Page 1

User’s Guide

Shop online at

omega.com

e-mail: info@omega.com

For latest product manuals:

omegamanual.info

IP710 SERIES

I/P Converters

Page 2

OMEGAnet®Online Service Internet e-mail

www.omega.com info@omega.com

Servicing North America:

USA: One Omega Drive, P.O. Box 4047

ISO 9001 Certified Stamford CT 06907-0047

TEL: (203) 359-1660 FAX: (203) 359-7700

e-mail: info@omega.com

Canada: 976 Bergar

Laval (Quebec) H7L 5A1, Canada

TEL: (514) 856-6928 FAX: (514) 856-6886

e-mail: info@omega.ca

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA

Customer Service: 1-800-622-2378 / 1-800-622-BEST

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN

TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA

Mexico: En Espan˜ ol: (001) 203-359-7803 e-mail: espanol@omega.com

FAX: (001) 203-359-7807 info@omega.com.mx

®

®

®

Servicing Europe:

Benelux: Postbus 8034, 1180 LA Amstelveen, The Netherlands

TEL: +31 (0)20 3472121 FAX: +31 (0)20 6434643

Toll Free in Benelux: 0800 0993344

e-mail: sales@omegaeng.nl

Czech Republic: Frystatska 184, 733 01 Karviná, Czech Republic

TEL: +420 (0)59 6311899 FAX: +420 (0)59 6311114

Toll Free: 0800-1-66342 e-mail: info@omegashop.cz

France: 11, rue Jacques Cartier, 78280 Guyancourt, France

TEL: +33 (0)1 61 37 29 00 FAX: +33 (0)1 30 57 54 27

Toll Free in France: 0800 466 342

e-mail: sales@omega.fr

Germany/Austria: Daimlerstrasse 26, D-75392 Deckenpfronn, Germany

TEL: +49 (0)7056 9398-0 FAX: +49 (0)7056 9398-29

Toll Free in Germany: 0800 639 7678

e-mail: info@omega.de

United Kingdom: One Omega Drive, River Bend T

ISO 9002 Cer

tified

Northbank, Irlam, Manchester

M44 5BD United Kingdom

TEL: +44 (0)161 777 661

ee in United Kingdom: 0800-488-488

oll Fr

T

e-mail: sales@omega.co.uk

1

echnology Centr

AX: +44 (0)161 777 6622

F

e

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI r

. OMEGA is constantly pursuing certification of its products to the European New Approach

apply

Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The infor

no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient-connected applications.

mation contained in this document is believed to be correct, but OMEGA Engineering, Inc. accepts

egulations that

Page 3

WARRANTY/DISCLAIMER

OMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a

period of

grace period to the normal

ensures that OMEGA’s customers receive maximum coverage on each product.

If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service

Department will issue an Authorized Return (AR) number immediately upon phone or written request.

Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no

charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits,

improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of

having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;

or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating

conditions outside of OMEGA’s control. Components which wear are not warranted, including but not

limited to contact points, fuses, and triacs.

OMEGA is pleased to offer suggestions on the use of its various products. However,

OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any

damages that result from the use of its products in accordance with information provided by

OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by it will be

as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, EXCEPT THAT OF TITLE,

AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF

LIABILITY: The r

OMEGA with respect to this order, whether based on contract, warranty, negligence,

indemnification, strict liability or otherwise, shall not exceed the purchase price of the

component upon which liability is based. In no event shall OMEGA be liable for

consequential, incidental or special damages.

CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic

Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical

applications or used on humans. Should any Product(s) be used in or with any nuclear installation or

activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility

as set forth in our basic WARRANTY/ DISCLAIMER language, and, additionally, purchaser will indemnify

OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the

Product(s) in such a manner.

13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month

one (1) year product warranty to cover handling and shipping time. This

emedies of purchaser set forth herein are exclusive, and the total liability of

RETURN REQUESTS/INQUIRIES

Direct all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE

RETURNING ANY PRODUCT(S) TO OMEGA, PURCHASER MUST OBT

(AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPARTMENT (IN ORDER TO AVOID

PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return

package and on any correspondence.

