Page 1

User’s Guide

omega.com

Shop online at

omega.com

TM

®

www.omega.com

e-mail: http://omegamanual.info

For latest information and

product manual visit

www.omegamanual.info.

ISO 9001

CERTIFIED

CORPORATE QUALIT Y

STAMFORD, CT

ISO 9002

CERTIFIED

CORPORATE QUALIT Y

MANCHESTER, UK

FMG-3000 SERIES Blind Version

Magmeter

Page 2

omega.com

omega.com

®

TM

OMEGAnet® Online Service

www.omega.com

Internet e-mail

info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certifi ed Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval, Quebec H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Español: (001) 203-359-7803 FAX: (001) 203-359-7807

info@omega.com.mx

e-mail: espanol@omega.com

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé arm

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342

e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certifi ed Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-48

e-mail: sales@omega.co.uk

.

dy 1868, 733 01 Karvin. 8

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certifi cation of its products to the European New Approach Directives.

OMEGA will add the CE mark to every appropriate device upon certifi cation.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifi cations without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

Omega FMG-3000 Series Magmeter

Topic: Page

1. Quick Start Guide 1

2. Specifi cations 2

3. Installation: Pipe Fittings 3

4. Selecting a Location 3

5. Hardware Confi guration 4

Topic: Page

7. Wiring the Magmeter with 4 to 20 mA Loop out 5

8. Wiring the Magmeter with Frequency Output 6

9. Calibration Data 7

10. Maintenance and Troubleshooting 11

11. Ordering Information 12

6. General Installation and Grounding Tips 5

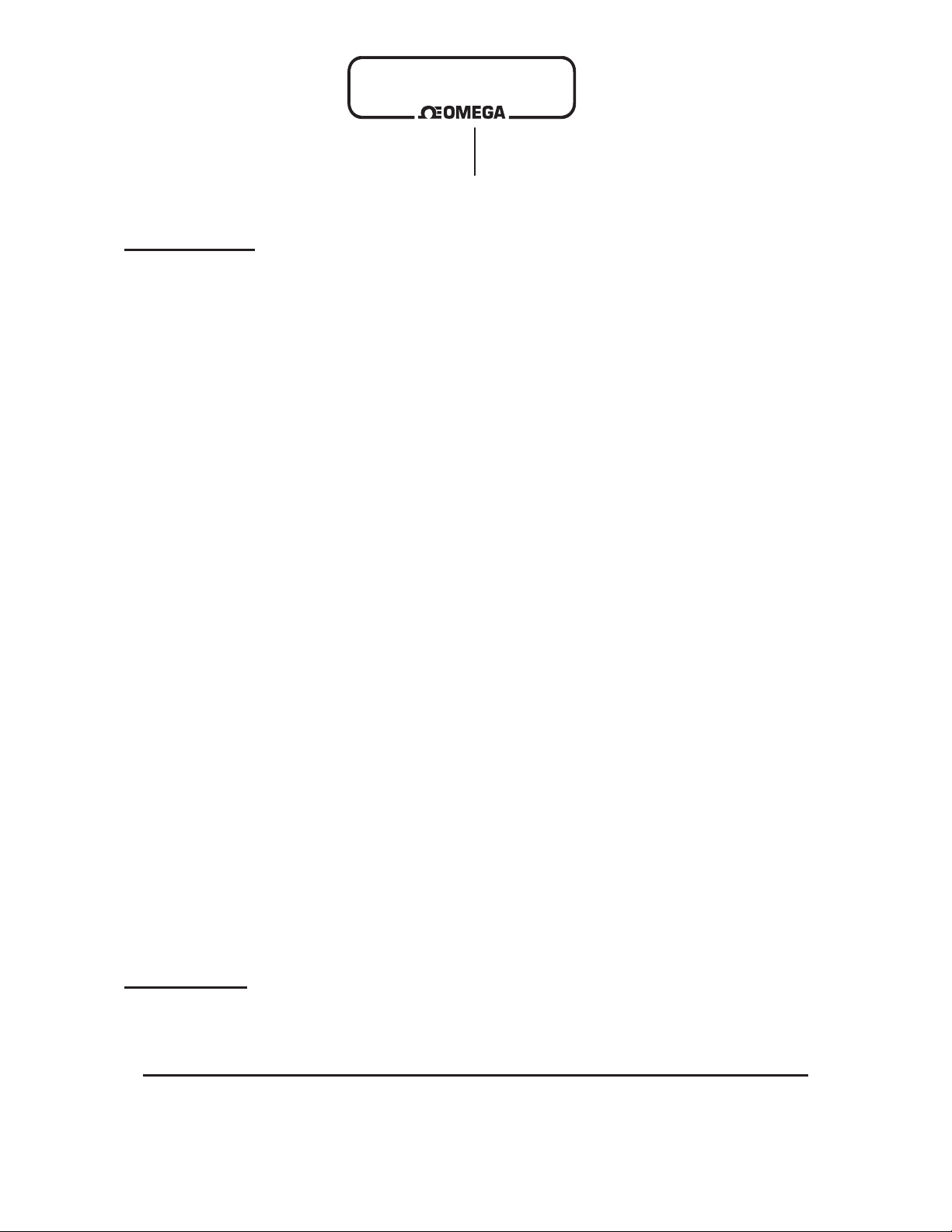

1. Quick Start Guide

This manual contains the general installation, wiring and calibration data for the Omega FMG-3000 Series Magmeter with Frequency or

Current output. The basic steps are outlined on this page. See each referenced section for detailed information.

HAND-TIGHTEN THE THREADED NUT ONTO THE

INSTALLATION FITTING. DO NOT USE TOOLS!

DO NOT USE THREAD SEALANT OR LUBRICANTS ON

THE FITTING THREADS OR THE SENSOR CAP.

1. Position the PIPE SIZE Jumper according

to your pipe size. See Sec. 5 Pg. 6.

2. Install the Magmeter into the pipe.

Use Omega installation fi ttings ONLY.

The installation fi tting is critical to

Magmeter performance.

See Sec. 3-4, Pg. 5.

3. Connect POWER and OUTPUT wiring.

FMG-3001 and FMG-3101 Frequency out:

See Sec. 8 Pg. 8.

FMG-3002 and FMG-3102 current out

wiring: See Sec. 7 Pg. 7.

