Omcan Food Machinery TR 110 Installation Manual

MANUALE USO E MANUTENZIONE

OPERATING AND MAINTENANCE MANUAL

MODE D’EMPLOI ET MAINTENANCE

BEDIENUNGS- UND WARTUNGSHANDBUCH

MANUAL DE INSTRUCCIONES PARA USO Y MANUTENCION

MOD. TR 75/C - TR 95 - TR 110 - TRD 110 - TR 110 S - TRD 110 S

MANUALE USO E MANUTENZIONE

OPERATING AND MAINTENANCE MANUAL

Thank you for choosing this machine. We are sure that its performance will meet your requirements.

It is in your interest to keep the machine in perfect running order. In this handbook you will

find the necessary instructions on how to use and service it.

SAFETY STANDARDS

Throughout the manual this symbol indicates important information warning you of

any hazardous operation. Always read the

message that follows it.

GENERAL WARNINGS

This machine has been manufactured to make your work as safe as possible.

Caution is, nevertheless, the golden rule to follow to prevent accidents.

KNOWING YOUR MACHINE

Caution: Store this manual in a safe

place, near the machine, and disclose its storage location to all involved

personnel.

Do not put this manual away without having

first read it, regardless of any previous personal

experience. A little time spent in reading will

save time and extra work.

Read this handbook thoroughly before proceeding with start-up, use, maintenance and

other operations. Read and rigorously follow the herein contained instructions and

recommendations:

• read all warning labels applied to any part of the machine, and promptly replace them

when they become worn or illegible;

• only trained and authorised personnel should operate the machine;

• if any part jams or locks up, before clearing make sure you first switch off the motor. DO

NOT clean, oil or grease by hand any moving parts of the machine. In addition, all repair

and setting operations of any moving parts with the motor running, are prohibited, unless

the necessary precautions to prevent any accidents have been taken beforehand;

• all moving parts are fitted with adequate guards and protections. Always remount

them after removal for servicing.