The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent

breakage in transit.

FOR

WARRANTY RETURNS, please have the

following information available BEFORE

contacting OMEGA:

1. Purchase Order number under which the product was PURCHASED,

Model and serial number of the pr

2.

oduct under

warranty, and

3. Repair instructions and/or specific problems

FOR NON-WARRANTY REPAIRS,

for current repair charges. Have the following

mation available BEFORE contacting OMEGA:

infor

chase Or

Pur

1.

of the repair,

2. Model and serial number of the product, and

3. Repair instructions and/or specific problems

relative to the product.

relative to the product.

OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our

customers the latest in technology and engineering.

ed trademark of OMEGA ENGINEERING, INC.

OMEGA is a r

© Copyright 2002 OMEGA ENGINEERING, INC. All rights reserved. This document may not be copied, photocopied, repro-

duced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior

written consent of OMEGA ENGINEERING, INC.

egister

AIN AN AUTHORIZED RETURN

consult OMEGA

der number to cover the COST

Page 4

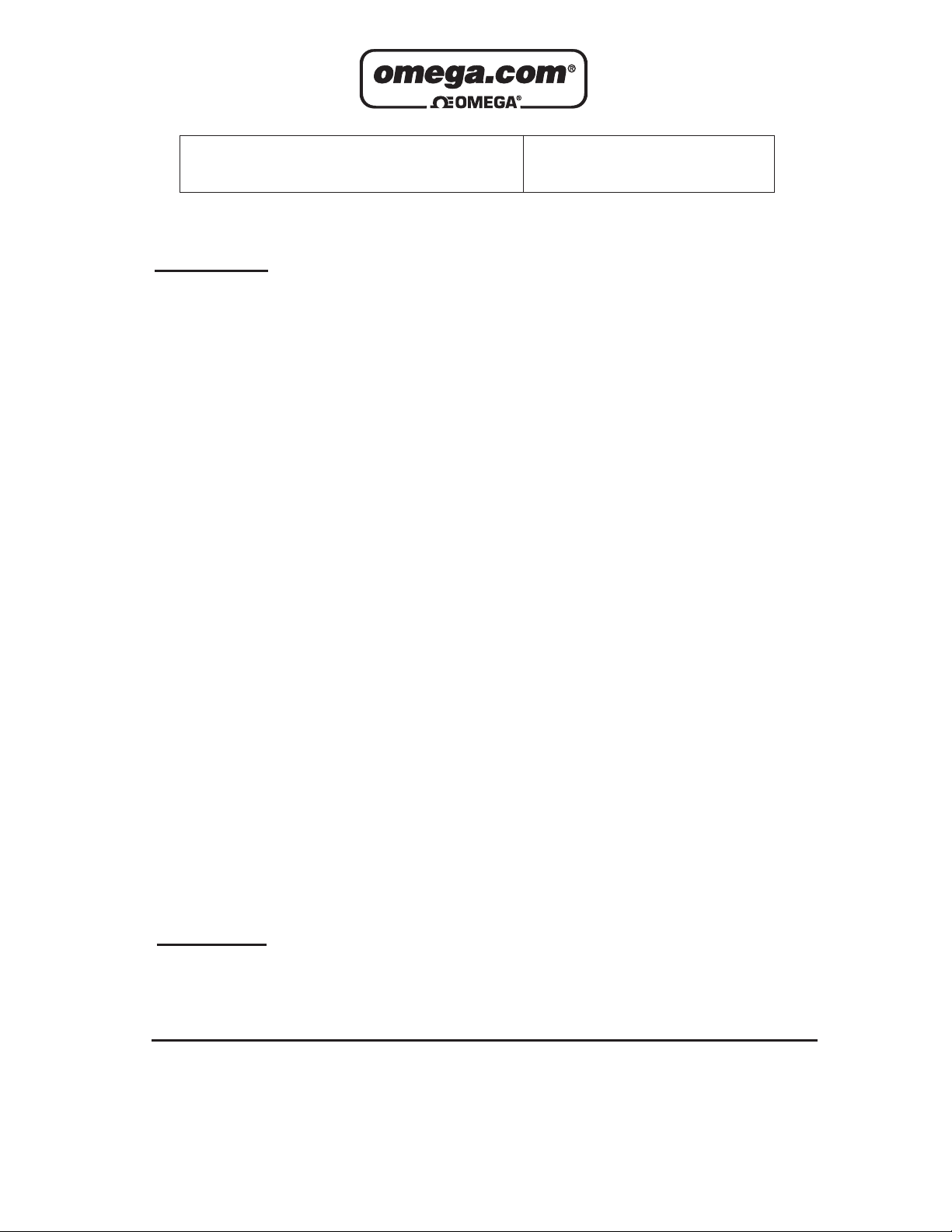

1

.00

25.4

2.94

74.7

1

2

3.69

93.7

2.18

55.4

.125

3.17

.500

12.7

1.80

45.7

1.30

33.0

1.50

38.1

Mounting Holes

#10–32 UNF–2B

X 3/8 Deep

2 Places

22 GA. wire leads

approx. 18" long

pos, neg, grd

In and out ports

1/4–20 NPT

4 places

1.13

28.7

3.12

79.2

.516

13.1

.383

9.72

.766

19.4

Vent

Back view typical of all units

NPT

IP710 SERIES

I/P Converters

Contents

Section Description Page

1.0 Description & Installation 3

2.0 Operation 6

3.0 Maintenance & Repairs 8

4.0 Troubleshooting 8

5.0

ning

ar

W

8

Page 1

Page 5

DANGER, WARNING, CAUTION and NOTE statements

DANGER

WARNING

CAUTION

NOTE

