Page 1

User’s Guide

Shop online at

www.omega.com

e-mail: info@omega.com

DPF75, DPF76

M1090 /071603

AND DPF78 SERIES

Rate/Totalizer

Page 2

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Rudé armády 1868, 733 01 Karviná 8

TEL: +420 (0)69 6311899 FAX: +420 (0)69 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

TEL: +33 (0)130 621 400 FAX: +33 (0)130 699 120

Toll Free in France: 0800-4-06342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.dl

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 3

TABLE OF CONTENTS

QUICK SET-UP GUIDE ..................................................................................................... ii

SPECIFICATIONS ............................................................................................................. 1

HOW TO MOUNT THE UNIT .............................................................................................2

WIRING ..............................................................................................................................3

UP/DOWN CONTROL AND QUADRATURE INPUTS ...................................................... 3

CONNECTING AC/DC POWER ........................................................................................ 4

WIRING CONSIDERATIONS ............................................................................................4

TYPICAL SENSOR HOOKUP ...........................................................................................4

TYPICAL QUADRATURE HOOKUP .................................................................................4

WHAT CAN YOU VIEW .....................................................................................................5

OUTPUT JUMPER SELECTIONS ..................................................................................... 5

MILLIVOLT INPUT OPTION JUMPER SELECTIONS .......................................................5

OPERATING FRONT PANEL ............................................................................................ 6

PROGRAMMING FLOW CHART ......................................................................................6

PROGRAM CODES & DESCRIPTIONS ...........................................................................7

TERMINATIONS ................................................................................................................8

CALCULATING SCALE FACTORS ...................................................................................9

PROGRAMMING PROCEDURE ..................................................................................... 10

SETTING SCALING FACTORS .......................................................................................10

SETTING THE COUNTER ...............................................................................................11

SETTING THE RATE .......................................................................................................12

SETTING THE LOCK CODE & LOCKING THE UNIT .....................................................13

SETTING THE RELAYS & PRESETS .............................................................................14

OUTPUT WIRING ............................................................................................................15

ANALOG OUTPUT OPTION ............................................................................................16

RS232/RS422 SERIAL COMMUNICATIONS .................................................................. 17

RS232/RS422 WIRING .................................................................................................... 19

TROUBLESHOOTING GUIDE .........................................................................................20

UNPACKING

Remove the Packing List and verify that you have received all equipment. If you have any

questions about the shipment, please call OMEGA Customer Service Department at

1-800-622-2378 or (203) 359-1660.

When you receive the shipment, inspect the container and equipment for any signs of damage.

Note any evidence of rough handling in transit. Immediately report any damage to the shipping

agent.

NOTE

The carrier will not honor any claims unless all shipping material is saved

for their examination. After examining and removing contents, save

packing material and carton in the event reshipment is necessary.

i

Page 4

QUICK SET-UP GUIDE

1) Determine what function the panel meter is to perform, e.g., rate display with alarm, batch

control, totalizer, etc.

2) Ensure compatibility with sensor. The DPF70 panel meters require a pulse (or contact

closure) input. The pulse must exceed 3 VDC and drop below 1 VDC. If necessary, as in the

case of paddle wheel, turbine meter or other types of inductive pick-up sensors, a signal

conditioner or pulse amplifier (such as FLSC-AMP) can be used.

3) The wiring is explained on pages 3 and 4. The 12 VDC output can be used to power the

FLSC-AMP. For the DPF75, a single input at pin 5 can be jumpered to pin 6: input B will be

the grand total.

4) The relay function can be altered by cutting and/or soldering jumper traces as shown on

page 5.

5) There are two main operating modes: RUN, PROGRAM. (See page 6 for a summary). In the

RUN mode, the view key allows you to toggle the display for rate, batch and grand total. The

PRE A, PRE B keys allow you to see and set the relay trigger points. The lock key allows you

to lock and unlock the keypad functions by entering the lock-out code.

The PROGRAM mode must be accessed to set up the function of the display. In this mode,

the RST key enters the displayed value into memory. The PRGM key toggles the selections

and the arrow keys bump that digit up to the next value or change the decimal point location.

PROGRAMMING EXAMPLE

For this example, let's assume you have an FP-5300 paddle wheel sensor, an FP-5310 1" fitting, the

FLSC-AMP pulse amplifier and DPF75. You want to see flow rate (GPM) batch and grand total. The

signal K-factor is 183.66 pulses/gallon, (from the manual for the FP-5300 flow sensor). Here are the

programming steps you will see, starting on page 1.

FACTOR STEP 1: DPF75, DPF76, & DPF78

A,) Set the decimal point for "dPFA" to allow two decimal places using the UP arrow key.

B.) Enter the K-factor next: 183.66, using the arrow keys.

C.) Do the same for "dPFB" (DPF75 only).

D,) Choose "HI CPS", as the input will exceed 40 Hz (DPF78 only).

ii

Page 5

COUNTER STEP 2: DPF75, DPF76:

A,) Reset to zero "rST 0" will allow us to count up. "SET Pr" counts down from the preset value.

B.) To read the total in whole gallons, set the decimal point to the far right.

C.) Since you do not want to sum or take the difference of two inputs, choose "A SEP B" (DPF75

only).

D.) The frequency will exceed 40 Hz, so you will need to select "HI CPS". "LO CPS" provides

debounce filtering for contact closures.

RATE STEP 3: DPF75, DPF78

A.) Select "SCALE" to engage the K-factor.

B.) Select "=60".

C.) Normalize at 1.5 seconds.

D.) Set 4 significant figures.

E.) Set 02 sec delay.

LOCK STEP 4: DPF75, DPF76 & DPF78

Before you finish this step, write down your personal lock-out code and store it in a safe place. Here

is where you select and enter the code and what will be locked. To lock the meter you must wait until

you are in the RUN mode. Press the "LOCK" key, use the arrows to display your code, then Enter.

Repeat to unlock.

RELAYS STEP 5: DPF75

The DPF76 relays can only trigger on batch or total. The DPF78 relays can only trigger on rate. The

DPF75 relays can be programmed to trigger on rate or total. The relay setpoints for rate or total for

all versions with relays are set with the PRE A and PRE B buttons. When the relays are set for nonlatching, the batch total will automatically reset at the batch preset. The programming is now complete. Here is what you will see with 100 Hz input frequency (equal to 32.66 GPM flow rate). The

rate is: "r 32.66". The batch will continuously increase: ("480"); the grand total will also continuously

increase ("...4.8.0"). Notice that the decimals points for the grand total are inverted - all are lit except

where the decimal point is actually located.

To read total gallons to a tenth of a gallon: in Step 2, change the dPLoC to allow one decimal place

"XXX.X" for the counter. But this will cause a shift in the rate display so you will also need to shift the

K-factor in Step 1. Change the K-factor to 18.366 to read the correct units. Now the 100 Hz signal

will yield "r 32.66", "480.0", ". . 4.8.00.".

iii

Page 6

DESCRIPTION & SPECIFICATIONS

DESCRIPTION:

The OMEGA DPF70 is a dual input (channel A and B) counter/

ratemeter, each with its own 5 digit dividing scale factor. The two 5

AMP preset relay outputs can be programmed by the user to apply

to the "A" total counter, the "A" ratemeter, or the "B" counter or the

net total of A and B inputs. The user can view the Net Total of

"A+B", the Net Total of "A-B", the rate of A, or A and B counters

separately. The "DPF75" version shows rate and total (as described above). The "DPF76" is exclusively a counter and the

"DPF78" is exclusively a ratemeter.

SPECIFICATIONS:

DISPLAY

6 digit, 0.55" High LED

INPUT POWER:

110 VAC ± 15% or 11 to 15 VDC

220 VAC ± 15% or 11 to 15 VDC

CURRENT:

250 mA DC max. or 6.5 VA AC

OUTPUT POWER (AC powered units only)

+12 VDC @ 50 mA, unregulated -10 + 50%

TEMPERATURE:

Operating: +32°F (0°C) to +130 F (+54°C)

Storage: -40 F (-40°C) to +200°F (93°C)

DIMENSIONS: See next page.

WEIGHT:

2 Lbs. (1 kg)

MEMORY

EEPROM stores data for 10 years if power is lost.

INPUTS:

3: High Impedance DC pulse input Open or 0-1 VDC

(low), 4-30 VDC (high), 10 KOhm imp. 10 KHz max.

speed. Accepts simultaneous inputs.

3M: Mag. Input, Input A only, accepts 30mV input (50 V max. P/P)

signals 10 KOhm imp. 5 KHz max. (Input B, 4-30V)

3MB: Mag. Input, Inputs A & B, accepts 30mV input (50 V max. P/P)

signals 10 KOhm imp. 5 KHz max.

5: 4-30 V Count pulses on Input A, 4-30 V Direction

Control input (level) on Input B.

5M: 30 mV Count pulses on Input A (50 V max. P/P)

4-30 V Direction Control input (level) on Input B

9: Quadrature, accepts 4-30 V pulses with 90°phase

shift for direction detection.

9MB: Quadrature, accepts 30 mV (50 V max. P/P) pulses with

90°phase shift for direction detection.

