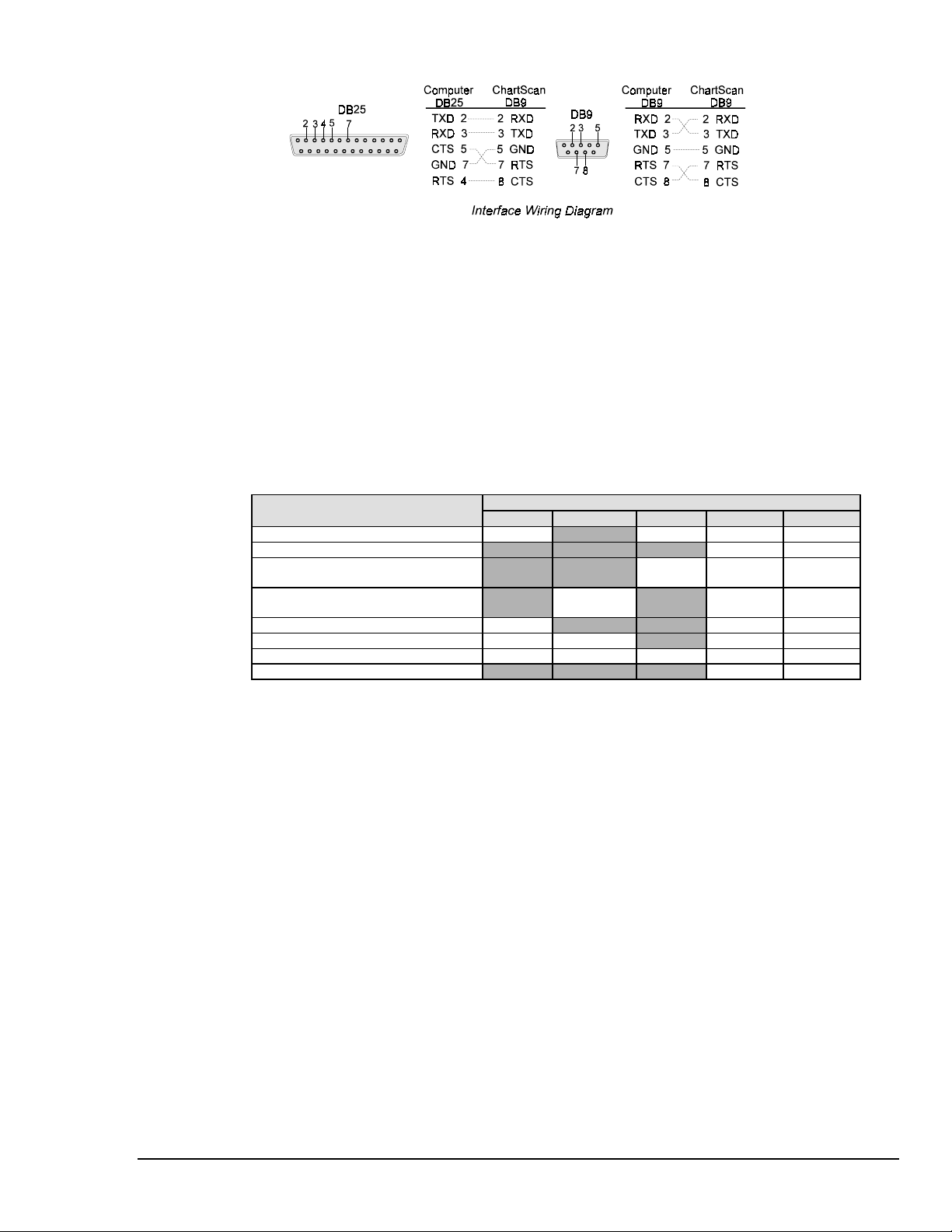

Use a CA-47 cable (or equivalent) to connect the ChartScan to your computer. The ChartScan end of

the CA-47 cable has a DB-9P connector, while the computer end has 2 connectors (DB9 and DB25).

Other crossover-type cables can be used if wired as shown in the following figure.

1-4 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 11

5. Apply Power to ChartScan

ChartScan can be powered from a standard AC outlet. Use the following steps to connect power to

your unit.

1. Make sure ChartScan’s power switch is in the “0” (OFF) position.

2. Plug power cord CA-1 into ChartScan’s power connector, located on the rear panel. Plug the other

end of the cord into an appropriate receptacle.

3. Turn ChartScan’s power switch to the “1” (ON) position. The Power LED should light up.

At initial power-up ChartScan performs automatic self-tests to ensure that it is fully functional. The

rear panel LEDs indicate errors, if they occur. Possible error conditions and their corresponding

indicator light patterns are shown in the following table. Any pattern not shown is an internal error that

is not field-serviceable; in this case, contact the factory. When only the POWER and ERROR LEDs

are on, a configuration error exists as a result of the setup information in NV-RAM.

Error Condition LED Indicators

General Hardware Failure ON ON -Flash- ON

ROM Invalid for U22, COMM2 -Flash- ON

ROM Checksum Error for

U21 Comm1

ROM Checksum Error for

U22 COMM2

Non-Volatile RAM Error ON -Flash- ON

Dynamic RAM Error ON ON -Flash- ON

Interprocessor COM Error ON ON ON -Flash- ON

Configuration Error ON ON

If you observe a configuration error, perform an error status query (see E? in Appendix A). If you

observe any other type of error condition, make note of the error and contact your service

representative.

If no problems are found ChartScan will begin its power-up initialization. This self-test is performed

each time the unit is powered up regardless of whether power-on was caused by the power switch or the

Power-On Reset (

During initialization, ChartScan self test performs the following steps:

• Checks for errors at power-up.

• Checks the flag in the NV-RAM to determine if it should power-up with factory default

• Loads appropriate registers with corresponding values in NV-RAM.

• Checks a flag to see if alarms should be enabled at power-up, and if so, enables them.

• Loads channel configuration registers.

• Loads program sequencer with appropriate channel configurations.

•

*R

settings or a user-defined configuration.

Resets computations processor to begin acquiring scans.

ALARM TRIGGER SCAN ERROR POWER

ON -Flash- ON

ON -Flash- ON

) command.

The self-test takes approximately 5 seconds to complete; after which, ChartScan is ready for normal

operation.

6. Connect Channel Signal Inputs

Connect channel inputs to your signal conditioning cards. Each signal conditioning card can support

up to 16 Channels. With use of the expansion chassis, you can have up to 8 signal conditioning cards.

Depending on the type(s) of cards used, your connections will be made via one or more of the

following: screw terminal, mini-plug, BNC, or safety jack type input connector.

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-5

Page 12

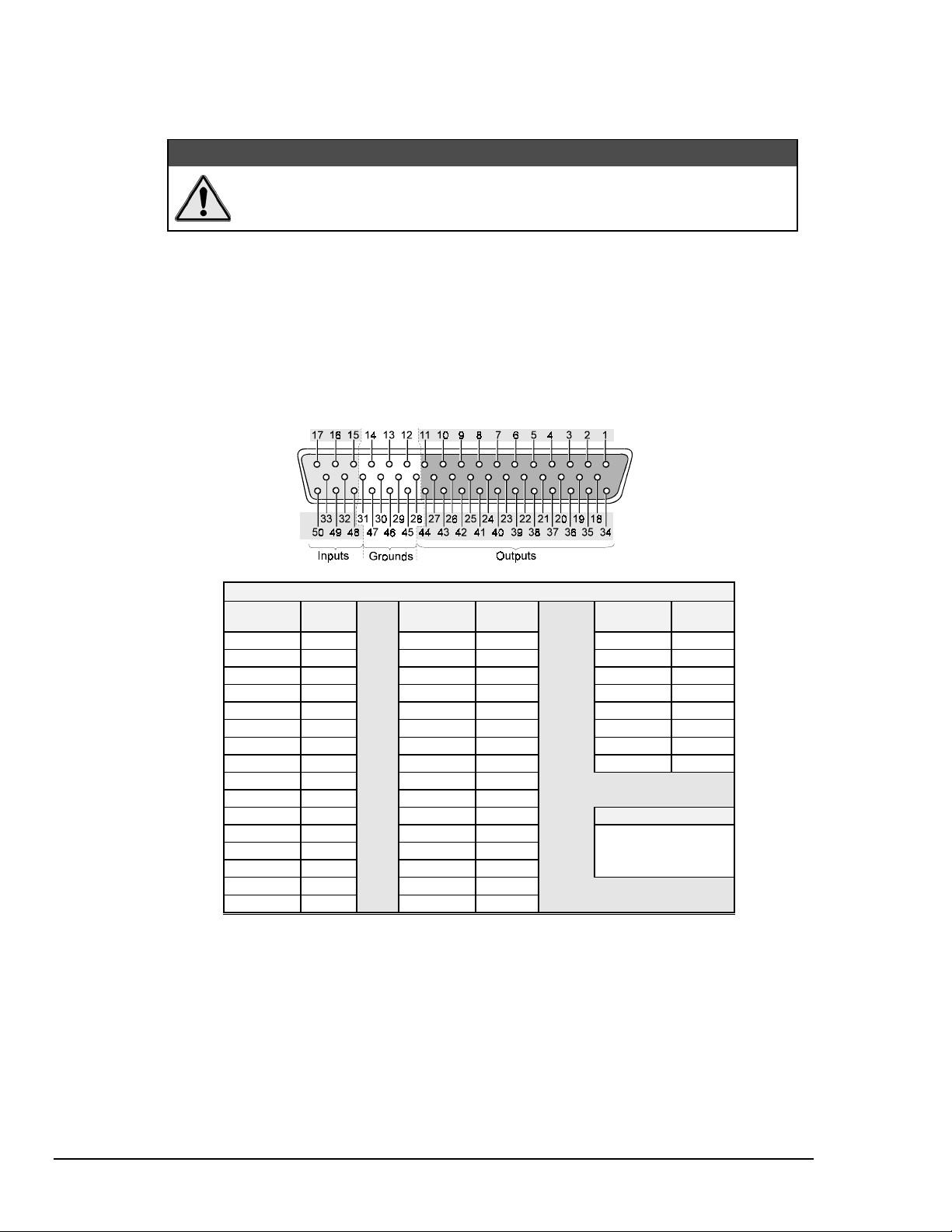

ChartScan has eight digital input lines and thirty-two digital output lines available on the rear panel

DB-50 connector.

