Page 1

omega.com

®

®

User’s Guide

http://www.omega.com

e-mail: info@omega.com

Universal Temperature & Process

CN3440 SERIES

Controllers

Installation Guide

Page 2

WARRANTY/ DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of 37 months from date of purchase. OMEGA Warranty adds an additional one (1) month

grace period to the normal three (3) year product warranty to cover handling and shipping time.

This ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s

Customer Service Department will issue an Authorized Return (AR) number immediately upon phone

or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired

or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of

the purchaser, including but not limited to mishandling, improper interfacing, operation outside of

design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows

evidence of having been tampered with or shows evidence of having been damaged as a result of

excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication;

misuse or other operating conditions outside of OMEGA’s control. Components which wear are not

warranted, including but not limited tocontact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes

liability for any damages that result from the use of its products in accordance with information

provided by OMEGA, either verbal or written. OMEGA warrants only that the parts

manufactured by it will be as specified and free of defects. OMEGA MAKES NO OTHER

WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED,

EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the

total liability of OMEGA with respect to this order, whether based on contract, warranty,

negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of

the component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a

“Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in

medical applications or used on humans. Should any Product(s) be used in or with any nuclear

installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes

no responsibility as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally,

purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever

arising out of the use of the Product(s) in such a manner.

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department.

RETURN REQUESTS / INQUIRIES

BEFORE RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBTAIN AN AUTHORIZED

RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the

return package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to

prevent breakage in transit.

FOR WARRANTY

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which

the product was PURCHASED,

2. Model and serial number of the product under

warranty, and

3. Repair instructions and/or specific

problems relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible.

This affords our customers the latest in technology and engineering.

OMEGA is a registered trademark of OMEGA ENGINEERING, INC.

© Copyright 1998 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied,

photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in

whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.

RETURNS, please have the

FOR NON-WARRANTY REPAIRS,

OMEGA for current repair charges. Have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number to cover the COST of

the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

consult

Page 3

CONTENTS

1 INTRODUCTION .................................. 2

2 PREPARATION .................................... 3

2.1 Checking the Code Number ......... 3

3 MECHANICAL INSTALLATION .......... 4

3.1 Siting .......................................... 4

3.2 Mounting ...................................... 5

4 ELECTRICAL INSTALLATION ............ 6

4.1 Access to Terminals ..................... 6

4.2 Setting the Input Selector Links ... 6

4.3 Setting the Isolated Output Link ... 6

4.4 Cable Glands and

Conduit Fixings ............................ 8

4.4.1 Cable Glands

(IEC – 20mm) ................... 8

4.4.2 Conduit Adaptors

(N. American – 0.5in) ........ 8

4.4.3 Cable Glands

4.5 Connections Summary ............... 10

4.6 Input Connections ...................... 12

4.7 Output Connections ................... 14

4.8 Relay Connections ..................... 14

4.9 Motorized Valve Connections .... 14

4.10 Logic Input Connections ............ 15

4.11 Power Supply Selection and

(N. American – 0.5in) ........ 9

4.6.1 Thermocouple

(THC) Inputs ................... 12

4.6.2 3-lead Resistance

Thermometer (RTD)

Inputs .............................. 12

4.6.3 2-lead Resistance

Thermometer (RTD)

