Page 1

TM

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

www.omegamanual.info

Universal 6/12 Channel ¼ DIN Panel Meter

DP606A/DP612A

Page 2

omega.com info@omega.com

Servicing North America:

Omega Engineering, Inc.

U.S.A.

800 Connecticut Ave, Suite 5N01

Headquarters:

Norwalk, CT 06854 USA

Toll-Free: 1-800-826-6342 (USA & Canada only)

Customer Service: 1-800-622-2378 (USA & Canada only)

Engineering Service: 1-800-872-9436 (USA & Canada only)

Tel: (203) 359-1660 Fax: (203) 359-7700

e-mail: info@omega.com

For Other Locations Visit omega.com/worldwide

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves

the right to alter specifications without notice.

Page 3

Table of

Contents

DP600A, DP606A, DP612A Series

Table of Contents

Section ..................................................................................... Page

Section 1 Introduction .................................................................................... 1

Section 2 Installation and Operating Conditions ..................................... 2

Section 3 Mounting Instructions .................................................................. 3

Section 4 Wiring Instructions ....................................................................... 4

4.1 Rear Panel Diagram ................................................................. 4

4.2 Connecting Power .................................................................... 5

4.3 Connecting Alarms .................................................................. 6

4.4 Connecting Communications ................................................ 7

4.5 Connecting Inputs .................................................................... 7

Section 5 Navigation ....................................................................................... 8

5.1 RUN Mode ................................................................................. 8

5.2 Lock Zones ................................................................................. 9

5.3 Clear Alarms ............................................................................. 9

5.4 Check Alarm Values ................................................................ 9

5.5 Function Select Mode ............................................................... 9

5.6 Reset Defaults ........................................................................... 9

5.7 Function Select Mode ............................................................ 10

5.8 Function 1-Enter Password .................................................. 11

5.9 Function 2-Set Active Zones ................................................ 11

5.10 Function 3 and 4-Set Low and High Alarms .................... 12

5.11 Function 5-Modbus Address ............................................. 13

5.12 Function 6-Set Scan Time ................................................... 13

5.13 Function 7-Set Device Configuration ......................... 14-15

5.14 Function 8-Password Enable/Disable ............................... 16

5.15 Function 9-Calibration ........................................................ 16

5.16 Function A/B-Alarm Relay Function ................................ 17

5.17 Function C/D-Scaling .......................................................... 18

5.18 Function F-Serial Configuration ....................................... 19

Section 6 Serial Interface ............................................................................. 20

6.1 Modbus Functions .................................................................. 20

6.2 Data Formats ........................................................................... 21

6.3 Multiple Register Reads ....................................................... 21

6.4 Multiple Register Writes ...................................................... 22

6.5 Request Packet Sizes ............................................................. 22

Page 4

Table of Contents

Section ..................................................................................... Page

Table of

DP600A, DP606A, DP612A Series

Contents

Section 7 Modbus Register Assignments ................................................. 23

7.1 System Registers ..................................................................... 23

7.2 Temperature Registers .......................................................... 24

7.3 Status Registers ...................................................................... 24

7.4 Zone Registers ........................................................................ 25

7.5 User Calibration ...................................................................... 26

7.6 Enumerated Values ............................................................... 26

7.7 Sensor Type ............................................................................. 26

7.8 RTD Type ................................................................................. 26

7.9 Thermocouple Type .............................................................. 27

7.10 Sensor Status ......................................................................... 27

7.11 System State .......................................................................... 27

7.12 Process Unit .......................................................................... 28

7.13 Alarm Type ............................................................................ 28

7.14 Alarm Status ......................................................................... 28

7.15 Setting Toggle ....................................................................... 28

Section 8 Specifications ................................................................................ 29

8.1 Alarm Relays ........................................................................... 29

8.2 Input Accuracy ....................................................................... 30

Section 9 Approvals Information ............................................................... 31

Page 5

Table of

Contents

DP600A, DP606A, DP612A Series

Table of Figures and Tables

Figures ..................................................................................... Page

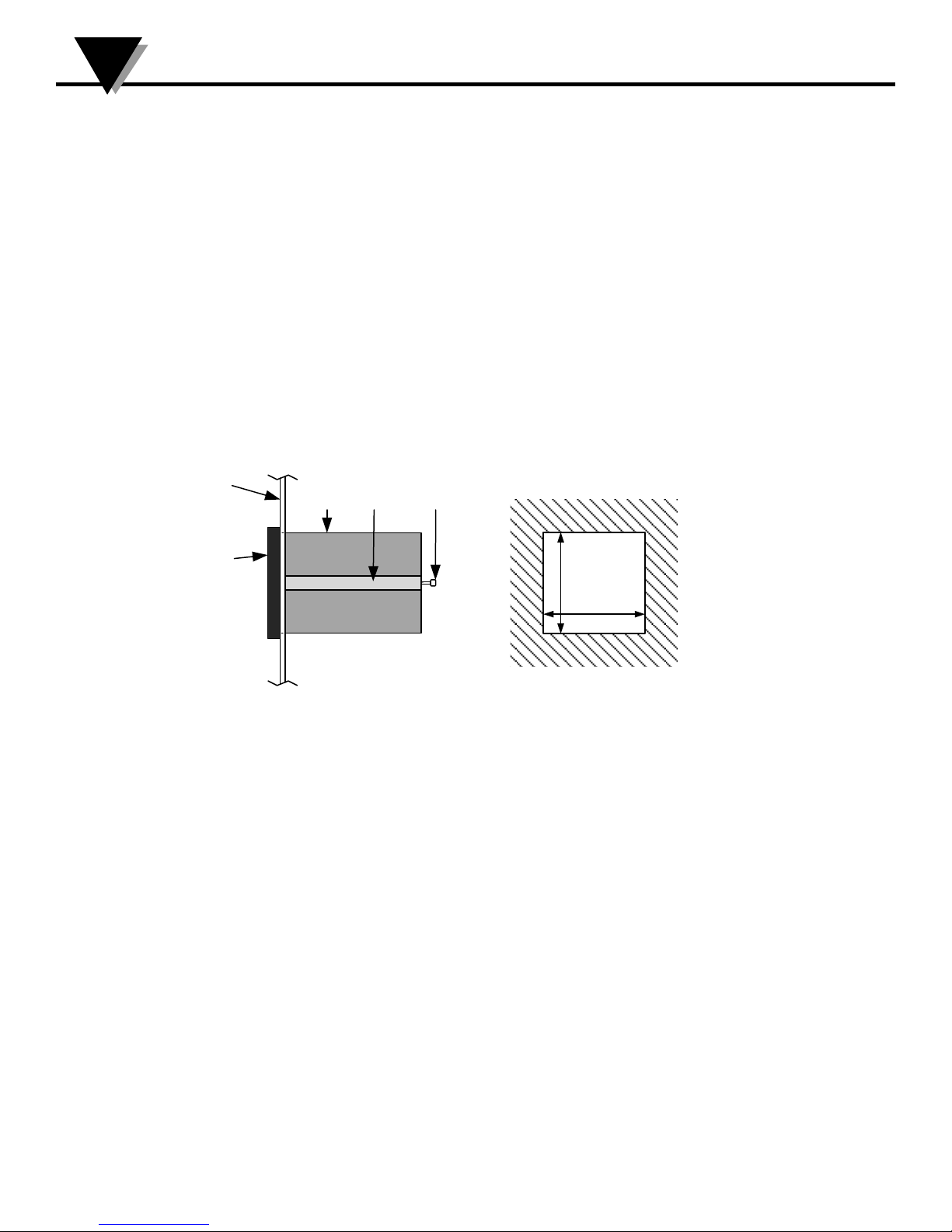

Figure 1 Side and Panel Cutout Views ...................................................... 3