Refers to conditions or hazards which could result in serious personal injury or death.

Refers to conditions or hazards which could result in personal injury.

Refers to conditions or hazards which could result in equipment or property damage.

Alerts you to facts or special instructions.

ALL DANGER, WARNING, AND CAUTION NOTICES MUST BE COMPLIED WITH IN FULL

SPECIFICATIONS

Functional Specifications

Inputs

Outputs

psig 1-17 3-15 3-27 6-30 2- 60 2-100

(BAR) (0.07-1.2) (0.2-1.0) (0.2-1.8) (0.4-2.0) (0.14-4.0) (0.14-6.9)

Supply

Pressure

psig

(BAR)

Air Consumption

*Zero-based units have

slightly higher air consumption

Flow Capacity 4.5 scfm (7.6 m3/hr) at

Standard Range High Output Range

4-20 mA

22-60 20-100 32-100 35-100 65-100 105-130

(1.5-4.0) (1.4-6.9) (2.2-6.9) (2.4-6.9) (4.5-6.9) (7.2-9.0)

1.5 scfh (0.04 m3/hr) at

mid range typical

25 psig (1.7 BAR) supply

4.5 scfh (0.13 m3/hr) at

mid range typical

20.0 scfm (34.0 m3/hr) at

130 psig (9.0 BAR) supply

12.0 scfm (20.0 m3/hr) at

100 psig (7.0 BAR) supply

Temperature Limits Operating: -40º to +160 º F (-40º to +71º C)

Storage: -40º to +200º F (-40º to +93º C)

Loop Load,

I/P Transducer 9.5 VDC @ 20 mA

Performance Specifications

Accuracy, Hysteresis

and Repeatability ±0.10% of span guaranteed

Deadband 0.02% of span

Position Effect No measurable effect

Vibration Effect Less than ±1.0% of span under the following conditions:

5-15Hz @ 0.8 inches constant displacement 15-500Hz @ 10g s

Supply Pressure Effect No measurable effect

Temperature Effect ±0.045%/F (0.07%/C) of span

Reverse Polarity Effect No damage occurs fr om reversal of normal supply curr ent (4-20mA)

or from misapplication of up to 60mA

RFI/EMI Ef fect Pending

Physical Specifications

Port Sizes Pneumatic: 1/4” NPT

Media Clean, dry, oil-free air-filter ed to 40 micr on

Mounting Wall, panel, 2” pipe, or DIN rail (optional)