EN G LI S H

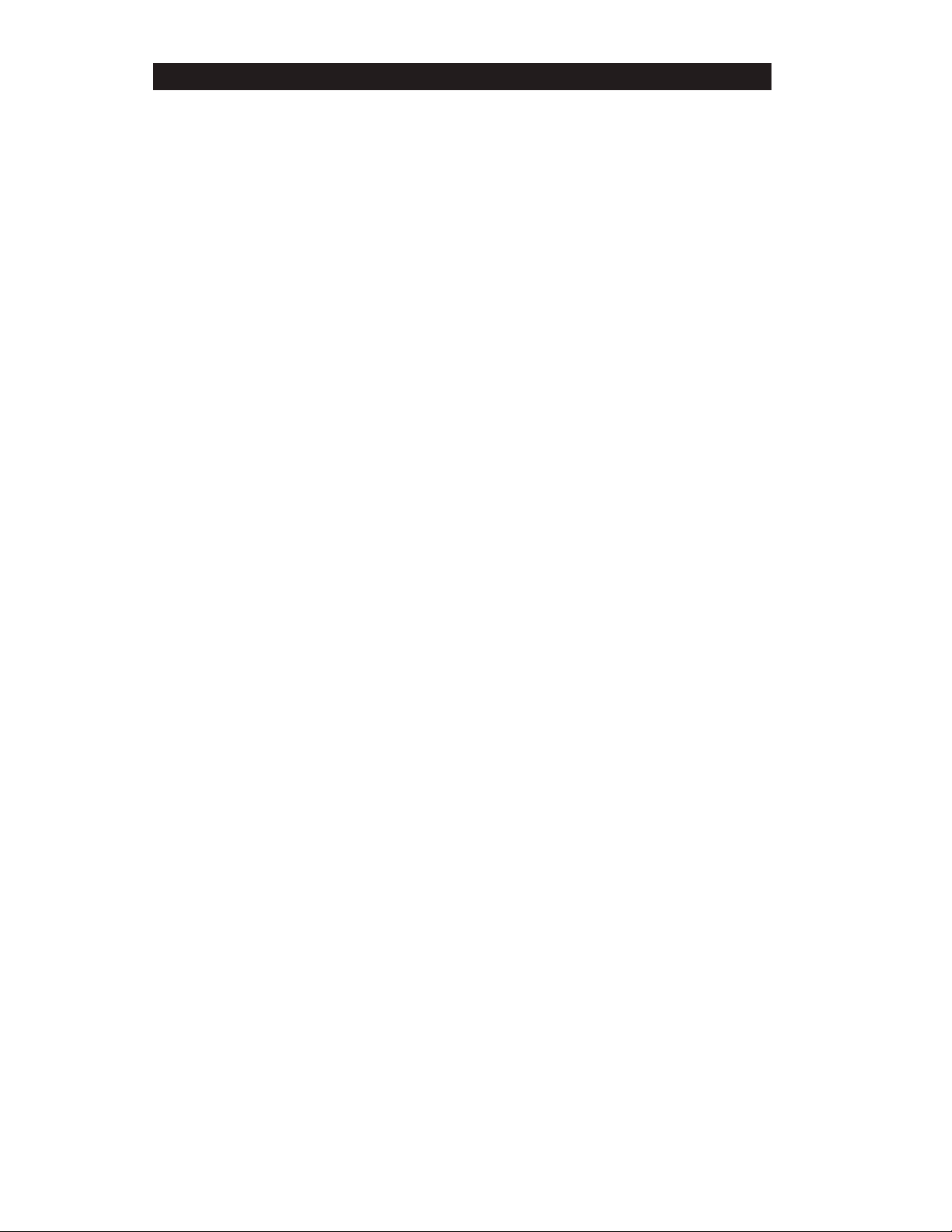

WEAR ADEQUATE CLOTHING

Be sure to wear tight-fitting clothing without any

loose parts. Never wear open or unfastened

jackets, shirts or overalls.

IMPORTANT

To prevent accidents and ensure best performance the machine must not be modified or altered unless authorised by the manufacturer. Nor must it be used in condi-

tions or for purposes other than those for which it has been expressly designed. Any

arbitrary modification implemented in this machine will automatically exempt the manufac-

turer from any liabilities for ensuing damage or injury.

This machine has been designed and engineered in conformity to European directives

89/392 EC, 91/368 EC, 93/44 EC and 93/68 EC.

BE SURE TO READ “IMPORTANT” MESSAGES

Information highlighted as “Important” in the Operator’s Manual and/or machine indicate

specific instructions about settings, maintenance and so on. Failure to comply with these

instructions may lead to damage to the machine.

ELECTRICAL SHOCK

For your own personal safety, before connecting the machine to mains:

• check that power mains leading to distribution socket is fitted with an appropriate multipolar

switch protected against overloads and shortcircuits.

• carry out all phase connections, as well as any neutral and ground connections (compul-

sory) with a standard plug compatible with the above mentioned socket. The protection lead

(ground) is the one with the yellow/green insulating sheath; make sure that the power supply cable is appropriate to its use, according to length, mains voltage and machine consumption.

• unless adequate protections against electrical shock are fitted, do not operate the machine

in damp or wet environments.

Strictly do not start up the machine without the protective panelling. This may jeopardise personnel safety and machine serviceability.

E N G L I S H

- SAFETY STANDARDS AND GENERAL WARNINGS page 26-27

- TECHNICAL SPECIFICATIONS page 30-31

- INSTRUCTIONS page 32

- 1. PREPARING THE MACHINE page 33

- 2. OPERATING PRINCIPLE page 33

- 3. USE OF THE MACHINE page 33

3.1 USEFUL ADVICE IN ORDER TO OBTAIN A GOOD DOUGH page 35

3.2 QUANTITIES IN ORDER TO OBTAIN A GOOD DOUGH page 36

3.3 INSTALLATION OF THE DRAWPLATE AND START-UP OF PRODUCTION page 37-38

3.4 VARIANT FOR MOD. TRD 110 S page 38

3.5 VARIANT FOR MOD. TRD 110 page 39

- 4. TRANSPORTATION AND HANDLING page 40-41

4.1 VARIANT FOR MOD. TR 110 S AND TRD 110 page 41

- 5. INSTALLATION, CONNECTION AND SET-UP page 42

5.1 CUTTING UNIT ASSEMBLY page 42-43

5.2 CONNECTION TO THE WATER SYSTEM page 43

5.3 VARIANT FOR MOD. TRD 110 S page 43

5.4 CONTROL OF THE INSTALLATION page 44

- 6. CLEANING page 45

6.1 LID AND POOL CLEANING page 46

6.2 CLEANING OF MIXER, ARCHIMEDEAN SCREW, METAL RING, FILTER,

DRAWPLATE AND KNIFE page 46

- 7. MAINTENANCE AND ADJUSTMENT page 47

7.1 BELT TIGHTENING page 47

- 8. MACHINE WHIRR page 48

- 9. STRIPPING-DOWN AND DEMOLISHING THE MACHINE page 48

- 10. PROBLEMS AND THEIR SOLUTIONS page 48

ANNEX A: DECLARATION OF COMPLIANCE.

