Page 1

1

2

INTRODUCTION

The instrument is a portable digital thermometer that

measures external thermocouples of type K, J, R, S, T, E,

N. The thermocouples types comply with the N.I.S.T. –

ITS 90 standard reference temperature/voltage tables.

The thermometer features a dual thermocouple input, an

adjustable T/C offset and an USB interface for uploading

data to a PC using optional software and cable.

SAFETY INFORMATION

WARNING

To avoid electrical shock, do not use this instrument

when working voltages at the measurement surface

over 24V AC or DC.

WARNING

To avoid damage or burns, do not make temperature

measurement in microwave ovens.

CAUTION

Repeated sharp flexing can break the thermocouple

leads. To prolong lead life, avoid sharp bends in the

leads, especially near the connector.

FEDERAL COMMUNICATIONS

COMMISSION

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two condi tions:(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

NOTE

This equipment has been tested and found to comply

with the limits for a C lass B digital device, pursuant to

Par

t 15 of the FCC Rules. These limits are designed to

provide reasonable p rotection. This equipment generates, uses and can radiated radio frequency energy and,

if not installed an d used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation If

this equipment does cause harmful interference

to radio or television reception, which can be determined

by turning the equipment off a nd on, the user is encouraged to try to correct the interference by one or

more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and

receiver.

- Connect the equipment into an outlet on a circuit d if-

ferent from that to which the receiver is connecte

d.

- Consult the dealer or an experienced radio/TV tech-

nician for help.

comply with emission limits.

Changes or modifications not expressly approved by

the party responsible for compliance could void the

user‘s authority to operate the equipment.

FCC (Domestic Use: USA)

FCC ID: DONGLE 80TR

FCC Identifer: VEA80TR

WIRELESS NOTE

Wireless receiver must keep a distance at least 40cm

from the meter and meter to meter must keep a dis-

tance at least 30cm.

SPECIFICATIONS

ELECTRICAL

Temperature Scale:

Celsius or Fahrenheit user-selectable

Measurement Range:

K-TYPE (0.1°) -200°C to 1372°C (-328°F to 2501°F)

J-TYPE (0.1°) -210°C to 1200°C (-346°F to 2192°F)

T-TYPE (0.1°) -200°C to 400°C (-328°F to 752°F)

E-TYPE (0.1°) -210°C to 1000°C (-346°F to 1832°F)

R-TYPE (1°) 0°C to 1767°C (32°F to 3212°F)

S-TYPE (1°) 0 °C to 1767°C ( 32°F to 3212°F)

N-TYPE (0.1°) -50°C to 1300°C ( -58°

F to 2372°F)

*Based on the ITS-90 temperature standard.

According to temperature standard ITS-90.

Accuracy:

K/J/T/E-TYPE

±(0.05% rdg + 0.3°C) on -50°C to 1372°C

±(0.05% rdg + 0.7°C) on -50°C to -210°C

±(0.05% rdg + 0.6°F) on -58°F to 2501°F

±(0.05% rdg + 1.4°F) on -58°F to -346°F

N-TYPE

±(0.05% rdg + 0.8°C) on -50°C to 0°C

±(0.05% rdg + 0.4°C) on 0°C to 1300°C

±(0.05% rdg + 1.6°F) on -58°F to 32°F

±(0.05% rdg + 0.8°F)

on 32°F to 2372°F

R/S-TYPE

±(0.05% rdg + 2°C) on 0°C to 1767°C

±(0.05% rdg + 4°F) on 32°F to 3212°F

Temperature Coefficient:

0.1 times the applicable accuracy specification per °C

from 0°C to 18°C and 28°C to 50°C (32°F to 64°F and

82°F to122°F).

Input Protection:

24V dc or 24V ac rms maximum input voltage on any

combination of input pins.

Reading Rate: 2.5 time per second.

Wireless Features:

Frequency range: 910~920MHz (HH806AW)

868.1~868.5MHz (HH806AWE)

Low current consumption less than 1mA.

The transmitting distance can reach 25M without magnetic interference.

