Omcan Food Machinery TQ8A Installation Manual

CLEANING INSTRUCTIONS FOR TQ8A

Always turn the machine off before proceeding with its cleaning

power source and deactivate power on breaker panel.

The machine should be cleaned daily, both before and after its use. Given the easy access to all its

components, the cutter/chopper is simple to clean using just warm water and a mild detergent. Never use

bleach nor any abrasive cleaners which could damage the stainless steel or other materials.

Never use steam or a high pressure jet of water to clean the cutter/chopper; avoid getting water in the

interior of the machine, especially through or around any electrical components.

After every operating session, use a brush to carefully clean the bowl, the knife shaft, and the interior part of

the knife lid, the hinge of the lid, and the lid holding screws if necessary.

Do not put your hands near the cutting edge of the knives without using adequate protection (gloves made

of reinforced metal fiber).

The knife head can be removed in one piece in order to clean it under running water; take care not to drop

the knife head assemblage on the floor or on your feet.

Do not wash the knives in water hotter than 60°C or colder than 10°C. Do not wash the knives immediately

after using the machine since a brusque change in temperature could cause internal micro fissures or

deformations.

It is extremely important to keep the surfaces holding the knives and separation rings clean to avoid build-up

of mixture residues. Such a build-up could create areas which bear more pressure than others, possibly

causing micro fissures that could damage or break the knife.

To clean the machine manually, always use appropriate safety equipment (latex gloves, plastic aprons, etc.).

Always rinse the machine thoroughly after using any kind of detergent or disinfectant and be sure to follow

the manufacturers’ instructions when using cleaning products.

Required Tools

For superficial cleaning use a spatula

machine parts if necessary.

For extensive cleaning use a mild detergent with a soft tipped brush

sponge, the water temperature should be 40/50ºC (100/120º F)

To verify cleanliness of machine, check critical points and problematic parts.

Use food approved Disinfectants with a spray pump or sponge.

Allow all areas to air dry.

to remove all residues directly after use, removing smaller

. Disconnect the machine from the main

. Rinsing with warm water and a

TQ Series

We mainly produce food processing equipment, baking equipment, professional kitchen

equipment, steel kitchen ware, commercial refrigeration equipment and ice cream machine, more

than 6 series, 127 kinds of products for you to choose. They are environment-friendly with excellent

designs. High technique to save power, complete functions, easy to operate, RXU products

are more competitive than those of the same line in the international market.

Attention

z New user or repairing this product must be performed by the experts or qualified person or those

who have gotten the license of installation, or those who are authorized by the manufacturer.

z When installation or maintenance, please obey the following instructions carefully to ensure the

safety use of this appliance.

z Please keep this instruction Manual for future reference, or hand it to next user.

z Put off the package to make sure none of the parts is missing or damaged. If there is any doubt

about the product, please do not use it, and consult it to the experts.

z Keep the packing material out of reach of the children to avoid accident( Especially the plastic

bag, screw etc)

z This appliance could be only operated by the person who is familiar with the unit.

z When not using the appliance or the operator is absent, please turn off the unit to avoid any

accidental injury or damage.

z When it needs to be repaired, please ask for expert, and use the original fitted spare part. It will

be dangerous if not following the above requirements.

z This appliance is just for commercial using, not for any other use, otherwise, it may be

dangerous.

z Do not rinse the equipment with water directly.

z Clean the surface of stainless steel periodically with appropriate method to prevent any damage

brought by oxidization or any other chemical interference.

Description

The machine is driven through enclosed-gear. The machine is compact in construction, easy

operable, electricity saving and high in efficiency. It can cut up meat, vegetable and fruit to filling

quickly. It is good looking and safety. All parts in contact with food are made of stainless steel or

AL—alloy, all in conformity with hygiene standard. It is a ideal machine for food preparation in

hotels, restanrants, institutional kitchens and cateens.