Inputs .............................. 12

4.6.4 Links for Unused Inputs .. 12

AC Connections ......................... 16

5 INSTALLATION RECORD ................. 17

1

Page 4

1 INTRODUCTION

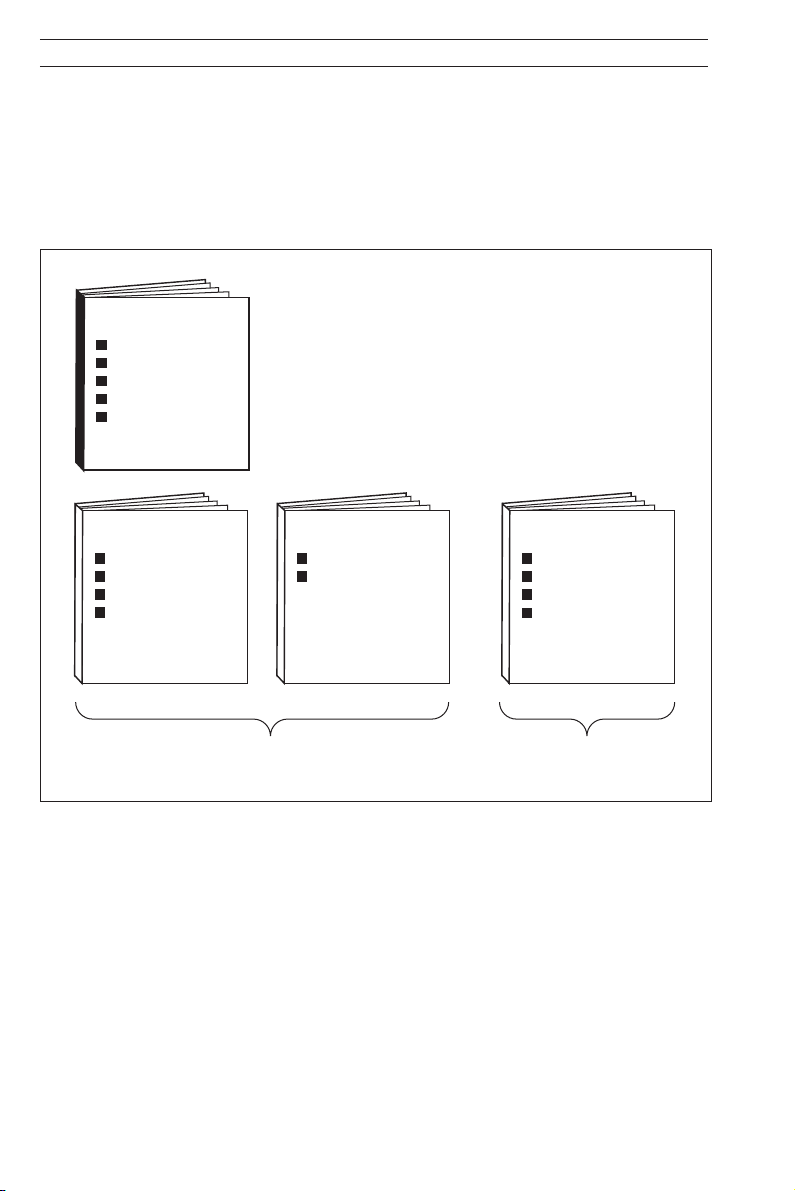

The instrument documentation is shown in Fig. 1.1. The Standard Manuals, including the

specification sheet, are supplied with all instruments. The Modbus Supplement is supplied with

instruments configured for Modbus Serial Communication.

This manual includes an Installation Record which should be completed as a log of the electrical

installation. The record is useful when carrying out initial instrument programming and can be

retained for future reference.

INSTALLATION

Product Identification

Siting

Mounting

Electrical Connections

Installation Record

OPERATION

Setting Up

Displays & Controls

Operating Level

Simple Fault-Finding

PROGRAMMING

Standard Manuals

Fig. 1.1 Documentation

Basic Config. Level

Advanced Config. Level

MODBUS (RTU).

Serial Adaptors

Serial Connections

Programming Page

MODBUS Registers

MODBUS Supplement

2

Page 5

2 PREPARATION

2.1 Checking the Code Number – Fig. 2.1

XXXX / X X X X X X X X

Fig. 2.1 Location of Code Number Label

Code Number Label

3

Page 6

3 MECHANICAL INSTALLATION

EC Directive 89/336/EEC

In order to meet the requirements of the

EC Directive 89/336/EEC for EMC

regulations, this product must not be used

in a non-industrial environment.

