Page 1

www.omega.com

e-mail: info@omega.com

User’s Guide

FPU5-MT-110, F P U5-M T-2 20

OMEGAFLEX

®

Peristaltic Pump Motor

Shop online at

MADE IN

Page 2

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

®

Customer Service: 1-800-622-2378 / 1-800-622-BEST

®

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

®

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé armády 1868, 733 01 Karviná 8

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Remove the Packing List and verify that you have received all equipment, including the

following (quantities in parentheses):

FPU5-MT-110 or FPU5-MT-220 Peristaltic Pump Motor (1)

Power Cord (1)

Spare Fuse (1)

Peristaltic Pump Quick Start Manual (Manual Number MQS2219) (1)

Peristaltic Pump Motor Quick Start Manual (Manual Number MQS2299) (1)

Operator’s Manual (1)

If you have any questions about the shipment, please call the Customer Service Department.

When you receive the shipment, inspect the container and equipment for signs of damage.

Note any evidence of rough handling in transit. Immediately report any damage to the

shipping agent.

The carrier will not honor damage claims unless all shipping material is saved

for inspection. After examining and removing contents, save packing material

and carton in the event reshipment is necessary.

Unpacking Instructions

i

From the Technical Library of ___________________________________________________________

NOTE

Page 4

Page

Unpacking Instructions ............................................................................ i

Chapter 1 Introduction ....................................................................... 1-1

1.1 Description .................................................................................... 1-1

1.2 Features .......................................................................................... 1-1

Chapter 2 Parts of the Pump Motor ................................................... 2-1

2.1 Front View ..................................................................................... 2-1

2.2 Left Side View ............................................................................... 2-2

2.3 Right Side View ............................................................................. 2-3

2.4 Membrane Keypad and Display ................................................ 2-4

2.5 Rear View........................................................................................ 2-6

Chapter 3 Getting Started .................................................................. 3-1

3.1 Attaching the Pump ..................................................................... 3-1

3.1.1 Introduction ................................................................................... 3-1

3.1.2 Attaching a Single Pump Directly to the Motor ....................... 3-2

3.1.3 Stacking Two Pumps on One Side of the Motor ...................... 3-3

3.2 Selecting Tubing ............................................................................ 3-4

3.3 Tubing Life ..................................................................................... 3-4

3.4 Loading the Tubing ...................................................................... 3-4

Chapter 4 Turning on the Power ........................................................ 4-1

4.1 Introduction to the Two Display Modes ................................... 4-1

4.2 Using the ON/OFF Switch .......................................................... 4-1

4.3 The STOPPED Display Mode ..................................................... 4-1

4.4 The RUNNING Display Mode ................................................... 4-2

Chapter 5 Operating the Pump Motor in the STOPPED Display Mode .. 5-1

5.1 Displaying Pump Messages in Five Different Languages ...... 5-1

5.2 Defining the Direction of Pumping ............................................ 5-3

5.3 Selecting the Tubing Inner Diameter ......................................... 5-4

5.4 Priming the Tubing ....................................................................... 5-6

5.5 Calibrating the Tubing ................................................................. 5-6

5.6 Measuring the Temperature of a Fluid ...................................... 5-9

5.7 Preparing for Pumping in a Specific Mode ............................... 5-9

Chapter 6 Operating the Pump Motor in the RUNNING Display Mode . 6-1

6.1 The RPM Mode ............................................................................. 6-1

6.1.1 Pumping in the RPM Mode ........................................................ 6-1

6.2 The FLOW RATE Mode ............................................................... 6-5

6.2.1 Pumping in the FLOW RATE Mode .......................................... 6-5

6.3 The TIME Mode .......................................................................... 6-11

6.3.1 Pumping in the TIME Mode ..................................................... 6-11

6.4 The TOTAL VOLUME Mode .................................................... 6-16

6.4.1 Pumping in the Total Volume Mode ........................................ 6-17

6.5 Preventing Tubing from Moving During Pump Operation . 6-21

Peristaltic Pump Motor

ii

TABLE OF

CONTENTS

Page 5

Peristaltic Pump Motor

iii

TABLE OF

CONTENTS

Page

6.6 Other Pumping Options ........................................................... 6-21

6.6.1 Auxiliary Out (Remote Monitor) .............................................. 6-21

6.6.2 Auxiliary In (Remote Start/Stop) ............................................. 6-22

Chapter 7 Troubleshooting Guide ....................................................... 7-1

7.1 Display Error Messages ............................................................... 7-1

7.2 Other Pumping Problems ............................................................ 7-8

Chapter 8 Technical Details ................................................................ 8-1

8.1 Theory of Operation ..................................................................... 8-1

8.2 Design Considerations ................................................................. 8-1

8.3 Design Solution ............................................................................. 8-1

8.4 Maintenance .................................................................................. 8-1

Chapter 9 Specifications .................................................................... 9-1

Chapter 10 Spare Parts and Accessories .......................................... 10-1

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the Operator’s Manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

NOTE

Page 6

Peristaltic Pump Motor

iv

TABLE OF

CONTENTS

Notes

Page 7

Index

I

I

A

Accessories ............................................ 10-1

Auxiliary In ........................................... 6-22

Auxiliary Out ....................................... 6-21

C

Calibrating the Tubing .......................... 5-6

Calibration Accuracy ............................. 9-1

Creeping, Preventing .......................... 6-21

D

Dual Pump Mounting ........................... 3-3

E

Error Messages ....................................... 7-1

F

Flow Rate Mode .............................. 1-1, 6-5

Fluid Temperature, Measuring ............ 5-9

I

Inner Tubing Diameters ....................... 5-5

K

Keypad, Parts of ..................................... 2-4

L

Language Button .................................... 2-7

Languages ............................................... 5-1

Line Filter ................................................ 4-1

Loading Tubing........................................3-4

M

Modes

Flow Rate .................................. 1-1, 6-5

RPM ........................................... 1-1, 6-1

Time ......................................... 1-1, 6-11

Total Volume .......................... 1-1, 6-17

Motor Turning

Clockwise ......................................... 5-4

Counter-clockwise .......................... 5-4

Mounting Configurations ..................... 3-1

P

Parts of the Pump Motor

Bottom Alignment Pin ................... 2-2

Display .............................................. 2-1

Face of Motor ................................... 2-2

Fuse ............................................ 2-2, 2-6

Groove of Motor Shaft .................... 2-2

Membrane Keypad .................. 2-1, 2-4

Motor Shaft ...................................... 2-2

Mounting Holes .............................. 2-2

ON/OFF Switch .............................. 2-1

Rubber Feet ...................................... 2-1

Safety Cover ..................................... 2-3

Top Alignment Pin ......................... 2-2

Power Requirement ............................... 4-1

Priming the Tubing ............................... 5-6

Pump Direction, Changing .................. 5-3

Pump Messages in

English .............................................. 5-2

French ............................................... 5-2

German ............................................. 5-2

Italian................................................. 5-2

Spanish ............................................. 5-2

R

Ranges

Flow Rate .......................................... 6-6

RPM .................................................. 6-2

Time ................................................ 6-12

Total Volume ................................. 6-17

RPM Mode ........................................1-1, 6-1

Running Display Mode ......................... 4-2

S

Safety Cover ............................................ 2-3

Single Pump Mounting ......................... 3-2

Spare Parts .............................................10-1

Specifications .......................................... 9-1

Stopped Display Mode ......................... 4-1

T

Thermocouple Probe (Type K) ... 1-1, 10-1

Time Mode .....................................1-1, 6-11

Total Volume Mode ......................1-1, 6-16

Tubing

Durometer ........................................ 9-2

Inlet ................................................... 5-4

Life .................................................... 3-4

Loading ............................................. 3-4

Materials ........................................... 3-4

Outlet ................................................ 5-4

Sizes .................................................. 3-4

Troubleshooting Guide ......................... 7-1

Page 8

Index

I

II

Notes

Page 9

Index

I

III

Page 10

Introduction

1-1

1

1.1 Description

The peristaltic pump motor offers microprocessor control and a digital display,

and is designed to be fully compatible with our peristaltic pump. No mounting

plate is needed, just two mounting screws. A

1

⁄10 HP (75W) motor provides flow

rates of up to 2280 mL/minute. A convenient membrane keypad lets you enter

values and control all pump operations. A dot matrix LCD provides for easy

view. Calibrating the unit is easy with the user-friendly control software.

Simply select a tubing size and the desired flow rate, and the pump motor locks

in the required RPM. Select nominal calibration values stored in ROM (read

only memory) or calibrate via gravimetric measurements. Fluid temperature

may be displayed (using an optional Type K thermocouple probe). The last

motor settings are stored in memory when the drives are shut off.

The peristaltic pump motor provides you with four different modes of pumping:

• The RPM Mode for pumping at a certain RPM setting for

an unlimited period of time

• The FLOW RATE Mode for pumping at a certain FLOW RATE

setting for an unlimited period of time

• The TIME Mode for pumping at a certain RPM or FLOW

RATE setting for a specific period of time

• The TOTAL VOLUME Mode for pumping at a certain RPM or FLOW

RATE setting to dispense a specific amount

of fluid

The pump is available in two versions: 110Vac and 220Vac.

