Page 1

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

DOCN600

Dissolved Oxygen System

Page 2

OMEGAnet®Online Service Internet e-mail

omega.com info@omega.com

Servicing North America:

U.S.A.: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 2900 FAX: +33 (0)1 30 57 5427

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 6611 FAX: +44 (0)161 777 6622

Toll Free in United Kingdom: 0800-488-488

e-mail: sales@omega.co.uk

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI

regulations that apply. OMEGA is constantly pursuing certification of its products to the European New

Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any

errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION 1

SPECIFICATIONS 2

INSTALLATION 4

DESCRIPTION OF FUNCTIONS 8

START-UP AND OPERATION 13

OPERATING HINTS 17

UTILITY MENU 18

DIAGNOSTICS 20

TROUBLESHOOTING AND SERVICE 21

Page 4

MODEL DOCN600 DISSOLVED OXYGEN ANALYZERS

AND MODEL DOE-601 DISSOLVED OXYGEN SENSOR

INSTRUCTION MANUAL

1.0 GENERAL INFORMATION

The DOCN600 Dissolved oxygen analyzer is a versatile industrial microprocessor based instrument.

Outputs are programmed through the menu with push buttons on the face of the instrument.

Calibration is also accomplished through the front panel menu. The instrument must be used in

conjunction with the DOE-601 dissolved oxygen sensor.

The instrument provides non-isolated 0-5 Vdc, 0-1 mA and isolated 4-20 mA analog outputs. The

analog outputs may be programmed to represent any segment of the measuring scale.

A membrane perforation alarm is provided which gives early warning of a membrane failure.

The instrument can also be used to take a temperature reading and one of the non-isolated analog

outputs can be used to give a continuous temperature signal.

The integrity of the system is ensured with a watch-dog timer and system alarm. A password

feature protects the stored values.

The instrument is housed in a NEMA 4X enclosure. The standard unit is provided with mounting

hardware for surface mount applications. Both panel and pipe mount kits can be ordered

separately.

Page 1

Page 5

2.0 SPECIFICATIONS

DISPLAY:

3 1/2 digit LED, 1/2" high digits

MEASURING RANGES:

D.O.: 0-20.00 ppm and 0-100% saturation, switch

selectable

Temperature: 0-40°C (32 to 104°F)

POWER REQUIREMENTS:

98-132 Vac, 50/60 Hz (less than 10 VA)

Optional: 196-264 Vac, 50/60 Hz

AMBIENT CONDITIONS:

-30 to 50°C (-22 to 122°F)

0 to 90% R.H. non-condensing

ANALOG OUTPUTS:

Non-isolated 0-1 mA, 100 ohms maximum load

Non-isolated 0-5 Vdc, 1000 ohms minimum load

Isolated 4-20 mA, 800 ohms maximum load

The isolated output is isolated from the input, ground

line power and all other outputs

Range Expand: The 4-20 mA analog output can be

made to represent any segment of the measuring

scale. Minimum segment is 10% of full scale.

Output Hold: The analog outputs are automatically

placed on hold during calibration or other setup

operations.

Temperature Output: The 0-5 Vdc output can be

programmed to follow either the process temperature

or dissolved oxygen.

TEMPERATURE COMPENSATION:

Automatic 0 to 100°C (32 to 212°F)

ALTITUDE COMPENSATION:

Automatic 0 to 40°C (32 to 104°F)

DIAGNOSTICS:

When system error is indicated, call STATUS to obtain

condition code. On-board simulated input to aid in

troubleshooting to obtain condition code.

MEMBRANE ALARM:

A relay activates if membrane is perforated.

TEST:

Display value and analog outputs can be set manually

to any value for testing and diagnostic purposes. This

feature allows the outputs to be tested independently

of process value.

SAFETY & SECURITY:

Non-volatile memory (EEPROM)

Passcode protected if selected

Watch-dog timer monitors microprocessor

Instrument automatically returns to on-line operation if

accidentally left in menu mode

(This feature may be held disabled if desired)

ACCURACY: % Saturation: ± 1%

ppm: ± 0.1

Temp: ± 0.2°C

STABILITY: 0.1% of span per 24 hrs., non-cumulative

RESOLUTION: % Saturation: 0.1

ppm: 0.01

Temp: 0.1°C

REPEATABILITY: 0.1% of span or better

RESPONSE TIME: 20 seconds to 90% of value upon

step change at 20°C

ENCLOSURE: NEMA 4X fiberglass reinforced polyester

enclosure with four 1/2” conduit holes and mounting

feet for surface mount

MOUNTING CONFIGURATIONS:

Standard is surface mount

Optional panel mount hardware. Part No.

Optional pipe mount hardware. Part No.

NET WEIGHT: 3 1/2 lbs. (1.6 kg)

DOCN600-PM

DOCN600-PIPE

Page 2

Page 6

Rating: 5A 115/230 Vac, 5A 30 Vdc. SPDT

Three LEDs indicate status or the three relays

CONTROL RELAYS:

Two relays can be independently set for operation in

response to rising or falling value and for fail-safe

operation. Deadband (hysteresis) independently

adjustable.

Rating: 5A 115/230 Vac, 5A 30 Vdc. SPDT

ALARM RELAY:

High-Low with fixed deadband of 2% of full scale.

Normal or fail-safe operation.

RELAY INDICATORS:

DOE-601 SENSOR

MODEL DOCN600 ADDITIONAL FEATURES

TEMPERATURE RANGE:

0-40°C (32 to 104°F)

WETTED MATERIALS:

PVC and Teflon F.E.P.

FAILURE ALARM:

5A SPDF relay closes if membrane is punctured. LED

on panel is illuminated

CABLE:

Integral 8 m (26 ft.) Maximum distance to analyzer

300 m (1000 ft.)

REPLACEMENT CARTRIDGE:

Part No. DOE-601-SC. Hermetically sealed.

MOUNTING HARDWARE

FLOTATION MOUNTING:

Model DOE-600-BFMK consists of ball float, extension

pipe, swivel bracket, junction box and 50 feet of

interconnect cable

SUBMERSION MOUNTING:

Model DOE-600-SMK consists of 5 ft. PVC pipe,

junction box and 50 feet of interconnect cable

Page 3

Page 7

3.0 INSTALLATION

3.1 Location

3.1.1 Locate the instrument within the reach of the cable provided for the DOE-601

sensor.