Materials Housing: Chromate-tr eated aluminum with baked paint, NEMA 4X (IP65)

Weight 13.0 oz. (0.4 kg)

Elastomers: Buna-N

Trim: Stainless steel; brass; zinc-plated steel

Page 2

Page 6

1. DESCRIPTION and INSTALLATION

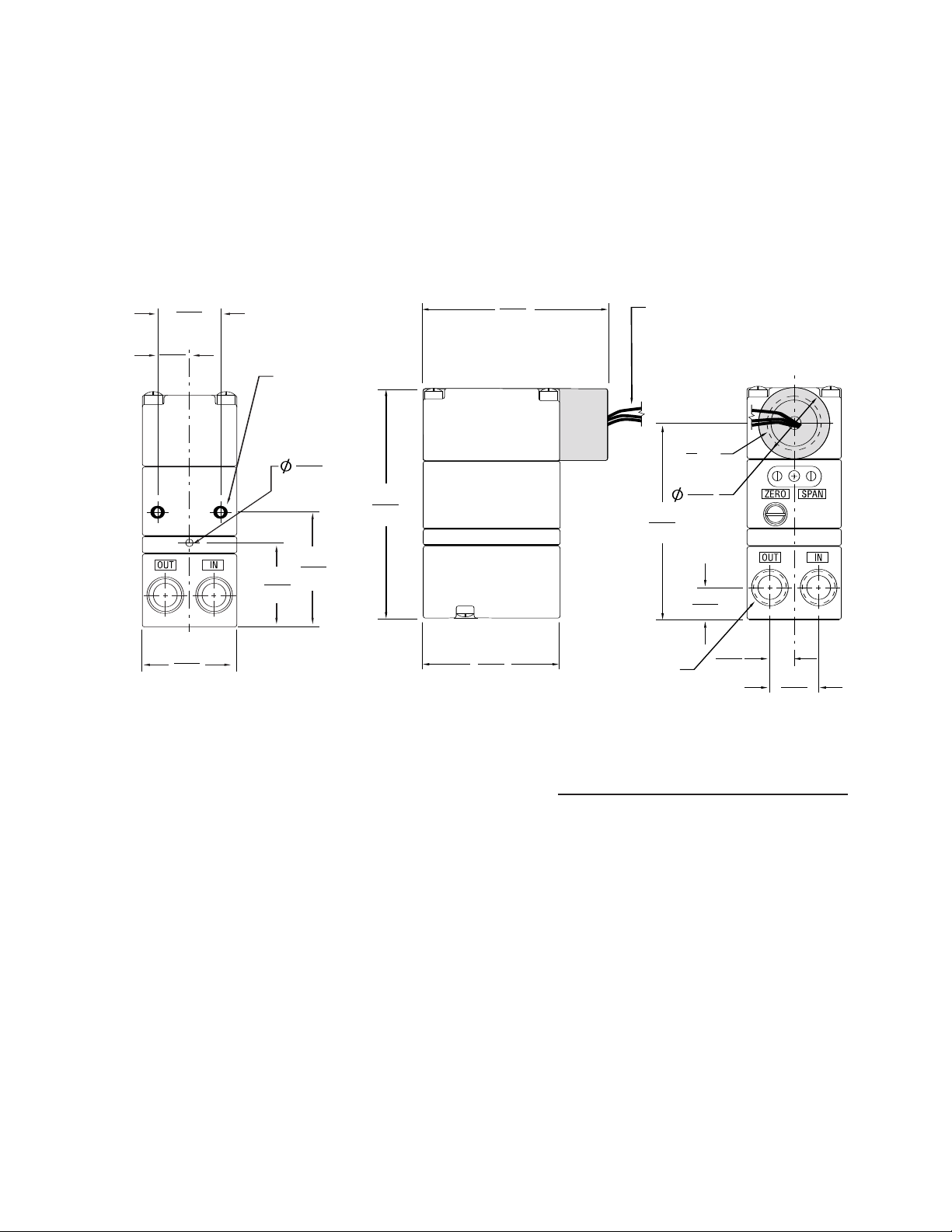

2.43

61.7

.312

7.92

1.50

38.1

.281

7.14

4.86

123.4

4.50

114.3

Mount using

(2) #1/4–20 screws

not included in kit

1.80

45.7

.312

7.92

1.50

38.1

2.25

57.2

3.36

85.3

Pipe clamp for

1–1/2 pipe

Standard bracket shown

with breakaway tabs removed

1.1 Description

1.1.1 The Omega IP710 converts a current input signal to a linearly proportional pneumatic output pressure. This unit

1.2 Principle of Operation

1.2.1 The IP710 transducer is a force balance device in which the piezo actuator is positioned in relation to a nozzle as the

1.3 Mounting

1.3.1 Each IP710 comes with a mounting kit which enables pipe, panel or wall mounting of the unit. An optional mount-

1.3.2 Panel: With access to rear of panel, attach transducer to panel using two 10-32 screws and the two threaded

utilizes a closed loop pressure feedback system that closely controls output and compensates for vibration,

mounting angle, temperature and supply pressure variations. The control mechanism is a piezoceramic actuator.

The unique properties of this actuator protect it against moisture and breakage associated with similar competi-

ive technologies.

t

input signal is varied. The application of an electrical signal causes axial movement of the actuator. The actuator

moves toward the nozzle and creates back pressure which acts as a pilot pressure to an integral booster relay.

ing kit is available for DIN-rail mountings. The IP710 may be mounted at any angle.

mounting holes on the back of the unit. With no access to the rear of a panel, attach bracket to transducer using