FREQUENCY OUT

DO NOT REMOVE

1.

Sensor Type Pipe Size Jumper Position

½ in. to 2½ in.

FMG3001 DN15 to DN65

FMG3002 3 in. to 4 in.

DN80 to DN100

FMG3101 5 in. to 6 in.

FMG3102 DN125 to DN150

8 in.

DN200

FMG3201 10 in. to 12 in.

FMG3202 DN250 to DN300

Connect output signals and power

to this 4-terminal block.

JP2

4

3

2

1

3.

3.

4.

GROUNDING

Without a good Earth Ground, the

Magmeter may not operate effi ciently. See

Sec. 6 Pg. 7.

4. Route the wiring out through the two cable

ports. Use appropriate hardware to secure

the FMG-3000 from moisture intrusion.

One Liquid Tight Connector is included.

See Sec. 5 Pg. 6.

2.

3

Page 4

SAFETY INSTRUCTIONS

1. Depressurize and vent system prior to installation or removal.

2. Confi rm chemical compatibility before use.

3. Do not exceed maximum temperature/pressure specifi cations.

4. Wear safety goggles or face shield during installation/service.

5. Do not alter product construction.

6. Disconnect power before attempting any service or wiring.

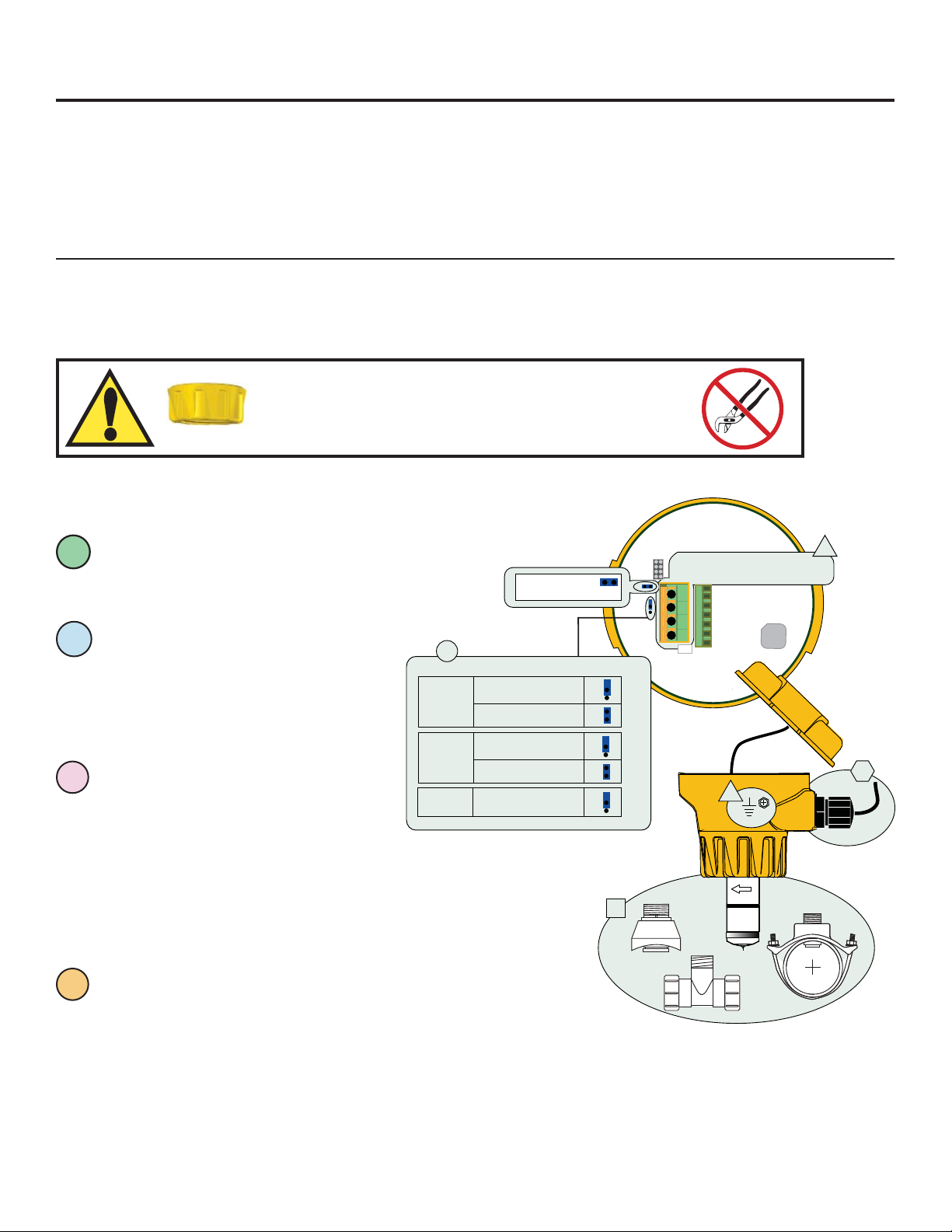

2. Specifi cations

Wetted Materials:

• Sensor body, electrodes and grounding ring:

• -PP: Polypropylene and 316L Stainless Steel

• -PVDF and 316L Stainless Steel

• O-rings: FPM standard

EPDM, (Perfl uoroelastomer optional)

Other Materials:

• Case: PBT

• Ground terminal: 316 Stainless Steel

Power Requirements

• 4 to 20 mA: 21.6 to 26.4 VDC, 22.1 mA maximum

400 mV p-p maximum ripple voltage

• Frequency: 5 to 26.4 VDC, 15 mA maximum

• Reverse polarity and short circuit protected

psi

bar

200

14

160

11

120

8

80

6

40

3

Operating Pressure

Pressure vs. Temperature

FMG-3000 series

Operating

Range

Performance

• Pipe Size Range: FMG-3000: ½ in. to 4 in.

FMG-3100: 5 in. to 8 in.

FMG-3200: 10 in. to 12 in.

• Flow Range Minimum: 0.05 m/s (0.15 ft/s)

Maximum: 10 m/s (33 ft/s)

• Linearity: ±(1% reading + 0.01 m/s)

±(1% reading + 0.033 ft/s)

• Repeatability ±0.5% of reading @ 25 °C

• Minimum Conductivity: 20 μS/cm

Output Specifi cations

Current output (4 to 20 mA)

• Programmable and eversible

• Loop Accuracy: 32 μA max. error

(@ 25 °C @ 24 VDC)

• Temp. drift: ±1 μA per °C max.

