Page 1

Programmable

Dual Channel Monitor

DP3300 Series User's Manual

OMEGA ENGINEERING, INC.,

ONE OMEGA DRIVE, STAMFORD, CT 06907

Page 2

DP3300 Series User’s Manual

SPECIFICATIONS:............................................................................................................................................................................3

DESCRIPTION:..................................................................................................................................................................................4

SAVING PROGRAMMED PARAMETER:......................................................................................................................................4

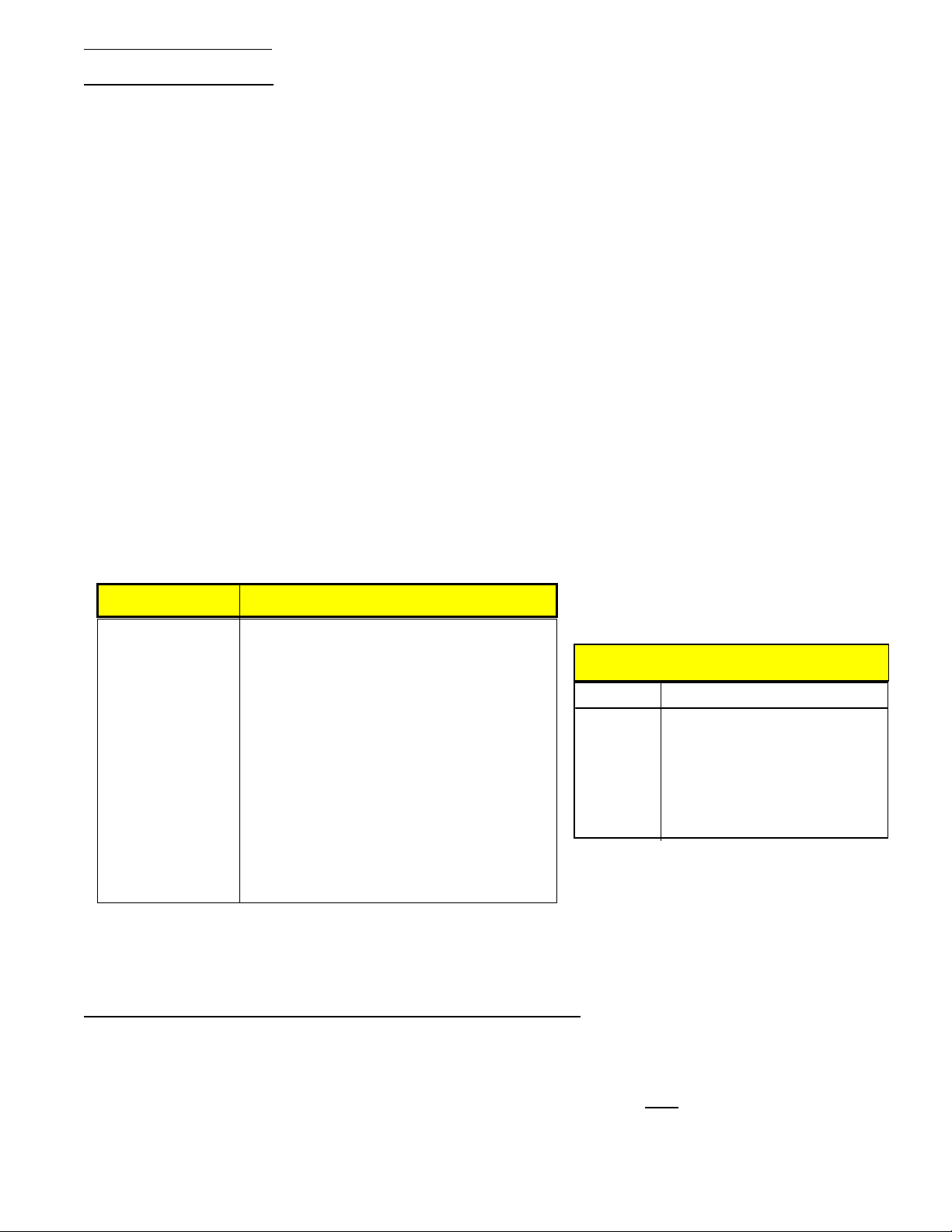

Table 1. How to Display Parameters..............................................................................................................................................5

PEAKS:...............................................................................................................................................................................................5

DISPLAYING PEAKS...................................................................................................................................................................5

RESETTING PEAKS .....................................................................................................................................................................6

RATE:.................................................................................................................................................................................................6

MODES OF OPERATION FOR PULSE CHANNEL:......................................................................................................................6

RATE MONITOR:..........................................................................................................................................................................6

RPM MONITOR.............................................................................................................................................................................6

FREQUENCY MONITOR:............................................................................................................................................................7

COUNTER......................................................................................................................................................................................7

MODES OF OPERATION FOR COUNTER:....................................................................................................................................8

COUNT UP CONFIGURATION:..................................................................................................................................................8

MODE 0: (Count up with manual reset to zero)........................................................................................................................8

MODE 1: (Count up to Preset with auto reset to zero)..............................................................................................................8

MODE 2: (Count up to Preset with auto Zero after delay)........................................................................................................8

COUNT DOWN CONFIGURATION............................................................................................................................................8

MODE 3: (Count down to zero with manual preset)..................................................................................................................8

MODE 4: (Count down to zero with auto preset).......................................................................................................................8

MODE 5: (Count down to zero with auto preset after delay)......................................................................................................8

RESETTING COUNT:.......................................................................................................................................................................9

RELAY DELAY PERIOD: ............................................................................................................ ....................................................9

TOTALIZER:......................................................................................................................................................................................9

BATCH COUNT: ...............................................................................................................................................................................9

SCALING:..........................................................................................................................................................................................9

TIME:..................................................................................................................................................................................................9

SETUP: .............................................................................................................................................................................................10

EXITING SETUP:............................................................................................................................................................................10

CHANNEL CONFIGURATION......................................................................................................................................................10

‘Input Type’ Setup ....................................................................................................................................................................10

‘Channel ON/OFF’ Setup..........................................................................................................................................................11

Setup for degrees Centigrade or Fahrenheit..................................................................................................................................11

‘Decimal Point Position’ Setup.................................................................................................................................................11

‘High Scale’ Setup....................................................................................................................................................................11

‘Low Scale’ Setup.....................................................................................................................................................................11

‘Offset’ Setup............................................................................................................................................................................11

‘Tare’ Setup...............................................................................................................................................................................12

‘Limits’ Setup ...........................................................................................................................................................................12

‘Deadband’ Setup......................................................................................................................................................................12

‘Relay Latched/Non-Latched Mode’ Setup...............................................................................................................................12

‘Relay Normally Open/Closed’ Setup.......................................................................................................................................12

‘Engineering Units’ Setup.........................................................................................................................................................13

‘Rate Time Base’ Setup.............................................................................................................................................................13

Input Signal type selection:...........................................................................................................................................................13

SYSTEM CONFIGURATION:........................................................................................................................................................13

Display Options.............................................................................................................................................................................14

‘Display Time’ Setup....................................................................................................................................................................14

Audio Alarm ON/OFF ..................................................................................................................................................................14

Cold Junction Setting....................................................................................................................................................................14

Calibration Mode ..........................................................................................................................................................................14

Thermocouple Calibration Procedure ...........................................................................................................................................14

Input Range Setup (for current and voltage):................................................................................................................................15

Voltage Range Setup (0-5vdc, 0-10vdc)...................................................................................................................................15

Voltage Range Setup (for millivolt inputs)...............................................................................................................................15

Current Range Setup.................................................................................................................................................................15

Correct Range Settings..............................................................................................................................................................15

Setup Examples.............................................................................................................................................................................15

Example #1: Use of the OFFSET Parameter.............................................................................................................................15

Example #2: Use of the LOW SCALE Parameter....................................................................................................................15

SETUP FOR A PULSE CHANNEL:................................................................................................................................................18

Page1

Page 3

DP3300 Series User’s Manual

Turning a Channel ON or OFF .....................................................................................................................................................18

MODES OF OPERATION FOR A PULSE INPUT CHANNEL:................................................................................................18

SETUP FOR COUNTER:.............................................................................................................................................................18

SETUP FOR HIGH AND LOW FREQUENCY MONITOR:...................................................................................... ................19

SETUP FOR RATE MONITOR:..................................................................................................................................................20

SETUP FOR RPM MONITOR:....................................................................................................................................................20

ALARM OUTPUTS:........................................................................................................................................................................21

Status:............................................................................................................................................................................................21

Resetting: ......................................................................................................................................................................................21

Open Collector (solid state) output Option:..................................................................................................................................22