ANNEX B: WIRING SYSTEM DIAGRAM FOR MACHINE SUPPLIED.

INDEX

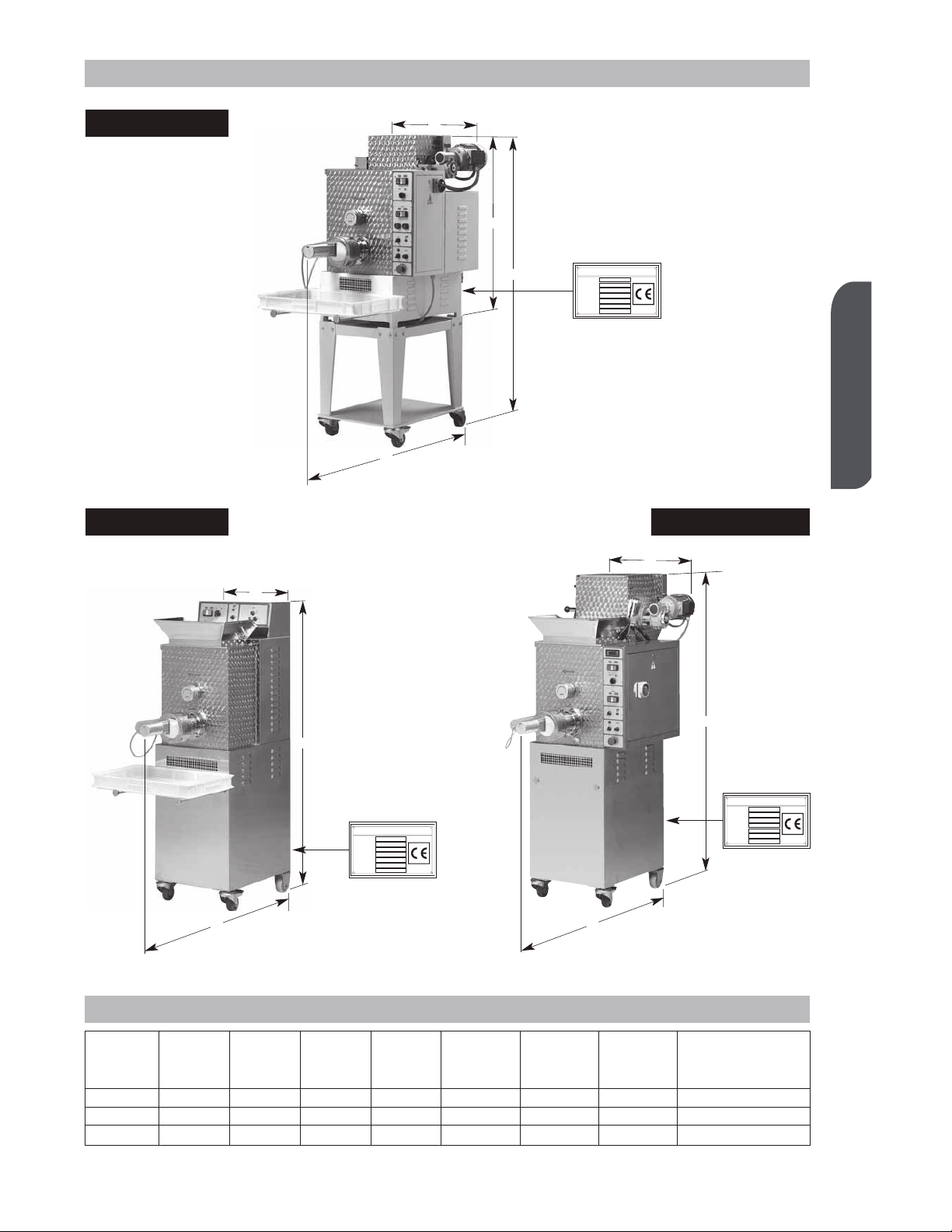

TECHNICAL SPECIFICATIONS OF MODELS

TR 75/C - TR 95 - TR 110

MOD. TR 75/C

MOD. TR 95 MOD. TR 110

MODELLO

N° DI SERIE

ANNO

VOLT

Hz

Kw

PESO

MADE IN ITALY

B

D

C

A

MODELLO

N° DI SERIE

ANNO

VOLT

Hz

Kw

PESO

MADE IN ITALY

