Page 1

MADE IN

NIST

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

User’s Guide

Shop online at

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

USA:

ISO 9001 Certified

Canada:

USA and Canada:

Mexico:

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the

European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without

notice. WARNING: These products are not designed for use in, and should not be used for, human applications.

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase.

OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and

shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’sCustomer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced

at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows

evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’scontrol. Components which wear are not

warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any

omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be as specified and free of defects.

OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not

exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or

special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in

or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic

WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING ANY PRODUCT(S) TO

OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER

TO AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

PATENTNOTICE: U. S. Pat. No. 6,074,089; 5,465,838 / Canada 2,228,333; 2,116,055 / UK GB 2,321,712 / Holland 1008153 / Israel 123052 / France

2 762 908 / EPO 0614194. Other patents pending.

FOR W

available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

2. Model and serial number of the product under warranty, and

3. Repair instructions and/or specific problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and

engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2004 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced, translated, or reduced to any electronic

medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

Servicing North America:

One Omega Drive, Box 4047

Stamford CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

En Espan˜ol: (001) 203-359-7803 e-mail:espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

WARRANTY/DISCLAIMER

RETURN REQUESTS / INQUIRIES

ARRANTY RETURNS, please have the following information

Benelux:

Czech Republic:

France:

Germany/Austria:

®

®

United Kingdom:

®

ISO 9002 Certified

FOR NON-WARRANTY REPAIRS,

Have the following information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems relative to the product.

Servicing Europe:

Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Frystatska 184, 733 01 Karviná, Czech Republic

Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

One Omega Drive, River Bend Technology Centre

Northbank, Irlam, Manchester

M44 5BD United Kingdom

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

consult OMEGA for current repair charges.

M4151/0507

HHT13

Pocket Laser Tachometer

with Remote Sensor Input

Page 2

SAFEGUARDS AND PRECAUTIONS

LASER RADIATION

AVOID DIRECT EYE EXPOSURE

CLASS 2 LASER PRODUCT

MAX OUTPUT POWER: 1mW

EMITTED WAVELENGTH: 650nm

CLASSIFIED TO IEC 60825-1:2001

14.0 OPTIONS / ACCESSORIES

HHT-RT-5 Reflective Tape, 5 foot [1.5 m] roll, ½ inch [13 mm]

wide

HHT13-RCA Remote Contact Assembly with 10 cm wheel,

concave and convex tips

WARNING - This product emits a visible beam of laser light.

Avoid exposure to the laser radiation. The use of optical viewing

aids (binoculars, for example) may increase the ocular hazard.

CAUTION - The laser beam should not be intentionally aimed at

people or animals.

CAUTION - Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

Read and follow all instructions in this manual carefully, and

retain this manual for future reference.

Do not use this instrument in any manner inconsistent with

these operating instructions or under any conditions that exceed

the environmental specifications stated.

This instrument is not user serviceable. For technical

assistance, contact the sales organization from which you

purchased the product.

In order to comply with EU Directive 2002/96/EC on Waste Electrical

and Electronic Equipment (WEEE): This product may contain material

which could be hazardous to human health and the environment. DO NOT

DISPOSE of this product as unsorted municipal waste. This product

needs to be RECYCLED in accordance with local regulations, contact

your local authorities for more information. This product may be returnable

to your distributor for recycling - contact the distributor for details.