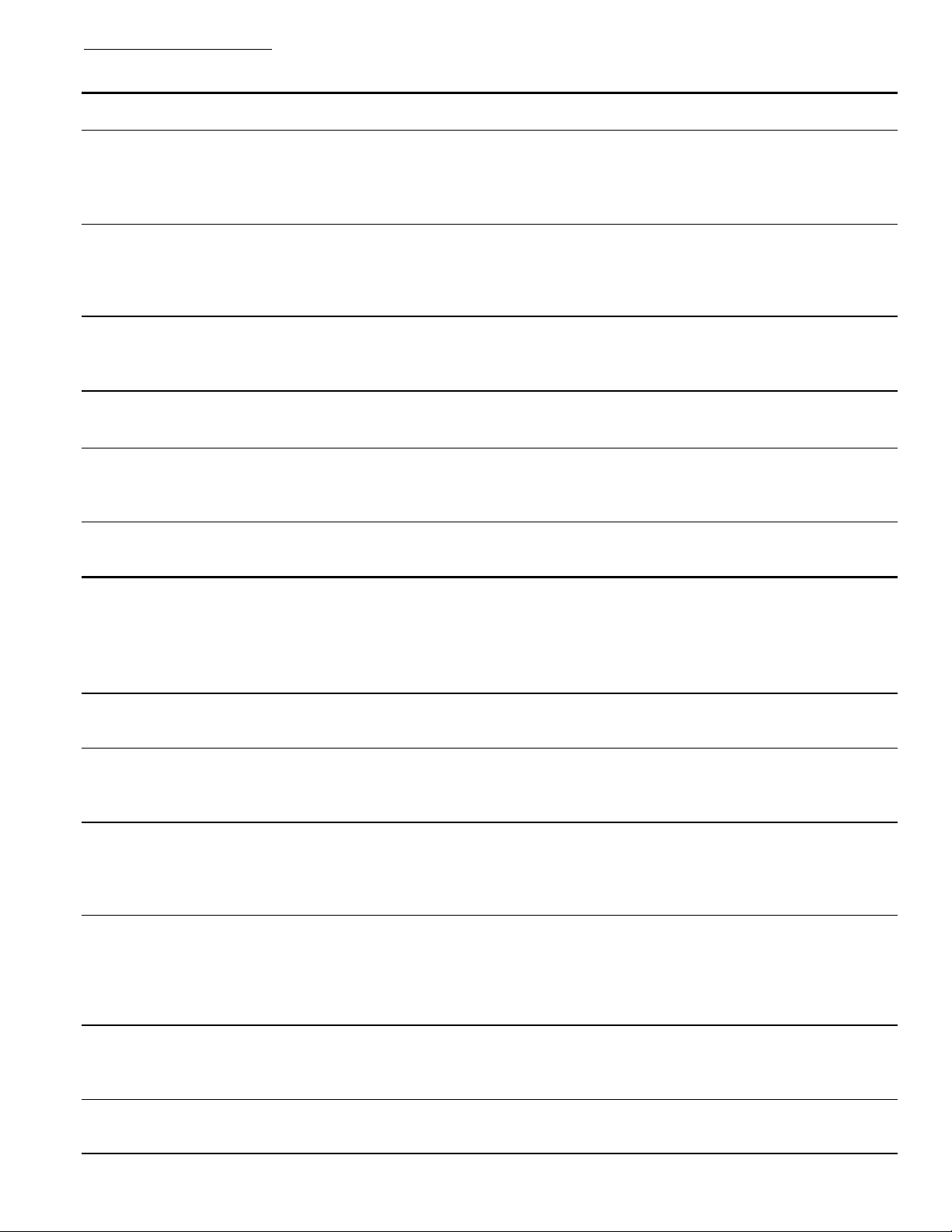

Figure 1. Open Collector Hookup Example.............................................................................................................................22

Electro-Mechanical Relay Option:...............................................................................................................................................22

Figure 2. Electro-mechanical Relays Hookup Example............................................................................................................22

POWER.............................................................................................................................................................................................22

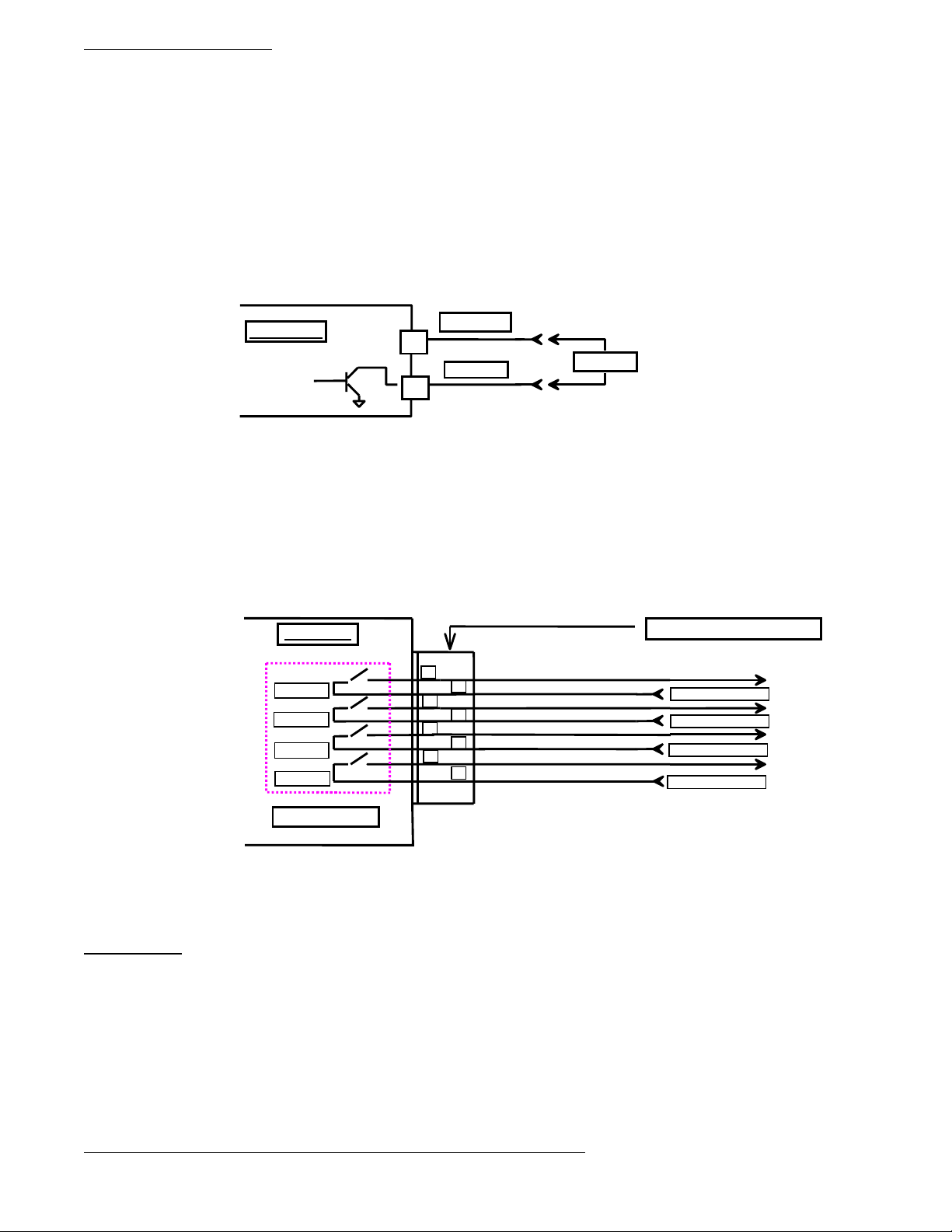

FIG. 3: Power, Input/Output connections & rear view of the instrument...........................................................................23

INPUT/OUTPUT CONNECTOR PIN ASSIGNMENTS.............................................................................................................23

MOUNTING.....................................................................................................................................................................................24

Figure 4. Panel Cutout Dimensions...............................................................................................................................................24

WARRANTY/DISCLAIMER..........................................................................................................................................................25

Page2

Page 4

DP3300 Series User’s Manual

SPECIFICATIONS:

(Typical @ 25C and rated supply voltage unless otherwise specified)

STANDARD INPUTS

• * 4-20ma 10-50ma 0-5Vdc 0-10Vdc

• Thermocouple inputs: J,K,T,E,R,S,B

• Cold junction compensation error: +/- 1C (10C to 40C)

• Open input indication: HELP displayed

• Temperature displayable in Degrees C or F

• Non standard inputs availab le --- consult factory.

ANALOG TO DIGITAL CONVERSION

• 4-1/2 Digit (20,000) Count) A/D Converter

• Dual slope integrating converter with 7 conversions /sec. (typical) rate.

SCAN RATE

• Fixed: two channels per second

DISPLAY

• Red seven segment displays--0.39" (10mm) digit height

• Over range indication: HELP

• Display test: Briefly displays 8.8.8.8.8.8.8 on power up.

• Seven digit display

SCALE/OFFSET

• Scale programmable from 1-30000 units

• Offset programmable from 0-99.99 MA (For MA Input)

• Offset programmable from 0-9.999 MV (For Voltage Input)

RELIABILITY/ACCURACY

• Calibration: NIST traceable (for thermocouples)

• Temperature resolution: 1C/1F, 0.1% of Full Scale

• Warranty: 1 Year

• Recalibration recommended at 12 month interval

POWER REQUIREMENT

• * 120Vac --- 60 HZ (Standard)

• * 240Vac --- 50 HZ (optional)

• * 8Vdc --- 12Vdc (optional)

OUTPUT (optional)

• Open collector outputs – 6 open collector outputs, maximum sink capability of 50ma per output

• Relays: Single pole single throw, 1 Amp @ 28Vdc or 0.5 Amp @ 120Vac resistive

• Output termination: Euro-style plugable connector

DECIMAL POINT:

• Programmable: None, 10

COUNT/RATE/RPM/FREQUENCY:

• Count Range : 1 – 9999999 Rate Range: 0 – 9999999 Frequency Range: 2.00 to 1000000 RPM Range: 0 - 9999999

• Scaler 0.00000 to 99.99999

• Division factor: 0 to 65000

• Rate Time Base: Programmable 1.000 Seconds to 9999.999 Seconds

th

position, 100th position, 1000th position

Page3

Page 5

DP3300 Series User’s Manual

DESCRIPTION:

A highly versatile series, DP3300 offers a unique combination of two analog channels or two pulse input channels or a

combination of pulse (square wave) on one channel and an analog signal on the other. This feature allows it to be used as

counter, rate, RPM or a frequency monitor along with displaying an analog signal such as 4-20ma loop current, voltage or

millivolts or a temperature signal from thermocouples, RTDS etc. For example, flow and temperature or flow and pressure can

easily be monitored in a single unit.

On the analog channel, signals from thermocouples, RTDS or thermistors are linearized and displayed in degrees Centigrade or

Fahrenheit. Voltage and milliamp signals (4-20ma etc.) are displayed in engineering units that correspond to the process being

monitored. Scaling is accomplished through front keys and does not require any tedious formulas.

The Pulse (or square wave input) channel functions like four monitors in one. It can be programmed as an up/down counter, rate,

rpm or frequency monitor. In counter mode, the channel can count up or down to a maximum count of 9,999,999 and also offers

three presets along with built in delay timers. As a rate indicator, it offers a programmable time base from 1.000 to 9999.999

seconds.

In RPM mode, the channel counts incoming pulses and displays the data as revolutions per minute. In frequency mode, an internal

crystal reference is used to indicate the frequency of incoming pulses (low frequency mode only). Measured frequency range is

from 1Hz to 1 megahertz. Two modes of operation are supported:

1. High frequency mode (resolution = 1Hz)

2. Low frequency mode ( resolution = 0.01 Hz)

NOTE: Check model number for the t ype of input and display units ---- thermocouples, 4-20ma, 0-5 Vdc, or 0-1 0Vdc

etc...

DP3300-TC

DP3300-TH

DP3300-RTD

DP3300-R

DP3300-S

DP3300-B

DP3300-MV

J,K,T,E Thermocouple, 4-20ma, 0-10vdc

& 0-5vdc pulse

Thermistor (400 Series) , 4-20ma, 0-10vdc and

0-5vdc pulse

100 Ohm RTD , 4-20ma, 0-10vdc and

0-5vdc pulse

'R' Thermocouple, 4-20ma, 0-10vdc and

0-5vdc pulse

'S' Thermocouple , 4-20ma, 0-10vdc and

0-5vdc pulse

'B' Thermocouple , 4-20ma, 0-10vdc and

0-5vdc pulse

100Millivolt , 4-20ma, 0-10vdc and

0-5vdc pulse

OPTIONS (Add to Model No)

SUFFIX DESCRIPTION

-1 240vac Power

-2 15vdc Power

-3 4 Relay Outputs

-4 4 Open collector outputs

SAVING PROGRAMMED PARAMETER:

DP3300 saves all the programmed parameters in an EEPROM (electrically erasable programmable read only memory).