3.1 Siting – Figs. 3.1 and 3.2

Minimum

A – Close to Sensor

B – At Eye-level Location

Sensor

55°C

Max.

0°C

Min.

A – Within Temperature Limits

0 to 90% RH

B – Within Humidity Limits

IP66/

NEMA4X

C – Within Protection Rating Limits

C – Avoid Vibration

Fig. 3.1 General Requirements

4

+

Caution. Select a location

away from strong electrical and

magnetic fields. If these cannot be

avoided, particularly in applications

where ‘walkie talkies’ are used,

connect using screened cables

within earthed metal conduit.

D – Use Screened Cables

Fig. 3.2 Environmental Requirements

Page 7

3 MECHANICAL INSTALLATION…

3.2 Mounting – Figs. 3.3 and 3.4

The instrument is designed for wall-/pipe-mounting – see Fig. 3.4. Overall dimensions are

shown in Fig. 3.3.

Dimensions in inches (mm)

6.3 (160)

9.84

(250)

2.72 (69)

Fixing Holes

(x3) 0.25 (6.5) Dia

Fixing Centres

8.43

(214)

7.9 (200)

Drill suitable

2

Allowance for

Cable Bends

Fig. 3.3 Overall Dimensions

holes

Position plates over ‘U’ bolts

1.65

2.68 (68)

(42)

Position ‘U’ bolts on pipe

3

/8 (61) O.D. Vertical or

2

Horizontal Post

1

2

9.13

(232)

Fixing Centres

3

Fix instrument to

wall using

suitable fixing

Pipe Mounting Kit

1

Mark fixing

centres

(see Fig. 3.3)

4

Fig. 3.4 Wall-/Pipe-mounting Details

Secure plates

3

Secure transmitter to mounting plate

5

Page 8

4 ELECTRICAL INSTALLATION

5

Warning. Before making any

connections, ensure that the power

supply, any high voltage-operated control

circuits and high common mode voltages

are switched off.

Note.

• Always route signal leads and power

cables separately, preferably in

earthed metal conduit.

• It is strongly recommended that

screened cable is used for signal

inputs and relay connections. Connect

the screen to the ground stud.

Information. Use cable appropriate

for the load currents. The terminals accept

cables up 12AWG (2.5mm2).

