Omcan Food Machinery SS-ES-0015-PA Installation Manual

Sausage Stuffers

Talsa Stuffers

Instruction Manual

Revised - 9/4/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model SS-ES-0015-PA / Model SS-ES-0015-PAM / Model SS-ES-0020-PA

Model SS-ES-0020-PAM / Model SS-ES-0026-PA / Model SS-ES-0026-PAM

Model SS-ES-0026-PAS / Model SS-ES-0026-PASM / Model SS-ES-0031-PAS

Model SS-ES-0031-PASM / Model SS-ES-0042-PAS / Model SS-ES-0042-PASM

Model SS-ES-0052-PAS / Model SS-ES-0052-PASM

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

----------------------------------------------------------------------------------------------------- 8 - 9

----------------------------------------------------------------------------------------------------- 9 - 11

----------------------------------------------------------------------------------------------- 11 - 15

--------------------------------------------------------------------------------------------- 3

---------------------------------------------------------------------------------------- 3 - 5

------------------------------------------------------------------------------------------------- 16

Page

------------------------------------------------------------------------------------ 5 - 7

Parts Breakdowns

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------------- 22

---------------------------------------------------------------------------------------- 17 - 19

------------------------------------------------------------------------------------ 20 - 21

----------------------------------------------------------------------------------------- 23

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

or oil leak, please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours,

so we may initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine

must be lled out within three days, from the delivery date shown in the shipping documents. Omcan has no

recourse for damaged products that were shipped collect or third party.

Safety and Warranty

This machine has moving mechanical parts and uses voltages that are potentially hazardous. Severe, even

life-threatening, personal injury could result if the instructions contained in this manual are not followed.

Before operating the unit, please read this manual thoroughly. This manual should be kept for future reference

and given to every user of the machine. The following clauses limit the liability of the manufacturer and its

representatives:

• This machine should only be installed by a qualied electrician. Once installed, do not tamper with the

electrical wiring or components of the machine.

• Do not use the machine without having received previous instructions about its use, maintenance and

safety devices from an experienced operator.

• Read the instruction manual carefully before using the machine.

• Do not use the machine without the personal safety equipment required by law.

• Do not tamper with the xed guards, the safety interlock electrical switches or any other safety devices.

• Always keep hands at a safe distance from the moving parts of the machine.

• Do not leave machine unattended while switched on or in operation.

• Always disconnect the power supply before removing shrouds, removable guards, covers, doors, fences,

panels, etc. for servicing, cleaning, or repairs.

• Do not open the machine or tamper with its internal parts. There are no internal components that require

adjustment or maintenance on the part of the user.

• Should the machine malfunction, turn it off immediately and notify the supervisor.

• Installation must be in accordance with the operating instructions and with local and state hygiene

standards and safety codes. Compliance with codes is the responsibility of the Owner and Installer.

3

Safety and Warranty

• Before operating the machine, make sure that it is properly grounded and/or connected to a circuit leakage

breaker and thermal switch. Failure to do so could result in electric shock.

• Make sure the safety signs and stickers are rmly afxed to the machine, that they are legible, and that

they have not been blurred or erased after the machine is cleaned. If they become damaged or lost, ask

your dealer for new ones and replace them.

• Keep your work area well lit and free of obstacles.

• When operating the machine never wear loose clothing or jewelry that could get caught in the moving

parts.

• Disconnect power.

• Keep children and on-lookers at a safe distance.

• Do not pull on the cord to remove the electrical plug from the socket.

• To avoid damaging the electrical cord, keep it out of areas where it can be stepped on.

• Do not alter or modify the machine’s original design in any way.

• Should the machine need repairs, consult the ofcial dealer where the machine was purchased.

• Use only genuine TALSA parts and accessories and have them properly installed by a qualied technician.

• This machine has been designed exclusively for meat processing. Any other use of this machine is not

in accordance with its intended application. The manufacturer assumes no responsibility for any possible

damage or injury resulting from improper use of this machine.