An EEPROM stores the programmed parameters even when the power is removed from the unit. However, it is important to note

that if the parameters are being changed during setup, they must be saved in the EEPROM by pressing and holding the RESET

key till the display reads 'SAVING' (also described under SETUP). If the parameters are NOT

from the unit, any newly changed values will be lost (the unit will, however, maintain the old values).

Page4

saved and the power is removed

Page 6

DP3300 Series User’s Manual

) Hold

sca

push the

SCN/

ce.

Table 1. How to Display Parameters

TO DISPLAY PERFORM FOLLO WING STEPS

1) Channel 1’s Process value a) Push CH SEL key once.

2) Channel 2's Process a) Push CH SEL key twice. First push selects channel 1 and the

Value second push will select and display channel 2's process reading.

3) Channel's high peak a) Select channel whose hi gh peak is desired (push CH SEL key)

b) Push HI/LO key once

4) Channel's low peak a) Select channel whose low peak is desired (push CH SEL key)

b) Push HI/LO key twice --- 1st push displays high peak,

2nd push , low peak.

5) Rate a) Select channel whose rate is desired (push CH SEL key)

b) Push DATA key once.

6) Channel Differential a) Select a channel by pushing CH SEL key ONCE

b) Push DATA key twice -- 1st push displays rate,

2nd push: Channel Differential

7) TOTAL a) Select a channel by pushing CH SEL key twice

b) Push DATA key SIX times till TOTAL displays in the window

The sequence is: Rate, Channel differential, Limit1, Limit2, Limit3, Total

8) BATCH a) Select a channel by pushing CH SEL key twice

b) Push DATA key SEVEN times till bATCH displays in the window,

The sequence is: Rate, Channel differential, Limit1, Limit2, Limit3, Total, Batch

9) LIMITS a) Push CH SEL key to select desired channel

b) Push DATA key THREE times to display channel's limit number 1

c) Each additional push after that will display limit 2 & limit 3

10) Elapsed time a) Push TIME key.

11 Scan a) If the unit is holding, push the SCN/HLD key once.

12

a) If the unit is

nning,

HLD key on

PEAKS:

A very useful function on the system is tracking the highest (peak) and the lowest (valley ) point attained by each channel. This is

particularly helpful if an operation is not being constantly watched or is left unattended e.g. overnight.

DISPLAYING PEAKS

The first step in displaying peaks is to select the channel whose peaks are desired. This is done by pushing the 'CH. SEL' key.

Once the desired channel has been selected, push the 'HI/LO' key. Pushing it once will show the high peak attained by the

selected channel. Pushing it a second time will indicate the low process value (NOTE: The second push, to display valley, must

be initiated before the display reverts to normal display mode). Before displaying high peak the display will read 'CHx HI'

(x=channel #). Similarly, for low peak the display will indicate 'CHx LO' (x=channel #) b efore showing the value.

If an attempt is made to display the high or low peak of a channel which has been turned off (in CH Setup), the display will read

'CHx OFF' (x=channel #) to indicate the channel status.

Page5

Page 7

DP3300 Series User’s Manual

RESETTING PEAKS

Peaks can be reset to current process value e.g. if channel 1 is reading 200 C, its peaks can be reset to 200. This will allow

tracking from the current process reading. To reset high peak, first select the channel whose peak is desired to be reset (by

pushing the ‘CH. SEL’ key). Once the channel has been selected, push the ‘HI/LO’ key and keep it pushed. The display will

read 'CHx HI' (x=channel #) following which the value of high peak will be displayed. With the HI/LO key still pushed, go on

to push the RESET key. The display will read 'RESEt' and the unit will then take the present value of process on that channel

and enter it as the new high peak. To reset low peak, release HI/LO key (from high peak display mode) and push it again

immediately -- and keep it pushed. The display will read 'CHx LO' and then the value of channel's low peak. With the HI/LO

key still pushed, press the RESET key. The display will read 'RESEt' and the unit will enter the present process value as

channel's new low peak.

RATE:

DP3300 tracks the rate of process change per programmed time base for each channel. This RATE is displayed by first pushing

the CH. SEL key to select the channel whose rate is desired and then pushing DATA key once. The display will briefly read

'rAtE' and then show the monitored rate for that channel.

MODES OF OPERATION FOR PULSE CHANNEL:

RATE MONITOR:

As a rate indicator, DP3300 series features crystal controlled accuracy and provides the flexibility of a programmable time base

for sampling. The time base can be set from 1.000 seconds through 9999.999 seconds in increment of 0.001 second and is done

during SETUP (look under SET-UP). Additionally, a division or scaler factor can also be programmed that will divide or scale the

incoming pulses. For a quicker update of rates , a scaler factor can be programmed (when a channel is programmed for a rate

mode). For example, if rate /minute is desired, then setting the time base to 1.000 and scaler to sixty, will give you rate/minute.

This rate, however, will be updated every one second. It may be noted that rate calculated this way may loose some accuracy.

Additionally, the unit shows the rate, based on the programmed time base in all the system modes i.e. frequency, counter and

RPM. This can be displayed by first selecting the desired channel (by pushing CH SEL key) and then pushing the DATA key.

(NOTE: In the RPM mode, the rate time base must be smaller than the selected filter value. If not, the system will

automatically consider the filter value as the time base for rate calculation. Also, a difference of 0.500 is recommended

between the filter and time base).

There are three rate based limits (two withoutputs, 1 audio/visual) that can be set anywhere from 1-9,999,999. These limits can be

configured to reset automatically when the rate falls below the set limit or alternately reset manually. This is done by going into

the setup mode and selecting the proper configuration (look under SETUP).

RPM MONITOR

In RPM mode, the system will accept 0-5V square wave or pulse input from a sensor and show revolutions per minute. The input

has a schmitt trigger so as to accept any kind of square wave or pulses, as long as the high and low specifications are met.

Also a filter function is provided in the RPM mode which allows to smooth out rapidly changing RPM. On the contrary, if it is

desired to see the variation in the RPM, then this feature alsocomes in handy. Select a low filter value to see variations in RPM

and a higher value for a more stable display. Selectable filter values are 1,2,4,6,10,15,20,30 and 6 0 and the selection is done in

SETUP mode.

Three RPM based limits (two with outputs, 1 audio/visual) are provided for each channel that can be set to activate internal relays

when a preset limit is exceeded. The ON/OFF status of these relays is indicated on the front panel by LEDs.

There are two modes of resetting the limits. First is automatic mode in which the limits reset automatically as soon as RPM falls

Page6

Page 8

DP3300 Series User’s Manual

below the limit (minus the relay) deadband. The second mode is manual reset. Once the limits are energized, they will stay

energized until manually reset.

(NOTE: In the RPM mode, the rate time base must be smaller than the selected filter value. If not, the system will

automatically consider the filter value as the time base for rate calculation. Also, a difference of 0.500 is recommended

between the filter and time base).

FREQUENCY MONITOR:

DP3300 monitor can also be programmed as a frequency monitor. In this mode the unit will display incoming frequency with a

crystal based reference. Input signal is used for gating one time period. An internal counter counts the clocks from a crystal based

oscillator and uses that to determine the frequency of incoming signal. Frequency range is from 5.00HZ to 1,000,000 HZ.

There are two frequency modes in which the system operates. Low frequency and high frequency. These modes are selected

during SETUP. In low frequency mode, the unit will show frequency in 100th of a hertz and the range is from 2.00 HZ to 500.00

HZ. In high frequency mode, the system displays the frequency in unit steps. The range is from 1 HZ to 1,000,000HZ.

During frequenc y mode, indicated rate is same as the frequency. Total and batch count is not updated during this mode. H igh and

low peaks are captured and can be displayed by pushing the HI/LO key.

Three Frequency based limits (two with outputs, 1 audio/visual) per channel are provided which activate when preset limit is

exceeded. The status of these limits is indicated on the front panel by LEDs.

There are two modes of resetting the limits. First is the automatic mode in which the limits reset automatically as soon as the

frequency falls below the limit minus the relay deadband. The second mode is manual reset. Once the relays are energized, they

will stay energized until manually reset.

NOTE: Channel 2 can be prog r ammed for low frequency mode, only if Channel 1 input is not configured for pulse. If

Channel one is configured for pulse input, Channel 2 does not allow low frequency config uration during setup and the low

frequency step is automatically skipped. Also, if Channel 2

setup as Analog Channel) and Channel 1

from low frequency to high frequency mode. Under this condition, limits must be reconfigured for proper value with no

decimal point on channel 2.

is switched from Analog to Pulse input, channel 2 will be a ut omatically switched

is configured for low frequency (e.g. with Channel 1 being

COUNTER

In counter mode, the system can be programmed to either count up or count down in six different modes. The limit relays can be

programmed to reset manually or automatically. Also, the delay time on automatic reset of the relays is programmable.

For scaling, the unit provides the convenience of a scaler and a division factor. The scaler can be programmed from 0.00000 to

99.99999, in increments of 0.00001. Scaler is a number with which the input count is multiplied. For Example a flow meter that

puts out one pulse for every 0.00024 gallons, would require a scaler of 0.00024. On a pulse count of 10000, the display will read

2.4 (10000 x 0.00024 = 2.4). Scaler is disabled if its value is set to 0.00000. Similarly, the division factor works on incoming

pulses and divides them with the programmed factor.

NOTE: Division factor is disabled

Various operating modes of the counter are explained below:

if a scaler value greater then 0.00000 is programmed.

Page7

Page 9

DP3300 Series User’s Manual

MODES OF OPERATION FOR COUNTER:

COUNT UP CONFIGURATION:

MODE 0: (Count up with manual reset to zero)

In this mode the system counts up from zero. Preset limits energize when the count reaches presets limit values. The unit

will continue counting up until manually reset. To reset the count manually, first select a channel by pushing CH SEL

key and ,while keeping CH SEL key pushed

and then the reset value of zero will be displayed. On resetting to zero, the outputs will automatically de-energize and

this will be indicated by the LED'S for the respective outputs turning off on the front panel.