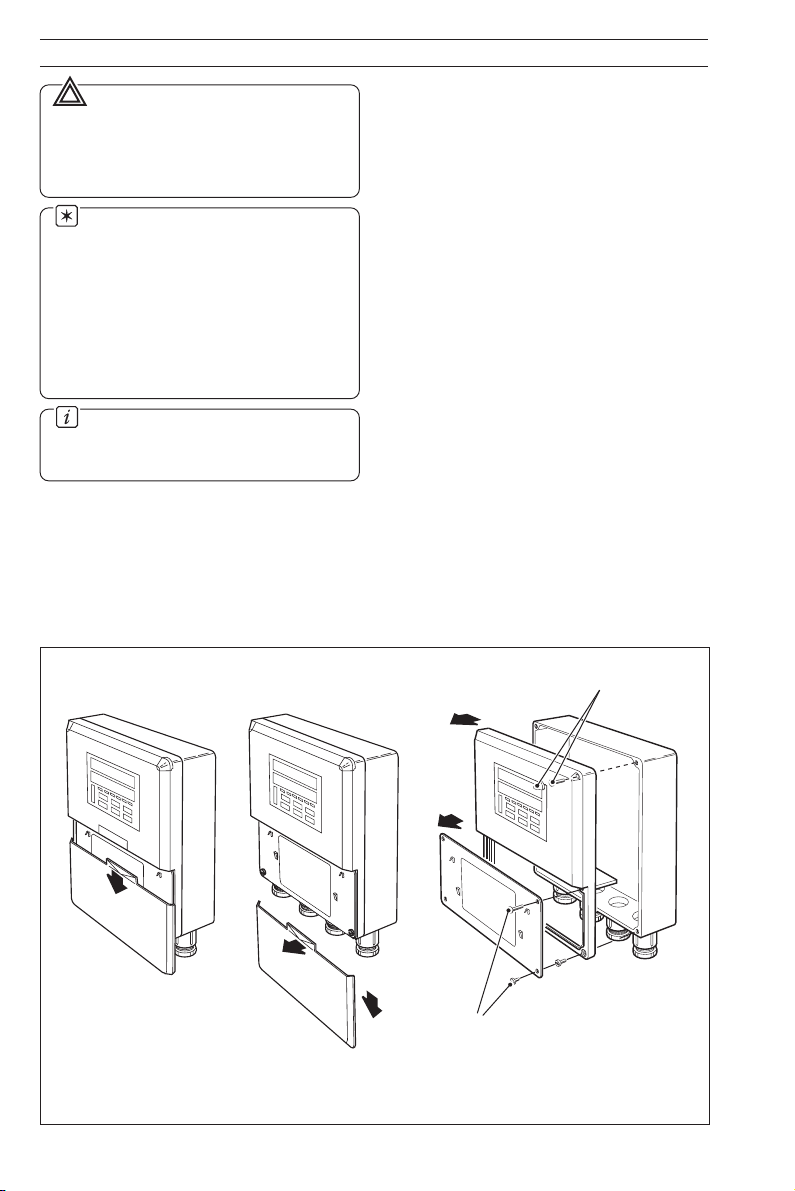

4.1 Access to Terminals – Fig. 4.1

For access to terminals – refer to Fig. 4.1,

steps 1 to 3.

4.2 Setting the Input

Selector Links – Fig. 4.2A

Plug-in links on the microprocessor p.c.b. are

positioned according to the type of Process

Variable Input, Remote Set Point Input and

Valve Position Feedback Inputs used.

Remove the instrument front panel – see

Fig. 4.1, steps 1 to 6.

Referring to Fig. 4.2A, set the link positions

for the input type required.

4.3 Setting the Isolated

Output Link – Fig. 4.2B

A plug-in link (PL7) on the microprocessor

p.c.b. is positioned according to the isolated

output required, either a current

proportioning control output (programmable

in range 0 to 20mA) or a 12V logic output

(minimum load 400Ω). Referring to Fig. 4.2B

– steps 1 and 2, set the link for the output

type required.

To use a 12V logic output, the control type

must be set to Time Proportioning Control –

see Fig. 3.1

of the Programming Guide

.

Remove cap

Remove front

6

panel

and screw

1

slide

down

2

Pull out

slightly…

2

…and

slide off

Fig. 4.1 Access to Terminals and Processor Board

3

Slacken captive screws and

remove protection cover

6

4

Remove front

panel screws

Page 9

1

4 ELECTRICAL INSTALLATION…

Identify Link PL7

Set links for output type required

2

PL7

PL7

1

1

Logic Output or

B – Isolated Output Types

Analog Output

mA

R, mV,

THC & RTD

2-wire

Transmitter

Input

PL1

Process

Variable

Input

12

PL1

1

12

PL1

1

12

V

PL1

1

12

PL1

1

Fig. 4.2 Setting the Selector Links

7

6

7

6

7

6

7

6

A – Input Types

Remote

Set Point

Input

8

PL2

1

8

PL2

1

8

PL2

1

PL2

5

4

5

4

5

4

PL3

Position

Feedback

Input

8

PL3

1

8

PL3

1

8

PL3

1

5

4

5

4

5

4

7

Page 10

…4 ELECTRICAL INSTALLATION

4.4 Cable Glands

and Conduit Fixings

4.4.1 Cable Glands

(IEC – 20mm) – Fig. 4.3

'O'-Ring

4.4.2 Conduit Adaptors

(N. American – 0.5in) – Fig. 4.4

Warning.

