Page 1

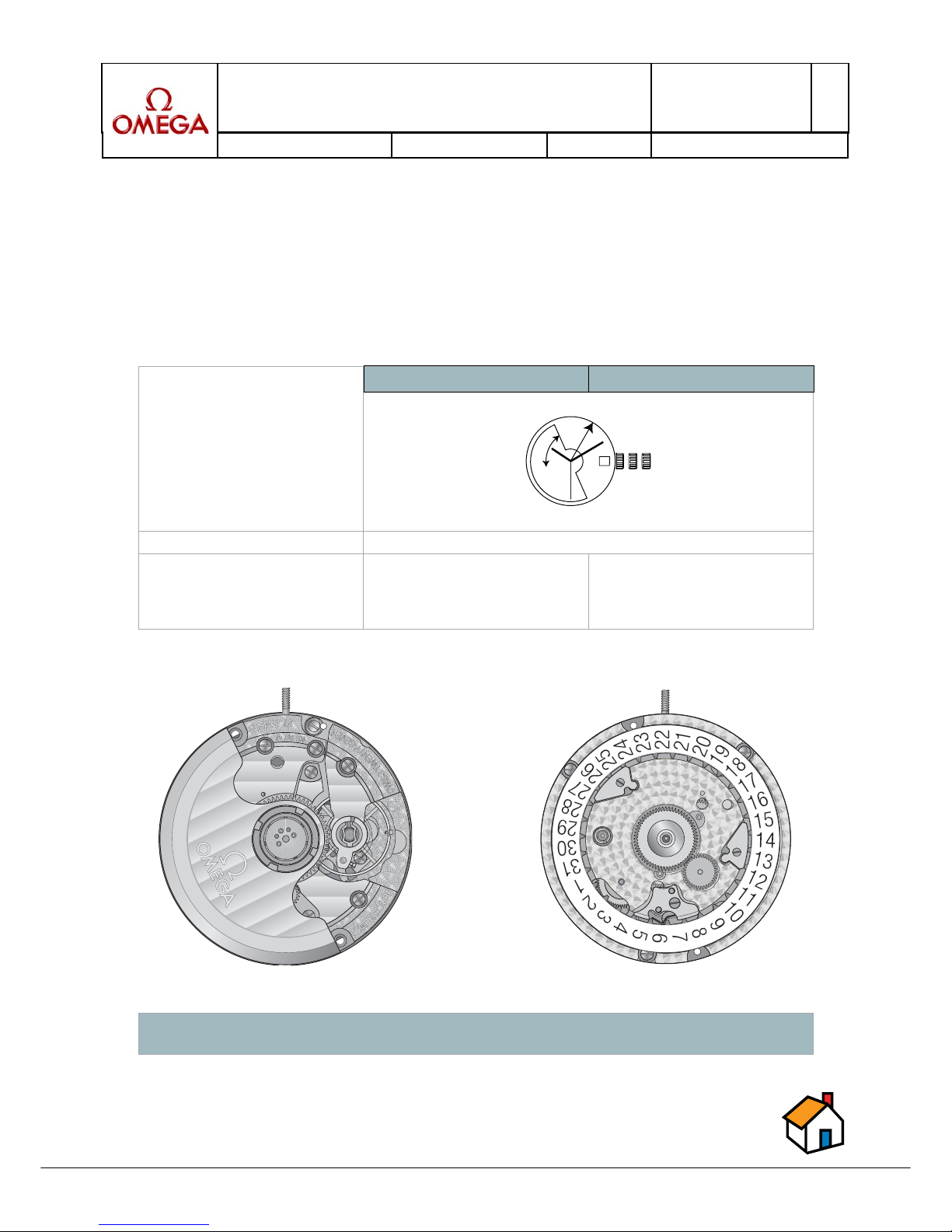

2628

2628

2628 A

111/2’’’