1.2 Features

• Digital Display of Flow Rate, RPM, Total Volume, Fluid Temperature (°C or

°F), Flow Duration, or Tube ID

• Ability to Calibrate Precise Flow Rates

• Flow Rates of 1 to 2280 mL/minute

•Reversible Motor for Pumping in Both Directions at Speeds of 10 to 600 RPM

• Easy-to-Read LCD Display

•Type K SMP Female Thermocouple Input

•Tachometer Feedback, ±0.5% Speed Control

• Accepts Two Pumps, One on Each Side or Two Stacked Together

•Membrane Keypad for Easy Operation and Calibration

• Remote Control Options - Aux In: Remote Start/Stop, TTL/CMOS

Aux Out: Open Collector

• Built-in Electronic Braking and Reversing for Fast Stops and Directional

Changes

•Accepts Metric or English Tube Sizes

•Displays Information in English, French, Spanish, German, or Italian

Page 11

Introduction

1

1-2

Notes

Page 12

Parts of the Pump Motor

2-1

2

2.1 Front View

Figure 2-1. Front View of the Pump Motor

Table 2-1. Front View

Item Description Function

1 ON/OFF Switch Toggles the unit’s power on and off

2Display Displays the pump messages; provides

information while the pump is running

3Membrane Keypad Allows you to select pump functions

4 Rubber Feet Support the pump motor on a table surface

2

INLET

SELECT

TEMP

RPM

FLOW

RATE

TUBE ID

TIME

TOTAL

VOLUME

CALIBRATE

PRIME

START

STOP

1

4

3

Page 13

Parts of the Pump Motor

2

2-2

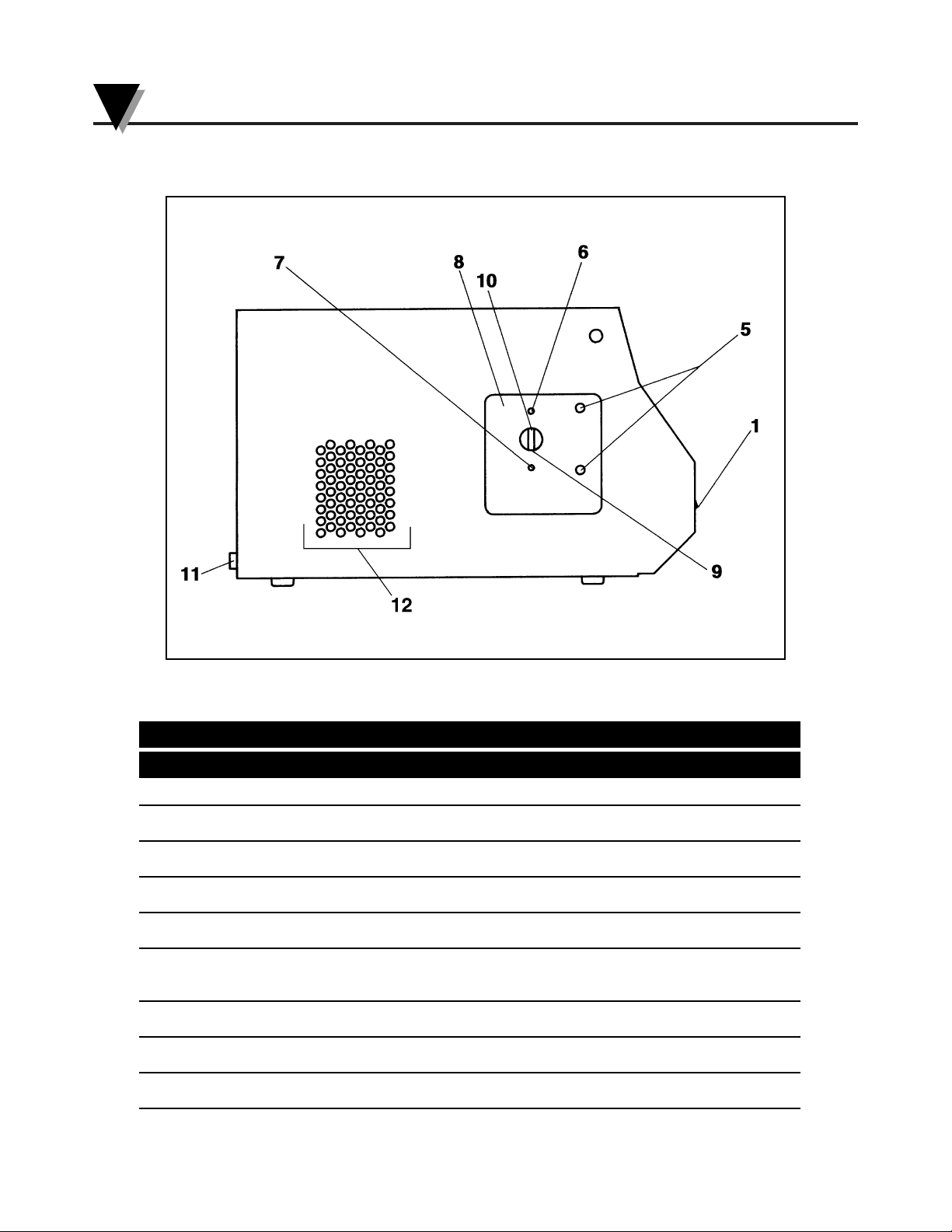

2.2 Left Side View

Figure 2-2. Left Side View of the Pump Motor

Table 2-2. Left Side View

Item Description Function

1 ON/OFF Switch Toggles the pump motor’s power on and off

5Mounting Holes Provides attachment sites for pump(s)

6 Top Alignment Pin Aligns the pump head during installation

7 Bottom Alignment Pin Aligns the pump head during installation

8 Face of Motor Provides a surface for attaching pump(s)

9Motor Shaft Turns the rotor assembly of pump(s)

during pumping

10 Groove of Motor Shaft Holds the back tab of pump(s) rotor shaft

11 Fuse Protects the unit from an overcurrent

12 Vent Holes Allow for cooling of pump motor

Page 14

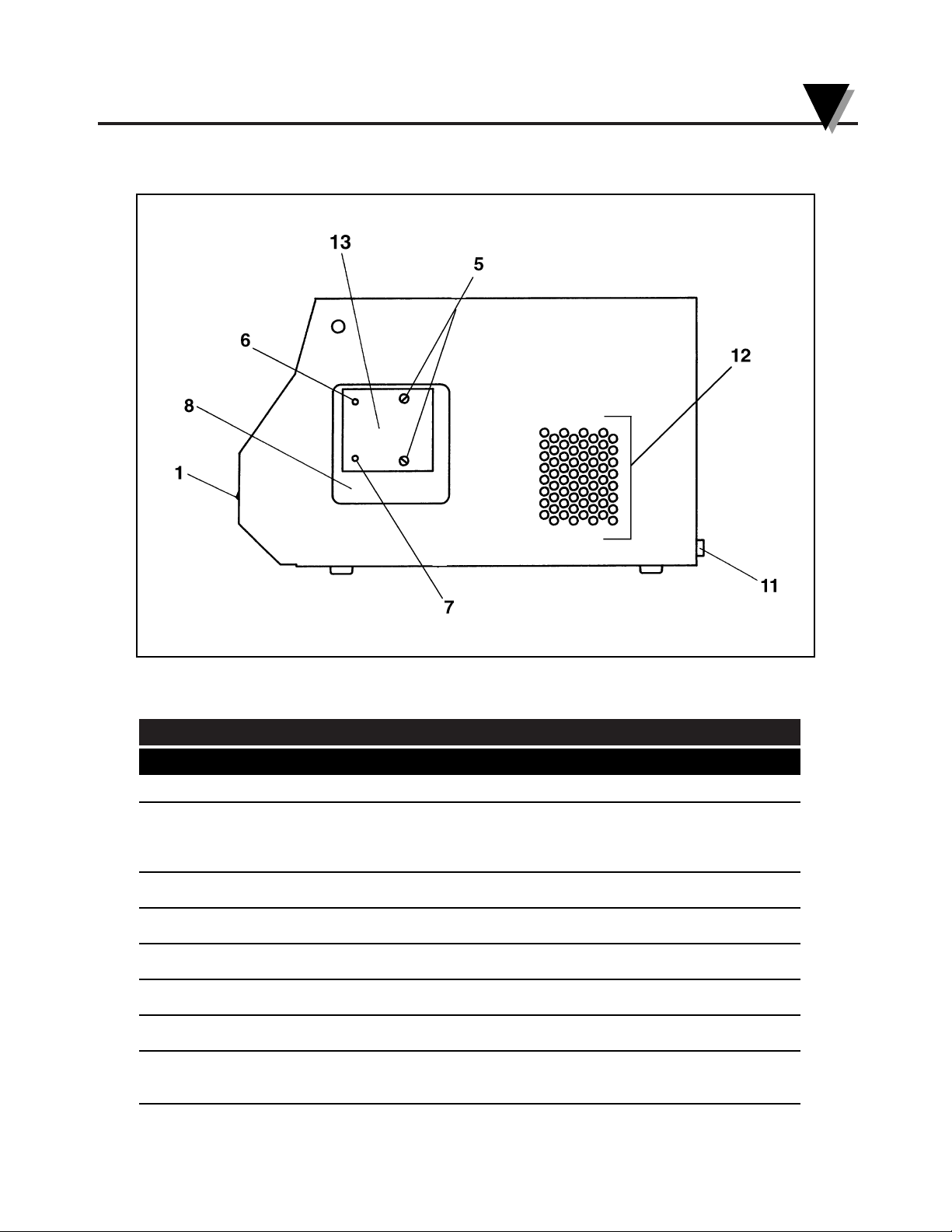

2.3 Right Side View

Figure 2-3. Right Side View of the Pump Motor

Table 2-3. Right Side View

Item Description Function

1 ON/OFF Switch Toggles the pump motor’s power on and off

5 Safety Cover Screws Secure safety cover to the motor - if safety cover

is not in place, the exposed holes are the

Mounting Holes

6 Top Alignment Pin Aligns the pump head during installation

7 Bottom Alignment Pin Aligns the pump head during installation

8 Face of Motor Provides a surface for attaching pump(s)

11 Fuse Protects the unit from an overcurrent

12 Vent Holes Allow for cooling of pump motor

13 Safety Cover (default side for Prevents fingers and clothing from getting caught

shipping) in the motor shaft during pump operation

Parts of the Pump Motor

2

2-3

Page 15

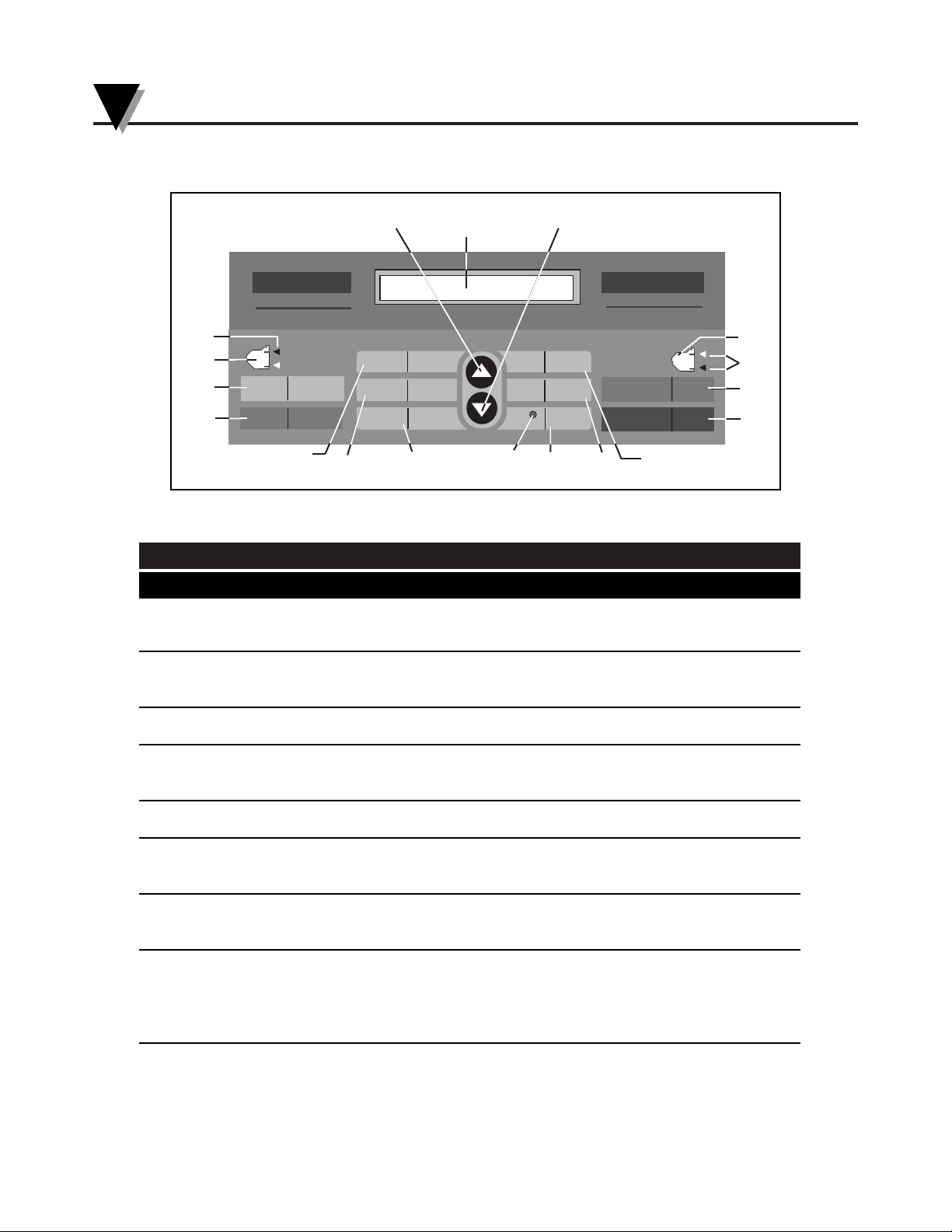

2.4 Membrane Keypad and Display

Figure 2-4. Membrane Keypad and Display

Table 2-4. Membrane Keypad Detail

Item Description Function

2Display Shows pump messages; provides quantitative

information while the pump is running

14 Left Pump Icon Side view of a pump(s); associated with two

green LEDs

15 Green LEDs for left pump Indicate left-mounted pump’s inlet and outlet

16 Right Pump Icon Side view of a pump(s); associated with two

green LEDs

17 Green LEDs for right pump Indicate right-mounted pump’s inlet and outlet

18 INLET SELECT key Selects tubing inlet for pump(s) mounted on

either side of the motor

19 TEMP key Displays the fluid’s temperature as measured

via an optional Type K thermocouple probe

20 RPM key Initiates the RPM Mode of pumping and

displays the RPM setting of the pump motor;

displays the actual pump motor speed, as it

occurs in time

Parts of the Pump Motor

2

2-4

30

TOTAL

VOLUME

CALIBRATE

25

TIME

INLET SELECT

RIGHT PUMP

24

23

PRIME

START

STOP

16

17

27

28

15

14

18

19

INLET

SELECT

TEMP

INLET SELECT

LEFT PUMP

20

21

29

RPM

FLOW

RATE

TUBE ID

22

2

26

Page 16

Table 2-4. Membrane Keypad Details (cont’d)