Additional operating instruction manuals are available from your dealer. Your local dealer will be happy to

answer any further questions you may have.

LIST OF POSSIBLE OPERATING HAZARDS

Read and review thoroughly the following operating hazards.

MECHANICAL HAZARDS

• Crushing hands, ngers etc. on the barrel when closing the lid.

• Crushing hands, ngers etc. between the lid and the piston while the latter is being raised, especially when

the lid is not completely open.

• Crushing hands, ngers etc. between the piston and the upper part of the base during the dismantling of

the removable barrel on E models.

• Personal injury should the machine tip over if it is raised too high while being moved (since the llers are on

wheels, this is an important hazard).

• Foot injuries should the piston fall during dismantling or cleaning.

ELECTRICAL HAZARDS

• Electric shock due to direct or indirect contact with electrical current.

• Electric shock due to defective electrical parts.

NOISE HAZARDS

• Hearing damage should any modication of the machine’s original design raise noise emission levels

above 85 dB(A).

4

Safety and Warranty

PERSONAL HEALTH HAZARDS

• Changes in the nature of the food mixture if hygiene and cleaning instructions have not been followed.

1 YEAR WARRANTY

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

5

Technical Specications

GENERAL INFORMATION

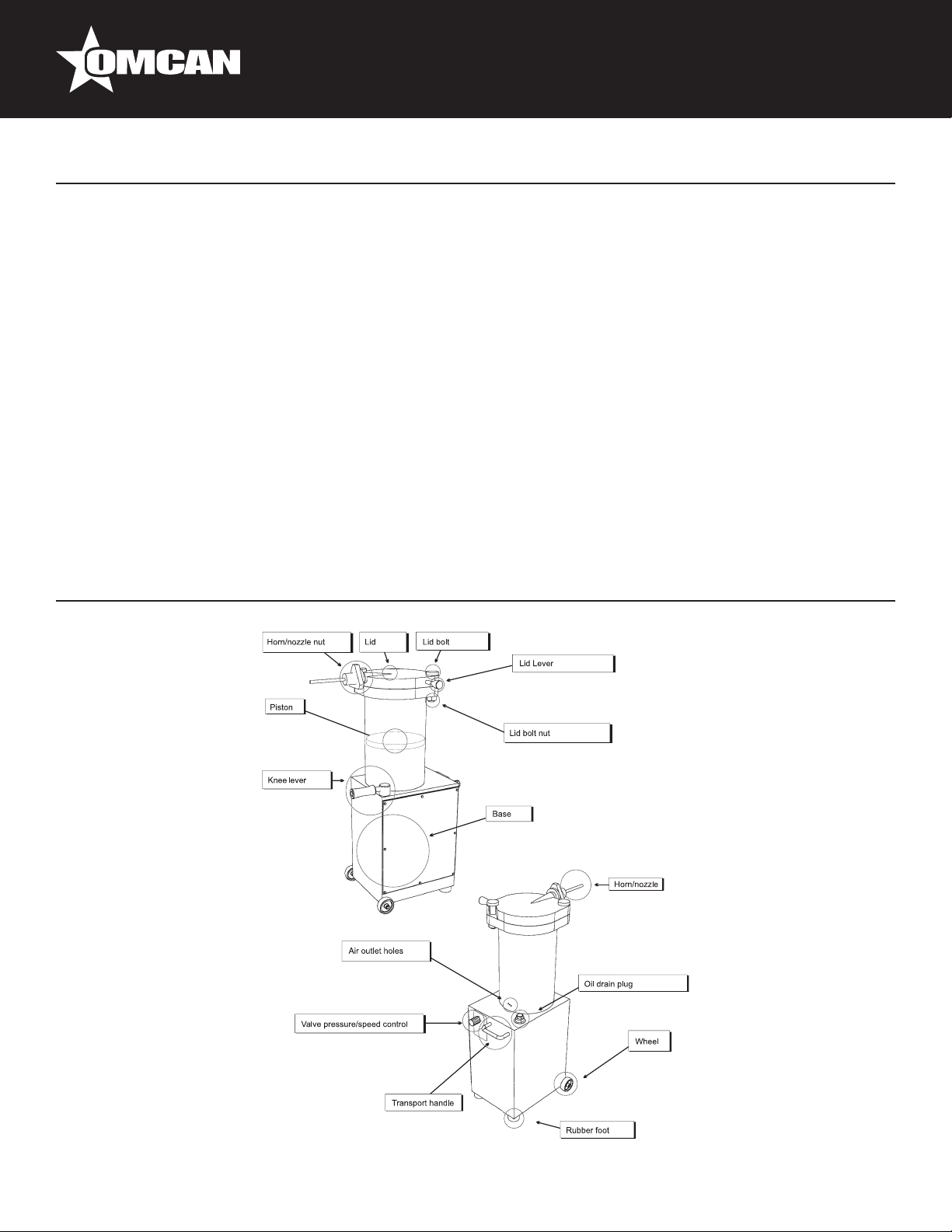

The H hydraulic piston llers/stuffers combine technology, superior materials, and high engineering standards

along with practical applications to provide quick and simple operation, as well as ease of maintenance.

• Totally enclosed hydraulic oil reservoir. Equipped with two plastic anti-vibration legs, as well as two noncastor wheels and a handle to make moving the machine easier.