• Rigid conduit must NOT be fitted to the

controller.

• Controller adaptors must incorporate

a face seal.

• Torque settings for the hubs and outer

nuts on the specified adaptors is 20ft.

lbs minimum, 25ft. lbs. maximum.

Information.

• Suitable adaptors for controller

(mandatory for FM installations):

APPLETON

ST-50 PLUS STG-50 or STB-50

PLUS STG-50.

Reusable ONLY with replacement

ferrule STF-50.

O.Z. GEDNEY

4Q-50, 4Q50T or 4Q-50TG.

Alternative

Face Seal

Fig. 4.3 Cable Gland

(Supplied as standard)

8

Face

Seal

Seal

(Present

in O.Z.

Gedney

Fittings)

Outer Nut

Fig. 4.4 Conduit Adaptors

Hub

Ferrule

Page 11

4.4.3 Cable Glands

(N. American – 0.5in) – Fig. 4.5

Warning.

• Controller glands must be fitted with a

face seal.

• Torque settings (hubs only) – 20ft. lbs

minimum, 25ft. lbs. maximum.

• Outer nuts – hand tight plus a half turn

only.

Information.

• Suitable Cable Glands: (mandatory for

FM installations):

O.Z. GEDNEY

SR-50-375 or SR-504

APPLETON

CG 3150 or CG-3150S (and STG50 sealing ring).

THOMAS & BETTS

2521.

• When fitting cable glands to the

controller, start with an outer gland

and also temporarily fit a gland at the

opposite end, to aid location of the

transmitter gland plate. Fit and tighten

glands consecutively from initial

gland.

4 ELECTRICAL INSTALLATION…

Alternative

Face Seal

Face

Seal

Fittings

vary

slightly

for

different

makes

Outer Nut

Illustration

typical for

O.Z.Gedney

Hub

Fig. 4.5 Cable Glands

9

Page 12

…4 ELECTRICAL INSTALLATION

4.5 Connections Summary – Fig. 4.6

Information.

Input impedances:

Low voltage(mV) >10MΩ

Voltage >10MΩ

Current 10Ω.

Power

Supply

12

Relay 1

4

56789

3

18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

MODBUS (RTU)

(if option fitted)

Retransmission Output

Fig. 4.6 Terminal Block Identification

Relay 3

Relay 2

Process Variable Input

Remote Set Point Input

10 11 12 13 14 15

Control Output

Position Feedback Input

16 17

Logic Input

10

Page 13

Terminal Number

AC Supply

1

L

2

24V, 115V or 230V a.c.

N

4 ELECTRICAL INSTALLATION…

– see Fig. 4.22

3 N/O

4 C

5 N/C

6 N/O

7 C

8 N/C

9 N/O

10 C

11 N/C

3rd lead/2-wire TX

12

Input 1+

13

Input 1–

14

3rd lead

15

Input 2+

16

Input 2–

17

18 Tx+

19 Tx–

20 Common

21 Rx+

22 Rx–

23 +

24 –

25 +

26 –

Relay 1 Output Motorized Valve Control Relay (open)

– see Fig. 4.17 – see Fig. 4.19A

Relay 2 Output Motorized Valve Control Relay (close)

– see Fig. 4.17 – see Fig. 4.19A

Relay 3 Output

– see Fig. 4.17

Alarm Relays

Process Variable Input or 2-wire Tx Power Supply

– see Figs. 4.7 to 4.9, – see Fig. 4.13

4.12 and 4.14

Remote Set Point Input – see Figs. 4.7 to 4.12 and 4.14

RS 485 Modbus Serial Communications Option 1 only – see

Modbus (RTU) Communications Supplement

Retransmission Output/Cool Output – see Fig. 4.15

Current Proportioning Control Output/Heat Output Fig. 4.15

or 12V Logic Control Output Fig. 4.16

27 3rd lead

28 Input 3+

29 Input 3–

30

31

32

Logic Input 1 – see Figs. 4.20 and 4.21

Logic Input 2 – see Figs. 4.20 and 4.21

Common

Position Feedback Input – see Figs. 4.18 , 4.19A and 4.19B

Table 4.1 Electrical Connections

11

Page 14

…4 ELECTRICAL INSTALLATION

4.6 Input Connections

Make connections to each input, as shown in Figs 4.4 to 4.14, first removing any factory-fitted

wire links not required.