3.1.2 Select an installation site which is:

• free of mechanical vibrations

• reasonably clean and dry

• protected from falling corrosive fluids within the ambient temperature and humidity

specifications

• remote from high voltage relay and power switches

3.2 Type of Mounting

3.2.1 If the instrument is to be pipe or panel mounted a special hardware kit will be

required. For panel mount order part number DOCN600-PM. For pipe mount order

part number DOCN600-PIPE. Instructions for both types of mounting will be

included with the kits.

3.2.2 For surface mounting, four feet brackets, together with fastening screws, are

provided with the instrument. These should be fastened to the back of the

instrument and then it may be screwed or bolted in the selected location.

3.3 Conduit Connections

3.3.1 Four 1/2" conduit holes are provided in the bottom of the enclosure. One of these is

fitted with an approved water tight plug. To maintain NEMA 4 integrity, approved

conduit hubs must be used to connect conduit. The hubs must be connected to the

conduit before being connected to the enclosure. Any unused conduit holes must

be closed with water tight plugs or connectors.

3.3.2 For convenience of internal connections the right conduit hole (viewed from the

front) should be used for power connection; the next hole to the left for relay

outputs; the next hole to the left for analog outputs and finally the fourth hole for

sensor input.

3.4 Electrical Connections

CAUTION: The instrument operates from line voltage. This constitutes a possible shock hazard.

Ensure that line power is removed before attempting connections. Note: A separate

source of line power may have been connected to the floating relay contacts.

3.4.1 To access the terminal strips open the door of the instrument and then unscrew the

captive retaining screw near the upper right hand corner of the panel. Now swing

open the panel to reveal the terminal strip on the power supply circuit board and the

smaller terminal strip on the back of the swing-out board.

Page 4

Page 8

3.5 Sensor Installation, Flotation Mounting

3.5.1 Refer to diagram below and proceed as follows:

a) Fasten elbow to 90-inch long pipe

NOTE: Thread sealant (Teflon tape) is recommended on all mounting hardware

and sensor threads to avoid leaks

b) Fasten adapter pipe with union to elbow

c) Insert adapter pipe with union into flotation ball and tighten union lock ring to

secure float assembly

Page 5

Page 9

d) The sensor may be attached to float assembly in one of two ways:

1. With sensor EXTENDED FROM BOTTOM of flotation ball:

Insert 12-inch long extender pipe into the flotation ball and fasten it to the

end of adapter pipe. This will extend the sensor’s membrane 12 inches

below the flotation ball. NOTE: Extender pipe supplied only when ordered.

2. With the sensor membrane FLUSH WITH BOTTOM of flotation ball:

Disregard using extender pipe and proceed with Step e).

e) Route sensor cable through assembled pipe sections, starting from bottom

section, and fasten sensor to pipe.

CAUTION: Do not remove measuring cell cartridge from hermetically sealed

package until it is to be used in step f). (Membrane will dry out and

damage measuring cell).

f) Install measuring cell cartridge. Unfasten union nut from sensor and make sure

to remove any moisture from cavity area and brass contact strips. Insert

cartridge in its correctly “keyed” position. Fasten union not tightly so that O-ring

compresses to create an effective water-tight seal.

g) Calibrate system in accordance with the procedure described in Section 5.3

before placing sensor into operation.

Page 6

Page 10

h) Install pivot mounting bracket and mount junction box on the bracket. Insert

pipe/sensor assembly through the bracket to the desired position. Tighten pipe

locking screw.

3.6 Sensor Installation, Submersion Mounting

3.6.1 a) Refer to diagram below and proceed as follows:

b) Route sensor cable through pipe and fasten sensor to pipe. The use of thread

sealant (Teflon tape) on all mounting hardware and sensor threads is

recommended to avoid leaks.

CAUTION: Do not remove measuring cell cartridge from hermetically sealed

package until it is to be used in step b). (Membrane will dry out and

damage measuring cell).

c) Install measuring cell cartridge. Unfasten union nut from sensor and make sure

to remove any moisture from cavity area and brass contact strips. Insert

cartridge in its correctly keyed position. Fasten union tightly so the O-ring

compresses to create an effective water-tight seal.

d) Mount the junction box within reach of the sensor cable.

e) Calibrate system in accordance with the procedure described in Section 5.3

before placing sensor into operation.