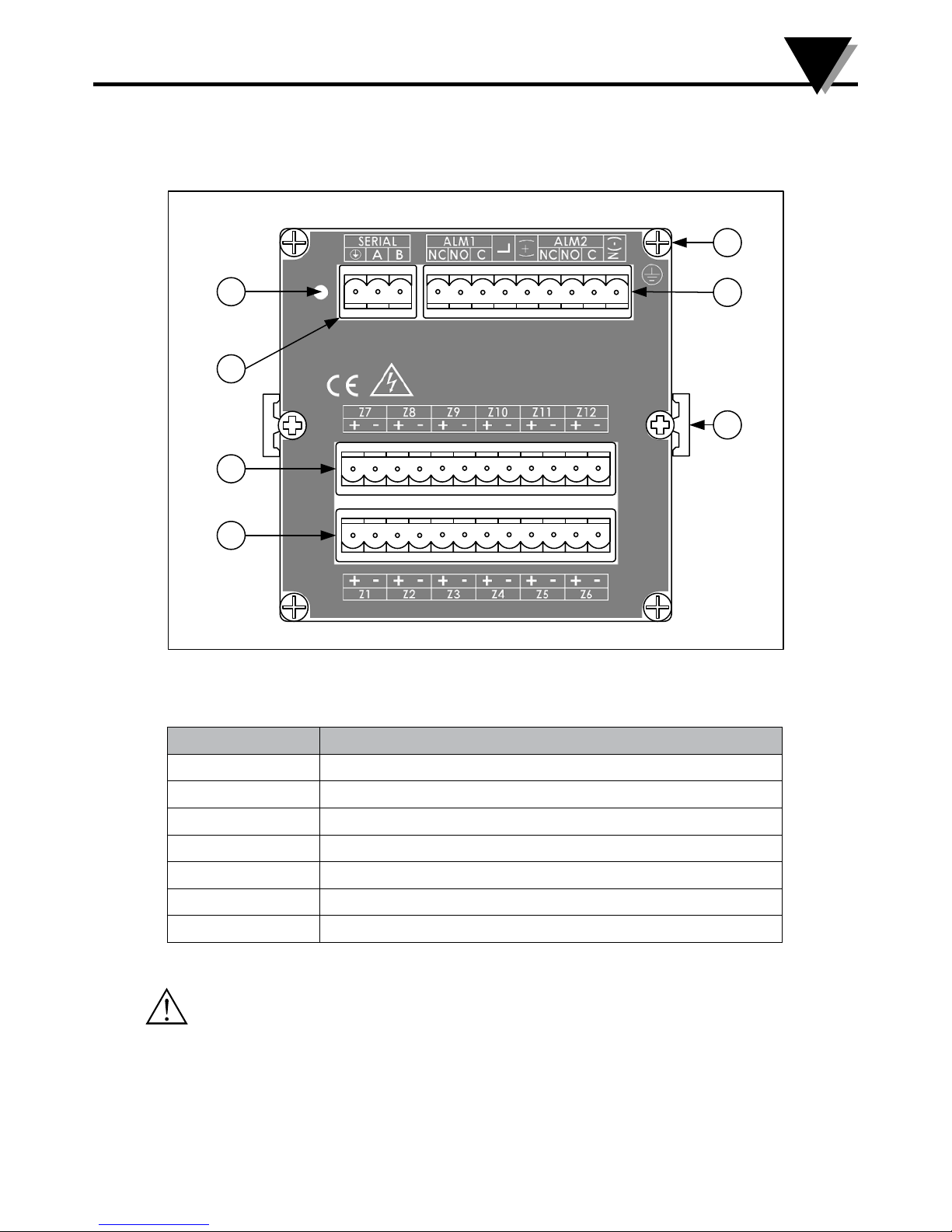

Figure 2 DP606A/DP612A: Rear Panel Connections ............................... 4

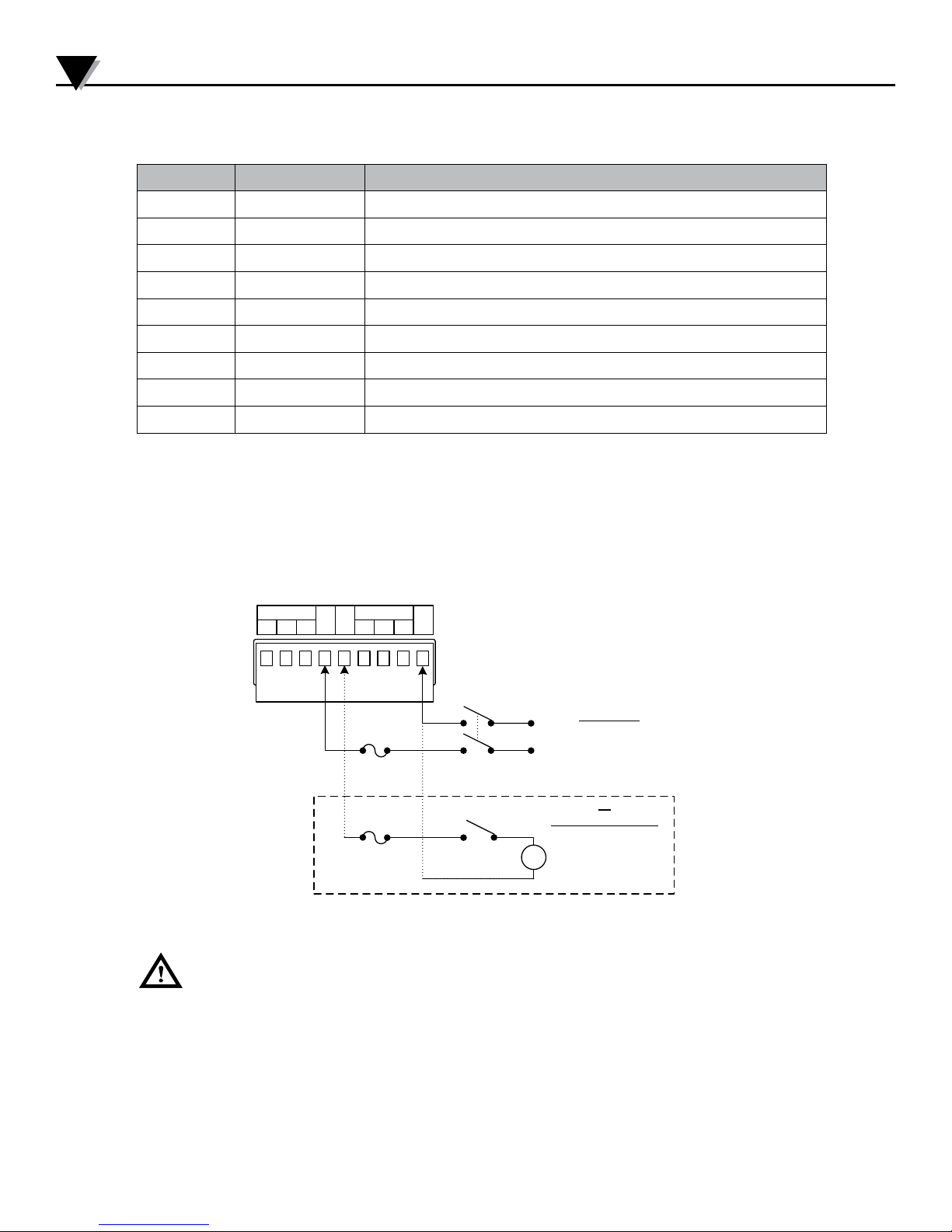

Figure 3 Main Power Connections ............................................................. 5

Figure 4 Relay Connections ......................................................................... 6

Figure 5 3 Wire RTD Wiring Diagram ....................................................... 7

Figure 6 Front Panel Diagram ..................................................................... 8

Figure 7 Process Input Scaling .................................................................. 18

Table ........................................................................................ Page

Table 1 Rear Panel Connections ................................................................ 4

Table 2 9 Pin Input Power/Relay Wiring Summary .............................. 5

Table 3 Connecting Communications ...................................................... 7

Table 4 Function Codes ............................................................................. 10

Table 5 Device Configuration .................................................................. 14

Table 6 Alarm Relay Configuration ....................................................... 17

Table 7 Serial Port Configuration ........................................................... 19

Table 8 Modbus Functions ....................................................................... 20

Table 9 Mulitple Register Writes ............................................................ 22

Table 10 Packet Sizes ................................................................................... 22

Table 11 System Registers .......................................................................... 23

Table 12 Temperature Registers ................................................................ 24

Table 13 Sensor Status Registers ............................................................... 24

Table 14 Zone Registers .............................................................................. 25

Table 15 User Calibration ........................................................................... 26

Table 16 Input Accuracy ............................................................................. 30

Page 6

1

Introduction

Section 1 - Introduction

The DP606A/DP612A Display Meter offers a flexible, easy to use 6 or 12 zone, 4 digit

temperature and process measurement solution in a rugged ¼ DIN Aluminum

housing. Selectable configuration eliminates the need for jumpers.