• TALSA Fillers are noted for having a totally rectied barrel (P models with xed barrel) and allowing for

simple dismantling and cleaning (E models with removable barrel).

• Start and stop the motor either manually by switch (I models) or automatically via contactor (A models). In

the A models, the machine uses electricity only when the knee lever is pressed. This results in savings on

electricity and less wear and tear on the machine’s components. It also allows for quieter operation, since

the motor-pump is not in constant use.

• Release of the knee lever causes piston decompression and instantly stops the product ow, regardless of

nozzle size or product density.

• The specially reinforced pressure system allows for easy processing of even the densest and coldest

sausage mixtures; machine equipped with pressure gauge (P models).

• Speed control knob situated near the operator for quick and precise adjustment.

• Operation via ergonomically positioned knee lever allows the operator to keep both hands free. The piston

is lowered by reversing the knee lever control.

• Automatic lid lock with adjustable pressure closing (P models) precludes the need for ywheels.

• The piston, which can be removed easily, has two gaskets to prevent the mixture from escaping between

the joints (except H42/H52 models). The machines have been designed to allow for quick access to all

components, thus enabling easy cleaning and maintenance.

• Appropriate for all kinds of natural or articial casings.

• Made to CE and USDA standards.

• Waterproof internal electric box (models A).

ACCESSORIES included: Three nozzles ø12, 20, 30 mm. Spanner and piston extraction screw. Spare lid

gasket. Horn holding nut. Oil. Instruction manual.

OPTIONS: H26 stainless steel lid, piston and nut (H26S model). Single phase. Portioning device PH500.

Curved nozzle valve. Special diameter or length nozzles (table 6.2 below).