B

D

C

A

MODELLO

N° DI SERIE

ANNO

VOLT

Hz

Kw

PESO

MADE IN ITALY

B

D

C

A

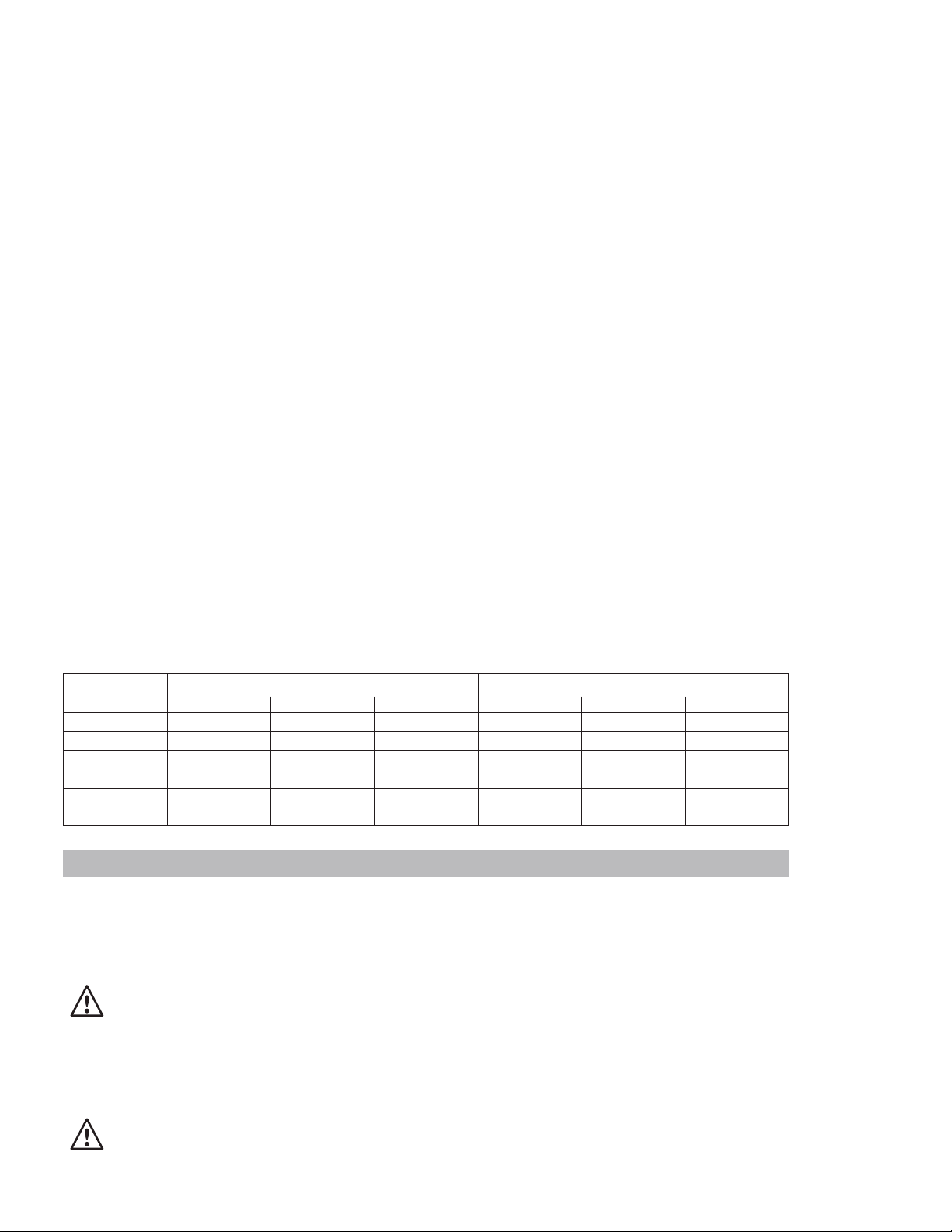

Model A B C D Kneading Mass Motor Maximum production

Length Width Height Height with capacity daN power per hour daN/h

trolley daN (based on the kind of

mm. mm. mm. mm. ≅kg. ≅kg. Kw drawplate used)