CAUTION

CAUTION

CAUTIONCAUTION

Do not exceed the 0.0 to 5.3 volts levels described above. Exceeding these levels

may damage the ChartScan unit in a way not covered by the warranty.

Each digital output line will drive five (5) standard TTL loads. All digital input lines are one-eighth

(0.125) TTL loads. All inputs are protected against damage from high static voltage. Normal

precautions should be taken to limit the input voltages to the range of 0.0 to 5.3 volts. All digital I/O

lines are referenced to the connector’s ground pins.

The following figure and table identify pin locations for outputs, inputs, and grounds associated with

the DB50 connector. Outputs 1 through 32 are typically used for alarms 1 through 32, respectively.

As mentioned above, outputs 1 through 16 can be used with a relay card option (see note 1).

DB50 Pin Descriptions

Output

Signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Pin

No.

34

18

35

19

36

20

37

21

38

22

Output

Signal

1

2

3

17

18

19

20

21

22

23

24

25

4

26

27

28

5

29

30

31

6

32

Pin No.

39

23

7

40

24

8

41

25

9

42

26

10

43

27

11

44

Input

Signal

Pin No.

1

2

3

4

5

6

7

8

Ground Pins

12, 13, 14,

28, 29, 30, 31,

45, 46, 47

15

48

32

16

49

33

17

50

Note 1: A CSN/Relay is available for high current alarm output applications. If used, this card must

be installed in the bottom slot of ChartScan’s main chassis. See page 1-3 for installation

instructions. For more detailed information regarding the card, refer to CSN/Relay Card (for

High-Current Digital Output), in Chapter 3.

1-6 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 13

7. Start ChartView, Configure System, and Collect Data

Note: First time users should skip this step and return to it after reviewing ChartView, Basic

Concepts and completing the ChartView Tutorial.

Note: The configuration file, discussed in this section, will not be present during your first start of

the program.

Use the ChartView icon in Windows to start the ChartView program. ChartView will run using the

latest configuration file. This is a file which is automatically saved upon exiting the program. The

configuration file contains all setup information, including that pertaining to channels, alarms, and

acquisition configuration.

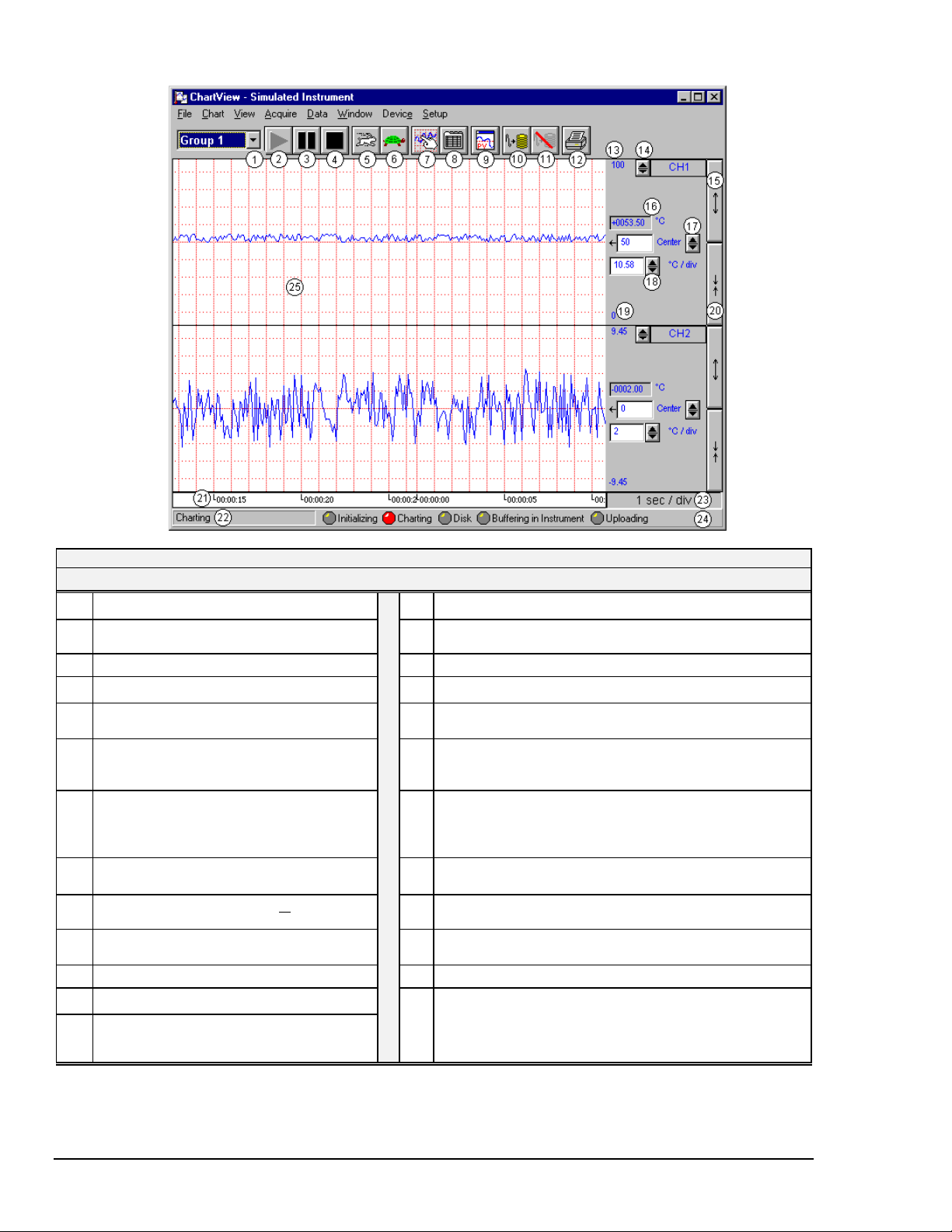

When ChartView opens using a configuration file, the program’s main window appears on the screen,

as indicated in the following figure.

Note: Item 24, Status LEDs and labels, does not appear when using Windows 3.1. However, when

using Windows 3.1, text will appear in region 24 to inform you of the status. This is in

addition to the text in the Status Message Box (Item 22).

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-7

Page 14

ChartView Main Window

ChartView Main Window Control Options

= Mouse, Ú= Arrow Keypads , = PageUp/PageDown Keypads

1 Group Select

2 Start Charts &

Indicators

3 Pause Charts

4 Stop Charts

5 Scroll Faster

6 Scroll Slower

7 Display Configuration

8 Channel Configuration

9 PostView post-acq

data viewer

10 Arm Acquisition

11 Disarm …

12 Print Charts

13 Chart Max. Scale

Value (Grid Limit Line)

Ctrl+G, or

and “right-click”

Current group will be

selected.

down menu

From Chart Pull-down

menu or Chart Setup

Dialog Box

Ú,

or

or, F5

or, F7

or, F6

or, Ctrl+Z

or, Ctrl+X

or, Pointer over chart

or, Windows Pull-

or, Ctrl+T

or, Ctrl+Y

or, Ctrl+P

14

Channel Selection

15

Multiply (x2)

16

Present Value of Selected Channel

17

Center (Value at Chart Mid-Line)

18

Units/Division

(Vertical increment per one grid box)

19

Chart Min. Scale Value (Grid Limit

Line)

20

Divide (÷2)

21

Time Scroll (hr:min:sec)

22

Status Message Box

23

Time/Division (Chart Speed),

the Horizontal increment per grid box

24

Status LEDs

25

Chart Display

Double-click left mouse button in selected chart to zoom in or zoom

back out. Right-click to bring up Chart Setup Dialog Box with the

current group and target chart selected.

Ú

or,

or,[Tab to and hit

Spacebar]

N/A

or, Ú, or type-in

or, Ú, or type-in

From Chart Pull-down

menu or Chart Setup

Dialog Box

or, [Tab to and hit

Spacebar]

Thru Pull-Down Menus

only

N/A

Ctrl+Z (Faster)

Ctrl+X (Slower)

