Page 1

hhtp://www.omega.com

e-mail:info@omega.com

CL23A, 24, 25, 26, 27

Digital Calibrator/Thermometer

Page 2

Servicing North America

USA: One Omega Drive, Box 4047

ISO 9001 Certified

Tel: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L5A1

Tel: (514) 856-6928 FAX: (514) 856-6886

e-mail: canada@omega.com

USA and Canada: Sales Service: 1-800-826-6342 / 1-800- TC-OMEGA

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico and

Latin America: Tel: (95) 800-TC-OMEGA

En Español: (203) 359-1660 ext: 2203 email: espanol@omega.com

Benelux: Postbus 8034 , 1180 LA Amstelveen, The Netherlands

Tel: (31) 20 6418405 FAX: (31) 20 6434643

Toll Free in Benelux: 06 0993344

e-mail: nl@omega.com

Czech Republic: Ostravska 767,733 01 Karvina

Tel: 42 (69) 6311899 FAX: 42 (69) 6311114

e-mail: czech@omega.com

France: 9, rue Denis Papin, 78190 Trappes

Tel: (33) 130-621-400 FAX: (33) 130-699-120

Toll Free in France: 0800-4-06342

e-mail: france@omega.com

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

Tel: 49 (07056) 3017 FAX: 49 (07056) 8540

Toll Free in Germany: 0130 11 21 66

e-mail: germany@omega.com

United Kingdom: 25 Swannington Road, P.O. Box 7, Omega Drive,

ISO 9002 Certified

LE9 6TU, England M44 5EX, England

Tel: 44 (1455) 285520 Tel: 44 (161) 777-6611

FAX: 44(1455) 283912 FAX: 44 (161) 777-6622

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly

pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device

upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for any errors

it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

Stamford, CT 06907-0047

For immediate technical or application assistance:

SM

Customer Service: 1-800-622-2378 / 1-800-622-BESTSM

MS

FAX: (95) 203-359-7807

Servicing Europe

Broughton Astely, Leicestershire, Irlam, Manchester,

Toll Free in England: 0800-488-488

e-mail: uk@omega.com

SM

Page 3

TABLE OF CONTENTS

General Information ...............................................................................2

Common Specifications........................................................................... 2

Unique Specifications.............................................................................. 5

Features ............................................................................................... 6

Manual Addenda .................................................................................... 6

Unpacking Your Unit ............................................................................... 7

Safety Information .................................................................................7

Safety Precautions ................................................................................. 7

Battery Installation/Replacement.............................................................. 9

Memory Backup ..................................................................................... 10

Operation with Rechargeable Battery ........................................................ 10

Operating Instructions ............................................................................ 11

1. Diagnostics and Error Messages....................................................... 11

2. Initial Turn On............................................................................... 11

3. Meter Mode Operation (Thermocouple)............................................. 13

4. Meter Mode Operation (RTD, Thermistor, Ohms)................................ 14

5. Data Logging & Recall .................................................................... 15

6. Calibrator Mode Operation (Thermocouples)...................................... 17

7. Calibrator Mode Operation (RTD, Thermistor, Ohms) .......................... 18

8. Storage and Recall of Calibrator Settings ..........................................20

9. Step Function................................................................................ 22

10. Ramp Function ............................................................................ 22

Service Information................................................................................ 23

1. Calibration Procedures.................................................................... 23

2. Calibration Verification ................................................................... 32

3. Mechanical Parts Diagram............................................................... 38

Warranty .............................................................................................. 45

Limitation of Warranty ............................................................................ 45

1

Page 4

GENERAL INFORMATION

This manual provides operating instructions and maintenance information for

five temperature instruments. These instruments are high performance cali brator-thermometers capable of simulating and measuring a wide-variety of

sensors. In addition, features such as data storage and ramping further

enhance their versatility.

It is recommended that you read this manual thoroughly, especially the sec tions on safety, prior to operating these instruments

.

COMMON SPECIFICATIONS

THERMOMETER INPUTS: THERMOCOUPLE; Miniature TC jack. RTD, OHMS,

THERMISTOR; T-series instrumentation connector.

CALIBRATOR OUTPUTS: THERMOCOUPLE; Miniature TC jack. RTD, OHMS,

THERMISTOR; T-series instrumentation connector.

THERMOCOUPLE TYPES: K, J, T, E, N, B, R, S, G, C, D.

RTD TYPES: 100Ω platinum (α = 0.00385)

1000Ω platinum (α= 0.00385

)

THERMISTOR TYPE: 2252Ω (YSI Series 400).

RANGES: K; -200°C to 1372°C, -328°F to 2502°F

J; -210°C to 760°C, -346°F to 1400°F

T; -200°C to 400°C, -328°F to 752°F

E; -230°C to 1000°C, -382°F to 1832°F

N; -200°C to 1300°C, -328°F to 2372°F

B; 500°C to 1820°C, 932°F to 3308°F

R; 0°C to 1768°C, 32°F to 3214°F

S; 0°C to 1768°C, 32°F to 3214°F

G; 300°C to 2316°C, 572°F to 4201°F

C; 0°C to 2316°C, 32°F to 4201°F

D; 0°C to 2316°C, 32°F to 4201°F

RTD; -200°C to 850°C, -328°F to 1562°F

THERMISTOR; -40°C to 150°C, -40°F to 302°F

OHMS; 0-999.99Ω

0-9,999.9Ω

0-99,999Ω

ACCURACY (18°C to 28°C ambient, 2 years)*:

K, J, T, E, N; ± 0.5°F (rdg ³ -50°F)

±1.0°F (rdg < -50°F)

B, R, S, G, C, D; ±1.7°F

2

Page 5

RTD; ±0.2°F (rdg> 50°F)

±0.5°F (rdg < - 50°F)

±0.2°F ±0.04% rdg (meter mode)

THERMISTOR; ±0.5F

OHMS; ±0.02% range

* Exclusive of sensor errors, and lead resistance induced errors.

RESOLUTION: TEMPERATURE; 0.1 °/1° F/C

OHMS; 0.01Ω/0.1Ω/1Ω

REPEATABILITY (1 week at constant ambient temperature):

K, J, T, E, N; ±0.2°F typ.

B, R, S, G, C, D; ±1.0°F typ.

RTD, THERMISTOR; ±0.1 °F typ.

OHMS; ±0.01 % rng typ.

TEMPERATURE COEFFICIENT:

From 18°C to 28°C, included in accuracy specifications.

From 0°C to 18°C, and 28°C to 50°C:

K, J, T, E, N; ±(0.002% rdg + 0.03°C)/°C

B, R, S, G, C, D; ±(0.002% rdg + 0.1°C)/°C

RTD, THERMISTOR, OHMS; ±(0.002% rdg + 0.004% rng)/°C

METER-MODE INPUT-CURRENT (THERMOCOUPLES): 50nA typ.

METER-MODE READING-RATE: 1 reading/second typ.

METER-MODE EXCITATION-CURRENTS:

100Ω RTD; <2μA

1000Ω RTD;<200μA

999.99Ω; <2μA

9999.9Ω; <200μA

99999Ω; <50μA

THERMISTOR; T <

T>113°F, <2mA

CALIBRATOR MODE OUTPUT LOAD (THERMOCOUPLES): 500Ω min.

CALIBRATOR-MODE EXCITATION-CURRENTS:

100Ω RTD; 0.5 - 1mA (0.1 - 2mA typ.)

1000Ω RTD; 50 - 100μA (10-200μA t yp.)

999.99Ω; Same as 100Ω RTD

9999.9Ω; Same as 1000Ω RTD

99999Ω; 10 - 20μA (1 - 20μA typ.)

THERMISTOR; T <

T>113°F, 0.5- 1mA

MAXIMUM COMMON MODE VOLTAGE: 42V peak to earth.