MODE 1: (Count up to Preset with auto reset to zero)

In this mode the counter counts up to a preprogrammed preset value (look under SETUP). On reaching preset the counter

automatically resets to zero and starts the up count again. The count can be reset manually before it reaches preset. To

reset the count manually, first select a channel by pushing CH SEL key and ,while keeping the CH SEL key pushe d

simultaneously push the RESET key. The display will read 'RESET' and then the reset value of zero will be displayed.

Preset limits energize when the count reaches limit values.

MODE 2: (Count up to Preset with auto Zero after delay)

In this mode the counter counts up from zero to a preset value. Preset limits energize when the count reaches limit

values. On reaching PRESET, the delay period starts. After the delay period is over, the count is automatically zeroed,

the limits, if energized (and in non-latch mode), are reset and the count up starts again. The delay period is programmed

in SET - UP mode.

For example, if PRESET is set to 9000 counts and the delay period is programmed for 10 seconds, then when the counter

reaches 9000, the delay period will start and after 10 seconds of reacing 9000 count, the count will be reset to zero.

, simultaneously push the RESET key . The display will read 'RESET'

,

COUNT DOWN CONFIGURATION

MODE 3: (Count down to zero with manual preset)

In this mode the counter counts down from a preset number (preset number is programmed during SETUP). On

reaching zero the counter will not decrement further until manually preset. To preset the counter value manually, push

CH SEL key to select a channel. While keeping CH SEL key pushed, go on to push the RESET key simultaneously.

The display will read 'RESET' and then the displayed value will be reset to zero. Count down will start immediately

thereafter.

When count goes down to a limit value the respective output is energized. The output will stay energized until the count

is preset as explained above.

MODE 4: (Count down to zero with auto preset)

In this mode the counter counts down from a pre-programmed preset value (look under SETUP). When count goes

down to limit value, the respective output gets energized. The display in the meantime will keep counting down. When

it reaches zero, it will automatically preset itself to the programmed preset value.

NOTE: i) Time delay in modes 2 and 5 must be less than the time required to count from zero to

preset or preset to zero.

MODE 5: (Count down to zero with auto preset after delay)

In this mode the counter counts down from a Preset value. Preset limits energize when the count reaches limit values. On

reaching zero, the delay period starts. After the delay period is over, the count is automatically preset, the limits, if

energized (and in non-latch mode), are reset and the count down starts again. The delay period is programmed in SET UP mode.

Page8

Page 10

DP3300 Series User’s Manual

RESETTING COUNT:

The COUNT shown for each channel can be reset to zero or preset for a count down (depending on counter mode) at any time. To

reset the count manually, first select a channel by pushing CH SEL key and ,while keeping the CH SEL key pushed

RESET key simultaneously. The display will read 'RESET' and then the reset value of zero will be displayed. If the counter is

set for count down mode, then the display will preset to the value that was programmed during SETUP.

, push the

RELAY DELAY PERIOD:

Relay delay period in counter modes 2 and 5 is programmable from 1 to 9999999 seconds (look under SETUP). Delay period is

the time for which the output stays in its current state on reaching zeroor preset. Following the end of delay period, the output is

either reset or preset (depending on the counter type seleted).

TOTALIZER:

DP3300 series keeps track of total in counter, RPM and rate mode and can be displayed by pushing the DATA key.

In rate mode, if the displayed rate is 500 units per minute, then over a period of half an hour the total would be 15000 (500 x 30 =

15000). Similarly in RPM mode the TOTAL is the accumulated revolutions over the time period the unit has been working.

In counter mode, the unit indicates the total count. This is irrespective of preset value i.e. if the preset is 5000 and the counter is in

count - up mode, then after the unit has gone through ten preset cycles, the display will indicate a total of 50,000 (5000 x 10 =

50,000). If in count down mode, the total represents the accumulated down counts.

BATCH COUNT:

DP3300 series also offers batching capability in counter mode. One batch constitutes of counting up or down (to preset or zero,

respectively) to or from the preprogrammed PRESET value e.g. if PRESET is set to 5000 (and the channel is in counter mode 3)

then each time the count goes up to 5000, it will reset to zero and start counting up again. This will constitute one batch.

To view the number of batches processed, first select a channel (by pushing CH SEL key) and then successively push DATA key

till BATCH shows on the display. To reset batch count, bring up the batch count on the display and while still holding in the

DATA key, simultaneously push the RESET key. The display will show 'RESET' followed by reseting of batch count.

SCALING:

Scaling is used for multiplying or dividing incoming pulses by a number. It is achieved by programming Scaler value or division

factor during SETUP. This feature is useful if each revolution of a shaft produces more then one pulse, e.g. if a shaft gives 100

pulses per revolution then programming the division factor equal to 100 will give the actual RPM of the shaft. This can also be

used in cases where a count is required on boxes with each box containing a certain number of parts, e.g. if it is required to obtain

the count on cartons containing soft-drink bottles with each carton containing 50 bottles, the scaler will be set to 50. Similarly

scaling can be use d to measure length o r flow of liquids.

Scaler can be programmed from 0.00000 to 99.99999, in increments of 0.00001. Scaler is a number with which the input count is

multiplied. For Example, a flow meter that puts out one pulse every 0.00024 gallons, would require a scaler of 0.00024. On a

pulse count of 10000 (and decimal point programmed in 10

is disabled if its value is set to 0.00000.

The difference between division factor and scaler is that division factor is in whole number where as scaler can be programmed in

increments of 10,000th of a unit. Also, the maximum scaler value that can be entered is 99.99999. However, SCALER should be

limited so that the display would not go into over range condition. For Example, if the SCALER is set to 65.12345 and the pulse

count goes to 1000000, the overall number becomes 65,123,450. This number is beyond the display capability of the unit).

th

position), the display will read 2.4 (10000 x 0.00024 = 2.4). Scaler

TIME:

The system keeps track of the process run time in Hours, minutes and seconds. To display the elapsed time since the system was

turned on or the time was last reset, push the TIME key. The display will first read "ELPSD T" ( for elapsed time) followed by

Page9

Page 11

DP3300 Series User’s Manual

the indication of the elapsed time. Maximum time indicated is 999.59.59 hours.

To reset the timing and start it all over again, first push the TIME key and while keeping it pushed,

time will reset and start over from 000.00.00 hours.

press the RESET key. The

SETUP:

Setup mode provides a means to customize the monitor to suit a particular application. It allows programming such parameters as

temperature units, limits, display mode, relay deadband, etc.

SETUP mode has 2 sections:

a) the SYS setup section to set system parameters

b) the CH setup section to set channel parameters for each channel.

To get into SETUP mode, push the SETUP key twice. The first push displays elapsed time and the second push brings the unit

into the SETUP mode. SETUP mode is indicated by 'SETUP' in the display window (the SETUP LED indicator will also be

illuminated) followed by 'ENtR PC' (for ENteR Pass-Code). The pass-code feature has been provided to keep unauthorized

personnel from changing any parameters. Each of the five keys on the front panel are labeled with a number in the lower right

corner. The pass-code is a four digit combination of these numbers. Enter the pass-code when the displays reads 'ENTR PC' .

For DP3300 units, the PASS-CODE # is 3254.

Three attempts at entering the correct pass-code are allowed. 'HELP' shows up in the display window if the attempted pass-code

is wrong. If a person fails in three attempts the system will go back to normal display mode. To make another attempt at this

point one has to get into SETUP mode again.

Three keys are used during setup --- SETUP, < NEXT >, and ^v. If, at any point during SETUP, it is desired to get out of

SETUP, push and hold the RESET key until the display reads 'SAVING'. The SETUP key takes you from one parameter to the

next. For Example, if you are setting up Channel O N/OFF, then after getting t he desired value p ush SETUP key to setup for

Degrees C/F. The <NEXT> and ^v keys are used for programming the values of parameters such as limits, setpoints, etc.

EXITING SETUP:

To exit from any point during SETUP procedure or to save the newly made changes, simply press and hold the RESET key until

the display shows 'SAVING'. This indicates that the unchanged and the newly made changes are being saved in the EEPROM for

permanent storage.

Once the correct pass-code has been entered, the display shows 'SYS CH', with CH blinking. At this point the operator may

choose between making channe l settings (CH), or system settings (SYS). Use ^v key to toggle between CH and SYS modes.

When the desired mode is blinking, press the SETUP key to begin setup of the parameters for that mode.

CHANNEL CONFIGURATION

After entering the correct pass-code and selecting the blinking 'CH' (ref. SETUP section), the display shows 'SLCt CH' (for

"Select Channel"). Use ^v key to display the desired channel. The selected channel will be displayed in the format 'CHANEL x'

(where x=channel#). Once the desired channel # is displayed, push SETUP key to go on to setup parameters for the displayed

channel #.

‘Input Type’ Setup

The display will briefly show 'IP TYPE' (for "Input type") after which current input type for the channel will be displayed.

Various inputs are: J T/C, CR.AL T/C (Chromel Alumel, type K T/C), T T/C, E T/C, CURRENT, VOLTAGE or PULSE

(Refer to model number on the unit to find input type). To change the displyed input, push ^v key till appropriate type is

displayed. Push SETUP key to move to the next step.

NOTE 1: Whenever input type is changed, the unit automatically clears the previously entered engineering display units.

Therefore, do not forget to enter new engineering units (ref. Display Units section) or the respective channel will display '. . .'

(three dots) when displaying a process value.

Page10

Page 12

DP3300 Series User’s Manual

‘Channel ON/OFF’ Setup

After displaying input type, the next step turns a channel ON or OFF. This determines whether a channel is scanned and

displayed or not. If for any reason a channel is not being used, it should be turned OFF. This will prevent the unit from spending

any time scanning it and also from displaying a 'HELP' message if there is no signal connected to its input. If a channel is OFF,

the display will show 'CHx OFF' , and if it is ON the display will show 'CHx ON' (x=channel #).

Use ^v key to display the desired ON/OFF setting, and then push SETUP key Setup For Decimal Point Position.

NOTE: If input type is voltage or current, then the next step performed in setup is selection of Decimal

Point position. For thermocouple, RTD or thermistor inputs, the following steps are performed:

Setup for degrees Centigrade or Fahrenheit

After turning a channel ON/OFF, the next step is to select temperature display units. At this point the display will read 'DEGRE

C' or ' DEGRE F'. Push ^v key to make an alternate selection. After the selection, push SETUP key to go to the next step ---

THE NEXT STEP IS SETTING UP OF LIMITS.

FOLLOWING STEPS (UP TO SETTING UP OF LIMITS) ARE PERFORMED ONLY

OR CURRENT INPUT:

‘Decimal Point Position’ Setup

After setting the channel ON or OFF, the next parameter for configuration is setting the decimal point position. This is indicated

by the display showing 'dP 9999' (dP=decimal point). The ^v key moves the decimal point thru all the possible positions. After

'9.999', the display goes to '9999' which indicates a display with no decimal point.