• Power Supply Rejection: ±1 μA per V

• Isolation: Low voltage <48 VAC/DC

from electrodes and auxiliary power

• Maximum Cable: 300 m (1000 ft)

• Maximum Loop Resistance: 300

• Error Condition: 22.1 mA

Frequency output:

• Max. Pull-up Voltage: 30 VDC

• Short Circuit Protected: 30 V @ 0 pull-up for one hour

• Reverse Polarity Protected - 40 V

• Overvoltage Protected to 40 V with pull-up resistor

• Max. Current Sink: 50 mA, current limited

• Maximum cable: 300 m (1000 ft)

Environmental Requirements

• Storage Temperature: -20 to 70 °C (-4 to 158 °F)

• Relative Humidity: 0 to 95% (non-condensing)

• Operating Temperature

Ambient: -10 to 70 °C (14 to 158 °F)

Media: 0 to 85 °C (32 to 185 °F)

°F

°C

0 40 80 120 160 200

-18 4

27

49

71 93

240

115

Media Temperature

Max. Operating Pressure: 10.3 bar @ 25 °C (150 psi @ 77 °F)

1.4 bar @ 85 °C (20 psi @ 185 °F)

Tests, Approvals & Standards

• NEMA 4X

• CE

Dimensions

94 mm

(3.7 in.)

79.25 mm

(3.12 in.)

3000 series = 58 mm (2.3 in.)

3100 series = 91 mm (3.6 in.)

3200 series = 167 mm (6.6 in.)

4

Page 5

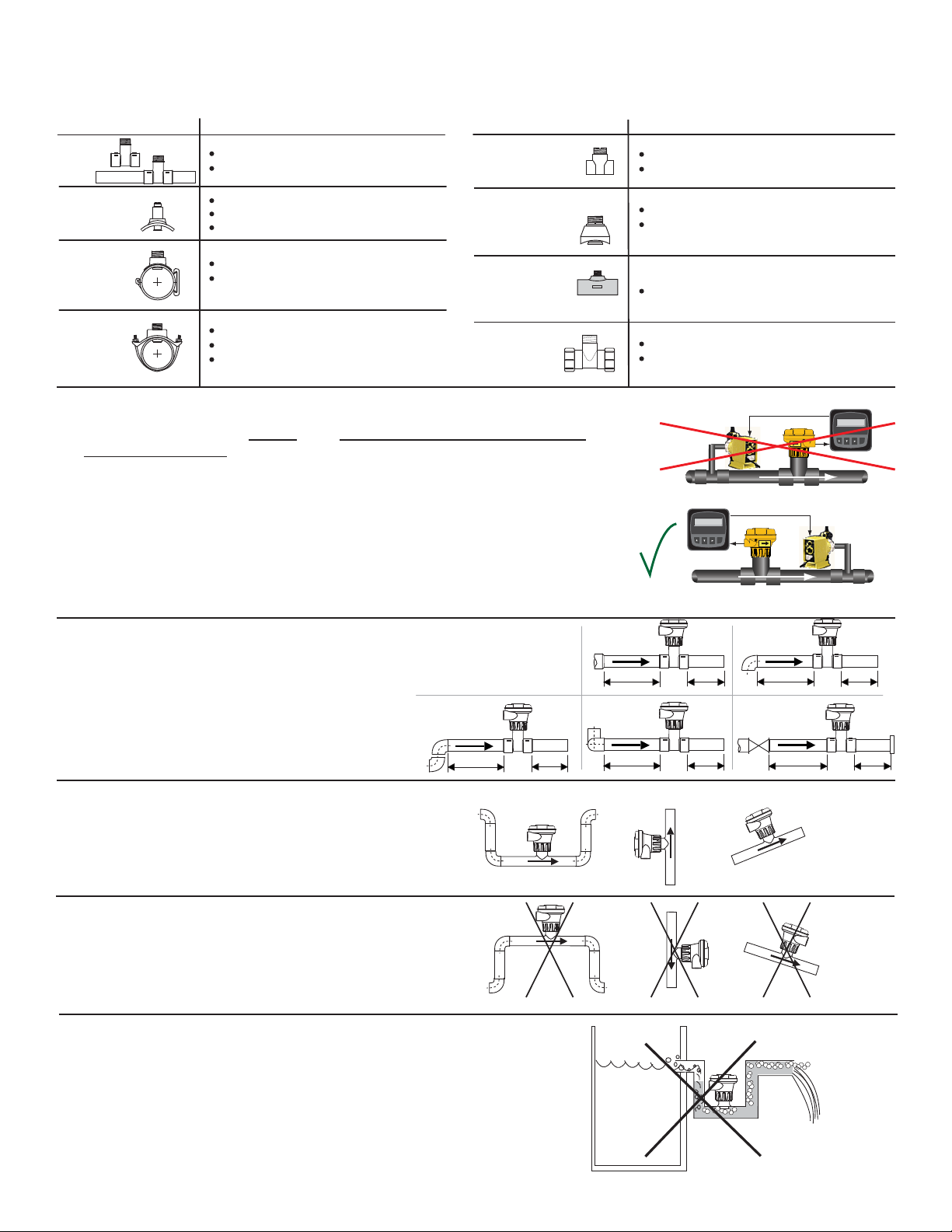

3. Installation: Pipe fi ttings

Omega offers a wide selection of installation fi ttings that control the position of the Magmeter electrodes in relation to the dimensions of

the pipe. You will fi nd a complete list of order numbers for installation fi ttings in the Calibration tables on pages 8-12.

Type Description

Plastic

tees

PVC

Glue-on

Saddles

0.5 to 2 inch versions

MPVC or CPVC

Available in 10 and 12 inch sizes only

Cut 2-1/2 inch hole in pipe

Weld in place using solvent cement

PVC

Saddles

2 to 4 inch, cut 1-7/16 inch hole in pipe

6 to 8 inch, cut 2-1/8 inch hole in pipe

Type Description

Iron, Carbon Steel,

316 SS Threaded

tees

Carbon steel &

stainless steel

Weld-on

Weldolets

Fiberglass

tees

FPT

Iron

Strap-on

saddles

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/8 inch hole in pipe

Special order 14 in. to 36 in.