113°F <50μA

113°F, 10 - 20μA

3

Page 6

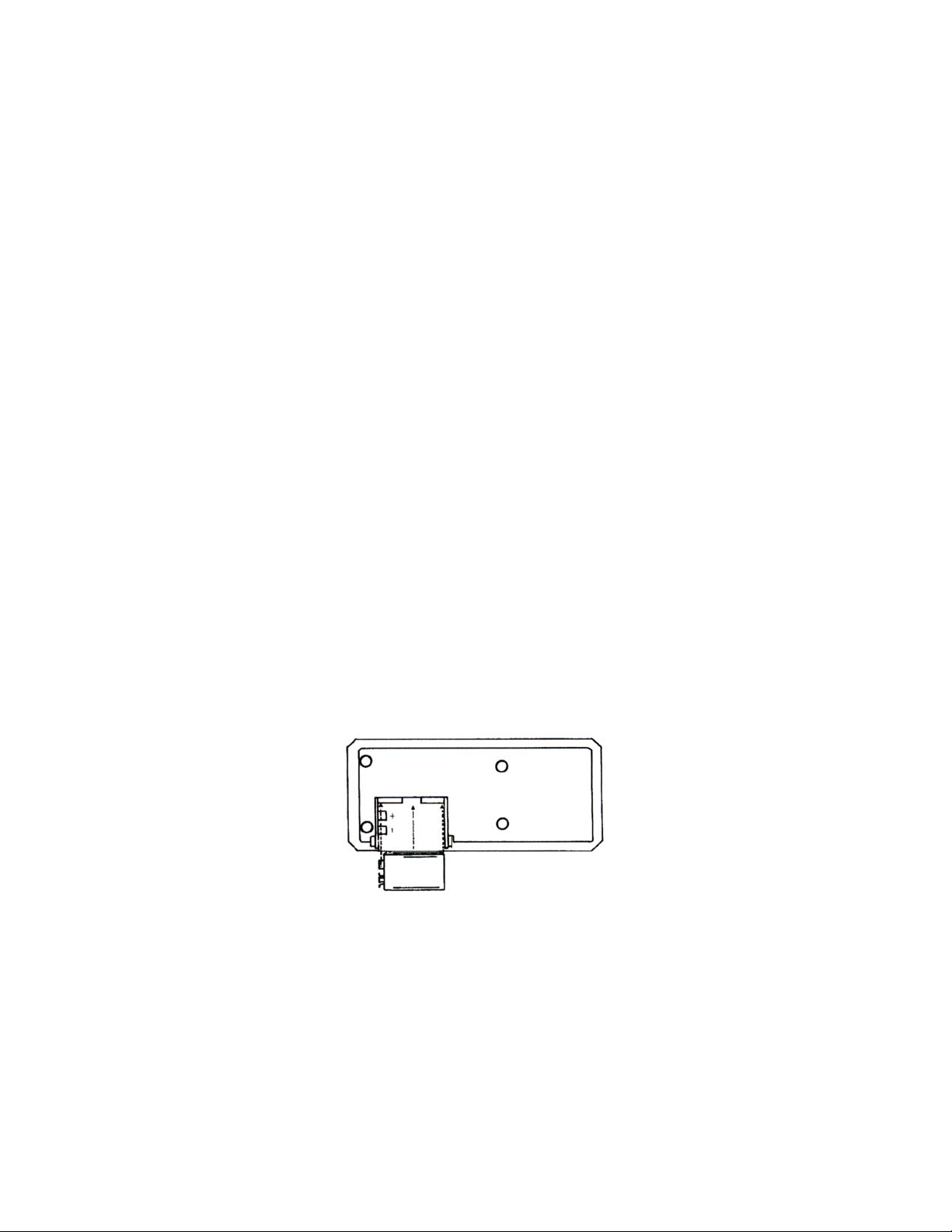

KEYPAD: 12 momentary switches with tactile feedback select;

• On/Off

• Change/Enter

• Clear/-0

• Sensor Select/1

• °F/°C/2

• Resolution/3

• Operate/4

• Store/5

• Recall/6

• Calibrator/Meter/Up Ramp/7

• Calibrator Step/Down Ramp/8

• Calibrator Ramp/Meter Hold/9

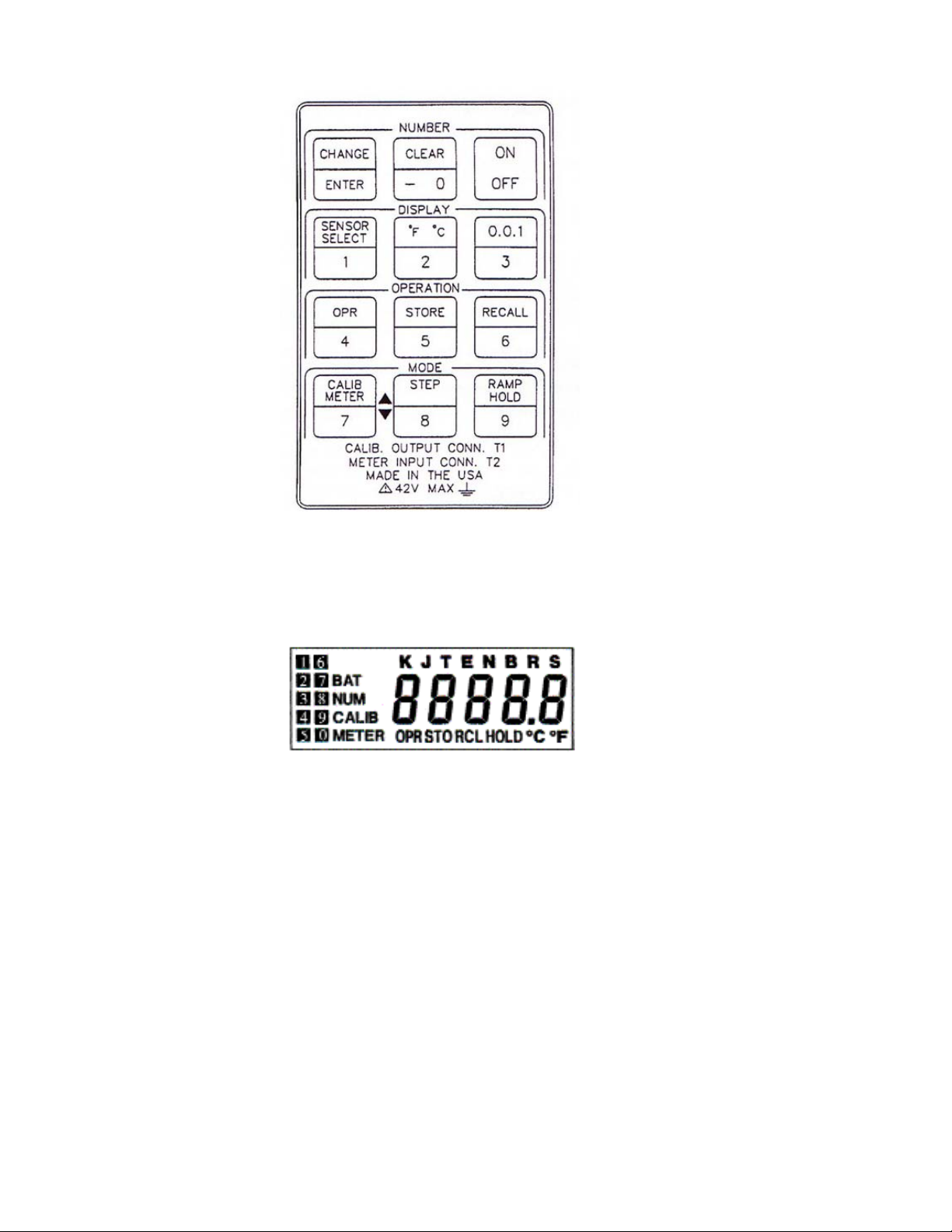

DISPLAY: 5 digit LCD, 0.4" height, and decimal point. Annunciators;

• Loaded Memory Locations (10 for data storage, 4 for ramp parameters)

• Low Battery (BAT)

• Number Change Mode (NUM)

• Calibrator Mode (CALIB)

• Meter Mode (METER)

• Operate Mode (OPR)

• Store Mode (STO)

• Recall Mode (RCL)

• Meter Hold (HOLD)

• Scale (°F/°C)

• Sensor Type

POWER OFF CONFIGURATION RETENTION: Instrument retains last selected;

• Sensor Type

• °F/°C Scale

• 0.1°/1° Resolution

• Calibrator/Meter Mode

• Memory Contents (data storage and ramp parameters).