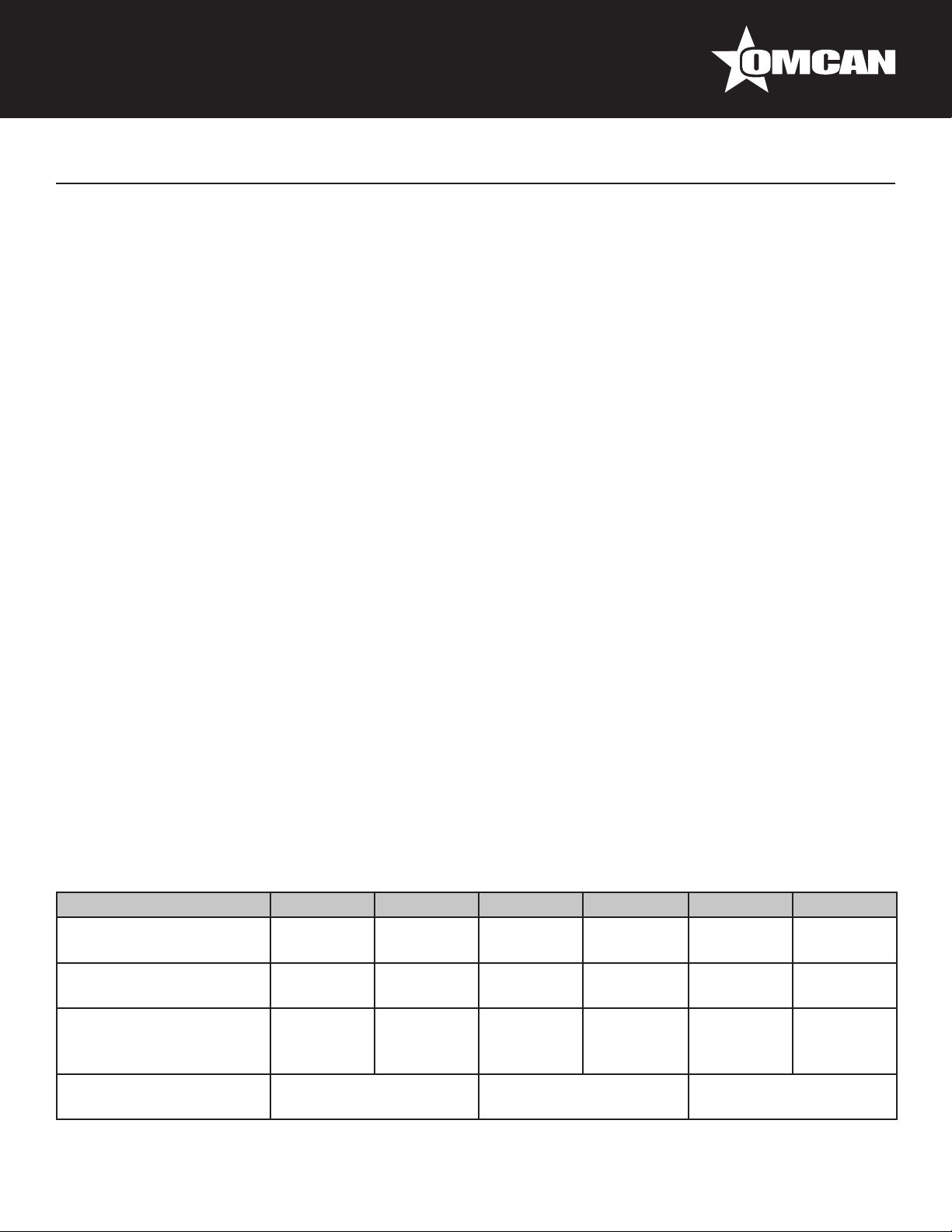

Model 0015 0020 0026 0031 0042 0052

Mixture barrel capacity

in liters

Mixture barrel capacity

in kg of meat (approx)

Barrel capacity in

pounds of meat

(approximate)

Hydraulic oil tank

capacity (liters)