N/A

1-8 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 15

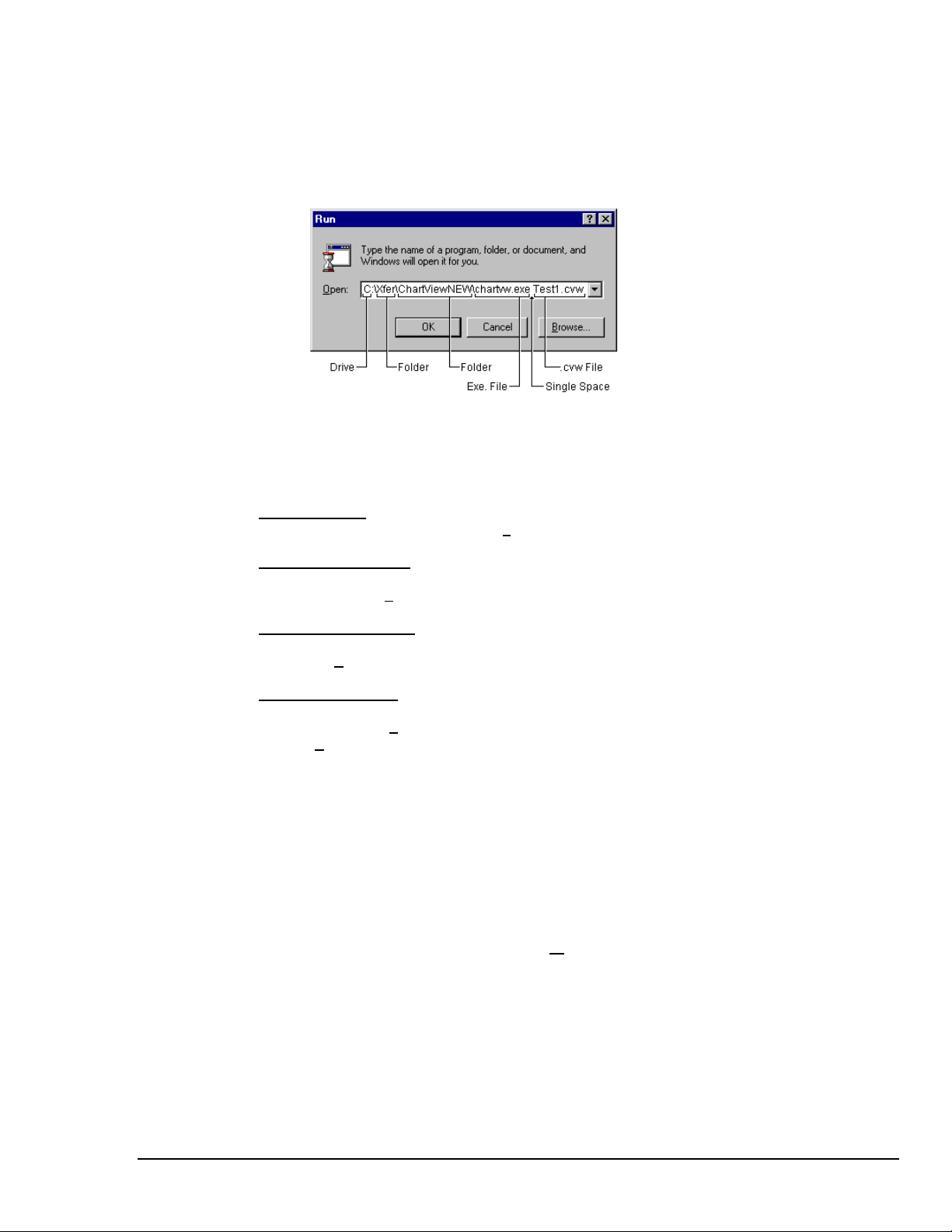

Once ChartView has a configuration file, you can start the program quickly using the Windows Run

dialog box. Before executing this command [by clicking on the OK box] specify a configuration file as

a command line parameter. In the following example, the user has specified a configuration file which

he had previously saved as Test1.cvw.

Note: The file name can be manually entered, or can be accessed using the pull-down arrow and

scrolling the list of available file names.

Example of Using Windows’ Run Dialog Box to Open a File

After executing the command, ChartView’s Main Window opens. At this point review the following

configurable items prior to Data Acquisition. Make changes, or load a different configuration file if

desired.

;;;;

Device Interface

Check the Interface and Status via the Device pull-down menu.

;;;;

Channel Configuration

Check channel and alarm configuration settings via the Channel Configuration Window. Access this

window through the Setup pull-down menu.

;;;;

Acquisition Parameters

Check the acquisition parameters via the Acquisition Configuration window. This window can be accessed

through the Setup pull-down menu.

;;;;

Data File Parameters

Check Data File Parameters. These parameters can be set from the Data Destination window

(accessible from the Setup pull-down menu), and from the Data File Parameters selection accessible

from the Data pull-down menu.

Using the Run Dialog box to specify a configuration file is very efficient. By using this method and

various configuration files, you should find that managing systems with more than one acquisition

device is relatively simple. With the use of a portable PC, you can quickly interface with a specific

acquisition system.

The pull-down menus and numbered areas represented in the previous figure and table are detailed in

the Chapter 4, ChartView and ChartView Plus.

To start the charts scrolling, push the “Start Charts and Indicators” button (item 2). More detailed

information pertaining to the charts and the ChartView Main Window appear in Chapter 4. In addition

to viewing the data as charts, you can select the Windows pull-down menu to select one or all of the

following:

•

ChartView Analog Meters

• ChartView Digital Meters

•

ChartView Bar Graph Meters

The meter-type data displays, along with the charts, can be on your computer screen at the same time.

They can be re-sized and repositioned as desired. Analog, Digital, and Bar Graph meters are detailed

in Chapter 4.

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-9

Page 16

ChartView, Basic Concepts

An understanding of the following basic concepts will help you master ChartView more quickly, and

should be understood before proceeding with the tutorial.

Configuration Files

ChartView makes use of one or more “user transparent” configuration files. Configuration files

maintain information regarding various aspects of your setup, serving as an initialization file for

subsequent ChartView startups. These files can be recognized by their

When you run ChartView for the very first time there will be no configuration file.

However, a configuration file will be generated and be saved, automatically, after

ChartView uses

each use of the program.

Chartvw.cvw

ChartView configuration information including:

Device Interface Mode

•

• Hardware Configuration

• Channel Settings:

⇒ Channel Enable/Disable (On/Off)

⇒ Type

⇒ Label

⇒ Units

⇒ Alarm Settings (Limits)

⇒ Hysteresis Setting

• Acquisition Configuration

• Data Storage Settings

.cvw

extensions.

as a default configuration file. This file maintains a location for

The configuration file ensures that when you restart ChartView, it will be in the same state upon your

last exit. This means that the

Chartvw.cvw

are using at the time you exit ChartView.

It is not catastrophic if a configuration file is deleted, since it is a simple task to start ChartView when

no configuration file exists. This is described in the tutorial.

Understanding Groups, Charts, & Channels

When starting the program with no configuration file present, a feature called Chart Setup Wizard is

automatically activated to assist you with your setup. To make the best use of Chart Setup Wizard you

need to understand the relationship of Groups, Charts, and Channels.

Note: ChartView, ChartView Plus, and Chart Setup Wizard are detailed in Chapter 4 of this manual.

Group. “Group” refers to a group of charts. ChartView makes use of one

chart group. ChartView Plus allows up to 64 groups, depending on the

capabilities of your PC, but only displays data from one chart group at a

time.

Chart. “Chart” refers to display area which reflects real-time channel data

values and can be scrolled at various rates. One chart can display data from

up to four channels. In addition, each chart will display real-time

information for a selected channel. You can assign up to 16 charts per

group.

Channel. “Channel” refers to a signal channel. You can have up to 4

channels assigned to one chart. Channels will be displayed in units of °C,

°F, °K, °R, mV, V, or in user-defined units, depending on the configuration

and type of signal conditioning card used. ChartScan’s signal conditioning

card options are detailed in Chapter 3.

file will be an updated copy of the configuration file you

1-10 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 17

Three Ways of Using ChartView

You can use ChartView to:

• chart and monitor specific channels with no acquisition of data to disk

• acquire data with no charting or meter use

• use charting and/or meters while acquiring data to disk

Chart channels (and/or monitor with meters) with no acquisition of data to disk

Prior to charting channels on ChartView’s Main Window, you need to configure a display in regard to

groups, charts, and channels. This aspect of configuration is performed through Chart Setup Wizard

(discussed in the following text), or through a Display Setup dialog box which is accessed through the

Display Configuration Setup button (item 7, page 1-8) on ChartView’s Main Window.

In addition to charting channels, you can monitor selected channels via digital, analog, and/or bar graph

meters. Meters are discussed in Chapter 4.

Note: For ChartView Plus users, up to four channels will overlap on their assigned Chart, and will

be visible when the applicable Group is selected.

Acquiring Data with no charting or meter use

Prior to acquiring data (for saving to disk) you need to configure the acquisition using the Acquisition

dialog box (accessed through the Setup pull-down menu of ChartView’s Main Window, or through use

of the related icon button). You can enable the desired channels, assign high and low alarm values

from the channel configuration dialog box.

Chart channels and/or use meters while acquiring data to disk

Prior to using ChartView for charting (and/or meter use) while simultaneously acquiring data to disk,

you need to configure a display and/or meter; as well as configure the acquisition. Note that the

channels from the display setup are automatically enabled. You can enable additional channels from

the channel configuration dialog box (for the data acquisition) to acquire more data; however, these

additional channels will not change your display setup, or the channels being monitored. In other

words, you can acquire data from channels which you do not monitor.

ChartView Tutorial

This tutorial is intended to help you gain a good understanding of ChartView. The tutorial is based on

an initial startup with no configuration file present

ChartView allows you to operate in one of four Device Interface modes (IEEE 488, RS-232/422,

NetWork or Simulated Instrument). The tutorial makes use of the Simulated Instrument mode. This

mode provides a means of running ChartView and inspecting its features without hardware concern.

Note that you can change the interface mode at anytime during a configuration setup.

The tutorial makes use of the Simulated Instrument mode. Note that both the

IEEE 488 and Network modes require the use of additional hardware, as discussed

The arrow symbol

are to complete. Text without the arrow is for information content, and does not require you to take

any action.

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-11

elsewhere in this manual.

, followed by a number, is used throughout the tutorial to indicate an action you

◊

.