two 10-32 holes on the back of the unit and mount bracket to panel using four 10-32 screws (see figure 1).

Figure 1 - Standard Panel Mount

1.3.3 In- Line: Due to it’

1.3.4

11/2” Pipe: Attach bracket to transducer using two 10-32 holes on the back of unit. Place U-bolt around pipe and

through bracket. Place nuts on U-bolt and tighten (see figure 2).

Figure 2 - Standard 11/2” Pipe Mount

s light weight, the IP710 may be supported by the piping used for supply and output.

Page 3

Page 7

Figure 3 - DIN 43650 Connector DIN Rail mounting kit IP610-DM

1.40

1.29

3

.90

3

.08

1.68

42.7

.

61

1

5.5

D

IN Rail Kit suitable for EN-50035, EN-50045 and EN-50022 Rails

Green Lead (Ground)

Red Lead (+)

Black Lead (-)

1

2

3

1.4 Pneumatic Connections

1.4.1 Clean all pipe lines to remove dirt and scale before installation.

1.4.2 Supply air must be filtered to 40 microns and free of moisture and lubricants.

1.4.3 The 1/4” NPT inlet and outlet connections are labeled on the body. Plug all unused ports with pipe plugs supplied

with the unit. Avoid getting pipe sealant inside the piping or transducer.

1.5 Electrical Connections

1.5.1 Conduit Connection (current to pressure) Electrical connections are made to the red (+) and black (-) leads. The

green lead is furnished for case ground (see figure 4).

Figure 4

I/P Conduit Connection

Figure 5 - DIN 43650 Connector

Terminal I/P Connection

1 Positive (+)

2

3 Unused

Figure 6 - I/P Conduit Connection

Negative (-)

Ground (+)

Page 4

Page 8

1.6 Factory Mutual Research Corporation (FM)

IP710

Transducer

(Red)

+

(Black)

-

3

4

1

2

28V

Single

Channel

Polarized

4–20mA

OV

Rail

Type 1

System

Controller

IP710

Transducer

(

Red)

+

(Black)

-

3

4

1

2

28V

Two-

C

hannel

Polarized

4–20mA

4–20mA

OV

Rail

1-5V

Type 2

System

C

ontroller

Diode

IP710

Transducer

(Red)