Ø 25,60 mm

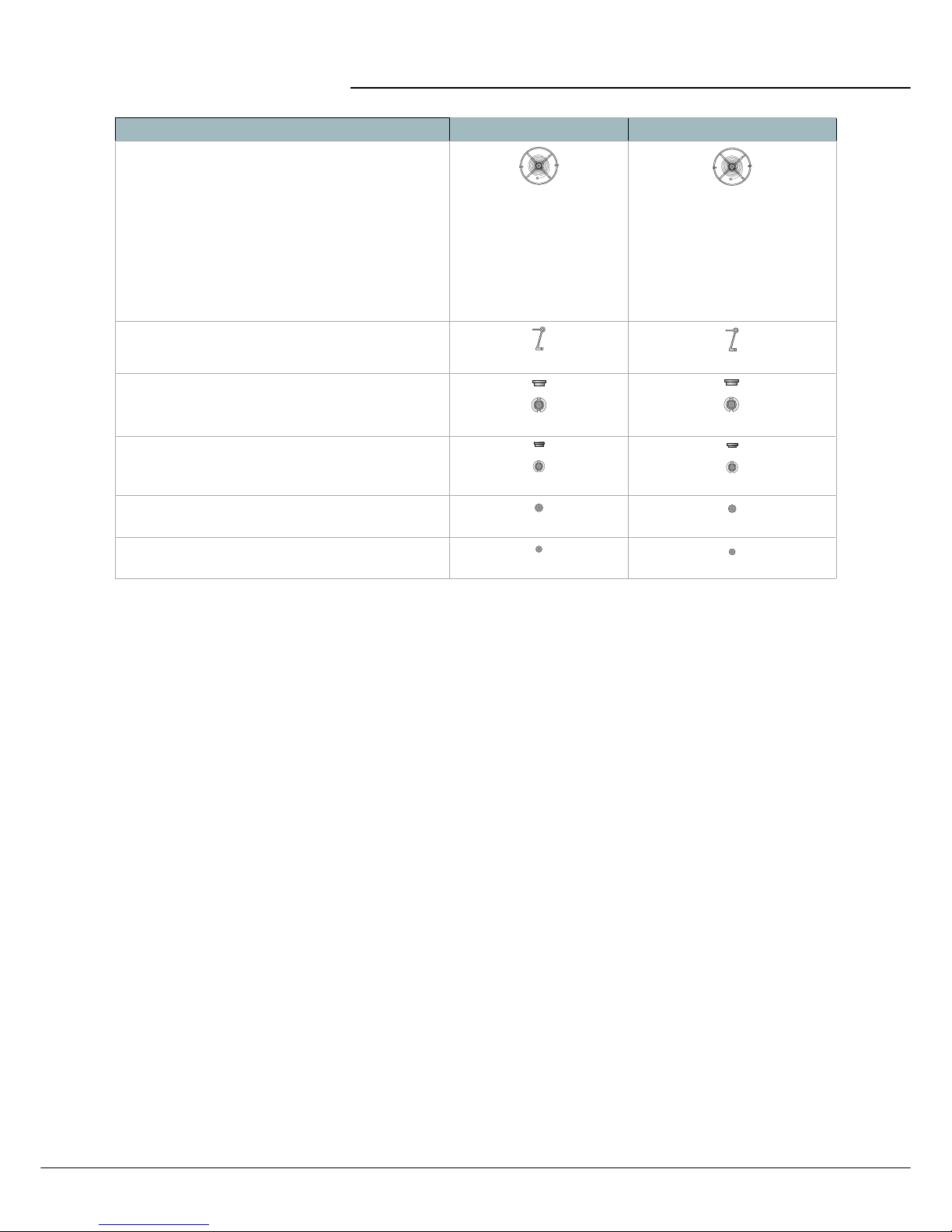

Version A Version B

1 2

3

Height on movement 5.20 mm

Power reserve

Number of jewels

Frequency

Lift angle

44 h

27

4 Hz (28’800 A/h)

30° / 38°

48 h

27

3.5 Hz (25’200 A/h)

38°

CALIBRE

2628

Automatic movement, Co-Axial escapement, date, Time zone function, GMT, COSC-certified,

Omega balance system without index. GMT, hour, minute and second hands in centre.

Technical Guide TG-19-C-006-E

D

Produced by : pelrom Date: 09.10.2008 3

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

/1

Page 2

Page

Calibre 2628 1

General information for Calibre 2628 3-4

Date correction / Improvements on version B / Complete balance bridge 3

Torques according to the screw threads / Measuring instruments 3

Technical modifi cations on version «A» and «B» / Hand fi tting / Tools / Lubricants 4

Exploded views for Calibre 2628 7-11

Dial side 7

Spare parts list for Calibre 2628 11-14

Spare parts list 11

Specifi c information for Calibre 2628 15-19

Assembling of escapement system / Lubrication of the escapement 15

Contents

Movement side 8

Movement side 9

Dial side 10

Assembling of the balance bridge / Disassembling of the balance bridge 16

Runners for hands setting and hand setting force / Height of hands 17

Components not requiring epilam coating 18

Special parameter settings / Timing key 19

Spare parts list 12

Spare parts list 13

Spare parts list 14

Differences between calibre 2628A and 2628B 5-6

Differences between calibres

5-6

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

/2

Page 3

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

/3

Date correction

The date Correction is not recommended between 10 p.m.

and 2 a.m.

Improvements on version B

Complete balance bridge (Ref. 10.058°)

Chronometer balance bridges are not available

(see CS-Info. Calibre No. 33).