Page 18

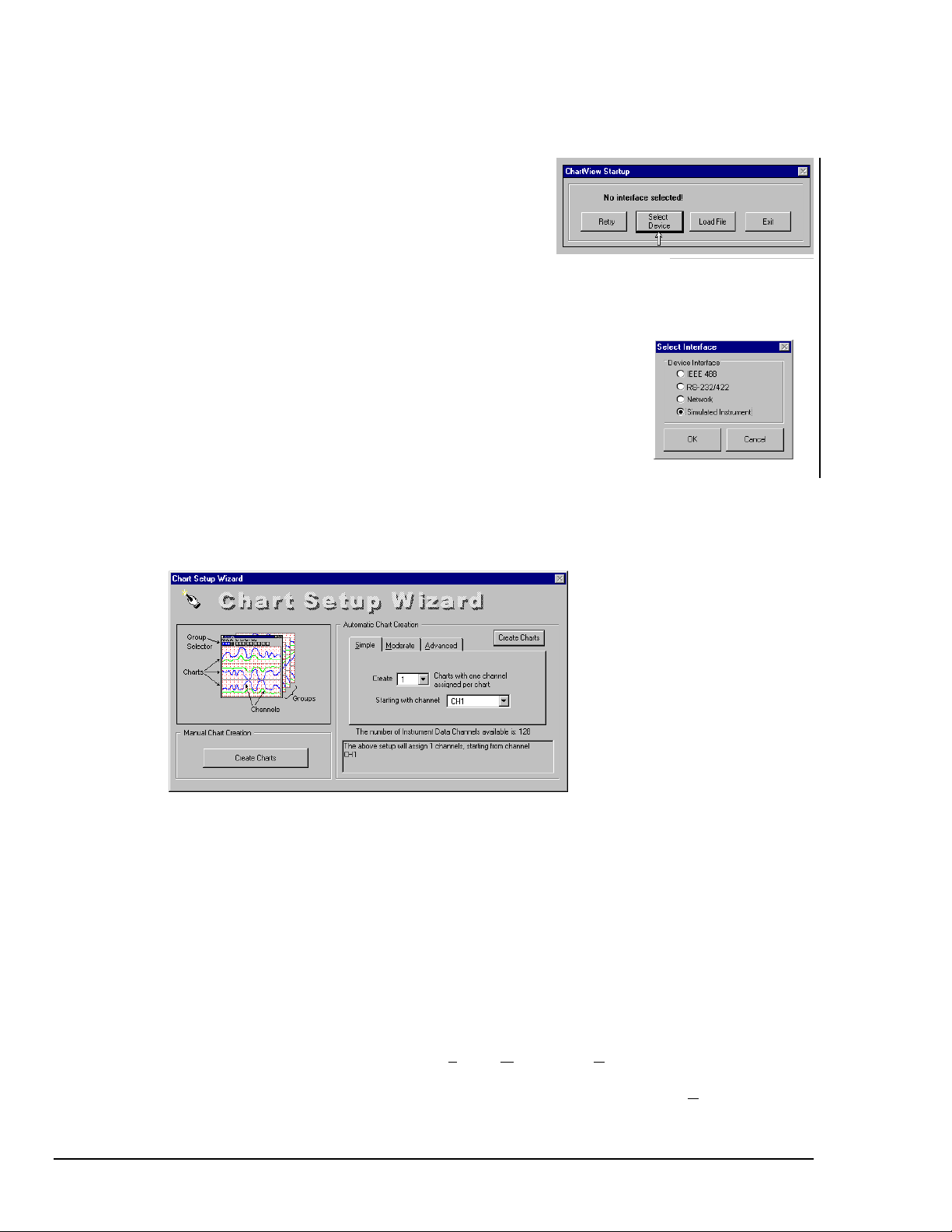

1. Select Interface Device

(1) From Windows, start ChartView by double-clicking on the

◊

ChartView icon. The ChartView Startup dialog box

appears.

(2) Choose the Select Device button. The Select Interface Dialog Box appears, as indicated in the following

◊

figure.

Note: The Load File button is for loading a previously saved configuration file.

(3) Select Simulated Instrument. In an actual application you would select

◊

IEEE 488, RS-232/422, or Network, whichever you configured your

acquisition system for. Network users should refer to the Net232 User’s

Guide, p/n 1037-0901.

2. Configure Chart Setup

(4) On the Select Interface box, shown in step 1, click “OK.” A Chart Setup Wizard window appears.

◊

ChartView Setup Dialog Box

Select Interface

Note: ChartView Plus has Chart Setup Wizard options including Moderate and Advanced Automatic

The chart setup determines how your ChartView Main Window will appear in regard to the number of

groups available for viewing, the number of charts shown for each selected group, and the number of

overlapping channels in each chart (not to exceed 4). As stated in the previous note, only

ChartView Plus allows the use of multiple groups and overlapping channels.

You can choose to manually create a configuration, or have one created automatically. In addition, you

can use Chart Setup Wizard to make a rough display configuration, and then manually fine tune it. The

automatic setup method offers three choices: Simple, M

The “Manual Chart Creation” option provides you with the same capabilities as the Advanced

Automatic Setup selection, but allows you to vary the number of assigned channels per chart, as well as

vary the number of charts per group.

1-12 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Chart Setup Wizard Window

Chart Creation, as well as the ability to create multiple groups. ChartView Plus features can

be unlocked by use of an authorized registration ID number as an unlock code. Contact your

service representative for more detailed information.

oderate, and Advanced.

Page 19

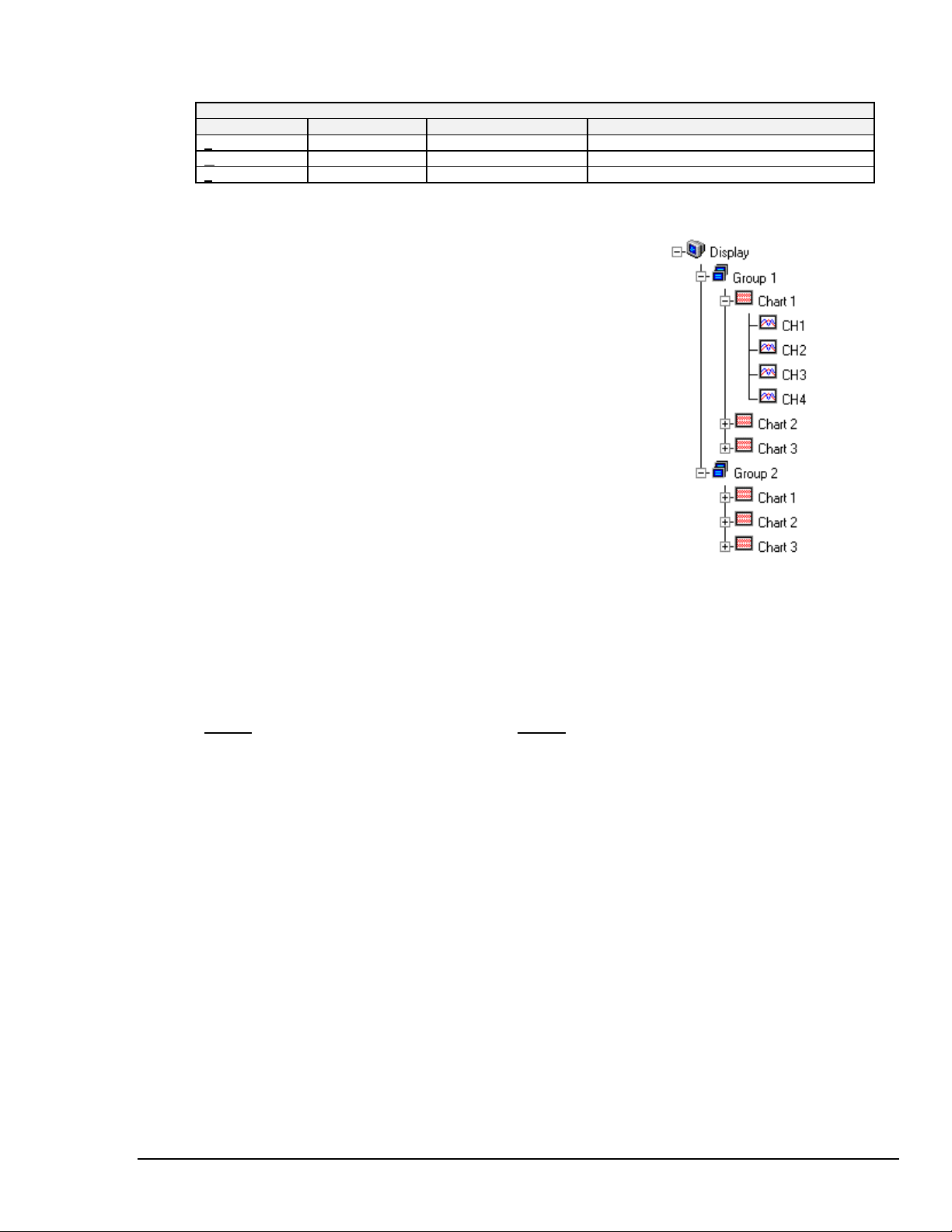

Chart Setup Wizard, Automatic Options

Setup Type

Simple

Moderate*

Advanced*

*Moderate and Advanced modes are only available with activation of ChartView Plus.

Group Setup

1 group only

1 group only

Up to 64 groups Up to 16 charts per group Up to 4 overlapping channels per chart

Chart Setup

Up to 16 charts

Up to 16 charts

Channel Setup

1 channel per chart

Up to 4 overlapping channels per chart

Note: Once your chart setup is complete you can always go

back and edit the setup.

For the purpose of our tutorial, complete the following steps. Note that

these steps are catered to ChartView Plus. Comments regarding

standard ChartView are presented in brackets [ ].

(5) Verify that the Advanced tab (under Automatic Chart Creation) is

◊

selected. [Simple must be used for standard program].

(6) Choose “2” for the number of groups. [Standard program is

◊

limited to 1 group].

(7) Choose “3” for the number of charts.

◊

(8) Choose “4” for the number of channels.

◊

(9) Click Automatic Chart Creations/Create Charts. At this point

◊

your chart appears on the Main Window.

(10) Click on the Display Configuration button (item 7, see figure on

◊

page 1-8). Though you usually won’t do this at this point, this

act permits you to see a representation of your configuration,

and permits you to make changes.

You should end up with a configuration display of two groups, each with 3 charts, and each chart with 4

channels [for standard ChartView users the display will be for 1 group only].

Because Automatic Chart Creation was chosen (starting with Channel 1) for ChartView Plus users, the Channel

arrangement was automatically assigned as follows:

Group 1

Chart 1

Chart 2

Chart 3

By using the mouse arrow and clicking on a Group, Chart, or Channel you will alter the appearance of the

CH1, CH2, CH3, CH4

CH5, CH6, CH7, CH8

CH9, CH10, CH11, CH12

Group 2

Chart 1

Chart 2

Chart 3

CH13, CH14, CH15, CH16

CH17, CH18, CH19, CH20

CH21, CH22, CH23, CH24

display, but not alter its actual configuration. For example, in the previous Display tree figure we see channels 1

through 4 assigned to Chart 1 of the first Group.