HHT13-CTE Concave/convex contact tips and 10 cm linear contact

wheel

HHT13-LCW 12 inch circumference wheel for use with HHT13-

RCA

HHT20-ROS Remote Optical Sensor

HHT-ROS-CABLE 25 foot extension cable for all sensors

HHT13-CC10 Padded Nylon Carrying Case

24

Page 3

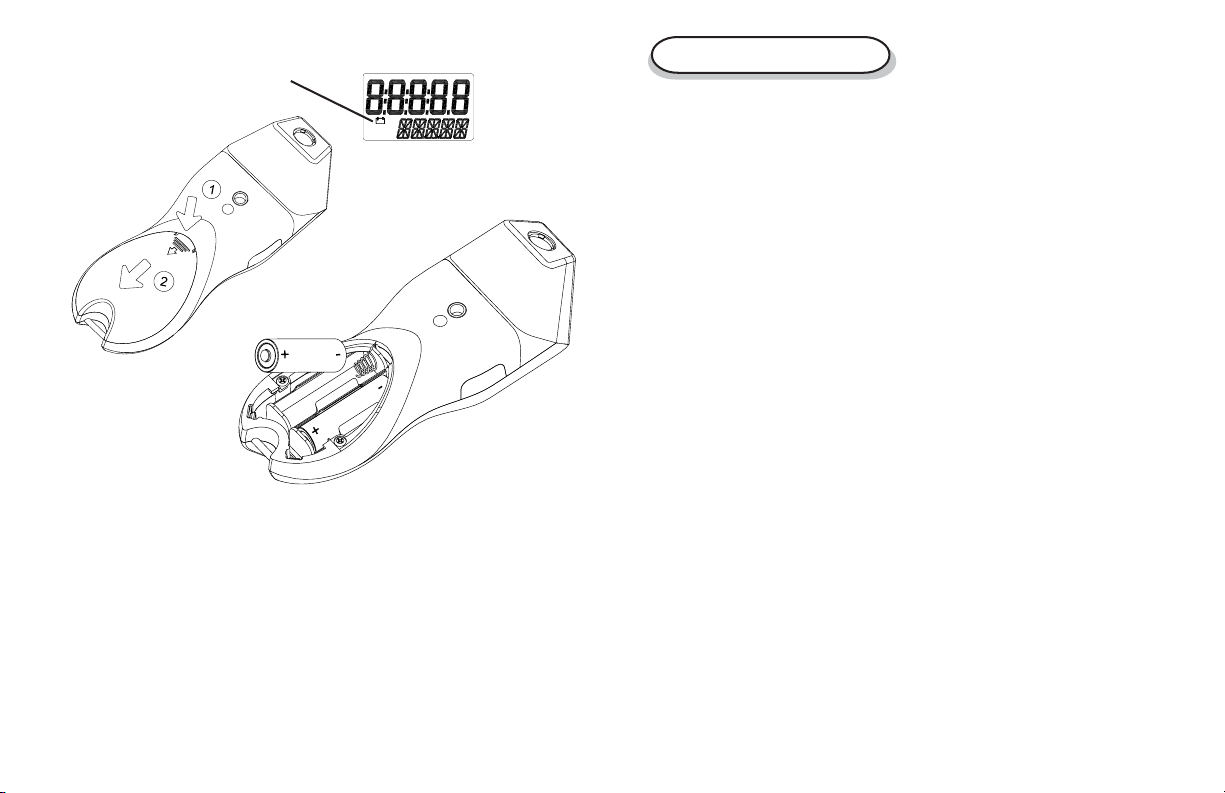

12.0 BATTERIES

When displayed, replace batteries.

Remove battery

cover

Install two 1.5V

“AA” alkaline

batteries

NOTE: Both

batteries face the

same direction.

13.0 CLEANING

To clean the instrument, wipe with a damp cloth using mild soapy solution.

TABLE OF CONTENTS

TABLE OF CONTENTS

1.0 OVERVIEW ............................................................................. 1

2. 0 FEATURE LOCATIONS ............................................................ 1

3.0 LCD DISPLAY SYMBOLS ....................................................... 2

4.0 HHT13 SPECIFICATIONS........................................................ 3

5. 0 PREPARATION FOR MEASUREMENT .................................... 7

5.1 Non-Contact Preparation ............................................. 7

5.2 Direct Contact Preparation.......................................... 7

5.3 Connecting External Sensors ..................................... 8

6.0 TACHometer Mode ................................................................ 9

6.1 TACHometer Setup ....................................................... 9

6.2 TACHometer Operation .............................................. 11

7.0 RATE Mode........................................................................... 12

7.1 RATE Setup ................................................................. 12

7.2 RATE Operation .......................................................... 14

8.0 TOTALizer Mode .................................................................. 15

8.1 TOTALizer Setup......................................................... 15

8.2 TOTALizer Operation .................................................. 18

9.0 TIMER Mode ......................................................................... 19

9.1 TIMER Setup ................................................................ 19

9.2 TIMER Operation ......................................................... 20

10.0 MAKING MEASUREMENTS .................................................. 21

10.1 Non-Contact Measurements ..................................... 21

10.2 Direct Contact Measurements .................................. 2 1

11.0 INPUT / OUTPUT .................................................................. 22

12.0 BATTERIES ........................................................................... 23

13.0 CLEANING ............................................................................ 23

14.0 OPTIONS /ACCESSORIES ................................................... 24

23

Page 4

1.0 OVERVIEW

The HHT13 is a precision hand-held multifunction Tachometer, Ratemeter,

Totalizer and Timer. It is programmable to display directly in Revs, Inches,

Feet, Yards, Miles, Centimeters and Meters or function as a stopwatch or

interval timer. Input / output sockets allow for remote sensing and pulse

output to external indicating devices. For ease of use, the instrument can be

“Locked-on” for continuous operation.