Metric

Union

Fitting

4. Selecting a Location

• The FMG-3000 requires a full pipe and a fully developed turbulent fl ow profi le for

accurate measurement.

• If the piping system harbors air pockets or bubbles, take steps to locate the sensor

so the air pockets will not contact the electrodes.

• In vertical installations, assemble the unit so the conduit ports are facing downward.

This prevents condensation inside the conduit from being directed into the

electronics housing.

• Chemical injection systems can temporarily alter the fl uid conductivity and cause

anomalies in the magmeter measurement.

To avoid this problem, install the Magmeter UPSTREAM of the injection point.

0.5 to 2 in. versions

Mounts on threaded pipe ends

2 to 4 inch, cut 1-7/16 inch hole in pipe

Over 4 inch, cut 2-1/8 inch hole in pipe

1.5 in. to 2 in. PVDF insert

For pipes from DN 15 to 50 mm

PP or PVDF

Flow 6.25 GPM

Total 1234567.8>

Signet Flow

Transmitter

Flow 6.25 GPM

Total 1234567.8>

Signet Flow

Transmitter

Flow

ENTER

Flow

ENTER

Select a location with suffi cient distance of

straight pipe immediately upstream of the

sensor.

Locating the sensor in a trap or where the fl ow

is upward helps to protect the sensor from

exposure to air bubbles when the system is in

operation.

These confi gurations are not recommended

because it is diffi cult to keep the pipe full.

In a gravity-fl ow system, the tank must be designed

so the level does not drop below the outlet.

2 x 90° Elbow

25 x I.D. 5 x I.D.

Reducer

15 x I.D. 5 x I.D.

2 x 90° Elbow

3 dimensions

40 x I.D. 5 x I.D.

90° Elbow

20 x I.D. 5 x I.D.

Pump/Valve

50 x I.D. 5 x I.D.

OKOK OK

+

GF

+

GF

+GF+

+GF+

+

Vertical flow is OK if the pipe remains full at all times.

+

GF

+

+

This causes the pipe to draw air in from the tank.

If air bubbles pass across the Magmeter electrodes,

the output will become erratic.

5

Page 6

5. FMG-3000 Magmeter Confi guration

s

Whether using the FMG-3000 frequency or 4 to 20 mA output,

the wiring terminals located on the inside of the yellow cover are

JP2 is for factory use only.

MAKE NO CONNECTIONS.

Connect output cables to

this 4-terminal block.

identical. All of the connections from the Magmeter to external

equipment (Datalogger, Chart Recorder, Flow meter, etc.) are

made at the large 4-position terminal connector.

When the cover is removed the wiring from the sensor can be

seen connected to the smaller terminal block. These connections

should always remain connected to prevent inadvertent damage

or miswiring.

The terminals on the FMG-3000 Magmeter are designed for

conductors from 16 AWG to 22 AWG.

WARNING!

If the second conduit port is used, carefully drill the

opening.

(The plastic is too strong to be punched out.)

• Secure the Magmeter in a vise to prevent damage or injury.

• The plastic inside the port is very thin. Do not allow the drill to

penetrate too deeply and damage the Magmeter wiring.

This blue jumper must

be in place for the

magmeter to operate

correctly.

Set this blue jumper

according to the pipe size.

½ in. (DN15)

¾ in. (DN20)

1 in. (DN25)

1¼ in. (DN32)

1½ in. (DN40)

2 in. (DN50)

2½ in. (DN65)

5 in. (DN125)

6 in. (DN150)

10 in. (DN250)

12 in. (DN300)

3 in. (DN80)

4 in. (DN100)

8 in. (DN200)

Use the yellow decal to mark

the direction of flow on the pipe

JP2

4

3

2

1

External Earth Ground Terminal

Important:

• The directional arrow on the body of the sensor must be pointed DOWNSTREAM

for correct operation.

• The FLOW arrow decal can be placed directly on the pipe to identify the direction of fl ow.

• Use a cable gland or a liquid tight connector to seal the cable ports from water intrusion.

• The yellow housing may be reversed to align the conduit ports as required.

• If the Magmeter is installed on a vertical pipe, the conduit ports should be turned to point downward.

This will prevent condensation from being channeled into the enclosure.

• Use plumber's tape or a suitable sealant on cable ports.

Blue

Brown

Black

Red

Yellow

White

Not used

Flow

The factory connects

the sensor cable to the terminal

inside the yellow cover.

FPM-5000-LTCK

Liquid tight connector

(one supplied)