Tightening and untightening torques according to screw

thread size

Screw Ø Tightening torque target cNm Untightening torque mini cNm

Ø threads ≤ S 0.50 mm 1.0 0.7

Ø threads S 0.6 mm 1.4 0.8

Ø threads S 0.7 mm 1.8 0.9

Ø threads S 0.8 mm 2.2 1.1

Ø threads S 0.9 mm 2.6 1.3

Ø threads S 1.0 mm 3.0 1.6

Ø threads S 1.2 mm 3.5 2.0

Ø threads S 1.4 and > 4.0 2.5

Type of intervention and the required

«Measure Instrument»

General information for Calibre 2628

Version A Version B

Quality of adjustment:

Good

Quality of adjustment:

Improved

Self-starting: Medium Self-starting: Good

Interventions Minimum equipment required Comments

Complete or Partial maintenance

service Co-Axial 3.5 Hz & 4 Hz

- Watch Expert II (White case)

- Chronoscope M1 (up-dated version)

- Chronoscope S1

Rate adjustment on new watches:

(Co-Axial 3.5 Hz & 4 Hz)

- Watch Expert (red case)

- Wicometer Professionnel

- Chronoscope M1 (old version)

Important: The amplitude will

not be indicated precisely.

This is acceptable for the

rate adjustment only!

Page 4

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

/4

General information for Calibre 2628

Technical modifi cations on version «A» and «B»

Hand fi tting

To fi t the hands, the movement must be placed in a suitable,

well-adjusted movement holder.

Tools Ref.

Hand fitting tool kit 507 0011

Movement holder for hand fitting 507 0017

Mainspring winder 502 150 0009

Timing key 506 0042

Tool for checking the escapement

functions 506 0002

Ball bearing set 502 S03 SET

Key-bolt key for oscillating weight 502 200 0361

Holder for oscillating weight 502 100 0381

Lubricants Ref.

Moebius SYNT-A-LUBE 9010 (2ml) 504 200 0001

Moebius HP-500 504 5012

Moebius SYNT HP-1300 Sans Colorant 504 5013

Moebius 9504 504 5014

Kluber P125 504 100 0071

Lubeta V105 504 5005

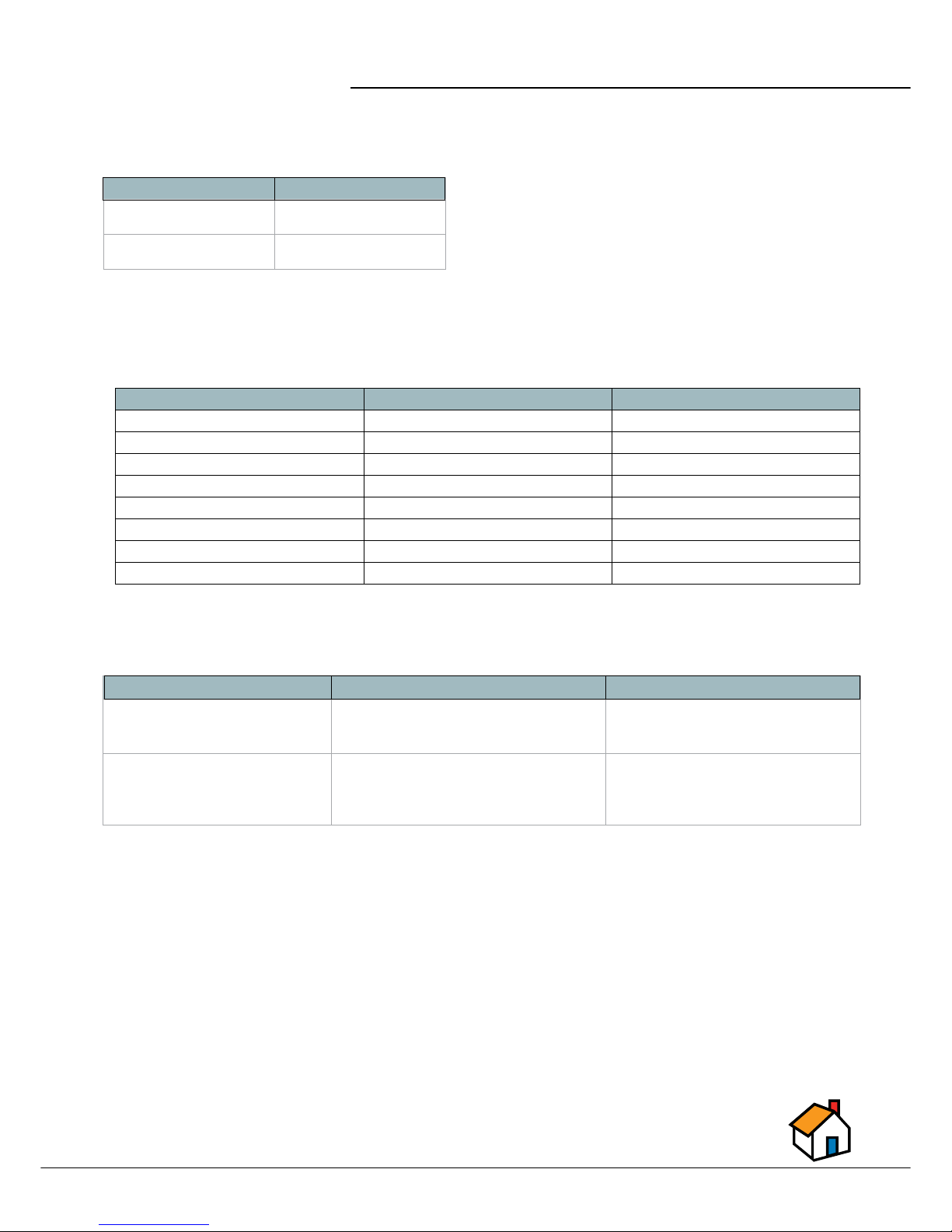

Intermediate escape wheel

Old version Risk New version Improvements Notes

7222500C30039

Black residues within

the engagement can

cause low amplitude or

a stop of the watch.