Use ^v key to move decimal point to the desired position, and then push SETUP key Setup High Scale.

‘High Scale’ Setup

After setting the channel's decimal point position, the next parameter to be set is the High Scale. This parameter determines what

number will be displayed when the transducer puts out its maximum signal. For example, suppose a pressure transducer produces

a 0Vdc to 10Vdc signal which corresponds to 0psi to 150psi. Then you would want the display to show 150 when 10Vdc is

measured. To do this, set High Scale=150.

After pushing the SETUP key, the display will briefly read 'HI SCLE' (for "High Scale"), and then show the current High Scale

setting. Active digit (the digit that can be changed) will be flashing. Pushing ^v key and keeping it pushed

digit. Releasing ^v key and then pushing it again will decrement the value (^v key works as a toggle -- alternating between

increment and decrement). To change the next digit, push <NEXT> key. This will advance the flashing to the following digit.

Use ^v key to change the value. After the desired High Scale setting is displayed, push SETUP key to go to the next step.

‘Low Scale’ Setup

After setting a channel's High Scale, the next parameter to be set is Low Scale. This parameter determines what number will be

displayed when the transducer puts out its minimum signal. For example, suppose a pressure transducer produces a 0Vdc to 5Vdc

signal which corresponds to 10psi to 75psi. In this case the display should read 10 when 0Vdc is measured. To do this, set the Lo

Scale=10.

After pushing SETUP key, the display will briefly read 'LO SCLE' (for "Low Scale"), and then show the present Low Scale

setting. Active digit (the digit that can be changed) will be flashing. Use ^v key (as described in Setup For High Scale) to change

the value. After the desired Low Scale setting is displayed, push SETUP key to go to the next step.

‘Offset’ Setup

After setting a channel's Low Scale, the next parameter to be set is channel offset. Offset is used for calibrating a channel to a

specific transducer that puts out a signal other than zero at its low end. If a transducer happens to output a small signal at its low

end excitation, then the OFFSET parameter is used to make the transducer's minimum signal appear to be zero. For instance,

FOR UNITS WITH VOLTAGE

, will increment the

Page11

Page 13

DP3300 Series User’s Manual

suppose a flow transducer outputs a 0.130Vdc to 5.000Vdc signal which corresponds to a flow rate of 0 to 40 gal./min. Then to

make the 0.130Vdc correspond to a display of 0, set OFFSET =0.130.

NOTE:

If the input type is VOLTAGE, the Offset value is entered in millivolts.

After pushing SETUP key at the completion of Setup For Low Scale, the display will briefly read 'OFFSEt', and then show the

present Offset value. The active digit will be flashing. Use ^v key (as described in Setup For High Scale) to enter a desired

OFFSET value. After the desired OFFSET value is displayed, push the SETUP key to go to the next step.

If the input type is CURRENT, the Offset value is entered in milliamps.

‘Tare’ Setup

After setting a channel's OFFSET value, the next parameter to be set is channel TARE. TARE is used if it is necessary to always

subtract a value from a reading prior to displaying that reading. For example, suppose a pressure transducer always includes

atmospheric pressure of 15 psi, and you only wish to display pressure differential from atmospheric (a gage reading of 19psi is to

be displayed as 4psi). To do this, enter the number you want subtracted from the measurement prior to displaying it.

The display will first show 'tARE' after which current TARE value will be displayed. Use ^v key (ref. Setup For High Scale) to

set the desired TARE number. Once the desired TARE value is displayed, push the SETUP key to enter that value and go to the

next step.

‘Limits’ Setup

DP3300 uses LIMIT parameter to determine when to activate output signal for a specific channel. When a reading exceeds

LIMIT value , then the output for that limit is activated. When a channel reading drops below the LIMIT setting by an amount

equal to the DEADBAND setting, then the channel’s output is de-activated.

The display will first show 'CHx Lt1' (where ‘x’ is the channel number) following which the LIMIT value will be displayed.

Use ^v key (ref. Setup For High Scale) to set a desired value. Once the desired LIMIT value is displayed, push SETUP key to

enter that value and go on to setting up limit 2. After limit 2 (which is setup just like limit1), limit 3 for the channel will be setup.

‘Deadband’ Setup

After setting a channel's limits, the next parameter to be set is the channel's output relay DEADBAND. This parameter is used to

eliminate relay "chatter" as a signal hovers around its LIMIT value. When channel reading drops below the LIMIT setting by an

amount equal to DEADBAND setting, then that particular limit output is de-activated. The minimum value of DEADBAND is 2.

The display will first show 'dEAd bd' after which the present DEADBAND value will be displayed. Use ^v key (ref. Setup For

High Scale) to set the desired DEADBAND value. Push SETUP key after programming DEADBAND value.

‘Relay Latched/Non-Latched Mode’ Setup

In Latched mode the relay is activated when its LIMIT value is exceeded and stays activated until the operator manually resets the

relay. To manually reset a relay on channel 1 or 2, first select the channel by pushing the CH. SEL. Then push the DATA key

until the desired limit number for the particular channel comes up on the display e.g. CH2 LT3 (Channel 2, limit number 3).

While keeping the DATA key pressed, simultaneously press the RESET key. This will reset the respective limit relay (NOTE:

Process reading should be below the limit value for the relay to reset. Otherwise, pushing of the keys will be ignored)

In Non-latched mode the relay is activated when its LIMIT value is exceeded. The relay is deactivated when the channel readings

drop below the LIMIT value by the DEADBAND setting.

The display will show 'NON LCH' for Non-Latch mode, or 'LAtCH' for Latch mode. Use ^v key to toggle between settings.

Once the desired setting is displayed, push SETUP key to enter that value and go to the next step.

‘Relay Normally Open/Closed’ Setup

After setting DEADBAND, the next parameter determines whether channel's output relays will operate as "Normally Open" or as

"Normally Closed". The relay itself is a Single Pole Single Throw (SPST) relay.

When this parameter is set for "Normally Open", the relay contacts are open when reading is below LIMIT, and closes when the

channel reading exceeds its LIMIT value.

Page12

Page 14

DP3300 Series User’s Manual

When this parameter is set for "Normally Closed", the relay is closed when readings are below LIMIT, and opens when the

channel reading exceeds its LIMIT value.

The display will show 'LTx N.O.' (where ‘x’ is the channel number) for a Normally Open setting or 'LTx N.C.' for a

'Normally Closed' setting. Use ^v key to toggle between two settings. Once the desired setting is displayed, push SETUP key to

go on to setting up limits 2 and 3 for the channel. The display format is 'LT2 N.O' or 'LT2 N.C.' and 'LT3 N.O' or 'LT3

N.C' respectively.

‘Engineering Units’ Setup

After setting a channel's relay for NORMALLY OPEN/CLOSED operation, the next step sets the 3 letters that follow the process

value in the display. These 3 letters represent the measurement units for analog channels (only analog channels have this feature).

Any desired combination of the following letters may be programmed:

A,B,C,D,E,F,G,H,I,J,L,N,O,P,Q,R,S,T,U,Y

The letter selection goes up to 'Y' and down to 'A' and from 'A' down to ' - ' sign. The ' -' sign indicates that that particular

digit will be blanked e.g. if the desired engineering unit was feet, then the display can be programmed to show ' Ft'. In this case

one letter (the letter to the left of letter 'F') will be blanked out by programming a ' - ' sign in its location.

If no engineering units have been programmed, then three dots will be displayed. Whenever the input type is changed from one

type to another, the system automatically clears the engineering units. Therefore, it is necessary to enter new units after a change

in the input type has been made. The only exception in this case is when a thermocouple selection is made. In that case, the unit

automatically enters an 'F' or 'C' (Fahrenheit or Centigrade) depending upon the selected display units. However, just like the

other inputs, any alternate units may be programmed for thermocouples.

The display will first show 'C1 UNIt' after which the present UNITS setting will be displayed. Use ^v key (ref. Setup For High

Scale) to setup the desired UNITS . Push SETUP key after the desired UNITS are displayed.

‘Rate Time Base’ Setup

Rate time base is used for calculating rate for the selected channel. The units for Time base are seconds and it can be entered in

increments of 1000

The display will first show 'rAtE tb' after which the current Time Base value will be displayed. Use ^v key (ref. Setup For High

Scale) to enter desired value. Push SETUP key after programming Rate Time base.

th

of a second. Minimum Time base is one second.

Input Signal type selection:

The display will briefly show 'IP TYPE' (for "Input type") after which the present input type for the selected channel will be

displayed. Various inputs available are: J T/C, CR.AL T/C (Chromel Alumel, type K T/C), T T/C, E T/C, CURRENT, or

VOLTAGE. If the unit has a noble metal thermocouple option, then only one T/C can be selected i.e. B T/C, R T/C, or S T/C.

Use ^v key to display the desired input type. Once the desired input type is displayed, push SETUP key to enter that input type

and go to the next step.

SYSTEM CONFIGURATION:

After entering correct pass-code and selecting the blinking 'SYS' (ref. SETUP section), the DP3300 goes into the SYSTEM

CONFIGURATION mode. This mode allows setting up parameters that affect all

Page13

the channels or the instrument in general.

Page 15

DP3300 Series User’s Manual

Display Options

On pushing SETUP key while the display is flashing SYS , the display briefly shows 'dSP OPt' (for display option) and then

the current Display Option setting. Following display options are selectable. Use ^v key to step thru these options. Once the

desired Display Option is shown, push SETUP key to enter the setting and go to set Display Time.

Option

Display Description

SCAN SCAN Scan all channels that are turned on.

HIGH POINT HIGH Pt Display peak value of all channels that are turned on.

LOW POINT LO Pt Display low reading of all channels that are turned on.

CH1 – CH2 CH1 – CH2 Channel 1 differentialwith respect to channel 2

CH2 – CH1 CH1 – CH2 Channel 2 differentialwith respect to channel 1

ELAPSED TIME ELPSEd t Elapsed time

‘Display Time’ Setup

The first parameter in system setup mode is the DISPLAY TIME. This determines how many seconds a channel's reading is

displayed before scanning to the next channel. The display will first show 'dSPLy t' (for Display Time), and then the present

setting in seconds. Use ^v key (ref. Setup For High Scale) to set the desired DISPLAY TIME value. Once the desired DISPLAY

TIME value is displayed, push SETUP key to enter that value and go to Setup For Relay Latch/Non-Latch

Audio Alarm ON/OFF

The next step lets you program the buzzer ON or OFF. The display will either read 'ALR ON' or 'ALR OFF'. To make an

alternate selection, push ^v key. After making any change or to retain current setting, push SETUP key. This will take you to the

very beginning of setup mode.