Sensor grounding ring

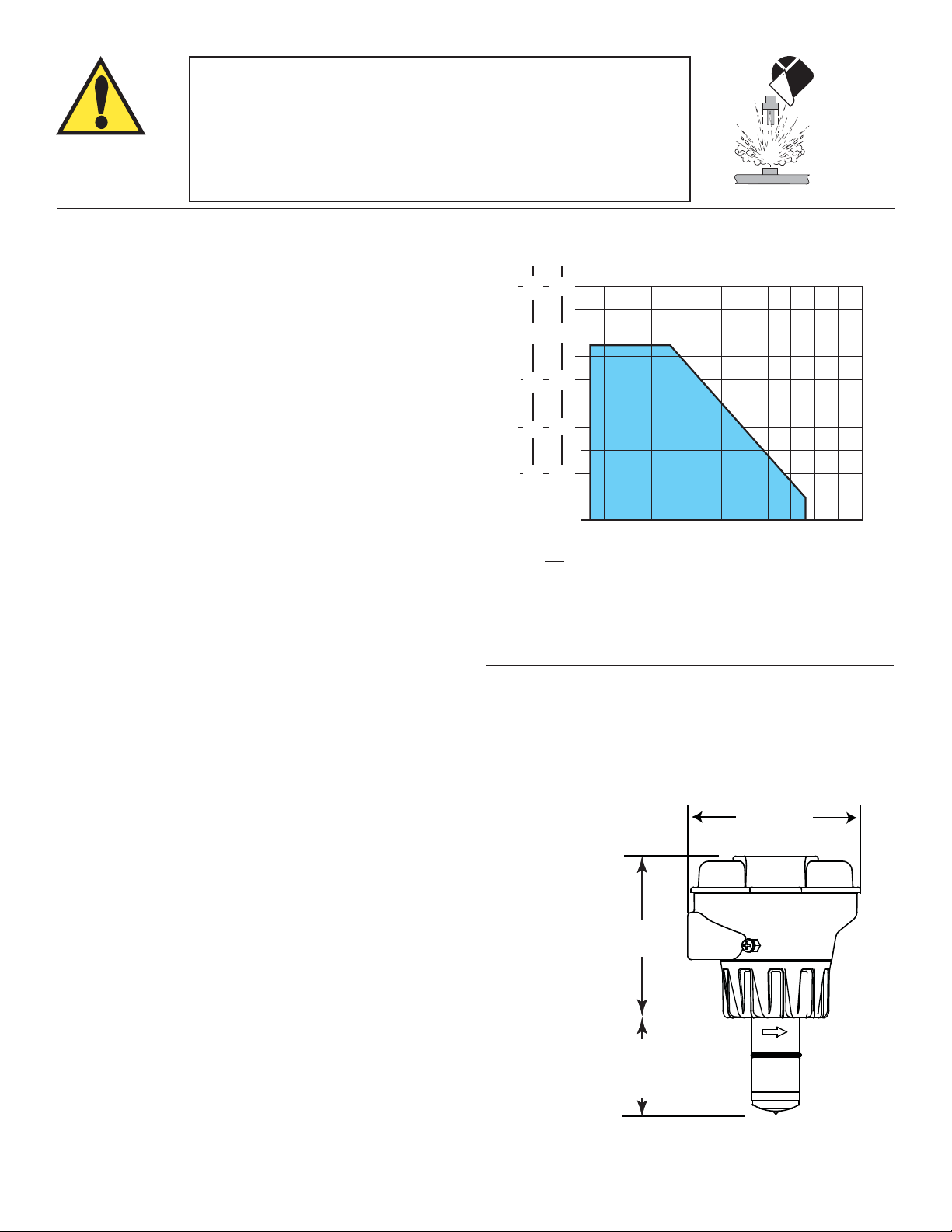

WARNING!

Flow

Do not use any tools to

tighten the yellow retaining

cap. DO NOT USE thread

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

THE SENSOR BEING EJECTED FROM THE PIPE!

• DO NOT USE ANY TOOLS ON THE RETAINING CAP. HAND

TIGHTEN ONLY.

• LUBRICATE O-RINGS WITH A NON-PETROLEUM BASED,

Lubricate O-rings with a viscous

non-petroleum based lubricant

(grease) compatible with the system.

sealant orlubricants on

retaining cap!

VISCOUS LUBRICANT (GREASE) COMPATIBLE WITH THE

SYSTEM.

• DO NOT USE THREAD SEALANT OR LUBRICANTS ON

THE RETAINING CAP OR ON THE PLASTIC FITTING

DO NOT USE thread sealant

or lubricants on the fitting threads.

THREADS.

• IF LEAKING IS OBSERVED FROM THE RETAINING CAP,

IT INDICATES DEFECTIVE OR WORN O-RINGS ON THE

SENSOR. DO NOT ATTEMPT TO CORRECT BY FURTHER TIGHTENING.

CHEMICAL COMPATIBILITY WARNING

The retaining nuts of Magmeters are not designed for prolonged contact with aggressive substances. Strong acids, caustic

substances and solvents or their vapor may lead to failure of the retaining nut, ejection of the sensor and loss of the process fl uid

with possibly serious consequences, such as damage to equipment and serious personal injury. Retaining nuts that may have been

in contact with such substances, e.g. due to leakage or spilling, must be replaced.

6

Page 7

6. General Installation and Grounding Tips

Sensor conditioning

The Magmeter output signal may be unstable immediately after installation. Allowing the sensor to soak in a full pipe (or in any

container of water) for 24 hours will stabilize the performance.

• Very low conductivity fl uids may require a longer conditioning period. The Magmeter may not operate properly in fl uids where the

conductivity is less than 20 μS/cm.

Grounding

The FMG-3000 Magmeter is unaffected by moderate levels of electrical noise. However, in some applications it may be necessary to

ground portions of the system to eliminate electrical interference. The grounding requirements will vary with each installation.

One or more of the following steps may be

applied if the FMG-3000 Magmeter is affected by

electrical noise:

The ground terminal on the outside of the

yellow housing is connected internally

to the grounding ring at the tip of the

sensor. Connect a wire (14 AWG/1.5 mm

recommended) from this terminal directly to

a local Earth ground.

Instrument

2

Install fl uid grounding devices immediately upstream and

downstream of the Magmeter.

Connect the fl uid grounds to the Earth ground terminal on the

FMG-3000.

Use fl anged grounding rings or metal electrodes on plastic pipes,

or metal clamps on metal pipes.

Fluid grounds must be in direct contact with the fl uid, and as

near to the Magmeter as possible.

The shield from the output cable must be terminated at the

remote instrument ONLY.

This shield must not be connected at both ends!

Connect an additional wire (minimum AWG 14/1.5 mm

remote instrument ground to the Magmeter ground terminal.

2

) from the

3.

4.

Do not terminate

shield at Magmeter

4 in. to 50 in.

(10 cm to 1.3 m)

Sensor

Grounding ring

Grounding rings on plastic pipe

(Install between flanges)

or

metal straps on metal pipe

1.

Earth ground

4 in. to 50 in.

(10 cm to 1.3 m)

2. 2.

7. Wiring the FMG-3002, 3102 and 3202 Magmeter with 4 to 20 mA Loop Output

The FMG-3002, 3102 and 3202 Magmeters are traditional 2-wire passive 4 to 20 mA loop transmitters.

• External loop power (24 VDC ±10%) is required.

• The maximum loop resistance the Magmeter can accomodate is 300 Ω.

• All FMG-3002, 3102 and 3202 Magmeters are shipped from the factory with the 4 to 20 mA output scaled for 0 to 5 m/s (0 to

16.4 ft/s). The Calibration charts on pages 8-12 list the 20 mA setpoint for each installation fi tting. Use this information to program

the 4 to 20 mA range of the loop device (PLC, Datalogger, recorder, etc.)