4.6.1 Thermocouple (THC) Inputs – Fig. 4.7

Note. Automatic Cold Junction Compensation (ACJC) is active when an input is

programmed for use with thermocouples. Use the correct compensating cable between the

THC and the terminals – see Table 4.2.

If an external fixed cold junction is used, the connections to the instrument must be made

with copper cable. The input must be programmed for mV input signals and the appropriate

THC linearizer selected – see Sections 4.5 and 4.6 of the

Programming Guide.

foepyT

elpuocomrehT

)K(lA-iN/rC-iN

)N(lisiN/lisirciN

)SdnaR(hR-tP/tP

)T(iN-uC/uC

)J(noC/eF

)01734NID(noC/eF ——

3481SB

nworB+

eulB–

deResaC

egnarO+

eulB–

egnarOesaC

etihW+

eulB–

neerGesaC

etihW+

eulB–

eulBesaC

wolleY+

eulB–

kcalBesaC

Table 4.2 Thermocouple Compensating Cables

ISNA

1.69CM

wolleY+

deR–

wolleYesaC

egnarO+

deR–

egnarOesaC

kcalB+

deR–

neerGesaC

eulB+

deR–

eulBesaC

etihW+

deR–

kcalBesaC

elbaCgnitasnepmoC

NID

41734

deR+

neerG–

neerGesaC

—

deR+

etihW–

etihWesaC

deR+

nworB–

nworBesaC

deR+

eulB–

eulBesaC

01734NID

der/eulB+

eulB–

eulBesaC

7394SB

03.oNtraP

neerG+

etihW–

*neerGesaC

kniP+

etihW–

*kniPesaC

egnarO+

etihW–

*egnarOesaC

nworB+

etihW–

*nworBesaC

kcalB+

etihW–

*kcalBesaC

—

4.6.2 3-lead Resistance Thermometer (RTD) Inputs – Fig. 4.8

The three leads must have equal resistance, not exceeding 50Ω each.

4.6.3 2-lead Resistance Thermometer (RTD) Inputs – Fig. 4.9

If long leads are necessary it is preferable to use a 3-lead RTD. If the RTD is to be used in a

hazardous area a 3-lead RTD must be used.

stiucricefasyllacisnirtnirofeulBesaC*

4.6.4 Links for Unused Inputs

To reduce susceptibility to electro-magnetic interference, ensure that the three terminals on

each unused input are shorted together with sleeved wire links.