+

(Black)

-

3

4

1

2

28V

Two-

Channel

Polarized

4–20mA

4–20mA

OV

Rail

1-5V

Type 3

System

Controller

10V

Hazardous

Location

Non-hazardous

Location

and Canadian Standards association (CSA)

ntrinsically Safe

I

Class I, II, III, Div. 1,

Groups C, D, E, F & G

Models IP710–*

Class I, Div. 1, Groups C & D

Models IP710–*

Factory Mutual and Canadian Standards Association I.S. Installation Drawing

uitable for:

S

Class I, Div. 2, Groups A, B, C & D

Models IP710–*

IP710–*

uitable for:

S

Class II & III, Div. 2, Groups F & G

Models IP710–*

*= Ouput pressure option does not

affect rating

Notes:

1. Control equipment connected to the Associated Apparatus must not use or generate more than 250 Vrms or Vdc.

2. The IS Barriers or Equipment (Associated Apparatus) must be FM Approved and CSA Certified and the

configuration of Associated Apparatus must be FM Approved and CSA Certified under the Entity Concept. The

Associated Apparatus may be installed within the Hazardous (Classified) location for which it is certified. The

Associated Apparatus and hazardous location loop apparatus manufacturer’s control drawings must be followed

when installing this equipment. An AEx [ib] Associated Apparatus is suitable only for connection to Class I, Zone

1, Hazardous (Classified) Locations and is not suitable for Class I, Zone 0, or Class I, Division 1 Hazardous

(Classified) Locations.

3. Installation should be in accordance with ANSI/ISA RP12.6 “Installation of Instrinsically Safe Systems for

Hazardous (Classified) Locations” and Article 500 of the National Electrical Code (ANSI/NFPA 70).

4. The standard conduit is suitable for Type 4X installations. All others must be mounted in a suitable enclosure.

5. The standard conduit is suitable for Class I, II and III, Division 2, Groups A, B, C, D, F & G hazardous (classified)

locations. Dust-tight conduit seal must be used when installed in Class II and Class III environments.

The connection option “D” is suitable for Class I, Division 2, Groups A, B, C and D hazardous (classified) locations.

Transducers to be installed in accordance with National Electrical Code (ANSI/NFPA 70) Division 2 hazardous

(classified) location wiring techniques.

6. The Instrinsic Safety Entity concept allows the interconnection of two FM Approved or CSA Certified intrinsically

safe devices with entity parameters not specifically examined in combination as a system when:

Ui or Vmax >Uo or V

oc or Vt > 7.2 volts

li or Imax > lo or lsc or It

Ca or Co > Ci + Ccable

La or Lo > Li + Lcable

Pi > Po.

7. No revision to this drawing is permitted without prior Factory Mutual Research Approval.

Entity Parameters for Models IP710–*

Ui (Vmax) = 30 V

Ii (Imax) = 125 mA

Pi = 0.7o watts

Ci = 0 uF

Li = 0 mH

Page 5

Page 9

2. OPERATION

Zero Adjustment Span Adjustment

2.1 Calibration

2.1.1 All units are shipped from the factory calibrated, direct acting.

.1.2 If the user requires a different mode of operation (i.e. reverse acting, split range) it is necessary to reposition inter-

2

2.1.3 It is not necessary to remove the cover of the unit for calibration if the direct acting mode is desired.

2.2 Direct Acting Calibration

.2.1 In direct acting operation the unit is calibrated so that minimum input signal corresponds to minimum output

2

2.2.2 Apply the minimum input signal of the range being used (e.g. 4mA for a 4-20mA unit) (see figure 6).

2.2.3 Observe the output pressure. If necessary, adjust the zero screw until reaching minimum output pressure setting.

2.2.4 Apply the maximum input signal of the range being used (e.g. 20mA for a 4-20mA unit).

2.2.5 Observe the output pressure. If necessary, adjust the span screw until reaching maximum output pressure setting.

2.2.6 After setting the span it will be necessary to recheck the zero. Repeat steps 1-4 until both end points are at

al electrical switches as indicated below. Though the units are factory calibrated for direct acting it is suggested

n

hat the user check the calibration.

t

pressure and increasing input signal results in increasing output pressure.