TR 75/C 750 320 725 1385 4 68 0.55 8

TR 95 900 380 880 1460 6 115 0.75 15

TR 110 930 460 895 1475 12 135 1.10 25

SPECIFICATIONS TABLE

Model A B C D Kneading Mass Motor Maximum production

Length Width Height Height with capacity daN power per hour daN/h

trolley daN (based on the kind of

mm. mm. mm. mm. ≅kg. ≅kg. Kw drawplate used)

TRD 110 1050 560 950 1520 12 + 8 200 1.10 + 0.55 40

TR 110 S 980 460 1500 – 12 175 1.80 50

TRD 110 S 1200 630 1650 – 12 + 12 220 1.80 + 0.55 60

EN G LI S H

MOD. TRD 110

MOD. TR 110 S

MOD. TRD 110 S

SPECIFICATIONS TABLE

TECHNICAL SPECIFICATIONS OF MODELS

TRD 110 - TR 110 S - TRD 110 S

MODELLO

N° DI SERIE

ANNO

VOLT

Hz

Kw

PESO

MADE IN ITALY

B

D

C

A

MODELLO

N° DI SERIE

ANNO

VOLT

Hz

Kw

PESO

MADE IN ITALY

B

C

A

MODELLO

N° DI SERIE

ANNO

VOLT

Hz

Kw

PESO

MADE IN ITALY

B

C

A

Model 3-phase standard power 1-phase optional power

230 50-60 Hz. 400 50-60 Hz. 415 50-60 Hz. 110 60 Hz. 230 50-60 Hz. 240 50 Hz.

TR 75/C

YES YES YES YES YES YES

TR 95

YES YES YES

/

YES YES

TR 110

YES YES YES

/

YES YES

TRD 110

YES YES YES

/ / /

TR 110 S

YES YES YES

/ / /

TRD 110 S

YES YES YES

/ / /

• The elements in contact with the noodles

are made of stainless steel or bronze for

foodstuffs.

• Moving parts mounted on ball bearings

with long-life sealing gaskets or with supports with greaser.

• Motor-powered; belt transmissions with

mainte n ance-free reduction g e a r and

mixer chain.

• Machine fitted with support toes with elastic caps and, on request, trolley with four

wheels, 2 of which fitted with a brake and

machine corner retaining rims.

• Connection by flameproof power cable

according to the supply voltage required,

standard length L = 3 m, without terminal

plug.

• Accessories supplied:

- pasta-collecting frame

- metal ring blocking key

- liquid measuring jar.

• Pasta cutting unit, fitted with a low voltage

operated motor and cutter.

• Fan for drying the pasta surface, to prevent product from sticking.

• Working elements with the ability of turning

in two directions: this enables the kneading of the initial dough, not yet ready,

without any damage to the drawing group.

• Iron parts are protected with stove-enamelled epoxy coating.

• Easy disassembling of the working parts;

the machine is freely accessible in order to

carry out thorough cleaning.

• The possibility of obtaining different products thanks to the change of the relevant

drawplate.

• Cooling unit with extrusion sleeve to ensure an ideal temperature and control of

parts in contact with the product, from

model TR 95 to model TRD 110 S, on

request only on model TR 75.

• Mod. TRD 110 and TRD 110 S: Machine

with twin dough preparation tank for continuous production. Independent controls

and inspection of the second tank.

NOODLES PRODUCING MACHINE

Produces different kinds of noodles and is basically made up of a

kneading part and an extrusion unit in order to cut the finished product

INSTRUCTIONS

The machine has been foreseen only for the preparation of cereal-based flour noodles

for noodle shops and catering facilities.

WARNING

For reasons of hygiene, health and warranty, it is strictly prohibited to use the

machine for the processing of substances other than foodstuffs. Any other uses

are contrary to the applications, as originally intended by the manufacturer, who shall

as a consequence, not be held liable for any damage to the machine itself or to other

objects, or for any injuries to persons that may arise thereof. In taking the risk of misuse, the user will be held responsible for any consequences.

Always keep children away from the machinery.

• Power:

Loading...

Loading...