The DP606A supports 6 independent zones and the DP612A supports up to 12 zone

(3 wire RTD limited to 6 zones on all models). All zones are scanned at a 400ms rate.

The display shows the reading of each zone sequentially. High and low Alarms with

SPDT relay outputs are available for monitoring and alarm purposes.

The universal input supports 9 thermocouple types (J, K, T, E, R, S, B, C, and N), 2 or

3 wire RTDs (Pt 100, Ni 120, Cu 10), DC voltage (0-1 Vdc), or DC current (0 – 24 mA).

Independent alarms are available for each zone. Each alarm can be configured for

above (HI), below (LO) or HI/LO triggering. Alarms conditions will be indicated on

the display meter and may be used to activate either of the 2 SPDT relay outputs.

A user selectable RS232 or RS485 serial port interface is standard on all models and

uses the Modbus RTU protocol for configuration management and data transfer.

The universal AC power supply accepts 90–240 Vac. The isolated DC power option

accepts 9–36 Vdc.

A security password can be used to prevent front panel tampering of the

configuration.

1

Page 7

Installation and Operating Conditions

Section 2 - Installation and Operating Conditions

This Instrument is marked with the international Caution symbol. It is important to

read and follow the Setup Guide before installing or commissioning this device. The

Guide contains important information relating to safety and EMC.

The instrument is a device protected in accordance with UL 61010:2010 Electrical

Safety Requirements for Electrical Equipment for Measurement, Control and

Laboratory. The device has no power-on switch. Installations must include a switch

or circuit breaker that is compliant to IEC 947-1 and 947-3. It must be suitably

located to be easily reached and marked as the disconnecting device for the

equipment.

WARNING: Do NOT connect AC power to your device until you have completed

all input and output connections. This device is a panel mount device protected in

accordance with Class I of EN 61010 (115/230 AC power connections), Class III for

the DC power option (9-36Vdc). It must be installed by a trained electrician with

corresponding qualifications. Failure to follow all instructions and warnings may

result in injury.

Use Copper conductors only, minimum 20 AWG, UL Rated, for power and outputs.

Insulation must be rated for at least 85ºC and 600V.

2

This device is not designed for use in, and should not be used for, patient-connected

applications.

Safety:

EMC:

WARNING: Failure to follow all instructions and warnings is at your own risk and

may result in property damage, bodily injury and/or death. Omega Engineering

is not responsible for any damages or loss arising or resulting from any failure to

follow any and all instructions or observe any and all warnings.

• Do not exceed the voltage rating on the label located on the device housing.

• Always disconnect power before changing signal and power connections.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

• Whenever EMC is an issue use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• If EMC problems occur Install Ferrite Bead(s) on signal wires close to the

instrument.

CAUTION: Risk of electric shock. Disconnect all power sources before servicing.

2

Page 8

3

Pane l

Bezel

Cas e Slide Sc re w

SideView

User

Acce ssible

BehindPanel

PanelCutout

92mm

92mm

Mounting Instructions

Section 3 - Mounting Instructions

Select a location for the monitor that is free from excessive shock, vibration, dirt,

moisture and oil. Mount the monitor into a 3 5/8” (92mm) square cutout. The

monitor as shipped is 1/4 DIN (92mm square), so it does not have to be removed

from its housing to be mounted. Remove the two screws that secure the mounting

slides. Remove the slides and insert the case into the cutout from the front side of

the panel. Reinstall the two slides and two screws. The length of the slides must be

reduced if the monitor is to be mounted in an extra thick panel.

Ensure that the unit is properly grounded to the panel which should be earth

grounded. Use the supplementary ground point indicated on the rear panel if a

good ground connection cannot be maintained from the mounting slides alone.

Figure 1 - Side and Panel Cutout Views

3

Page 9

1

2

3

4

5

6

19

13

1 12

7

Section 4.1 - Rear Panel Diagram

Wiring Instructions

4

Figure 2 - DP606A/DP612A: Rear Panel Connections

Item Description

1 Reset Pinhole

2 Serial Connector

3 Input 7 through 12

4 Input 1 through 6

5 Supplementary Ground Point

6 Power and Alarm Connector

7 Mounting Slide

Caution: Use only provided terminals. Torque all connections to 0.5-0.6Nm.

Table 1 - Rear Panel Connections

4

Page 10

4

NC

L

ALM1

NO C

(+)

N(-)

NC

ALM2

NO C

19

N

L

SW

Fuse

SW

+

-

Or

DCPOWEROPTION

90–240Vac

9–36Vdc

ACP O WER

Fuse

Wiring Instructions

Section 4.2 - Connecting Power

Pin No. Code Description

1 N(-) Neutral Power / DC-Power supply

2 ALM2 C Alarm Relay 2 Common

3 ALM2 NO Alarm Relay 2 Normally Open

4 ALM2 NC Alarm Relay 2 Normally Closed

5 (+) DC + Power supply (9-36 VDC)

6 L Line Power (90-240 VAC)

7 ALM1 C Alarm Relay 1 Common

8 ALM1 NO Alarm Relay 1 Normally Open

9 ALM1 NC Alarm Relay 1 Normally Closed

Table 2 - 9-Pin Input Power/Relay Wiring Summary

Connect the main power connections to pins 4 and 9 (AC Power) or pins 5 (+) and 9

(-) (DC Power) of the 9pin power / output connector as shown in Figure 3.

Figure 3 - Main Power Connections

For the low-voltage power option, maintain the same degree of protection as the

standard high-voltage input power units (90–240 Vac) by using a Safety Agency

Approved DC source with the same Overvoltage Category and pollution degree as

the AC model.

The Safety European Standard EN61010-1 for measurement, control, and laboratory

equipment requires that fuses must be specified based on IEC127. This standard

specifies the letter code “T” for a Time-lag fuse.