External Connections:

1. USB Port

2. DC power JACK(12V)

HH806AW

HH806AWE

WIRELESS MULTILOGGER THERMOMETER

INSTRUCTION

SHEET

M4553/0611

Shop online at: omega.com e-mail: info@omega.com

For latest product manuals: omegamanual.info

OMEGAnetOn-Line Service

omega.com

Internet e-mail

info@omega.com

Servicing North America:

U.S.A: One Omega Drive, Box 4047

Stamford, CT 06907-0047

ISO 9001 Tel: (203) 359-1660 FAX: (203) 359-7700

Certified

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A Sales Service: 1-800-826-6342/1-800-TC-OMEGA

®

and Customer Service: 1-800-622-2378/1-800-622-BEST

®

Canada:

Mexico: En Espan ol: (001) 203-359-7803

e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LAAmstelveen, The Netherlands

Tel: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Frystatska 184, 733 01 Karviná, Czech Republic

Republic: Tel: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

Tel: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/ Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Austria: Tel: + 49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United One Omega Drive, River Bend Technology Centre

Kingdom: Northbank, Irlam, Manchester

ISO 9002 M44 5BD United Kingdom

Certified

Tel: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all

worldwide safety and EMC/EMI regulations that apply. OMEGA

is constantly pursuing certification of its products to the

European New Approach Directives. OMEGA will add the CE

mark to every appropriate device upon certification.

The information contained in this document is believed to be

correct, but OMEGA accepts no liability for any errors it

contains, and reserves the right to alter specifications without

notice.

These products are not designed for use in, and

should not be used for, human applications.

Shielded interface cables must be used in order to

MADE IN TAIWAN

Page 2

ENVIRONMENTAL

Ambient Operating Ranges:

0°C to 50°C (32°F to 122°F) <80% R.H.

Storage Temperature:

-20°C to 60°C (-4°F to 140°F) <70% R.H.