Item Description Function

21 FLOW RATE key Initiates the FLOW RATE Mode of pumping

and displays the FLOW RATE setting of the

pump motor; displays the actual fluid flow

rate, as it occurs in time

22 TUBE ID key Selects the inner diameter of a tube

23 TIME key Initiates the TIME Mode of pumping and

displays the TIME setting of the pump motor;

displays of the actual time for which the pump

has been running

24 TOTAL VOLUME key Initiates the TOTAL VOLUME Mode of

pumping and displays of the TOTAL VOLUME

setting of the pump motor; displays the actual

volume of fluid dispensed, as it occurs in time

25 CALIBRATE key Starts and completes calibration of a tube

26 Red LED for the CALIBRATE key Lights after calibration is complete, indicating

that the motor is pumping according to that

calibration

27 PRIME key Allows for momentary running of the motor;

useful for filling a tube with fluid before

calibrating

28 START/STOP key Alternately starts and stops the pump

29 (UP ARROW key) Increases values of a setting after you have

pressed a key choosing that setting (refer to

Table 2-5)

30 (DOWN ARROW key)Decreases values of a setting after you have

pressed a key choosing that setting (refer to

Table 2-5)

Parts of the Pump Motor

2

2-5

Page 17

Table 2-5. UP and DOWN ARROW Keys Scrolling Limits

If you last pressed the: The ARROW Keys Will Scroll Through:

RPM key RPM settings from 10 RPM to 600 RPM

TIME key SECONDS (from 0 to 59), MINUTES (from 0 to 59),

and HOURS (from 0 to 12); for overall TIME settings

from 00:00:00 to 12:59:59

FLOW RATE key FLOW RATE settings that depend on the tube size

chosen

TOTAL VOLUME key TOTAL VOLUME values from 1 mL to 10,000 liters

TUBE ID key Pre-programmed tube inner diameters in inches or

millimeters or the message “CALIBRATED TUBE!” (refer

to Table 5-2)

2.5 Rear View

Figure 2-5. Rear View of the Pump Motor

Table 2-6. Rear View

Item Description Function

11 Fuse Protects the unit from overcurrent

31 Removable Panel and Allows access to the circuit board for future

Mounting Screws upgrades

32 Auxiliary IN Terminals Allow remote starting and stopping of the motor

Parts of the Pump Motor

2

2-6

37

36

31

Aux

Aux

Out

In

GND GND

V+

32

V+

33

Language

34

Zero

TC-K

35

Span

Fuse

K

11

Power Supply

38

Page 18

Table 2-6. Rear View (cont’d)

Item Description Function

33 Auxiliary OUT Terminals Allow remote monitoring of the motor’s start or

stop status

34 LANGUAGE Button Changes the language of the pump messages in

the display window

35 SMP Type K Thermocouple Allows the user to connect a Type K

Connector thermocouple probe and measure a fluid’s

temperature

36 Zero Potentiometer Used for motor unit temperature calibration

37 Span Potentiometer Used for motor unit temperature calibration

38 Power Supply Connects to line cord and line voltage

Parts of the Pump Motor

2

2-7

Page 19

Parts of the Pump Motor

2

2-8

Notes

Page 20

Getting Started

3-1

3

3.1 Attaching the Pump

3.1.1 Introduction

There are five possible mounting configurations for using the peristaltic pump

motor. Table 3-1 describes these mounting configurations.

Table 3-1. Pump Motor Mounting Configurations

Number of Pumps on Number of Pumps on Reference Section

Left Side Right Side

103.1.2

013.1.2

203.1.3

023.1.3

113.1.2

Your pump motor is equipped with a safety cover for whichever side of the

motor is not being used.

You must remove the safety cover before attempting to attach pump(s) to the

side.

NOTE

Page 21

Getting Started

3

3-2

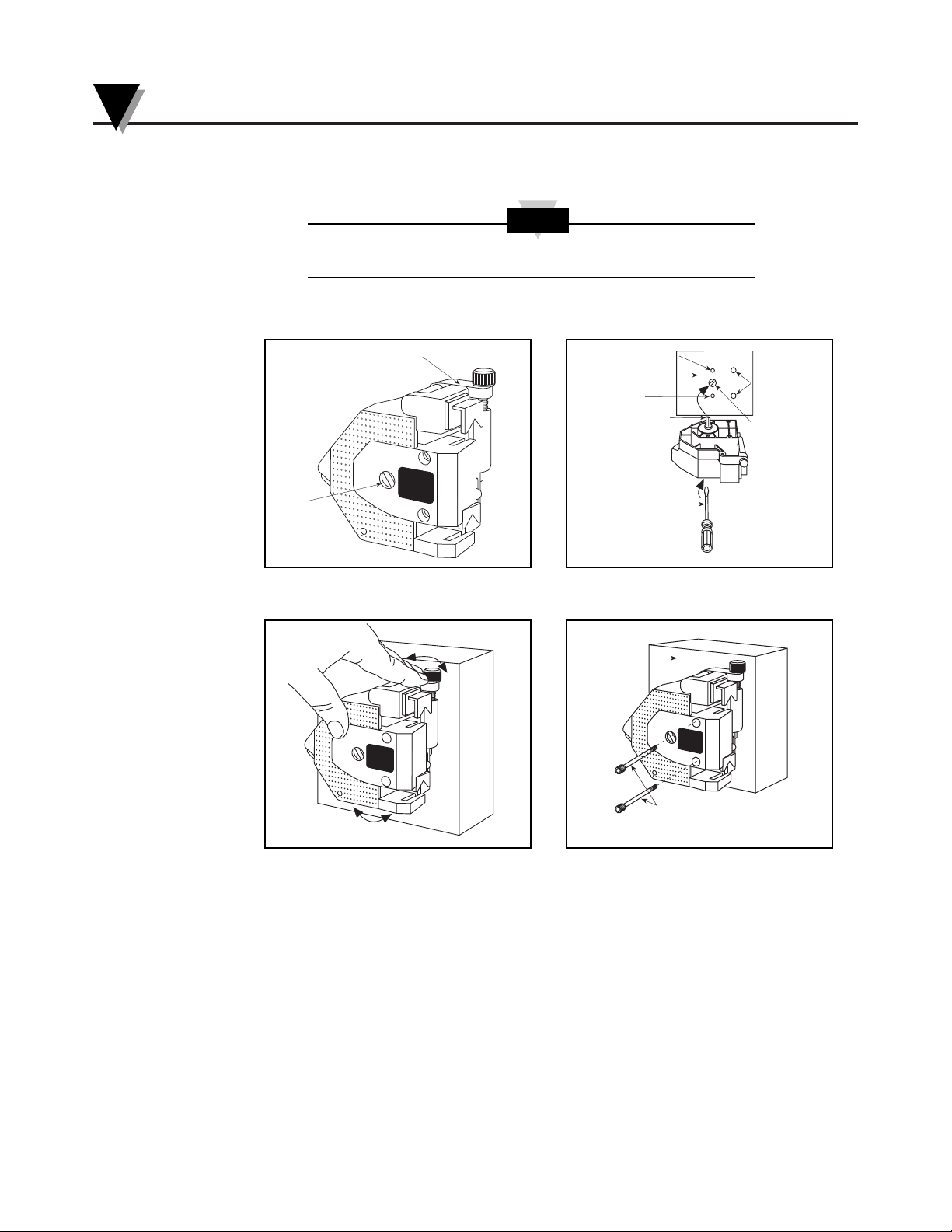

3.1.2 Attaching a Single Pump Directly to the Motor

Perform ALL of the steps in Chapter 3 before turning the motor on.

Refer to Figures 3-1 through 3-4.

Figure 3-1. Pump in Closed Position Figure 3-2. Aligning the Rotor Shaft

Figure 3-3. Pump in Closed Position Figure 3-4. Aligning the Rotor Shaft

1. Remove the safety cover if it is on the side of the motor you wish to use. If you

are using one side of the motor only, attach the safety cover to the other side.

2. Refer to Figure 3-1. Make sure the pump is in the closed position.

3. Refer to Figure 3-2. Place the blade of a flathead screwdriver in the groove of

the Rotor Shaft. Rotate the Rotor Shaft until its back tab slips into the groove of

the motor shaft. Do not try to force the pump onto the motor until you perform

Step #4.

4. Refer to Figure 3-3. Swivel the pump back and forth slightly to align the holes

on the back of the Base with the alignment pins on the face of the motor. Press

the pump base up against the face of the motor.

FACE OF

MOTOR

STANDARD

MOUNTING

SCREWS

FACE OF

MOTOR

TOP ALIGNMENT

PIN

BOTTOM

ALIGNMENT PIN

ROTOR SHAFT

FLAT HEAD

SCREWDRIVER

MOUNTING

HOLES

MOTOR

SHAFT

Base

Rotor

Shaft

CAUTION

Page 22

5. Refer to Figure 3-4. With the pump and motor aligned, insert the mounting

screws through the mounting holes in the pump, until they make contact with the

threaded mounting holes in the face of the motor.