Turn zero screw clockwise to decrease and counter clockwise to increase.

Turn span screw clockwise to decrease and counter clockwise to increase.

required values.

Figure 6 - Zero Adjustment and Span Adjustment

Figure 7 - Direct Acting -

Standard setting as supplied by factory.

Signal

4-20 mA

Position of switches for forward acting operation (all output ranges).

Page 6

Page 10

2.3 Reverse Acting Calibration

2.3.1 When calibrated to operate in the reverse acting mode the minimum input signal produces the maximum output

pressure and increasing the input signal results in decreasing the output pressure. Setting the unit to operate in

the reverse acting mode is accomplished by positioning internal electrical switches.

CAUTION

2.3.2 Disconnect input signal and supply pressure. Take off the top cover by removing the four screws.

CAUTION

2.3.3 Position switches as illustrated in figure 8. Replace cover.

2.3.4 Set the input signal to the minimum valve being used. Turn the zero screw to set the maximum output pressure.

2.3.5 Set the span by applying the maximum input signal. Turn the span screw to set the minimum output pressure.

2.3.6 It may be necessary to repeat steps 2.3.4 – 2.3.5 until both end points are at desired values.

Figure 8 - Position of switches for Reverse Acting Operation

Note: Switches not shown match Direct Acting Settings (see figure 7).

Do not reverse the input leads.

Avoid touching circuit board. Shorting possible.

2.4 Split Range

2.4.1 When calibrated to operate in the split range mode, a full input signal (i.e. 4-20mA) will operate the unit

2.4.2 Disconnect input signal and supply pressure. Take off the top cover of the unit by removing the four screws.

at one half the normal output span (i.e. 3-9 psig, 9-15 psig). Setting the unit to operate in the split range

mode is accomplished by positioning internal electrical switches.

CAUTION

2.4.3 Position switches as illustrated in figure 9. Replace cover

2.4.4 After setting switches, refer to the appropriate calibration procedure (Direct Acting or Reverse Acting) to get to

desired output range (i.e. 3-9 psig, 9-15 psig).

Figure 9 - Position of switches for Split Range Operation

4-20 mA

Note: Switches not shown match Direct Acting Settings (see figure 7).

Avoid touching circuit board. Shorting possible.

Page 7

Page 11

3. MAINTENANCE AND REPAIRS

NOTE

nder normal circumstances, no maintenance should be required.

U

3.1 Cleaning

3.1.1 If clean, dry air is not used the orifice can become blocked. To clear, first turn off supply air, then remove the

3.1.2 Used compressed air to blow out any loose particles inside the orifice screw assembly.

screw located under the zero adjustment. The orifice is located between the two black o-rings. You may need a

magnifying glass to see it. Unplug the orifice by running a wire that has a smaller diameter than 0.012” (0.30mm)

hrough it.

t

3.2 Precautions

3.2.1 The bonnet should be removed only if a different operation mode is desired which requires a change in circuit

3.2.2 Never handle circuit board unless properly grounded to prevent ESD (Electro-static Discharge).

3.2.3 If ESD grounding equipment is not available, hold the IP710 by its castings and adjust switches using a non-con-

3.2.4 Never remove circuit board for any reason. This will shift other components and possibly damage the pressure

3.2.5 Use caution when replacing bonnet. If any resistance is felt, remove bonnet and determine the interference.

3.2.6 Clean, dry air should be used with the IP710. Foreign matter in the supply line can clog the orifice openings.

3.2.7 The electrical specifications as outlined in the IP710 instructions must be complied with. If more than one IP710

3.2.8 If difficulty is experienced during calibration or if turning the zero or span screw has no effect on the unit, a reset-

3.2.9 Reverse Acting Mode: For reverse acting units, the zero adjustment refers to the minimum electrical signal and

board switch settings. In this case, precautions are necessary.

ductive devise such as a pencil or a small rubber handled screwdriver.

sensor, both cases resulting in malfunction.