The old version is yellow.

7222500C30039

Improvement of surface

and material.

The new version is grey.

Available since 21/2008

The new version must

automatically be assembled

if black residues within the

engagement are visible.

Page 5

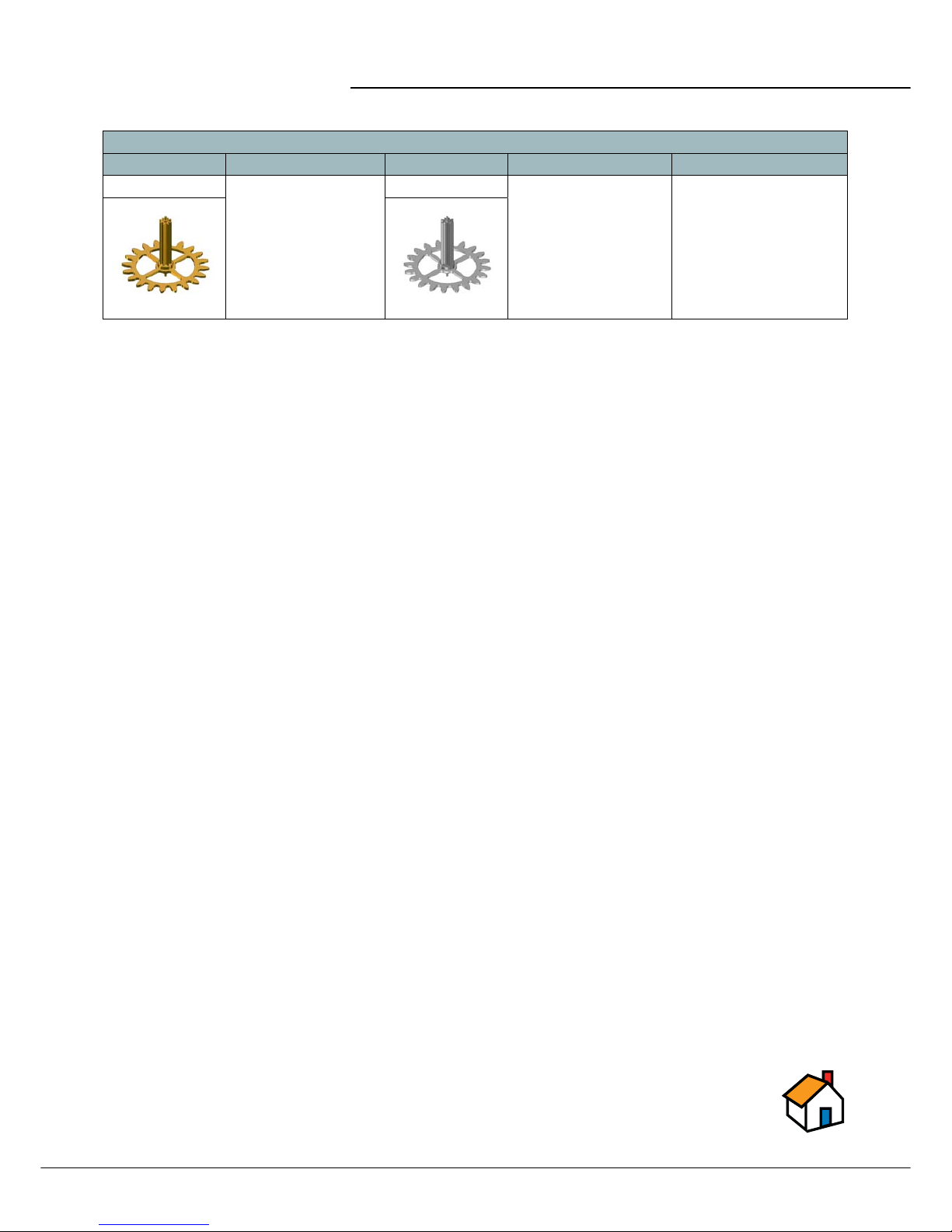

2628A (4 Hz) 2628B (3.5 Hz)