6. Tighten the screws fully with a 9/64 (M3.5) allen wrench.

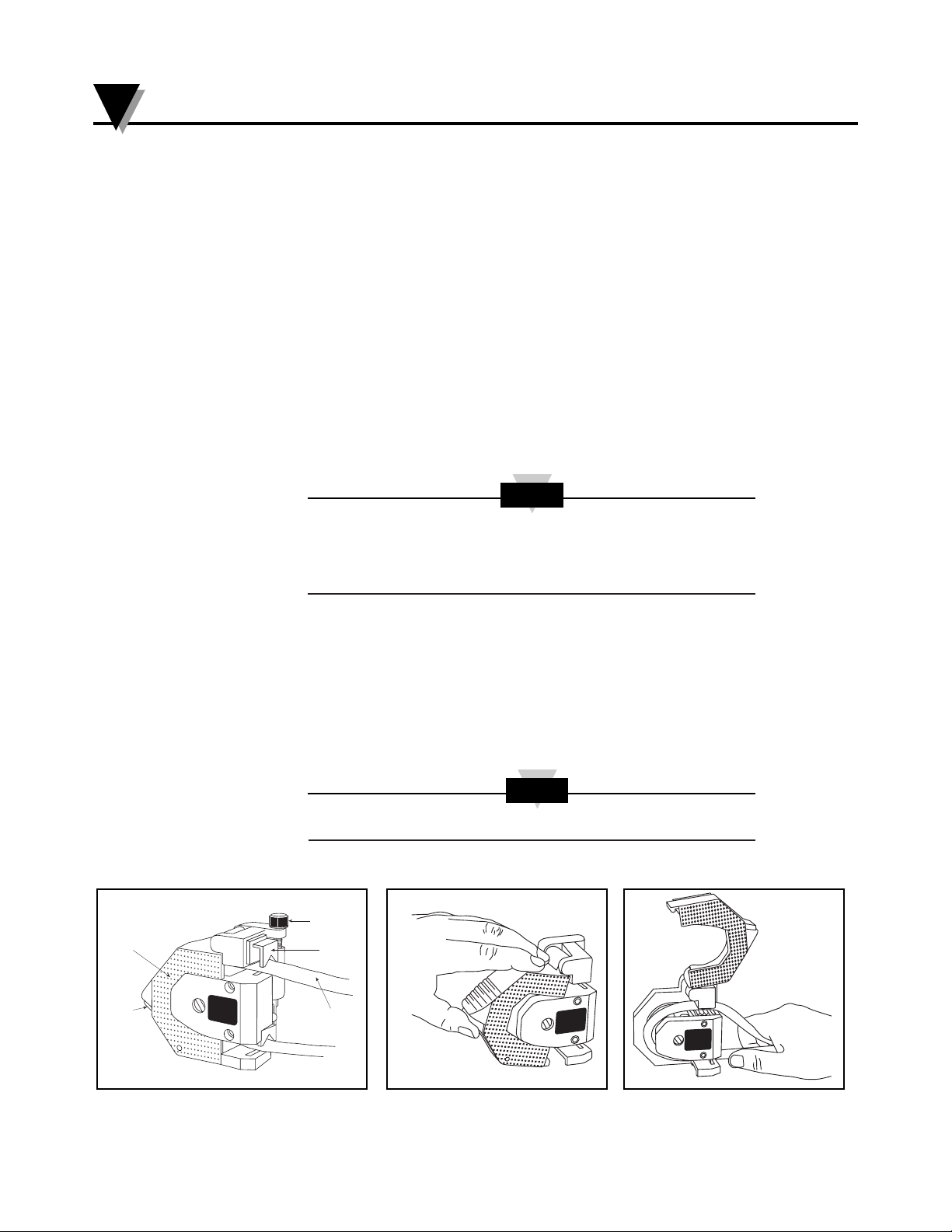

3.1.3 Stacking Two Pumps on One Side of the Motor

Perform ALL of the steps in Chapter 3 before turning the motor on.

Figure 3-5. Placing the Second Pump Figure 3-6. Aligning the Rotor Shaft Figure 3-7. Securing Both Pumps to

on Top of the First Pump of the Second Pump the Motor

1. Remove the safety cover if it is on the side of the motor you wish to use. Attach

it to the other side.

2. Refer to Figure 3-1 through Figure 3-3. Perform Steps 1, 2 and 3 in Section

3.1.2 to put the first pump on the face of the motor.

3. Refer to Figure 3-1. Make sure the second pump is in the closed position.

4. Refer to Figure 3-5 and Figure 3-6. Place the blade of the flathead screwdriver

in the groove of the Rotor Shaft of the second pump. Rotate the Rotor Shaft of

the second pump until its back tab slips into the groove of the Rotor Shaft of the

first pump.

5. Refer to Figure 3-7. With the pumps and motor aligned, insert the optional

LONG mounting screws through the mounting holes in both pumps, until they

make contact with the threaded mounting holes in the motor.

6. Tighten the long screws fully with a small flathead screwdriver.

LONG

MOUNTING

SCREWS

FACE OF

MOTOR

FLAT HEAD

SCREWDRIVER

FIRST PUMP

SECOND

PUMP

FACE OF

MOTOR

FIRST

PUMP

SECOND

PUMP

Getting Started

3

3-3

CAUTION

Page 23

3.2 Selecting Tubing

Select a tubing material and size that is right for your application (the fluid and

flow rate that you are pumping).

Table 9-2 in Chapter 9, shows the average flow rates for different size tubing.

Normalized flow rates (mL per revolution) vary significantly, based on motor

speed, tubing materials, viscosity, and mechanical tolerances in pump dimensions.

Table 9-3 outlines the variances resulting from differences in motor speed, tubing

materials, and mechanical tolerances. Table 9-6 outlines the variances due to

differences in viscosity.

To determine the chemical compatibility of a particular tubing material, it is

recommended that you test the tubing under actual conditions.

Tubing materials that can be used include Vinyl, Viton, Tygon, Silicone,

Santoprene, and Norprene. Up to 68 durometer tubing can be used.

Poor tubing life results were obtained for 5⁄16" (8.0mm) inner diameter

Santoprene tubing. This particular tubing should not be used with the

pump motor.

3.3 Tubing Life

Over time and high speeds, flow rates will drop as the tubing wears out. Tubing

life for various materials and sizes are shown in Table 9-4 in Chapter 9. Tubing

should be periodically inspected for wear. Either move the tubing to a fresh

section, or replace tubing entirely (refer to Section 3.4).

3.4 Loading the Tubing

Perform ALL of the steps in Chapter 3 before turning the motor on.

Follow this procedure (refer to Figures 3-8 through 3-12):

Figure 3-8. Parts of the Pump Figure 3-9. Opening the Stator Figure 3-10. Loading the Tubing

Clamp

Screw

Stator

Latch

Tubing

Clamp

Plate

Getting Started

3

3-4

NOTE

CAUTION

Page 24

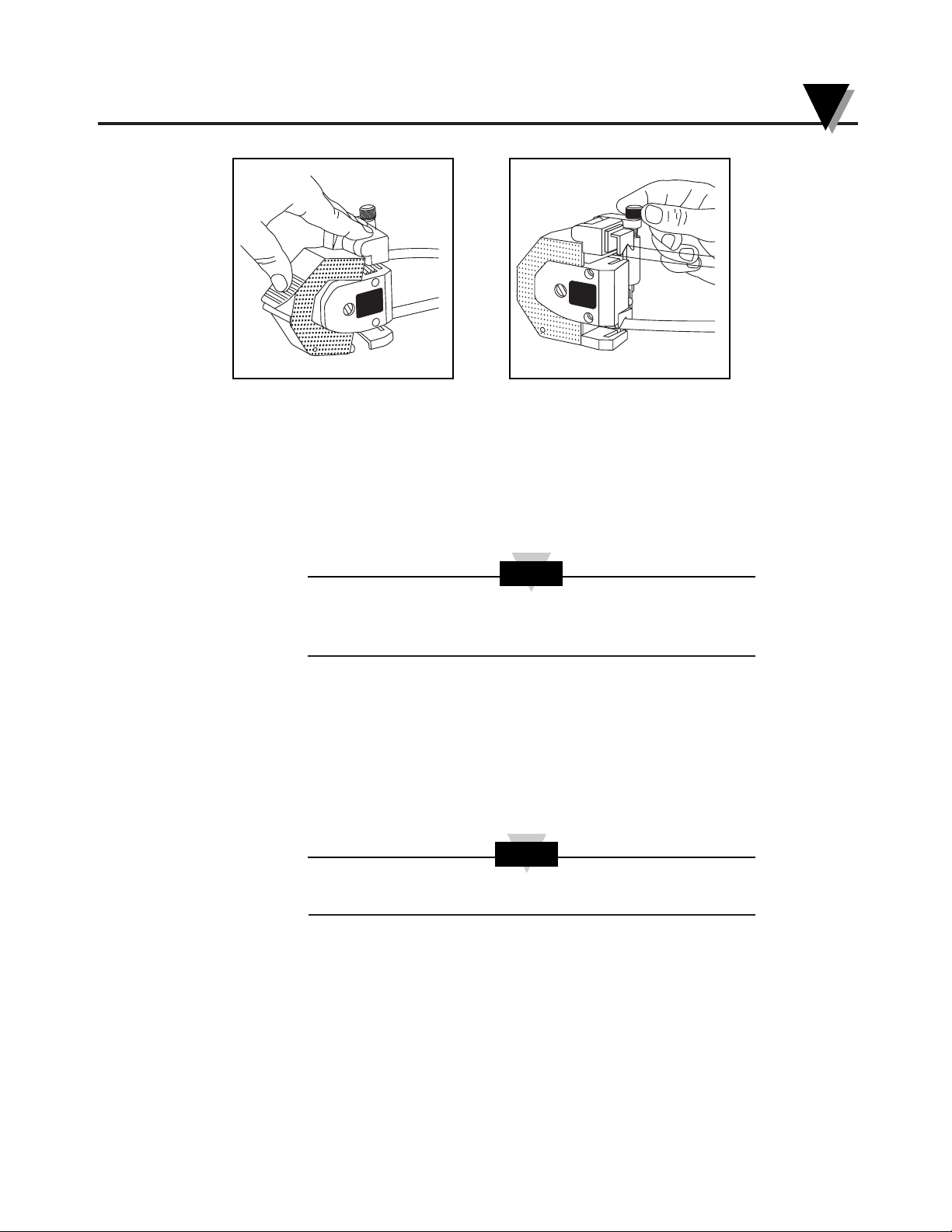

Figure 3-11. Closing the Stator Figure 3-12. Adjusting the Clamp Screw

1. Refer to Figure 3-8 and Figure 3-9. Snap open the Stator by pushing the

spring-loaded area of the Latch. Remove any old tubing from the pump, if

necessary.

2. Refer to Figure 3-8 and Figure 3-10. Loop the Tubing over the rollers. This is

easy to do even for stacked pumps.

Tubing can be changed on stacked pumps without detaching either of the

pumps from the motor.

3. Refer to Figure 3-11. Push the Stator closed until you hear the Latch engage.

4. Refer to Figure 3-12. Tighten the Clamp Screw until the Clamp Plate contacts

the Tubing, securing it in place.

5. Set up the source and drain containers so that the tubing inlet is immersed in the

fluid in the source container and the tubing outlet is in the drain container.

See Section 5.2 to set the pumping direction.

Getting Started

3

3-5

NOTE

NOTE

Page 25

Getting Started

3

3-6

Notes

Page 26

Turning on the Power

4-1

4

4.1 Introduction to the Two Display Modes

The pump motor has two modes of operation defined by whether or not the

motor is running. Refer to Table 4-1. These two modes are known as the

STOPPED Display Mode and the RUNNING Display Mode.

Table 4-1. STOPPED vs. RUNNING Display Modes

Condition Status During Status During

Stopped Display Mode Running Display Mode

ON/OFF Switch ON ON

Motor STOPPED RUNNING

Pump STOPPED RUNNING

Display FLASHING NOT FLASHING

Green LEDs NOT FLASHING FLASHING

Fluid NOT FLOWING FLOWING

4.2 Using the ON/OFF Switch

When the ON/OFF switch is pushed upwards the unit’s power is on. When the

switch is pushed downward, the unit’s power is off and the top of the switch

labeled “0” is visible.

4.3 The STOPPED Display Mode

To enter the STOPPED Display Mode, do the following:

1. Plug in the pump motor to a convenient ac wall outlet. Use ac power within the

range of 90 to 130 Vac (for 115 Vac units) or 190 to 260 Vac (for 220 Vac

units).

A line filter is already installed in the pump motor.

2. Attach the pump(s). Refer to Section 3.1.

NOTE

Page 27

Turning on the Power

4

4-2

3. Turn on the unit’s power. You are now in the STOPPED Display Mode (refer

to Figure 4-1). The motor and the pump(s) are stopped. The display flashes,

indicating that the pump motor is waiting for you to do something. The nonflashing, green LEDs indicate the tubing inlets (refer to Section 5.2), but fluid is

not flowing.

Figure 4-1. STOPPED vs. RUNNING Display Modes

4.4 The RUNNING Display Mode

Figure 4-2. RUNNING Display Mode

To enter the RUNNING Display Mode, do the following:

1. From the STOPPED Display Mode, press the START/STOP key. You are

now in the RUNNING Display Mode. Refer to Figure 4-2. The pump

motor starts. The attached pump(s) begin pumping fluid. The display is not

flashing. The green LEDs flash and point to the tubing inlets.