DIAGNOSTICS: Display codes indicate following conditions;

• 'BAT': Low Battery

• 'OPEN': Open Input Thermocouple, RTD or Thermistor.

• 'E-1' (momentary): Invalid Keypad Entry

• 'E-2' (momentary): Ramp Function Not Installed

• 'H

• 'LO': Temperature Reading or Keypad Entry Too Low For Accuracy

• LCD Test: During power-up, all segments and annunciators enabled momentarily

ENVIRONMENTAL LIMITS FOR OPERATING: 0°C to 50°C, less than 90% relative

humidity (R.H.) up to 35°C; reduce R.H. limit by 3%/°C from 35°C to 50°C.

ENVIRONMENTAL LIMITS FOR STORAGE: -35°C to 60°C, less than 95% relative humidity

(R.H.) up to 35°C; reduce R.H. limit by 3%/°C from 35°C to 60°C.

POWER: 9 volt alkaline battery (NEDA 1604A).

I': Temperature Reading or Keypad Entry Exceeds Rating

4

Page 7

BATTERY LIFE, CONTINUOUS: 10 hrs. typical, alkaline; 3 hrs typical, Ni-Cd (rechargeable).

BATTERY INDICATOR: Display indicates BAT when less than 10% of life remains.

DIMENSIONS, WEIGHT: 7.0" x 2.9 x 1.1". Net weight 12 oz.

UNIQUE SPECIFICATIONS

NOTE: The specifications below are spe cific to the model(s) as identified by model number. The

difference specifications are in addition to the OVERALL SERIES SPECIFICATIONS found on

pages 2-5.

• MODEL CL23A/CL23EC:

SENSOR SELECTION: K, J, T Thermocouples

ACCURACY: (18°C to 28°C ambient, 2 years): ±0.5°F (rdg >

±0.04% rdg (rdg > 1250°F)

±1.0°F (rdg < -50°F)

TEMPERATURE COEFFICIENT: 18°C to 28°C; included in accuracy specifications.

From 0°C to 18°C, and 28°C to 50°C; less than ±(0.006% rdg +0.03°C)/°C.

RAMP FUNCTION: Not Included.

BATTERY LIFE, CONTINUOUS: 16 hrs typical, alkaline; 4 hrs typical, Ni-Cd (re chargeable).

• MODEL CL24:

SENSOR SELECTION: K, J, T, E Thermocouples

ACCURACY: (18°C to 28°C ambient, 2 years): ±0.5°F (rdg >

±0.04% rdg (rdg > 1250°F)

±1.0°F (rdg <-50°F)

TEMPERATURE COEFFICIENT: 18°C to 28°C; included in accuracy specifications.

From 0°C to 18°C, and 28°C to 50°C; less than ±(0.006% rdg +0.03°C)/°C.

RAMP FUNCTION: Not Included.

BATTERY LIFE, CONTINUOUS: 16 hrs typical, alkaline; 4 hrs typical, Ni-Cd (rechargeable).

• MODEL CL25/CL25EC:

SENSOR SELECTION: K, J, T, E, N, B, R, S, G, C, D Thermocouples

RAMP FUNCTION: Included.

BATTERY LIFE, CONTINUOUS: 16 hrs typical, alkaline; 4 hrs typical, Ni-Cd (re chargeable)

• MODEL CL26:

SENSOR SELECTION: K, J, T, E Thermocouples

100Ω Platinum RTD

2252Ω Thermistor

1,000Ω/100,000Ω Resistance

-50°F).

-50°F).

5

Page 8

ACCURACY: (18°C to 28°C ambient, 2 years): ±0.5 °F (rdg >

±0.04% rdg (rdg > 1250°F)

±1.0°F (rdg <-50°F)

OHMS; ±0.04% range

TEMPERATURE COEFFICIENT: 18°C to 28°C; included in accuracy specifications.

From 0°C to 18°C, and 28°C to 50°C.

K, J, T, E; ±(0.006% rdg + 0.03°C)/°C

RTD, THERMISTOR, OHMS; ±(0.006% rdg +0.012% rng)/°C

RAMP FUNCTION: Not Included.

• MODEL CL27/CL27EC:

SENSOR SELECTION: K, J, T, E, N, B, R, S, G, C, D Thermocouples

100Ω/1000Ω Platinum RTD

1,000Ω/10,000Ω Resistance

RAMP FUNCTION: Included.

-50°F).

FEATURES

•Combination calibrator, thermometer and datalogger.

•Function selection and numeric data entered via 12 keyswitch color coded keypad.

•Keyswitches have tactile feedback.

•5 digit LCD includes annunciators for operating modes.

•Up to 11 thermocouple types, 2 RTD types, and thermistor.

•1° or 0.1° resolution over temperature range of each sensor.

•°F and °C scales.

•Reading hold mode.

•10 memory locations for saving meter readings and/or calibrator outputs.

•Step mode for quick sequential recall of calibrator outputs from memory.

•Manual/automatic ramping for testing controller setpoints.

•Conforms to ITS-90 thermocouple & RTD tables.

•Dust proof, splash proof, drop proof construction.

•Built-in tilt stand/hanger for bench use or hands free field measurements.

•User friendly programming.

•Retains data and programming, even when turned off.

•Performs diagnostic tests and indicates fault conditions.

•Low battery and open sensor indications.

MANUAL ADDENDA

Improvements or changes to this manual will be explained on an addendum included with the

instrument. All change information should be incorporated immediately into the appropriate

places in the manual.

6

Page 9

UNPACKING AND INSPECTION

Remove the Packing List and verify that you have received all equipment. If you have any

questions about the shipment, please call the OMEGA Customer Service Department at 1-800622-2378 or (203) 359-1660.

When you receive the shipment, inspect the container and equipment for any signs of damage.

Note any evidence of rough handling in transit. Immediately report any damage to the shipping

agent.

NOTE: The carrier will not honor any claims unless all shipping material

is saved for their examination. After examining and removing contents, save

packing material and carton in the event reshipment is necessary.

Make sure that you have the following items in the packing box.

• 1 CL20 Series Calibrator and Holster

• 1 Operator’s Manual

• 1 NIST Certificate

• 1 Accessories Kit

SAFETY INFORMATION

SAFETY SYMBOLS AND TERMS

The symbol on the instrument denotes that the user should refer to the

The WARNING used in this manual explains dangers that could result in personal injury or

death.

The CAUTION used in this manual explains hazards that could damage the instrument .

operating instructions.

SAFETY PRECAUTIONS

WARNING

These instruments are intended for use by qualified person nel trained in the safe operation of electronic testing equip ment. Read the instruction manual thoroughly before using,

to become familiar with the instrument's operations and

capabilities.

7

Page 10

WARNING

Do not touch a temperature probe sheath when measuring excessively high or low

temperatures, or toxic substances.

WARNING

Do not attempt to measure temperatures beyond the range ofthe probe being used.

Probe damage or personal injury could result from exceeding a probe's maximum

temperature rating.

WARNING

The American National Standards Institute (ANSI) states that a shock hazard exists

when probes or sensors are exposed to voltage levels greater than 42VDC or 42V peak

AC. Do not use this instrument where v oltages at the measurement surface exceed

these levels.

WARNING

Do not substitute a metal part for the nylon screw in the rear case. Doing so will

degrade electrical isolation of the case.

WARNING

The battery is accessible through a cover on the back of the instrument. To avoid

electrical shock hazard, disconnect all temperature probes and sensors and turn the

unit off before removing the cover.

WARNING

Never use this instrument or any probe or sensor inside a microwave oven.

CAUTION

Avoid making sharp bends in probe or sensor lead wires. Bending lead wires at a sharp

angle can damage the wire causing probe failure.

8

Page 11

CAUTION

Keep inputs electrically isolated from outputs. Do not con nect an external voltage source between the two connectors,

and avoid any external electrical pathways between input

and output (T2 & T1).

Failure to do so will disturb meter readings and calibrator

output levels. Damage to the instrument is also possible.

Where the meter and calibrator connectors are simultane ously wired into a system lacking the above isolation, it is

necessary to use an "ungrounded" (i.e. electrically isolated)

probe at the thermometer input.

BATTERY INSTALLATION/REPLACEMENT

A 9V alkaline battery is supplied with the instrument but not installed. Read the following

installation instructions before attempting to install or remove the battery. Replacement

batteries should also be alkaline types.