5

Page 11

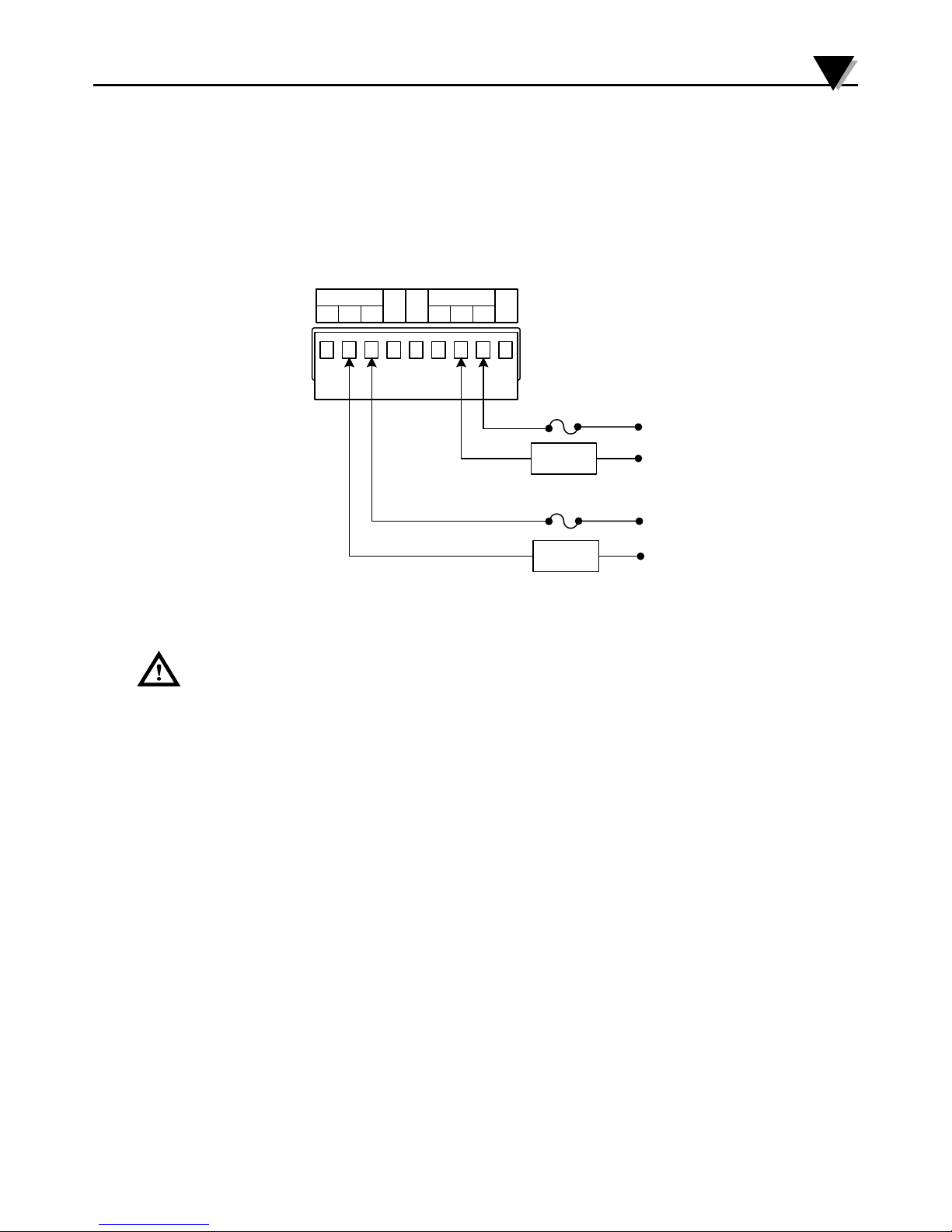

Section 4.3 - Connecting Alarms

NC

L

ALM1

NO C

(+)

N(-)

NC

ALM2

NO C

19

Fuse

Fuse

Lo ad

Load

The DP606A/DP612A Series includes SPDT mechanical relays with internal

snubbers on the normally open contact side. When powered and not in an alarm

state the relays are Energized and the NO contact is connected to the Relay

common contact. If an alarm condition occurs or if the unit loses power the relay is

deenergized and the NC contact is connected to the Relay common contact.

Wiring Instructions

4

Figure 4 - Relay Connections

WARNING: For the low-voltage power option, maintain the same degree of

protection as the standard high-voltage input power units (90–240 Vac) by using a

Safety Agency Approved DC or AC source with the same Overvoltage Category and

pollution degree as the standard AC unit (90–300 Vac).

The Safety European Standard EN61010-1 for measurement, control, and laboratory

equipment requires that fuses must be specified based on IEC127. This standard

specifies the letter code “T” for a Time-lag fuse.

6

Page 12

4

+ -Z1+ -Z2+ -Z3+ -Z4+ -Z5+ -

Z6

+ - + - + - + - + - + -

Z7 Z8 Z9 Z10 Z11 Z12

Wiring Instructions

Section 4.4 - Connecting Communications

Pin No. Code Description

1 B RS485 B signal, RS232 TX (to remote device)

2 A RS485 A signal, RS232 RX (from remote device)

3 RTN signal for serial communications

Table 3 - Connecting Communications

Note: The RTN signal is isolated from the Signal RTN and the Power GND.

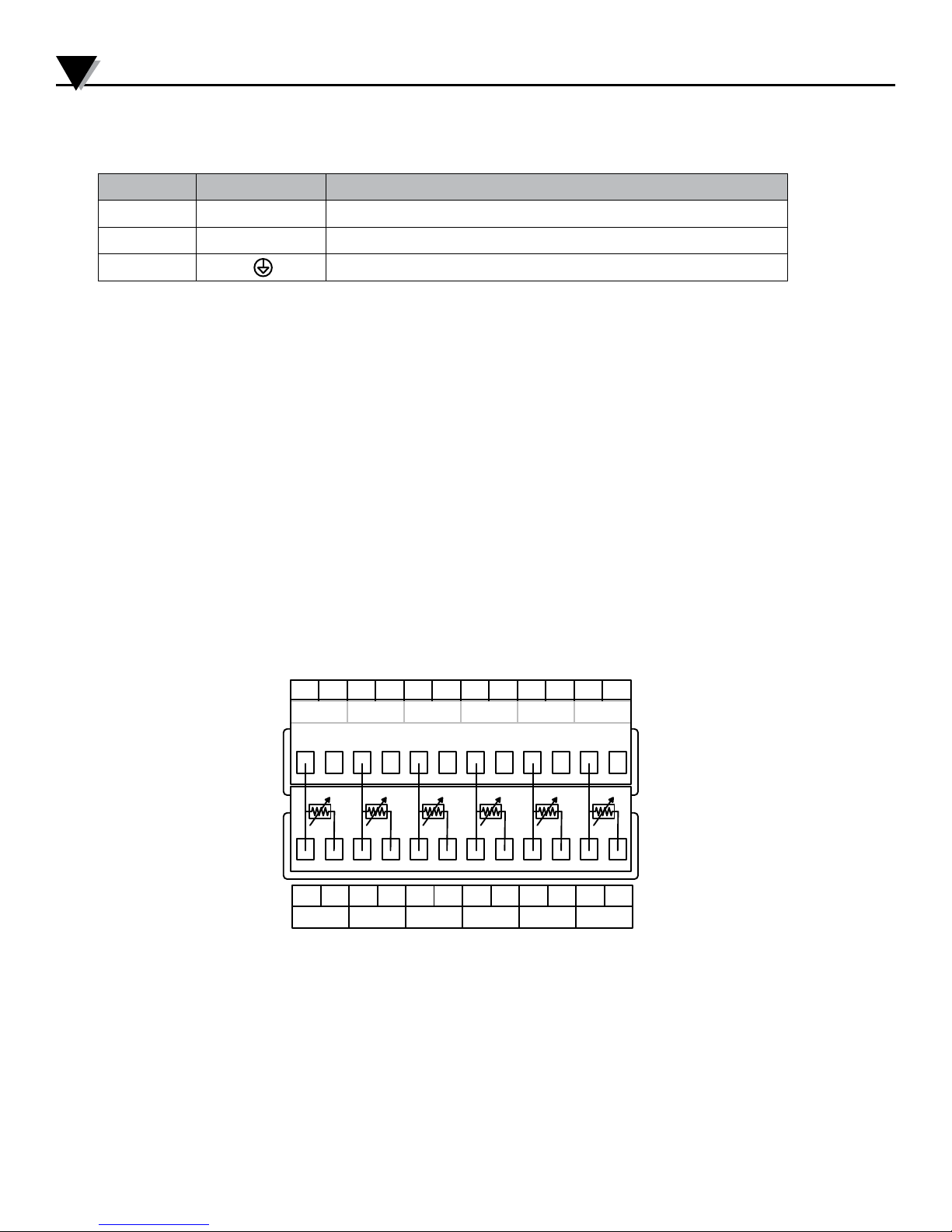

Section 4.5 - Connecting Inputs

Connect Input sensors to the terminals Marked Zone 1 though Zone 12 (Z1 – Z12) on

the rear panel. For the DP606A only Zones 1 through 6 are active and Terminals Z7

– Z12 are only used for 3 Wire RTDs. When connecting sensors follow the polarity

indicated on the rear panel. For Thermocouples the Negative wire is Red (NA) or

White (IEC 584-3). For Process Inputs the Negative terminal is ground.

For the RTD 3 wire option the common wires must be connected to the + terminals

of both the upper (Z1 – Z6) and lower (Z7 – Z12) input boards. The negative terminal

of Z7- Z12 remains unconnected. If a 2 wire RTD needs to be used in 3 Wire mode

use a jumper wire to connect the upper and lower terminals together. Refer to the

wiring diagram below.

Note that all negative input terminals share a common internal ground connection.

Ensure that all sensors share a common ground or are fully isolated.

Figure 5 - 3 Wire RTD Wiring Diagram

7

Page 13

Section 5 - Series Navigation

ºC

ºF

mA

mV

Function Zone

1

2

3

7

6

5

4

Series Navigation

5

Item Description

1 Main Display

2 Function Display

3 Advance Button

4 Increment Button

5 Select Button

6 Zone Display

7 Unit/Mode Indicator

Section 5.1 - RUN Mode

When power is applied to the unit it will automatically enter the RUN mode,

sequentially scanning each active zone and activating alarms if required. The Main

display shows the measured value of the indicated zone. The unit will change to

each active zone in sequence the user determined rate.