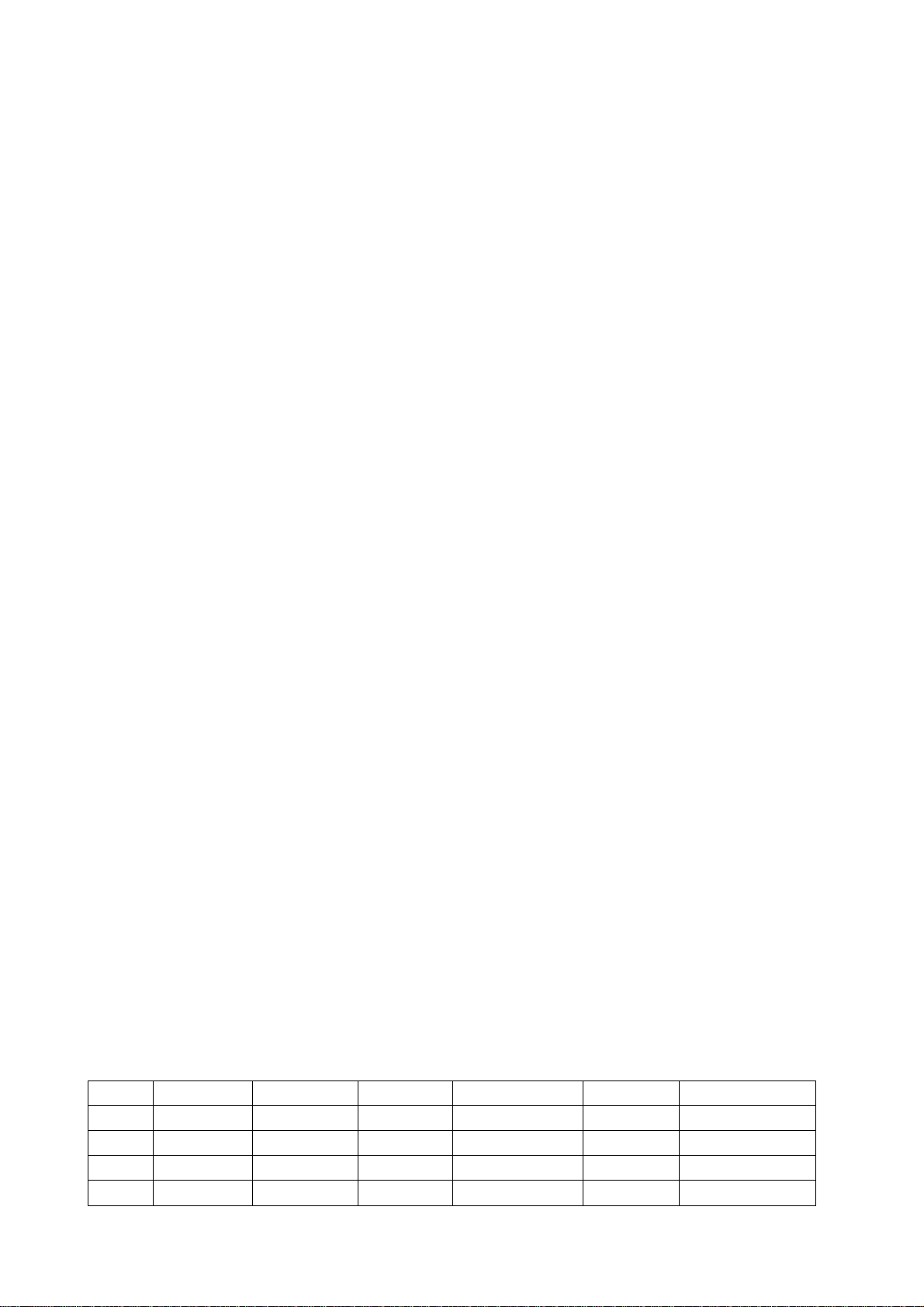

Technical specifications

Model Power(kW) Capacity (L) Voltage(V) Productivity(kg) Weight(kg) Dimensions(mm)

TQ5 0.37 5 110/220 120 62 530×420×540

TQ5A 0.37 5 110/220 120 62 530×420×540

TQ8 0.75 8 110/220 120 90 800×550×550

TQ8A 0.75 8 110/220 120 90 800×550×550

Loading...

Loading...