WARNING

Turn the unit off and disconnect any input/output connec tions before replacing the batter y. Put the cover back into

place on the battery compartment before resuming use of

the instrument.

1. Remove the cover from the battery compartment by sliding it off in the direction of the arrow

located on the battery cover.

Figure 1. Battery Installation

9

Page 12

2. Remove the old battery.

3. Place the new battery in the battery compartment. Be sure to observe proper polarity.

4. Re-install the battery cover before resuming use of the instrument.

NOTES:

• Less than 10% of battery life remains when the BAT annunciator turns on.

• When the battery is excessively discharged, the display is blanked.

• If the instrument is going to be stored for a long period of time or in a high

temperature environment, remove the battery to prevent leakage damage.

• After a new battery is installed, allow approximately 5 seconds for

display turn-on the first time the unit is turned on. During this period,

microcomputer initialization is performed.

MEMORY BACKUP

During battery replacement, the contents of user-programmed memory (data, operating modes,

etc.) can be saved. Prior to removing the old battery, turn off the instrument, and connect an

HH22-AC battery charger. Then exchange batteries, and disconnect the battery charger. Do not

leave the battery charger connected to instruments with non-rechargeable batteries.

OPERATION WITH RECHARGEABLE

BATTERY

HH22-AC provides a 9-volt Ni-Cd battery and recharger suitable for use with the unit. This

battery provides 3-4 hours of continuous operation. This duration can be extended to several

days by operating simultaneously from both the battery and recharger.

Turn off the instrument to recharge the battery. Allow 7 hours to fully recharge the battery.

Then unplug the recharger to avoid overcharging.

10

Page 13

OPERATING INSTRUCTIONS

1. DIAGNOSTICS AND ERROR MESSAGES

Unit self-diagnostics provide fault condition readouts which are described below:

PROBLEM: LIKELY CAUSE:

Blank display, unit does not (1) Improper battery installation.

power-up. Check battery polarity.

(2) Dead battery.

BAT Annunciator. (1) Low battery voltage, install a new

battery. If problem persists, consult factory.

Display reads OPEN. (1) No thermocouple, RTD or thermistor is plugged

into the meter input.

Display reads E1 momentarily. (1) This indicates that an invalid key pad entry has been made. Review

keystroke sequence, or consult

manual for input instructions.

Display reads E2 momentarily. (1) Attempt made to activate non installed ramp function. NOTE:

RAMP Function enabled on

Models CL25 and CL27 only.

Display reads HI. (1) Meter-mode input-temperature

exceeds rating of selected sensor.

(2) Calibrator-mode keypad-entry

exceeds rating of sensor type.

Display reads LO. (1) Meter-mode input-temperature too

low for accurate measurement.

(2) Calibrator-mode keypad-entry too

low for accurate simulation.

2. INITIAL TURN ON

Turn on the instrument by depressing the ON-OFF keyswitch once (Figure 2). At power-up, the

unit first performs a display test. All segments and annunciators of the liquid crystal (LCD) are

momentarily turned on for visual confirmation by the user (Figure 3).

NOTE: In case of missing or poor-contrast segments, contact factory.

11

Page 14

Figure 2. Keypad

Figure 3. Display Test

If the unit is turning on for the first time after a new battery is installed, it will

automatically default to the METER mode (ie. temperature measurement operation). It also

defaults to K-type thermocouples, and °F readings with 0.1° resolution. The corresponding LCD

annunciators are enabled:

12

Page 15

METER: (unit functioning as a thermometer)

K: (K-type thermocouple)

°F: (Fahrenheit readings)

OPR: (Instrument is operational)

If no input thermocouple is connected to the unit at this time, the numeric

segments will indicate "OPEN".

Plugging a thermocouple into the meter jack (connector T2, on the top right

side) will give actual thermocouple temperature readings.

NOTE: To obtain full accuracy, allow 1-2 minutes after connect ing a thermocouple plug, for thermal setting.

If the instrument is to be used as a thermometer or ohmmeter, refer to the

Meter Mode Operation section for detailed instructions. For use as a tem perature-calibrator or ohms simulator, refer to Calibrator Mode Operation

3. METER MODE OPERATION (Thermocouples)

Set-Up:

1. Turn on instrument by depressing the ON/OFF key.

2. Check that the BAT annunciator turns off following the power-up LCD test.

If it does not turn off, less than 10% of battery remains. Refer to Battery

Installation/Replacement instructions.

3. If the meter is already in the METER mode, the METER annunciator will

be on. Otherwise the calibrator mode is enabled and the CALIB annunciator is on. Depress

the METER key to return to meter mode.

4. Connect an input thermocouple (TC) to connector T2. Select the appropriate TC Type with

the select-key. A display annunciator will indicate the selected TC-type.

NOTE: Space and legibility constraints on the display preclude the use of dedicated

annunciators for the less common Tungsten-Rhenium thermocouple types (G, C & D).

Instead, these types are annunciated momentarily on the alpha-numeric display when

first selected. Both T and R annunciators remain on to indicate a Tungsten-Rhenium

selection. To recall the actual G, C, D selection, turn the unit off, then on again for

another momentary readout.

5. Select temperature scale with °F/°C key. The corresponding annunciator is enabled.

13

Page 16

6. Select display resolution with 0.0.1 key.

NOTE: Set-up is retained during power-off.

Hold:

Meter readings can be put on hold at any time by depressing the HOLD key.

At this time, the HOLD annunciator turns on, the reading is frozen, and all keys (except ON/OFF

and HOLD) are locked out. Depress the HOLD key again to return to real-time readings, and reenable the keypad.

4. METER MODE OPERATION (RTD, Thermistor & Ohms)

Set-Up:

1. Connect a sensor or unknown resistance to the instrument as shown in Figures 4, 5, or 6.

The 2-wire configuration is simplest, but includes lead-wire resistance in the measurement.

2-wire measurements are generally limited to high resistance sensors (e.g. 1000-ohm RTDs,

2252-ohm thermistors).

(RTD, Thermistor, etc.)

Figure 4.2-Wire Resistance Measurement

Figure 5.3-Wire Resistance Measurement

14

Page 17

Figure 6.4-Wire Resistance Measurement

Lead resistance errors are compensated for in 3-wire configurations. However full

compensat ion require s equal resistan ce in each lead. This config uration is common

with 100-ohm RTDs.

In 4-wire configurations, accuracy is unaffected by lead resistance, and resistance

differences between leads.

NOTE: These instruments measure input voltages on all 4 terminals,

and are able to distinguish between 2-4 and 3-wire hookups. Switching

between these measurement modes is automatic.

2. Set instrument to METER mode.

3. Use the sensor-select key to set the instrument to the appropriate function and range.

NOTE: Due to limited display area, 100Ω and 1000Ω RTD’s are indicated on the

display by a momentary readout of “RTD-100” (or “RTD-1000”) when first selected.

Thermistors are identified by a momentary alpha-numeric readout of “Y-400” (signifying

YSI Series-400 typ e thermisto r ).

Any of these readouts can be recalled by turning the unit off and back on.

5. DATA LOGGING AND RECALL

Operating as a meter, the unit can save and recall up to 10 readings (each

with independent parameters: eg. °F/°C, TC-type and resolution) in random

access memory.

15

Page 18

To Save Readings:

1. While in the METER OPR mode, depress the STORE key. Note that the OPR annunciator is

replaced by STO.

2. Next depress one of the memory location numbers (keys 0, 1, ..., 9). The

corresponding memory annunciator turns on and the meter returns

momentarily to the OPR mode, displaying thermocouple temperature.

eg. STORE 7

NOTES:

• The enabled location annunciator indicates that the meter reading at the instant

that the location number key was hit, was stored in memory.

• When data is stored in a location already filed with data, the new data replaces

the old.

• Stored readings are retained during power-off.

To Recall Readings:

1. While in the METER OPR mode, readings stored earlier can be displayed

by first depressing the RECALL key. Note that the OPR annunciator is replaced by

RCL, and all memory location annunciators are blanked.

2. Next depress the keypad number corresponding to the desired location.

Note that the annunciator for this location turns on, and the memory contents are

displayed.

3. Several stored readings can be randomly recalled by a key sequence such as:

Figure 7.