14.9 19.9 25.6 30.8 41.5 51.6

±12 ±16 ±22 ±28 ±36 ±44

±26 ±35 ±48 ±62 ±79 ±96

10 15 25

6

Technical Specications

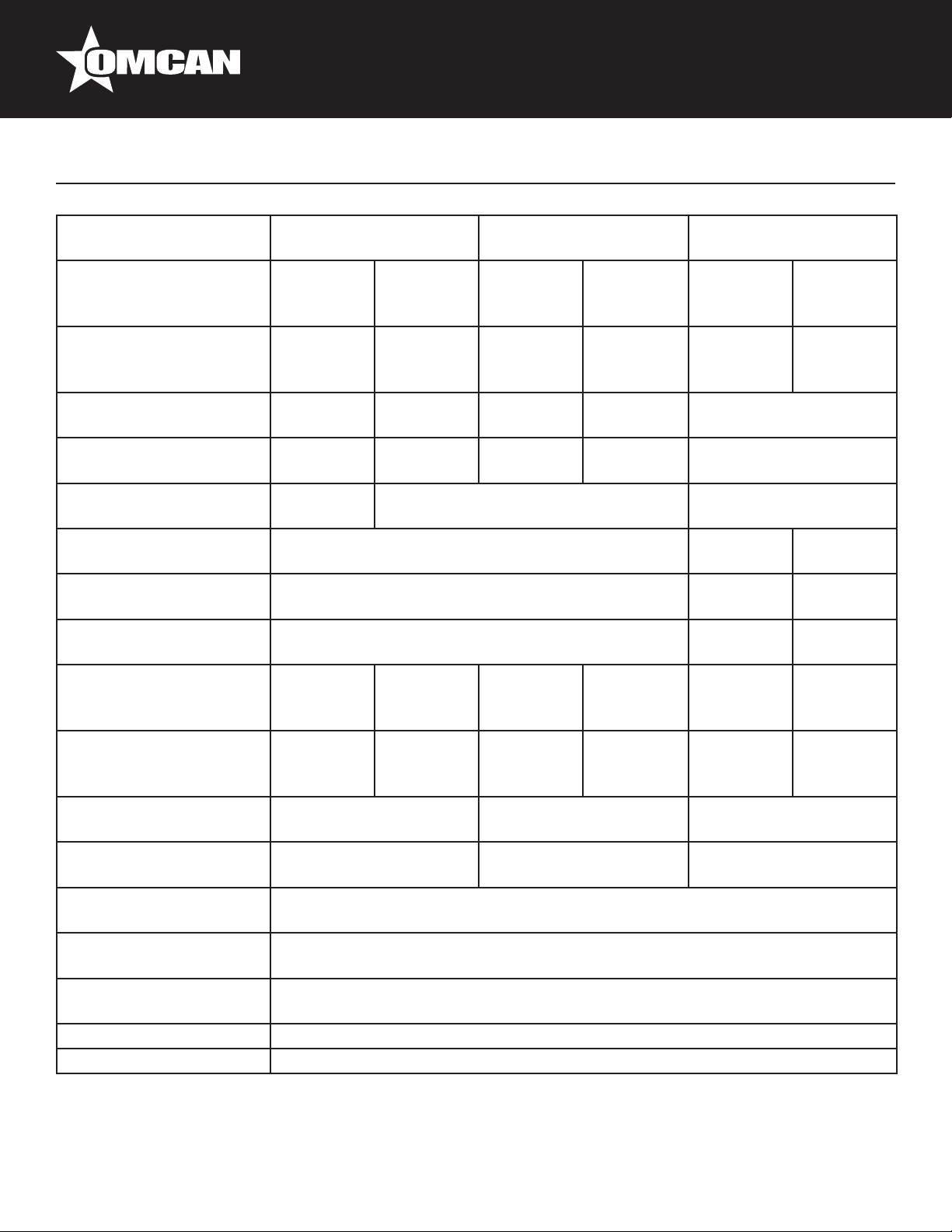

Hydraulic oil tank

capacity (US gallons)

Mach measurements

(width x depth x height),

cm

Mach measurements

(width x depth x height),

in.

Cardboard packaging

measurements, cm

Cardboard packaging

measurements, inches

Cardboard packaging

volume, m³/cbm

Wooden crate packaging

measurements, cm

Wooden crate packaging

measurements, inches

Wooden crate packaging

volume, m³/cbm

Net/gross weight of

3-phase machine with

oil, kg

Net/gross weight

3-phase of mach with

oil, pounds

3-phase motor noise

level dB(A) LEQ at 1 m

1-phase motor noise

level dB(A) LEQ at 1 m

Max./min. environmental

relative humidity, %

Recommended

hydraulic oil viscosity

Max./min. environmental

temperature ºC / ºF

Stainless steel grade AISI304 (equiv. DIN 1.4301, AFNOR Z6CN 18.09)