(11) ChartView Plus users: click on the word/number “Group 2.”

◊

(12) ChartView Plus users: click on the word/number “Chart 3” (of Group 2). You should now see channels

◊

21 through 24 listed at that location.

The channels in the setup you just created will be automatically enabled and will appear in chart form on

ChartView’s Main Window. The Channels will overlap on their assigned Chart, and will be visible when the

applicable Group is selected. Note that only one group of charts can be viewed at a time, even if you are using

ChartView Plus.

You can enable additional channels from the Channel Configuration window. This allows you to acquire more

data; however, it will not change your display on ChartView’s Main Window. In other words, you can acquire

data from channels which you do not monitor.

(13) Click “Okay” to exit the dialog box.

◊

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-13

Page 20

3. Configure Channels & Alarms

Configure channels and alarms as follows.

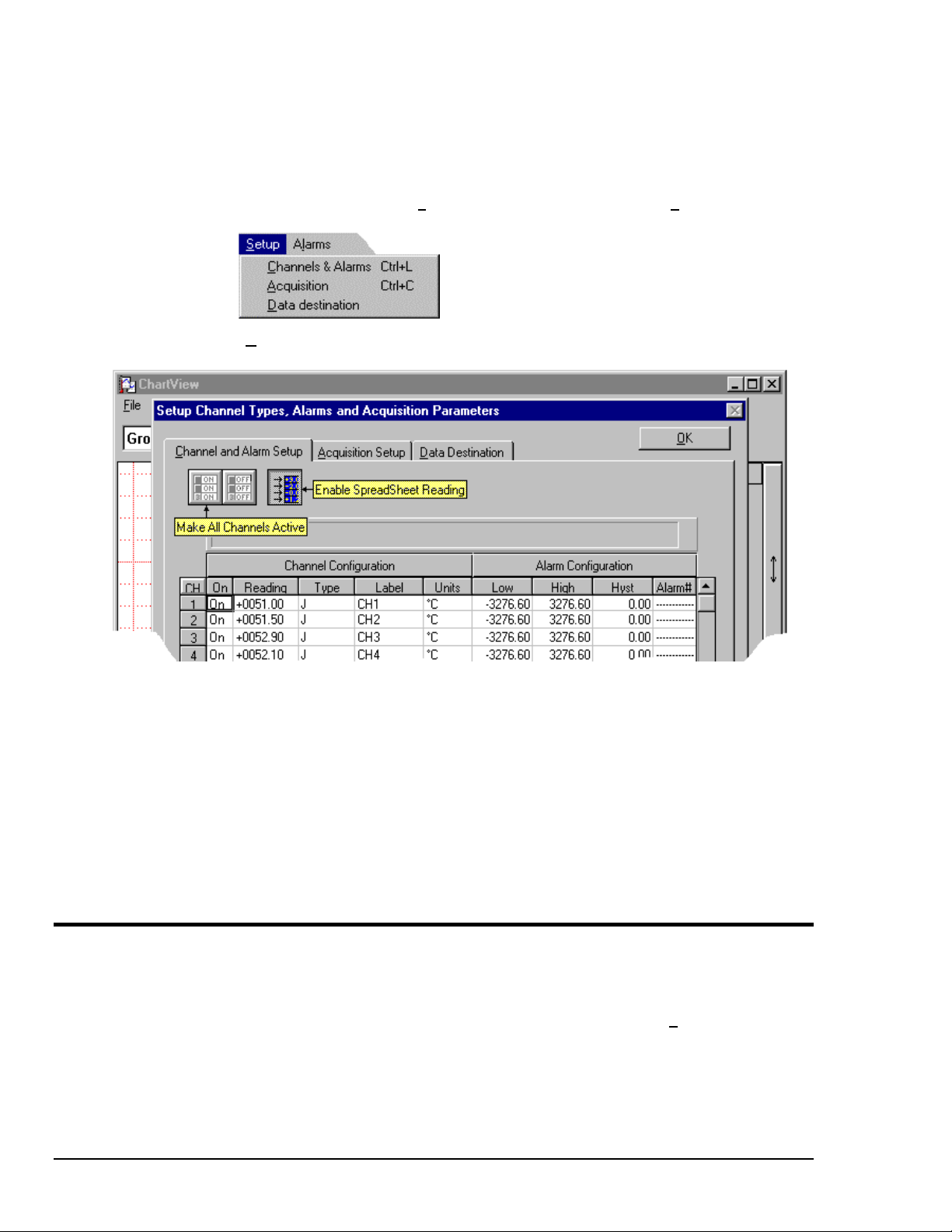

(14) On ChartView’s Main Window, click on Setup in the pull-down menu row. The S

◊

menu appears, allowing you to make more specific selections.

(15) Click on the Channels & Alarms selection. The Channel and Alarm Setup dialog box appears, similar

◊

to that shown in the following figure.

etup pull-down

(16) Enable the desired channels. You can enable channels by double-clicking on the applicable channel’s

◊

“On” column, obtaining “On” indicating enabled or “Off” indicating disabled. You can also use a

pull-down list which appears for enable/disable. See Chapter 4 if more detail is needed.

Note: Channels set up for your display will be automatically enabled. You can enable additional channels

for data acquisition. These additional channels will not appear on ChartView’s Main Window, but

data from them will still be acquired.

(17) Click on the “Enable SpreadSheet Reading” button (see previous figure). This activates the display

◊

scanned data in the reading column. Since we are in the Simulated Instrument mode, the Reading

column of the Analog Input SpreadSheet will now display simulated data. Selecting the Enable

SpreadSheet Reading button again will freeze the Reading column’s display.

4. Configure Acquisition.

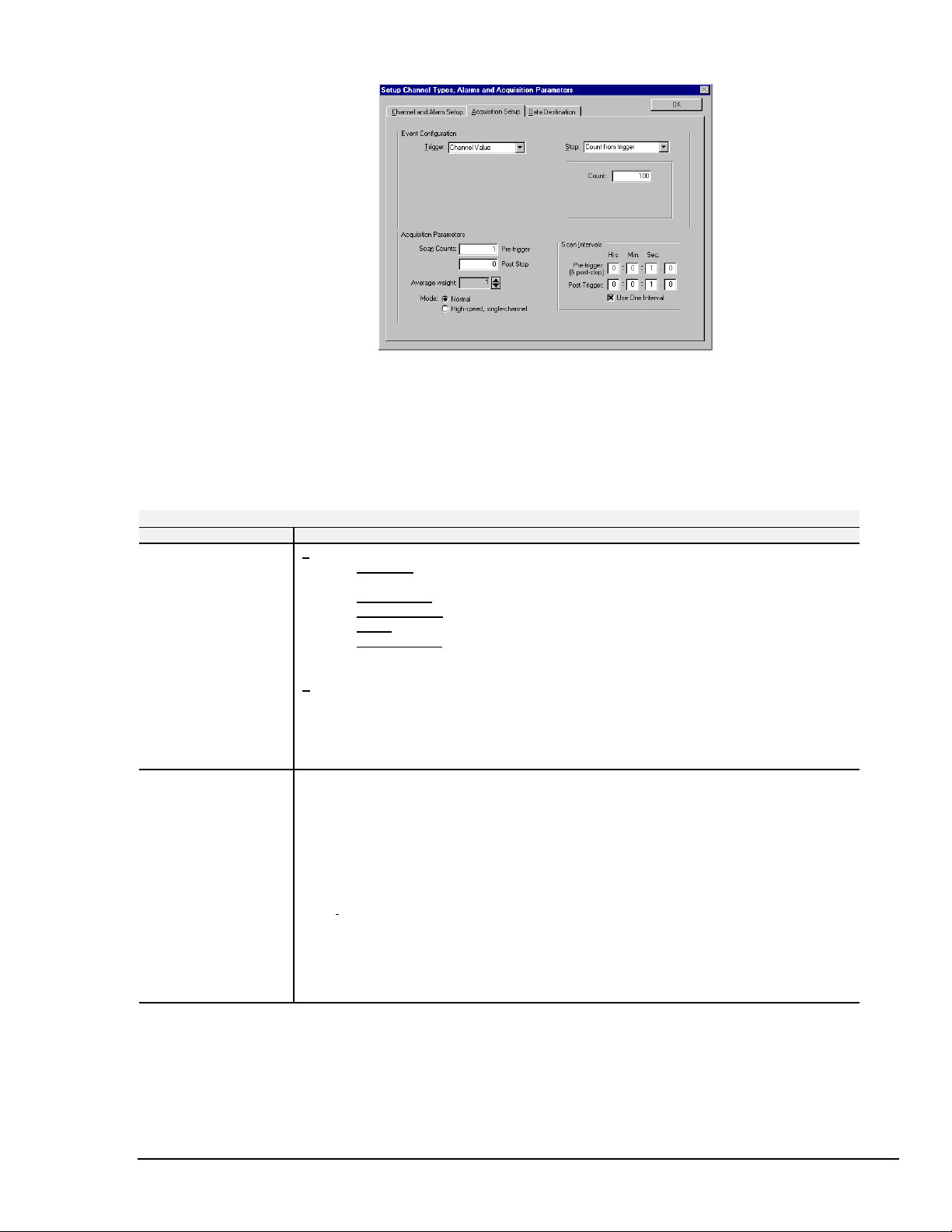

(18) Click on the Acquisition Setup tab (see previous figure). An Acquisition Configuration dialog box

◊

appears. The box can be in either of two modes – (1) Normal, or (2) High-speed, single channel.

Note that you can also access the Acquisition Configuration dialog box from the Setup pull-down

menu or the Channel Configuration button (item 8, page 1-8).

The information entered in the Acquisition window is used by the Arm Acquisition command to set up

the acquisition of data to disk. When the trigger is satisfied, the scans are collected at the selected scan

frequency and stored to disk in the designated file.