Cold Junction Setting

The next parameter is the cold junction reference temperature. The display will first show 'COLd JN', and then the cold

junction temperature will be indicated. IF NECESSARY

Once the correct temperature is displayed, push PROG key to enter that setting and go to Controller Calibration.

NOTE 1:

junction reading.

NOTE2: Cold Junction temperature is the temperature at the connector where thermocouple connects (and forms the juntion) into

the unit. IT IS NOT THE AMBIENT TEMPERATURE.

The unit should be powered up for at least fifteen to twenty minutes before any adjustments are made to the cold

, use the ^v key to adjust until the display reads proper temperature.

Calibration Mode

After setting the Cold Junction Reference temperature, the next step is calibration of channels. This allows easy calibration of

each channel without the instrument scanning from channel to channel. The display will show channel input reading in the form

'x-nnnnn' (where x=channel numbe r and nnnnn is the pro cess reading).

NOTE 1

NOTE 2: Only analog channels can be calibrated.

: ONLY channels that are turned ON will be displayed at this time!

Thermocouple Calibration Procedure

Note

: Make sure the unit is reading correct cold junction temperature before calibration.

If incorrect, adjust as described in the "Program For Cold Junction" section.

For calibrating a thermocouple Channel, the following steps should be performed. Note that calibrating one channel will

automatically calibrate the other channel. Also, only one type of thermocouple input needs to be calibrated i.e. J,K,T or E. For

example, if the calibration is done for a type K thermocouple, types J, T, and E are automatically calibrated.

Page14

Page 16

DP3300 Series User’s Manual

1. Connect a thermocouple calibration source to the unit.

2. Dial in 1100 degrees centigrade on the calibrator (Note: unit must be programmed for displaying in centigrade).

3. Adjust the gain pot (see diagram of rear view of instrument) on the back of the instrument until the display reads '1100'.

4. Short Channel #1's input with a wire or shorting bar (make sure to disconnect the calibrator so as not to damage it).

5. Push DATA key. The display will read '0002' --- or some other value.

6. Adjust offset pot on back of instrument (ref. Fig. 3) until the display reads '0000'.

7. Push PROG key once -- the display will show Cold Junction temperature.

8. Remove the shorting bar from Channel one input and connect the thermocouple calibrator again.

9. Repeat steps 2 through 7 till the unit reads prop er temperature. Press ‘PROG’ key to step thedisplay to next Channel.

Input Range Setup (for current and voltage):

Voltage Range Setup (0-5vdc, 0-10vdc)

After calibration, the VOLTAGE range may be setup. The display will briefly show 'U rAnGE' (for "Voltage Range"). Then

the display will show the present setting. Use ^v key (ref. Setup For High Scale) to set the desired VOLTAGE value. Once the

desired VOLTAGE value is displayed, push SETUP key to enter that value and go to the next step.

Voltage Range Setup (for millivolt inputs)

For Millivolt input units (i.e. the units that have millivolt input option instead of thermocouples), the display will first show 'HV

rnGE' (for "High Voltage Range"). After the High Voltage range is set, the display shows 'LV rnGE' (for "Low Voltage

Range" i.e. for millivolt input). Enter values for respective inputs.

Current Range Setup

After the VOLTAGE range, the CURRENT range may be set. The display will briefly show 'C RANGE' (for "Current

Range") followed by previous value . Use ^v key (ref. Setup For High Scale) to set the desired CURRENT value. Once the

correct CURRENT range is displayed, push SETUP key to enter that value and return to 'SYS CH' display.

Correct Range Settings

Following RANGE values should be entered for various inputs:

INPUT

0-5 Vdc 5.000

0-10 Vdc 10.000

0-100 Mv 100.0

4-20 Ma. (loop current) 20.00

RANGE Value

Setup Examples

Example #1: Use of the OFFSET Parameter

Setup for a 4-20ma transducer signal corresponding to 0-500 gallons of fluid (reading in 10th of a gallon resolution):

DECIMAL POINT = 999.9 OFFSET = 4.000

HIGH SCALE = 500.0 TARE = 0.000

LOW SCALE = 000.0

Example #2: Use of the LOW SCALE Parameter

Setup for a 4-20ma transducer signal corresponding to 500-2000 degrees Fahrenheit temperature i.e. 500 degrees at 4ma and 2000

degrees at 20ma (one degree resolution):

DECIMAL POINT = 9999 OFFSET = 4.00

HIGH SCALE = 2000 TARE = 0.000

LOW SCALE = 500

Page15

Page 17

DP3300 Series User’s Manual

d

N

N

SYS

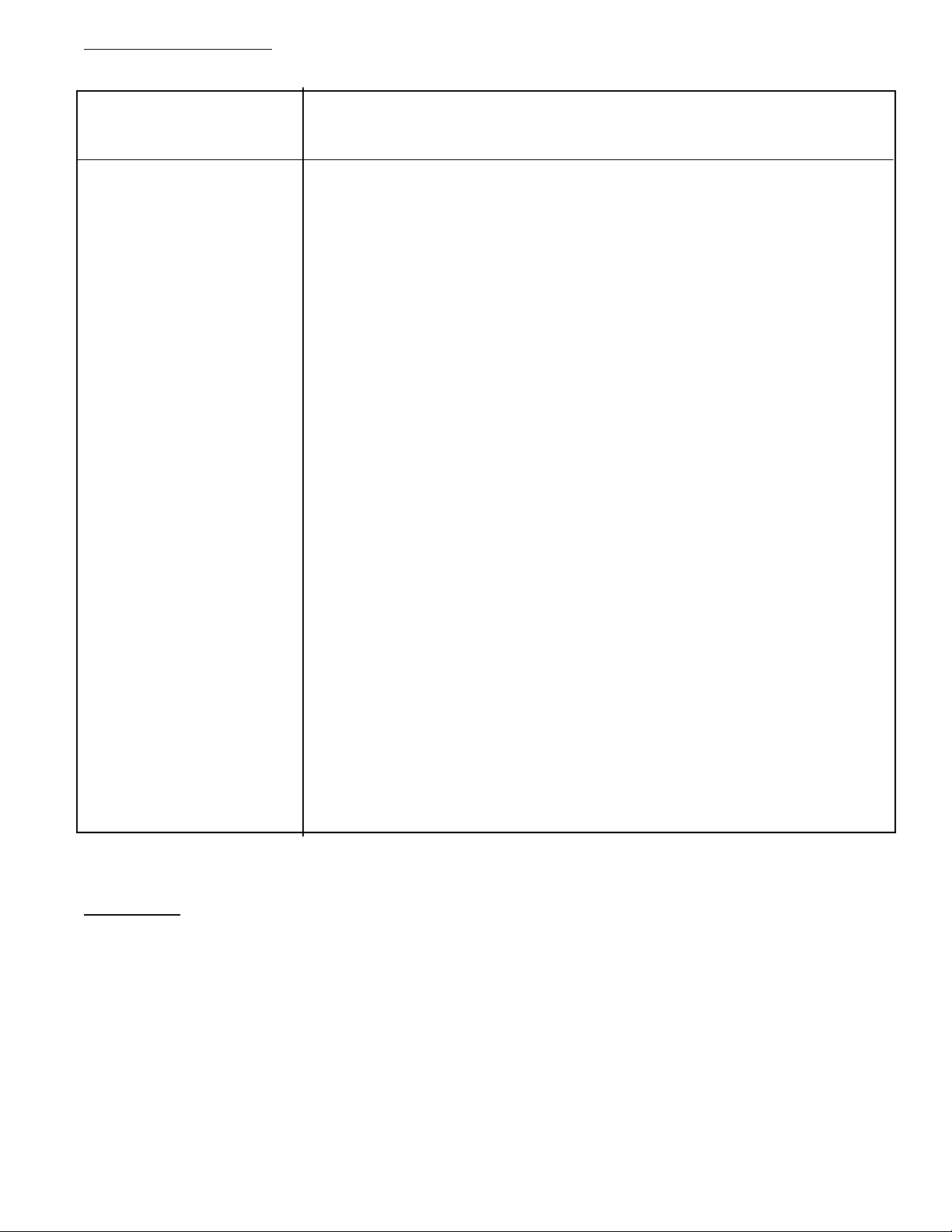

FLOW CHART FOR ANALOG INPUT

SET UP

TEM OR CHANNEL

SYSTEM SETUP

Select Display Option

1.Scan

2.High point

3.Low point

4.CH 1 – CH 2

5.CH 2 – CH 1

6.Elapsed Time

Enter Display Time

Select Audio alarm On/Off

Calibrate Cold Junction

Channel Calibration

Select Channel

Thermocouple / RTD / Thermister Setup

Turn Ch On/Off

Select Input Type

Select Display Units

Degree C/F

Enter Process Limits

(1 thru 3)

Enter Relay Deadband

Prog. Relay Latching/

on Latching

CHANNEL SETUP

Voltage or Current Setup

Turn Ch On/Off

Select Input Type

Enter

Decimal Point

Enter High Scale

Enter Low Scale

Enter Off Set

Enter Tare

Enter Voltage Range

Enter Current Range

Select Relays Normally

Open /Normally Closed

(Limits 1thru 3)

Prog. Engineering Units

Enter Rate Time Base

Enter Process Limits

(1 thru 3)

Enter Relay Deadban

Prog. Relay Latching/

on Latching

Select Relays Normally

Open /Normally Closed

(Limits 1thru 3)