16

Page 19

eg.RECALL 3

RECALL 5

RECALL 2

etc.

4. To return the meter to the operate mode, depress OPR after recalling the last reading. All

active location annunciators will turn on again, together with the OPR annunciator.

NOTE: Recalling data from unused (ie, empty) locations will give a zero reading.

To Erase Data Locations (Meter Mode):

1. Individual data locations can be erased by recalling the location to be cleared, followed

by a CLEAR key input. Note that the annunciator for the cleared location is turned off,

and the meter returns to OPR.

eg.RECALL 3

CLEAR

NOTES: There is no need to clear a location if new data is ready

for saving in this location. Just STORE the new data. It will write

over and delete the old.

6. CALIBRATOR MODE OPERATION (Thermocouples)

Set-Up:

1. Turn on the instrument by depressing the ON/OFF key.

2. Check that the BAT annunciator turns off after display check. If not, refer

to Battery Installation/Replacement instructions.

3. When operating as a calibrator, the display indicates CALIB. Should the

instrument be in the METER mode, hit the CALIB key to change to the calibrator function.

4. Select the thermocouple type that will be used.

NOTE: Space and legibility constraints on the display preclude

the use of dedicated annunciators for the less common tungsten rhenium thermocouple types (G, C, & D). Instead, these types are

annunciated momentarily on the alpha-numeric display when first

selected. Both T and R annunciators remain on to indicate a

Tungsten-Rhenium selection. To recall the actual G, C, D selection, turn

the unit off, then on again for another momentary readout.

5. Select the desired temperature scale (°F/°C key).

17

Page 20

6. Select the resolution desired (0.0.1 key).

NOTE: With 1° resolution, one less key stroke will be required to

enter calibrator output temperatures via the keypad.

7. The unit accepts numeric inputs by first changing the keypad to its number-entry mode

(NUM) by depressing the CHANGE/ENTER key once. The numeric display will flash, the OPR

annunciator will turn off, and the NUM annunciator will turn on. Key in desired temperature

value, most significant digit first. After the desired temperature value is keyed in, hit

CHANGE/ENTER to return to OPR mode.

To enter a value of 212° with 0.1° resolution, the following keystrokes are

used:

CHANGE/ENTER, 2, 1, 2, 0, CHANGE/ENTER

NOTES:

• Invalid numeric entries (eg. a temperature beyond the span of

the selected TC type) will cause a corresponding error code to

be displayed.

• To enter negative (ie. minus) temperatures, hit the -0 key first

when in the NUM mode. The first hit on this key enters the negative sign.

Subsequent hits enter zeros.

• To correct a numeric entry while in the NUM mode, hit the

CHANGE/ENTER key twice. This will return number entry to the beginning of a

new number.

• To return the calibrator output to 0° while in the OPR mode, hit the CLEAR key.

• The unit can be used as a convenient °F to °C or °C to °F calculator.

For example, to convert 77°F to a Celsius reading, go to the CALIB OPR

mode, enter the reading to be converted, and change scale.

eg.°F

CHANGE/ENTER

77

CHANGE/ENTER

°C (Display reads 25°C)

7. CALIBRATOR MODE OPERATION (RTD, Thermistor & Ohms)

Set-Up:

1. Connect measurement equipment under test (eg. RTD thermometer,

ohmmeter, etc.) to the instrument as shown in Figures 8, 9, or 10.

18

Page 21

19

Page 22

The same performance tradeoffs apply to 2, 3 and 4-wire simulations as

to 2, 3, and 4-wire measurements. Refer to RTD, Thermistor and Ohms

Meter-Mode section above for wiring guidelines.

2. Set instrument to CALIBRATOR mode.

3. Use the sensor-select key to set the instrument to the appropriate function and range.

NOTE: To ensure accurate calibrator outputs, observe specified

limits to excitation currents. If in doubt, check current levels with

a DMM in series with either source lead (1 or 3).

NOTE: Due to limited display area, 100Ω and 1000Ω RTD's are

indicated on the display by a momentary readout of "RTD-100"

(or "RTD-1000") when first selected.

Thermistors are identified by a momentary alpha-numeric readout

of "Y-400" (signifying YSI Series-400 type thermistor).

Any of these readouts can be recalled by turning the unit off and

back on.

8. STORAGE AND RECALL OF CALIBRATOR SETTINGS

While operating as a calibrator, the unit can store and recall up to 10 output

settings (each with independent parameters, eg. °F/°C, sensor type, and resolution) in random access memory.

To Store Outputs:

1. While in the CALIB OPR mode, depress the STORE key. Note that the

OPR annunciator is replaced by STO.

2. Next depress one of the memory location numbers (keys 0, 1, 2, .... 9).

The corresponding memory annunciator turns on, and the calibrator

returns to the OPR mode.

eg. STORE 2

NOTES:

• The enabled memory annunciator shows that the output set-up

has been saved.

• When a set up is stored in a location already in use, the new

set-up replaces the old.

• Saved set-ups are retained during power-off.

• To store a reading of 0° just hit the CLEAR while in the CALIB

OPR mode. Then depress STORE and a location number.

20

Page 23

To Recall Outputs:

1. While in the CALIB OPR mode, set-ups saved earlier in memory can be

recalled to program the calibrator output. First depress the RECALL key

to recall a set-up.

Note that the RCL annunciator turns on, OPR turns off, and all memory

locations annunciators are blanked.

2. Next hit the key with the number corresponding to the desired memory

location. The corresponding annunciator turns on, and the LCD updates

to show the new calibrator setting.

eg.RECALL 8

3. Several stored set-ups can be randomly recalled by a key sequence such as:

eg.RECALL 6

RECALL 3

RECALL 9

etc.

4. To return the unit to the CALIB OPR mode after recalling the last set-up,

hit the OPR key.

NOTES:

• Any other key except ON/OFF and CLEAR will also return the

OPR mode.

• Set-ups recalled from unused locations will display and output 0°.

• Calibrator set-ups can be recalled even when the unit is functioning in

the meter mode. The same 10 storage locations are shared in both

meter and calibrator modes.

• Readings stored in memory while operating as a METER, can

be recalled in the CALIB mode. In this unusual application, the

unit generates calibrator outputs that simulate earlier stored

meter inputs.

To Erase Set-Up Locations (Calibrator Mode):

1. Individual set-up locations can be erased by recalling the location followed

by a hit to the CLEAR key.

eg. RECALL 5

CLEAR

21

Page 24

9. STEP FUNCTION

When operating in the CALIBRATOR mode, the STEP key will sequentially

recall data stored in memory (up to 10 steps). At each step, the calibrator will

display and output these parameters. The STEP function is non-functional in

METER mode.

10. RAMP FUNCTION: CL25 and CL27

This feature allows the calibrator to automatically ramp up and down a userdefined staircase. Up and down keys allow for manual ramping by the user.

To activate the RAMP function, the instrument must first be in the CALI BRATE mode.

Depress the RAMP key once to enter the ramp programming mode. The display

reads "prog", with memory annunciators 1-4 flashing. A second hit to the RAMP key

starts automatic ramping. A third hit turns off the RAMP function.

User definable RAMP memory locations 1, 2, 3, & 4 are dedicated to storage

of RAMP parameters; step size, staircase starting point, upper limit, and

lower limit respectively. These memory locations are accessible only when in

RAMP “prog” mode, and are independent of the other 10 memory locations.

Numeric values for RAMP parameters can be set, stored, recalled, and

cleared like other calibrator settings. (Refer page 17, CALIBRATOR MODE

OPERATION).

When automatic ramping is in progress, a hit to either the 7 or 8 key activates

manual up-ramping or down-ramping respectively. Whenever the battery is

replaced (and memory backup is not performed), the ramp parameters

default to factory-set values:

LOC 1 Step Size =10°F (K TC)

2 Start Point = 500°F

3 High Limit = 550°F

4 Low Limit = 450°F

22

Page 25

SERVICE INFORMATION

WARNING

All service information is intended for qualified electronic mainte nance personnel only.

1. CALIBRATION PROCEDURES

This is a two-part procedure. Products with thermocouple functions only, follow the

Thermocouple Calibration procedure below. Products with resistance functions (RTD,

thermistor, ohms) follow first the Thermocouple Calibration procedure, then the Resistance

Calibration procedure.