Mainplate

ref. 72226281002007

Engraving 2628A

ref. 7222628B81002007

Engraving 2628B

Balance bridge

ref. 7222500B10058°

ref. 7222500C10058°

Barrel, complete

ref. 7222500B20010 ref. 722112020010

Mainspring

ref. 7222500B20102 ref. 722112020102

Oscillating weight

2628

2628

ref. 72226282201006

2628B

2628B

ref. 7222628B2201006

Second wheel

ref. 722112830027*

96 teeth and eight arms

ref. 7222628B30027*

105 teeth and fi ve arms

Intermediate escape wheel

ref. 7222500B30039

8-leaf pinion

ref. 7222500C30039

10-leaf pinion

Cutout in upper pivot shank

Co-Axial wheel

ref. 7222500B30040

Pinion Ø = 1.999 mm

ref. 7222500C30040

Pinion Ø = 2.119 mm

Pallet fork

Old shape

ref. 7222500B40010

New shape

ref. 7222500C40010

Differences between versions 2628A and 2628B

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D -2628

/5

Page 6

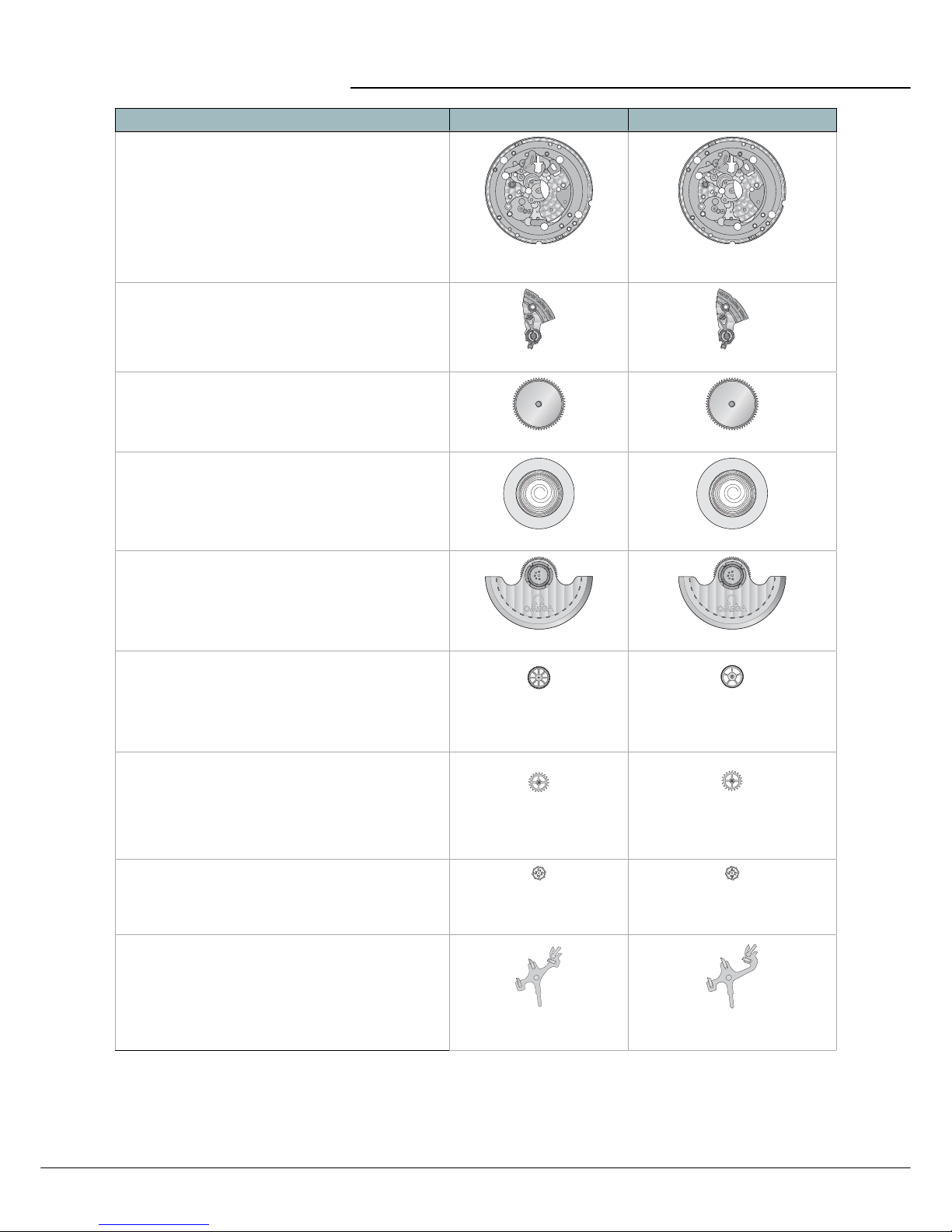

Differences between versions 2628A and 2628B

2628A (4 Hz) 2628B (3.5 Hz)

Balance complete with stud

Inertia

Diameter

Balance rim thickness

Pivots

Shock absorber

Rate correction with 1 screw-revolution (on both screws)

ref. 7222500B4005021

7.2 (mgcm2)

8.54 mm

0.37 mm

0.08 mm cylindrical

0.09 mm = pivot hole Ø

57 seconds

ref. 7222500C4005021

9.4 (mgcm2)