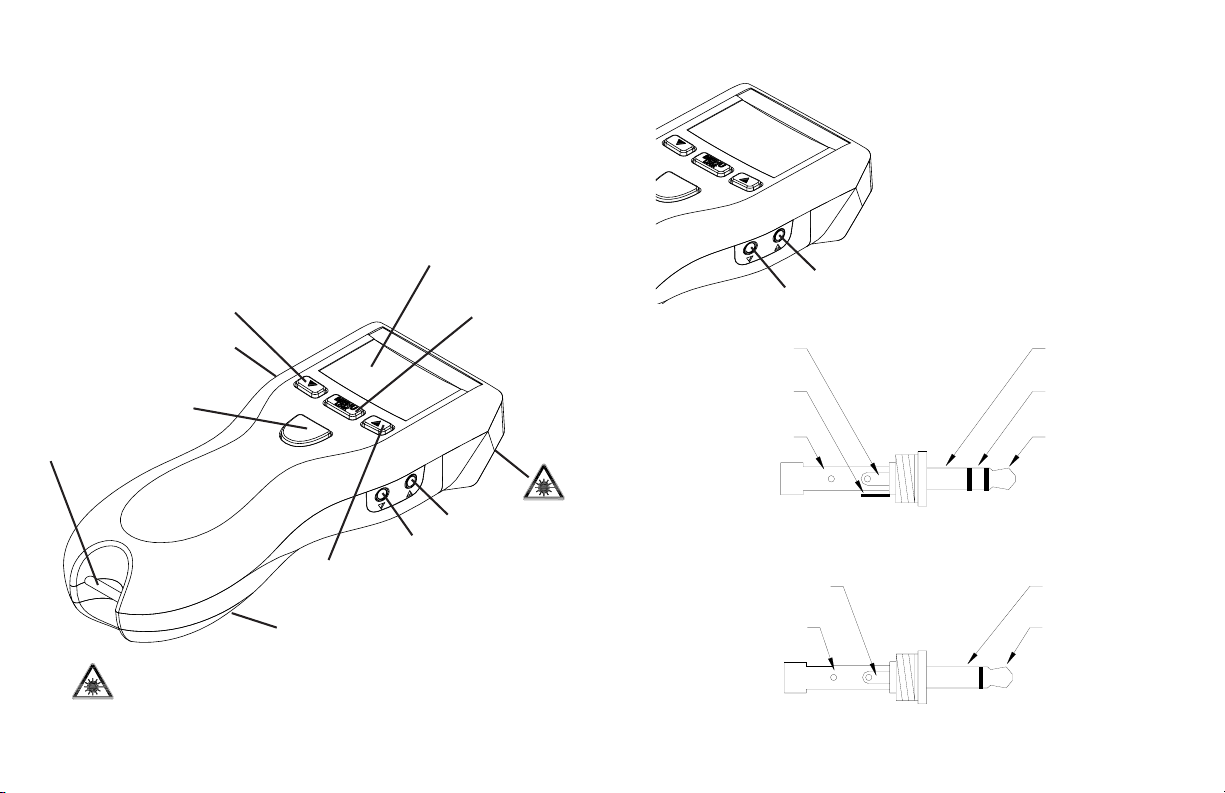

2.0 FEATURE LOCATIONS

LCD display

Min / Scroll

Down arrow

Tripod mounting bushing

(underside)

Start / Reset button

Belt clip

Menu / Select

and Lock-on

button

11.0 INPUT / OUTPUT

Input socket (

Output socket (

Signal Input

+3V Out to

Sensor

Common

(GND)

Input: Accepts remote sensor or

Remote Contact Assembly

(HHT13-RCA). 1/8”

(3.5mm) stereo phone plug.

Output: 1 pulse per revolution TTL

output on internal operation.

Pulse repeater with external

sensors. 1/8” (3.5mm) mono

phone plug.