A. THERMOCOUPLE CALIBRATION

Test Equipment Required:

1. Thermocouple simulator (OMEGA CL521, or equivalent) calibrated to ITS-90.

2. Microvolt DMM (OMEGA OM7551, or equivalent)

3. Calibration cables, per Figures 11, 12, 13.

NOTE: The copper constantan cables used in Figures 12 and 13

need to be calibrated. Voltage errors in these cables should be com pensated at the simulator.

4. Calibration cover (OMEGA 820-307-4).

Ambient Conditions:

Units should be calibrated at an ambient temperature of 23°C ±1°C, with relative humidity less

than 80%.

Preparation for Calibration:

1. Remove battery from unit under test (U.U.T.). Refer to Battery

Installation/Replacement section in the manual.

2. Remove bottom-cover from U.U.T. Refer to Disassembly Instructions.

3. Remove calibration-jumpers J1 and J2 from printed-circuit board.

NOTE: Removal of J1, J2 causes partial loss of previously stored

calibration data. Do not remove these jumpers unless recalibration

is intended.

23

Page 26

NOTE: For calibrators with the older, single-jumper configuration, refer to calibration

procedure beginning on page 39.

4. Install calibration cover in place of bottom-cover.

5. Re-install battery.

6. Hook up test-equipment, calibration cables, and U.U.T. per Figure 11.

7. Turn on DMM and TC simulator for warmup. Allow at least 30 minutes.

8. Set the DMM to 200mV DC range.

9. Set the TC simulator to its COPPER output mode, with a reference temperature of 32.0°F.

10. Turn on U.U.T. and verify that "RTD" and "Ω," annunciators are flashing

on the display. This verifies removal of J1 and J2 respectively.

NOTE: Flashing "RTD" indicates that zero-offset corrections can be stored in EEPROM.

It also indicates that cold-junction compensation is disabled.

Flashing 'Ω’ indicates that error corrections for the cold-juncti on

sensors can be stored or recalled from EEPROM.

11. Clear the EEPROM locations used to store E1 (meter cold-junction sensor error) and E2

(calibrator cold-junction sensor error) as follows:

a. Set U.U.T to CALIB, OPR, K, °F mode.

b. Key in: CHANGE/0.0/ENTER/STO/1/OPR (E1 is set to 0.0°F)

c. Key in: CHANGE/0.0/ENTER/STO/2/OPR (E2 is set to 0.0°F)

NOTE: Both 1 & 2 memory annunciators should be turned on,

but the "RTD" annunciator will have turned off.

d. Perform RECALL 1 and RECALL 2 to verify storage of 0.0°F in both

locations.

NOTE: At the completion of calibration, E1 and E2 will be saved

in EEPROM. Memory locations 1 and 2 will be free for normal use.

e. Set U.U.T. to METER, OPR, K, °F.

f. Turn U.U.T. OFF, then ON to re-enable 'RTD' and 'Ω,' annunciators.

24

Page 27

Calibration Adjustments:

NOTE: Do not deviate from the calibration adjustment sequence

that follows. This will ensure that adjustments to be stored in

EEPROM go to the correct locations.

1. Set meter-mode zero and gain adjustments per Table 1.

2. Hit OPR key (RTD annunciator turns off).

3. Set U.U.T. to CALIB, OPR, K, °F.

4. Turn U.U.T. OFF, then ON, to re-enable RTD & Ω, annunciators.

5. Set calibrator-mode zero and gain adjustments per Table 2. Hit

CHANGE and ENTER at the completion of each step in Table 2.

6. Hit OPR key (RTD annunciator turns off).

7. Install J1 jumper.

8. Set U.U.T. to METER, OPR, T, °F

9. Change TC simulator output to Type T, 32°F, ALLOY mode.

10. Reconfigure calibration set-up per Figure 12. Allow 2-3 minutes for thermal stabilization.

11. Calculate E1 as follows: E1 = U.U.T. Reading — 32.0.

12. Set U.U.T. to CALIB, OPR, T, °F mode.

13. Store E1; CHANGE/(E1 value)/ENTER/STO/1/OPR.

14. Go to METER mode, and verify U.U.T. reading of 32.0 ±0.1°F.

15. Reconfigure calibration setup per Figure 13. Leave simulator output at

32°F, Type T, ALLOY mode. Allow 2-3 minutes for thermal stabilization.

16. Set U.U.T. to CALIB mode, 32°F, Type T.

17. Calculate E2 as follows:

E2 = DMM Reading (in mV)

-22

(For example with DMM reading of +11mV, E2 = -0.5°F)

18. Store E2; CHANGE/(E2 value)/ENTER/STO/2/OPR.

19. Install J2 jumper.

20. Re-set U.U.T. output to 32°F, DMM reading should be 0±2mV.

21. Turn OFF U.U.T.

22. Thermocouple calibration is complete. Remove calibration cover. Reinstall original back cover, unless going on to Part B (Resistance Calibration).

25

Page 28

*exclusive of noise.

**on EC models, G replaced by L.Calibrate L per J.

26

27

Page 29

Page 30

B. RESISTANCE CALIBRATION

NOTE: Thermocouple and resistance calibrations are independent. However,

potentiometer P1 is used in both thermocouple and resistance calibrations to set

EEPROM constants. Follow calibration procedures carefully to ensure that

thermocouple and resistance calibrations do not disturb one another.

Test Equipment Required:

1. Resistance Decades (General Resistance RTD-100, RTD-500/1000, and

RDS-54, or equivalent).

2. Current Source (Fluke 5101B, or equivalent).

3. Digital Multimeter (OMEGA OM7551, or equivalent).

4. Calibration cables per Figure 14.

Ambient Conditions:

Unit should be calibrated at an ambient temperature of 23°C±1°C, with relative humidity less than 80%.

Preparation For Calibration:

1. Turn off unit, and remove bottom-cover. Refer to Disassembly Instructions.

2. Secure battery with a piece of adhesive tape.

NOTE: Momentary loss of battery power during the following calibration

will invalidate previous adjustments, both resistance and thermocouple.

3. Hook up test-equipment and unit per Figure 14.

4. Set current-source to 1mA, STANDBY mode.

5. Set DMM to 2V DC range.

6. Turn on unit.

7. Set unit to METER mode, RTD-100, °F.

8. Turn off unit. Remove jumper J1. Turn on unit. 'RTD' annunciator should

be flashing.

NOTES: Flashing 'RTD' indicates that calibration adjustments

will be written to memory. Avoid selecting thermocouple

functions while in this mode.

Should it be necessary to scroll through thermocouple

functions, first hit the OPR key (disables flashing 'RTD'),

and start again at Step 7 above.

28

Page 31

Figure 14. Resistance Calibration Setup

29

Page 32

Calibration Adjustments:

NOTE: Do not deviate from the calibration adjustment sequence

that follows. This will ensure that adjustments to be stored in

EEPROM go to the correct locations.

1. Perform meter-mode adjustments and verifications per Table 3 (use Table

5 for RTD-Thermistor models).

2. Hit OPR key (Flashing 'RTD' annunciator turns off).

3. Install J1 jumper.

4. Set unit to CALIB mode, RTD-100, °F.

5. Switch current source to OPERATE mode.

6. Perform calibrator-mode adjustments and verifications per Table 4 (use

Table 6 for RTD-Thermistor models).

7. Turn off unit. Remove tape holding battery.

8. Re-install back cover. Resistance-function calibration is complete.

Table 3: Calibration of Meter-Mode Resistance Functions

(RTD-100/1000)

* exclusive of noise.

** adjust as necessary to obtain steps 2,5.

30

Page 33

* exclusive of noise

31

Page 34

Table 6: Calibration of Calibrator-Mode Resistance Functions

(RTD-Thermistor)

*exclusive of noise

2. CALIBRATION VERIFICATION

Calibration is verified with the same instrument hookups as used for calibration (ie. Figures 12

and 13 for thermocouple functions, Figure 14 for resistance functions).

While one hookup serves to verify all resistance functions (RTD, thermistor,

ohms), a full check-out of thermocouple functions requires a set of calibration

cables for each thermocouple type.