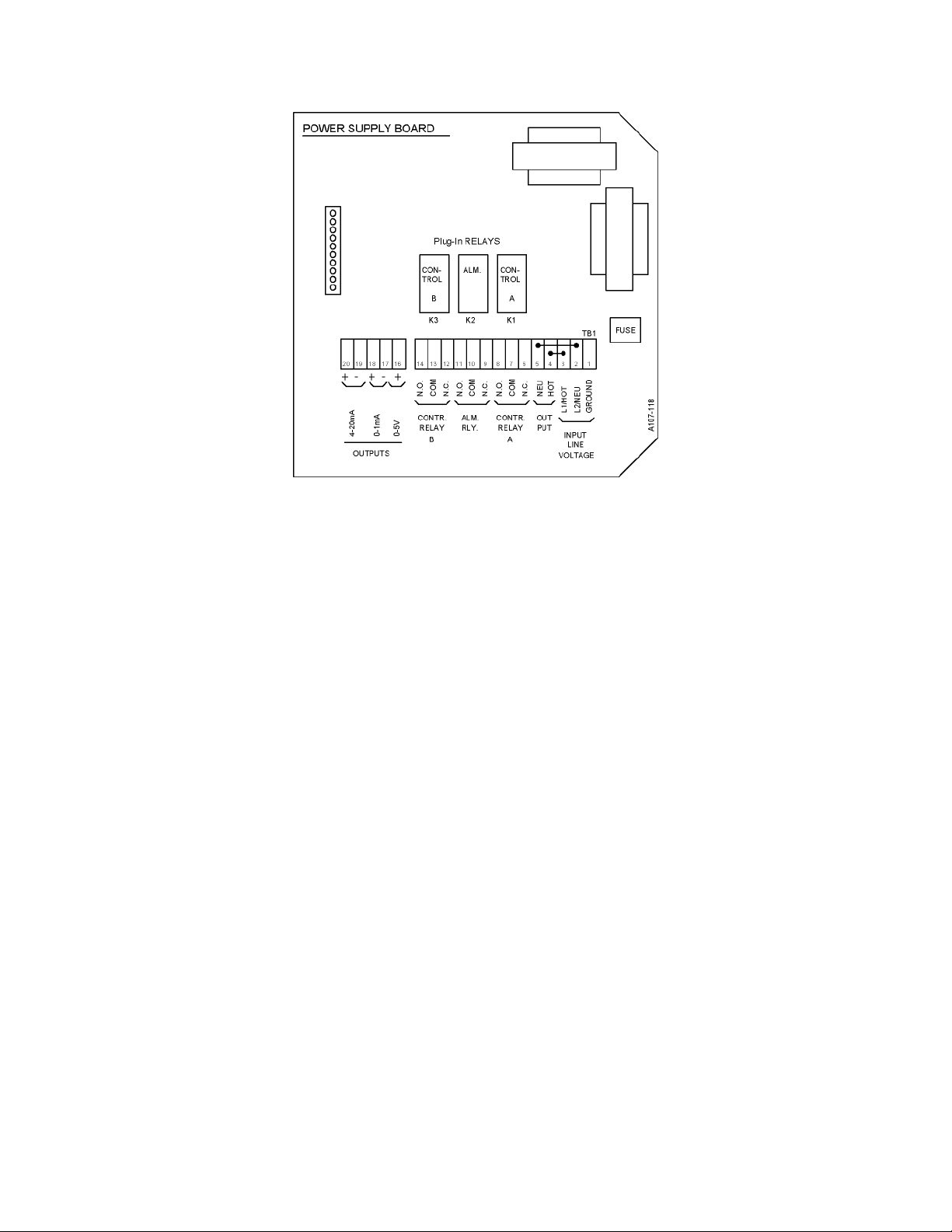

3.6.2 The terminal strip on the power supply board at the back of the instrument is

labeled for power supply, relay outputs and analog outputs. Connect wiring in

accordance with this labeling. CAUTION: Connecting the line voltage power

supply to incorrect terminals may cause serious damage.

3.7 Probe Connections

3.7.1 The interconnect cable as supplied will normally be connected to the sensor cable

in the junction box. If this is not the case, connect the six wires and the shield of the

extension cable to the numbered wires in the junction box as shown below:

Extension Cable

Junction Box

Blue 1

Red 2

Black 3

Green 4

White 5

Yellow 6

Shield Unnumbered (Green/Yellow)

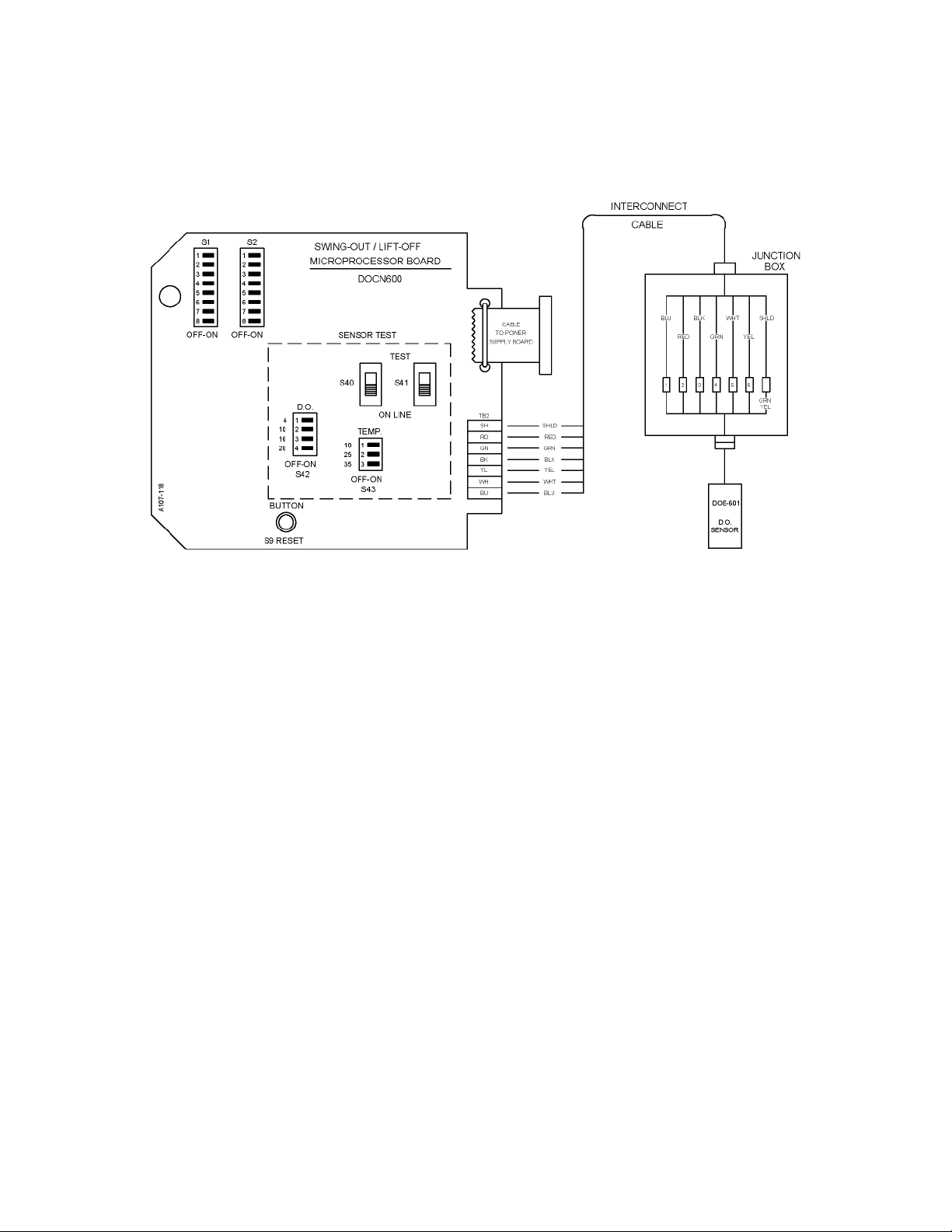

3.7.2 Connect the six wires of the interconnect cable to the terminal strip on the swing-out

board being sure to match colors as printed on the board. Connect the shield to the

terminal post located above the terminal strip.

3.7.3 Running the sensor and interconnect cable in 1/2” metal conduit for protection

against moisture and mechanical damage is recommended. Do not run power or

control wiring in the same conduit (“electrical noise” may interfere with sensor

signal).

Page 7

Page 11

4.0 DESCRIPTION OF FUNCTIONS

4.1 Overview

4.1.1 The DOCN600 is a microprocessor based dissolved oxygen analyzers are designed

for industrial applications. They operate in conjunction with the DOE-601 sensor.