GENERAL

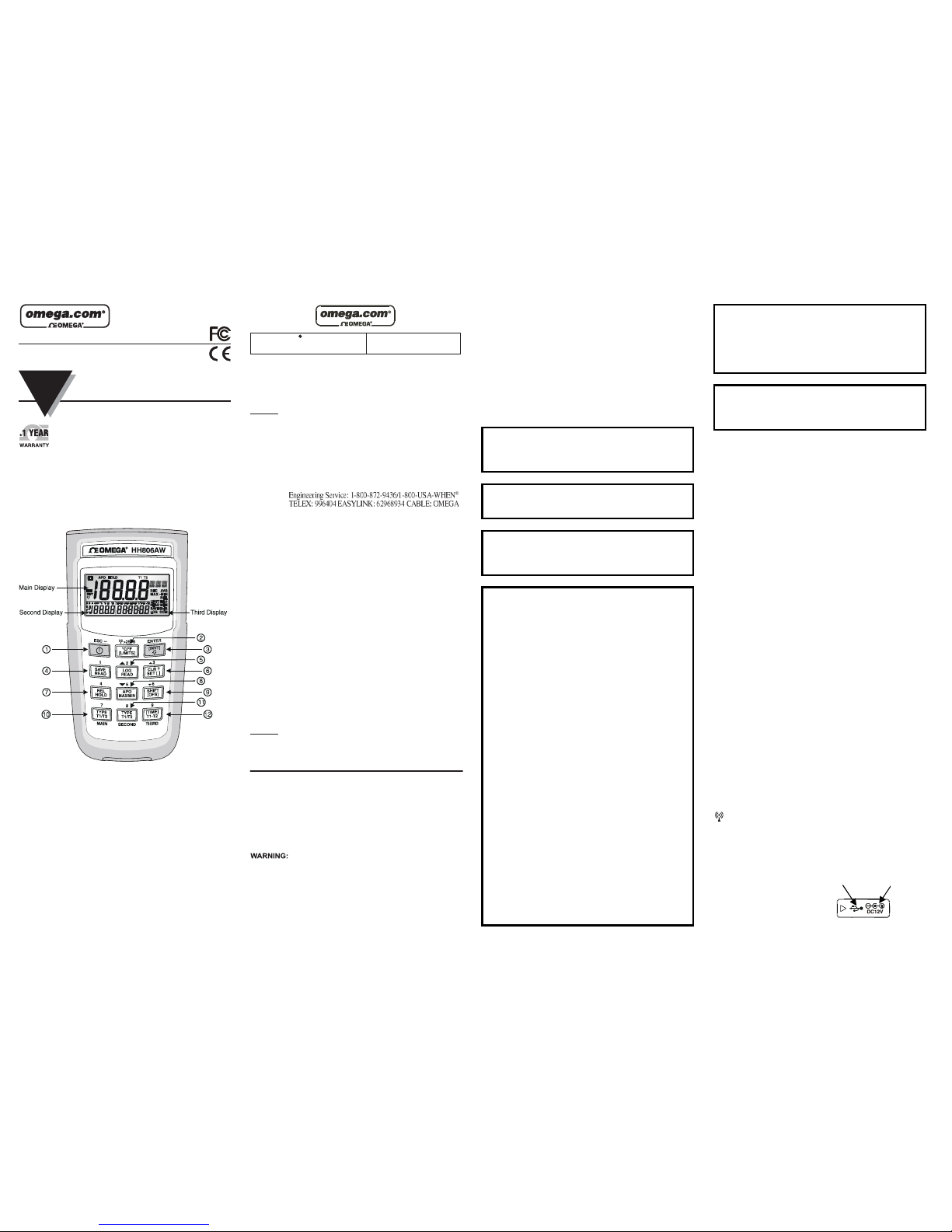

Display:

There are three display areas on the HH806 series LCD

(liquid crystal display). The Main and Second displays

are 4 ½ digits with a maximum reading of 19999. These

are used for displaying the value of T1 or T2. The Third

display is for the date, time, or the differential value of

T1 to T2.

Overload: “----.-” or “OL” is display.

Battery: 1.5V x 4 PCS (SIZE AAA) UM-4 R03.

Battery Life: 120 hours typical with carbon zinc battery.

Dimensions: 160mm(H) x 83mm(W) x 38mm(D).

Weight: Approx. 365g including batteries.

Supplied Thermocouple:

1 meter (40”) type K insulated beaded wire thermocouple.

Maximum insulation temperature is 482°C (900°F).

Thermocouple accuracy is ±1.1°C or 0.4% of reading

(whichever is greater) from 0°C to 1250°C.

OPERATING INSTRUCTIONS

1. OPERATIONAL MODE

There are three operation modes-Normal, Shift, and

Setup Mode.

NORMAL MODE:

This is the default mode, the operating functions for

the normal mode are printed on the top of each button

in white.

SHIFT MODE:

The operating functions for the shift mode are printed

in gray on the buttons. While in the normal mode,

press the SHIFT button to switch to shift mode. At the

lower-right corner of the display, the word “Shift” is

displayed to indicate shift mode. To switch back to

normal mode, press the SHIFT button again.

SETUP MODE:

Press the set[ ] button in normal mode to switch to

setup mode, the indicator “SET” is shown on the left

side of the display. To switch back to normal mode,

press SET[ ] button.

WIRELESS MODE:

Press the “ ” key for more than two seconds to start

wireless function. Press the “ ” key again for another

two seconds to stop wireless function. The wireless

mode will shut down if there is no wireless signal for

two minutes.

To SET CH/ID to 00,00, by pressing “T1-T2” key and

“ ” power key for more than 6 seconds with the meter powered down. The meter will set channel and ID

to 00,00 status. The second display will show 00,

which means that the channel and ID has been set to

00.

To check the channel and ID of the meter:

When the meter is off press “ ” key and “ ” for 5

seconds, LCD’s main display will show channel number, the second display will show ID number.

2. NORMAL MODE

The following functions can only be used in the normal

mode.

(1) “ ” Power Button

The “ ” button turns the thermometer on or off.

When the meter is in MAX/MIN record mode, the

power off function is disabled.

(2) “[LIMITS]” Button (only Main display)

The limits function will alert the user when a measurement exceeds a specified limit. To set the limit values, refer to limits function in the setup mode. Press

the [LIMITS] button to activate the limits function; the

word “LIMIT” should be displayed on the LCD.

When the value of the main display exceeds the Hi

limit, the word “Hi” will be displayed and the thermometer will beep in a pulsed tone. If the value of the

main display is lower then the Lo limit, the word “Lo”

will be displayed and the thermometer will beep in a

continuous tone. To exit the limits function, press the

[LIMITS] button.

(3) “ ” Button

The backlight function is represented by this button

“ ”. Pressing the button will turn on or off the LCD

backlight. The backlight will turn off automatically after.

(4) “SAVE/READ” Button

The read data function works in conjunction with the

save function in the shift mode, it is used for reading

saved data. The save function can be activated in shift

mode. Press the SAVE/READ button to read saved

data; the word “READ” should be displayed on the

LCD. To navigate around the save data table, press the

overlay “SECOND” button until the “#” sign is displayed on the second display. The location of the read

pointer within the saved data table will be displayed.