12

Page 15

4 ELECTRICAL INSTALLATION…

Remote Set Point

Process Variable

Sleeved

Link

Fig. 4.7 Thermocouple Input Connections

Remote Set Point

Process Variable

Red Red

Fig. 4.8 3-lead Resistance

Thermometer Input Connections

Remote Set Point

Process Variable

Sleeved

Link

White

Fig. 4.9 2-lead Resistance

Thermometer Input Connections

Remote Set Point

%

White

%

^%&

£@

+

&^

£@

$

&^%

$£@

^

&

$

–

Red

%

^

Remote Set Point

Process Variable

Sleeved

Link

Fig. 4.12 Current Input Connections

@

£

+

Tx

Fig. 4.13 2-wire Transmitter

Power Supply Input Connections

Remote Set Point

Process Variable

Sleeved

Link

Fig. 4.14 Voltage Input Connections

Retransmission O/P

or 'Cool' Analogue O/P

in Heat/Cool

Current Proportioning

Control Output

&

@

£

$

+

–

$

–

%

^

&

@

£

$

–

+

232524

+

26

–

Fig. 4.10 3-lead Resistance

Remote Set Point Input Connections

%

^

Remote Set Point

Sleeved Link

Fig. 4.11 2-lead Resistance

Remote Set Point Input Connections

&

Fig. 4.15 Current Proportioning Control

and Retransmission Output Connections

12V Logic Output for ON/OFF

or Time-proportioning Control

Fig. 4.16 Logic Control Output Connections

25 26

+

–

13

Page 16

…4 ELECTRICAL INSTALLATION

0%

100%

Motorized Valve Drive

27 2928

Link

4.7 Output Connections

Make connections as shown in Figs 4.15 and

4.16.

4.8 Relay Connections – Fig. 4.17

For relay functions refer to the following

table.

1yaleR2yaleR3yaleR

lortnoCffO/nO

✓

)taeH(.porPemiT

✓

)looC(.porPemiT

—

evlaVdezirotoM nepOesolC

mralA

✓✓✓

Relay 3

Relay 2

Relay 1

Normally Open

Common

Normally Closed

Fig. 4.17 Relay Connections

——

——

✓

09

76

43

—

—

!

8

5

4.9 Motorized Valve

Connections – Figs. 4.18 and 4.19

5

3

4

100%

Valve

Positioner

Power

Supply

(L)

(N)

L

N

A – Standard Feedback Slidewire

Configuration

0%

Link

6

7

8

Motorized

Valve Drive

100%

28

27

0%

29

Sleeved Link

Fig. 4.18 Motorized Valve Feedback

Connections (using V, I or mV feedback)

+

Motorized Valve

Drive

14

2927 28

B – Alternative Feedback Slidewire

Configuration

Note. Link must be connected

–

at the motorized valve drive

terminals and not the Controller

terminals.

Fig. 4.19 Motorized Valve Connections

(using feedback slidewire)

Page 17

4 ELECTRICAL INSTALLATION…

4.10 Logic Input Connections – Figs. 4.20 and 4.21

Each logic input can be programmed to perform one of a number of functions – see Section

3.10 of the

Programming Guide

.

30

Logic Input 1

Logic Input 2

31

Common

32

5V

Logic switching

0V

3130

32

5V

Logic switching

0V

32

30

31

Auto/

Manual

Selection

Automatic

Manual

Automatic

Manual

Local/Remote

Set Point

Selection

Local

Remote

or Dual

Dual Set Point

Selection

Local

Remote (Dual)

Fixed Dual

Set Point 2

Fixed Dual

Set Point 1

Fixed Dual Set Point 2

Note. Only one function may be

performed by each input at any one time.

Fig. 4.20 Standard Logic Input Functions

Hold

(Soak)

Start

Profile

* Profile

Reset

Alarm

Acknowledgement

* Alarm

Acknowledge

* Leading 'edge-triggered'

(minimum duration 200ms)

Alarm Ack.Fixed Dual Set Point 1

* Skip

Segment

* Leading 'edge-triggered'

(minimum duration 200ms)

Logic Input 1

30

31

Logic Input 2

32

Common

P–SKIPP–Strt P–rSEt

Hold/ (Soak)

Start Profile

Profile Reset

Skip Current Segment

Note. Only one function may be

performed by each input at any one time.

Fig. 4.21 Additional Logic Input Functions for Profile Selection

15

Page 18

…4 ELECTRICAL INSTALLATION

4.11 Power Supply Selection and AC Connections – Fig. 4.22

115V

115

230

230V

1

2

Selector not Fitted (24V AC)

A – Selecting the Supply Voltage

115

Digit 7

C31 x x xx x x x x x

3

Code Label

16

Information.