The software in the unit makes the instrument very easy to operate and maintain.

4.1.2 The outputs include voltage-free relay contacts and industry standard analog

transmission signals. A relay to indicate a perforated membrane is provided. The

analog output signals transmit low power signals to peripherals such as data

recorders or control systems.

4.1.3 The software is designed for ease of operation. It uses a simple menu with all items

indicated on the panel. The user interface consists of six buttons on the front panel.

The buttons are scanned and responded continuously. In addition, an extensive

system checking for values and parameters is performed by the software. All of the

operating parameters are stored in non-volatile memory, without the need of a

battery.

4.1.4 The DOCN600 operates like a normal analog converter with a number of additional

functions made possible by the microprocessor in the instrument.

Page 8

Page 12

Some of these are:

• Recall and easy adjustment of relay and output parameters

• Push button calibration

• A HOLD function for outputs

• Continuous sensor check during measurement

• Continuous self check and watch-dog timer to ensure correct operation

• Password protection of stored values

• Temperature Output

• Simulated input for testing

4.2 Calibration

4.2.1 The DOCN600 is calibrated at the factory, with the sensor purchased with the

instrument. However, the system should be field calibrated when installed and from

time to time thereafter. The calibration procedure is given in Section 5.3.

4.3 Temperature Compensation

4.3.1 A temperature sensor in the DOE-601 sensor provides the means of continually

compensating the D.O. reading for variation in the temperature of the process.

4.4 Relay Outputs

4.4.1 Three SPDT relays are provided. The normally open contacts, NO, are open when

no alarm or control is active.

4.4.2 The two control relay can be programmed to close on either rising or falling D.O.

They can be set to close at any point on the scale. The deadband, sometimes

termed hysteresis, defines the point at which the relays open. See Sections 4.8,

5.8, and 5.9.

4.4.3 The third relay functions as a high-low alarm. It has two programmable setpoints

(high and low). The deadband is fixed at 2% of full span. This relay is also

activated in the event of a perforated membrane. (See Section 4.5) The alarm

contact can be programmed to also signal memory loss in the DOCN600 controller.

See Section 4.8, 5.12, and 5.13.

4.4.4 All relays can be programmed for "fail-safe" operation which reverses the normal

operation of the relay. In this mode the relays will fail-safe (transfer) in the event of

power failure.

4.5 Membrane Alarm Relay

4.5.1 A single pole double throw relay is provided to give an output in the event of a

perforated membrane.

4.5.2 This relay can be programmed to also signal memory loss. See Section 4.8.

4.5.3 When this relay is activated the contacts will close and the FAIL LED will be

indicated on the panel.

Page 9

Page 13

4.6 Analog Outputs

4.6.1 The analog output signals consist of a non-isolated 0-1 mA, 0-5 Vdc, and isolated 420 mA signals.

4.6.2 From the factory all of the analog outputs have a linear range corresponding to the

full range of the instrument. The 4-20 mA output can be programmed to another

linear range by entering two values:

• Output High: This is the D.O. value at which you wish to have 100% output.

• Output Low: This is the D.O. value at which you wish to have 0% output.

4.6.3 When programming, you must ensure that the output range has a span of at least

10% of the full range of the instrument. For applications that require the output to

decrease as the process value increases, i.e. an inverted output, the Output High

value will be less than the Output Low. See Section 5.4.

4.6.4 The instrument may be used to measure the temperature of the process either in

Celsius or in Fahrenheit. The DOCN600 does not control temperature but the 0-5

Vdc and 0-1 mA analog outputs can be dedicated to follow the process

temperature. See Sections 5.6.

4.7 Operation Menu

4.7.1 The operation menu allows the user to recall and to adjust the parameters, required

by the analyzer functions.

4.7.2 When the analyzer is powered up, the program will display D.O. readings. None of

the LEDs in the operation menu will be illuminated.

4.7.3 Five buttons on the panel are used to operate the menu. Use the CALL button to

step through the items in the menu, one at a time. The red LEDs beside each item

makes it very easy to follow the menu. The function of the RUN button is to return

to the on-line D.O. display from anywhere in the menu. The analyzer has a built-in

timer which, when enabled, by DIP Switch 7 Bank S1 (Section 4.8), returns the

program to RUN mode if no button has been pressed for 10 minutes. This time-out

has the same effect as pressing the RUN button.

Page 10

Page 14

4.7.4 When in the menu mode, the display initially shows the current value of the

parameters, such as the Setpoint of the control relay, while putting all of the outputs

on hold. The two arrow buttons are used to adjust the display value up or down.

To accept the new value press ENTER twice. While the value on the display is

being changed, the relay outputs and the analog outputs remain on hold.

The items that appear in the operation menu are:

• Password

• % Sat/ppm

• Test

• Calibration

• Temperature

• Status

• Output High

• Output Low

• Relay A Setpoint

• Relay A Deadband

• Relay B Setpoint

• Relay B Deadband

• Alarm Relay High

• Alarm Relay Low

4.8 DIP Switches

4.8.1 The controls which are frequently used in the normal operation of the instrument are

all accessible on the control panel. Some switches, which are infrequently used are

located on the back of the swing-out board.

4.8.2 The DIP switches are scanned on RESET, power-up and every time the instrument

is taken into the menu mode. Therefore, after changes to the DIP switch settings,

you must take the unit offline by pressing CALL in order for the instrument to scan

the new DIP switch values.

4.8.3 The following table describes the use of the 16 DIP switches:

DIP Switch

Bank S1

Switch Switch

Description of Use OFF ON

1 Selects temperature unit °F °C

2 Enables use of Password Feature YES NO

3 Fail Safe mode for Relay A NO YES

4 Direction of Control Relay A Rising Falling

5 Alarm Relay to Activate for Memory Loss YES NO

6 Fail Safe mode for Alarm Relay NO YES

7 Auto Return from menu if no button pressed NO YES

8 0-5 Vdc / 0-1 mA selector Temperature D.O.

Page 11

Page 15

Dip Switch

Bank S2

1 Fail-safe for Relay B NO YES

2 Direction of Control for Relay B Rising Falling

3 Reserved

4 Reserved

5 Reserved

6 Reserved

7 Reserved

8 Reserved

4.9 Output Hold

4.9.1 Output hold, is a function which freezes all output signals at the last value to

prevent the occurrence of wild distortions during programming and maintenance.