8.70 mm

0.45 mm

0.07 mm conical

0.08 mm = pivot hole Ø

86 seconds

Stop lever

ref. 722250056070

ref. 7222500C56070

Shock-absorber, upper

ref. 722112070530

ref. 7222500C70530

Shock-absorber, lower

ref. 722112070531

ref. 7222500C70531

In settings, upper

ref. 722112070640

ref. 7222500C70640

In settings, lower

ref. 722112070641

ref. 7222500C70641

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D -2628

/6

Page 7

Parts listed in order of assembly

1 = 31120

2 = 31121

3 = 5101021

4 = 53022

5 = 5108006

6 = 51050

7 = 51091

8 = 3503 (1x)

9 = 31100

9

5

8

7

4

6

3

1

2

Moebius SYNT HP-1300 Sans Colorant

Moebius 9504

Exploded views - Dial side for Calibre 2628

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D -2628

/7

Page 8

8

7

6

5

1

3

11

12

18

17

16

15

14

19

9

20

24

25

10

21

4

23

22

Versions A&B

see page 5

Restrictions:

see page 3

Versions A&B

see page 6

2

13

See page 15

Versions A&B

see page 5

Versions A&B

see page 5

Versions A&B

see page 5

Parts listed in order of assembly

1 = 1004107

2 = 32033

3 = 31023

4 = 31024

5 = 31021

6 = 51120

7 = 81036

8 = 3509 (1x)

9 = 30012

10 = 20010

11 = 31020

12 = 1004107

13 = 3503 (3x)

14 = 30039

15 = 30025

16 = 30027*

17 = 1004807

18 = 3505 (1x)

19 = 30040

20 = 40010

21 = 1005707

22 = 3511 (1x)

23 = 3511 (1x)

24 = 10058°

4005021

Moebius SYNT-A-LUBE 9010

Moebius SYNT HP-1300 Sans Colorant

Moebius SYNT HP-500

Moebius SYNT HP-1300 Sans Colorant

Kluber P125

Exploded views - Movement side for Calibre 2628

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D -2628

/8

Page 9

Parts listed in order of assembly

1 = 56070

2 = 1203007

3 = 32032

4 = 32031

5 = 32037

6 = 52040

7 = 1205107

8 = 3504 (1x)

9 = 2201006

10 = 3507 (3x)

11 = 3503 (3x)

12 = 52041

13 = 12124

14 = 3506 (1x)

11

12

14

13

1

2

3

4

5

6

9

7

8

10

11

2628

2628

Versions A&B

see page 6

See CS-Info Calibre no. 26 Lubeta V105

When Lubeta V105 is available, do not

use Moebius 9010

Moebius SYNT-A-LUBE 9010

Moebius SYNT HP-1300 Sans Colorant

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Exploded views - Movement side for Calibre 2628

/9

Page 10

Parts listed in order of assembly

1 = 31083*

2 = 31041

3 = 31100

4 = 31101

5 = 10062

6 = 3503 (1x)

7 = 31101

8 = 33032

9 = 31046*

10 = 33014

11 = 1601006

12 = 3502 (3x)

13 = 91440

14 = 53080

15 = 13111

16 = 3501 (1x)

17 = 13105 (2x)

18 = 3500 (2x)

19 = 3104706*

Moebius 9010

Moebius SYNT HP-1300 Sans Colorant

Moebius SYNT HP-1300 Sans Colorant

Moebius 9504

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Exploded views - Dial side for Calibre 2628

/10

*

5

6

2

1

7

3

15

16

18

14

8

10

19

13

17

11

12

4

9

Additional lubrication:

See CS-Info Calibre no. 32

Lubrication spot (Moebius 9010, small quantity)

at the exit of the second wheel axe - centre tube.

Page 11

Main plate, pre-assembled Version Reference Reverser maintaining plate Version Reference

2628A 72226281002007 2628A

722112012124

2628B 7222628B1002007 2628B

Barrel bridge Version Reference Date indicator maintaining plate Version Reference

2628A

7222500B1004107

2628A

722112813105

2628B 2628B

Wheel train bridge Version Reference Date jumper maintaining plate Version Reference

2628A

7222500B1004807

2628A

722112813111

2628B

2628B

Pallet bridge, pre-assembled Version Reference

Display mechanism

platform, assembled

Version Reference

2628A

72225001005707

2628A

72226281601006

2628B

2628B

Balance bridge

Version Reference Barrel complete Version Reference

2628A 7222500B1005824 2628A 7222500B20010

2628B 7222500C1005824 2628B

722112020010

Minute train bridge Version Reference Barrel drum and cover Version Reference

2628A

722112810062

2628A

722112020030

2628B

2628B

Dial fastener Version Reference Barrel arbor Version Reference

2628A

722112010300

2628A

722112020060

2628B

2628B

Upper automatic bridge Version Reference Mainspring Version Reference

2628A

7222500B1203007

2628A 7222500B20102

2628B 2628B

722112020102

Lower automatic bridge Version Reference Oscillating weight, assembled Version Reference