1-14 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 21

Acquisition Dialog Box, Normal Mode

(19) Click “Okay” to exit the Acquisition dialog box. Note that we are using the Acquisition default settings,

◊

and the Data Destination default settings in this tutorial (as shown in the above figure).

Note: The following table provides a brief description of various acquisition setup parameters.

Acquisition Setup

Parameter

Event Configuration

Trigger: Set a trigger scan in the Acquisition by using one of the following:

Keyboard - Use Console Trigger dialog box to start trigger scan.

Note: If the Keyboard Trigger is selected the use of Pre-trigger is disabled.

External TTL - Use an external signal to start the trigger scan.

Channel Value - Use specified value of a given channel.

Alarm - Use an Alarm value to start the trigger scan.

Absolut e Time - Use a time of day to start the trigger scan.

Note: If Absolute Time is selected, the use of Auto Re-arm is disabled.

Options

Stop: Set a stop scan in the Acquisition by using one of the above selections or Count (as

specified below). Keyboard isn’t applicable. If a MultiScan or ChartScan is connected

and High-Speed Single-Channel (Burst Mode) is selected, then “Count from trigger” is

the only Stop available for the event configuration.

Count: Specify a number of scans to be read before a stop scan is set.

Acquisition Parameters

Scan Counts: Specify the number of scans in an acquisition

Average weight: Average weight can be specified only when in the Normal Mode. The value for

Scan Intervals: Time between scans (frequency of scans)

High Speed Setup:

Pre-trigger

Post Stop

the average weight determines the number of samples to be averaged when in

Normal Mode. Values of 1, 2, 4, and 8 are for high-speed multiple channel

applications for thermocouples and DC voltages where noise filtering is not an

issue.

Values of 16, 32, 64, 128, and 256 are recommended for AC noise rejection.

Pre-trigger and Post Stop

Post-trigger

Use one Interval

Allows for channel and scan rate entries for high-speed, single channel mode.

Note: These parameters cannot be altered while an acquisition is in progress.

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-15

Page 22

5. Review Configuration.

Reviewing the configuration prior to data acquisition is optional; however, you should complete a

review at this time (in the tutorial) to help with your familiarization of ChartView. In an actual

application, a review such as this provides you with a chance to correct configuration errors.

Device Interface

(20)

◊

Check the Interface and Status via the Device pull-down menu.

Channel Configuration

(21)

◊

Check channel and alarm configuration settings via the Channel Configuration Dialog Box. Access this box

through the Setup pull-down menu.

Acquisition Parameters

(22)

◊

Check the acquisition parameters via the Acquisition Configuration Dialog Box. This box can be accessed

through the Setup pull-down menu.

Data File Parameters

(23)

◊

Check Data File Parameters. These parameters can be set from the Data Destination Dialog Box (accessible from

the Setup pull-down menu), and from the Data File Parameters selection accessible from the D

menu.

6. [Optional]. Save Configuration File.

Although the updated

you want to manually initiate a save. This will help you save time if an error occurs that may corrupt

your configuration. You may create a new configuration file by using an existing one and making the

necessary changes. In actual applications, use the File pull-down menu to manually save configuration

files, if this option is desired.

Note: The

.cvw

file contains all setup information. Setup information includes channel information, alarm

configurations, and acquisition configuration information.

Chartvw.cvw

ata pull-down

file will automatically save upon Exit, there may be times when

7. [Optional]. Check the System Inventory and Device System Time.

Check the System Inventory and Device System Time via the Status selection from the

down menu.

In an actual application, if the System Inventory and Device System Time configurations were

acceptable, you would proceed to Arm an Acquisition by clicking the Arm Acquisition button (item 10,

page 1-8), or by using the Arm Acquisition selection in the Acquire pull-down menu.

8. Start Charts.

(24) Push the Start Charts and Indicators button (item 2, page 1-8). Charts will begin scrolling. More

◊

detailed information pertaining to the charts and the ChartView Main Window appear in Chapter 4’s

ChartView Main Window section. In addition to viewing the data as charts, you can select the

Windows pull-down menu to select one or all of the following:

•

ChartView Analog Meters

• ChartView Digital Meters

•

ChartView Bar Graph Meters

(25) Select the Windows pull-down menu and try each meter option. Push the triangular play button of each

◊

meter’s specific toolbar to activate that meter.

Meters and charts can be on your computer screen at the same time. They can be re-sized and

repositioned as desired. Analog, Digital, and Bar Graph meters are detailed in Chapter 4.

Note that a PostView Post Acquisition viewing program is also selectable from the Windows menu.

PostView is discussed in Chapter 5.

Device

pull-

1-16 ChartScan – Unit Startup and ChartView Tutorial ChartScan User’s Manual

Page 23

A Note In Closing.

This completes the tutorial. You may continue running ChartView in the simulated instrument mode

and try various options to get a better feel for the program. Remember, while in the simulated

instrument mode there are no ChartScan hardware concerns.

ChartScan User’s Manual ChartScan - Unit Startup and ChartView Tutorial 1-17

Page 24

ChartScan User’s Manual

Page 25

General Information 2

CAUTION

CAUTION

CAUTIONCAUTION

If equipment is used in any manner not specified in this manual, or if specification limits

are exceeded, the function of the equipment, as well as the protection provided by it, may

be impaired.

General Description……2-1

Operational Aspects……2-2

Data Handling and Triggering……2-2

Software and Hardware……2-2

ChartScan Specifications……2-3

General Description

ChartScan is an easy to use, advanced hybrid data recorder that combines the desirable features of common

paper-based strip-chart recorders with the latest PC-based data acquisition technology. In addition to chart

displays, ChartScan allows you to display digital, analog, and bar graph meters.

ChartScan requires no external signal conditioning or use of multiplexers. The unit can measure up to 64

differential input channels; and can easily be expanded up to 128 channels with the use of an expansion module.

ChartScan is well suited for temperature and voltage measurements requiring channel-to-channel isolation. This

isolation is made possible by the use of individual relays on each of the 64 channels. The unit provides 500 V

isolation for voltage inputs and 200 V isolation for thermocouples. The instrument scans at a rate of up to 147

channels per second and includes a single-channel burst mode for digitizing waveforms at rates up to 20 kHz.

Measurements include:

•

isolated temperature from thermocouples

DC volts

•

AC volts

•

waveforms

•

ChartScan includes ChartView, a software program which provides a Windows-based graphical-user-interface

approach to obtaining data collection and display; PostView, a post-acquisition data review program; and

ScanCal, a software application that automates instrument calibration.

Although ChartScan can acquire temperature readings at a rate of 147 channels/sec, you may also program the

unit to acquire data at specified time intervals using the

hh:mm:ss.t format. For the ultimate in flexibility, you

may also program separate pre-trigger and post-trigger sample rates. As an example, ChartScan can be

programmed to sample data once per hour and then sample once per second when channel 2 reaches 70°C.

An interface card can be plugged into ChartScan unit through a slot on the unit’s rear panel. When the only

interface desired is RS-232, no interface card is needed and the card interface port is shielded with a removable

protective cover.

Statistics such as High, Low, and Last are available for each channel for data reduction. In addition, up to

32 alarms may be programmed using the programmable high and low limits for each channel.

Optional software, shipped with separate documentation, includes the following:

CIMScan

is a HMI/SCADA application. A single screen can display data from [and control outputs of]

several acquisition devices connected through a network. With CIMScan, users can customized applications

accessing thousands of channels from network-connected devices. CIMScan does not require programming

knowledge.

ScanServer is a driver that permits access to multiple acquisition devices from popular HMI/SCADA

applications (including those from Wonderware

and Intellution.) ScanServer supports OPC/DDE-compliant

environments, such as Microsoft Excel.

ChartScan User’s Manual

12-28-98

2-1

Page 26

In addition to the features of ChartScan described thus far, the unit includes:

• Thirty-two TTL (Transistor-to-Transistor Logic) digital alarm outputs and 8 TTL-compatible

digital inputs.

• Two programmable scan rates: (1) a programmable scan rate for pre-trigger and post-trigger

sampling, and (2) a programmable scan rate for accelerated sampling on-event detection.

•

A built in real-time clock that synchronizes the acquisition to the time of day, and provides time

and date stamping for trend analysis. Time stamping may be in relative or absolute time.

• Standard RS-232 interface and optional IEEE 488 interface. Connection to computer can also be

made via a Hayes-compatible modem.

• 256 Kbytes of memory, expandable up to 8 Mbytes. If your application must gather large amounts

of data, options are available for expanding the standard 256 kB of memory to 1 MB, 4 MB, or

8 MB. Readings may then be transferred at greater than 300 Kbytes per second over the IEEE 488

bus or up to 9,600 baud using its standard RS-232 serial port. Though the RS-232 serial interface

is always available with ChartScan, an interface card must be used for IEEE 488 applications.

• Capable of channel expansion up to 128 channels with the use of a CSN/Exp expansion chassis.

Operational Aspects

Data Handling and Triggering

Note: Also see Software & Hardware table and ChartScan Specifications.

Data Handling

Built-in memory

RS-232 interface

Time & date stamping

Digital inputs

Programmable alarm

outputs

Triggering

Digital trigger input

Analog trigger input

Trigger on “time of day”

Pre-trigger scan rate

Post-trigger scan rate

256 Kbyte

3

3

8

32

3

3

3

Programmable

Programmable

Software and Hardware

Software

ChartView

PostView

ScanCal

CIMScan

ScanServer

(optional)

(optional)

2-2 General Information ChartScan User’s Manual

Page 27

16-Channel Signal Conditioning Cards (Optional)

Low-voltage

terminal block input module

Low-voltage

module

Low-voltage

input module

Isolated TC/voltage

plug type input module

Isolated high-voltage

safety jack input module

Cables

CA-7-3,

CA-47,

Computer-to-ChartScan Cable

PC/AT/XT serial port (9- & 25-pin sub D) to ChartScan (9-pin sub D)

RS-232/422 cable, 6 ft.