NOTE: The Mag. inputs have filtering as follows: up to 300hz

@30mV, 5KHz @ .25V to 50V max.

RESET:

Front Panel:

Resets displayed value and control output

Remote:

4-30 VDC negative edge resets COUNTER "A" and control

output

K FACTOR/SCALING

In the standard unit a fixed K-Factor is used to convert the input

pulses to engineering units. The 5 digit K-Factor dividers, with

decimal keyed into any position, allow easy direct entry of any KFactor from 0.0001 to 99999. Separate factors may be entered for

the 2 separate input channels.

CONTROL OUTPUTS:

Relays:

2 each N.O. Relay; 5 Amps120/240 VAC or 28 VDC.

(N.C. relay contacts and NPN transistor output

available with solder jumpers. Transistor output is

internally pulled up to 10 VDC through relay coil, sinks

from 10 VDC to .5 V @ 100 mA)

Analog Output:

An optional 4-20mA (0-20mA) output is available for

the DPF70 series. The output can be programmed

to track rate or total. This feature is available by

adding suffix A to the part number. Connections are

via a 2 terminal pluggable screw connector.

Programming is accomplished by using the front panel

in conjunction with rear dip switches.

Accuracy: 50uA worst case.

Compliance Voltage: 3 to 30 VDC non inductive.

RS232/RS422SERIAL INTERFACE

If the serial interface option is supplied, up to 99 units can be linked

together. (The terminal addressing the unit must be capable of

driving all loads in the loop.) Unit status and new set points can be

communicated by serial communication. Mode changes, however,

must always be made on the front panel. Data is transmitted at

selected baud rates using standard seven bit ASCII characters and

parity with two additional bits of “Start” and “Stop” to make up the

standard ten bit character.

Data is received and transmitted over standard EIA RS232 or

RS422 levels. Each 10 bit character is made up of a start bit, 7 bit

ASCII code, parity bit and stop bit. Unit number, baud rate and

parity are entered in the “Program Setting” set up mode and remain

in memory even if power is off.

Note that the input impedance of RS232 is 3K or 7K Ohm worst

case. The terminal addressing the unit must be capable of driving

all loads in the loop. RS422 input impedance is much higher and

there is usually no problem driving 25 units. Unit serial transmit line

remains in a high impedance “OFF” state until addressed.

PRESETS

Two control outputs are provided. To set relay values, press “menu”

button until “Relay” appears on the display, the A and B outputs

can be assigned to the ratemeter (high/low), one preset for rate

and one for total, or two presets (2 stage shut off) on the A and B

counters. A 5 digit value can be entered for both presets and the

decimal point location is the same as the counter. The outputs can

be set to energize from 0.1 to 99.9 seconds or latch (0.0). If a value

other than 0.0 is entered, the counters will auto reset at the preset .

In the A-B or A+B versions, the relays will be assigned to either net

total or A rate.

LOCKOUT

Unauthorized front panel changes can be prevented by entering a

user selected 5 digit code, in the “LOC” , . mode. The front panel

can be completely locked out or the presets can remain accessible.

RATEMETER

Accurate to 4 1/2 digits (±1 display digit). The rate meter can be

programmed to accept almost any number of pulses per unit of

measurement, sample from 2 to 24 seconds maximum, and autorange up to 5 digits of significant information. In the “RPS” mode,

the ratemeter displays in units per second, and in the “scale” mode,

units per hour or per minute. The unit will display the rate of the A

Input only.

COUNTER

The two 6-digit counters can count at 10Khz speed. Each can

have a 5-digit dividing scale factor. The counter advances on the

positive edge of each pulse. Count up or down modes available, as

are quadrature inputs from encoders for position or length measurement. The unit can be programmed to view the net value of

"A+B" or "A-B", or A and B as separate counters.

1

Page 7

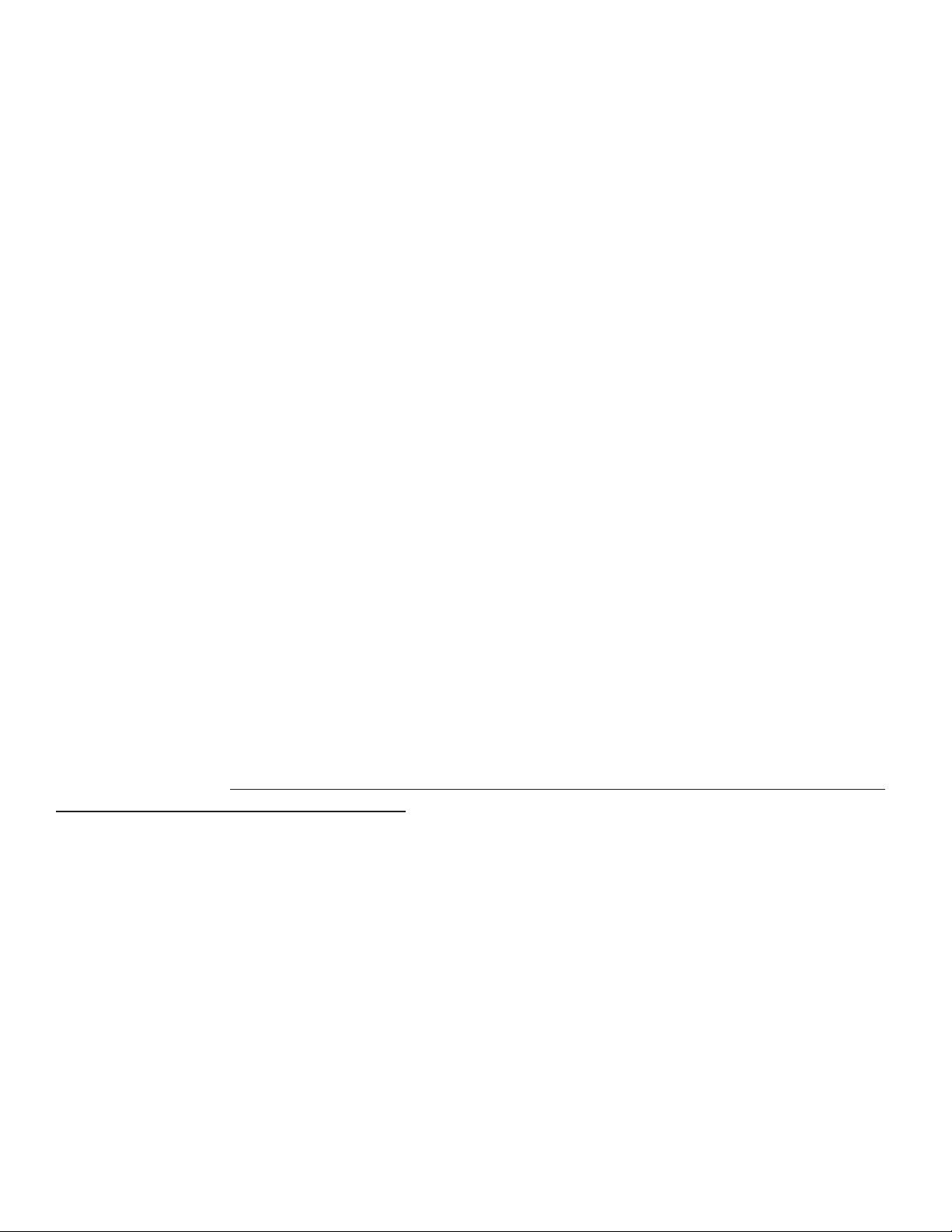

HOW TO MOUNT THE UNIT

The unit is designed to be mounted with a gasket providing a water tight seal. Two mounting brackets are provided to

secure the unit to the panel. A panel less than .1" may distort if the clamps are screwed too tightly.

Slide the body of the unit through the rubber gasket. Insert the unit into the panel. As shown in "FIG. A", slide the brackets

up the groove to press against the back of the panel. Insert screws into rear of brackets and tighten them evenly and

alternately. Do not over tighten! A normal level of torque is required. Maximum torque should be 3" pounds.

This product is designed to be panel mounted and is NEMA 4 rated if proper mounting procedures are followed and the

required and supplied hardware is correctly used.

If the panel in which the unit is mounted is less than .125 of an inch thick, the possibility exists that there will be some

flexing. Should this flexing occur, the resulting deformation of the panel could cause a loss of the water tight seal. In case

this should occur, the use of silicone or other sealant would be recommended.

This product is designed to the NEMA 4 rated. However, the fact that we are unable to control either the location in which

the device is installed or the actual installation itself requires that the company's liability shall extend only to the repair or

replacement of a defective product.

We are prepared to offer additional assistance in those special situations where normal mounting methods do not seem to

satisfy the customers needs. This assistance may be obtained by calling the factory and asking for Application Engineering.

DIMENSIONS

3.925

(99.7)

FIG. A

4.437

(112.7)

2.625

(66.68)

0.587

(14.91)

BEZEL

GASKET

4.245

(107.8)

CUSTOMER PANEL

Panel Thickness 0.062" (1.5)

to 0.187" (4.7) max.

3.622

(92)

1.772

(45)

Dimensions in inches (mm)

2

Page 8

WIRING

The rear terminal contains 12 screw terminals for connecting #14 to #28 gauge wire.