2628A

72211201205107

2628B

2628B

2628A 72226282201006

2628B 2628B 7222628B2201006

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Spare parts list for Calibre 2628

/11

Page 12

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Spare parts list for Calibre 2628

/12

Ball bearing Version Reference Hour wheel Version Reference

2628A

722112022040

2628A

722112831046*

2628B 2628B

Oscillating weight bolt Version Reference Hour wheel, 24 hours Version Reference

2628A

722112022042

2628A

72211203104706*

2628B

2628B

Intermediate wheel Version Reference Cannon pinion with driving wheel Version Reference

2628A

722112030012

2628A

722112831083*

2628B 2628B

Third wheel Version Reference Setting wheel Version Reference

2628A

722112030025

2628A

722112831100

2628B 2628B

Second wheel Version Reference Intermediate setting wheel Version Reference

2628A 722112830027* 2628A

722112831101

2628B 7222628B30027* 2628B

Intermediate escape wheel Version Reference Winding pinion Version Reference

2628A 7222500B30039

2628A

722112831120

2628B 7222500C30039

2628B

Co-Axial wheel Version Reference Sliding pinion Version Reference

2628A 7222500B30040

2628A

722112831121

2628B 7222500C30040

2628B

Ratchet wheel Version Reference Reduction wheel Version Reference

2628A

722112031020

2628A

722112032031

2628B 2628B

Intermediate ratchet wheel Version Reference Intermediate reduction wheel Version Reference

2628A

722112031021

2628A

722112032032

2628B

2628B

Crown wheel Version Reference Ratchet wheel driving wheel Version Reference

2628A

722112031023

2628A

722112032033

2628B

2628B

Intermediate crown wheel Version Reference Reversing wheel Version Reference

2628A

722112031024

2628A

722112032037

2628B 2628B

Minute wheel Version Reference Intermediate date wheel Version Reference

2628A

722112831041

2628A

722112833014

2628B

2628B

Page 13

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Spare parts list for Calibre 2628

/13

Date wheel Version Reference Stop lever Version Reference

2628A

722112833032

2628A 722250056070

2628B 2628B 7222500C56070

Pallet fork Version Reference Shock-absorber, upper Version Reference

2628A 7222500B40010

2628A 722112070530

2628B 7222500C40010

2628B 7222500C70530

Balance complete with stud Version Reference Shock-absorber, lower Version Reference

2628A 7222500B4005021 2628A 722112070640

2628B 7222500C4005021 2628B 7222500C70640

Stud support Version Reference In settings, upper Version Reference

2628A

7222500B40200

2628A 722112070531

2628B 2628B 7222500C70531

Winding stem Version Reference In settings, lower Version Reference

2628A

72211285101021

2628A 722112070641

2628B 2628B 7222500C70641

Yoke Version Reference Cap jewel, upper Version Reference

2628A

722112051050

2628A

722112070900

2628B 2628B

Setting lever Version Reference Cap jewel, lower Version Reference

2628A

72211285108006

2628A

722112070901

2628B 2628B

Setting lever jumper Version Reference Shock-absorber spring, upper Version Reference

2628A

722112051091

2628A

722112078004

2628B 2628B

Click Version Reference Shock-absorber spring, lower Version Reference

2628A

722112051120

2628A

722112078005

2628B 2628B

Reverser Version Reference Centre tube Version Reference

2628A

722112052040

2628A

722112880400

2628B 2628B

Auxiliary reverser Version Reference Click plate Version Reference

2628A

722112052041

2628A

722112081036

2628B 2628B

Date corrector

operating lever

Version Reference Date indicator Version Reference

2628A

722112853022

2628A

722262891440*

2628B 2628B

Date jumper Version Reference

Screw for date indicator

maintaining plate

Version Reference

2628A

722262853080

2628A

72211283500

2628B 2628B

Page 14

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Spare parts list for Calibre 2628

/14

Screw for date jumper

maintaining plate

Version Reference

2628A

72211283501

2628B

Screw for display

mechanism platform

Version Reference

2628A

72211283502

2628B

Screw for setting lever jumper Version Reference

2628A

72211203503

2628B

Screw for minute train bridge Version Reference

2628A

72211203503

2628B

Screw for automatice device Version Reference

2628A

72211203503

2628B

Screw for barrel bridge Version Reference

2628A

72211203503

2628B

Screw for balance bridge Version Reference

2628A

72211203503

2628B

Screw for lower automatic

device bridge

Version Reference

2628A

72211203504

2628B

Screw for wheel train bridge Version Reference

2628A

72211203505

2628B

Screw for reverser

maintaining plate

Version Reference

2628A

72211203506

2628B

Screw for ball bearing Version Reference

2628A

72211203507

2628B

Screw for click plate Version Reference

2628A

72211203509

2628B

Screw for pallet bridge Version Reference

2628A

72225003511

2628B

Screw for stud Version Reference

2628A

2628B

72225003512

Page 15

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

/15

1

2

3

4

5

Fig. 1.0

1.0 Assembling of the escapement system

Key points

The order of assembly must be respected (See page 11).

