Omcan Food Machinery JDR520 Installation Manual

Dough Sheeter

Item No. 27960

Instruction Manual

Version 1

3115 Pepper Mill Court, Mississauga, ON, L5L 4X5

4450 Witmer Industrial Estates, Unit 4, Niagara Falls, NY, 14305

1-800-465-0234

www.omcan.com

Table of Contents

Model JDR520

Section

General Information

Safety & Warranty

Technical Specications

Installation

Operation

Maintenance

-------------------------------------------------------------------------------------------- 5

-------------------------------------------------------------------------------------------- 5

---------------------------------------------------------------------------------------- 6

-------------------------------------------------------------------------------- 3

---------------------------------------------------------------------------------- 3

Page

---------------------------------------------------------------------- 4 - 5

Troubleshooting

Parts Breakdowns

Electrical Schematics

Warranty Registration

-------------------------------------------------------------------------------- 7 - 8

--------------------------------------------------------------------------- 9 - 15

---------------------------------------------------------------------------- 16

---------------------------------------------------------------------------- 17

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

Thanks for using this high performance, reversible sheeter. It will assist in making bread, cheese, cake and

many other products. Before using this machine, please carefully read this manual and follow the procedures

to operate the machine.

Safety and Warranty

All the safety devices must be checked before operation. Maintenance should be done immediately when

defects or malfunction are found.