While in the RUN mode the user may lock the display at the current zone, clear any

latched alarms, examine the current Alarm values or enter the PROGRAMMING

mode.

Figure 6 - Front Panel Diagram

8

Page 14

5

Series Navigation

Section 5.2 - Lock Zones

Symbol Description

The display stops cycling thru each display. The currently selected

zone information will be continuously updated on the display. Note

that all active zones continue to be read and any alarm conditions

will activate the enabled alarm relays.

The Lock option is released and the value display will cycle thru all

active zones.

Section 5.3 - Clear Alarms

Any active, latched alarm is cleared.

Section 5.4 - Display Alarm Values

Displays the Alarm Value for the current zone and stops scanning.

The Main display shows the Alarm value. The Zone display shows

the zone.

Increments the Zone number and displays the next

Alarm Value.

Switches between HI and LO Alarm Values. The Function

display shows 3 when displaying Low values and 4 when

displaying High Values.

Return to Run Mode

Section 5.5 - Function Select Mode

Enter Function Select Mode from Run Mode

Section 5.6 - Reset Defaults

Hold all 3 buttons down for 5 seconds to reset unit to Factory

Defaults. The unit will reboot and return to Run Mode.

9

Page 15

Section 5.7 - Function Select Mode

While in function select mode 1 is displayed in the Function Display and the

selected function is displayed in the Main display.

The DP606A/DP612A monitor has several different Functions listed in the table

below.

Function Description

0 Return to Run Mode

1 Function Select / Enter Password

2 Set Active Zone

3 Set Low Alarms

4 Set High Alarms

5 Set Modbus Address

6 Set Scan Time

7 Set Model Options

Series Navigation

5

8 Password Enable and Disable

9 Calibration

A Set Alarm 1 Options

B Set Alarm 2 Options

C Set Low Scale

D Set High Scale

F Set Serial Options

Table 4 - Function Codes

Navigate Function Select Mode using the button below.

Increments the Function Code displayed in the

Main display.

Enters the Function displayed in the Function

display.

If the Password option is enabled only Functions 0 and 1 will be available. Entering

the correct password in Function 1 will unlock the rest of the menu options. If the

Password is disabled Function 1 will not be available.

10

Page 16

5

ºC

ºF

mA

mV

Function Zone

Series Navigation

Section 5.8 - Function 1 - Enter Password

A password may be enabled to prevent unintended changes to the unit. The

password is a 4 digit code and the default Password is 1011. The password can only

be changed using the serial port.

Use the buttons below to enter the password.

Increment the flashing digit of the Main display

Selects the next digit of the Main display, causing it to flash

Enters the Password

After entering the password the unit will return to function select mode. If the

password is correct all of the functions will be available. If the password was entered

incorrectly it must be re-entered by selecting Function 1 again.

Section 5.9 - Function 2 - Set Active Zones

The main display is blank when selecting active zones. The current zone being

edited is shown in the Zone Display. Active zones are displayed solid while disabled

zones are displayed flashing. By default all zones are active.

Disabled zones are skipped while scanning and do not generate alarms. Use the

buttons below to change the active zone.

Advance to the next zone.

Toggles the current zone between enabled (solid) or disabled

(flashing).

Stores the enabled / disabled state for all zones and returns to

Function Select mode

11

Page 17

Section 5.10 - Function 3 and 4 - Set Low and High Alarms

ºC

ºF

mA

mV

Function Zone

The High and Low alarm values determine the readings that the Alarms will

activate at for each zone. The function selected is indicated in the function display.

Function 3 sets the low alarms and Function 4 sets the high alarms. The default Low

alarm is -900 and the default High alarm is 9000 for all zones.

The alarms for each zone are independent. The zone for the current alarm being

edited is shown in the zone display.

The current alarm value for the selected zone is shown in the main display. The left

most digit blinks indicating it can be edited. Use the buttons indicated below to edit

the alarm values.

Series Navigation

5

Increment the flashing digit of the VALUE display.

Selects the next digit of the VALUE display, causing it to flash.

Changes the decimal point.

Stores the current VALUE display as the alarm value for the

current zone and advances to the next zone.

Stores all values and returns to Function Select mode.

12

Page 18

ºC

ºF

mA

mV

Function Zo ne

5

ºC

ºF

mA

mV

Function Zo ne

Series Navigation

Section 5.11 - Function 5 - Set Modbus Address

The Modbus address is used for serial communications to determine which device

on a bus is being accessed. The current Modbus Address is shown in the Main

Display. The first digit flashes to indicate it can be edited. Use the buttons below to

edit the address.

By Default the Modbus address is 1 and any address from 1 to 247 can be used. The

unit will not allow an invalid address to be displayed. Trying to enter a number

greater than 247 will cause the display to roll back to a valid number.

Increment the flashing digit of the Main display.

Selects the next digit of the Main display, causing it to flash.

Stores the Device address and returns to the Function Select

mode.

Section 5.12 - Function 6 - Set Scan Time

The scan time is the time each zone is displayed on the front panel before advancing

to the next zone. By Default, the scan time is 3 seconds. The current scan time is

displayed in the Main Display and the zone display is blank. The left most digit

blinks indicating it can be edited. Use the buttons below to edit the scan time.

Increment the flashing digit of the VALUE display.

Selects the next digit of the VALUE display, causing it to flash.

Stores the current VALUE display as the SCAN time and returns

to the Function Select mode.

13

Page 19

Section 5.13 - Function 7 - Set Device Configuration

ºC

ºF

mA

mV

Function Zone

Function 7 sets the device configuration including the Alarm Type, Units and input

type. The default setting for Function 7 is 2204 which represents Thermocouple

Type K inputs with High/Low Latching alarms in Degrees Celsius.

Each digit in the Main Display represents a different function. Refer to the table

below for the specific functions.

Series Navigation

5

Digit 1 Digit 2 Digit 3 Digit 4

Alarm

Type

Unit

Alarm

Latch

Input Type

TC

Type

RTD

Type

Decimal

Points

0 High 0 C Latching 0 TC 0 B Pt100 0

1 Low 1 F Latching 1 RTD2 1 C Ni120 1

2 High/

Low

3 Off 3 F Non-

2 C Non-

Latching

2 RTD3 2 E Cu10 2

3 mA 3 J 3

Latching

4 User 4 mV 4 K

5 R

6 S

7 T

8 N

Please note: Digit 4 is dependent upon the “Input Type” selected under Digit 3. Ex: If “TC” is selected under “Input Type” under Digit 3, Digit

4 becomes one of the following “B, C, E, J, etc.” under “TC Type.”

Table 5 - Device Configuration

14

Page 20

5

Series Navigation

Section 5.13 - Function 7 - Set Device Configuration cont.

Digit 1 is the Alarm type. High alarms will deactivate the relay when the Zone

process value is Above the High Alarm Value defined in Function 4. Low alarms will

deactivate the relay when the Zone process value is below the Low alarm defined in

Function 3. High/Low will trigger on both alarms and Off will not trigger alarms at

all. If different operation is desired for Relay 1 and Relay 2 or if different alarm types

need to be used per zone these can be setup in Functions A and B by selecting

User controlled.

Digit 2 defines the Units displayed for TC and RTD inputs. It also selects between

Latching and Non-Latching alarms. Latching alarms will remain active until the

latch is cleared by the user regardless of the current input value. Non-latching

alarms will deactivate as soon as the input no longer meets the alarm conditions.

The Alarm Latch Type is overwritten by the User settings if user is selected for the

Alarm Type.

Digit 3 selects between the available input types. The input type cannot be changed

individually per zone. When selecting RTD 3 wire input only 6 zones will be active

on a 12 Zone unit.

Digit 4 is context sensitive and depends on Digit 3. If TC or RTD type input are

selected Digit 4 selects the type of sensor. If mV or mA type input are selected

Digit 4 represents the maximum number of decimal points that will be displayed.