FMG-3000 Series Magmeter

4

Loop - (Ground)

3

2

1

Loop + (24 VDC)

+

+

4 to 20 mA Loop

-

-

monitor

(Maximum 300 Ω)

24 VDC ± 10%

7

Page 8

8. Wiring the FMG-3001 and FMG-3101 with Frequency output

• The FMG-3001 and FMG-3101 Magmeters output an open collector frequency signal.

• A 10 KΩ pull up resistor must be connected between terminals 1 and 2 if the magmeter is used with third-party equipment..

Blue Jumper

ON

Frequency

4

3

Magmeter

Not used

4

Ground

3

Frequency Out

2

10KW

1

Install a pull-up resistor when connecting the

Magmeter to other manufacturer's flowmeters.

5 to 24 VDC

Magmeter FP90 Flow Transmitter

Not used

4

3

2

1

Ground

Frequency

5 to 24 VDC

9

8

7

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

Connect AUX power on

the FP90 to provide the

power to the FMG3000

OPEN COLLECTOR

output.

9. Calibration Data: K-Factors* and Full Scale Current Values

Metal Installation Fittings

Iron Saddles

PIPE SIZE FITTING K-Factor K-Factor 20 mA= 20 mA=

(IN.) TYPE Gallons Liters* in GPM in LPM

SCH 80 IRON SADDLE ON SCH 80 PIPE

2 FP-5320GIS 194.85 51.48 153.96 582.75

2½ FP-5325GI 142.28 37.59 210.86 798.10

3 FP-5330GI 87.53 23.13 342.72 1297.20

4 FP-5340GI 40.62 10.73 738.58 2795.54

5 FP-5350GI 29.28 7.74 1024.43 3877.48

6 FP-5360GI 22.30 5.89 1345.58 5093.03

8 FP-5380GI 12.52 3.31 2395.41 9066.64

10 FP-5381GI 7.94 2.10 3778.75 14302.5

12 FP-5382GI 5.65 1.49 5311.45 20103.8

SCH 80 IRON SADDLE ON SCH 40 PIPE

2 FP-5320GIS 185.35 48.97 161.85 612.61

2½ FP-5325GI 127.47 33.68 235.36 890.83

3 FP-5330GI 76.62 20.24 391.54 1481.99

4 FP-5340GI 40.23 10.63 745.72 2822.57

5 FP-5350GI 27.32 7.22 1098.24 4156.83

6 FP-5360GI 19.71 5.21 1521.92 5760.46

8 FP-5380GI 11.61 3.07 2584.23 9781.30

10 FP-5381GI 7.36 1.94 4078.8 15438.2

12 FP-5382GI 5.18 1.37 5793.39 21927.9

8

Page 9

9. Calibration Data: K-Factors* and Full Scale Current Values

Plastic Installation Fittings: PVC Tees and Saddles

PIPE SIZE FITTING K-Factor K-Factor 20 mA= 20 mA=

(IN.) TYPE Gallons Liters* in GPM in LPM

SCH 80 PVC TEES FOR SCH 80 PVC PIPE

½ FP-5305M 2277.00 601.58 13.10 49.60

¾ FP-5307M 1407.6 371.90 20.97 79.38

1 FP-5310M 861.17 227.52 34.21 129.50

1¼ FP-5312M 464.91 122.83 67.10 253.99

1½ FP-5315M 331.43 87.56 92.54 350.25

2 FP-5320M 192.89 50.96 145.15 549.38

SCH 80 PVC TEES FOR SCH 80 CPVC PIPE

½ FP-5305CM 2277.0 601.58 13.18 49.87

¾ FP-5307CM 1407.6 371.90 21.31 80.67

1 FP-5310CM 861.17 227.52 34.84 131.86

1¼ FP-5312CM 464.91 122.83 64.53 244.24

1½ FP-5315CM 331.43 87.56 90.52 342.62

2 FP-5320CM 192.89 50.96 155.53 588.70

SCH 80 PVC SADDLES FOR SCH 80 PVC PIPE

2 FP-5320S 193.83 51.21 154.77 585.81

2½ FP-5325S 138.01 36.46 217.38 822.78

3 FP-5330S 83.89 22.16 357.62 1353.60

4 FP-5340S 40.88 10.80 733.88 2777.74

6 FP-5360S 22.53 5.95 1331.85 5041.06

8 FP-5380S 12.52 3.31 2395.41 9066.64

10 FP-5381S 7.94 2.10 3778.75 14302.57

12 FP-5382S 5.71 1.51 5256.69 19896.57

SCH 80 PVC SADDLES FOR SCH 40 PVC PIPE

2 FP-5320S 180.01 47.56 166.66 630.81

2½ FP-5325S 123.72 32.69 242.49 917.82

3 FP-5330S 75.81 20.03 395.71 1497.76

4 FP-5340S 41.87 11.06 716.56 2712.19

6 FP-5360S 19.71 5.21 1521.92 5760.46

8 FP-5380S 11.73 3.10 2558.12 9682.50

10 FP-5381S 7.43 1.96 4037.60 15282.3

12 FP-5382S 5.23 1.38 5734.87 21706.48

9

Page 10

9. Calibration Data: K-factors* and Full Scale Current Values

Plastic Installation Fittings for Metric Pipes:

Polypropylene True Union Tees

PVDF True Union Tees

PVC True Union Tees

PIPE SIZE FITTING K-Factor K-Factor 20 mA= 20 mA=

(IN.) TYPE Gallons Liters* in GPM in LPM

POLYPROPYLENE FITTINGS (DIN/ISO ,BS, ANSI)

½ FP-5105PO 2192.73 579.32 13.68 51.78

¾ FP-5107PO 1327.81 350.81 22.59 85.52

1 FP-5110PO 737.16 194.76 40.70 154.04

1¼ FP-5112PO 453.46 119.81 66.16 250.41

1½ FP-5115PO 275.03 72.66 109.08 412.86

2 FP-5120PO 156.87 41.45 191.24 723.83

PVDF FITTINGS (DIN/ISO ,BS, ANSI)

½ FP-5105 1946.49 514.26 15.41 58.34

¾ FP-5107 1158.05 305.96 25.91 98.05

1 FP-5110 749.09 197.91 40.05 151.58

1¼ FP-5112 439.51 116.12 68.26 258.36

1½ FP-5115 248.93 65.77 120.52 456.16

2 FP-5120 146.85 38.80 204.30 773.26

PVC FITTINGS (DIN/ISO, BS, ANSI)