Aluminum grade AFNOR AG6T-Y (equiv. ASTM G8A - UNE L2331)

42x67x100 42x67x120 46x72x112 47x73x112 55x78x120 59x80x120

17”x26”x39” 17”x26”x47” 18”x28”x44” 18”x29”x44” 22”x31”x47” 23”x32”x47”

55x60x116 55x60x139 55x60x139 55x60x139 --

22”x24”x46” 22”x24”x55” 22”x24”x55” 22”x24”x55” --

0.38 0.46 --

±100 / ±115 ±117 / ±135 ±135 / ±155 ±180 / ±200 ±260 / ±290 ±330 / ±360

±220 / ±253 ±258 / ±298 ±298 / ±342 ±397 / ±441 ±573 / ±683 ±777 / ±848

2.6 4 6.6

-- 67x72x147 67x72x147

-- 26”x28”x58” 26”x28”x58”

-- 0.70 0.70

±58 ±61 ±64

±61 ±64 ±67

20 to 90%

5º Engler 50ºC (equiv. ISO3498: cat HL VG46, DIN8659: HL-46)

+5 to +40ºC (+40 to +110ºF)

7

Installation

(Estimated time: 45 minutes. Machine should only be installed by a qualied technician and in compliance with

local codes).

The electrical installation of the workplace should be equipped with power surge full protection, which should

then be adjusted to the technical specications of your particular unit (see below).

UNPACKING AND POSITIONING

Always keep the machine in a vertical position. Take the machine out of its box. Remove the knee lever (and

the upper lid screws for E models) from the inside of the barrel and set them in their proper positions. Do not

use the knee lever to move the machine. The machine comes with two xed (non-castor) wheels in the front

and two plastic anti-vibration legs in the back; lift the back part of the machine using the transport handle and

move the machine to the desired location (two people are necessary for moving the heavier H42 and H52

models). Do not raise the ller/stuffer too high when moving it since it could tip over, causing personal injury.

Place the machine on a level surface. Should the machine wobble, adjust the anti-vibration legs until it is

perfectly stable and level. The machine should be placed so that the plug is easily accessible.

IMPORTANT: Remove the protective transport cap on the oil inlet (marked OIL) and replace it with the

depressurized oil cap/dipstick enclosed with the machine. Also make sure that the air holes located at the base

of the barrel are totally clear; if not, the piston will not function properly.

CONNECTING THE MACHINE

Make sure the electrical characteristics of the machine (connection, voltage, and frequency) are suited to your

power source. (These specications are given in detail on the technical specications sticker afxed to the

machine itself; there is a tolerance of ±10% for voltage and of ±2% for frequency). If the specications are

compatible with your power source, refer to the OPERATING INSTRUCTIONS section below. If the electrical

features of the machine are not compatible with your power source and your machine is a dual voltage, threephase unit, adjust the voltage as described below in the CHANGING VOLTAGE section. Once the machine has

been installed and the oil level inside the reservoir has been checked using the dipstick attached to the oil inlet

screw, check the turning direction of the three-phase motor. If the phases are correctly adjusted, the piston will

rise and fall when the knee pedal is pushed. If the phases are incorrect, the pump will not work properly; the

motor will make noise, but the piston will not move. Stop immediately and interchange two of the three phases

in the plug. Make sure that the plug and outlet are appropriate for the machine.

IMPORTANT: the wiring in the electrical cord is normally assigned as follows: Phase(s): • Black, Brown,

Gray • Ground wire: Two-colored Yellow/Green or Green. Check the wiring before connecting; call a qualied

electrician if the electrical specications do not correspond with your power source.

HYDRAULIC OIL FILLING

The H ller/stuffer is delivered with hydraulic oil already in the internal reservoir; therefore, the initial addition of

oil to the hydraulic system is usually unnecessary. In the exceptional case that a machine is delivered without

hydraulic oil in the reservoir, do not turn it on. Fill the reservoir as follows:

• Remove the oil reservoir screw (marked OIL) located in the upper part of the base.

8

Loading...

Loading...