Common

(GND)

+3V Out to

Sensor

Signal Input

TT

T)

TT

SS

S)

SS

Input socket

Output socket

Max / Scroll Up

arrow

Battery compartment

Input Connector Detail (Stereo plug)

Signal Input

Common

(GND)

Common

(GND)

Signal Input

AVOID EXPOSURE - LASER RADIATION IS

EMITTED FROM THIS APERTURE

Output Connector Detail (Mono plug)

1

22

Page 5

10.0 MAKING MEASUREMENTS

10.1 Non-Contact Measurements

Hand-held

OR

Laser

10.2 Direct Contact Measurements

Rotational Linear

(Use concave

tip for small

shafts)

to RCA

from HHT13 from HHT13

ONLY USE MODERATE PRESSURE

WARNING: Making measurements in direct contact with rotating

equipment can be dangerous. Keep all loose clothing and hair

away from exposed moving machinery. Keep the hand holding

the instrument well behind the back end of the Remote Contact

Assembly. Properly replace all machinery guards after completing

measurement. Do not use for rotation greater than 20,000 RPM.

21

External Sensor (HHT20-ROS

shown)

Light

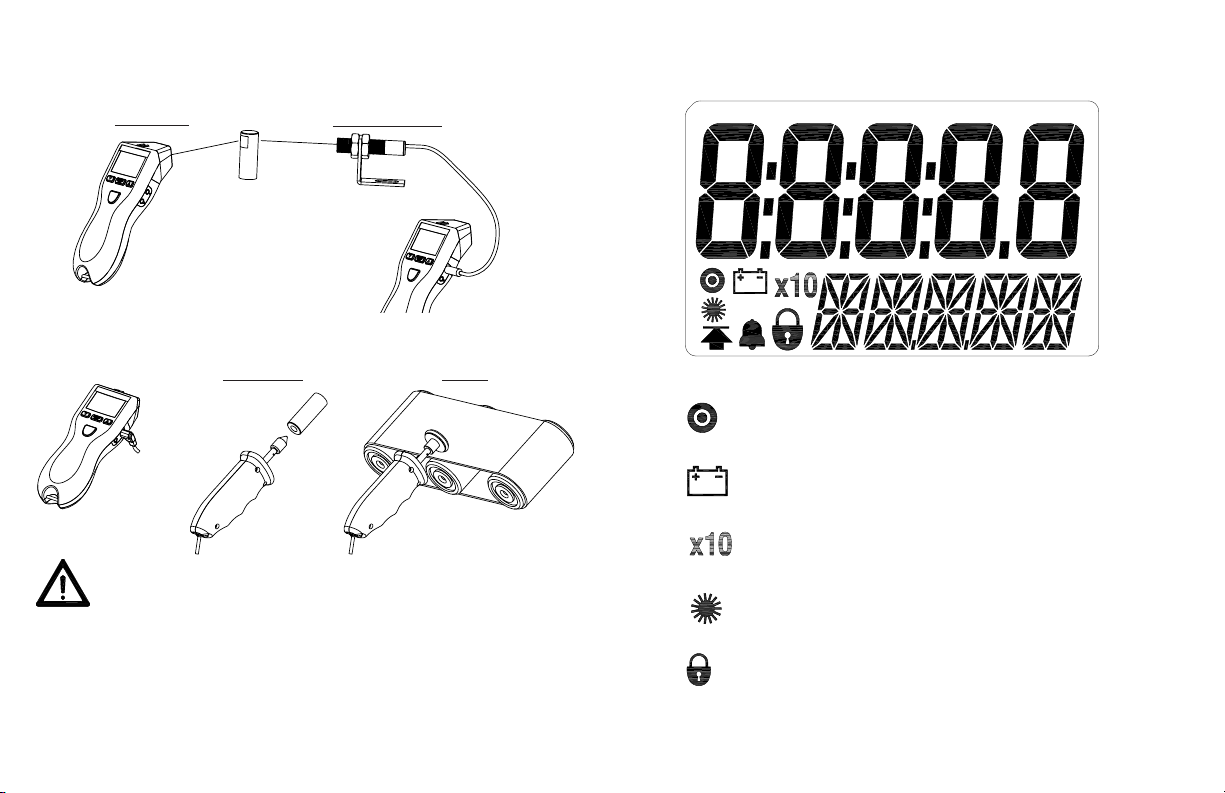

3.0 LCD DISPLAY SYMBOLS

On Target Indicator. Blinks on whenever there is an input

signal. Will appear to be solid on at higher frequencies.