1. Check the warning signs on the machine.

2. Clean up any water, oil and liquids on the machine immediately when found. This will prevent injury.

3. Keep your body away from any moving part of the machine.

4. Do not let foreign objects enter the machine while operating.

5. Do not climb onto the machine while it is running.

6. If any problems occur in the process of operation, press the Emergency Stop button.

1 YEAR WARRANTY

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

3

Technical Specications

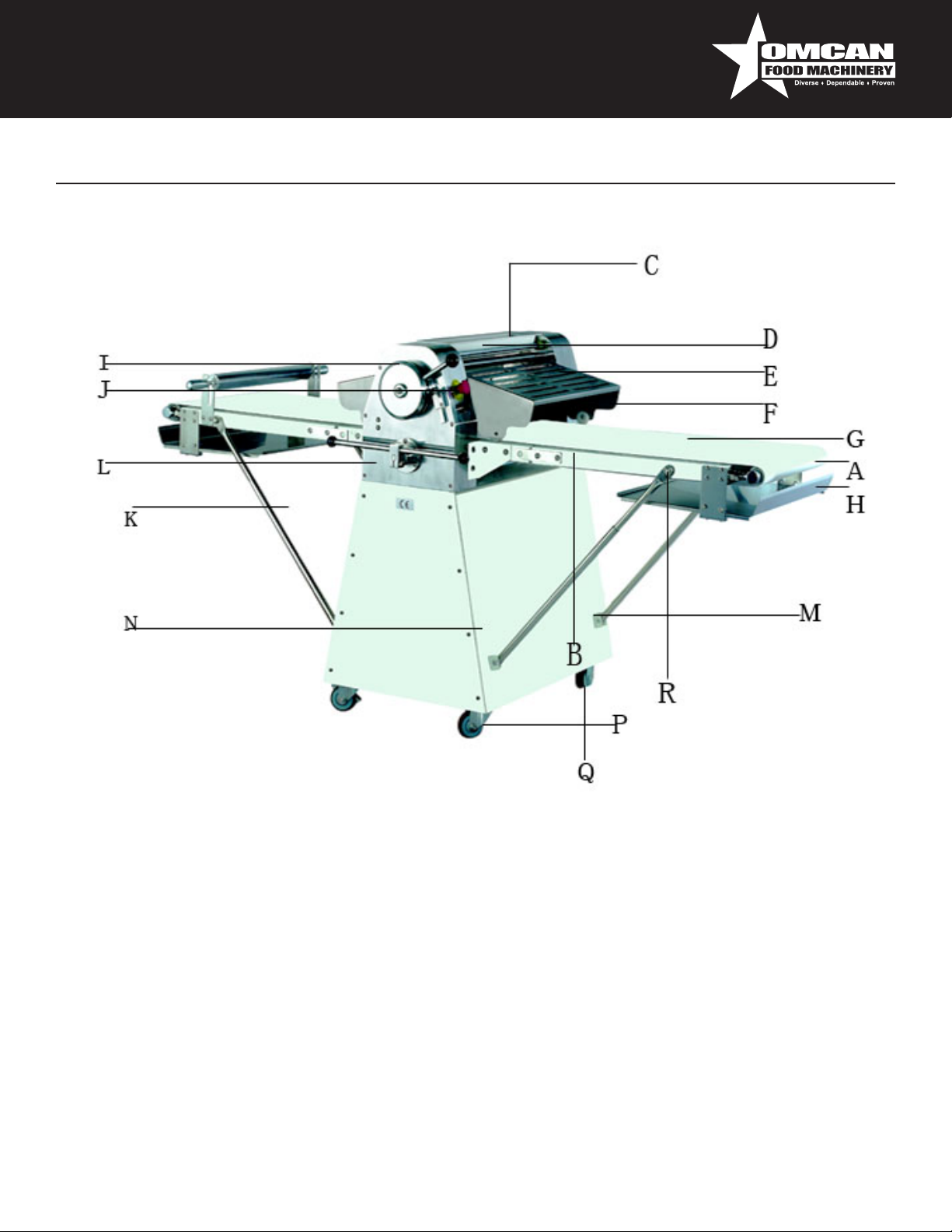

A: Roller (Active X2, Passive X2)

B: Table (Small X2, Big X2)

C: Upper Machine Body

D: Flour Tray

E: Upper pressing Roller ,Upper scraper X2

Lower pressing Roller ,Upper scraper X2

F: Safety Guard - Left&Right

G: Conveyor - 2pcs.

H: Producer Tray - 2pcs.

I: Thickness Handle

J: Emergency stop button

K: Support - 4 pcs.

L: Start Lever

M: Electrical Cabinet

N: Lower Machine Body

P: Fixed Wheel - 2 pcs

Q: Active Wheel With Brake - 2 pcs.

R: Conveyor Adjusting Nut - 4 pcs.