½ FP-5105M 2067.76 546.30 14.51 54.91

¾ FP-5107M 1136.61 300.29 26.39 99.90

1 FP-5110M 716.52 189.31 41.87 158.47

1¼ FP-5112M 446.07 117.85 67.25 254.56

1½ FP-5115M 278.83 73.67 107.59 407.23

2 FP-5120M 159.36 42.10 188.26 712.55

10

Page 11

9. Calibration Data: K-factors* and Full Scale Current Values

Metal Installation Fittings:

Carbon Steel Tees and Weldolets

Stainless Steel Tees and Weldolets

Galvanized Iron Tees

PIPE SIZE FITTING K-Factor K-Factor 20 mA= 20 mA=

(IN.) TYPE Gallons Liters* in GPM in LPM

CARBON STEEL TEES ON SCH 40 PIPE

½ FM-5305CS 1572.66 415.50 19.08 72.20

¾ FM-5307CS 1086.73 287.11 27.61 104.49

1 FM-5310CS 582.34 153.86 51.52 194.99

1¼ FM-5312CS 377.48 99.73 79.48 300.81

1½ FM-5315CS 267.79 70.75 112.03 424.02

2 FM-5320CS 167.85 44.35 178.73 676.48

STAINLESS STEEL TEES ON SCH 40 PIPE

½ FMG-5305 1601.26 423.05 18.74 70.91

¾ FMG-5307 937.78 247.76 31.99 121.08

1 FMG-5310 606.18 160.15 49.49 187.32

1¼ FMG-5312 279.68 73.89 107.26 405.99

1½ FMG-5315 147.65 39.01 203.19 769.06

2 FMG-5320 111.90 29.56 268.09 1014.73

STAINLESS STEEL WELDOLETS ON SCH 40 PIPE

2½ FMG-5325 106.31 28.09 282.19 1068.10

3 FMG-5330 72.27 19.09 415.12 1571.25

4 FMG-5340 36.84 9.73 814.34 3082.28

4 FMG-5350 29.28 7.73 1024.70 3878.50

4 FMG-5360 20.29 5.36 1478.26 5595.21

8 FMG-5380 11.73 3.10 2557.72 9680.96

10 FMG-5381 7.45 1.97 4028.83 15249.1

12 FMG-5382 5.24 1.39 5722.73 21660.5

CARBON STEEL WELDOLETS ON SCH 40 PIPE

2½ FM-5325CS 105.70 27.93 283.82 1074.27

3 FM-5330CS 70.68 18.67 424.45 1606.56

4 FM-5340CS 36.38 9.61 824.65 3121.30

4 FM-5350CS 29.28 7.73 1024.70 3878.50

6 FM-5360CS 20.29 5.36 1478.26 5595.21

8 FM-5380CS 11.73 3.10 2557.72 9680.96

10 FP-5381CS 7.45 1.97 4028.83 15249.1

12 FP-5382CS 5.24 1.39 5722.73 21660.5

GALVANIZED IRON TEES ON SCH 40 PIPE

1 FP-5310GI 558.50 147.56 53.71 203.31

1¼ FP-5312GI 334.45 88.36 89.70 339.51

1½ FP-5315GI 248.97 65.78 120.49 456.07

2 FP-5320GI 146.00 38.57 205.48 777.76

11

Page 12

9. Calibration Data: K-factors* and Full Scale Current Values

Metal Installation Fittings:

Bronze and Copper Tees and Brazolets

PIPE SIZE FITTING K-Factor K-Factor 20 mA= 20 mA=

(IN.) TYPE Gallons Liters* in GPM in LPM

BRONZE TEES ON SCH 40 PIPE

1 FP-5310BR 582.34 153.86 51.52 194.99

1¼ FP-5312BR 330.54 87.33 90.76 343.53

1½ FP-5315BR 254.76 67.31 117.76 445.71

2 FP-5320BR 157.36 41.58 190.64 721.58

COPPER TEES FITTING ON COPPER PIPE SCH K

½ FP-5305CU 2459.19 649.72 12.20 46.17

¾ FP-5307CU 1108.02 292.74 27.08 102.48

1 FP-5310CU 649.87 171.70 46.16 174.73

1¼ FP-5312CU 422.03 111.50 71.09 269.06

1½ FP-5315CU 281.43 74.35 106.60 403.47

2 FP-5320CU 136.02 35.94 220.55 834.78

COPPER TEES FITTING ON COPPER PIPE SCH L

½ FP-5305CU 2406.30 635.75 12.47 47.19

¾ FP-5307CU 1174.77 310.37 25.54 96.66

1 FP-5310CU 672.28 177.62 44.62 168.90

1¼ FP-5312CU 402.84 106.43 74.47 281.87

1½ FP-5315CU 294.99 77.94 101.70 384.92

2 FP-5320CU 149.63 39.53 200.50 758.89

COPPER/BRONZE BRAZOLET ON SCH 40 PIPE

2½ FP-5325BR 117.31 30.99 255.74 967.96

3 FP-5330BR 78.62 20.77 381.58 1444.28

4 FP-5340BR 45.13 11.92 664.77 2516.15

5 FP-5350BR 32.79 8.66 914.91 3462.95

6 FP-5360BR 22.73 6.01 1319.87 4995.72

8 FP-5380BR 13.14 3.47 2283.68 8643.71

10 FP-5381BR 8.34 2.20 3597.17 13615.29

12 FP-5382BR 5.87 1.55 5109.58 19339.76

12

Page 13

10. Maintenance

The FMG-3000 series Magmeter requires very little maintenance. There are no user-serviceable components in the Magmeter.

• If the fl uid contains deposits and solids that may coat the electrodes, a regular cleaning schedule is recommended.

• Do not use abrasive materials on the metal electrodes. Clean with soft cloth and mild detergent only.

• Use a cotton swab and mild detergent to remove deposits on the metal electrodes at the tip of the sensor.

10.1. Environmental Recommendations:

• When used properly, this product presents no inherent danger to the environment.

• Please follow local ordinance when disposing of this or any product with electronic components.

10.2. Troubleshooting

Symptom Possible Cause Solution

Relocate the magmeter to have straight

uninterrupted pipe upstream of the sensor for

at least 10 x the pipe diameter.