Prog. Engineering Units

Enter Rate Time Base

Page16

Page 18

DP3300 Series User’s Manual

Non

N

N

Non

N

N

Non

N

N

Non

N

N

Non

N

N

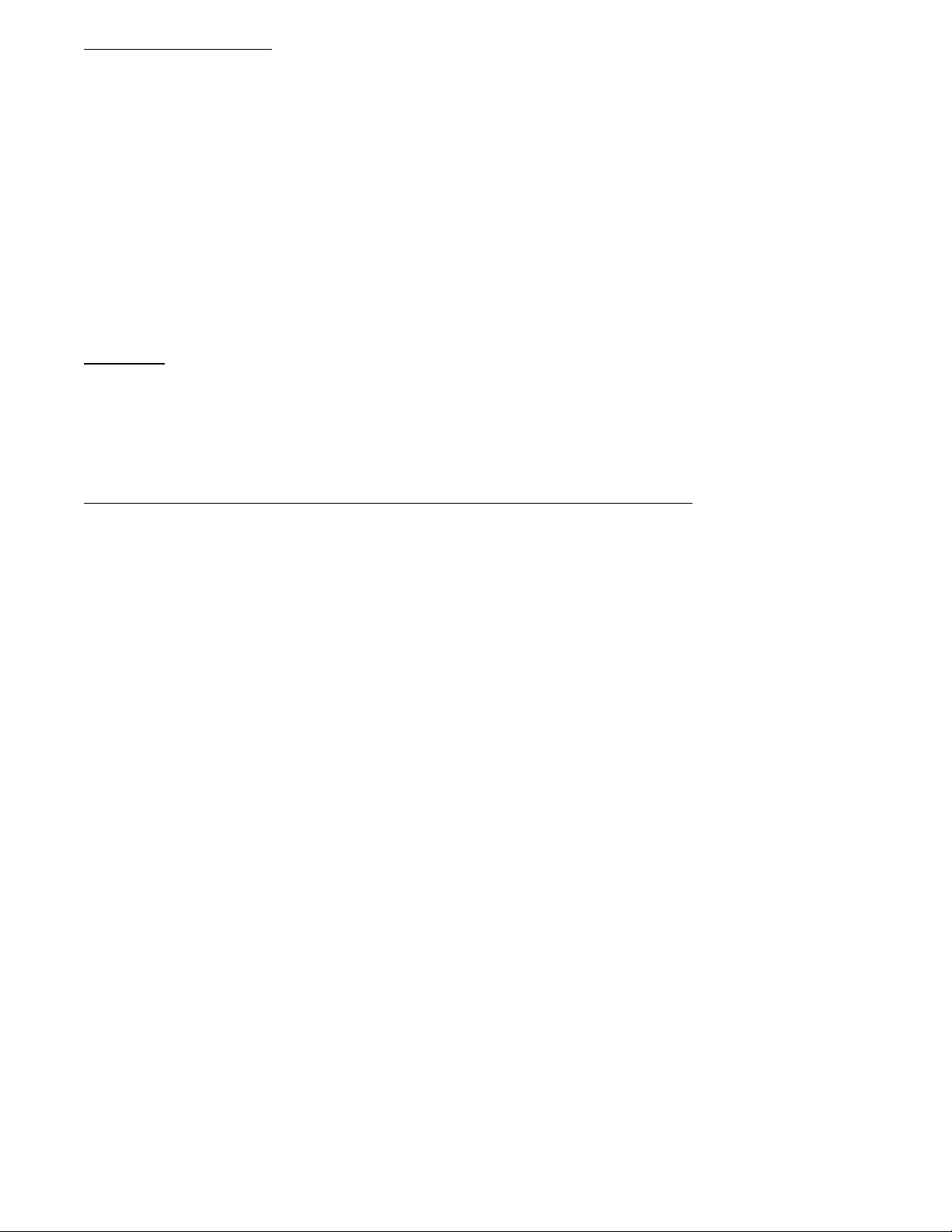

FLOW CHART FOR PULSE INPUT:

Select System or Channel Programming

SET UP

1. Voltage 2. Current 3. J T/C

4. K T/C 5. T T/C 6. E T/C

7. Pulse

Low Freq.

Scaler

Division Factor

Enter Limits

(1 thru 3)

Deadband

RelayLatching/

- Latching

Select Limits

ormally Open /

ormally closed

(Limits 1 thru 3)

Turn CH On/Off

SELECT INPUT TYPE

High Freq.

Scaler

Division Factor

Enter Limits

(1 thru 3)

Deadband

RelayLatching/

- Latching

Select Limits

ormally Open /

ormally closed

(Limits 1 thru 3)

Enter Rate Time

Base

Select Dec.Pt

Position

Scaler

Division Factor

Enter Limits

(1 thru 3)

Deadband

RelayLatching/

- Latching

For System Programing Refer to

Flow Chart for Analog Input

RPM Counter Rate

Select Filter

Value

Select Dec.Pt

Position

Scaler

Division Factor

Enter Limits

(1 thru 3)

Deadband

RelayLatching/

- Latching

Select Counter

Mode

0,1,2,3,4,5

Enter Preset Value

Enter delay

Select Dec.Pt

Position

Scaler

Division Factor

Enter Limits

(1 thru 3)

Select Limits

ormally Open /

ormally closed

(Limits 1 thru 3)

Page17

Select Limits

ormally Open /

ormally closed

(Limits 1 thru 3)

Enter Rate Time

Base

Deadband

RelayLatching/

- Latching

Select Limits

ormally Open /

ormally closed

(Limits 1thru 3)

Enter Rate TimeBase

Page 19

DP3300 Series User’s Manual

SETUP FOR A PULSE CHANNEL:

Turning a Channel ON or OFF

The very first thing after selecting a channel is to turn it on or off. A channel should be turned off if it is not being used. Use ^v

key to select the desired setting. If a channel is OFF, the display will show 'CHx OFF' (where ‘x’ is the channel number) and

if it is ON the display is 'CHx ON'. Use ^v key to display the desired ON/OFF setting, and then push SETUP key to go to the

next parameter .

MODES OF OPERATION FOR A PULSE INPUT CHANNEL:

A pulse Channel can operate in any one of the following modes:

MODE

Counter Mode COUntEr For a Channel being configured as a counter.

Rate Mode rAtE For a Channel being configured as a rate monitor.

RPM mode SyS rP For a Channel being configured as RPM monitor.

High Frequency Mod e HI FrEq For a Channel be ing configured as high frequency meter.

Low Frequency Mode LO FrEq For a Channel being confi gured as low frequency meter.

To change operating mode of the system push ^v key. After obtaining the desired mode, push SETUP key.

The next function to be configured depends on the operating mode selected a bove. To c onfigure for diffe rent modes, loo k under

appropriate headings.

DISPLAY SHOWS DESCRIPTION

SETUP FOR COUNTER:

If a channel is setup as a counter, then the following steps have to performed. To abort at any point during the setup, push RESET

key once to get to the very beginning of SETUP, or push and hold (till SAVING is displayed) to get out of SETUP altogether.

FUNCTION DISPLAY SHOWS TO CHANGE

Counter mode 0 Cntr 0 Push ^v key till

Counter mode 1 Cntr 1 desired mode is

Counter mode 2 Cntr 2 selected .

Counter mode 3 Cntr 3

Counter mode 4 Cntr 4

Counter mode 5 Cntr 5

Preset value entry 'PrESEt' followed by preset Push ^v key to increment or decrement

value e.g. 10.024 with active digit. Push <NXT> key to change

active digit flashing. active digit.

Relay Delay entry 'dELAY' followed by preset Push ^v key to increment or decrement

value e.g. 24 with active active digit. Push <NXT> key to cha nge

digit flashing. active digit.

Decimal point dP 9999 Push ^v key to

placement dP 999.9 move decimal

dP 99.99 point to desired

dP 9.999 position.

Scaler 'SCALER' followed by preset Push ^v key to increment or decrement

Scaler value e.g. 0.00024 with active digit. Push <NXT> key to change

Page18

Page 20

DP3300 Series User’s Manual

FUNCTION DISPLAY SHOWS TO CHANGE

active digit flashing. active digit.

Division Factor 'dIV FAC' followed by preset Push ^v key to increment or decrement

division factor e.g. 12 with active digit. Push <NXT> key to

active digit flashing. change active digit.

Limit 1 'CH1 LT1' followed by preset Limit 1 Push ^v key to increment or decrement

Limit 2 value e.g. 123.4 with active digit active digit. Push <NXT> key to

Limit 3 flashing. active digit.

For limits 2 &3 CH1 LT2, CH1 LT3 NOTE: Limit3 is audio visual alarm only

followed by limit value. --- it has no relay output.

Relay deadband 'dEAdbd' followed by deadband Push ^v key to increment or decrement

value e.g. 0002 active digit. Push <NXT> key to make

next digit active.

Latching or non - 'LATCH' for latching mode. Push ^v key to obtain alternate mode.

latching relay setup. 'NON LCH' for non- latching mode.

Limit outputs prog- LT1 N.O. or LT1 N.C Use ^V key to obtain

rammed as normally LT2 N. O. or LT2 N.C alternate mode.

open or closed LT3 N.O. or LT2 N.C

Time base for RATE 'T B ASE' followed by previously Push ^v key to increment or decrement active

calculation (In seconds) programmed value e.g. '1.999' digit. Push <NXT> key to make next digit active

SETUP FOR HIGH AND LOW FREQUENCY MONITOR:

If the unit is setup as a frequency meter, then following SETUP steps are performed.

FUNCTION DISPLAY SHOWS TO CHANGE

Scaler 'SCALER' followed by preset scaler Push ^v key to increment or decrement

value e.g. 10.00024 with active digit active digit. Push <NXT> key to

flashing. change active digit.

Division Factor 'DIV FAC' followed by preset division Push ^v key to inc rement or

decrement by preset division factor. (e.g. 12` active digit. Push <NXT> key to

with active digit flashing). change active digit.

Limit 1 'CH1 LT1' followed by preset Limit 1 Push ^v key to increment or decrement

Limit 2 value e.g. 123.4 with active digit active digit. Push <NXT> key to

Limit 3 flashing. active digit.

For limits 2 &3 CH1 LT2, CH1 LT3 NOTE: Limit3 is audio visual alarm only

followed by limit value. --- it has no relay output.

Relay deadband 'dEAdbd' followed by deadband Push ^v key to increment or decrement

value e.g. 0002 active digit. Push <NXT> key to make

next digit active.

Page19

Page 21

DP3300 Series User’s Manual

FUNCTION DISPLAY SHOWS TO CHANGE

Latching or non - 'LATCH' for latching mode. Push ^v key to obtain alternate mode.

latching relay setup. 'NON LCH' for non latching mode.

Limit outputs prog- LT1 N.O. or LT1 N.C Use ^V key to obtain

rammed as normally LT2 N. O. or LT2 N.C alternate mode.

open or closed LT3 N.O. or LT2 N.C

SETUP FOR RATE MONITOR:

If channel 2 is programmed to operate in RATE mode, then the following steps are performed during SETUP procedure:

FUNCTION DISPLAY SHOWS TO CHANGE

Time base for RATE 'rAtE tb' followed by previously Push ^v key to increment or decrement active

calculation (In seconds) programmed value e.g. '1.999' digit. Push <NXT> key to make next digit active

Decimal point dP 9999 Push ^v key to

placement dP 999.9 move decimal

dP 99.99 point to desired

dP 9.999 position.

Scaler 'SCALER' followed by preset scaler Push ^v key to increment or decrement

value e.g. 10.00024 with active digit active digit. Push <NXT> key to change

flashing. active digit.