4.9.2 When the Operation Menu is entered by pressing CALL, the alarm relays and the

analog outputs are automatically placed on hold and remain on hold until the

instrument returns to on line. The output hold will remain for a maximum of 10

minutes after the last button was pressed, if this feature has been enabled. See

Section 4.8.

4.10 Parameter and Operation Checking

4.10.1 The instrument continuously checks all parameters in its memory, while taking D.O.

readings. When it detects an invalid value, it flashes the LEDs in the operation

menu to indicate the parameter is at fault. You must then access the operation

menu to take corrective actions.

4.11 Simulated Input for Testing

4.11.1 TEST is function for test and diagnostic purposes. Values can be simulated

internally and adjusted with the arrow buttons to set display reading and analog

outputs to any desired value without disrupting instrument calibration.

4.12 Utility Menu

4.12.1 The Utility Menu is provided to enable authorized personnel to change the range

and fine tune the analog . See Section 7.0.

4.13 Watchdog Timer and Self Diagnostics

4.13.1 The DOCN600 continuously monitors the condition of all key components of the

measuring system to ensure that the measurements are reliable. Invalid entries and

memory loss are indicated on the panel. See Section 8.0.

Page 12

Page 16

5.0 START-UP AND OPERATION

5.1 Password

5.1.1 To enter the menu press CALL then PASSWORD will be indicated. With each

press of CALL you will step through the menu. When the last item is reached the

menu wraps around to “%sat/ppm”. If you have enabled PASSWORD by placing

DIP Switch 2 Bank S1, in the off position you must enter the password “6” when

PASSWORD is indicated if you wish to change any stored value. You do not need

to enter the password to proceed to other items in the menu for recall of stored

values.

If PASSWORD has not been enabled you do not need to enter the password to

change stored values.

5.2 Percent Saturation/ppm

5.2.1 The instrument provides measurement of dissolved oxygen in either percent

saturation or ppm. In ppm measurement the reading is automatically compensated

for temperature changes in the medium.

a) To select units of measurement enter the menu by pressing CALL to indicate

%sat/ppm.

b) Press the UP arrow button to select %sat or the DOWN arrow button or select

ppm.

c) Press RUN to return to on line or press CALL for another menu selection.

5.3 Calibration

5.3.1 To calibrate the instrument you will need a container of fresh clean water. For best

results a bubbler such as that used in a tropical fish tank should be in the container.

a) Clean the sensor with a soft cloth and mild soap solution.

b) Place the sensor over the water container for a few minutes. (There is no need

to remove it from the float if so installed.)

c) Press CALL to enter the menu.

d) If the password function is enabled, enter the password then press CALL to

illuminate the “%sat/ppm” indicator. If the password function is not enabled,

“%sat/ppm” will illuminate at the first press of CALL.

e) Use the UP arrow button to illuminate the %sat LED located to the right of the

display.

f) Press CALL twice to illuminate the CALIBRATION indicator.

g) Use the arrow buttons to make the display read 100.0.

h) Press ENTER as soon as the reading stabilizes. The display will flash until

ENTER is pressed again to confirm entry.

Page 13

Page 17

i) If you wish to change the measuring unit to ppm, press CALL a number of times

to return to “%sat/ppm” and change ppm with the down button.

j) Press RUN to return to on line measurement.

NOTE: If a major change is necessary to make the display read 100% the display

will flash when you press ENTER. This is to warn that you may have made

a mistake such as using “stale” water. If you are confident your procedure

was correct, press ENTER a second time. Otherwise, repeat the calibration

procedure by pressing CALL a sufficient number of times to go through the

menu and return to CALIBRATION.

5.4 Analog Output Range Expand

5.4.1 The 4-20 mA isolated analog output may be spread over any section of the scale as

long as that section is at least 10% of full scale. The best way to describe this

setup is by example. Suppose you wish the 4-20mA output to span 5 ppm to 10

ppm. Proceed as follows:

a) Press CALL as many times as required until OUTPUT HIGH is indicated. Now

use the arrows to make the meter read 10 ppm. Press ENTER. The display

will flash until ENTER is pressed again to confirm entry.

b) Press CALL once to indicate OUTPUT LOW. Now use the arrow buttons to

make the meter read 5 ppm. Press ENTER twice as above.

c) The analog output will now be at 4 mA when the D.O. of the solution is 5 ppm

and will increase to 20 mA when the D.O. of the solution is 10 ppm.

d) Press RUN to place the instrument on line or press CALL for another menu

selection.

e) To invert the output (i.e. decreasing output for increasing process value) simply

adjust for 4 mA on OUTPUT HIGH and for 20 mA on OUTPUT LOW.

NOTE: A range expand of less than 10% of full scale is an invalid entry which will

be indicated by the LED flashing when you return to RUN. To correct,

return to the menu and correct the output settings.

5.5 Test

5.5.1 To test your setup press CALL the number of times required to indicate TEST. Now

by using the arrow buttons you can “sweep” through the digital display.

5.5.2 With the instrument in TEST you can check the analog output at any desired

reading with a meter connected to the appropriate output terminals.

5.5.3 Another use of this feature is to check the stability of the system. When in TEST,

use the arrow buttons to select any value, say 10 ppm. Now return online by

pressing RUN. Return to the meter some hours or days later. Press CALL to

indicate TEST. If the instrument is still in calibration and if no one has interfered the

meter should read 10 ppm.

Page 14

Page 18

5.6 Temperature

5.6.1 The temperature of the process can be read at any time by entering the menu and

calling for TEMPERATURE. Either °C or °F will be indicated depending on the

position of DIP switch No. 1. Bank S1. See Section 4.8.

5.6.2 The 0-5 Vdc and 0-1 mA analog outputs can be dedicated to follow the process

temperature by simply placing DIP switch No. 8 in the off position. The temperature

span of the output is set to the utility menu. See Section 4.8 and 7.4.

5.7 Status

5.7.1 The DOCN600 continuously checks the integrity of all stored data and monitors the

condition of the measuring system. If a fault is detected, the FAIL LED above the

display will turn red. The STATUS in the operation menu will provide a numerical

code, giving a possible cause and a suggested remedy.

5.7.2 The following table shows the display codes, causes and remedies:

Code

Possible Cause Suggested Remedy

0 Normal Condition No action required

1 Reserved

2 Temperature Sensor off Scale Verify process. Check for open or short

connections.

3 D.O. reading off Scale Verify process. Check for open or short

connections.