Low Battery icon. Indicates that the batteries are low and

need to be replaced.

Times Ten icon. Indicates that the value shown is ten times

that which is displayed.

Laser Indicator. Red laser is on when this indicator is

illuminated.

Lock icon. Indicates that the unit is “Locked” on and making

continuous measurements (Lock mode).

2

Page 6

4.0 HHT13 SPECIFICATIONS

Laser Specifications:

Classification: Class 2 (per IEC 60825-1 Ed 1.2 2001-8)

Complies with FDA performance standards for laser products except

for deviations pursuant to Laser Notice No. 50, dated July 26, 2001.

Maximum Laser Output: 1mW

Pulse Duration: Continuous

Laser Wavelength: 650 nm

Beam Divergence: < 1.5 mrad

Beam Diameter: 4 x 7 mm typical at 2 meters

Laser Diode Life: 8,000 operating hours MTBF (1 year

warranty)

Non-Contact Specifications:

Ranges: RP M 5 – 200,000

RPS 0.084 – 3,333.3

RPH 300-999,990

Resolution: Fixed: 1 (10 above 99,999)

Auto-ranging: 0.001 to 1.0 (10 above 99,999)

Accuracy: ±0.01% of reading or resolution limit

Operating Range: up to 25 feet (7.62 m) or up to 70 degrees off

perpendicular to reflective tape target

Contact Specifications using optional Remote Contact Assembly:

Range: Contact Tips: 0.5 to 20,000 RPM

10 cm / 12-inch Wheel: 0.5 to 12,000 RPM

Resolution: Fixed: 1 (10 above 99,999)

Auto-ranging: 0.001 to 1.0 (10 above 99,999)

3

8. Save and

advance

9. Exit Setup –

Ready to

measure

Unit will remember these settings (including lock on/off) even if turned off

and back on.

DONE, then Units

selected

9.2 TIMER Operation

Measure:

Manual

Auto

Reset

Lap

Power Off

Each press toggles Start and Stop

Start and Stop triggered by

OR

Remote Optical Sensor

(HHT20-ROS)

With Timer stopped Resets time to 00:00.0

With Timer running Stops at elapsed time to date.

To continue, press again.

Automatic after 90 seconds

OR

if unit not Locked on

20

Page 7

9.0 TIMER Mode

9.1 TIMER Setup

1. Turn Power

ON

1a. To toggle Lock

On/Off

Press and Hold

2. Enter Setup

Mode

3. Enter selection

of Mode

4. Select TIMER

Mode

5. Save and

advance

6. Enter selection

of Timer

function

7. Select Timer

function

19

Last Units selected

are displayed

Locked On

Last Mode selected

is displayed

OR

OR Toggles between

Repeat until

TIMER displayed

MAN or AUTO

Manual and

Auto

Contact Specifications (continued):

Accuracy: Revs: ±0.05% of reading (RPM) or resolution limit

(with no slippage)

Linear: ±0.5% of reading or resolution limit (with no

slippage)

Contact Measurements Ranges:

TACHOMETER:

Revolutions per Minute (RPM) 0.5 to 20,000 RPM

Revolutions per Second (RPS) 0.0833 to 333.33 RPS

Revolution per Hour (RPH) 30 to 999,990 RPH

RATES: Wheel Circumference:

Inches per Second 10 cm: 0.033 to 1312.3 IPS

12 in: 0.100 to 2,400.0 IPS

Inches per Minute 10 cm: 1.969 to 78,740 IPM

12 in: 6.000 to 144,000 IPM

Inches per Hour 10 cm: 118.11 to 999,990 IPH

12 in: 360.00 to 999,990 IPH

Feet per Second 10 cm: 0.003 to 109.36 FT/S

12 in: 0.009 to 200.00 FT/S

Feet per Minute 10 cm: 0.164 to 6,561.7 FT/M

12 in: 0.500 to 12,000 FT/M

Feet per Hour 10 cm: 9.843 to 393,700 FT/H

12 in: 30.000 to 720,000 FT/H

Yards per Second 10 cm: 0.001 to 36.453 YPS

12 in: 0.003 to 66.667 YPS

Yards per Minute 10 cm: 0.055 to 2,187.2 YPM

12 in: 0.167 to 4,000.0 YPM

4

Page 8

Contact Measurements Ranges (continued):

RATES: Wheel Circumference:

Yards per Hour 10cm: 3.281 to 131,233 YPH

12 in: 10.000 to 240,000 YPH

Miles per Hour 10 cm: 0.002 to 74.564 MPH

12 in: 0.006 to 136.36 MPH

Centimeters per Second 10 cm: 0.084 to 3,333.3 CM/S

12 in: 0.21 to 3,048.0 CM/S

Centimeters per Minute 10 cm: 5.000 to 200,000 CM/M

12 in: 15.240 to 365,760 CM/M

Centimeters per Hour 10 cm: 300.00 to 999,990 CM/H

12 in: 914.40 to 999,990 CM/H

Meters per Second 10 cm: 0.001 to 33.333 M/SEC

12 in: 0.003 to 60.960 M/SEC

Meters per Minute 10 cm: 0.050 to 2,000.0 M/MIN

12 in: 0.153 to 3,657.6 M/MIN

Meters per Hour 10 cm: 3.000 to 120,000 M/H

12 in: 9.144 to 219,460 M/H

TOTALIZER:

Counts: 0 to 999,999

Scale Totals in Inches, Feet, Yards, Centimeters or Meters

Input: Internal or External optics or linear contact wheel

Timer Specifications:

Minutes:Seconds.Tenths to 99:59.9

Accuracy: ±0.2 second

Resolution: 0.1 second

5

8.2 TOTALizer Operation

Measure

Press and hold Lock on

Recall Max

or Min

Recall Time

in seconds

If unit is

Locked on:

Power Off

NOTE: Pressing

OR

Max or Min Speed (in

last selected Tach or Rate

mode units)

Shows time in seconds

from when the Start /

Reset button is pressed

until the last input signal

measured.

Resets Max/Min, Total and

Measurement Time

Automatic after 90 seconds if

OR

unit not Locked on

OR

once before 90

seconds will keep

measurements in

memory and the

display turned on

longer.

18

Page 9

TOTALizer Setup (continued):

9. Enter selection

of number of

decimal places

10. Select decimal

places

11. Save and

advance

12. Exit Setup –

Ready to

measure

Units = COUNT: Rotational/Linear Units:

DONE,

then Units selected

Unit will remember these settings (including lock on/off) even if turned off

and back on.

OR

NONE, 1, 2 or 3

Repeat until

desired decimal

places displayed

DONE,

USE CONTACT TIP or

[wheel selected],

then Units selected

Display: 5 x 0.5” (12.7mm) numeric digits plus 5 Alpha-numeric LCD

Batteries: 2 “AA” 1.5 V (DC) alkaline included

(Note: Batteries are NOT rechargeable.)

Battery Life: 30 hours continuous typical with batteries provided

External Input:

Absolute max: -0.3 V to 5 V (DC)

Minimum: low below 1.2 V and high above 2 V (TTL compatible)

Edge: Triggers on Positive edge

Power Out: 3.0 V nominal, approx. 2.8 V @ 20 mA max

Pulse Output: 0 V to 3.3 V (DC) pulse

Same shape as External Input signal or high when internal

optics sees a reflection

Dimensions: 6.92” (17.58 cm) H x 2.4” (6.10 cm) W x 1.6” (4.06 cm) D

Weight: Approx. 7 oz. (210 g)

This product is designed to be safe for indoor use under the following

conditions (per IEC61010-1).

Installation Category II per IEC 664

Pollution Degree Level II per IEC 664

Temperature: 40 °F to 105 °F (5 °C to 40 °C)

Humidity: Maximum relative humidity of 80% for temperatures up

to 88 °F (31 °C) decreasing linearly to 50% relative

humidity at 100 °F (40 °C). Humidity non-condensing.

Specifications subject to change without notice.

617

Page 10

5.0 PREPARATION FOR MEASUREMENT

5.1 Non-Contact Preparation

For Internal operation (Red laser) or External operation

using optional Remote Optical Sensor (ROS-Red LED).

1. Clean

Shaft

2. Apply 1/2”

square T-5

Reflective

tape

6. Enter

selection of

Units

Internal or External ROS: External RCA:

COUNT

Only

7. Select Units

Different options displayed for

Internal or External operation.

Rotational: REV

Linear: INCH, FEET,

YARDS, CM, METER

OR Repeat until

desired Units

displayed

For Small Shafts:

5.2 Direct Contact Preparation

For External operation ONLY using optional Remote

Contact Assembly (HHT13-RCA).

