Omcan Food Machinery IC-CN-0012 Installation Manual

Ice Maker

Model IC-CN-0012

Instruction Manual

Revised - 1/14/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model IC-CN-0012

Section

General Information

Safety & Warranty

Technical Specications

Operation

Maintenance

Troubleshooting

----------------------------------------------------------------------------------------- 7 - 8

----------------------------------------------------------------------------------- 9 - 12

--------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------- 4

----------------------------------------------------------------------------- 12 - 19

Page

---------------------------------------------------------------------- 5 - 6

French Instructions

Spanish Instructions

Parts Breakdowns

Electrical Schematics

Notes

Warranty Registration

------------------------------------------------------------------------------------------- 56 - 58

------------------------------------------------------------------------- 20 - 36

-------------------------------------------------------------------------- 53 - 54

----------------------------------------------------------------------- 36 - 52

---------------------------------------------------------------------------- 55

---------------------------------------------------------------------------- 59

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan ne

sont pas responsables de tout dommage ou blessure causé du fait que toute personne ait utilisé

cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de plus de 18

ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour utiliser

cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication de la

machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine ou

des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan no son responsables de ningun daño o perjuicío causado por cualquier persona inadecuada o

el uso descuidado de este equipo. El producto solo podra ser operado por una persona mayor de 18

años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido entrenado

en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada. Cualquier

modicación a la máquina anúla la garantía y puede causar daños a las personas usando la máquina

mientras esta en el funcionamiento.

3

General Information

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Safety & Warranty

• Turn the unit off and unplug before performing any cleaning, maintenance or repairs.

• Do not operate the unit with a damaged power cord. If a damaged power cord is found, immediately turn

the unit off and unplug it. Do not operate again until trained personnel have xed the problem.

• Only operate the unit on a at, level ground. Do not place the unit near any heat sources.

• Only use original spare parts for repairs.

1 YEAR PARTS AND LABOUR BENCH WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule a drop off to either

an Omcan authorized service depot in the area, or to an Omcan Service warehouse to repair the

equipment.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures not

improper use.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

4

Technical Specications

Capacity 50 lbs./day

Electrical 115V/60Hz/1

Current 3A - 3.6A

Refrigerant R134a

Weight 83.75 lbs.

Dimensions 14.5” × 23.5” × 33.25”