4

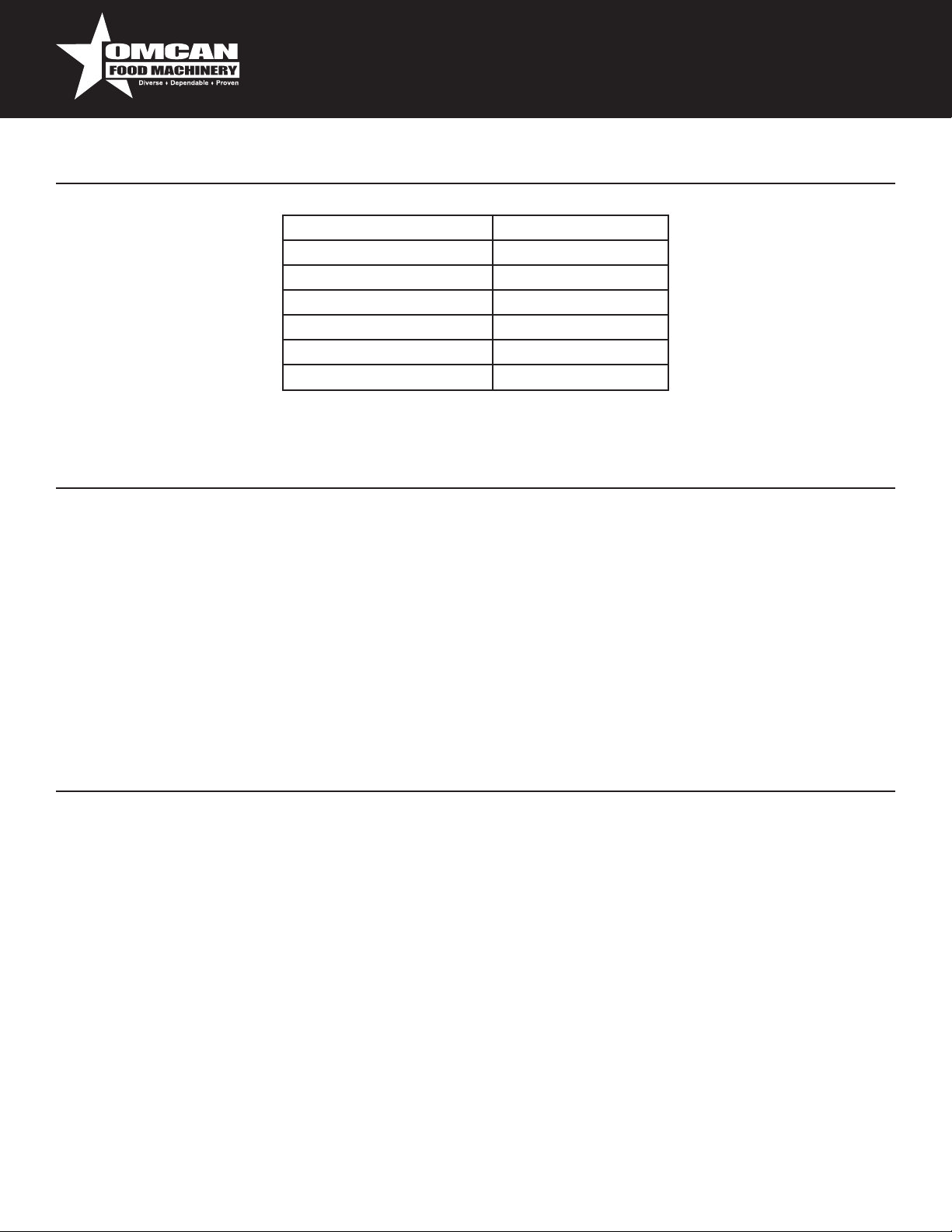

Technical Specications

Power 0.75 HP

Roller Length 20.5”

Height Adjustment Range 1 mm - 35 mm

Conveyor Width 19.75”

Electrical 220V/60/1

Weight 419 lbs.

Dimensions (WDH) 82” × 33.25” × 41.5”

Installation

1. Installation must be performed on a at, dry surface with a stable temperature environment. Press down

pedals of active wheels (Q) to lock the machine.

2. Follow the instructions on the plaque of electrical cabinet (M) to connect power supply. The breaker for

power supply should be installed on the wall with 1.7 m height from the oor.

3. Pull conveyor (G) straight, put down the table (B) and then put down both safety guards (F).

4. Then check the movement of the conveyors. Press the left-hand side pedal and the conveyors move left.

Press the right-hand side pedal and the conveyors move right. If the movement is in the wrong direction,

change the two wires of the power supply and re-test the machine.

5. The power cord must be grounded.

Operation

1. When using machine, set up the thickness handle (1) to the farthest left position.

2. Note: do not put hands in or near the safety guard.

3. Switch off the power when cleaning and disconnect the power mains.

4. Turn off power switch (J) and then lift up the safety guards (F) after operation.

The machine needs to be placed in a dry, stable temperature environment. Make sure the safety guards are

always used during operation. To start, use the pedal switch. Press the left-hand side switch and the conveyors

move left. Press right-hand side switch, the conveyors will move right. If the movement is opposite from the

desired direction, change the two wires of the power supply and re-test the machine. Make sure the electrical

requirements of the machine correspond with the power supply before operating this machine.

5

Maintenance

REPLACING THE GEARS:

First switch off the power and lift up the safety guards. Then use a screw driver to dismantle the side plate of

lower machine body and disconnect the three (3) electrical wires on the connecting box. Then set the thickness

handle to scale “O”. Use the alan-key on M5 to open the cover take out the gear housing. Next replace the

gears. After replacement, reverse the listed procedures and set the thickness handle to scale “O”.

REPLACING THE DRIVING ROLLER AND BEARING:

Switch off the power and lift up the safety guards. Then use the alan-key to open the cover. Loosen the nuts of

bearing using a cross type screw driver to move the bearing through the joint or roller and bearing. Replace the

roller and assembly by reversing the listed procedures.

CHANGING THE CONVEYORS:

• Remove the roller by following the procedures mentioned above.

• Apply spanner M8 to take the belts on roller and remove product tray.

• Apply spanner M24 to loosen the nuts of roller.

• Use spanner M16 to loosen the belts of support and separate the table.

• Use spanner M10 to take away the belts from the table holder and separate them.

• Dismantle the table and belts for replacement.

• Complete assembly by reversing the listed procedures.

• The tightness of belts should be correct. When the machine is running press the belts slightly and check if

a slip happened between belts and roller.

CLEANING:

Wash the conveyor belt with clean water after every operation. Do not use the machine until the conveyor belt

is completely dry. DO NOT USE EXCESSIVE WATER OR JET SPRAY.

6

Loading...

Loading...