The unit is controlled by a microprocessor and, therefore, an electrically "noisy" environment could cause operating

problems. The input power line should not be common to power lines for motors, pumps, contactors, etc.

The unit is designed to be immune from line or RF voltage interference. In some environments voltage spikes of over 100

volts, even 1000 volts, can occur. When common to a power line driving motors voltage fluctuations can be extreme and

rapid. Lines driving DC or AC solenoids, relays, or actuators can also cause problems.

Four sources of noise can occur:

1) AC power line noise - If the unit cannot be connected to a clean power source, an inductive load suppressing device

(MOV as GE # V130LA1 or Resistor Capacitor as Paktron # .2 uf/220 ohm @ 400V) can be installed. Although locating

the suppressor across the AC supply at the unit should help, best results are obtained by connecting the suppressor

across the leads of the "load" at the device causing the spike.

2) Input line noise -The noise is carried on the input and D.C. ground lines. Make sure the input wires are never run into

the unit in a bundle with power input lines. Also, keep these input lines isolated from inductive lines from devices

drawing heavy loads. If there is a possibility of electrical noise, we recommend using shielded cable, with the shield

being hooked to the D.C. ground terminal on the instrument, and to "earth" at one point in the circuit, preferably at the

D.C. ground terminal of the unit.

3) Output lines - The unit has two relay outputs. When these outputs are used to run external relays or solenoids, spikes

can be generated upon activation. This noise can spread through the instrument causing operating problems. If the

source is a D.C. operated device, a general purpose diode (IN4004) placed across the solenoid prevents electrical

noise spikes. Connect the cathode (banded side) to the more positive side of the coil. If the source is an A.C. operated

device, use a MOV or Resistor Capacitor across the coil.

4) 12 VDC output supply - Noise can be generated on the 12 VDC output supply if it is used to drive inductive loads or if

the current draw exceeds 50 mA. Insure that all inductive loads have a diode (such as IN4004) across the coil and that

the current does not exceed 50 mA.

UP/DOWN CONTROL AND QUADRATURE INPUTS

QUADRATURE INPUT:

When programming the counter section for quadrature input, you must set the unit for A net B and A sub B (see step 2 in

programming section). This insures proper operation. The rate can only be viewed in one direction. If the unit is a

ratemeter only (DPF78), connect only one of the quadrature channels to Input A (pin 5).

UP/DOWN CONTROL:

When using the up/down control option, Input A (pin 5) is the count input and Input B (pin 6) is the up/down control

(direction) input. The counter must be set for A net B and A sub B (see step 2 in programming section).

When the direction input is high (4-30VDC) the count inputs will count up, when the direction input is low (open or less than

1VDC) the count inputs will count down. The direction input must precede the count input by 1 msec when the unit is set for

low CPS and 1 usec when set for high CPS.

3

Page 9

CONNECTING AC / DC POWER

NOTE: Connect power only after other connections are finished. Do not touch the live AC power terminals! The unit has

been designed with an isolated AC input. Thus, polarity is not a concern for the AC input. The chassis is plastic, therefore

earth ground is not used. For D.C. operation, connect + 12V to pin 7 and - D.C. to pin 8.

WIRING CONSIDERATIONS

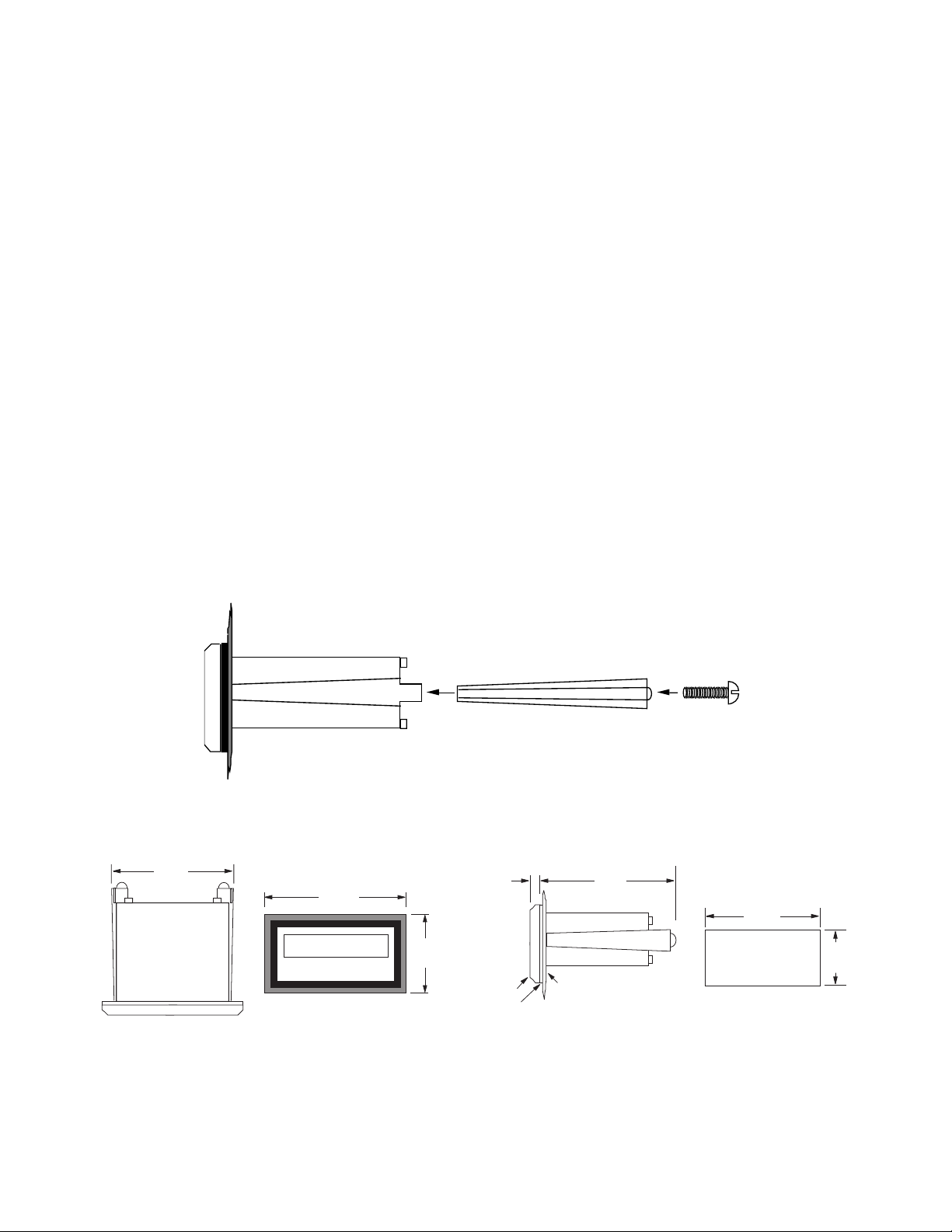

Connecting the DPF70 Series to Omega Flowmeters and Amplifiers:

FTB4605 & FTB4607 Water Meters:

DO NOT USE PIN 7 WITH THESE METERS!

Connections:

Customer supplied 1/4 Watt 2000Ω

(approximateley) resistor

FTB4605 & FTB4607

Water Meters

Green

White

Brown

RELAYS

1 COMMON

2 N.O.(N.C./NPN)

3 COMMON

A

B

13- V+

14- I SINK

4 N.O.(N.C./NPN)

5 A INPUT

6 B INPUT

7 11 to 19V @ 50mA OUT/+DC IN

8 -DC (GROUND)

9 RESET INPUT

10 6 to 14V @ 50mA

11 A.C. INPUT

SWITCH

ON

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

12 A.C. INPUT

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

ANALOG

FTB600 Series Flow Meters:

DO NOT USE PIN 7 WITH THESE METERS!

Connections:

FTB600

Flow Meters

FLSC-AMP Amplifier:

Connections:

Flowmeter

(Turbine-Mag Pickup)

Brown

Green

White

1

2

3

TB1

FLSC-

AMP

FLSC-AMP

Amplifier

1 COMMON

2 N.O.(N.C./NPN)

3 COMMON

4 N.O.(N.C./NPN)

5 A INPUT

6 B INPUT

7 11 to 19V @ 50mA OUT/+DC IN

8 -DC (GROUND)

9 RESET INPUT

10 6 to 14V @ 50mA

11 A.C. INPUT

12 A.C. INPUT

1 COMMON

2 N.O.(N.C./NPN)

3 COMMON

4 N.O.(N.C./NPN)

5 A INPUT

6 B INPUT

7 11 to 19V @ 50mA OUT/+DC IN

8 -DC (GROUND)

9 RESET INPUT

10 6 to 14V @ 50mA

11 A.C. INPUT

12 A.C. INPUT

TB2

3

2

1

RELAYS

A

B

SWITCH

ON

RELAYS

A

B

SWITCH

ON

13- V+

14- I SINK

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

13- V+

14- I SINK

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

ON

CAL.

0-20mA

COUNT

SET

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

ANALOG

OUTPUT

ANALOG

4

Page 10

WHAT CAN YOU VIEW?