If all decimal points cannot be displayed the display will be rounded to the nearest

displayable number. Temperature readings can only be displayed to the nearest

whole number.

Increment the flashing digit of the VALUE display.

Selects the next digit of the VALUE display, causing it to flash.

Stores the current VALUE display as the Input Type advances

to the next zone. Note that this button will have no effect if the

VALUE display is selecting an invalid input type.

15

Page 21

Section 5.14 - Function 8 - Password Enable/Disable

ºC

ºF

mA

mV

Function Zo ne

ºC

ºF

mA

mV

Function Zone

Using Function 8, a user password may be enabled to protect the unit from

inadvertent changes. By Default the Password is disabled.

The default password is 1011. This can only be changed using the serial port.

Toggle the password from enabled (1) and disabled (0)

Stores the current VALUE display as the password enabled

state and returns to the Function Select mode.

Series Navigation

5

Section 5.15 - Function 9 - Calibration

The DP600A and DP612A are factory calibrated and do not require additional user

calibration under most circumstances. For 2 wire RTDs Function 9 may be used to

calibrate out lead wire resistance. This calibration is done independently for each

channel.

To perform lead wire calibration short the RTD that needs to be calibrated at the

end of the lead wire. Next select the Zone to be calibrated in the primary Display

using the increment button. Press the select button to perform the calibration. While

the unit is calibrating the Zone flashes to indicate it is busy. Once the calibration

is complete the Zone will stop flashing. If the lead wire resistance is more than 10

ohms the unit will display “FAIL” and the calibration value will be set to 0.

Scroll to next zone

Perform Calibration on current zone

Returns to Function Select mode

16

Page 22

ºC

ºF

mA

mV

Function Zo ne

5

Series Navigation

Section 5.16 - Function A/B - Alarm Relay Function

When split operation is selected in Function 7, Alarm relay operation is customized

using functions A and B.

Function A Controls Alarm 1 and Function B controls Alarm 2. Each zone may be

assigned to one or more relays. By Default, Alarm 1 is assigned high / low alarms

for all zones and Alarm 2 is Disabled for all zones. The Current Zone being edited is

shown in the Zone Display. The current mode for that zone is displayed in the Main

Display.

Increment the flashing digit of the VALUE display

Selects the next digit of the VALUE display, causing it to flash

Moves to the next zone

Stores all values and returns to Function Select mode

Digit 1 Digit 2

Alarm Latching Alarm Type

0 Not Latched 0 High Alarm

1 Latching relay 1 Low Alarm

2 High and Low Alarm

3 Alarm Disabled

Table 6 - Alarm Relay Configuration

17

Page 23

Section 5.17 - Function C/D - Scaling

ºC

ºF

mA

mV

Function Zone

C

D

InputCurrent/Voltage

Functions C and D set the scaling for the mA and mV input. Function C sets the

Low Scale and Function D sets the High Scale. The scaling factors for mA and mV

are separate so the values corresponding to the input type selected in Function 7 are

shown.

By default the scaling is set to display the measurement in mA/mV.

Scaling factors are applied independently for each zone. The current zone being

modified is displayed in the Zone Display. Enter the value to be displayed at 4mA or

0V in Function C and the value to be displayed at 20mA or 1V in function D. Values

between the two points are linearly interpolated.

Series Navigation

5

Increment the flashing digit

Selects the next digit, causing it to flash

Changes the decimal point

Stores the current scaling factor for the indicated zone

advances to the next zone.

Stores all values and returns to Function Select mode

Figure 7 - Process Input Scaling

18

Page 24

5

Series Navigation

Section 5.18 - Function F - Serial Configuration

Function F sets up the serial port of the device. The default serial settings are RS485,

115.2k baud no Parity.

Increment the flashing digit on the display

Selects the next digit of the VALUE display, causing it to flash.

Stores the current VALUE display as the Serial configuration and

returns to the Function Select mode. This button will have no effect if the current VALUE is does not match a valid configuration.

Digit 1 Digit 2 Digit 3 Digit 4 (LSD)

Signaling Type Baud Rate Parity

0 RS485 0 4800 0 None 0 Reserved

1 RS232 1 9600 1 Odd

2 19200 2 Even

3 38400

4 57600

5 115200

Table 7 - Serial Port Configuration

19

Page 25

Section 6 - Serial Interface

The DP606A and DP612A uses the Modbus/RTU interface as described in MODBUS

APPLICATION PROTOCOL SPECIFICATION (V1.1b3).

The Modbus specification allows accessing to up 65535 internal ‘holding’ registers

using register READ, register WRITE and WRITE MULTIPLE commands. Each

Modbus holding register is defined as a 16 bit entity structured as BIG ENDIAN

values (most significant byte always presented first).

Modbus is structured using a MASTER-SLAVE topology, in which there is one

MASTER device and up to 247 slave devices. All transactions are initiated by the

MASTER device. The DP606A and DP612A acts as a slave device, with a device

address in the range 1 to 247.

Modbus slave devices are individually accessed using a one byte SLAVE address.

The MASTER device initiates a transaction by sending a request packet to a specific

slave. The SLAVE device processes the transaction and returns either response

packet indicating success or failure.

Address 0 is reserved as a ‘broadcast’ address, in which all slave devices will accept

and process the transaction but will not send a response.

Serial Interface

6

Section 6.1 - Modbus Functions

The DP606A and DP612A Modbus interface supports the following Modbus

FUNCTION requests.

Function Code Mnemonic Description

0x03 Read Holding Register Reads one or more consecutive 16 bit

holding registers

0x06 Write Single Register Writes a specific 16 bit holding register

0x07 Read Exception status Reads structured status information

0x08 Reserved

0x10 Write Multiple Registers Write one or more consecutive 16 bit

holding registers

0x0b Get Comm events Read communication event counters

Table 8 - Modbus Functions

20

Page 26

6

Serial Interface

Section 6.2 - Data Formats

Modbus holding registers are represented as 16 bit entities. The following encoding

is used for extended data items. Note that ‘byte 0’ will be the first byte received/

transmitted.

For data types that can be represented in 16 bits (Boolean, byte, char, int16 and

uint16) a single register is used.

For data types that require 32 bits two consecutive registers are used. The lower

number register will represent the most significant data. The 2nd register represents

the leas significant data.

Section 6.3 - Multiple Register Reads

When reading a dual register entity the lower order register should be used as the

requested ‘holding register’, with a request for a minimum of 2 registers. Internally

the entire entity is read and data is then built into a response packet.

The access can be split into 2 consecutive single register reads. When the lower

(base) register is accessed the entire 32 bit entity is read and the two most

significant bytes are returned. The following single register read must specify the

next consecutive register address. The two least significant bytes of the internally

buffered data used in the response.

Attempts to access the two least significant bytes without first reading the two most

significant bytes will result in an error response.

21

Page 27

Section 6.4 - Multiple Register Writes

When writing a dual register entity the lower order register should be used as the

requested ‘holding register’, with a request for minimum of 2 registers. The write

data is internally buffered and transferred to the database entry as a 32-bit value.

The access can be split into 2 consecutive single register writes. When the lower

(base) register is written the 16-bit entity is internally buffered BUT NO DATA

TRANSFER IS MADE TO THE DATABASE. The following single register write

must specify the next consecutive register address. The two least significant bytes

of the write request are combined with the previous write data and the entire 32-bit

entity is written to the database.

Attempts to write the two least significant bytes without first writing the two most

significant bytes will result in an error response.

Series Interface

6

Data

Types

Number of

Registers

0 1 2 3

Byte

Description

Boolean 1 LSB N/A Zero= OFF, non-zero = ON

Byte,

Char

Int16,

uint16

Int32,

uint32

float 2 Sign+E xpMantisa

1 LSB N/A Entity contained in LSB of

register, Byte 0 ignored.

1 MSB

0

LSB

1

N/A

2 3

Entity contained in MSB/LSB of

register. (dual register data)

2 MSB B-1 B-2 LSB Requires 2 consecutive

registers, MSB transferred first

MSB

B-1 Mantisa

LSB

IEEE formatted value contained in 2 consecutive registers

Table 9 - Multiple Register Writes

Section 6.5 - Request Packet Sizes

Multiple consecutive registers may be accessed in a single transaction.