The arrow buttons on the overlay are used for scrolling

through the saved data. Press the smaller arrows “ ”

or “ ” to step through the data one at a time. Press the

larger arrows “ ” or “ ” to step through the data

ten at a time. Pressing the overlay “ESC” button deactivates the read data function.

(5) “LOG/READ” Button

The read log function works in conjunction with the

log function. It is used for reading logged data. The log

function can be activated in the shift mode. Press the

LOG/READ button to activate the log read function;

the word “READ” is displayed on the LCD. Press the

overlay SECOND button to rotate through following

display menus: T1, T2, GRP, and #. T1 and T2: Displays the T1 or T2 saved data. GRP: Displays the current group number. #: Displays the current location of

the read pointer within a selected group. The arrow

buttons on the overlay are used for scrolling through

the data and groups. Press the smaller arrows “ ” or

“ ” to step through the logged data or groups one at a

time. Press the larger arrows “ ” or “ ” to step

through the data or groups ten at a time. To navigate

the logged data and groups, press the overlay

SECOND button until GRP appears in the second display panel. Then select the group using the arrows.

Press the SECOND button again until the “#” sign is

displayed. The location of the read pointer in the selected group will be displayed. Use the arrows to

scroll through the data. Pressing the overlay “ESC”

button deactivates the read data function.

(7) HOLD Mode (only Main display)

When HOLD mode is selected, the thermometer holds

the present readings and stops all further measurements. To activate the data hold mode, press the

HOLD button, and “HOLD” is displayed on the LCD.

Pressing the HOLD button again cancels the function,

and the instrument will automatically resume measurements.

(8) MIN/MAX with Time record Mode

(only Main display)

The MIN/MAX function records the highest and lowest value recorded, and it calculates the average reading, and the differences of MAX to MIN. Press

MIN/MAX button to enter the MIN/MAX recording

mode. The beeper emits a tone when a new minimum

or maximum measurement is recorded. Press the

MIN/MAX button again to rotate through the current

readings: MAX: The highest measurement recorded.

MIN: The lowest measurement recorded. MAX-MIN:

The difference of the highest and the lowest measurement. AVG: The average values of the measurements.

This mode works in conjunction with the hold function,

pressing the HOLD button will stop the recording and

measurements (Previously recorded readings are not

erased). Press HOLD button again to resume recording

and measurements. To prevent accidental loss of MIN,

MAX and AVG data, the MIN/MAX function can only

be cancelled by pressing and holding down the MIN

MAX key for more then 2 seconds. The automatic

power-off feature, and the power, °C/°F, REL, SET,

Hi/Lo Limits, TYPE, T1/T2 buttons are also disabled.

(10) “T1/T2” Button (Main display)

The input selection button [T1/T2] selects the input for

the main display, T1 thermocouple or T2 thermocouple. Press the T1/T2 button to switch between the two

inputs. When meter is turned on, it is set to the display

that was last in use.

(11) “T1/T2” Button (Second display)

The input selection button [T1/T2] selects the input for

the second display, T1 thermocouple or T2 thermocouple. Press the T1/T2 button to switch between the

two inputs. When meter is turned on, it is set to the

display that was last in use.

(12) “T1-T2/TIME” Button (Third display)

The input selection button [T1-T2] selects the system

time and date, or the differential between the two thermocouples (T1-T2) for the third display. Press the

T1-T2 button to switch the display options. When me-

ter is turned on, it is set to the display that was last in

use.

3. SHIFT MODE

The following functions can only be used in the shift

mode.

(2) “°C/°F” Button

Press the °C/°F button to select the temperature scale,

readings can be displayed in Celsius (°C) or Fahrenheit

(°F). When the thermometer is turned on, it is set to

the temperature scale that was last in use.

(4) “SAVE” Button

The save function stores the T1, T2 data in a nonvolatile memory. Press the SAVE button to save the current data, the word SAVE is displayed to indicate the

data has been saved. The built in memory can store up

to 256 data. The data can be read using the read function in the normal mode.

(5) “LOG” Button

The data log function continuously records the data

according to a specified time interval. The time interval can be set using the interval setup function [INVT]

in the set up mode. Press the LOG button to activate

the log function; the indicatosr “LOG” and “MEM”

will be displayed on the LCD. There are 16 groups that

are used for storing the log data. A maximum of

16,000 data point can be saved in one log session.

Press the LOG button again to exit the data log function.

(6) “CLR ?” Button

The CLR function clears all the saved and logged data

in memory. When the CLR button is pressed, indicator

“MEM” is displayed and the “CLR” on upper-right of

LCD will blink. Pressing the “ENTER” button printed

on the overlay in white will clear all saved and logged

data. Press “ESC” button to exit this function without

clearing data.