J4

J5

J6

J3

J1

J2

CR1

R3

C8R7R5

R4

U1

CR2

REV

20229

CR6

CR3

U3

P1

R10R6C6

C7

CR4

CR5

C4

R2

R1

C3

C5

U2

U4

U6

U5

R8

R9

C1

C2

C9

B

1) "A sub B" - If you have selected the "A sub B" mode, pressing "view" shows:

A) The net result of subtracting input B from input A. Pulses on input B will subtract (count down). Pulses on input A

will add (count up) if "reset to 0" is selected, if "set to preset" is selected, input A will subtract (count down).

B) The rate of input A.

2) "A add B" - If you have selected "A add B" mode, pressing "view" shows:

A) The net result of adding "A" and "B" inputs. Pulses on input B will add (count up). Pulses on input A will add

(count up) if "reset to 0" is selected, if "set to preset" is selected input A will subtract (count down).

B) The rate of input A.

3) "A sep B" - If you have selected " A sep B" mode, pressing "view" shows:

A) The total counts of input A. If "reset to 0" is selected A counts up, if "set to preset" is selected A will count down.

B) The rate of input A.

C)* The total counts of input B. B will always count up.

NOTE: In "A sep B" mode, B can be used in 3 ways:

1) As a separate totalizing counter

2)** As a Batch Total Counter for input A

3)** As a Grand Total Counter for input A

NOTE:

* All decimal points are inverted when "B total" is being displayed.

** See below on how to modify for Batch Count and "B" as a Grand Total Counter.

OUTPUT JUMPER SELECTIONS

FUNCTION

"A" RELAY

N.C. OUTPUT

"B" RELAY

N.C. OUTPUT

"A" PRESET

*

TRANSISTOR (NPN)

*

"B" PRESET

TRANSISTOR (NPN)

"B" AS BATCH

COUNTER

"B" AS GRAND

TOTAL COUNTER

BOTTOM VIEW AT TERMINAL

* The unit must be removed from the case to access jumpers C & F, all

other jumpers can be accessed by removing the plastic extender.

NOTE: All three pads at jumpers 2 and 4 are connected.

12 11 10 9 8 7 6 5 4 3 2 1

L

20192

MODIFICATION

CUT JUMPER

AT "A" "B" TO "2"

CUT JUMPER

AT "D" "E" TO "4"

CUT JUMPER

AT "A" "C" TO "2"

CUT JUMPER

AT "D" "F" TO "4"

SELECT JUMPER

"A SEP B" "H" TO "G"

SELECT CONNECT

"A SEP B" PULSES TO

"A" & "B"

FC

H

G

DE

4

AB

2

MILLIVOLT INPUT OPTION

JUMPER SELECTIONS

If the unit has the millivolt input bd.# 20229, A & B inputs can be

separately solder jumper programmed to accept either a low millivolt or 4-30 V input. Each unit shipped is programmed according

to part number. If solder jumpers are made, the part number

should be modified to reflect the changes made

C=CLOSE, O=OPEN

4-30V INPUT Millivolt INPUT

Input A J1-O, J2-C, J3-O J1-C, J2-O, J3-C

InputB J4-O, J5-C, J6-O J4-C, J5-O, J6-C

5

Page 11

D

OPERATING THE FRONT PANEL

Press to ENTER in

the programming

mode.

Press to RESET

displayed total in

operating mode.

Start Here

PRGM

Press to "enter"

LOCK code to

LOCK and

UNLOCK front

RST

A

ENTER

LOCK

Press to view or

change Preset A

C

B

PRE A

PRE B

Press to view or

change Preset B

D

VIEW

E

PRGM

Press to alternately

view A Rate& Net

Total or A Rate, A

Total & B Total.

panel.

Use keys A, B, C, D, & E to advance digits during a numeric entry sequence.

PROGRAMMING FLOWCHART

NOTE: Several programming selections will not appear with DPF76 and DPF78 units.

Press this key to step through menu choices.

PRGM

RST

Press this key to enter displayed value

ENTER

Press to cycle

through

PROGRAM

choices;

Press to step

through set up

choices in program mode.

FACToR

ENTER

DP F A

ENTER

#####

ENTER

DP F B

ENTER

#####

ENTER

RUN MODE

Hi

PRGM

CPS

ENTER

PRGM

ENTER

Lo

CPS

RATE METER

(DPF78)

(MR2) ONLY

RST

0

A

NET

B

A

AD

B

Hi

CPS

CouNT

ENTER

PRGM

ENTER

DPLoC

ENTER

PRGM

PRGM

ENTER

PRGM

ENTER

PRGM PRGM

SET

PR

SCALE RPS

ENTER

Z3600

A

SEP

ENTER

B

RATE

ENTER

PRGM

PRGM

ENTER

NoR ##

ENTER

FiguR#

A

SuB

B

Lo

ENTER

DLY #

ENTER

RUN MODE

CPS

Z60

ENTER

LoC

LC

PRg

CoDE

#####

RUN MODE

ENTER

PRGM

ENTER

ENTER

PRGM

LC

ALL

RELAY

A

PRGM

ToT

ENTER ENTER

A ##.#

B

PRGM

ToT

ENTER ENTER

B ##.#

RUN MODE

RUN MODE

RUN MODE

6

Page 12

PROGRAM CODES AND DESCRIPTIONS

The following is a list of abbreviations as they appear on the display and front panel of the unit.

ABBREVIATION DESCRIPTION

FACTOR

DP F A

DP F B

COUNT

RST 0

SET PR

DP LOC

A NET B

A SEP B

A SUB B

SCALING FACTOR - For A and B Inputs. Each input has a separate 5 digit dividing scale factor.

DECIMAL POINT FOR FACTOR A - Enter location of decimal point for scaling Factor A by pressing the

button under the digit where the decimal is desired.

DECIMAL POINT FOR FACTOR B - Enter location of decimal point for scaling Factor B by pressing the

button under the digit where the decimal is desired.

PORTION OF MENU FOR SETTING COUNTER VARIABLES

RESET TO 0 - Counter will reset to 0. Input A will count up from 0. Input B will subtract (count down) in A

Sub B mode. Input B will add (count up) in A Add B mode.

SET TO PRESET - Counter will reset to preset A. Input A will count down from preset A. Input B will count

up (add) in "A add B" mode and input B will count down (subtract) in "A sub B" mode.

DECIMAL POINT LOCATION - Enter desired location of decimal by pushing the button under the digit where

the decimal is desired. Changing the decimal will change the decimal location in the A & B counters as well

as the rate display.

NET RESULT OF ADDING OR SUBTRACTING A & B INPUTS

A & B INPUTS ARE SEPARATE - A & B are not added or subtracted.

A SUBTRACT B - The number of scaled pulses from Input B are subtracted from the number of scaled pulses

from Input A. (-99999 TO 999999)

A ADD B

HI CPS

LO CPS

RATE

RPS

SCALE

Z 60

Z 3600

NOR##

FIGUR ##

DLY##

A ADD B - The number of scaled pulses from the A Input are added to the number of scaled pulses from the

B Input.

HIGH COUNTS PER SECOND - This sets the unit for high count speeds (0-9.99KHz)

LOW COUNTS PER SECOND – This sets the unit for contact debounce filtering (0-40Hz)

PORTION OF MENU FOR SETTING RATE VARIABLES

RATE PER SECOND - The display will read in rate per second.

SCALING - Allows unit to display rate per minute or rate per hour.

DIVIDE K FACTOR BY 60 - This sets the unit for rate per minute; equal to 60 times rate per second.

DIVIDE K FACTOR BY 3600 - This sets the unit for rate per hour; equal to 3600 times rate per second.

NORMALIZING FACTOR - Normalizes (averages) the data being received. Higher settings provide more

normalizing (averaging) for a more stable display. Derived from the equation:

(Old Data x "NOR" + New Data)

("NOR" + 1)

SIGNIFICANT FIGURE - This sets the amount (1-5) of meaningful figures the unit will display. (RATE DIS

PLAY ONLY). FOR EXAMPLE: If "2" is set as the figure, a rate of 273.45 will be displayed as 270.

DELAY FACTOR - The amount of time (02 to 24 sec.) the unit will "look" for valid data, before the display

defaults to zero. (RATE DISPLAY ONLY)

7

Page 13

LOC

LOCK - This portion of the menu allows you to:

1) lock the program (presets are still accessible)

2) lock all (presets and program are locked).

LC PRG

LC ALL

CODE

RELAY

A TOT

A RATE

A##.#

B TOT

LOCK PROGRAM - This will lock the program and allow the presets to be changed when the unit is in the

lock mode.

LOCK ALL - This will lock the program and the presets when the unit is in the locked mode. The presets can

be viewed, but not changed.

LOCK CODE - This message (code) will flash on display for approximately 3 seconds. It will be followed by a

5 digit number (xxxxx). The number you enter here will be the code to lock and unlock the unit.

RELAY - This portion of the menu allows you to set your relay operation variables.

RELAY A FOR TOTALIZER - When this is selected relay A will activate when the net total has reached

Preset A ("A NET B" Mode ). Relay A will activate when the total of input A reaches preset A ("A SEP B"

Mode).