4* Memory Loss Call your OMEGA Rep. Or OMEGA

directly

5 Reserved

6 Sensor Fault Check probe membrane for perforation

7 Factory Setting in force, as a Perform procedure according to Section 9.2

result of the ESCAPE procedure

NOTE: Code 4 could be a serious failure so the alarm relay will energize in addition to the red

illumination of the FAIL LED, if DIP switch 5 Bank S1 is OFF.

5.8 Relay A Setpoint

5.8.1 As shipped from the factory, Relay A is configured to control decreasing D.O.

However, you may change the direction of control by changing the position of DIP

switch 4 Bank S1. Please refer to Section 4.8.

Page 15

Page 19

5.8.2 The relay setpoint may be at any place on the scale. To establish the setpoint

proceed as follows:

a) Press CALL to enter the MENU. If the PASSWORD function is enabled, enter

the password then press CALL to illuminate the “%sat/ppm” indicator. If the

PASSWORD function is not enabled, “%sat/ppm” will illuminate at the first press

of CALL.

b) Use the down arrow button to illuminate the PPM LED located to the right side

of the display.

c) Press CALL the required number of times until RELAY A SETPOINT is

indicated. Now use the arrows to make the display read the desired value.

Press ENTER. The display will flash until ENTER is pressed again to confirm

entry. A LED above the display indicates when Relay A is activated.

d) Press RUN to place the instrument on line or press CALL for another menu

selection.

5.9 Relay A Deadband

5.9.1 If you have configured the instrument with the DIP switch on the back of the panel

for falling D.O. you will wish to have the deadband (sometimes called “hysteresis”)

at a higher value than the setpoint. If you have established a setpoint of 3 ppm you

may wish the deadband to be between 6 ppm and 3 ppm. Proceed as follows:

a) Enter the menu and press CALL the required number of times to indicate

RELAY A DEADBAND. Use the arrow buttons to make the display read the

desired value (in this example, 6). Press ENTER. The display will flash until

ENTER is pressed again to confirm the entry.

b) In this example, after the instrument has been returned to RUN, the relay will be

energized when the D.O. falls to 3 ppm and will remain energized until the

reading rises above 6 ppm.

c) When Relay A is activated a LED above the display will be illuminated.

d) Press RUN to place the instrument on line or press CALL for another menu

selection.

5.10 Relay B Setpoint

5.10.1 Relay B Setpoint is configured in the same way as Relay A Setpoint. See Section

5.8. A LED above the display indicates when Relay B is activated.

5.11 Relay B Deadband

5.11.1 Relay B Deadband is configured in the same way as Relay A Deadband. See

Section 5.9.

NOTE: A deadband setting on the wrong side of the setpoint in an invalid entry

which will be indicated by the LED flashing when you return to RUN. To

correct return to the menu and change the deadband setting or, if the

direction of control is the problem, change the position of the relevant DIP

switch. See Sections 4.8 and 5.9.

Page 16

Page 20

5.12 Alarm High

5.12.1 The instrument is fitted with a relay, which is set to activate on both high and low

alarm conditions. The deadband is factory set. To set the ALARM HIGH proceed

as follows.

a) Enter the menu and press CALL until ALARM HIGH is indicated. With the

arrow buttons make the display read the desired alarm value. Press ENTER.

The display will flash until ENTER is pressed again to confirm the entry.

b) Press RUN to place the instrument on line, or press CALL, for another menu

selection.

5.13 Alarm Low

5.13.1 a) Press CALL until ALARM LOW is indicated. With the arrows make the meter

read the desired value. Press ENTER. The display will flash until ENTER is

pressed a second time to confirm entry.

b) Press RUN to place the instrument on line, or press CALL, for another menu

selection.

NOTE: A low alarm point higher than the high alarm point is an invalid entry, which

is indicated by the LED flashing when you return to RUN. To correct, return

to the menu and reset the alarm points.

6.0 OPERATING HINTS

6.1 Cell Care

6.1.1 If the sensor membrane is exposed to the atmosphere for more than 24 hours, the

electrolyte inside the membrane can dry out. If this occurs, the cartridge will need

to be replaced. To avoid membrane dry-out, place the sensor in a container of

clean drinking water until it can be reinstalled into the aeration basin.

6.1.2 Sensor cartridges can be stored for up to 5 years if the seal on its storage container

is not broken and the temperature is between 70°F and 80°F with 50 to 80%

humidity. Do not store sensor cartridges at temperatures below freezing point

(32°F). The electrolyte solution will crystallize at 25-30°F.

6.1.3 Cleaning the sensor membrane before each calibration is recommended. Use soft

cloth and mild soap solution to remove material from the membrane. When

cleaning, take care to avoid puncturing the sensor membrane. Should this occur,

the complete sensor cartridge must be replaced.

6.2 Calibration

6.2.1 Depending on the application, system calibration should be performed periodically

to maintain measurement accuracy. Frequent checks are suggested until the

operational history indicates the optimum period between checks.

Page 17

Page 21

6.3 Reset

6.3.1 The instrument can be reset without losing calibration or any of the stored values by

pressing and releasing the S9 reset button (located at the bottom of the board near

the center) This action is equivalent to turning the power off and on.

6.4 Output Hold

6.4.1 It may be useful during some system maintenance procedures to place the relay

and analog outputs on hold. To accomplish this simply press CALL. To return to

on line operation press RUN.

NOTE: To safeguard against the operator forgetting to press RUN the instrument

will automatically go back on line ten minutes after the last button was

pressed provided this feature has been enabled by placing DIP switch

No.7, Bank S1, in the ON position.

7.0 UTILITY MENU

7.1 Utility Menu Functions

7.1.1 The Utility Menu enables authorized personnel to perform the following:

• Adjust the temperature output range.

• Adjust the offset and span of the 0-1 mA/ 0-5 Vdc output

• Adjust the offset and span of the 4-20 mA output

• Perform the altitude compensation

7.2 Access to Utility Menu

7.2.1 The Utility Menu is protected by password. To access the Utility Menu press and

hold both RUN and ENTER for five seconds until the PASSWORD LED illuminates.

The RUN LED will flash to warn that Utility Menu is in use. Now with the arrow keys

make the display read the password, "7". Press ENTER.

7.2.2 The Utility Menu is entirely separate from the Operation Menu but uses the same

LED display. Press CALL to step through the menu items.