2. Press the START/STOP key again. The pump motor stops. Fluid stops

dispensing. You return to the STOPPED Display Mode.

enters RUNNING Display Mode

ACTION

Pump(s) starts

Display

STOPPED

Display Mode

STOPPED

DISPLAY

MODE

RUNNING

DISPLAY

MODE

START

STOP

START

STOP

START

STOP

Page 28

Operating the Pump Motor in the

STOPPED Display Mode

5-1

5

5.1 Displaying Pump Messages in Five Different Languages

The LANGUAGE button, located toward the bottom on the back of the pump

motor, changes the language of the pump messages.

1. To display pump messages in another language, press the LANGUAGE button.

The language of the pump messages changes according this sequence: English,

French, Spanish, German, then Italian. This manual only shows pump

messages in English in the display. Table 5-1 shows the English, French,

Spanish, German, and Italian messages.

2. If the new language is the language you want, resume pumping. All the pump

messages are now in the new language.

3. If the new language is not the one you want, press the LANGUAGE button

repeatedly, so that the pump motor can cycle through the sequence to reach the

proper LANGUAGE setting.

English

French

Spanish

German

Italian

ACTION

Language

Changes

Display shows

Language

Page 29

Table 5-1. Pump Messages

English French Spanish German Italian

CAL OVERFLOW DÉPASSEM-ÉTALON! EXCES. CAL.! KAL ÜEBERLAUF! ECCEDENZA CALIB

CALIBRATED! ÉTALONNE! CALIBRADO! KALIBRIERT! CALIBRATO

Calibration FAIL ÉCHEC d’étalon FALLA Cal. KalibrierFEHLER Calib. FALLITA

Dispensing... Remplissage... Bombeando... Pumpe läuft... Erogaz. in corso

Enter TOTAL VOL. Entrer QTÉE ÉTAL. ENT.CANT CAL... KALMENGE angeben Indica Q.tà CAL.

Lost PHASE SYNC! Perte PHASE SYNC! SINC. FASE PERD! Keine PHASENSNC! FASE SINCR persa

OVERCURRENT! SURCHARGE! SOBRRECORRIENTE!

ÜEBERSTROM! SOVRACORRENTE

Must SET RPM! RÉGLER RÉGIME! Ajustar RPM! U/MIN angeben! Imposta GIRI/MIN

Must SET TIME! RÉGLER LA DURÉE! Programar hora! ZEIT angeben! Imposta TEMPO

Set TOTAL VOLUME RÉGLER LA QTÉ! Ajustar Cant.! MENGE angeben! Imposta Q.tà

Must STOP first! ARRÊTER d’abord! Parar primero! Erst STOP! Prima FERMARE

not applicable sans objet no se aplica Unzutreffend non applicabile

not available sans objet no disponible Nicht möglich non disponibile

not calibrated non étalonné sin calibrar Nicht kalibriert non calibrato

Prime or START? Amorcer/DÉMAR.? Cebar o INICIAR? Vorpumpen/START? Adescamo AVVIO?

Priming... Amorçage Cebando... Füllen... Adescam in corso

Locked Rotor? Rotor bloqué? Rotor bloqueado? Rotor gesperrt? Rotore bloccato?

Short circuit? Court-circuit? Corto circuito? Kurzschluss? Corto circuito?

Is pump running? Pompe en marche? Bomba en operac? Läuft Pumpe? Pompa in uso?

Set RPM or RATE! Rég. RPM/DÉBIT? Progr RPM/FLUJO U/MIN/RATE ang! GIRI/M o VEL

Select a MODE! Choisir un MODE! Selec. MODO! MODUS wählen! Selezionare MODO

START or CAL? DÉMAR./ÉTAL.? INIC O CAL? START/KALIBR? AVVIO O CALIB?

STOP to PRIME... STOP par AMORC.! PARAR P/CEBAR... STOP dann VORPMP. FERMA per ADESC

CALIBRATED TUBE! TUBE ETALONNE! TUBO CALIBRADO! ROHR KALIBRIERT! TUBO CALIBRATO!

TUBE ID = 1/32 DI TUBE = 1/32 DI TUBO = 1/32 ROHR ID = 1/32 ID TUBO = 1/32

TUBE ID = 1/16 DI TUBE = 1/16 DI TUBO = 1/16 ROHR ID = 1/16 ID TUBO = 1/16

TUBE ID = 1/8 DI TUBE = 1/8 DI TUBO = 1/8 ROHR ID = 1/8 ID TUBO = 1/8

TUBE ID = 3/16 DI TUBE = 3/16 DI TUBO = 3/16 ROHR ID = 3/16 ID TUBO = 3/16

TUBE ID = 1/4 DI TUBE = 1/4 DI TUBO = 1/4 ROHR ID = 1/4 ID TUBO = 1/4

TUBE ID = 5/16 DI TUBE = 5/16 DI TUBO = 5/16 ROHR ID = 5/16 ID TUBO = 5/16

TUBE ID = 1.0mm DI TUBE = 1.0mm DI TUBO = 1,0mm ROHR ID = 1,0mm ID TUBO = 1,0mm

TUBE ID = 2.0mm DI TUBE = 2.0mm DI TUBO = 2,0mm ROHR ID = 2,0mm ID TUBO = 2,0mm

TUBE ID = 3.0mm DI TUBE = 3.0mm DI TUBO = 3,0mm ROHR ID = 3,0mm ID TUBO = 3,0mm

TUBE ID = 4.0mm DI TUBE = 4.0mm DI TUBO = 4,0mm ROHR ID = 4,0mm ID TUBO = 4,0mm

TUBE ID = 5.0mm DI TUBE = 5.0mm DI TUBO = 5,0mm ROHR ID = 5,0mm ID TUBO = 5,0mm

TUBE ID = 6.0mm DI TUBE = 6.0mm DI TUBO = 6,0mm ROHR ID = 6,0mm ID TUBO = 6,0mm

TUBE ID = 7.0mm DI TUBE = 7.0mm DI TUBO = 7,0mm ROHR ID = 7,0mm ID TUBO = 7,0mm

TUBE ID = 8.0mm DI TUBE = 8.0mm DI TUBO = 8,0mm ROHR ID = 8,0mm ID TUBO = 8,0mm

>10,000 Liters!! >10,000 litres! >10,000 Litros! >10,000 Liter!! >10.000 litri!!

>12:59:59! >12:59:59! >12:59:59! >12:59:59! >12:59:59!

>12 Hours!! >12 heures!! >12 HORAS!! >12 stunden!! >12 ore!!

Must SET RATE! RÉGLER LE DÉBIT!! ADJISTAR FLUJO!! RATE angrben!! INDICARE VELOC.

Press QUANTITY Presser QTÉ

... Pulsar CANT! MENGE drücken! Premi QUANTITA

Press TIME Presser DURÉE... Pulsar HORA! ZEIT drücken! Premi TEMPO

rpm régime rpm U/min giri/min

mL mL mL ml ml

Liters litres Litros Liter litri

mL/min mL/min mL/min ml/min ml/min

L/min L/min l/min l/min l/min

°F °F °F °F °F

°C °C °C °C °C

Operating the Pump Motor in the STOPPED Display Mode

5

5-2

Page 30

5.2 Defining the Direction of Pumping

The INLET SELECT key, left and right pump icons, and green LEDs define the

direction of pumping by specifying the tubing inlets and outlets.

1. Refer to Figure 5-1.

2. To determine the direction of pumping, look at the left and right pump icons and

green LEDs. Only one of each pair of LEDs is lit. The lit LED points to the tubing

inlet.

A top tubing inlet on the left pump corresponds to a bottom tubing

inlet on the right pump and vice versa.

Two pumps stacked on one side of the motor will pump fluid in the same

direction. Two pumps mounted on opposite sides of the motor will pump

fluid in opposing directions.

Operating the Pump Motor in the STOPPED Display Mode

5

5-3

NOTE

INLET

SELECT

Display shows

<no change>

ACTION

LEDs indicate new

pump direction

Page 31

Figure 5-1. Defining the Direction of Pumping

3. To change the direction of pumping, press the INLET SELECT key. The lit, green

LEDs change positions. Fluid flows in the opposite direction.

4. To change back to the original direction of pumping, simply press the INLET

SELECT key again.

5.3 Selecting the Tubing Inner Diameter

The TUBE ID, and UP and DOWN ARROW keys allow you to select the inner

diameter of the tubing.

With the peristaltic pump motor, you can either select a tubing size from

those shown in the display (using the TUBE ID key), or you can calibrate

each piece of tubing you use (using the CALIBRATE key, as described in

Section 5.5).

START

STOP

TIME

TOTAL

VOLUME

CALIBRATE

PRIME

RPM

FLOW

RATE

TUBE ID

INLET

SELECT

TEMP

INLET SELECT

LEFT PUMP

INLET SELECT

RIGHT PUMP

INLET

OUTLET

INLET

OUTLET

Left Pump

START

STOP

TIME

TOTAL

VOLUME

CALIBRATE

PRIME

RPM

FLOW

RATE

TUBE ID

INLET

SELECT

TEMP

INLET SELECT

LEFT PUMP

INLET SELECT

RIGHT PUMP

INLET

INLET

OUTLET

OUTLET

Left Pump

Right Pump

Right Pump

MOTOR TURNING

CLOCKWISE

MOTOR TURNING

COUNTER-CLOCKWISE

MOTOR TURNING

COUNTER-CLOCKWISE

MOTOR TURNING

CLOCKWISE

Operating the Pump Motor in the STOPPED Display Mode

5

5-4

NOTE

Page 32

1. Press the TUBE ID key. The display shows the last TUBE ID setting used, in

inches or millimeters. Table 5-2 lists all the pre-programmed tubing inner

diameters.

2. Use the UP and DOWN ARROW keys to enter a TUBE ID on the display. Once

you start the pump motor, after selecting a mode (refer to Chapter 6), the pump

will dispense fluid at a flow rate calculated based on the last TUBE ID displayed

before the pump starts to run.

If the red LED next to the CALIBRATE key is lit, the pump motor is running

according to the last calibration complete (refer to Section 5.5).

If you press the TUBE ID key while the red LED is lit, the display shows

“CALIBRATED TUBE!”.

Table 5-2. Tube Inner Diameters

Tube Inner Diameters

English Metric

1

⁄32" 1.0 mm

1

⁄16" 2.0 mm

1

⁄8" 3.0 mm

3

⁄16" 4.0 mm

1

⁄4" 5.0 mm

5

⁄16" 6.0 mm

7.0 mm

8.0 mm

Operating the Pump Motor in the STOPPED Display Mode

5

5-5

Using the UP ARROW key () will cause the TUBE ID value to scroll up through

the available choices.

Using the DOWN ARROW key () will cause the TUBE ID value to scroll down

through the available choices.

OR

NOTE

TUBE ID

Display shows

TUBE ID = XXX

ACTION

Displays current

TUBE ID

Page 33

5.4 Priming the Tubing

Pressing the PRIME key causes the tubing to fill with fluid.

1. To prime the tubing, press and hold down the PRIME key. As long as you hold

down the PRIME key, fluid flows in the tubing, and the display shows

“Priming...”.

2. To stop priming a tube, simply release the PRIME key. The pump motor stops

running, and fluid stops flowing.

Extensive testing has shown that the minimum motor speed required to prime

the tubing varies significantly with the size of the tubing. These variances are

shown in Table 9-3 in Chapter 9. If the tubing will not prime regardless of motor

speed, simply press on the pump stator (refer to Figure 3-11) while the stator is

shut and the motor is running. Pressing on the stator enhances the priming

action of the pump. Release pressure after the tubing is primed.

5.5 Calibrating the Tubing

Operating the Pump Motor in the STOPPED Display Mode

5

5-6

CALIBRATE

PRIME

Display shows

Priming. . .

ACTION

Pumps fluid at

current RPM or

FLOW RATE setting

as long as button is

pressed

Display shows

CALIBRATE

Display shows

Prime or START?