RELAY A FOR RATE - When this is selected relay A will activate when the Rate of input A equals or exceeds

preset A when in "A NET B" or "A SEP B" mode. The relay will drop out when the rate of A falls below preset

A.

RELAY A DURATION - This message will appear when "A TOT" is selected. It is the duration which the

relay will remain energized (00.1 to 99.9 sec). If 00.0 is selected, the relay will latch until reset. When the

duration is not at 00.0, the unit will autorecycle.

RELAY B FOR TOTALIZER - When this is selected relay B will activate when the net total has reached preset

B ("A NET B" Mode). Relay B will activate when the total of input B has reached preset B ("A SEP B" Mode).

B RATE

B##.#

RELAY B FOR RATE - When this is selected relay B will activate when the rate of input A equals or exceeds

preset B when in "A NET B" or "A SEP B" mode. The relay will drop out when the rate of A falls below preset

B.

RELAY B DURATION - Follow same procedure as A ##.#.

TERMINATIONS

ANALOG

1- COMMON

2- N.O.(N.C./NPN)

3- COMMON

A

B

13- V+

14- I SINK

RELAYS

4- N.O.(N.C./NPN)

5- INPUT A

6- INPUT B

7- 11 - 19 V @ 50mA OUT/+DC IN

8- -DC (GROUND)

9- RESET INPUT

10- 6 - 14 V @ 50mA

11- A.C. INPUT

SWITCH

ON

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

12- A.C. INPUT

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

Analog Out Setup SwitchesSerial Port

1 2 3 4

13 14

REAR VIEW

1 2 3 4 5 6 7 8 9 10 11 12

ON

8

Page 14

CALCULATING SCALE FACTORS

There are two separate dividing scale factors, one for input "A" and one for input "B". The factor to enter is the number of

pulses per the desired unit of measurement. The factor ranges from 0.0001 to 99999. The factor is the same for rate and

count on input "A". Because the "units per second", "minute", or "hour" are field programmable from the keypad, scale

factor calculations for the ratemeter are easy. Here are some examples:

SCALING FACTOR EXAMPLES:

BATCHING: You want to count the number of batches (10 boxes each) being loaded onto a pallet.

Solution - Dial in a scale factor of 10.

UNIT COUNTING: You pick up a notch on a paper roll (1 pulse per shaft revolution). Each revolution equals 3 feet. To

find the number of pulses per foot, simply divide "1 pulse" by "3 feet" (1÷ 3 = .3333).

Solution - One foot equals 0.3333 pulses, enter this as the scale factor and the display will read in feet.

RATE: The shaft of a motor has a flywheel with 10 spokes. A prox switch is mounted to sense 10 pulses per revolution.

RPM of the shaft is the desired readout.

Solution: Enter a Factor of 10 and for every 10 pulses, "1" will appear on the display. Set rate per

second, minute or hour as desired.

A conveyor carrying bottles must be controlled for bottle speed. For each revolution of the front roller, three bottles

travel by. Thus, one revolution equals 3 bottles. A wheel with seven spokes is mounted on the roller. The user

can't sense bottles because they are traveling through a washer, so a sensor is placed at the roller, sensing seven

pulses per revolution of the shaft, which equals 3 bottles per revolution.

To calculate the scale factor (7 ppr ÷ 3 bottles) = 2.3333 scale divider. Set rate per second, minute or hour as

desired.

A flow meter is generating 52.6 pulses per gallon. The desired readout is in liters. Since there are 3.785 liters per

gallon, divide 52.6 by 3.785 to find the number of pulses per liter (52.6 ÷ 3.785 = 13.897).

Enter 13.789 as the scale factor so the display will read in liters.

An aluminum sheeting plant has a cut to length application to customer specification. A ten pulse per revolution

encoder with a 12" wheel is used to sense. The travel of aluminum sheets is in inches. Thus, after 10 pulses, you

want 12 to appear on the display. Thus, 10 ÷ 12 = .8333. Enter .8333 as your scale factor.

9

Page 15

PROGRAMMING

STEP

1

SETTING

SCALING

FACTORS

THIS SECTION

WILL ONLY

APPEAR IN THE

RATE METER

ONLY VERSION

(DPF78)

PRESS

PRGM

ENTER

ENTER

ENTER

DISPLAY

factor

dp f a

#####

hi cps

or

lo cps

REMARKS

This section of the menu is used to set

up the scaling factors for inputs A & B.

This sets the decimal for factor A.

Press the arrow key under the digit

where the decimal is desired. To clear

the decimal, press the arrow key furthest to the right (PRGM) .

This is the scaling factor for input A. To

change, press the arrow key under the

digit(s) to change. Press ENTER to

enter the displayed value.

This section will only appear in the

RATE only version. Press the PRGM

key to choose HIGH CPS (0-9.99KHz)

or LOW CPS (0-40Hz). Press the

ENTER key to enter the displayed

choice.

ENTER

ENTER

dp f b

#####

This sets the decimal for factor B.

Press the arrow key under the digit

where the decimal is desired. To clear

the decimal, press the arrow key furthest to the right (PRGM) .

This is the scaling factor for input B. To

change, press the arrow key under the

digit(s) to change. Press ENTER to

enter the displayed value.

10

Page 16

PRESS DISPLAY REMARKS

STEP

2

SETTING

THE

COUNTER

DPF75

&

DPF76

ONLY

PRGM

PRGM

ENTER

ENTER

ENTER

factor

count

rst 0

or

set pr

dp loc

a net b

or

a sep b

This section of the menu sets up the counter

information.

Press the PRGM key to choose RST 0 (reset

to 0, count up) or SET PR (set to preset, count

down), press the ENTER key to enter the

displayed choice.

This sets the decimal location for the A & B

counters. Press the arrow key under the

desired digit location. To clear the decimal,

press the arrow key furthest to the right. Press

the ENTER key to enter the displayed location.

Press the program key to choose A NET B

(add or subtract A & B) or A SEP B (view A &

B as separate counters). Press the ENTER

key to enter the displayed choice.

ENTER

ENTER

a sub b

or

a add b

hi cps

or

lo cps

This section will only appear if A NET B was

selected. Choose A SUB B (A subtract B) or

A ADD B. Press the ENTER key to enter the

displayed choice.

Press the PRGM key to choose HIGH CPS

(0-9.99KHz) or LOW CPS (0-40Hz). Press

the ENTER key to enter the displayed choice.

11

Page 17

STEP

3

SETTING

THE RATE

PRGM

PRGM

REMARKSPRESS DISPLAY

factor

count

DPF75

&

DPF78

ONLY

PRGM

ENTER

ENTER

ENTER

ENTER

rate

rps

or

scale

z 60

or

z 3600

nor ##

figur #

This section of the menu is used to set up the

rate information.

Press the PRGM key to choose RPS (rate per

second) or SCALE (RPM, RPH). Press ENTER

to enter displayed choice.

Press PRGM to choose ÷60 (RPM) or ÷3600

(RPH). Press ENTER to enter displayed choice.

This sets the normalizing (averaging) factor.

Press the arrow keys under the desired digits to

change. Press ENTER to enter displayed value.

This sets the number of significant figures to be

displayed. Press the arrow key under the digit to

change. Press ENTER to enter displayed value.

ENTER

dly #.#

This sets the delay time (0.0 to 9.9) that the unit

will "look" for valid input data before the display

falls to 0. Press the arrow key under the digits to

change. Press ENTER to enter displayed value.

12

Page 18

PRESS

DISPLAY REMARKS

STEP

4

SETTING

LOCK

SETTING

THE

LOCK

STATUS

PRGM

PRGM

PRGM

PRGM

ENTER

ENTER

LOCK

ENTER

factor

count

rate

loc

LC PG

or

LC ALL

CoDE

Flashes

followed by:

#####

CoDE

Flashes

followed by:

0

LoC

or

uN LoC

This section of the menu is used to set up the

lockout type and code.

LC PG = Locks program but presets and reset

are accessible.

LC ALL= Locks entire keypad.

Press the PRGM button to toggle between

choices; Press ENTER to enter displayed choice.

After CODE flashes the display will show the

existing lock code. To change the code press

the key under each digit to be changed. Press

ENTER to enter displayed value.

Key in the lock code (see programming step 4)

by pressing the keys under the digits to be

changed. Press the ENTER key to enter the

displayed code.

After the code is entered the unit will display

LOC (unit is locked) or UN LOC (unit is unlocked). This message will be displayed for

approximately 3 seconds before the unit returns

to the run mode.

13

Page 19

DISPLAYPRESS

REMARKS

STEP

5

SETTING

THE

RELAYS

This step will only

appear on DPF75

This step will only

appear on DPF75

PRGM

PRGM

PRGM

PRGM

PRGM

ENTER

ENTER

ENTER

factor

count

rate

loc

relay

a tot

or

a rate

A ##.#

b tot

or

b rate

This section sets up the relay information.

Press the PRGM key to choose A TOT (A

assigned to total) or A RATE (A assigned to

rate). Press ENTER when the desired choice

is displayed.

This is the duration (.1 to 99.9 sec) that relay

A will remain energized. If 00.0 is selected,

the relay will latch until reset.