Typically it will be the strain relief grommet on the wires. The grommet should be oriented so it sits beside the

switches.

(.013” for a 3-15 psig unit, smaller for higher range units.) Foreign matter can also collect on the actuator causing

erratic operation. Moisture in the supply line can damage circuit board components.

mA unit is driven by the same PLC, there must be a minimum of 9.5 v DC available to each unit. For a IP710 voltage unit, there must be a constant supply voltage of 7-30 v DC applied to the red wire. The variable control voltage is applied to the orange wire.

ting technique can be taken. Turn both the zero and span screw a minimum of 30 revolutions in one direction.

Then turn both screws exactly 15 revolutions in the opposite direction. This procedure will put the potentiometers

at their midpoint of effective adjustability. Next, calibrate to desired settings starting with the zero screw.

maximum output pressure. The span refers to the maximum signal and the minimum output pressure. For calibration in reverse mode the resetting technique can be taken if necessary and calibration should always begin with

the zero screw.

4. TROUBLESHOOTING

PROBLEM CHECK SOLUTION

Sluggish performance Blocked orifice Clean orifice (3.1)

educed range Supply pressure Increase supply pressure (see specs)

or r

Leakage Connections Check seal at port

Low or impr

Erratic operation Moisture in air supply Use clean, dry air (see specs)

oper span Supply pr

Connections Check seal at port

Loose wires or connections Check wiring (1.5)

Dip switch settings Reset dip switches (2.2/2.3/2.4)

essure

Increase supply pressure (see specs)

5. WARNING

AILURE MODES:

F

pr

the supply por

tion, possibly causing physical damage, personal injury and/or property damage.

essur

e pr

This device must not be used for pr

esent at the supply por

t, then pressure relieving or pressure limiting devices must be employed to protect the devices from over pressuriza-

t. If devices connected to the output port have a pressure rating less than the pressure present at

otecting final contr

ol elements connected to the output por

om the ef

t fr

fect of

Page 8

Page 12

Where Do I Find Everything I Need for

Process Measurement and Control?

OMEGA…Of Course!

Shop online at www.omega.com

TEMPERATURE

MU

Thermocouple, RTD & Thermistor Probes, Connectors, Panels & Assemblies

MU

Wire: Thermocouple, RTD & Thermistor

MU

Calibrators & Ice Point References

MU

Recorders, Controllers & Process Monitors

MU

Infrared Pyrometers

PRESSURE, STRAIN AND FORCE

MU

Transducers & Strain Gages

MU

Load Cells & Pressure Gages

MU

Displacement Transducers

MU

Instrumentation & Accessories

FLOW/LEVEL

MU

Rotameters, Gas Mass Flowmeters & Flow Computers

MU

Air Velocity Indicators

MU

Turbine/Paddlewheel Systems

MU

Totalizers & Batch Controllers

pH/CONDUCTIVITY

MU

pH Electrodes, Testers & Accessories

MU

Benchtop/Laboratory Meters

MU

Controllers, Calibrators, Simulators & Pumps

MU

Industrial pH & Conductivity Equipment

DATA ACQUISITION

MU

Data Acquisition & Engineering Software

U

M

Communications-Based Acquisition Systems

MU

Plug-in Cards for Apple, IBM & Compatibles

MU

Datalogging Systems

MU

ders, Printers & Plotters

Recor

HEATERS

U

M

Heating Cable

MU

Cartridge & Strip Heaters

MU

Immersion & Band Heaters

MU

Flexible Heaters

MU

Laboratory Heaters

ENVIRONMENTAL

MONITORING AND CONTROL

MU

Metering & Control Instrumentation

MU

Refractometers

U

M

Pumps & Tubing

MU

Air, Soil & Water Monitors

MU

Industrial W

MU

pH, Conductivity & Dissolved Oxygen Instruments

ater & W

astewater T

eatment

r

P/N 541-622-081

M-4063/0307

Loading...

Loading...