Fuse Rating - 5A Type T

Remove plug to

make connection

B – Power Supply Connections

Fig. 4.22 Power Supply Selection and AC Connections

Fuse

Neutral

Line

Ground

Page 19

Connection/Terminal Number

L

1

Power Supply

N

2

NO

3

Relay 1 Output

Relay 2 Output

Relay 3 Output

4

5

6

7

8

9

10

11

C

NC

NO

C

NC

NO

C

NC

Power Supply

230V AC

115V AC

Output Type:

Output Function:

Output Type:

Output Function:

Output Type:

Output Function:

4 ELECTRICAL INSTALLATION…

(Tick Box)

24V AC

Process Variable

Input

Remote Set Point

Input

Modbus Serial

Communications

Option 1 only

Retransmission

Output

12

13

14

15

16

17

18

19

20

21

22

23

24

3rd

+

–

3rd

+

–

Tx+

Tx–

Common

Rx+

Rx–

+

–

mA VmV/THC/RTD 2-wire Tx

Link Positions

VmA mV/THC/RTD

Termination Resistors

Linked-out

Linked-in

Output Type:

Output Function:

Link Positions

(Tick Box)

(Tick Box)

(Tick Box)

17

Page 20

…4 ELECTRICAL INSTALLATION

Connection/Terminal Number

+

25

Control Output

–

26

3rd

27

Analog Output Logic Output

Link Positions

Link Positions

(Tick Box)

(Tick Box)

Position Feedback

Input

Logic Input 1

Logic Input 2

Common

28

29

30

31

32

+

–

VmA mV

R

18

Page 21

NOTES

19

Page 22

…NOTES

20

Page 23

omega.com

®

®

OMEGAnet®On-Line Service Internet e-mail

http://www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, Box 4047

ISO 9001 Certified Stamford, CT 06907-0047

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-826-6342 FAX: (95) 203-359-7807

En Espan˜ol: (95) 203-359-7803 e-mail: espanol@omega.com

SM

SM

SM

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

Czech Republic: ul. Rude armady 1868, 733 01 Karvina-Hranice

France: 9, rue Denis Papin, 78190 Trappes

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

United Kingdom: One Omega Drive, River Bend Technology Centre

ISO 9002 Certified Northbank, Irlam, Manchester

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: nl@omega.com

Tel: 420 (69) 6311899 FAX: 420 (69) 6311114

Toll Free: 0800-1-66342 e-mail: czech@omega.com

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: info@omega.de

M44 5EX, United Kingdom

Tel: 44 (161) 777-6611 FAX: 44 (161) 777-6622

Toll Free in the United Kingdom: 0800-488-488

e-mail: info@omega.co.uk

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that

apply. OMEGA is constantly pursuing certification of its products to the European New Approach

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

Page 24

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

TEMPERATURE

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

Wire: Thermocouple, RTD & Thermistor

Calibrators & Ice Point References

Recorders, Controllers & Process Monitors

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

Transducers & Strain Gauges

Load Cells & Pressure Gauges

Displacement Transducers

Instrumentation & Accessories

FLOW/LEVEL

Rotameters, Gas Mass Flowmeters & Flow Computers

Air Velocity Indicators

Turbine/Paddlewheel Systems

Totalizers & Batch Controllers

pH/CONDUCTIVITY

pH Electrodes, Testers & Accessories

Benchtop/Laboratory Meters

Controllers, Calibrators, Simulators & Pumps

Industrial pH & Conductivity Equipment

DATA ACQUISITION

Data Acquisition & Engineering Software

Communications-Based Acquisition Systems

Plug-in Cards for Apple, IBM & Compatibles

Datalogging Systems

Recorders, Printers & Plotters

HEATERS

Heating Cable

Cartridge & Strip Heaters

Immersion & Band Heaters

Flexible Heaters

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

Metering & Control Instrumentation

Refractometers

Pumps & Tubing

Air, Soil & Water Monitors

Industrial Water & Wastewater Treatment

pH, Conductivity & Dissolved Oxygen Instruments

M2954/0702

Loading...

Loading...