Press the PRGM key to choose B TOT (B

assigned to total) or B RATE (B assigned to

rate). Press ENTER when the desired choice

is displayed.

SETTING

THE

PRESETS

ENTER

PRE A

PRE B

b ##.#

PRE A

Followed by

last PRE A

entered

PRE B

Followed by

last PRE A

entered

This is the duration (.1 to 99.9 sec) that relay

B will remain energized. If 00.0 is selected,

the relay will latch until reset.

PRE A = Preset A (Final Preset); The set point

at which output A will trigger. If the displayed

value is not the desired preset, press the

key(s) under the digit to be changed.

PRE B = Preset B (Prewarn); The set point at

which output B will trigger. If the displayed

value is not the desired preset, press the

key(s) under the digit to be changed.

14

Page 20

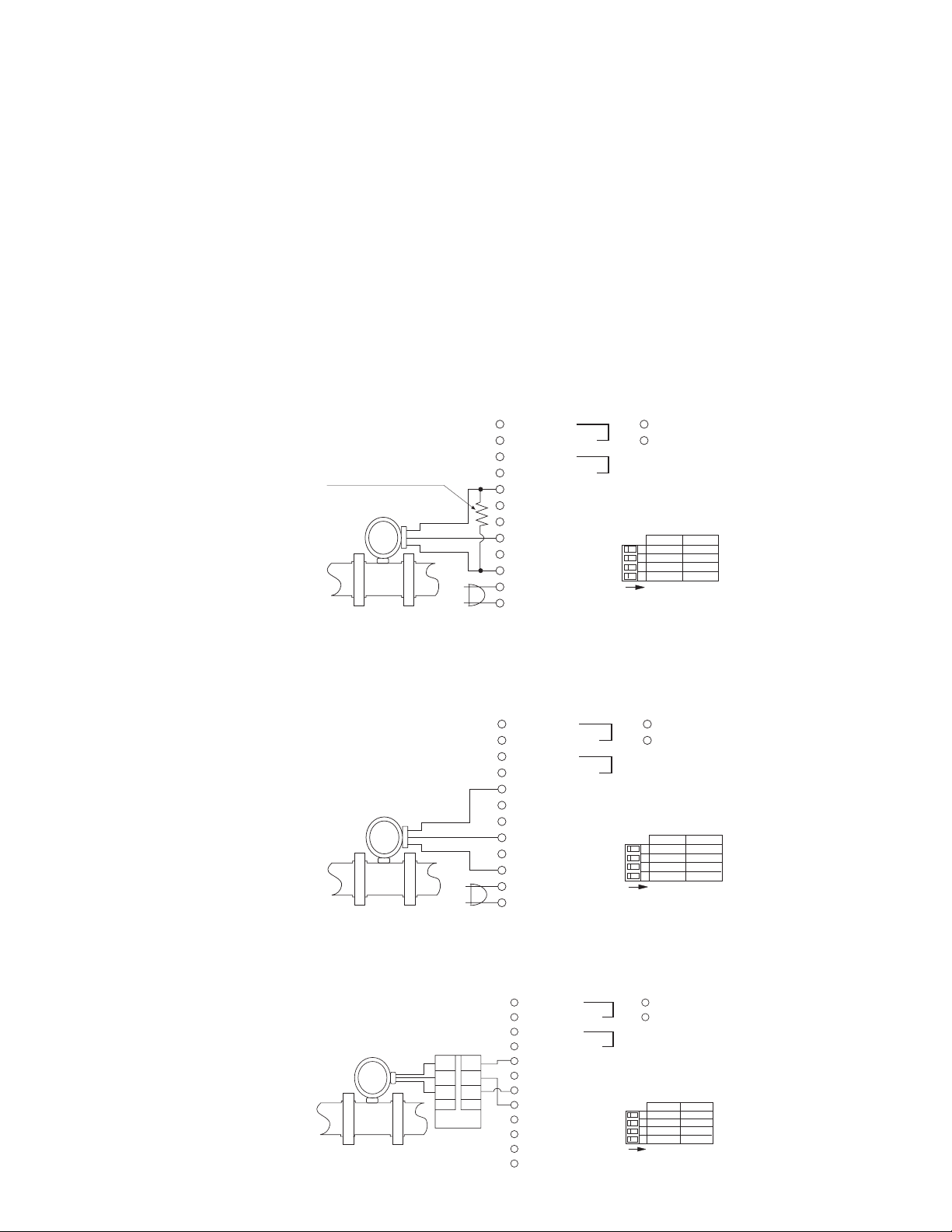

OUTPUT WIRING

The following diagrams detail the connection of the relay and analog output options. Each relay consist of a form A contact

(Normally Open). NPN transistor or Normally Closed contacts are available with solder jumpers (see Jumper Options).

SOLENOID (Single Stage)

Use Relay A (pins 1 & 2) for single stage preset. When the count or rate (selectable) reaches Preset A, Relay A will

energize. When Relay A closes, current passes through the solenoid for activation. When operating AC solenoids,

we recommend the use of an MOV to reduce inductive kickback (use a diode for DC solenoids).

ANALOG OUTPUT

The analog output can be selected to output 4-20 mA or 0-20 mA and can be selected to track the rate or count.

Pin 13 supplies 12 to 18V to power the current loop. Pin 14 supplies the current sinking driver. When connecting

a strip chart recorder, make connections as follows:

SOLENOID

MOV

recommended

PNP

Prox Sensor

BLK

BRN

BLU

RELAYS

1 COMMON

2 N.O.(N.C./NPN)

3 COMMON

4 N.O.(N.C./NPN)

5 INPUT A

6 INPUT B

7 11 - 19 V @ 50mA OUT/+DC IN

8 -DC (GROUND)

9 RESET INPUT

10 6 - 14 V @ 50mA

11 A.C. INPUT

12 A.C. INPUT

A

B

SWITCH

ON

13 V+

14 I SINK

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

ANALOG

ALARMS

STRIP CHART

ANALOG

RECORDER

TURBINE FLOWMETER

+

-

PULSE OUTPUT

+12V

GND

RELAYS

1 COMMON

2 N.O.(N.C./NPN)

3 COMMON

4 N.O.(N.C./NPN)

5 INPUT A

6 INPUT B

7 11 - 19 V @ 50mA OUT/+DC IN

8 -DC (GROUND)

9 RESET INPUT

10 6 - 14 V @ 50mA

11 A.C. INPUT

12 A.C. INPUT

A

B

SWITCH

ON

13 V+

14 I SINK

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

The relays can be used to trigger alarms which warn the operator that a batch is complete or the rate has

exceeded a set speed. The outputs are programmable to be assigned for rate or count. When assigned to the

count, the relays can have a user selectable on time (duration) or can be latched until reset.

ANALOG

OUTPUT

ON

CAL.

0-20mA

COUNT

SET

LIGHT

BELL

RELAYS

1 COMMON

2 N.O.(N.C./NPN)

3 COMMON

A

B

13 V+

14 I SINK

4 N.O.(N.C./NPN)

5 INPUT A

6 INPUT B

7 11 - 19 V @ 50mA OUT/+DC IN

8 -DC (GROUND)

9 RESET INPUT

10 6 - 14 V @ 50mA

11 A.C. INPUT

SWITCH

ON

OFF

RUN

4-20mA

RATE

RUN

1 2 3 4

12 A.C. INPUT

15

Page 21

ANALOG OUTPUT OPTION

Description:

An optional 4-20mA (0-20mA) output has been added to the DPF70

series. The output can be programmed to track rate or total. This

feature is available by adding suffix A to the part number. Connections are via a 2 terminal pluggable screw connector.

Connections: (see FIG. 1)

PIN13 supplies the 12 to 18 VDC to power the current loop.

PIN14 is the control sink driver

Accuracy:

50uA worst case

Compliance Voltage:

3 to 30 VDC non conductive

Setup:

The optional analog output feature uses 4 dip switches on the back

for setup. These switches are used as follows:

SW1 - View or change "set low" and/or "set high" values

SW2 - Select output for rate or total

SW3 - Select 4-20mA or 0-20mA

SW4 - Calibrate the unit.

After the regular parameters shown in the programming flowchart

have been set, locate the 4 switches on the back of the unit. (see

FIG. 1)

Switch Settings:

SWITCH 1: Enter Analog Low & High (normally off)

Switch 1 is used to load in the low (4mA or 0mA) and/or the high

(20mA) output settings. With power on, set switch 1 ON (up).

SWITCH 4: Calibrate (normally off)

Switch 4 is used for calibration. Calibration is done at the factory

and should not be needed (see SWITCH 1 to enter high and low

values). If recalibration is desired, a calibrated 20mA ammeter

with 1uA resolution is needed. Attach the "+" lead of the meter to

pin 13 and the "-" lead to pin 14. Set switch 4 ON (up). The unit

will output approximately 20.000mA and a decimal will light in the

third position. Read the output using the ammeter. Press PRE A.

If the display is the same as the ammeter reading, press ENTER.

If not, press buttons A through E to step to ammeter reading and

ENTER. (Disregard display which now shows the last count reading with decimal point in third position) Return switch 4 to OFF

(down) position.