Below is the cross-reference between menu items:

Display LED

Output High Temperature Output 100% (5 Vdc)

Output Low Temperature Output 0% (0 Vdc)

%Sat/ppm 0-1 mA / 0-5 Vdc Output Adjust Low

Test 0-1 mA / 0-5 Vdc Output Adjust High

Calibration 4-20 mA Output Adjust Low

Temperature 4-20 mA Output Adjust High

Status Altitude Compensation

Meaning in Utility Menu

Page 18

Page 22

7.3 Temperature Output

7.3.1 The 0-5 Vdc and 0-1 mA outputs may be programmed to track the temperature of

the process. The factory outputs have a linear range corresponding to 0°C to 40°C,

(or 32°F to 104°F.) Suppose you wish the output to span 10°C to 45°C. Proceed

as follows:

a) Enter the Utility Menu as described in 7.2.1.

b) Press CALL to indicate OUTPUT HIGH, which is the “Temperature output,

100% point” in the Utility Menu. (See table in 7.2.2). Now use the arrow button

to show 45.0 on the display. Press ENTER. The display will flash until ENTER

is pressed again to confirm entry.

c) Press CALL to indicate OUTPUT LOW, which is the “Temperature output, 0%,

point” in the Utility Menu. (See table in 7.2.2). Now use the arrow buttons to

show 10.0 on the display. Press ENTER twice as above.

d) Press RUN to return to on line or press CALL to proceed to another item in the

Utility Menu.

7.4 Adjust 0-1 mA / 0-5 Vdc Output

7.4.1 It may be desirable to fine tune the 0-1 mA / 0-5 Vdc output to take into account the

characteristics of your particular loop. The following method involves a high and

low calibration and requires the use of a digital multi-meter (DVM). Proceed as

follows ignoring the instrument display:

a) Turn off the power to the instrument. Connect your DVM to the 0-5 Vdc output

terminals on the power supply board.

b) Turn on the power. Enter the Utility Menu as described in 7.2.1.

c) Press CALL to indicate “%sat/ppm”, which is "0-1 mA/ 0-5 Vdc output adjust,

low" in the Utility Menu (See table in 7.2.2). Use the arrow keys to make your

DVM read 1.25V. Press ENTER twice to confirm.

d) Press CALL to indicate TEST, which is "0-1 mA / 0-5 Vdc Output adjust, high" in

the Utility Menu (See table in 7.2.2.) Use the arrow keys to make your DVM

read 3.75V. Press ENTER twice to confirm.

e) Press RUN to return to on line or press CALL to proceed to another item in the

Utility Menu.

7.5 Adjust 4-20 mA Output

7.5.1 It may be desirable to fine tune the 4-20 mA isolated output to take into account the

characteristics of your particular loop. Before deciding that the adjustment is

necessary, be aware of the "Output High" and "Output Low" settings you may have

programmed as described in Section 5.4. The following method involves a high and

low calibration and requires the use of a Digital Multimeter (DVM). Proceed as

follows ignoring the instrument display.

a) Turn off the power to the instrument. Connect your DVM to the 4-20 mA output

terminals on the power supply board.

Page 19

Page 23

b) Turn on the power. Enter the Utility Menu as described in 7.2.1.

c) Press CALL to indicate CALIBRATION, which is "4-20 mA Output adjust, low" in

the Utility Menu (See table in 7.2.2.) Now use the arrow keys to make your

DVM read 8 mA. Press ENTER twice to confirm.

d) Press CALL to indicate TEMPERATURE, which is "4-20 mA Output adjust,

high" in the Utility Menu (See table in 7.2.2). Now use the arrow keys to make

your DVM read 16 mA. Press ENTER twice to confirm.

e) Press RUN to return to on line or press CALL to proceed to another item in the

Utility Menu.

7.6 Altitude Compensation

7.6.1 The instrument can be compensated for the altitude at which it is located by the

following procedure:

a) Go to the UTILITY MENU as described in 7.2.1.

b) Press CALL to indicate “STATUS” which is “ALTITUDE COMPENSATION” in

the Utility Menu.

c) Adjust the display to your altitude in thousands of feet. For example, 0.34 on

display corresponds to an altitude of 340 feet. Press ENTER. The display will

flash until ENTER is pressed again to confirm entry.

d) The supported altitude range is from –1,000 to 30,000 ft. (-305 to 9,144 m) or –

1.00 to 30.00 on the display. As shipped from the factory the altitude is set to

zero. i.e. sea level.

e) Press RUN to go on line, or CALL to proceed to another Utility Menu item.

8.0 DIAGNOSTICS

8.1 Description

8.1.1 The DOCN600 has diagnostic features which alerts the operator to invalid entries

and memory loss. Invalid entries are indicated by the flashing of the appropriate

menu LED. The flashing will commence after RUN is pressed and will continue

until the errors are corrected. Memory loss is indicated by the flashing of TEST and

by the alarm relay if enabled by DIP Switch No. 5 of Bank S1. See Section 4.8.3.

8.2 Invalid Output

8.2.1 Invalid output will be indicated if the expanded range is less than 10% of full scale.

To correct, refer to Section 5.4.

Page 20

Page 24

9.0 TROUBLESHOOTING AND SERVICE

9.1 Isolate the cause

9.1.1 When a measurement problem occurs, the first step is to try to isolate the cause. If

the DOCN600 is powered, go through the menu and check your settings. A

convenient way to do this is to call TEST. See Section 5.5.

9.1.2 If your DOCN600 appears dead or intermittent, check the breaker, make sure that

the instrument is set up for the available line voltage and make sure the line voltage

is actually available at the terminals. Now measure that sufficient voltage is

available at all times; it should be 98 Vac to 132 Vac or 187 Vac to 243 Vac

respectively. Shut line power off, making sure it is off. CAUTION: Power to the

relays may be supplied from a separate source, shut it off too. Check and if

necessary replace the internal 0.25A fuse. Push the connector of the ribbon cable

firmly into its socket. If these steps do not solve the problem it may be necessary to

replace the power supply board. See Section 9.3.1 below.

9.1.3 If the process value seems wrong, clean the sensor as described in Section 6.1.3.

Inspect the sensor, wire, terminal block connections and interconnections.

Calibrate and resume operation.

9.1.4 To find out whether the problem is in the sensor, or in the analyzer, use the selftesting features. Leave the instrument in RUN mode and proceed as follows:

a) Move the slide switches S40 and S41 on the back of the swing-out panel from

position "ON LINE" to position "TEST."

b) Press CALL to enter the menu and go to “%sat/ppm.”

c) Set the D.O. simulation DIP switch Bank S42 switch No. 1, On, Switches No. 2,

3, and 4, Off. The display should show 4 ppm ±5%.

d) Now proceed to turn each of the other S42 switches On with the remaining

switches Off.