To simplify the verification of thermocouple calibration, software has been

enhanced to reactivate the copper-mode used during calibration. This feature

is available on products that use the following (and later) software revisions:

32

Page 35

Model Software Revision

CL23A 6.7

CL24 7.7

CL25 3.7

CL26 5.6

CL27 4.16

(Software revision is marked on a label attached to integrated-circuit U1 on

the mother-board).

"Copper-mode" is a non-compensated mode of operation during which

cold-junction compensation of inputs and outputs is disabled. This permits

the use of copper-wire interconnections between instruments, while avoid ing the time and expense of multiple thermocouple-cable hookups. At the

conclusion of calibration verification, cold-junction compensation is re enabled, and operation returns to "alloy-mode".

"Alloy-mode" refers to Thermocouple operations; for example, a Type-K

thermocouple is made up of Nickel/Chromium and Nickel/Al uminum alloys.

Referring to the OMEGA Calibrator(s) in TC operation, "Alloy-mode" means

in effect "other than Copper-mode." In order to make accurate measure ments using a thermocouple device one must eliminate erroneous voltage

signals. In "Alloy-mode", the OMEGA calibrator automatically calculates the

cold-junction compensation for the selected TC type, based on the value(s)

from the ITS-90 table. This feature enables the user to make accurate tem perature measurements without making manual calculations for error cor rections.

COPPER MODE VERIFICATION PROCEDURE FOR THERMOCOUPLE

FUNCTIONS

Equipment Required:

1. OMEGA Model to be verified.

2. Voltmeter accurate to 1μV resolution.

3. Thermocouple simulator.

4. Cable assembly (Fig. 11).

1. Start your calibration with a fresh battery.

2. Press the ON function button to turn the unit on.

3. Select the calibrator mode ("CALIB" on display) by pressing the

CALIB/METER function button.

33

Page 36

4. Select type K thermocouple ("K" on display) by pressing the SENSOR

SELECT function button until type K is reached.

5. Select the tenth degree display (with a digit appearing after the decimal

point on the display) by pressing the 0.0.1 function button.

6. Select °F ("°F" on display) by pressing the °F °C function button.

7. Press the CHANGE function button. The numerical display should blink.

8. Press 9 9 9 9 9. ("9999.9" should appear blinking on display).

9. Press the ENTER function button. The display will blink "Hi" once or

twice, and then will display "0.0 °F" blinking. There will also be an "Ω"

symbol blinking in the upper left. It will blink with the "0.0 °F" display.

10. Press the ENTER function button. The "0.0 °F" display will stop blinking,

and the "Ω" will continue to blink. You are now in the copper mode. If or

when you turn off the power (or remove the battery) the unit will no longer

be in the copper mode and you would have to repeat the above steps to

return to the copper mode. As long as you see the "Ω" blinking you

are in the copper mode.

11. While in the copper mode attach the Copper Mode Calibrator Verification

Cable to the connector on the top of the CL25 that is labeled T1

other end of the cable to a precision voltmeter.

12. Press the CHANGE function button. The "0.0 °F" display will blink, and

"NUM" will appear on the display.

13. Press 3 2 0 buttons and then press the ENTER function button. "NUM"

will disappear and "32.0 °F" will appear, not blinking. The voltmeter

should read 0.000 mV.

14. Press the CHANGE function button. The "32.0 °F' display will blink, and

"NUM" will appear on the display.

15. Press 2 5 0 0 0 buttons and then press ENTER function button. "NUM"

will disappear and "2500.0 °F" will appear, not blinking. The voltmeter

should read 54.856 mV.

16. Press the CHANGE function button. The "2500.0 °F" display will blink,

and "NUM" will appear on the display.

17. Press 3 2 0 buttons and then press the ENTER function button. "NUM"

will disappear and "32.0 °F" will appear, not blinking. The voltmeter

should read 0.000 mV.

18. Press the SENSOR SELECT function button. The sensor type will

change to type J. The "K" will disappear from the display and a "J" will

appear on the display. The voltmeter should read 0.000 mV.

. Attach the

34

Page 37

19. Press the SENSOR SELECT function button. The sensor type will

change to type T. The "J" will disappear from the display and a "T" will

appear on the display. The voltmeter should read 0.000 mV.

20. Press the SENSOR SELECT function button. The sensor type will

change to type E. The "T" will disappear from the display and an "E" will

appear on the display. The voltmeter should read 0.000 mV.

21. Press the SENSOR SELECT function button. The sensor type will

change to type N. The "E" will disappear from the display and a "N" will

appear on the display. The voltmeter should read 0.000 mV.

22. Press the SENSOR SELECT function button. The sensor type will

change to type B. The "N" will disappear from the display and a "B" will

appear on the display. "LO" will also appear on the display.

23. Press the CHANGE function button. The "32.0 °F" display will blink, and

"NUM" will appear on the display.

24. Press 1 0 0 00 buttons and then press ENTER function button. "NUM"

will disappear and "1000.0 °F" will appear, not blinking. The voltmeter

should read 1.438 mV.

25. Press the SENSOR SELECT function button. The sensor type will

change to type R. The "B" will disappear from the display and a "R" will

appear on the display.

26. Press the CHANGE function button. The "1000.0 °F" display will blink,

and "NUM" will appear on the display.

27. Press 3 2 0 buttons and then press ENTER function button. "NUM" will

disappear and "32.0 °F" will appear, not blinking. The voltmeter should

read 0.000 mV.

28. Press the SENSOR SELECT function button. The sensor type will

change to type S. The "R" will disappear from the display and a "S" will

appear on the display. The voltmeter should read 0.000 mV.

29. Press the SENSOR SELECT function button. The sensor type will change

to type G. The "R" will disappear from the display and a "g" will appear

momentarily in the center of the display. "LO" will then appear in the center

of the display and both the "T" and "R" will appear along the top row of

the display.

30. Press the CHANGE function button. The "32.0 °F" display will blink, and

"NUM" will appear on the display.

31. Press 6 0 0 0 buttons and then press ENTER function button. "NUM" will dis appear and "600.0 °F" will appear, not blinking. The voltmeter should read

2.238 mV.

35

Page 38

32. Press the SENSOR SELECT function button. The sensor type will change

to type C. A "C" will appear momentarily in the center of the display.

"600.0" will then appear in the center of the display and both the "T" and

"R" will appear along the top row of the display.

33. Press the CHANGE function button. The "600.0 °F" display will blink, and

"NUM" will appear on the display.

34. Press 3 2 0 buttons and then press ENTER function button. "NUM" will dis-

appear and "32.0 °F" will appear, not blinking. The voltmeter should read

0.000 mV.

35. Press the SENSOR SELECT function button. The sensor type will change

to type D. A "d" will appear momentarily in the center of the display. "32.0"

will then appear in the center of the display and both the "T" and "R" will

appear along the top row of the display. The voltmeter should read 0.000 mV.

36. Press the SENSOR SELECT function button. The sensor type will change

to type K. The "T" and the "R" will disappear from the display and a "K" will

appear on the display. The voltmeter should read 0.000 mV.

37. Select the meter mode by pressing the CALIB/METER function button.

38. Output the voltages from table 1 into the U.U.T. from the thermocouple

simulator, changing the thermocouple type on the U.U.T. as noted in the

table. Observe the correct readings on the display of the U.U.T.

39. Select the calibrator mode by pressing the CALIB/METER function button and

type “K” thermocouple by pressing the sensor/select button. The voltmeter

should read 0.000mV.

40.Press the OFF function button. The unit will turn off.

41. Press the ON function button. The unit will power up and return to the cali-

brator mode. "CALIB" will appear on the display along with the "K" enunciator,

the "OPR" enunciator, and "32.0 °F" will be displayed. The blinking

"Ω" symbol will have completely disappeared indicating that you have exited

the copper mode.

42. Remove the Copper Mode Calibrator Verification Cable from both the volt-

meter and the OMEGA UUT.

43. The copper mode verification is now complete. Press the OFF function but-

ton to turn the unit off.

ALLOY MODE VERIFICATION PROCEDURE FOR THERMOCOUPLE

FUNCTIONS

Equipment Required:

1. OMEGA Model to be verified.

2. Precision temperature simulator / voltage source.

3. Voltmeter accurate to 1 uV resolution.

4. Cable assembly.

1. Start your calibration with a fresh battery.

2. Press the ON function button to turn the unit on.

36

Page 39

3. Select the calibrator mode ("CALIB" on display) by pressing the

CALIB/METER function button.