ACTION

Press PRIME to

prime tube or

START to dispense

desired amount of

fluid

Press Start/Stop button to

dispense fluid. Press again

Priming...

Hold button down to dispense fluid

ACTION

START

STOP

Display shows

Dispensing . . .

ACTION

to stop the process.

PRIME

Display shows

xxx mL or xxx Liters

Scrolls up. Enter TOTALVOLUME dispensed

ACTION

Display shows

CALIBRATED!

ACTION

Red LED next to

Calibrate key

lights up

Page 34

Since tubes of different materials, sizes, ages, and durometers produce different

flow rates, the CALIBRATE key allows you to calibrate each piece of tubing you

use. Calibration accuracy data is shown in Table 9-1 in Chapter 9. Once the

tubing is calibrated, you no longer need to be concerned about flow rate

variances outlines in Table 9-3.

Along with the usual pumping equipment (pump(s), pump motor), you will

need calibrated beakers or cylinders to function as source and drain

containers.

1. Before you initiate the calibration process, you must set the pump up for

pumping in the same direction as you plan to use during normal pump

operation (refer to Section 5.2). In addition, make sure the display shows

STOPPED Display Mode (the motor is not running).

2. Set either the RPM or FLOW RATE setting of the pump motor:

2a. To set the RPM, press the RPM key. The display flashes the current RPM

setting (xxx rpm). Use the UP and DOWN ARROW keys to adjust the

setting.

2b. To set the FLOW RATE, press the TUBE ID key and use the UP and DOWN

ARROW keys to select the inner diameter of the tube you are using. Press

the FLOW RATE key. Use the UP and DOWN ARROW keys to adjust the

setting.

3. When the display shows the RPM or FLOW RATE setting you desire, you are

ready to initiate the calibration process.

4. Press the CALIBRATE key. The display should flash and show, “Prime or

START ?”.

5. To prime the tube, press and hold down the PRIME key. As long as you hold

down the PRIME key, fluid flows in the tube, and the display shows,

“Priming...”.

6. When fluid has completely filled the tube, simply release the PRIME key. The

pump motor stops running, and fluid stops flowing.

7. To dispense fluid for calibration, hold the tubing outlet over the drain container

and press the START/STOP key. Fluid flows, and the display enters the Running

Display Mode, showing the message, “Dispensing...”.

8. When you have allowed fluid to dispense for a minute or two, press the

START/STOP key to stop the pump. Fluid stops dispensing, and the display

returns to the STOPPED Display Mode. The display momentarily flashes the

message, “Enter TOTAL VOL.” and then flashes the total volume dispensed (xxx

ml or xxx Liters) alternating with the message “Start or CAL ?”.

9. To continue to dispense fluid, press the START/STOP key again. Fluid flows,

and the display returns to the Running Display Mode, showing the message,

“Dispensing...”.

Operating the Pump Motor in the STOPPED Display Mode

5

5-7

NOTE

Page 35

10. After you have finished dispensing, press the START/STOP key to stop the pump

motor. Then measure the dispensed fluid’s volume using your calibrated beaker.

11. When you have determined the volume of the dispensed fluid, use the UP and

DOWN ARROW keys to enter this volume on the display.

12. Once the display shows the correct volume of fluid dispensed, press the

CALIBRATE key to complete the calibration. The display flashes and shows,

“CALIBRATED!”, and the red LED next to the CALIBRATE key lights up.

13. Now you can select a mode (RPM, FLOW RATE, TIME or TOTAL VOLUME)

(refer to Chapter 6). Once started, the fluid will be pumped according to the

calibration.

If you replace your tubing, make sure to press the TUBE ID key and select a

different tube id size using the UP or DOWN ARROW keys.

You can independently calibrate only one pump at a time. If

you have two pumps attached to the motor (even if they are stacked), only

one of the pumps can be calibrated.

For optimum FLOW RATE or TOTAL VOLUME accuracy, you will need to

recalibrate the tubing as a result of:

•

Using a different tube size (inner diameter)

•

Using a different tubing material

•

Using a tube of a different age (calibration should be checked

every 5-10 hours.)

•

Using a different back pressure in the tube

•

Changing the fluid being pumped

•

Changing the fluid’s temperature or density

•

Changing the RPM or FLOW RATE setting

•

Reversing the direction of pumping

•

Changing the clamp screw adjustment of the pump(s)

TIPS FOR OPTIMUM CALIBRATION ACCURACY:

Presented below are three useful techniques that will help you obtain optimum

calibration accuracy.

•Calibrate the unit at the speed you plan to use for normal pump operation.

• When dispensing fluid during calibration, allow the pump to dispense the

largest total volume that your measurement equipment supports.

• When measuring the dispensed fluid during calibration, calculate the

volume by measuring the fluid's mass with an accurate gram scale and

dividing this mass by the fluid's density.

Operating the Pump Motor in the STOPPED Display Mode

5

5-8

NOTE

NOTE

Page 36

5.6 Measuring the Temperature of a Fluid

The TEMP key displays the temperature of the fluid, as measured via an optional

Type K thermocouple probe. The pump motor is equipped with an SMP Type K

female thermocouple jack, located near the bottom on the back of the pump

motor.

1. To measure the temperature of the fluid, plug one end of an optional Type K

thermocouple probe (equipped with an SMP male connector) into the SMP jack

and immerse the other end of the probe in the fluid.

2. Press the TEMP key. The display shows the fluid’s temperature in (°F or °C).

3. If you are reading the temperature in °F and wish to switch to °C (or if you are

reading the temperature in °C and wish to switch to °F), press the TEMP key

again. The display shows the fluid's temperature in the unit of measure to

which you switched.

If the optional thermocouple probe is not connected to the pump motor, the

reading on the display will be 300°F (149°C).

5.7 Preparing for Pumping in a Specific Mode

There are four specific modes in which to pump fluid: RPM, FLOW RATE,

TIME, and TOTAL VOLUME. These modes correspond to the criteria the pump

motor uses to dispense the fluid. These four modes are described on the next

page.

When you press the START/STOP key and the pump starts running, the

active pumping mode is the last mode displayed before you pressed the

START/STOP key.

Detailed instructions on how to select a pumping mode and adjusting the

settings in that mode appear in Chapter 6.

Operating the Pump Motor in the STOPPED Display Mode

5

5-9

NOTE

NOTE

TEMP

Display shows

xxx °C

ACTION

Display alternates

when the button is

pressed; °C then °F

then back to °C

Page 37

Operating the Pump Motor in the STOPPED Display Mode

5

5-10

Using the UP ARROW key () will cause the FLOW RATE value to scroll up to

the maximum FLOW RATE determined by TUBE ID then scrolls over to the

minimum FLOW RATE.

Using the DOWN ARROW key () will cause the FLOW RATE value to scroll

down to the minimum FLOW RATE determined by TUBE ID then scrolls over

to the maximum FLOW RATE.

OR

Using the UP ARROW key () will cause the display to scroll up to a maximum of

10000 liters then over to 1 mL.

Using the DOWN ARROW key () will cause the display to scroll down to 1 mL

then roll over to 10000 liters.

OR

Using the UP ARROW key () will cause the flashing TIME setting to scroll up

to maximum then roll over to “0”. The maximum time is 12 hours, 59 minutes

and 59 seconds (12:59:59).

Using the DOWN ARROW key () will cause the flashing TIME setting to scroll

down to “0” then roll over to the maximum. The maximum time is 12 hours,

59 minutes and 59 seconds (12:59:59).

OR

The flashing group

(SECONDS, MINUTES, or

HOURS) is the one that will

scroll when the UP or

DOWN ARROW key is

pressed. Pressing the TIME

key again will select a

different group.

Using the UP ARROW key () will cause the RPM setting to scroll up to 600 rpm

then roll over to 10 rpm.

Using the DOWN ARROW key () will cause the RPM setting to scroll down to

10 rpm then roll over to 600 rpm.

OR

RPM

Display shows

xxx rpm

ACTION

Displays current

RPM setting

FLOW

RATE

Display shows

xxx mL/min

ACTION

Displays current

FLOW RATE setting

TIME

Display shows

xx:xx:xx

ACTION

Displays current

TIME setting

Display shows

xxx mL or xxx Liters

ACTION

Displays current

TOTAL VOLUME

setting

TOTAL

VOLUME

Page 38

Operating the Pump Motor in the

RUNNING Display Mode

6-1

6

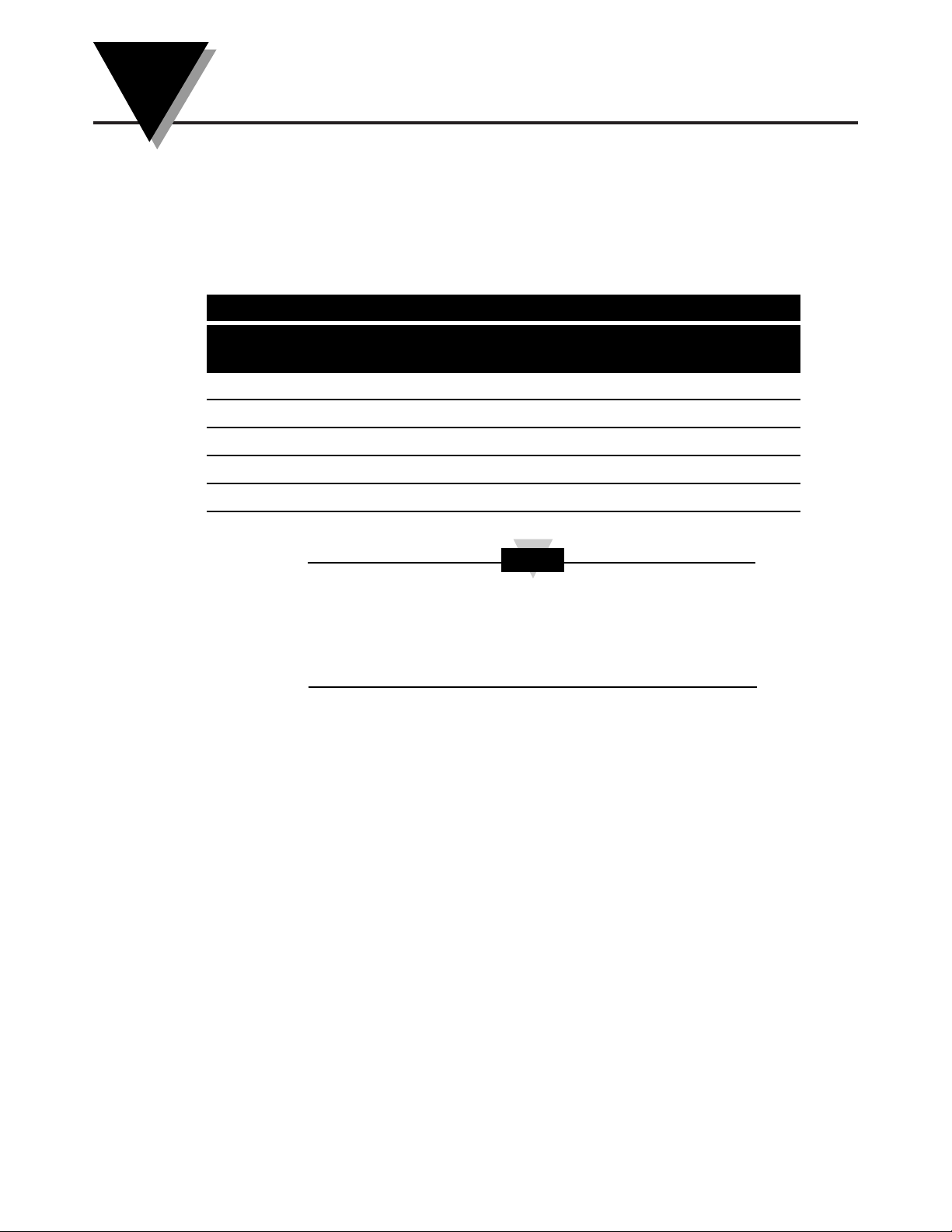

6.1 The RPM Mode

Figure 6-1 shows the overall block diagram of the RPM Mode in the RUNNING

Display Mode.