The display should read within 5% of 10 ppm with switch 2 On, 16 ppm with

switch 3 On, and 20 ppm with switch 4 On.

If this is the case the analyzer is in order and the problem is with the probe.

e) Return S40 and S41 to “On line” and ensure that all S42 switches are Off.

9.1.5 a) To check the temperature channel move the slide switches S40 and S41 from

position “On line” to position “TEST”.

f) Set the DIP switch 1 Bank S1 On.

g) Go to the TEMPERATURE menu item.

d) Set the temperature simulation DIP switch Bank S43 switch No. 1 On, switches

No. 2 and 3 Off. The display should show 10 degrees Celsius ±5%.

Page 21

Page 25

e) Now proceed to turn each of the other S43 switches On with the remaining

switches Off.

The display should read within 5% of 25°C with Switch 2 On and 35°C with

Switch 3 On.

If this is the case the analyzer is in order and the problem is in the sensor.

Otherwise the problem is in the analyzer.

f) Return S40 and S41 to “On line” and ensure that all S43 switches are Off.

9.2 Escape

9.2.1 If the instrument appears to be "DEAD", for example not responding to the buttons,

or not performing on line measurement and control, always try the reset feature

first, as described in 6.3.1.

9.2.2 a) The "ESCAPE" procedure is to be used normally at the factory only, when the

unit is powered with a new MCU. As a result, the internal non-volatile memory

(EEPROM) is "FORMATTED" and the factory values are loaded into it.

b) The "ESCAPE" procedure is to be used if a unit is serviced for a new MCU

insertion, in case where the MCU was not calibrated at OMEGA, or in case of a

memory loss problem, when so advised by OMEGA service support.

9.2.3 Before performing the "ESCAPE" procedure it is important to know that this

procedure provides the option to erase all programmed values and replace them

with the factory set default values. This is also true for the control setpoints and

deadbands, then alarm settings and the analog outputs scaling. Also, the

temperature and the D.O. calibration points will be set to their initial values. This

means, that the temperature and the D.O. calibration must be performed after an

“ESCAPE” procedure. After that, all the control, alarm and scaling parameters

mentioned above must be set to the user values.

9.2.4 To perform the ""ESCAPE"" proceed as follows.

a) Turn off the power.

b) Press and hold the RUN button for about 3 seconds, while turning on the

power.

The FAIL LED will turn on and STATUS LED will become red and status code 7

will be obtained to show that the ESCAPE procedure was just performed.

9.2.5 After the "ESCAPE" procedure it is necessary to do the following:

a) Tune the analog outputs and the temperature output span to suit your particular

application and loop. See Sections 7.3, 7.4, and 7.5.

b) Calibrate the system, as described in Section 5.3.

c) Set up the user values for:

• Output High and Low - See Section 5.4.

• Control Relay - See Sections 5.8 and 5.9.

• Alarm Relay - See Sections 5.12 and 5.13.

Page 22

Page 26

d) After all the above operations are performed the FAIL LED will turn off and

STATUS LED will turn green and Status “0” should be obtained.

e) The unit may be tested now, using the TEST menu item (See Section

5.5), or the built-in self-testing feature, (See Section 9.1.4)

f) Bring the unit on line for measurement and control.

9.3 Printed Circuit Board Replacement

9.3.1 a) To replace printed circuit boards or relays shut off all power to the DOCN600,

including any independent power to the relay contacts. Make a record of the

external wiring, then disconnect the wires. Unplug the ribbon cable connector.

b) The power supply circuit board is fastened to the back of the enclosure by four

screws, remove the screws and the board is free. Reverse the procedure to

mount a replacement board.

c) The microprocessor circuit board is located on the swing-out assembly behind

the door. Swing the assembly out, lift it up to unseat the lower hinge pin (the

upper hinge pin is spring loaded.) The assembly is now free. The circuit board

is fastened to the front panel by three screws. Remove the screws to release

the circuit board.

9.4 Sensor Fault

9.4.1 If the membrane of the sensor cartridge is pierced, the alarm relay contacts will

close and the FAIL LED and STATUS LED will be illuminated. However, it may be

difficult to see the leakage with the naked eye. A slight pressure on the membrane

with a finger will produce a drop of liquid. The cartridge must be replaced. See

Section 9.4.3.

9.4.2 With operating time silver oxide will build up on the anode (silver wire). When the

anode becomes brown as a result of the deposit, it is time to replace the sensor

cartridge.

9.4.3 To replace the sensor cartridge, unscrew the retaining nut, remove and discard the

spent cartridge and replace with a new cartridge. Part No. DOE-601-SC.

9.5 Relay Replacement

9.5.1 The relays are plugged into the power supply board just above the terminals. Be

sure all the power including independent power to the relay is off. Unplug the relay

in question and replace with a new relay. Contact OMEGA Engineering for

assistance.

Page 23

Page 27

STATEMENTS OF CONFORMITY FROM THE MANUFACTURER

U.S.A.

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instructions manual, may

cause interference to radio communications. It has

been tested and found to comply with the limits for a

Class A computing device pursuant to Subpart J of Part

15 of FCC Rules, which are designed to provide

reasonable protection against such interference when

operated in a commercial environment.

Canada

This digital apparatus does not exceed the Class A

limits for radio noise emissions from digital apparatus

set out in the radio interference regulations of the

Canadian Department of Communications.

Le pres

radio

appareils num

R

le minist

ént appareil numérique n’émet pas de bruits

électriques dépassant les limites applicables aux

ériques de la classe A prescrites dans le

églement sur le brouillage radioélectrique édicté par

ére des Communications du Canada.

Page 24

Page 28

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of

grace period to the normal

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,

including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the

company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF

TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

one (1) year product warranty to cover handling and shipping time. This

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED RETURN

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR

WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product

was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific problems

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords

our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the

prior written consent of OMEGA ENGINEERING, INC.

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

information available BEFORE contacting OMEGA:

1. Purchase Order number to cover the COST

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult OMEGA

Page 29

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

MU

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

Recorders, Printers & Plotters

HEATERS

MU

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

MU

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial Water & Wastewater Treatment

MU

pH, Conductivity & Dissolved Oxygen Instruments

M4177/0805

Loading...

Loading...