4. Select type K thermocouple ("K" on display) by pressing the SENSOR

SELECT function button until type K is reached.

5. Select the tenth degree display with a digit appearing after the decimal

point on the display) by pressing the 0.0.1 function button.

6. Select °F ("°F" on display) by pressing the °F °C function button.

7. Attach the Alloy Mode Calibrator Verification Cables per Fig. 13.

8. Press the CHANGE function button and the numerical display will blink

and "NUM" will appear on the display.

9. Press 3 2 0 buttons and then press the ENTER function button. "NUM"

will disappear and "32.0 °F" will appear, not blinking.

10. Adjust the Thermocouple Temperature Simulator to 32.0 °F.

Note: The reading on the voltmeter should read null. 0.000 mV. Adjusting

the U.U.T. to any temperature and adjusting the Temperature Simulator to

the same temperature should result in a null, or 0.000 mV on the volt meter.

11. Disconnect the cables from the equipment and UUT and reconfigure the set-up

per figure 12.

12. Select the meter mode by pressing the CALIB/METER function button on the

U.U.T. and ensure the U.U.T. is still set for °F and type “K” thermocouple.

13. Set the thermocouple simulator to type “K” and an output of 32.0°F. The

U.U.T. should read 32.0°F.

14. Set the thermocouple simulator to 2500°F. The U.U.T. should read 2500°F.

15. Set the thermocouple simulator to - 320°F. The U.U.T. should read -320°F.

16. Remove the Alloy Mode Calibrator Verification Cable from all equipment.

17. The Alloy Mode verification is now complete. Press the OFF function but-

ton to turn the unit off.

37

Page 40

38

Page 41

CALIBRATION PROCEDURES

Test Equipment Re quired:

1. Thermocouple simulator (OMEGA CL25, or equivalent).

2. Microvolt null-meter (Keithley 155, or equivalent)

3. Calibration cover (OMEGA 820-307-4).

4. Calibration cables, T.C. types K, J, T & E (as required) per Figure 1 below.

5. Low-thermal (eg. copper) shorting-link for null-meter.

NOTE: The (2) alloy-copper junctions in the calibration cables

can be either solder-joints (cleaned to remove flux), or crimp-con nections. Insulate each junction with heat-shrink tubing, then

wrap them close together in copper-foil to ensure that they main tain identical temperatures (ambient).

Ambient Conditio ns:

Units should be calibrated at an ambient temperature of 23°C ±1°C, with rel-

ative humidity less than 80%. Test equipment and the unit-under-test

(U.U.T.) should have 1 hour to reach thermal equilibrium with ambient-tem perature.

Calibration Adjus t ments:

1. Remove battery from unit under test (U.U.T.). Refer to Battery

Installation/Replacement instructions in the manual.

2. Remove bottom-cover from U.U.T. Refer to Disassembly Instructions.

3. Remove calibration-jumper J1 from printed-circuit board.

NOTE: When installed, J1 protects the contents of EEPROM

locations where zero-offset adjustments are stored. Once J1 is

removed, this data is erased when the U.U.T. is turned on.

4. Install calibration cover in place of bottom-cover.

5. Re-install battery.

6. Connect U.U.T. to test equipment per Figure 2 (page 43) using the K-type calibra-

tion cable.

7. Turn on U.U.T. and allow 2-3 minutes for thermal re-stabilization of the

TC mini-plug and input-jack.

NOTE: • U.U.T. will be in the Type K, °F meter-mode. The FUNC

annunciator is on, indicating that new constants will be

stored in EEPROM.

39

Page 42

• With J1 removed, the digital-filters in the U.U.T. are dis-

abled. This is to speed up U.U.T. response to calibra tion adjustments. In this mode ±0.1 °F of reading noise

is normal.

• Do not deviate from the calibration adjustment sequence

that follows. This will ensure that zero adjustments for each

TC type will be stored in the appropriate memory lo cations.

8. Apply 32°F (Type K) to U.U.T. Adjust potentiometer P1 for a reading of

32.0°F (exclusive of noise).

9. Apply 2500°F (Type K) to U.U.T. Adjust potentiometer P11 for a reading

of 2500.0°F.

NOTE: Adjustment steps 8 & 9 are interactive. Repeat these

steps as necessary to get the desired readings.

10. Hit OPR key to store K-meter zero-adjustment in EEPROM. Note that

"FUNC" annuciator turns off.

11. Select Type J thermocouple (KJT key on CL23A, SENSOR SELECT key

on CL24).

12. Turn off U.U.T.

13. Replace K calibration-cable with J calibration-cable.

14. Turn on U.U.T. Note that "FUNC" annunciator is on again. Allow 2-3 min-

utes for thermal restabilization.

15. Apply 32°F (Type J). Adjust P1 for a reading of 32.0°F (exclusive of

noise).

16. Hit OPR key to store J-meter zero-adjustment.

17. Select Type T thermocouple.

18. Turn off U.U.T.

19. Replace J calibration-cable with T calibration-cable.

20. Turn on U.U.T. Allow 2-3 minutes for thermal stabilization.

21. Apply 32°F (Type T). Adjust P1 for a reading of 32.0°F (exclusive of noise).

22. Hit OPR key to store T-meter zero-adjustment.

NOTE: Steps 23 thru 28 apply to Model CL24 only. For Model

CL23A, go to step 29 next.

40

Page 43

23. Select Type-E thermocouple.

24. Turn off U.U.T.

25. Replace T calibration-cable with E calibration-cable.

26. Turn on U.U.T. Allow 2-3 minutes for thermal stabilization.

27. Apply 32°F (Type E). Adjust P1 for a reading of 32.0°F (exclusive of

noise).

28. Hit OPR key to store E-meter zero-adjustment.

29. Select Type-K thermocouple.

30. Select CALIB mode.

31. Turn off U.U.T.

32. Connect U.U.T. to test-equipment per Figure 3 (page 43) using the K calibration-

cable.

33. Turn-on U.U.T. and allow 2-3 minutes, for thermal stabilization

34. Set both the U.U.T. and TC-simulator to output 32.0°F (Type K). Adjust

P2 for a null-meter reading of 0±3mv.

35. Set both the U.U.T. and T-simulator to output 2400°F (Type K). Adjust

P41 for a null-meter reading of 0±3mV.

NOTE: Steps 34 and 35 are interactive. Repeat each as neces-

sary to get the desired null readings.

36. Hit OPR key to store K-calib zero adjustment.

37. Select J thermocouple.

38. Turn off U.U.T.

39. Replace K calibration-cable with J calibration-cable.

40. Turn on U.U.T. Allow 2-3 minutes for thermal stabilization.

41. Set both the U.U.T. and TC-simulator to output 32.0°F (Type J). Adjust

P1 for a null-meter reading of 0±3mV.

42. Hit OPR Key to store J-calib zero adjustment.

43. Select Type-T thermocouple.

44. Turn off U.U.T.

41

Page 44

45. Replace J calibration-cable with T calibration-cable.

46. Turn on U.U.T. Allow 2-3 minutes for thermal stabilization.

47. Set both the U.U.T. and TC-simulator to output 32.0°F (Type T). Adjust

P1 for a null-meter reading of 0±3mV.

48. Hit OPR key to store T-calib zero adjustment.

NOTE: Steps 49 thru 54 apply to Model CL24 only. For Model

CL23A go next to ste p 55.

49. Select Type-E thermocouple.

50. Turn off U.U.T.

51. Replace T calibration-cable with E calibration-cable.

52. Turn on U.U.T. Allow 2-3 minutes for thermal stabilization.

53. Set both the U.U.T. and thermocouple-sim ulator to 32.0°F (Type E).

Adjust P1 for a null-meter reading of 0±3mV.

54. Hit OPR Key to store E-calib zero adjustment

55. Turn off U.U.T.

56. Remove calibration cover. Be careful not to disturb battery connections.

57. Re-install J1 jumper.

58. Re-install original back cover. Calibration is complete.

42

Page 45

NOTES

43

Page 46

NOTES

44

Page 47

Loading...

Loading...