Figure 6-1. Block Diagram: Pumping in the RPM Mode

In the RPM Mode, you pump fluid at a certain motor speed, without setting the

amount of time you pump or the volume you dispense. The pump motor

measures the time of pumping and volume of fluid dispensed but ignores the

TIME and TOTAL VOLUME settings.

6.1.1 Pumping in the RPM Mode

To pump fluid in the RPM Mode, do the following:

1. Set up the pump motor for pumping, according to Chapter 3.

2. Toggle the ON/OFF switch to turn on the unit’s power. The display is in the

STOPPED Display Mode. Refer to Figure 6-1.

3. Either set the tube ID for the tube you are using (following Section 5.3) or

calibrate the tubing (following Section 5.5) before continuing.

4. Press the RPM key. The display flashes the current RPM setting (xxx rpm).

CURRENT

SETTING

RPM

STOPPED

DISPLAY

MODE

START

STOP

TUBE ID

RPM

ACTUAL

VALUE

TUBE ID

CURRENT

RPM

SETTING

RUNNING

DISPLAY

MODE

OR

OR

TUBE ID SETTING

TO BE USED IN

PUMPING

RPM SETTING

TO BE USED IN

PUMPING

START

STOP

(Refer to Section 5.5)

CALIBRATE

(Optional)

RPM

Display shows

xxx rpm

ACTION

Displays current

RPM setting

Page 39

5. Use the UP and DOWN ARROW keys to enter the RPM setting you desire.

Figure 6-2 shows the range of the RPM numbers you can work with.

Figure 6-2. RPM Range

5. Once the display shows the RPM setting you desire, press the START/STOP key.

As the fluid begins to dispense, the non-flashing display shows the actual RPM

value of the pump.

For details on how to prevent the tubing from moving through the pump,

refer to Section 6.5.

6. To stop pumping in the RPM Mode, simply press the START/STOP key again.

The pump stops running, and the display returns to the STOPPED Display

Mode.

Table 6-1 shows how other keys and buttons can be used while pumping in the

RPM mode.

Operating the Pump Motor in the RUNNING Display Mode

6

6-2

NOTE

Display shows

xxx RPM

ACTION

RPM setting scrolls up

Display shows

xxx RPM

ACTION

RPM setting scrolls down

Range

10

11

12

.

.

.

599

600

Range

600

599

.

.

.

12

11

10

START

STOP

Display

xxx RPM

ACTION

Pump(s) starts;

press again pump(s)

stops

Page 40

6-3

Table 6-1 RPM MODE

KEY DISPLAY ACTION TAKEN

SHOWS AND PROCEDURE

xxx rpm

Pump motor’s power

NOTE: if you turn off the pump motor’s power, the pump stops

running.

To continue pumping, turn on the unit’s power. The display

returns to the STOPPED Display Mode and shows the current

RPM setting. The accumulated time of pumping and volume

dispensed is reset to zero. Then press the START/STOP key.

ON/OFF Switch

xxx rpm

Pump(s) stops; press again pump(s) starts

To resume pumping at the current setting, press the

START/STOP key. The display enters the RUNNING Display

Mode, and the fluid begins to dispense.

START

STOP

Must STOP first!

LEDs indicate new pump direction

To select the other inlet and reverse the direction of pumping:

1. Press the START/STOP key. The display returns to the

STOPPED Display Mode.

2. Press the INLET SELECT key to reverse the direction of

pumping.

3. Press the START/STOP key again to resume pumping.

4. For detailed instructions on “Defining the Direction of

Pumping, refer to Section 5.2.

STOP to Prime...

Pumps fluid at current RPM setting as long as the key is pressed

To prime a tube:

1. Press the START/STOP key to stop the pump. The display

returns to the STOPPED Display Mode.

2. Press and hold down the PRIME key to prime the tube.

3. Press the START/STOP key again to resume pumping.

4. For detailed instructions on “Priming a Tube”, refer to Section

5.4.

INLET

SELECT

PRIME

xxx °C

Display alternates when pressed,

°C then °F

NOTE: The TEMP key functions the same whether the pump is

stopped or running. Refer to Section 5.6.

TEMP

RPM

xxx rpm

Displays current RPM setting

1. Press the RPM key. The display flashes the RPM setting

you selected just before starting the pump.

2. Use the UP and DOWN ARROW keys to enter the RPM

setting you desire. As you use the UP and DOWN ARROW

keys, the display changes accordingly.

TIME

xx:xx:xx

Displays cumulative TIME

since start

Press the TIME key. The display flashes the time that the pump

has been running (xx:xx:xx).

Page 41

6-4

Table 6-1 (cont’d) RPM MODE

KEY DISPLAY ACTION TAKEN

SHOWS AND PROCEDURE

FLOW

RATE

xxx mL/min

or

xxx Liter/min

Displays actual FLOW

RATE

Press the FLOW RATE key. The display flashes the fluid flow

rate calculated for the RPM setting previously selected (xxx

mL/min or xxx L/min).

TOTAL

VOLUME

TUBE ID

xxx mL

or

xxx Liters

Displays current TOTAL VOLUME

1. Press the TOTAL VOLUME key. The display flashes the

calculated volume of fluid dispensed since the pump started

running (xxx mL or xxx Liters).

TUBE ID=xxx

Displays current TUBE ID

Press the TUBE ID key. If the red LED next to the CALIBRATE

key is not lit, the display flashes the current TUBE ID setting. If

the red LED next to the CALIBRATE key is lit, the display flashes

the message “CALIBRATED TUBE!”.

CALIBRATE

CALIBRATED!

or

not calibrated

Displays calibration state

1. Press the CALIBRATE key. If the red LED next to the

CALIBRATE key is not lit, the display shows “not calibrated”.. If the red LED next to the CALIBRATE key is lit, the

display shows “CALIBRATED!”.

To calibrate a tube:

2. Press the START/STOP key to stop the pump. The display

returns to the STOPPED Display Mode. For detailed

instructions on “Calibrating a Tube”, refer to Section 5.5.

and

xxx rpm

NOTE: if you press the UP and DOWN ARROW keys, the dis-

play shows the current RPM setting. This setting

changes accordingly as you use the UP and DOWN

ARROW keys but does not wrap around at 10 RPM and

600 RPM while the pump is running. Refer to Figure 6-2.

NOTE: if you press the Language button, the display changes to

the next language in the sequence: English, French,

Spanish, German, and Italian.

Language

Button

Page 42

6.2 The FLOW RATE Mode

Figure 6-3 shows the overall block diagram of the FLOW RATE Mode in the

RUNNING Display Mode.

Figure 6-3. Block Diagram: Pumping in the FLOW RATE Mode

In the FLOW RATE Mode, you pump fluid at a certain flow rate, without setting

the amount of time you pump or the amount of fluid you dispense. The pump

motor measures the time of pumping and volume of fluid dispensed but ignores

the TIME and TOTAL VOLUME settings.

6.2.1 Pumping in the FLOW RATE Mode

To pump fluid in the FLOW RATE Mode, do the following:

1. Set up the pump motor for pumping, according to Chapter 3.

2. Toggle the ON/OFF switch to turn on the unit’s power. The display is in the

STOPPED Display Mode. Refer to Figure 6-3.

3. Either set the TUBE ID for the tube you are using (following Section 5.3) or

calibrate the tube (following Section 5.5), before continuing.

4. Press the FLOW RATE key.

The display flashes the current FLOW RATE setting (xxx mL/min or xxx L/min).

Operating the Pump Motor in the RUNNING Display Mode

6

6-5

STOP

CURRENT

TUBE ID

SETTING

CURRENT

FLOW RATE

SETTING

CALCULATED

FLOW RATE

STOPPED

DISPLAY

MODE

FLOW

RATE

TUBE ID

START

OR

OR

FLOW RATE

SETTING

TO BE USED IN

PUMPING

RUNNING

DISPLAY

MODE

TUBE ID SETTING

TO BE USED IN

PUMPING

(Refer to Section 5.5)

CALIBRATE

(Optional)

START

STOP

FLOW

RATE

Display shows

xxx mL/min

ACTION

Displays current

FLOW RATE setting

Page 43

5. Use the UP and DOWN ARROW keys to enter the FLOW RATE setting you

desire.

Figure 6-4 shows the ranges allowed for the various tubing sizes.

Figure 6-4. FLOW RATE Ranges

Range (3/16” tube ID)

19 mL/min

20 mL/min

.

499 mL/min

500 mL/min

.

1139 mL/min

1140 mL/min

Range (3/16” tube ID)

1140 mL/min

1139 mL/min

.

500 mL/min

499 mL/min

.

20 mL/min

19 mL/min

Range (5/16” tube ID)

38 mL/min

39 mL/min

.

1999 mL/min

2000 mL/min

.

2279 mL/min

2280 mL/min

Range (5/16” tube ID)

2280 mL/min

2279 mL/min

.

2000 mL/min

1999 mL/min

.

39 mL/min

38 mL/min

Range (1/4” tube ID)

30 mL/min

31 mL/min

.

999 mL/min

1L/min

.

1.7 L/min

1.8 L/min

Range (1/4” tube ID)

1.8 L/min

1.7 L/min

.

999 mL/min

1L/min

.

31 mL/min

30 mL/min

Range (1/32” tube ID)

1 mL/min

2 mL/min

.

15 mL/min

16 mL/min

.

29 mL/min

30 mL/min

Range (1/32” tube ID)

30 mL/min

29 mL/min

.

16 mL/min

15 mL/min

.

2 mL/min

1 mL/min

Range (1/16” tube ID)

3 mL/min

4 mL/min

.

79 mL/min

80 mL/min

.

131 mL/min

132 mL/min

Range (1/16” tube ID)

132 mL/min

131 mL/min

.

80 mL/min

79 mL/min

.

4 mL/min

3 mL/min

Range (1/8” tube ID)

9 mL/min

10 mL/min

.

249 mL/min

250 mL/min

.

539 mL/min

540 mL/min

Range (1/8” tube ID)

540 mL/min

539 mL/min

.

250 mL/min

249 mL/min

.

10 mL/min

9 mL/min

Operating the Pump Motor in the RUNNING Display Mode

6

6-6

FLOW RATE setting scrolls up

Display shows

xxx mL/min

ACTION

Display shows

xxx mL/min

ACTION

FLOW RATE setting scrolls down

Page 44

Figure 6-4. FLOW RATE Ranges (cont’d)

Range (4.0 mm tube ID)

15 mL/min

16 mL/min

.

399 mL/min

400 mL/min

.

856 mL/min

857 mL/min

Range (4.0 mm tube ID)

857 mL/min

856 mL/min

.

400 mL/min

399 mL/min

.

16 mL/min

15 mL/min

Range (5.0 mm tube ID)

21 mL/min

22 mL/min

.

599 mL/min

600 mL/min

.

1256 mL/min

1257 mL/min

Range (5.0 mm tube ID)

1257 mL/min

1256 mL/min

.

600 mL/min

599 mL/min

.

22 mL/min

21 mL/min

Range (6.0 mm tube ID)

27 mL/min

28 mL/min

.

799 mL/min

800 mL/min

.

1606 mL/min

1607 mL/min

Range (6.0 mm tube ID)

1607 mL/min

1606 mL/min

.

800 mL/min

799 mL/min

.

28 mL/min

27 mL/min

Range (2.0 mm tube ID)

4 mL/min

5 mL/min

.

199 mL/min

200 mL/min

.