RS232 & RS422 Operation:

When the unit is suppled with RS232 or RS422, the analog output

"low" and "high" settings can be accessed and changed through

the serial port. The codes are as follows:

AL Unit will display (transmit) analog out "low" value.

AL(S)XXXXX Unit will load analog out "low" with entered

number. (S) = space

AH Unit will display (transmit) analog out "high" value.

AH(S)XXXXX Unit will load analog out "high" with entered

number. (S) = space

FIG. 1

Analog Out Setup SwitchesSerial Port

13 14

1 2 3 4

ON

LOW SETTING is viewed or changed by pressing PRE A. If the

displayed value is correct, press ENTER. If not, press buttons A

through E to step to the desired value and press ENTER. (disregard the display which will show the last count reading).

HIGH SETTING is viewed or changed by pressing PRE B. If the

displayed value is correct, press ENTER. If not, press buttons A

through E to step to desired value and press ENTER.

Return switch 1 to OFF (down) position, PRE A and PRE B buttons

now function to view or change relay trip values.

SWITCH 2: Select Count or Rate

SW2 OFF (down): Analog output follows rate

SW2 ON (up): Analog output follows count

SWITCH 3: Select 4-20mA or 0-20mA

SW3 OFF (down): Selects 4-20mA output range

SW3 ON (up): Selects 0-20mA output range

REAR VIEW

1 2 3 4 5 6 7 8 9 10 11 12

Typical Wiring:

RELAY A COM.

RELAY A N.O.

RELAY B COM.

RELAY B N.O.

INPUT A

INPUT B

11 to 19V @50mA OUT/ +DC IN

-DC (GROUND)

RESET INPUT

6 to 14V @ 50mA

110 / 220 VAC

110 / 220 VAC

11 to 19V OUT

ANALOG OUT (SINK)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PULSE OUTPUT

+12V

GND

TURBINE FLOWMETER

+

-

STRIP CHART

RECORDER

16

Page 22

INTERFACE CARD RS 232/422 OPERATION

RS 232/422 SET-UP:

All serial communication mode changes must be done

through serial communications. Mode changes cannot be

done through the front panel. To initialize the unit, place a

jumper between pin 7(+12V )[bottom board] and pin 1(init) [DB

-9 connector] on initial power up. The unit defaults to: 300

baud rate,"MARK" parity and device number 01. To enter the

program mode you must set your terminal for 300 baud rate

and "MARK" parity. Next, type D1(s), (s)= space bar. The

unit will echo back "DEVICE #1:". Now type EP (enter

program) and a carriage return (ENTER). The unit will echo

back "PROGRAM SETTING". You are now in the programming mode.

SETUP PROCEDURE:

The following sections consist of the communications setup

options as they appear in the menu. (If you wish to exit the

program mode, at any time you can hit the "escape key" (Hex

Code: 1B) and the unit will save the changes made but not

effect the remaining data values.) When each section of the

setup menu is displayed, the current data will appear in the <

> signs. If you wish to change the data, type in the number

of the desired choice and press return (ENTER). If you wish

to keep the current data, simply press return.

DEVICE NUMBER:

Each unit in the hook-up must be assigned it's own device

number (1 to 99). Zero is reserved for a dedicated hook-up to

only one terminal, and it's transmit output line remains in an

"on" active state. The device number is entered in the

program mode. The unit will prompt you:

DEVICE# <XX>?

If XX is the desired device number press return (ENTER), if

not enter the desired number after the question mark and

press return (ENTER).

BAUD RATE:

The baud rate is the speed at which data is transmitted,

expressed in bits per second. Baud rates of 300, 600, 1200,

2400, 4800 or 9600 are available. When in the baud rate

section of the menu, the unit will list :

BAUD RATES:

1:300 2:600 3:1200

4:2400 5:4800 6:9600

then prompt you:

BAUD RATE <300>?

Press return (ENTER) if this is the desired baud rate or enter

the assigned number of one of the six possible baud rates. If

an invalid baud rate is entered the unit will prompt you to

choose another baud rate. This will occur until a valid baud

rate is entered or escape is pressed.

PARITY:

Parity is a bit of information that is inserted before the stop bit

and is used to help check if the transmission is correct. When

setting the parity you may select "ODD" (parity bit is logic 0 if

total number of logic 1's in the first seven data bits is odd),

"EVEN" (parity bit is logic 0 if total number of logic 1's in the first

seven data bits is even), "MARK" (parity bit is always logic 1

- High / Mark) or "SPACE" (parity bit is always logic 0 - Low /

Space). If a "MARK" parity is chosen, it will appear that two

stop bits are used. Use the "MARK" parity with terminals using

parity "OFF" or "NONE". These terminals ignore the parity.

The unit does not check the parity but does transmit the parity

chosen. When setting the parity, the unit will print:

PARITIES:

MARK-0 SPACE-1 EVEN-2 ODD-3

Then the unit will prompt you:

PARITY<MARK>?

If this is the desired parity press return (ENTER), if it isn't enter

the number of the desired parity then press return (ENTER).

STROBE LIST:

The serial interface card is also equipped with a strobe line.

When the strobe line is triggered, a chosen set of data will be

transmitted to be displayed or printed. The selections for the

display list are entered in the program mode. Enter "1" to add

selections to the list and enter "0" to delete selections from the

list. The seven available items for the strobe display list are:

(1) Preset A, (2) Preset B, (3) K-Factor A, (4) K-Factor B, (5)

Rate of A, (6) Count A, (7) Count B. In the "A net B" mode

Count A will display the Net Count and Count B is an invalid

command and the unit will transmit useless data. When

setting the strobe list the unit will print :

ENTER STROBE LIST:

DO NOT DISPLAY-0 DISPLAY-1

The unit will prompt you:

PRESET A<DISPLAY>?

PRESET B<DISPLAY>?

K-FACTOR A<DISPLAY>?

K-FACTOR B<DISPLAY>?

RATE<DISPLAY>?

COUNT A<DISPLAY>?

COUNT B<DISPLAY>?

If the above choices are entered, when the strobe line is

triggered (3-30V positive pulse) the unit will transmit:

DEVICE# 1:

PA XXXXX

PB XXXXX

KA XXXXX

KB XXXXX

DR XXXXXX

DA XXXXXX

DB XXXXXX

(SEE COMMANDS BELOW FOR DESCRIPTION OF COMMAND CODES).

Each time the strobe line gets triggered the unit will transmit

this data unless the program mode is entered and the strobe

list altered.

After these four items have been entered they will remain

unaltered unless the program mode is entered again and the

values changed. The unit is now set and must be addressed

by its device number to come on line again.

17

Page 23

SERIAL INPUT COMMANDS:

To get a unit on line you must address it by its device number.

This is done by typing DXX(S), XX= device number. The unit

comes on line and echoes back DEVICE# XX. Insure that

"DEVICE# XX:" is received before requests are sent. The unit

is now ready to receive a command or string of commands

separated by a space. A carriage return (enter) will enter the

commands and processing of requests begins. The carriage

return (Hex Code "D") puts the unit "off line" after data is

processed.

COMMANDS:

EP...........Unit will enter program mode.

DA..........Unit will display (transmit) Count A.

DB..........Unit will display (transmit) Count B.

DR..........Unit will display (transmit) rate A.

KA..........Unit will display K-factor A.

†*KA(S)XXXXX....Unit will load K-factor A

with entered number.

KB..........Unit will display K-factor B

†*KB(S)XXXXX....Unit will load K-factor B

with entered number.

PA...........Unit will display Preset A.

†PA(S)XXXXX....Unit will load Preset A with

entered number.

PB...........Unit will display Preset B

†PB(S)XXXXX....Unit will load Preset B with

entered number.

RA..........Counter A will reset

†*RA(S)XXXXXX...Unit will set Counter A to

entered number.

RB..........Counter B will reset.

†*RB(S)XXXXXX...Unit will reset Counter B to

entered number.

*THE UNIT WILL RECOGNIZE A DECIMAL IF ONE IS

PLACED IN ANY OF THESE DATA VALUES.

†THE UNIT WILL ONLY RECOGNIZE THE LAST FIVE

DIGITS ENTERED (SIX DIGITS FOR RA & RB).

The following is an example of requests and responses:

Transmit from terminal Receive from unit

(s)=Space

D5(s) [Unit #5 Activated] DEVICE# 5:

PA(s)12345(s)PA PA 12345 PA

KA(s)1576(s)KA KA 1576 KA

KB(s)6751(s)KB KB 6751 KB

RA(s)RB[RETURN] RA RB

(UNIT PRESETS AND A & B K-FACTORS ARE SET AND

BOTH COUNTERS ARE RESET)

12345

1576

6751

SERIAL INTERFACE OPERATION:

Data is received and transmitted over standard EIA RS232 or

RS422 levels. Each ten bit character is made up of a start bit,

seven bit ASCII code, a parity bit and a stop bit. Device

number, baud rate, parity and strobe list are entered in the

program setup mode and will remain in memory even if power

is lost.

The input impedance of RS232 is 3KΩ to 7KΩ worst case. The

terminal addressing the unit must be capable of driving all

loads in the loop. The input impedance of RS422 is much

higher and there should be no problem driving as many as 99

units. The transmit line remains in a high impedance "off"

state until addressed. Only one unit is to be on line at a time!!!