Select and install contact option:

1. Contact Tip (Convex tip shown.

Use Concave tip for small shafts.)

7

As small as 1/8” wide

on side or radius edge

Align flats

8. Save and

advance

Only for Linear Units:

8a. Enter selection

of Wheel

8b. Select Wheel

8c. Save and

Advance

OR

COUNT or REV Linear Units

Last Wheel

selected is

displayed

OR

Toggles

between

10CM and

12IN

16

Page 11

8.0 TOTALizer Mode

8.1 TOTALizer Setup

2. 10 cm Wheel 3. 12 inch Wheel

OR

1. Turn Power

2. Enter Setup

3. Enter

4. Select

5. Save and

15

ON

Internal or External ROS: External RCA:

Last Units

selected

1a. To toggle Lock On/

Off

Press and Hold

Mode

selection of

Mode

TOTAL

Mode

advance

Different messages displayed for

Internal or External operation.

OR Repeat until

EXTRN, then scrolling

message, then last

Units selected

Locked On

Last Mode selected

is displayed

TOTAL displayed.

Install with

pin in shaft

Tighten screw

securely into flat

on shaft.

fully seated

in slot.

Tighten

screw.

5.3 Connecting External Sensors

Plug sensor into

Input socket

SS

S

SS

In

Remote Optical Sensor

(HHT20-ROS)

Remote Contact Assembly

(HHT13-RCA)

(shown with optional 12 inch wheel)

8

Page 12

6.0 TACHometer Mode

6.1 TACHometer Setup

11. Save and

advance

1. Turn

Power

ON

1a. To toggle Lock On/

Off

2. Enter

Setup

Mode

3. Enter

selection

of Mode

4. Select

TACH

Mode

5. Save and

advance

6. Enter

selection

of Units

Press and Hold

OR

Last Units selected are

displayed

Locked On

Last Mode selected is

displayed

Repeat until TACH

displayed

RPS, RPM or RPH

12. Exit Setup –

Ready to

measure

Unit will remember these settings (including lock on/off) even if turned off

and back on.

DONE,

USE CONTACT TIP or

[wheel selected],

then Units selected

7.2 RATE Operation

Measure

Press and hold Lock on

Recall Max

Recall Min

If unit Locked

on:

Power Off

OR

Max Speed

Min Speed

Resets Max/Min

Automatic after 90 seconds

OR

if unit not Locked on

9

14

Page 13

RATE Setup (continued):

6. Enter selection

of Units

Linear: IPS, IPM, IPH, FT/S, FT/M, FT/H, YPS, YPM,

YPH, MPH, CM/S, CM/M, CM/H, M/SEC, M/MIN, M/H

7. Select Units

8. Save and

advance

Only for Linear Units:

8a. Enter

selection of

Wheel

Rotational: C RPS,

C RPM or C RPH

OR Repeat until

desired Units

displayed

OR

Rotational Units

Linear Units

Last Wheel

selected is

displayed

7. Select Units

8. Save and

advance

9. Enter selection

of number of

decimal places

10. Select decimal

places

11. Save and

advance

OR Repeat until

desired Units

displayed

NONE, 1, 2 or 3

OR

Repeat until

desired decimal

places displayed

8b. Select

8c. Save and

9. Enter selection

of number of

decimal places

10. Select decimal

places

13

Wheel

Advance

OR Toggles

NONE, 1, 2 or 3

OR

Repeat until

desired decimal

places displayed

between 10CM

and 12IN

12. Exit Setup –

Ready to

DONE, then Units

selected

measure

Unit will remember these settings (including lock on/off) even if turned off

and back on.

10

Page 14

6.2 TACHometer Operation

Measure

OR

7.0 RATE Mode

NOTE: External Remote Contact Assembly (HHT13-RCA) must be

inserted into input socket.

Recall Max

Recall Min

If unit Locked

on:

Power OFF

Press and hold

Lock on

Max Speed

Min Speed

Resets Max/Min

Automatic after 90 seconds

OR

if unit not Locked on

7.1 RATE Setup

1. Turn

Power

ON

1a. To toggle Lock

On/Off

Press and Hold

2. Enter

Setup

Mode

3. Enter

selection

of Mode

4. Select

RATE

Mode

5. Save and

advance

OR

EXTRN, then scrolling

message, then last Units

selected

Locked On

Last Mode selected is

displayed

Toggles between

RATE and TOTAL.

Select RATE.

11

12

Loading...

Loading...