Division Factor 'DIV FAC' followed by preset division Push ^v key to increment or decrement

by preset division factor. (e.g. 12` active digit. Push <NXT> key to

with active digitflashing). change active digit.

Limit 1 'CH1 LT1' followed by preset Limit 1 Push ^v key to increment or decrement

Limit 2 value e.g. 123.4 with active digit active digit. Push <NXT> key to

Limit 3 flashing. active digit.

For limits 2 &3 CH1 LT2, CH1 LT3 NOTE: Limit3 is audio visual alarm only

followed by limit value. --- it has no relay output.

Relay deadband 'dEAdbd' followed by deadband Push ^v key to increment or decrement

value e.g. 0002 active digit. Push <NXT> key to make

next digit active.

Limit outputs prog- LT1 N.O. or LT1 N.C Use ^V key to obtain

rammed as normally LT2 N. O. or LT2 N.C alternate mode.

open or closed LT3 N.O. or LT2 N.C

SETUP FOR RPM MONITOR:

Page20

Page 22

DP3300 Series User’s Manual

If the unit is setup as an RPM monitor then following steps are performed for setting up various parameters:

FUNCTION DISPLAY SHOWS TO CHANGE

Filter value 1,2,4,6,10,15,20,30,60 Push ^v key to obtain desired value

Decimal point dP 9999 Push ^v key to

placement dP 999.9 move decimal

dP 99.99 point to desired

dP 9.999 position.

Scaler 'SCALER' followed by preset scaler Push ^v key to increment or decrement

value e.g. 10.00024 with active digit active digit. Push <NXT> key to change

flashing. active digit.

Division Factor 'DIV FAC' followed by preset division Push ^v key to increment or decrement

by preset division factor( e.g. 12` active digit. Push <NXT> key to

with active digit flashing). change active digit.

Limit 1 'CH1 LT1' followed by preset Limit 1 Push ^v key to increment or decrement

Limit 2 value e.g. 123.4 with active digit active digit. Push <NXT> key to

Limit 3 flashing. active digit.

For limits 2 &3 CH1 LT2, CH1 LT3 NOTE: Limit3 is audio visual alarm only

followed by limit value. --- it has no relay output.

Relay deadband 'dEAdbd' followed by deadband Push ^v key to increment or decrement

value e.g. 0002 active digit. Push <NXT> key to make

next digit active.

Latching or non - 'LATCH' for latching mode. Push ^v key to obtain alternate mode.

latching relay setup. 'NON LCH' for non latching mode.

Limit outputs prog- LT1 N.O. or LT1 N.C Use ^v key to obtain

rammed as normally LT2 N. O. or LT2 N.C alternate mode.

open or closed LT3 N.O. or LT2 N.C

ALARM OUTPUTS:

Status:

The system has optional process alarm outputs that are activated when limit is exceeded on any of the two channels. The alarms

can be programmed as normally open or normally closed (see SETUP) and latching or non-latching. The status of these alarms is

indicated on the front panel by LEDs. When ever an alarm is activated the respective LED is turned on. Each channel has two

outputs (relay or open collector) and one audio visual alarm. Audio visual alarm provides a visual indication on the front panel

(LED) and a buzzer output if a programmed limit value is exceeded. Buzzer can be turned off, if so desired (look under SETUP).

Resetting:

Once energized, alarms can be reset in two differ ent ways --- automatically or manually (non latching or la t ching). In nonlatching mode, the alarm outputs will de-energize on their own when process variable drops below the limit value. In latching

mode, they stay energized even if the process variable drops below the limit. To reset the energized outputs in the latching mode,

first make the display indicate the limit that needs to be reset (e.g. "CH1 LT2"), by pushing the DATA key. Next, keeping the

DATA key pushed while limit value is displayed, go on to push the RESET key. The respective alarm output will de-energize

and the system will indicate so by displaying RLY RST.

Page21

Page 23

DP3300 Series User’s Manual

NOTE: Process value for respective relay must be below limit value for it to reset. Other wise the key sequence will be ignored.

Open Collector (solid state) output Option:

DP3300 units can be ordered with either open collector outputs or electro-mechanical relays. (Check model number printed on

the unit for option). If ordered with open collector outputs, then these outputs are programmed during Setup to operate as either

Normally Open (NO) or Normally Closed (NC). The default setting is Normally Open.

Whenever a limit is reached, an open collector output provides a 5 Vdc signal at 50milliamp on the output connector, eg.. Limit

#1 provides its 5 volt output signal between pins 1 and 2.

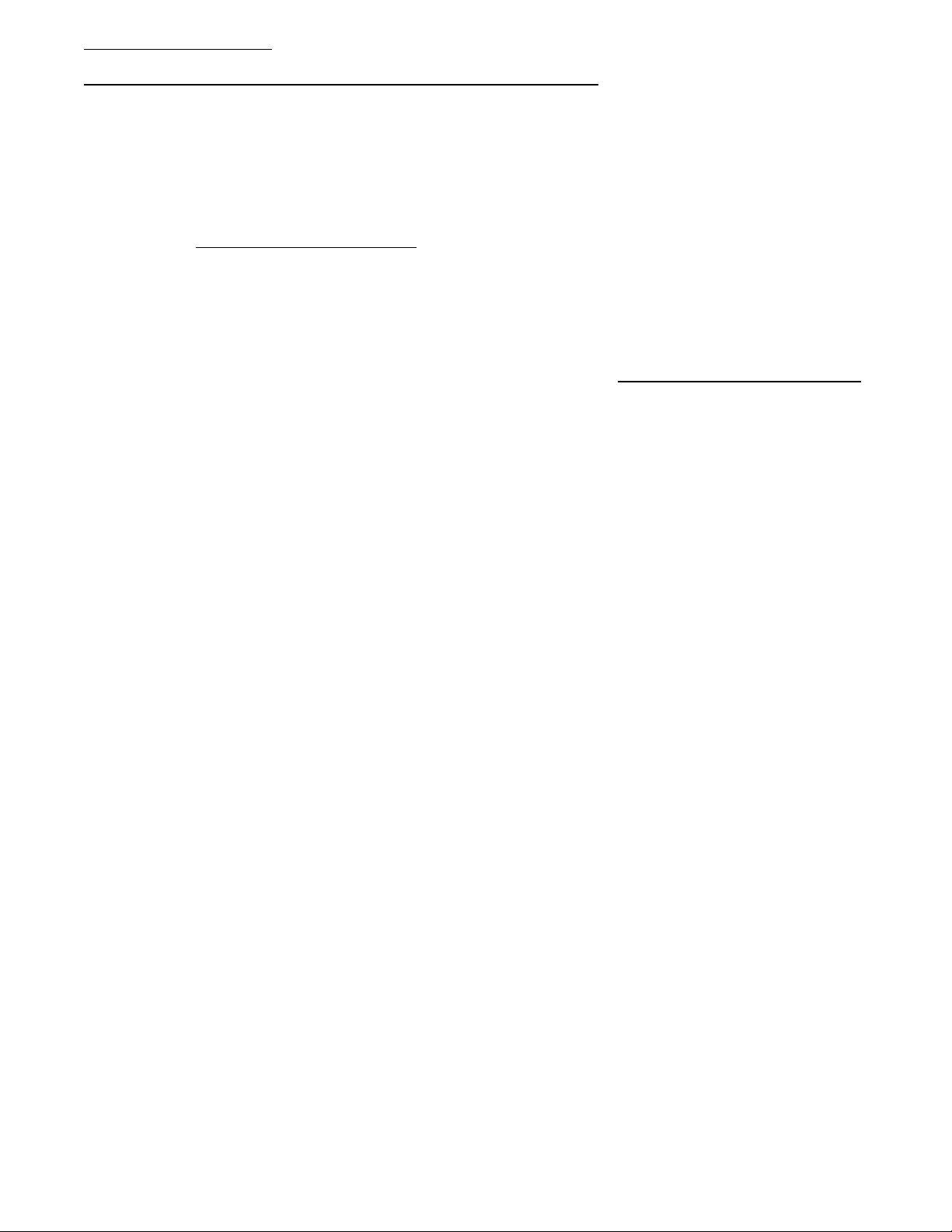

Figure 1. Open Collector Hookup Example

Instrument

1

2

+OUTPUT

-OUTPUT

LOAD

Electro-Mechanical Relay Option:

DP3300 units can be ordered with either open collector outputs or electro-mechanical relays. (Check model number printed on

the unit for option). If ordered with relays, then these relays are programmed during Setup to operate as either Normally Open

(NO) or Normally Closed (NC). The default setting is Normally Open. Each of these limit relays provides a switched output

whenever a limit is reached. The maximum rating for a 120Vac unit is 120Vac @ 0.5 amp or 28 Vdc @ 1.0 amp. A 240Vac unit

is rated at 240Vac @ 0.25 amp. or 28Vdc @ 1.0 amp.

Figure 2. Electro-mechanical Relays Hookup Example

Instrument

LIMIT # 4

LIMIT # 3

LIMIT # 2

LIMIT # 1

8

7

6

5

4

3

2

1

LIMIT RELAYS

NOTE: LOOK UNDER SPECIFICATIONS FOR RATING ON RELAYS & OPEN COLLECTOR OUTPUTS.

UNDER NO CONDITION SHOULD THE RELAYS & OPEN COLLECTOR OUTPUTS BE OPERATED

BEYOND THEIR RATED CAPACITY. DOING SO CAN DAMAGE THE UNIT PERMANENTLY.

OUTPUT CONNECTOR

120 VAC @ 0.5 AMPS

120 VAC @ 0.5 AMPS

120 VAC @ 0.5 AMPS

120 VAC @ 0.5 AMPS

Switched Output

Switched Output

Switched Output

Switched Output

POWER

Power connection should be made to the three terminal connector as shown in figure 3. Also, make note that it is very important

that the power line inputs and the power ground are not switched. Doing so will permanently damage the instrument. Refer to the

schematic for proper connections. For convenience, the printed circuit board is labeled L1 L2 GND on the under side of

three terminal power connector.

For instruments with the 12Vdc power option, refer to Figure 3.

NOTE: WHILE MAKING POWER CONNECTION TO THE UNIT, MAKE SURE THAT AC POWER

LINE L1 OR L2 IS NOT ACCIDENTALLY CONNECTED INTO THE GROUND (GND)

TERMINAL. THIS WILL RESULT IN PERMANENT DAMAGE TO THE INSTRUMENT.

DOUBLE CHECK THE CONNECTIONS BEFORE APPLYING POWER!!

Page22

Page 24