209 mL/min

210 mL/min

Range (2.0 mm tube ID)

210 mL/min

209 mL/min

.

200 mL/min

199 mL/min

.

5 mL/min

4 mL/min

Range (3.0 mm tube ID)

8 mL/min

9 mL/min

.

199 mL/min

200 mL/min

.

481 mL/min

482 mL/min

Range (3.0 mm tube ID)

482 mL/min

481 mL/min

.

200 mL/min

199 mL/min

.

9 mL/min

8 mL/min

Range (1.0 mm tube ID)

1 mL/min

2 mL/min

.

19 mL/min

20 mL/min

.

47 mL/min

48 mL/min

Range (1.0 mm tube ID)

48 mL/min

47 mL/min

.

20 mL/min

19 mL/min

.

2 mL/min

1 mL/min

Operating the Pump Motor in the RUNNING Display Mode

6

6-7

Page 45

Figure 6-4. FLOW RATE Ranges (cont’d)

6. Once the display shows the FLOW RATE setting you desire, press the

START/STOP key.

As the fluid begins to dispense, the non-flashing display shows the calculated

fluid flow rate.

Refer to Section 6.5 to learn about how to prevent tubing from moving

through the pump.

7. To stop pumping in the FLOW RATE Mode, simply press the START/STOP

key again. The pump stops running, and the display returns to the STOPPED

Display Mode.

Table 6-2 shows how other keys and buttons can be used while pumping in the

FLOW RATE mode.

Operating the Pump Motor in the RUNNING Display Mode

6

6-8

NOTE

Range (7.0 mm tube ID)

37 mL/min

38 mL/min

.

1999 mL/min

2000 mL/min

.

2186 mL/min

2187 mL/min

Range (8.0 mm tube ID)

39 mL/min

40 mL/min

.

1999 mL/min

2000 mL/min

.

2315 mL/min

2316 mL/min

Range (7.0 mm tube ID)

2187 mL/min

2186 mL/min

.

2000 mL/min

1999 mL/min

.

38 mL/min

37 mL/min

Range (8.0 mm tube ID)

2316 mL/min

2315 mL/min

.

2000 mL/min

1999 mL/min

.

40 mL/min

39 mL/min

START

STOP

Display

xxx mL/min

ACTION

Pump(s) starts;

press again pump(s)

stops

Page 46

6-9

Table 6-2 FLOW RATE MODE

KEY DISPLAY ACTION TAKEN

SHOWS AND PROCEDURE

XXX mL/min

or

XXX L/min

Pump motor’s power

NOTE: if you turn off the pump motor’s power, the pump stops

running.

To continue pumping, turn on the unit’s power. The display

returns to the STOPPED Display Mode and shows the current

FLOW RATE setting. The accumulated time of pumping and

volume dispensed is reset to zero. Then press the START/STOP

key .

XXX mL/min

or

XXX L/min

Pump(s) starts; press again pump(s) stops

To start pumping at this setting, press the START/STOP key.

The display enters the RUNNING Display Mode, and the fluid

begins to dispense.

START

STOP

ON/OFF Switch

Must STOP first!

LEDs indicate new pump direction

To select the other inlet and reverse the direction of pumping:

1. Press the START/STOP key. The display returns to the

STOPPED Display Mode.

2. Press the INLET SELECT key to reverse the direction of

pumping.

3. Press the START/STOP key again to resume pumping.

4. For detailed instructions on “Defining the Direction of

Pumping, refer to Section 5.2.

INLET

SELECT

STOP to Prime...

Pumps fluid at current flow rate

setting as long as the key is pressed

To prime a tube:

1. Press the START/STOP key to stop the pump. The display

returns to the STOPPED Display Mode.

2. Press and hold down the PRIME key to prime the tube.

3. Press the START/STOP key again to resume pumping.

4. For detailed instructions on “Priming a Tube”, refer to

Section 5.4.

PRIME

xxx °C

Display alternates when pressed, °C then °F

NOTE: The TEMP key functions the same whether the pump is

stopped or running. Refer to Section 5.6.

TEMP

RPM

xxx rpm

Displays actual RPM

Press the RPM key. The display flashes the actual pump motor

speed (xxx rpm).

Page 47

6-10

Table 6-2 (cont’d) FLOW RATE MODE

KEY DISPLAY ACTION TAKEN

SHOWS AND PROCEDURE

TIME

FLOW

RATE

xx:xx:xx

Displays cumulative TIME

since start

Press the TIME key. The display flashes the time that the pump has

been running (xx:xx:xx).

xxx mL/min

or

xxx L/min

Displays current FLOW

RATE setting

1. Press the FLOW RATE key. The display flashes the flow rate

setting you selected just before starting the pump.

2. Use the UP and DOWN ARROW keys to enter the FLOW

RATE setting you desire. As you use the UP and DOWN

ARROW keys, the display changes accordingly. Refer to

Figure 6-4.

TOTAL

VOLUME

TUBE ID

xxx mL/min

or

xxx Liters

Displays current TOTAL VOLUME

Press the TOTAL VOLUME key. The display flashes the calculated

volume of fluid dispensed since the pump started running (xxx mL or

xxx Liters).

TUBE ID=xxx

Displays current TUBE ID

Press the TUBE ID key. If the red LED next to the CALIBRATE key

is not lit, the display flashes the current TUBE ID setting. If the red

LED next to the CALIBRATE key is lit, the display flashes the

message “CALIBRATED TUBE!”.

CALIBRATE

CALIBRATED!

or

not calibrated

Displays calibration state

1. Press the CALIBRATE key. If the red LED next to the

CALIBRATE key is not lit, the display shows “not calibrated”..

If the red LED next to the CALIBRATE key is lit, the display

shows “CALIBRATED!”.

To calibrate a tube:

2. Press the START/STOP key to stop the pump. The display

returns to the STOPPED Display Mode. For detailed instructions on “Calibrating a Tube”, refer to Section 5.5.

and

xxx mL/min

or

xxx L/min

NOTE: if you press the UP and DOWN ARROW keys, the display

shows the current FLOW RATE setting. This setting

changes accordingly as you use the UP and DOWN

ARROW keys but does not wrap around at maximum and

minimum values while the pump is running.

NOTE: if you press the Language button, the display changes to

the next language in the sequence: English, French,

Spanish, German, and Italian.

Language

Button

Page 48

6.3 The TIME Mode

Figure 6-5 shows the overall block diagram of the TIME Mode in the

RUNNING Display Mode.

Figure 6-5. Block Diagram: Pumping in the TIME Mode

In the TIME Mode, you pump fluid at a certain motor speed or flow rate, for a

particular amount of time. The pump motor uses the RPM or FLOW RATE

setting. It measures the volume of fluid dispensed, but ignores the TOTAL

VOLUME setting.

6.3.1 Pumping in the TIME Mode

To pump fluid in the TIME Mode, do the following:

1. Set up the pump motor for pumping according to Chapter 3.

2. Toggle the ON/OFF switch to turn on the unit’s power. The display is in the

STOPPED Display Mode. Refer to Figure 6-5.

3. Using the procedure outlined in Sections 6.1.1. and 6.2.1, adjust either the

RPM or FLOW RATE setting.

STOPPED

DISPLAY

MODE

OR

TUBE ID SETTING

TO BE USED IN

PUMPING

OR

CURRENT

TUBE ID

SETTING

CURRENT

RPM

SETTING

OR

OR

FLOW

RATE

CURRENT

FLOW RATE

SETTING

FLOW RATE

SETTING

TO BE USED IN

PUMPING

(Optional)

CALIBRATE

TUBE ID

RPM SETTING TO BE

USED IN PUMPING

(Optional)

CALIBRATE

RPM

TIME

START

STOP

RUNNING

DISPLAY

MODE

and

TIME ELAPSED

DURING PUMPING

CURRENT

TIME SETTING

TIME SETTING

TO BE USED IN

PUMPING

TIME

START

STOP

(Forced Stop)

(Time Runs Out)

(Refer to Section 5.5)

(Refer to Section 5.5)

Operating the Pump Motor in the RUNNING Display Mode

6

6-11

Page 49

4. When the display flashes the RPM or FLOW RATE setting you desire, press the

TIME key.

The display shows the current TIME setting (xx:xx:xx) with either the HOURS,

MINUTES, or SECONDS flashing.

5. To change the HOURS setting, press the TIME key repeatedly, until the HOURS

flash. Use the UP and DOWN ARROW keys to enter the HOURS setting you

desire. Figure 6-6 shows the Time range.

Figure 6-6. TIME Range

6. To change the MINUTES setting, press the TIME key repeatedly, until the

MINUTES flash. Use the UP and DOWN ARROW keys to enter the MINUTES

setting you desire.

Range

00:00:00

00:00:01

.

.

00:00:59

00:01:00

.

.

00:58:59

00:59:00

.

.

00:59:59

01:00:00

01:00:01

.

.

12:59:59

Range

12:59:59

12:59:58

.

.

12:59:00

12:58:59

.

.

12:00:00

11:59:59

.

.

00:00:01

00:00:00

Operating the Pump Motor in the RUNNING Display Mode

6

6-12

Display shows

Displays current

TIME setting

TIME

xx:xx:xx

ACTION

Page 50

7. To change the SECONDS setting, press the TIME key repeatedly, until the

SECONDS flash. Use the UP and DOWN ARROW keys to enter the SECONDS

setting you desire.

8. Once the display shows the TIME setting you desire, press the START/STOP key.

As the fluid begins to dispense, the non-flashing display shows the actual time

that the pump has been running.

In the TIME Mode, the pump stops running after it counts up to the TIME

setting.

To stop pumping before that time, press the START/STOP key. The pump

stops running, and the display returns to the STOPPED Display Mode.

Table 6-3 shows how other keys and buttons can be used while pumping in the

TIME mode.

Operating the Pump Motor in the RUNNING Display Mode

6

6-13

NOTE

TIME

Display shows

xx:xx:xx

ACTION

Displays current

TIME setting

Display shows

xx:xx:xx

ACTION

TIME setting scrolls up

START

STOP

Display

xx:xx:xx

ACTION

Pump(s) starts;

press again pump(s)

stops

Display shows

xx:xx:xx

ACTION

TIME setting scrolls down

Page 51

6-14

Table 6-3 TIME MODE

KEY DISPLAY ACTION TAKEN

SHOWS AND PROCEDURE

xx:xx:xx

Pump motor’s power

NOTE: if you turn off the pump motor’s power, the pump stops

running.

To continue pumping, turn on the unit’s power. The display

returns to the STOPPED Display Mode and shows the time

elapsed during pumping. Then press the START/STOP key.

ON/OFF Switch

xx:xx:xx

Pump(s) stops; press again pump(s) starts

To resume pumping for the remainder of the TIME setting, press

the START/STOP key. The display enters the RUNNING Display

Mode, and the fluid begins to dispense.

Must STOP first!

LEDs indicate new pump direction

To select the other inlet and reverse the direction of pumping:

1. Press the START/STOP key. The display returns to the

STOPPED Display Mode.

2. Press the INLET SELECT key to reverse the direction of

pumping.

3. Press the START/STOP key again to resume pumping.

4. For detailed instructions on “Defining the Direction of

Pumping, refer to Section 5.2.

START

STOP

INLET

SELECT

STOP to Prime...

Pumps fluid at current rpm or flow rate

setting as long as the key is pressed

To prime a tube:

1. Press the START/STOP key to stop the pump. The display

returns to the STOPPED Display Mode.

2. Press and hold down the PRIME key to prime the tube.

3. Press the START/STOP key again to resume pumping.

4. For detailed instructions on “Priming a Tube”, refer to

Section 5.4.

xxx °C

Display alternates when pressed,

°C then °F.

NOTE: The TEMP key functions the same whether the pump is

stopped or running. Refer to Section 5.6.

PRIME

TEMP

RPM

xxx rpm

Displays actual RPM