More than one unit on line could damage the unit or destroy

the transmitted data.

When the unit is active (on line) it will operate in a full duplex,

echo back mode, so that data sent from the terminal will be

transmitted back for verification. When the unit is "on line",

use the proper serial transmit commands to request data or

set a new value. Up to 80 characters of data can be linked

together and transmitted to the unit in a string as long as there

is a space between the commands. If an error is made, a

correction can be made by back spacing and retyping correct

data before the return (enter) is sent. Once a return (enter) is

sent, the unit begins processing the data and will transmit the

requested data on a non-priority basis over the data transmit

line. A keypad entry or incoming data will halt the data

communication cycle. Therefore, there should be a pause

after data is requested to insure that all data has been

transmitted before making another request or addressing

another unit. If the unit is not busy, it should not take longer

than 300 msec to process each request. To find the cycle time

to process and transmit a request, calculate the bit transmit

time by using this formula: [(1÷ baud rate) x (80) + .005] x

number of requests made. This time will be extended if the

unit must service the front keypad. If transmission has not

started within two seconds after data is requested, it can be

assumed that there is a problem. The unit transmits a carriage

return and line feed after each data value. Any new communication must be started with DXX(S) (device number and

space).

RS232/RS422 - IBM-PC INTERFACE:

The following program is for IBM basic to set up RS232/RS422

on serial port (#1) at 300 baud. Run this program after

connecting the serial interface connections.

10 SCREEN 0,0:WIDTH 80

20 CLS:CLOSE

30 OPEN "COM1:300,n,7,1,CS,DS,CD" AS #1

40 ON ERROR GOTO 110

50 B$=INKEY$

60 IF B$< >"" THEN PRINT #1,B$;

70 IF EOF (1) THEN 50

80 A$=INPUT$ (LOC(1),#1)

90 PRINT A$;

100 GOTO 50

110 RESUME

18

Page 24

RS232 / RS422 WIRING

234

5

678

9

COMPUTER HOOKUP:

RS 232: When connecting the unit to a computer with RS 232

communication, only three connections are needed. These

connections are: Receive data, Transmit data and Ground.

The connections should be made as follows:

DP -9 CONNECTOR COMPUTER

Transmit data (pin 2) Receive data

Receive data (pin 3) Transmit data

Ground (pin 5) Ground

RS 422: When connecting the unit to a computer with RS 422,

five connections are needed. These connections are: Receive data A (+), Receive data B (-), Transmit data A (+),

Transmit data B (-) and Ground. The connections should be

made as follows:

RST

B C

D E

A

ENTER LOCK PRE A PRE B VIEW PRGM

RST

B C

D E

A

ENTER LOCK PRE A PRE B VIEW PRGM

RS 232

RECEIVE PIN (3)

TRANSMIT PIN (2)

GROUND PIN (5)

RS 422

RECEIVE A (+) PIN (3)

RECEIVE B (-) PIN (8)

TRANSMIT A (+) PIN (2)

TRANSMIT B (-) PIN (7)

GROUND PIN (5)

1

DP -9 CONNECTOR COMPUTER

Transmit data A(+) (pin 2 Receive data A(+)

Transmit data B(-) (pin 7) Receive data B(-)

Receive data A(+) (pin 3) Transmit data A(+)

Receive data B(-) (pin 8) Transmit data B(-)

Ground (pin 5) Ground

PRINTER HOOKUP:

When connecting the unit to a printer, you must first program

the desired baud rate, parity and strobe list with a computer.

After the unit is programmed it can be connected to the printer.

Connect the transmit line(s) of the unit to the receive line(s) of

the printer and be sure that both devices have common

grounds. When the strobe line is triggered the unit will transmit

the selected strobe list which you had previously programmed.

RS 232

1. INITIALIZE

2. TRANSMIT

3. RECEIVE

4. N/C

5. GROUND

6. STROBE

7. N/C

8. N/C

9. N/C

RST

B C

D E

A

ENTER LOCK PRE A PRE B VIEW PRGM

RS 232

STROBE PIN (6)

+12V PIN (7)

(BOTTOM BOARD)

TRANSMIT PIN (2)

GROUND PIN (5)

RS 422

STROBE PIN (6)

+12V PIN (7)

(BOTTOM BOARD)

RS 422

1. INITIALIZE

2. TRANSMIT A (+)

3. RECEIVE A (+)

4. N/C

5. GROUND

6. STROBE

7. TRANSMIT B (-)

8. RECEIVE B (-)

9. N/C

RST

B C

A

ENTER LOCK PRE A PRE B VIEW PRGM

TRANSMIT A (+) PIN (2)

D E

TRANSMIT B (-) PIN (7)

GROUND PIN (5)

19

Page 25

TROUBLESHOOTING GUIDE

PROBLEM SOLUTIONSPOSSIBLE CAUSES

Power is applied to unit but the display

does not light.

Unit works, but occasionally the display

freezes or skips counts.

Input signal is connected but the unit

does not count or display rate.

Rate is displaying: r FFFFF.

1. AC or DC power wiring is incorrect.

1. Line noise is affecting the processor

due to a current spike or surge.

1. Input wiring is incorrect.

2. Scale factors are incorrect.

3. Transmitting device is defective.

4. Wrong debounce filtering selected.

5. Unit is defective.

1. The unit is trying to display a

number which it can't (too small or

too large).

2. Line noise affected unit on power

up.

1. Recheck power wiring

1. Use a different power supply or

install a surge suppressor.

1. Recheck input wiring.

2. Recheck scale factors and factor

calculations.

3. Replace transmitting device.

4. Recheck debounce filtering selection

"hi cps" or "lo cps".

5. To confirm set scale factors at one

and connect a wire to pin #7 and

touch it to pin # 5 (input A). Each

time pin #5 is touched counter A

should count once. If not, call

OMEGA. (this test will not

work on units with quadrature input)

1. Check scaling factor, if it is correct,

lower the number of significant

figures.

2. Reprogram the unit, be sure to enter

a decimal (enter one and remove it if

a decimal is not desired).

Relays are not activating properly.

Counter resets before reaching 999999.

Various menu items are not being

displayed.

1. Wrong relay duration.

2. Relay set for wrong activation

i.e. count instead of rate.

1. Relay duration is set at a value other

than 00.0. This causes the counter

to auto-reset at the preset.

1. The menu flow chart and the setup

steps show the setup for the units

with rate and total (DPF75). When

using a unit which has only count

(DPF76) or only rate (DPF78)

several menu items will not be

displayed.

1. Recheck programmed relay duration.

2. Recheck programmed relay

activation mode.

1. If relay outputs are not being used,

set the relays for rate (DPF75 only).

2. Set the relay durations to 00.0.

1. The menu items which do not

appear are not used for the models

without the ratemeter (DPF76) or

without the counter (DPF78).

Therefore, disregard any menu items

which appear on the flowchart and

setup steps, but do not appear on

the unit's display.

20

Page 26

NOTES

21

Page 27

NOTES

22

Page 28

NOTES

23

Page 29

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

grace period to the normal one (1) year product warranty to cover handling and shipping time. This

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR W

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

2. Model and serial number of the product under

3. Repair instructions and/or specific problems

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

ARRANTY RETURNS, please have the

was PURCHASED,

warranty, and

relative to the product.

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 30

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

䡺⻬

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

䡺⻬

Wire: Thermocouple, RTD & Thermistor

䡺⻬

Calibrators & Ice Point References

䡺⻬

Recorders, Controllers & Process Monitors

䡺⻬

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

䡺⻬

Transducers & Strain Gages

䡺⻬

Load Cells & Pressure Gages

䡺⻬

Displacement Transducers

䡺⻬

Instrumentation & Accessories

FLOW/LEVEL

䡺⻬

Rotameters, Gas Mass Flowmeters & Flow Computers

䡺⻬

Air Velocity Indicators

䡺⻬

Turbine/Paddlewheel Systems

䡺⻬

Totalizers & Batch Controllers

pH/CONDUCTIVITY

䡺⻬

pH Electrodes, Testers & Accessories

䡺⻬

Benchtop/Laboratory Meters

䡺⻬

Controllers, Calibrators, Simulators & Pumps

䡺⻬

Industrial pH & Conductivity Equipment

DATA ACQUISITION

䡺⻬

Data Acquisition & Engineering Software

䡺⻬

Communications-Based Acquisition Systems

䡺⻬

Plug-in Cards for Apple, IBM & Compatibles

䡺⻬

Datalogging Systems

䡺⻬

Recorders, Printers & Plotters

HEATERS

䡺⻬

Heating Cable

䡺⻬

Cartridge & Strip Heaters

䡺⻬

Immersion & Band Heaters

䡺⻬

Flexible Heaters

䡺⻬

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

䡺⻬

Metering & Control Instrumentation

䡺⻬

Refractometers

䡺⻬

Pumps & Tubing

䡺⻬

Air, Soil & Water Monitors

䡺⻬

Industrial Water & Wastewater Treatment

䡺⻬

pH, Conductivity & Dissolved Oxygen Instruments

Loading...

Loading...