The DP606A and DP612A Modbus interface imposes a maximum of 72 bytes for the

total transaction. Allowing for the required framing, addressing and CRC results

in the following data size restrictions using the READ and WRITE MULTIPLE

functions.

Format Protocol Overhead Maximum Read data Maximum Write data

RTU 8 24 Registers 24 Registers

Table 10 - Packet Sizes

22

Page 28

7

Modbus Register Assignments

Section 7 - DP606A and DP612A Modbus Register Assignments

All accesses to the DP606A and DP612A database information is made thru the

following Modbus registers.

Data types:

R – single 16 bit register (may be Boolean, byte, char, int16 or uint16 data)

L – dual (32 bit) register (may be int32 or uint32 data)

F – IEEE Floating point value

B – Byte Array

All data is transferred using Big Endian formatting, where the most significant byte

is transmitted first.

Section 7.1 - System Registers

Index Mnemonic Type Access Description

0x0000 40000 Layout Version R R Hardware layout version

0x0001 40001 Device Description R R Device description

0x0002 40002 FW Version Major Minor R R First two octets of Firmware Version

0x0003 40003 FW Version Minor Fix R R Last two octets of Firmware Version

0x0004 40004 HW Version R R Hardware version

0x0005 40005 Max Zones R R Max zones supported by device

0x0006 40006 Temperature Scale R RW Select Fahrenheit or Celsius degree

0x0007 40007 Sensor Type R RW Enumerated sensor type

0x0008 40008 Sensor Subtype R RW Enumerated sensor sub-type

0x0009 40009 Password R RW 4 digit password

0x000a 40010 Modbus Address R RW Device address on the bus.

0x000b 40011 Scan Time Second R RW Display time per zone in seconds

0x000c 40012 Active Zone R RW Bitmap of currently active zone

0x000d 40013 Hours Operation R RW Accumulated hours of operation

0x0013 40019 Factory Default R RW Reset device to factory default

0x0015 40021 System State R RW Enumerated system state

0x0018 40024 System Alarm Type R RW Enumerated alarm type

0x0019 40025 System Alarm Latch R RW Enumerated setting toggle

0x001A 40026 Password Enable R RW Enumerated toggle setting

0x001b 40027 Decimal Point R RW Enumerated decimal point setting

Table 11 - System Registers

23

Page 29

Modbus Register Assignments

Section 7.2 - Temperature Registers

Index Mnemonic Type Access Description

0x0100 40256 Temperature Zone 1 F R Zone 1 Process Value

0x0102 40258 Temperature Zone 2 F R Zone 2 Process Value

0x0104 40260 Temperature Zone 3 F R Zone 3 Process Value

0x0106 40262 Temperature Zone 4 F R Zone 4 Process Value

0x0108 40264 Temperature Zone 5 F R Zone 5 Process Value

0x010a 40266 Temperature Zone 6 F R Zone 6 Process Value

0x010c 40268 Temperature Zone 7 F R Zone 7 Process Value

0x010e 40270 Temperature Zone 8 F R Zone 8 Process Value

0x0110 40272 Temperature Zone 9 F R Zone 9 Process Value

0x0112 40274 Temperature Zone 10 F R Zone 10 Process Value

0x0114 40276 Temperature Zone 11 F R Zone 11 Process Value

0x0116 40278 Temperature Zone 12 F R Zone 12 Process Value

Table 12 - Temperature Registers

7

Section 7.3 - Status Registers

Index Mnemonic Type Access Description

0x0180 40384 Sensor Status Zone 1 R R Zone 1 Sensor status

0x0181 40385 Sensor Status Zone 2 R R Zone 2 Sensor status

0x0182 40386 Sensor Status Zone 3 R R Zone 3 Sensor status

0x0183 40387 Sensor Status Zone 4 R R Zone 4 Sensor status

0x0184 40388 Sensor Status Zone 5 R R Zone 5 Sensor status

0x0185 40389 Sensor Status Zone 6 R R Zone 6 Sensor status

0x0186 40390 Sensor Status Zone 7 R R Zone 7 Sensor status

0x0187 40391 Sensor Status Zone 8 R R Zone 8 Sensor status

0x0188 40392 Sensor Status Zone 9 R R Zone 9 Sensor status

0x0189 40393 Sensor Status Zone 10 R R Zone 10 Sensor status

0x018a 40394 Sensor Status Zone 11 R R Zone 11 Sensor status

0x018b 40395 Sensor Status Zone 12 R R Zone 12 Sensor status

0x018c

0x018d

40396 Sensor Status Bitmap R R Sensor status bitmap for all zones

40397 Alarm Status Bitmap R R Alarm status bitmap for all zones

Table 13 - Sensor Status Registers

24

Page 30

7

Modbus Register Assignments

Section 7.4 - Zone Registers

The zone specific registers are repeated

Zone 1 Register Base = 0x200

Zone 2 Register Base = 0x280

Zone 3 Register Base = 0x300

Zone 4 Register Base = 0x380

Zone 5 Register Base = 0x400

Zone 6 Register Base = 0x480

Zone 7 Register Base = 0x500

Zone 8 Register Base = 0x580

Zone 9 Register Base = 0x600

Zone 10 Register Base = 0x680

Zone 11 Register Base = 0x700

Zone 12 Register Base = 0x780

Index Mnemonic Type Access Description

Base + 0x00 Setpoint High F RW Setpoint High for alarm

Base + 0x02 Setpoint Low F RW Setpoint Low for alarm

Base + 0x04 Alarm 1 Mode R RW Enumerated alarm mode

Base + 0x05 Alarm 1 Latch R RW Enumerated setting toggle

Base + 0x06 Alarm 1 Status R RW Enumerated alarm status

Base + 0x07 Alarm 2 Mode R RW Enumerated alarm mode

Base + 0x08 Alarm 2 Latch R RW Enumerated setting toggle

Base + 0x09 Alarm 2 Status R RW Enumerated alarm status

Base + 0x0a Current Scale High F RW High scale reading for current input

Base + 0x0c Current Scale Low F RW Low scale reading for current input

Base + 0x0e Voltage Scale High F RW High scale reading for voltage input

Base + 0x10 Voltage Scale Low F RW Low scale reading for voltage input

Table 14 - Zone Registers

Example:

Current Scale High register for Zone 7

Index = 40,000 + Base + Index = 40,000 + 0x500 + 0x0a = 41290

25

Page 31

Modbus Register Assignments

Section 7.5 - User Calibration

Index Mnemonic Type Access Description

0x1d7c 47548 Zone 1 RTD offset F RW Offset Ohm for Zone 1

0x1d7e 47550 Zone 2 RTD offset F RW Offset Ohm for Zone 2

0x1d80 47552 Zone 3 RTD offset F RW Offset Ohm for Zone 3

0x1d82 47554 Zone 4 RTD offset F RW Offset Ohm for Zone 4

0x1d84 47556 Zone 5 RTD offset F RW Offset Ohm for Zone 5

0x1d86 47558 Zone 6 RTD offset F RW Offset Ohm for Zone 6

0x1d88 47560 Zone 7 RTD offset F RW Offset Ohm for Zone 7

0x1d8a 47562 Zone 8 RTD offset F RW Offset Ohm for Zone 8

0x1d8c 47564 Zone 9 RTD offset F RW Offset Ohm for Zone 9

0x1d8e 47566 Zone 10 RTD offset F RW Offset Ohm for Zone 10

0x1d90 47568 Zone 11 RTD offset F RW Offset Ohm for Zone 11

0x1d92 47570 Zone 12 RTD offset F RW Offset Ohm for Zone 12

Table 15 - User Calibration

7

Section 7.6 - Enumerated Values

The following define the Enumerated values.