Note: A 10BASE-T cable and 10BASE-T crossover adapter are included

with the optional Net232 Ethernet/RS-232 converter.

with removable

with BNC input

with safety jack

with

with

Shielded IEEE 488 cable, 6 ft.

(CSN14/LV/T)

(CSN14/LV/B)

(CSN14/LV/S)

(CSN14/TC/P)

(CSN14/HV/S)

Additional Hardware Options

4-slot expansion chassis

Memory expansion options:

1 Mbyte, 4 Mbyte, or 8 Mbyte

IEEE 488 interface card (see important notice, below)

16 output CSN/Relay card

Net232, Ethernet/RS-232 Converter

An IOtech Personal488 product is required for

IEEE 488 operation with ChartView. A device

named WAVE must be configured in IOtech

Driver 488/W31, /W95, or /WNT (when available).

ChartScan Specifications

If equipment is used in any manner not specified in this manual, or if specification limits

are exceeded, the function of the equipment, as well as the protection provided by it,

may be impaired.

NOTE: Specifications for signal conditioning cards and for the ChartScan Expansion Chassis appear in their

respective sections of this manual.

Measurement Parameters

A/D resolution

Accuracy (with type J TC)

TCs supported

DCV

ACV

Ch-to-ch isolation

Ch-to-system isolation

AC line rejection

Scanning Parameters

Switching Technology

Max scan rate

Max single-ch scan rate

Min channel configuration

Max channel configuration

CAUTION

CAUTION

CAUTIONCAUTION

16 bit w/over sampling

± 0.5°C

J,K,T,E,R,S,B,N

3

3

500 V or 200 V

500 V

3

mechanical relays

147 chs. per sec.

20 Khz

16 channels

128 channels

General Information ChartScan User’s Manual 2-3

Page 28

General

Installation Category:

• CE: Category 2 for Line Voltage Input terminal.

All other terminals are Category 1.

Warm Up:

•

1 hour to rated accuracy.

Expansion Connector:

•

40-conductor connector for connecting expansion chassis via ribbon cable.

ChartScan’s expansion connector (PH401) is located on the analog backplane.

Chassis Ground Connection:

•

Screw terminal.

Dimensions:

•

330 mm wide × 241 mm deep × 152 mm high (13” × 9.5” × 6”).

Weight:

• ≈ 6.75 kg (15 lbs.) with 4 signal conditioning cards installed

Operating Environment:

• Standard: Indoor use, 0 to 50°C;

0 to 95% RH (non-condensing) to

35°C; linearly derate 3% RH/°C

from 35 to 50°C.

Control:

• Power Switch, RS-232 or IEEE 488 option, handshake, parity, baud rate,

calibration memory write enable/disable.

Rear Panel LED Indicators:

• ALARM, TRIGGER and SCAN; SEND and RECEIVE (for standard serial

interface); ERROR and POWER.

•

TALK, LISTEN and SRQ (on optional IEEE 488 interface card)

Power:

• 105-125V, or 210-250V, 50/60 Hz; 20 VA maximum. Set via internal,

two-position slide switch.

Transient Overvoltage according to Installation Categories:

•

Overvoltage Category II for mains supply. The minimum and normal

category is II.

Pollution Degree:

•

I − in accordance with IEC 664

• CE: Indoor use at altitudes below 2000 m,

5 to 40°C; 0 to 80% RH up to 31°C

decreasing linearly to 50% RH at 40°C.

Channels

Number of Option Card Slots:

• 4

Number of Channels:

•

up to 64 channels, expandable to 128 with ChartScan expansion chassis

• 16 channels per card

•

up to 4 cards installed in ChartScan

(up to 4 additional cards with use of ChartScan expansion chassis)

Channel Attributes:

• High and low set points; hysteresis values for high and low set points.

Scan Sequence:

•

Any combination of temperature and voltage channels may be scanned, but

channels are scanned in ascending numerical order.

Scan Interval:

• Absolute time between scans (

max = 99:59:59.9. Note: Specifying a value of 00:00:00.0 results in no delay

between channel scans.

2-4 General Information ChartScan User’s Manual

hh:mm:ss.t); min = 00:00:00.0,

Page 29

Triggers

Installation Category:

• CE: Category 1

Programmable Triggering:

• Temperature or Voltage level (above or below), absolute time of day, alarm

condition (on or off), IEEE GET, IEEE TALK, external TTL trigger (rising or

falling), specified number of readings.

Temperature-Level Trigger:

•

Programmable value for any one channel. Not available in Burst mode.

TTL Trigger:

• Programmable for rising or falling edges.

Pre-Trigger Count and Post-Trigger Count:

• Programmable integer (< memory size -1); and programmable integer..

Digital Filtering:

• Average 16 samples at 50/60 Hz for line cycle noise.

TC Reference:

• TC reference tables based on the IPTS-68 standard as listed with the US

Department of Commerce (NTIS). International Electrotechnical

Commission (IEC) 43 760.

Trigger Input Connector:

External BNC connector

Data Storage & Format

Trigger Output Connector:

External BNC connector

Storage:

•

128 K reading (256 Kbyte) standard; optional 500 K reading (1 Mbyte), 2 M

reading (4 Mbyte), 4 M reading (8 Mbyte).

Data Formats:

• ASCII and binary; binary format returns a 16-bit compensated and linearized

temperature value (0.1°C/bit); user-programmable for hi/low byte or low/hi

byte. Note: High speed DMA transfers are binary format only.

Statistical Parameters:

• High, Low, and Last available per channel (during acquisition only). Not

available in single channel burst mode.

Time Stamp:

• Available for each scan group and for each channel’s high, low, and last

parameters.

Time Format:

•

Relative time (

date and time (

burst mode.

Alarm Stamp:

•

Available for each scan group. Not available in single channel burst mode.

hh:mm:ss.mil), absolute time (hh:mm:ss.mil) or absolute

dd/mm/yy hh:mm:ss.mil). Not available in single channel

General Information ChartScan User’s Manual 2-5

Page 30

Digital I/O Interface & Alarms

Installation Category:

• CE: Category 1

Number of Digital Inputs:

• 8 bits, LS-TTL compatible.

Number of Digital Outputs:

•

32 bits, TTL level compatible. Can be programmed as alarms.

Note: The 32 TTL outputs can be set or cleared via program control.

Alarm Conditions:

• May be detected by

Alarm Update Rate:

• Alarms are updated whenever a channel assigned to an alarm is measured.

Connector:

• Female DB50 50-pin (32 Alarms, 8 digital inputs, 10 ground pins), mating

connector supplied.

Note: See chapter 3 for information regarding External TTL BNC Connectors.

Service must be performed by qualified personnel. All electrical connections to device,

including the AC line and analog inputs, must be disconnected prior to opening ChartScan

main unit or expansion chassis casing. Internal voltage potentials exist which could cause

bodily injury or death!

SRQ

or by software query (SPOLL or U command).

WARNING

WARNING

WARNINGWARNING

WARNING

WARNING

WARNINGWARNING

ChartScan’s ground (on the AC power connector) must be connected to an external earth

ground. Failure to make such a connection could present an electric shock hazard, causing

bodily injury or death!

Fuse:

1/2A, 250V, Slo Blo, 3AG for 100-140V power line, or

1/4A, 250V, Slo Blo, 3AG for 200-240V power line

CAUTION

CAUTION

CAUTIONCAUTION

Fuse failure indicates a possible problem within the device circuitry. If a fuse blows, contact

a qualified service representative. Replacement fuses are to be installed by qualified service

personnel with the unit disconnected from the power source and with all other terminals

disconnected. If the line voltage selector is changed, then the fuse designated for that line

voltage must be used.

2-6 General Information ChartScan User’s Manual

Page 31

Calibration

Calibration must be completed periodically to ensure equipment is accurate, and

can be performed manually, or with the use of ScanCal. Chapter 6 contains

instructions, including calibration equipment requirements, for the following:

ChartScan main unit calibration for offset and gain

Offset calibration for all card types

Gain calibration for low volts cards

Gain calibration for high volts cards

Cold junction calibration for TC cards

Note: ChartScan main unit constants are stored in NV-RAM.

Signal Conditioning Card constants stored in each card’s EEPROM.

Note: Industry standard calibration period is once every year.

General Information ChartScan User’s Manual 2-7

Page 32

−

Notes

2-8 General Information ChartScan User’s Manual

Page 33

Hardware 3

Overview ……3-1

Front Panel ……3-1

Rear Panel ……3-2

Power Aspects ……3-3

Changing the Voltage Setting ……3-3

Replacing the AC Power Supply Fuse ……3-4

Memory Configuration ……3-4

Expanded Memory Options ……3-4

Calibration Memory Write Enable/Disable ……3-6

RS-232/422 Interface Configuration ……3-6

Configuring RS-322/422 Parameters …… 3-6

Serial Port Pin Connectors ……3-8

Ethernet Interface Configuration ……3-9

IEEE 488 Configuration (Option) ……3-11

Digital I/O Lines ……3-13

Logic Levels ……3-13

Digital I/O Port Pinout ……3-13

Overview

This section provides information regarding ChartScan hardware. The chapter begins with brief discussions and

illustrations regarding the unit’s front and rear panels. The text is divided into sub-sections which include material

on voltage settings, fuse replacement, memory expansion, and serial interface configuration (RS-232/422). Ethernet

configuration is detailed in the Net232 User’s Guide, p/n 1037-0901.

External TTL BNC Connectors ……3-14

Signal Conditioning Cards ……3-14

CSN14/TC/P Thermocouple and Low Volts Card

with Subminiature Plugs ……3-15

CSN14/LV/ (T, B, & S) Low Voltage Cards ……3-17

CSN14/HV/S High Voltage Card with Safety Jack

Connectors ……3-18

CSN/Relay Card (for High-Current Digital-

Output) ……3-19

CSN/Relay Card Specifications ……3-20

Expansion Chassis, CSN/Exp (Option) ……3-20

Connecting the Expansion Chassis ……3-20

Automatic Channel Assignment ……3-22

Additional hardware-related topics are included, such as signal conditioning cards and the optional ChartScan

Expansion Chassis.