(7) “REL” Button (Main display)

The relative value function can be used for comparing

the saved reference value with other measurements.

Press the “REL” button to store the current measurement as the reference value, and “REL” should be displayed on the right part of the LCD. The next measurement will display the current value compared to the

reference value. Press “REL” button again to clear the

reference value and deactivate the relative value measurement function.

(8) “APO” Button

Press the APO button to turn the “Auto power off”

function on or off. When this function is enabled, the

indicator “APO” is shown at the upper left part of the

LCD. When APO (Auto power off) is enabled, it will

automatically turn the thermometer off no button is

pressed for a period longer than the set time interval

(the default time for APO is 5 minutes). Press power

button to resume operation.

(10) “TYPE” Button (Main display)

Press this button to change the type of thermocouple in

the main display (K/J/T/E/R/S/N). If the inputs of the

Page 3

main and second display are the same, then pressing

this button will change the thermocouple type for both

displays.

(11) “TYPE” Button (Second display)

Press this button to change the type of thermocouple in

the second display (K/J/T/E/R/S/N). If the inputs of the

main and second display are the same, then pressing

this button will change the thermocouple type for both

displays.

4. SETUP MODE

The following functions can only be use in the setup

mode.

(2)

“[LIMITS]” Button (Hi/Lo limit setting)

Press the LIMITS button to enter the Hi/Lo limit setup

function. The words “LIM IT” and “Hi” will be flash

on the LCD along with the previous value for the Hi

limit. Enter the new Hi limit value using the number

keys printed in white on the overlay. The resolution of

Hi/Lo limit setup is 1 count. The “-” button (same

button as the ESC) can be used

to enter negative values. Press t he “ENTER” button to c onfirm the new

limit. You will then be prompted to enter a new Lo

limit value. Enter the new value and then press enter

to finish setup of limits.

(3) “[INVT]”

Button

(Interval time setting)

To setup the time interval for the log function, press

the [INVT] button. The indicator “INV” will blink on

the top-right of the LCD and the previous interval is

displayed

. Press the number buttons printed in white

on the overlay to change the time interval. Setting is

from left to right of the following format (HH:MM:SS).

Press the overlay “ENTER” button to confirm. To exit

this function, press the ESC button.

HH: interval Hour (0~23)

MM: interval Minute (0~59)

SS: interval Second (0~59)

MAX: 23:59:59

MIN: 00:00:01

(8) “APO” Button (Auto power off time setting,

min. 1 minute)

Use this function to change the time for the auto power

off (APO) function. Press the APO button in setup

mode, and the indicator “APO” and the current time

will flash on the LCD. The default time for APO is 5

minutes. Press the number button printed in white on

the overlay to set the APO time. Press the overlay

“ENTER” button to c onfirm. To exit this function

without changing the setting, press the ESC button.

MAX: 19999 minutes

MIN: 0001 minutes

(9) “[OFS]” Button (Thermocouple offset ad-

just)

When the main display input is T1 and a thermocouple

is connected, the instrument can adjust the offset of the

thermocouple. The same can be done for T2 when on

the main display. In the setup mode, press this button

to enter the thermocouple Offset Setup Function (OFS)

and the indicator CAL should be d isplayed on the

top-right of the LCD and the current setting is also

shown

. Press the number buttons printed in white on

the overlay to change the offset of the thermocouple.

The resolution of the setup is 0.1°. Press the “-” button

to set a negative value. Press the overlay “ENTER”

button to confirm. MAX: ±1999.9 °C/°F.

(12) “[TIME]” Button (System time setting)

To set the system time, press the [ TIME] button in the

setup mode. The th ird display should show th e current

date and time with the year

flashing. Enter the new

value from left to right in the following format

YY:MM:DD and HH:MM:SS. Press th e number buttons printed in white on the overlay to set the system

date and time. Press the “ENTER” button to confirm.

Exit this function by pressing ESC button.

Error messages:

When the meter ap pears wrong messages such as Err-01,

Err-02 and Err-03.

Err-01: In the “SAVE” mode, if memory is full, the lower

right display will show E

rr-01. If you would like

to record the new value. Please clear all old records.

Err-02: In the “LOG” mode, if memory is full, the lower

right display will show Err-02. If you would like

to record the new value. Please clear all old records.