Section 7.7 - Sensor Type

0 THERMOCOUPLE Thermocouple input

1 RTD 2 WIRE Two wire RTD input

2 RTD 3 WIRE Three wire RTD input

3 CURRENT Process Current input

4 VOLTAGE Process Voltage input

Section 7.8 - RTD Type

0 PT_100 Platinum Pt100 RTD

1 NI_90 Nickel Ni90 RTD

2 CU_10 Copper Cu10 RTD

Sensor Type

RTD Type

3 NI_120 Nickel Ni120 RTD

26

Page 32

7

Modbus Register Assignments

Section 7.9 - Thermocouple Type

0 TYPE_B Thermocouple B type

1 TYPE_C Thermocouple C type

2 TYPE_E Thermocouple E type

3 TYPE_J Thermocouple J type

4 TYPE_K Thermocouple K type

5 TYPE_R Thermocouple R type

6 TYPE_S Thermocouple S type

7 TYPE_T Thermocouple T type

8 TYPE_N Thermocouple N type

Section 7.10 - Sensor Status

Thermocouple Type

0 VALID Sensor is normal

1 OUT_OF_RANGE_LOW Sensor Reading is below valid range

2 OUT_OF_RANGE_HIGH Sensor Reading is above valid range

3 SHORT_CIRCUIT Sensor is short circuit

4 OPEN_CIRCUIT Sensor is open circuit

Section 7.11 - System State

0 PROGRAM_MODE Alarms are disabled

1 RUN_MODE Alarms are enabled.

Sensor Status

System State

27

Page 33

Modbus Register Assignments

Section 7.12 - Process Unit

Process Unit

0 DEGREE_C Process unit is Celsius

1 DEGREE_F Process unit is Fahrenheit

Section 7.13 - Alarm Type

Alarm Type

0 ALARM_HIGH Alarm activated when PV > Alarm High SP

1 ALARM_LOW Alarm activated when PV < Alarm Low SP

2 HI_LOW_ALARM Alarm activated when Alarm Low SP < PV < Alarm

High SP

3 ALARM_OFF Alarm is disabled.

7

4 ALARM_SPLIT_A_B Alarm 1 activates Alarm relay A, alarm 2 activates

Alarm relay B

Section 7.14 - Alarm Status

Alarm Status

0 ALARM_NONE No alarm condition is triggered

1 ALARM_HIGH Alarm high condition is triggered

2 ALARM_LOW Alarm low condition is triggered

3 ALARM_HIGH_LOW Alarm high low condition is triggered

Section 7.15 - Setting Toggle

Toggle

0 DISABLE Setting is disabled.

1 ENABLE Setting is enabled.

28

Page 34

8

Display Meters User’s Guide

Section 8 - Specifications

Display 4-digit, 7-segment LED; red, 21 mm (0.83)

Dimensions 95 x 95 x 135mm

Panel Cutout ¼ DIN 92 x 92mm

Environmental Conditions -20 to +70°C (-4 to +158°F), 90% RH non-condensing

External Fuse Required Time-Delay, UL 248-14* listed:

(Operating)

-40 to +85°C (-40 to +185°F), 90% RH non-condensing

(Storage)

Pollution Degree 2

Altitude of up to 2000 meters

Indoor use

• 25 mA/250 V

• 300 mA/250 V (Low-Voltage Option)

Time-Lag, IEC 127-3 recognized:

• 25 mA/250 V

• 300 mA/250 V (Low-Voltage Option)

Line Voltage/Power 120/240 Vac, 50/60Hz, 3W Max

Low-Voltage/Power Option External power source must meet Safety Agency Ap-

Protection NEMA-1/Type 1 front bezel

Weight 725 g

Communications Selectable RS232 / RS485

* For UL installations

Section 8.1 - Alarm Relays

AC Power Option 2x SPDT, 240Vac, 5A Load

DC Power Option 2x SPDT, 36Vdc, 3A Load

provals.

9–36 Vdc, 3W Max

Modbus RTU

5A External Fuse Required

3A External Fuse Required

29

Page 35

Section 8 - Input Accuracy

Measurement Ranges and Accuracies based on

Input Type Description Range

Process

Type T/C J Iron-Constantan

Type T/C

Type T/C Copper-Constantan

Type T/C

Type T/C Pt/13%Rh-Pt

Type T/C Pt/10%Rh-Pt

Type T/C 30%Rh-Pt/6%Rh-Pt

Operating Temperature

Process Voltage 0 to 1000 mV ± 1 mV ± 1 mV ± 1 mV

Process Current 0 to 24.00 mA ± 10 µA ± 10 µA ± 10 µA

-150 to 0°C ± 1.0°C ± 2.0°C ± 6.0°C

0 to 1200°C ±1.0°C ± 1.0°C ± 2.0°C

CHROMEGA™ ALOMEGA™

-150 to 0°C ± 1.0°C ± 2.0°C ± 5.0°C

0 to -1372°C ± 1.0°C ± 1.0°C ± 2.0°C

-150 to 0°C ± 1.0°C ± 2.0°C ± 7.0°C

0 to 400°C ± 1.0°C ± 1.0°C ± 2.0°C

CHROMEGA™

-Constantan

-150 to 0°C ± 1.0°C ± 2.0°C ± 5.0°C

0 to 1000°C ± 1.0°C ± 1.0°C ± 2.0°C

-50 to 0°C ± 1.0°C ± 2.0°C ± 6.0°C

0 to 1788°C ± 1.0°C ± 1.0°C ± 2.0°C

-50 to 0°C ± 1.0°C ± 2.0°C ± 5.0°C

0 to 1768°C ± 1.0°C ± 1.0°C ± 2.0°C

150 to 700°C ± 1.0°C ± 2.0°C ± 3.0°C

700 to 1820°C ± 1.0°C ± 1.0°C ± 1.0°C

Display Meters User’s Guide

8

Operating Temperature

Accuracy (25°C) Accuracy (0 to 50°C) Accuracy (-20 to 70°C)

Type T/C 5%Re-W/26%Re-W 0 to 2320°C ± 1.0°C ± 1.0°C ± 3.0°C

Type T/C Nicrosil-Nisil

-150 to 0°C ± 1.0°C ± 2.0°C ± 5.0°C

0 to 1300°C ± 1.0°C ± 1.0°C ± 2.0°C

Pt, 0.00385, 100 Ω -200 to 850°C ± 1.0°C ± 1.0°C ± 1.0°C

2/3 Wire

2

⁄3 Wire

2

⁄3 Wire

Cu, 0.00427, 10 Ω -200 to 260°C ± 1.0°C ± 1.0°C ± 1.0°C

Ni, 0.00672, 120 Ω -80 to 260ºC ± 1.0ºC ± 1.0ºC ± 1.0ºC

Table 16 - Input Accuracy

* Absolute Maximum 3.3V (Process Voltage) or 30mA (Process Current).

30

Page 36

9

Approvals information

This product conforms to the EMC: 2014/30/EU (EMC Directive).

Electrical Safety:

This product conforms to the LVD: 2014/35/EU (Low Voltage Directive)

UL / CSA

UL 61010-1 / CSA C22.2 NO. 61010-1-12

Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use

UL 61010-2-201 / CSA C22.2 NO. 61010-2-201:14

Standard for Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use. Part 2-201: Particular requirements for control

equipment

UL File Number: E209855

Correct Disposal of This Product

(Waste Electrical & Electronic Equipment)

In conformity with Directive 2012/19/EU-WEEE, this marking shown on the product or its

literature, indicates that it should not be disposed of, with other household wastes at the

end of its working life. To prevent possible harm to the environment or human health from

uncontrolled waste disposal, please separate this product from other types of wastes

and recycle it responsibly to promote the sustainable reuse of material resources.

Household users should contact either the retailer where they purchased this product, or

their local government office, for details of where and how they can return this item for

environmentally safe recycling.

Business users should contact their supplier and check the terms and conditions of the

purchase contract. This product should not be mixed with other commercial wastes for

disposal

31

Page 37

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 25 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace

period to the normal two (2) year product warranty to cover handling and shipping time. This ensures

that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for

any damages that result from the use of its products in accordance with information provided

by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN (AR)

NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID PROCESSING

DELAYS). The assigned AR number should then be marked on the outside of the return package and on any

correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR WARRANTY RETURNS, please have the

following information available BEFORE contacting

OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

OMEGA is a trademark of OMEGA ENGINEERING, INC.

© Copyright 2018 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS, consult

OMEGA for current repair charges. Have

the following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

Page 38

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors,

Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Communications-Based Acquisition Systems

MU

Data Logging Systems

MU

Wireless Sensors, Transmitters, & Receivers

MU

Signal Conditioners

MU

Data Acquisition Software

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

M5685/0718

Loading...

Loading...