Eliminate air bubbles in the pipe.

Remove the magmeter and reinstall with

the fl ow direction arrow on the sensor body

pointed DOWNSTREAM.

Review the grounding of the magmeter and

the pipe. Install adequate Earth ground to

allow the Magmeter to operate properly.

Soak sensor overnight in fl uid.

Increase the Low Flow Cutoff.

Modify grounding to protect the Magmeter

from interference.

Install 10 kΩ resistor. (page 8)

Unsuitable application for Magmeter.

Output is erratic and unstable.

Output is not 0 when fl ow is stopped.

4 to 20 mA output is incorrect.

Frequency output is inoperative

Loop output is inoperative.

Output is 22.1 mA

Magmeter installed too close to upstream

obstruction.

Magmeter located in area exposed to air

bubbles/pockets.

Magmeter is installed in pipe backwards.

Electrical noise is interfering with the

measurement.

Electrodes are coated with solids. Carefully clean the electrodes.

New sensor; metal surface not properly

conditioned.

Electrodes not adequately conditioned. Soak sensor overnight in fl uid.

Vibration or other movement in pipe causes

magmeter to detect fl ow.

Electrical noise interference

Defective Magmeter Return to factory for service.

4 to 20 mA is not scaled same as Loop device. Respan Loop device to match Magmeter.

Range Jumper not placed correctly. Set Range Jumper correctly.

Defective Magmeter Return to factory for service

Blue jumper not in correct position Place blue jumper correctly. (page 6)

Wiring is not correct. Check wiring, make corrections.

Frequency input to other manufacturer's fl ow

instrument does not have pull-up resistor.

Conductivity is less than 20 μS/cm (The fl uid is

too clean for Magmeter.)

Electronic component failure. Return Magmeter to factory.

Troubleshooting with the RED and BLUE lights

The FMG-3000 uses two colored LEDs to indicate the status of the instrument.

They are located at the top of the magmeter, inside the clear plastic cap.

No Lights: The power is off or the sensor is not connected

Solid Blue (D7): The power is on, the pipe is full, but there is no fl ow in the pipe.

Blinking Blue (D7): Normal operation, blink rate is proportional to the fl ow rate.

Alternating Red-Blue: Empty pipe indication (electrodes are not wet.)

Blinking Red (D6): System errors (Electrical noise interference)

Solid Red (D6): Instrument error (defective electronics component)

JP2

4

3

2

1

D7

D6

Flow Flow

13

Page 14

11. Ordering Information

Order number Output Body material/Electrode material, Pipe size range

FMG-3001-PP Freq PP/316SS, 0.5 to 4 in.

FMG-3101-PP Freq PP/316SS, 5 to 8 in.

FMG-3201-PP Freq PP/316SS,10 to 12 in.

FMG-3001-PVDF-HA Freq. PVDF/Hast, 0.5 to 4 in.

FMG-3101-PVDF-HA Freq PVDF/Hast, 5 to 8 in.

FMG-3201-PVDF-HA Freq PVDF/Hast,10 to 12 in.

FMG-3002-PP Loop PP/316SS, 0.5 to 4 in.

FMG-3102-PP Loop PP/316SS, 5 to 8 in.

FMG-3202-PP Loop PP/316SS, 10 to 12 in.

FMG-3002-PVDF-HA Loop PVDF/Hast, 0.5 to 4 in.

FMG-3102-PVDF-HA Loop PVDF/Hast, 5 to 8 in.

FMG-3202-PVDF-HA Loop PVDF/Hast,10 to 12 in.

Replacement Parts and Accessories

FPP-1220-0021 O-ring, FPM

FPP-1224-0021 O-ring, EPDM

FPP-1228-0021 O-ring, FFPM

FPM-5000-LTCK Liquid Tight Connector Kit

14

Page 15

USASA

MAD E

IN

IN

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period

of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the

normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers

receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department

will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by

OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY

does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling,

improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This

WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having

been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specifi cation;

misapplication; misuse or other operating conditions outside of OMEGA’s control. Components which wear are not

warranted, including but not limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes

responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its

products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that

the parts manufactured by it will be as specifi ed and free of defects. OMEGA MAKES NO OTHER WARRANTIES

OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnifi cation, strict liability

or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall

OMEGA be liable for consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component”

under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on

humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on

humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER

language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage

whatsoever arising out of the use of the Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RETURNING

ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR) NUMBER FROM

OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING DELAYS). The assigned AR

number should then be marked on the outside of the return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.

FOR WARRANTY RETURNS, please have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number under which the product was

PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specifi c problems relative to

the product.

FOR NON-WARRANTY REPAIRS,

current repair charges. Have the following information

available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST of the

repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specifi c problems relative to

the product.

consult OMEGA for

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers

the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2011 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, reproduced,

translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of

OMEGA ENGINEERING, INC.

Page 16

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

•

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

•

Wire: Thermocouple, RTD & Thermistor

•

Calibrators & Ice Point References

•

Recorders, Controllers & Process Monitors

•

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

•

Transducers & Strain Gages

•

Load Cells & Pressure Gages

•

Displacement Transducers

•

Instrumentation & Accessories

FLOW/LEVEL

•

Rotameters, Gas Mass Flowmeters & Flow Computers

•

Air Velocity Indicators

•

Turbine/Paddlewheel Systems

•

Totalizers & Batch Controllers

pH/CONDUCTIVITY

•

pH Electrodes, Testers & Accessories

•

Benchtop/Laboratory Meters

•

Controllers, Calibrators, Simulators & Pumps

•

Industrial pH & Conductivity Equipment

DATA ACQUISITION

•

Data Acquisition & Engineering Software

•

Communications-Based Acquisition Systems

•

Plug-in Cards for Apple, IBM & Compatibles

•

Datalogging Systems

•

Recorders, Printers & Plotters

HEATERS

•

Heating Cable

•

Cartridge & Strip Heaters

•

Immersion & Band Heaters

•

Flexible Heaters

•

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

•

Metering & Control Instrumentation

•

Refractometers

•

Pumps & Tubing

•

Air, Soil & Water Monitors

•

Industrial Water & Wastewater Treatment

•

pH, Conductivity & Dissolved Oxygen Instruments

6-2551.090-OM (F-3/12) M-4210/0312

Loading...

Loading...