Err-03: In the “READ LOG” and “READ SAVE” mode,

when the main display shows 6028 and the lower

right display shows “OL, Err-03”. Which means

that there might appear two situations:

1. Th

ere is no data in the memory.

2. The memory is full, and the meter will warn

the user this is the last sample.

OPERATOR MAINTENANCE

WARNING

To avoid possible electrical shock, disconnect the

thermocouple connectors from the thermometer before

removing the cover.

Battery Replacement

1. Power is supplied by 4pcs 1.5V (AAA SIZE) UM-4

R03.

2. The “

” appears on the LCD display when replacement is needed. To replace battery remove screw from

back of meter and lift off the battery cover.

3. Remove the battery from battery contacts and replace.

4. When not in use for long periods remove battery.

5. Do not store in locations with high temperatures, or

high humidity.

Cleaning

Periodically wipe the case with a damp cloth and detergent, do not use abrasives or solvents.

*Soft

ware Operation manual is on the Software disk.

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

Thermocouple, RTD & Thermistor Probes,

Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gages

Load Cells & Pressure Gages

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Data Logging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

WARRANTY/DISCLAIMER

OMEGA ENGINEERIN G, INC. warrants this unit to be free of defe cts in

mater ials and wo rkmansh ip fo r a period of 13 months f rom d ate o f

purchase. OMEG A’s WARRANTY adds an additional one (1) month grace

period to the normal one (1) year product warranty to cover handling

and shipping time. This ensures that OMEGA’s customers receive maximum

coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation.

OMEGA’s Customer Service Department will issue an Authorized Return (AR)

number immediately upon phone or written request. Upon examination by

OMEGA, if the

unit is found to be defective, it will be repaired or replaced at

no charge. OMEGA’s WARRANTY does not apply to defects resulting from

any action of th e purc haser, i ncluding but not li mited to mish andling,

improper interfacing, operation outside of design limits, improper repair, or

unautho rized modificati on. Thi s WARRAN TY is VOID if th e unit shows

evidence of having been tampered with or shows evidence of having been

damaged as a result of excessive corrosion; or current, heat, moisture or

vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not

warranted, i

nclude but are not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various

products. However, OMEGA neither assumes responsibility for any

omissions or errors nor assumes liability for an y damages that

result from the use of its products in accordance with information

provided by OMEGA , either verbal or written. OMEGA w arrants

only that the parts man ufacture d by the compa ny wi ll b e as

sp ecif ied an d f ree of de fect s. OME GA MAKE S N O O THE R

WA RRAN TIE S OR REP RES ENTAT ION S OF AN Y KI ND

WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE HE REBY DI SCLA IMED . L IMIT ATION OF LI ABIL ITY: The

remedies of purchaser set forth herein are exclusive, and the total

liability of OMEGA with respect to this order, whether based on

contract, warranty, negligence, indemnification, strict liability

or

otherwise, shall not exceed the purchase price of the component

upon which liability is based. In no event shall OMEGA be liable

for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor

shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in

or with any nuclear installation or activity; or (2) in medical applications or

used o n humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in

any way, OMEGA assumes no respon sibility as set forth in o ur ba sic

WARRAN TY/ DISC LAIMER langu age, and, additio nally, purcha ser w ill

indemnify OMEGA and hold OMEGA harmless from any liability or

damage

whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS / INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer

Service Department. BEFORE RETURNING ANY PRODUCT(S) TO OMEGA,

PURCHAS ER MUS T OBTAIN AN AUTHORIZE D RETU RN (AR) NUMBE R

FROM OME GA’S C USTOM ER S ERVICE DEPA RTMENT (IN ORD ER T O

AVOID PROCESSING DELAYS). The assigned AR number should then be

marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and

proper packaging to prevent breakage in transit.

FOR W

ARRANTY RETURNS, please

have the following information

available BEFORE contacting

OMEGA:

1. Purchase Order number under

which the product was

PURCHASED,

2. Model and serial number of the

product under warranty, and

3. Repair instructions and/or specific

problems relative to the product.

FOR NON-WARRANTYREPAIRS,

consult OMEGA for current repair

charges. Have the following

information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover

the COST of the repair,

2. Model and serial number of the

product, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever

an improvement is possible. This affords our customers the latest in

technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This

document may not be copied, photocopied, reproduced, translated, or

reduced to any electronic medium or machine-readable form, in whole or

in part, without the prior written consent of OMEGA ENGINEERING, INC.

Loading...

Loading...