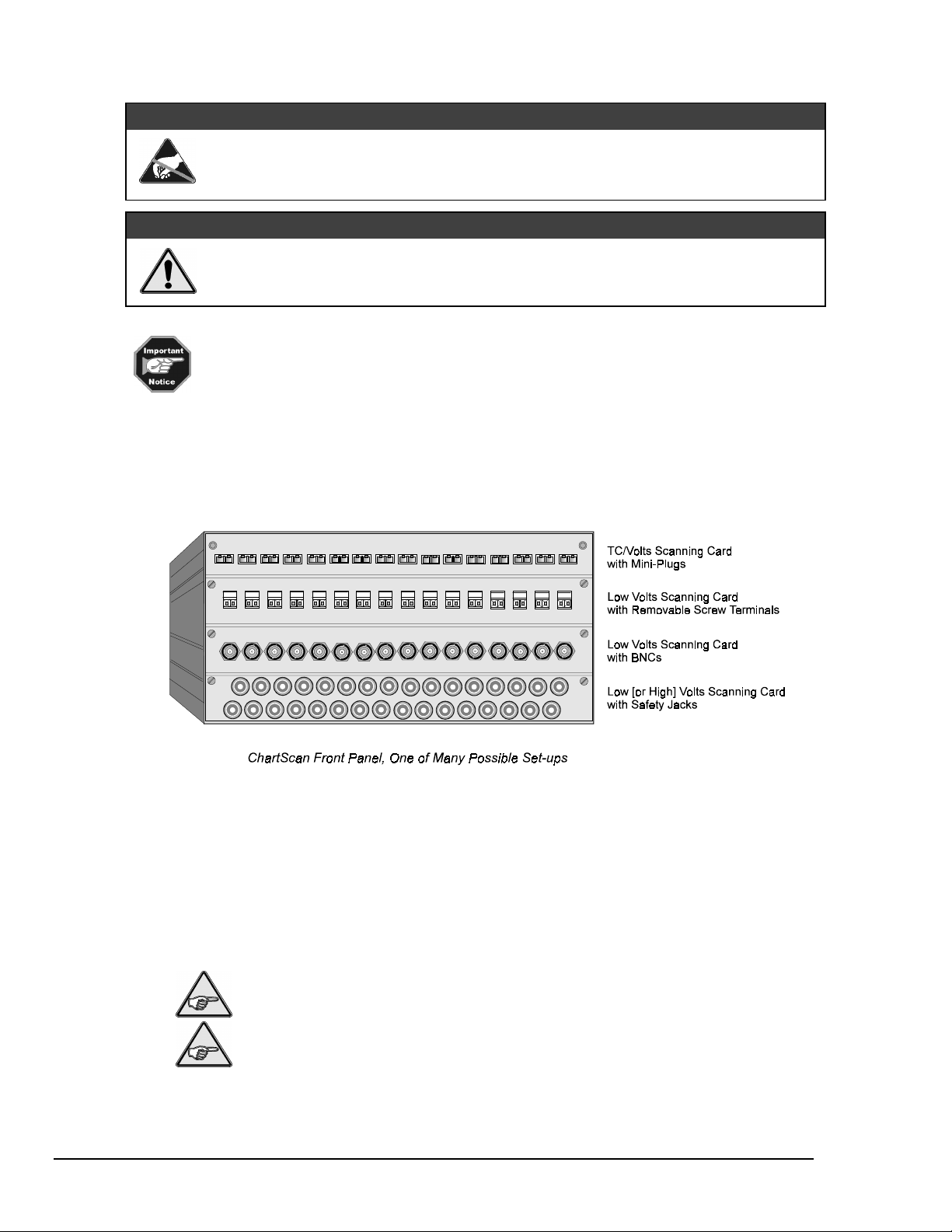

Front Panel

ChartScan’s front panel reveals up to four sets of connectors, one set for each signal-conditioning card used. The

front panel contains no switches or other types of control. Each connector row is dependent upon the type of signal

conditioning card used. With different combinations of cards, a variety of setups is possible.

ChartScan Front Panel, One of Many Possible Set-ups

ChartScan User’s Manual,

12-28-98

3-1

Page 34

Rear Panel

ChartScan’s rear panel contains several items, including a set of LEDs for status indication. The LED indicators are

described in the following table. Other rear panel items are listed in a separate table following the illustration.

LED Indicators, Chassis

ALARM ON when an alarm has occurred. The indicator remains ON until the alarm condition clears.

TRIGGER Flashes when ARMed (waiting for a trigger), is ON continuous when triggered; is OFF when

SCAN ON when ChartScan is storing a channel scan in its internal buffer.

SEND ON when transmitting data to the serial interface (for RS-232 operation only).

RECEIVE ON when receiving data from the controlling computer (for RS-232 operation only).

ERROR

POWER ON when power is applied to ChartScan and the power switch on the back panel is in the ON

OFF when no alarm condition exists.

data collection is finished. Trigger is also turned OFF by IEEE DCL or SDC.

ON when an error has occurred, OFF when no error condition exists. See the Error Query (E?)

command for more information.

position (depressed). OFF if power is not present.

Item Description

Power

Connector

Power Switch

Chassis Ground

Calibration

Enable/Disable

Trigger In

TTL Output

Alarms & Digital I/O

(DB50) Connector

RS-232/422 (DB9)

Connector

DIP Switch

Interface Card Slot

LED Indicators

Provides a means for connecting ChartScan to one of two voltage supplies:

105 - 125V, or 210 - 250V. The connected power supply must agree with that selected by

ChartScan’s internal slide switch (described later in this chapter).

Turns power ON or OFF.

A single point grounding node for, but not limited to, thermocouple shield termination.

Pushbutton used to enable/disable the hardware protected portion of NVRAM during ChartScan

main unit calibration. Note that this pushbutton does not exist on early production units.

Early production units use micro-switch #9 (on the DIP switch) instead of a calibration

pushbutton.

Refer to Chapter 6 for detailed information regarding calibration.

BNC Trigger input for initiating and/or stopping acquisition with TTL input signal

BNC TTL Scan output signal occurs for each channel scan; used for synchronizing other

equipment with ChartScan acquisition.

DB50 connector offers easy access to Alarms and Digital I/O (32 digital outputs and 8 digital

inputs)

Serial port for operation at remote distances from controlling computer. Supports various baud

rates using RTS/CTS or XON/XOFF handshaking. When ChartScan is configured for

RS-232 serial communications, this port can be used to connect ChartScan to a Net232

ethernet/RS-232 converter for ethernet operations. Refer to the Net232 User’s Guide for

ethernet-related information.

Used for selecting RS-232 or RS-422 and respective communication parameters, i.e.,

handshaking, parity and Baud Rate. Also allows for section of IEEE 488 and address

settings. An IEEE 488 interface card is required for IEEE 488 operations.

For installing the optional IEEE 488 interface card. Note that RS-232 serial interface is the

default and is possible with or without an interface card.

See previous table, LED Indicators, Chassis.

ChartScan Rear Panel

3-2 ChartScan User’s Manual

Page 35

Power Aspects

Changing the Voltage Setting

Based on your order, your ChartScan system was set at the voltage indicated by a sticker or tag (located on the rear

of the unit, near the power switch). If you need to change the voltage selection, complete the following steps.

Never disassemble ChartScan’s case while it is connected to the AC power line! Internal

voltage potentials exist which could cause bodily injury or death!

Prior to disassembly:

(1) turn off power

(2) disconnect analog lines

(3) disconnect AC power line

(4) disconnect all additional lines

Never disconnect the AC power line from ChartScan while analog connections to an

external device exist! Common mode voltage potentials exceeding 60 VDC or 30 Vrms may

exist which could cause bodily injury or death!

Use approved ESD precautions, including static-free work area and grounded wrist strap,

when handling circuit boards and electronic components. Failure to do so could cause

equipment damage due to electrostatic discharge.

WARNING

WARNING

WARNINGWARNING

WARNING

WARNING

WARNINGWARNING

CAUTION

CAUTION

CAUTIONCAUTION

1. Ensure the ChartScan is not connected to any power source.

2. Remove two upper side screws (near front of unit, and on side of unit) and slide top cover plate free of

ChartScan unit.

3. Locate the two-position slide on the power supply board. You will notice the switch above the AC

power inlet. The number visible (115 or 230) indicates the selected power setting.

4. As indicated in the figure, press down on the switch to change the setting from 115VAC to 230VAC;

or, to change the setting from 230 to 115VAC, you press up on the switch.

5. Replace ChartScan’s cover plate and secure with screws.

6. Add a new sticker, or tag, stating the newly selected voltage.

Hardware 3-3

Page 36

Replacing the AC Power Supply Fuse

Fuse: 1/2A, 250V, Slo Blo, 3AG for 105-125V power line, or

1/4A, 250V, Slo Blo, 3AG for 210-250V power line

Fuse failure indicates a possible problem within the device circuitry. If a fuse blows, contact

a qualified service representative. Replacement fuses are to be installed by qualified service

personnel with the unit disconnected from the power source and with all other terminals

disconnected. If the line voltage selector is changed, then the fuse designated for that line

voltage must be used.

Replace the AC power supply fuse as follows:

1. Turn ChartScan’s power to “OFF.”

2. Open the fuse drawer on the rear panel.

3. Remove the fuse.

4. Ensure correct rating of replacement fuse.

5. Install replacement fuse.

6. If you changed the value of the fuse due to a new voltage selection, replace the spare fuse with a fuse of

the new value.

CAUTION

CAUTION

CAUTIONCAUTION

7. Close the fuse drawer until it snaps into place.

Memory Configuration

Memory configuration of ChartScan consists of installing expanded memory boards (optional), and selecting writeenable or write-disable for calibration memory.

Expanded Memory Options

ChartScan can accommodate up to 8 MBytes of memory, which is ideal for both high-speed and long-term data