After assembling, the escapement functions must be

checked accurately with the corresponding tool.

The pallet bridge positions the co-axial wheel and the pallet fork. To ensure the functioning of the escapement it is

necessary to respect the following order of assembly:

1. Position the co-axial wheel.

2. Position the pallet fork.

3. Position the pallet bridge, screw no (4) must be correctly

placed in their beds.

4. To position the pallet bridge, screw no (4) must be fi xed

fi rst.

5. The second screw (5) fixes the bridge.

2.1 Assembling of the balance bridge

As the table roller is under the pallet fork, the

balance must be assembled carefully.

1. Position the complete balance bridge

(with balance). The bridge is pointing

towards the center of the movement.

2. Check the position of the balance. The pivot of the

balance-staff must be correctly placed in its bed.

3. Carefully turn the bridge to its normal position.

4. Fix the bridge with its screw.

2.2 Disassembling of the balance bridge

The balance bridge must be disassembled by removing the

parts in the opposite order of procedure 2.2. To avoid any

risk of damaging the balance, the bridge has to be turned

towards the center of the movement. In this position the

bridge may be removed without any risk.

Specifi c information for Calibre 2628

4

1

2

3

Fig. 2.1

Fig. 2.2

Page 16

Specifi c information for Calibre 2628

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Description Movement holder

Nbr. of runners for

hand setting

Minimum force

(N)

Maximum force

(N)

Support

(jewel)

GMT hand

507 0017

7 10 50 no

Hour hand

5 10 50 no

Minute hand

2 10 30 no

Second hand

1 10 30 yes

3.0 Runners for hand setting and hand

setting force

/16

2628 A

VBXH2 H5

Calibre Ω + version

Hauteur aiguillage (H5)

Code de fabrication

2628

2628

2628

A

VBAH2 H

5

Fig. 3.2

3.2 Height of hands

The star next to a supply reference in the part list means

that there are several heights of hands.

e.g.: 722112831083*.

To order movement parts, you must enter the order as fol-

lows:

e.g. : 7221128310835.

The last figure indicates the wheel height.

Page 17

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

Specifi c information for Calibre 2628

/17

Description Reference

Balance assembled on the balance bridge * 40055 + 10058°

Complete balance 40055

Pallet fork 40010

In-setting, upper *

In-setting, lower *

70640

70641

Pallet fork bridge 1005707

Barrel complete**

Mainspring

20010

20102

Reversing wheel 32037

* Do not treat the shock-absorber settings with epilam; the cap jewels should however be treated

** Do not treat the complete barrel with epilam, only the drum, cover and arbour separately.

4.0 Components that must not be

epilam-treated after cleaning

Page 18

Fig. 5.1

REF. 506 0042

Fig. 5.0

Fig. 5.2

OMEGA SA WORLD SERVICE ORGANIZATION GT-19-C-006-E - D - 2628

/18

Special parameter settings

Instrument type

Co-Axial

4 Hz calibres

Co-Axial

3.5 Hz calibres

Comments

Former Witschi instruments

- Watch Expert (red case)

- Wicometer Professional

- Chronoscope M1 (old version)

Lift angle

set to 30°

Lift angle

set to 38°

3.5 Hz calibres:

The frequency parameters

(25’200 A/h) should be

set manually so that the

instantaneous rate is

All measurements

are correct

The amplitude

is not measured

correctly

New Witschi instruments

- Watch Expert II (white case)

- Chronoscope M1 (up-dated version)

- Chronoscope S1

Lift angle

set to 38°

Lift angle

set to 38°

Test mode:

Parameters must be set

for «Spe1»!

All measurements

are correct

All measurements

are correct

5.0 Timing key

A special timing key tool has been developed to adjust

the rate even when the movement is cased in. The rate

can be corrected according to the table below by turning

the two balance screws a complete turn. A scale is found

on the outside of the tool. A division corresponds to a rate

correction of 1 second. (according to the table below).

One screw is located between two arms on the balance

which are specially marked by points (see Figure 5.2) for

easy identification of each screw during the correction

process.

Balance

The annular balance has two adjusting micro-screws. A

slow rate deviation is corrected by tightening the microscrews (towards the centre of the balance), which reduces its moment of inertia and makes it run faster. A fast

rate deviation is corrected by loosening the micro-screws

(away from the centre of the balance). This increases its

moment of inertia and makes it run slower.

Important:

The rate is always corrected using both adjustment

screws to prevent an unbalance of the balance.

Demagnetise the movement according to Working

Instruction 34.

Values to be checked

Please consult Working Instructions 5 and 28 for

instructions and tolerances.

Version A Version B

One correction turn = 57 seconds One correction turn = 86 seconds

One division = 1 second One division = 1.5 seconds

Specifi c information for Calibre 2628

Loading...

Loading...