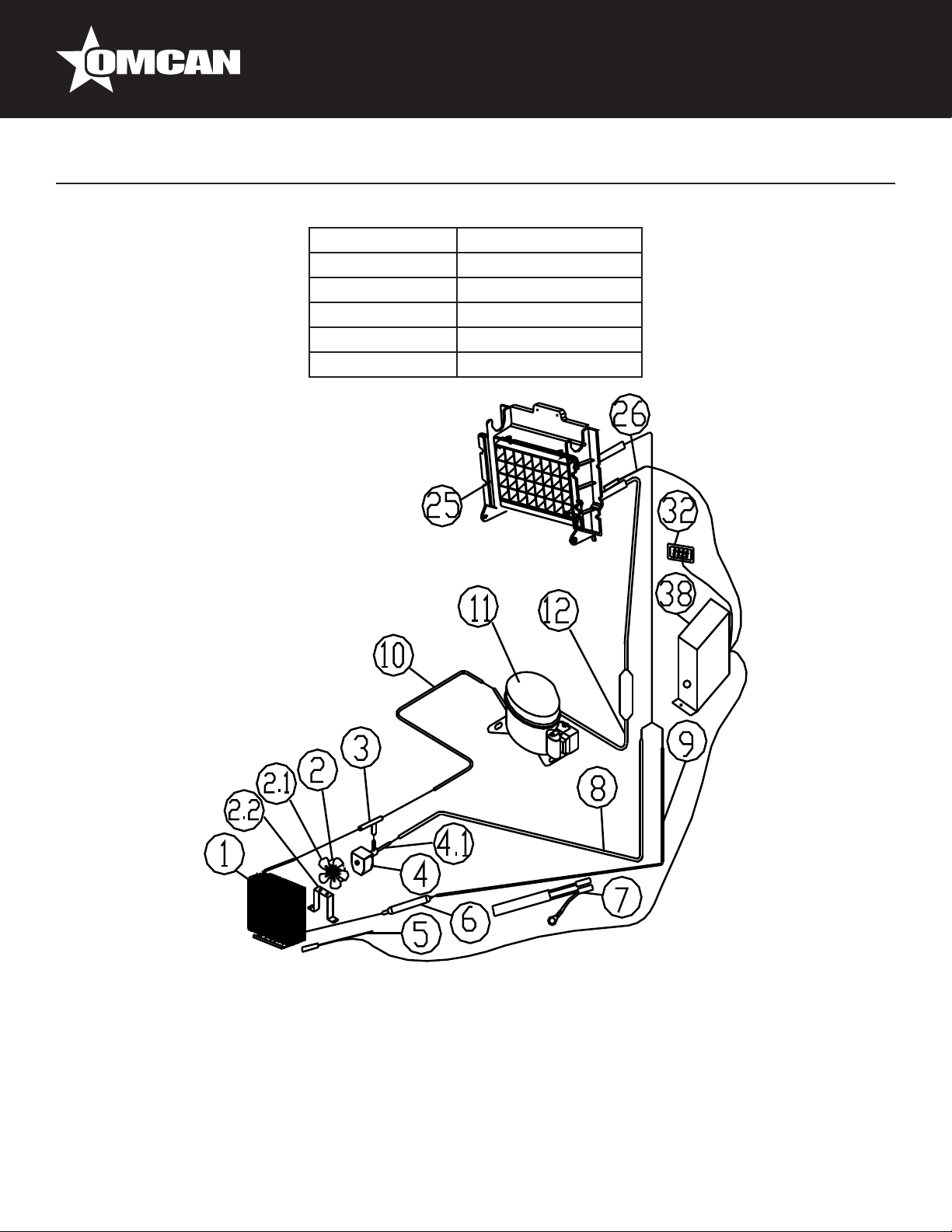

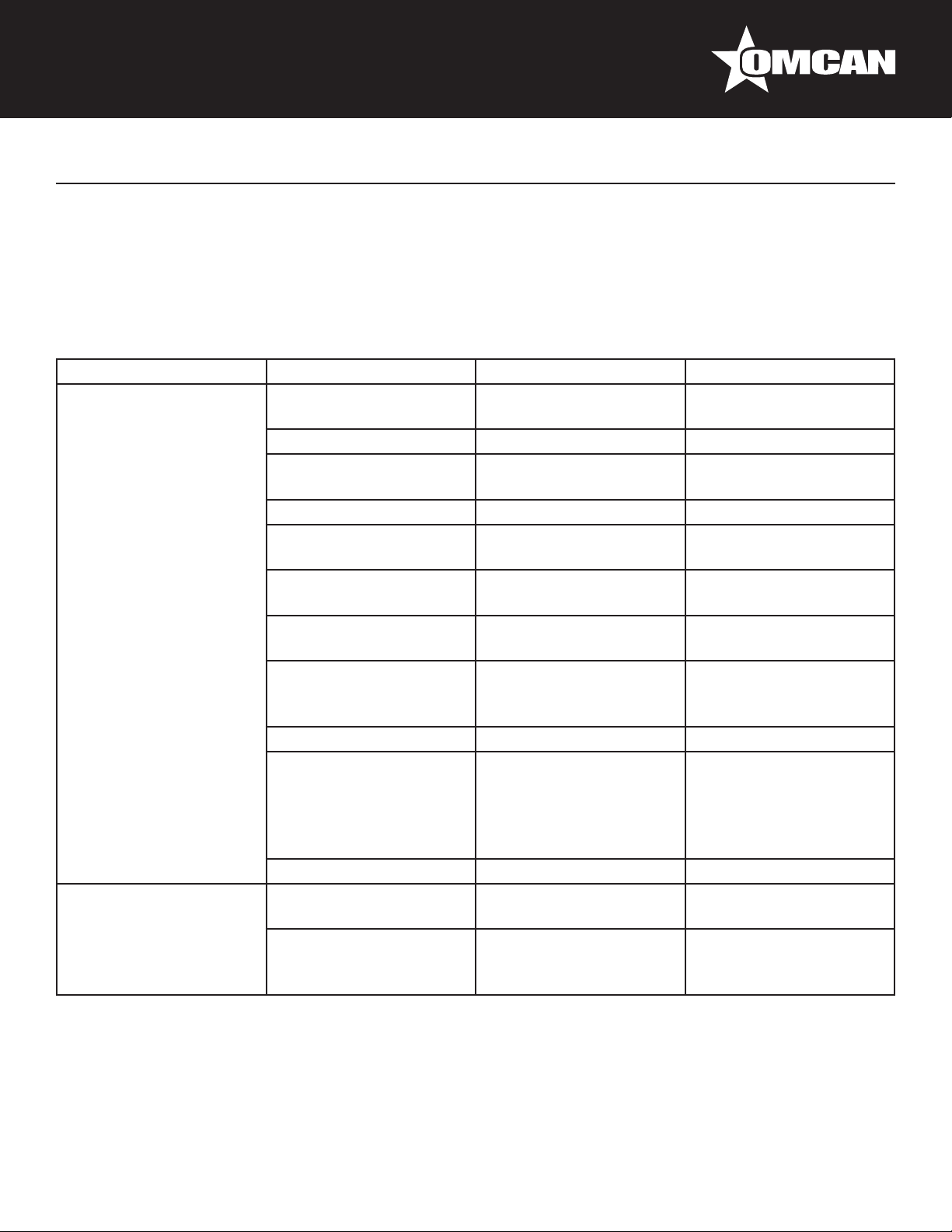

MAIN COMPONENTS

1. Condenser

2. Fan motor

2.1. Fan blade

2.2. Fan motor support

3. Multi-connection pipe

4. Hot gas valve coil

4.1. Hot gas valve body

5. Temperature sensor of

the condenser

6. Drier & Filter

7. Wiring harness

8. Hot gas tube

9. Capillary tube

10. Discharge tube

5

11. Compressor

12. Suction tube

25. Evaporator (Ice Mold)

26. Temperature sensor of the evaporator

32. Control panel

38. Controller box

Technical Specications

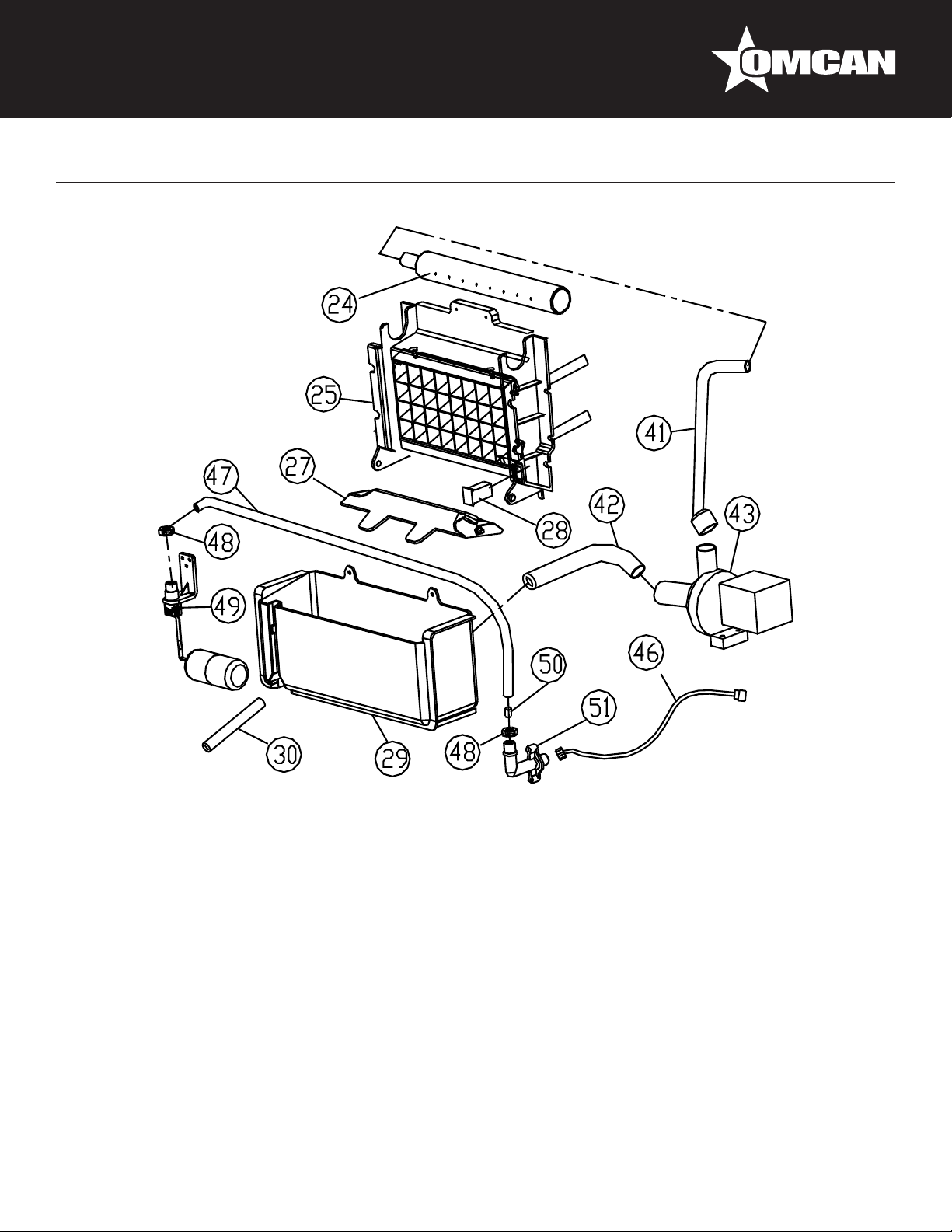

MAIN COMPONENTS

24. Water distribution tube.

25. Evaporator.

27. Ice slide way.

28. Ice full probe.

29. Water trough.

30. Water trough drain tube.

41. Water pump outlet tube.

42. Water pump inlet tube.

43. Water pump.

46. Water supply pipe.

47. Water inlet tube.

48. Nut of water inlet tube.

49. Floater valve.

50. Water inlet plug.

51. Water inlet.

6

Operation

MAJOR FUNCTIONS

1. The operating procedure is completely automatic.

2. When the ice storage bin is full of ice cubes the machine stops making ice automatically. It starts making

ice again after ice cubes are removed.

3. The different colors of the LED display indicate various work modes.

4. A sensitive probe and accurate timer enhance the performance of the ice maker.

5. A compressor protection system is built in.

CONTROLLER DISPLAYS

Instructions for LEDs and buttons:

1. Red LED: Ice full indicator light. When this LED is lit, the ice storage bin is full of ice or there is something

between the sensor in the ice storage bin. The unit will stop making ice. When ice cubes are taken out of

the ice storage bin making the ice-full probe free, the red LED will keep ashing for 3 minutes. Then the

unit will restart and return to the ice making mode.

2. Green LED: Ice making indicator light. When this LED is lit, the unit is working in the ice making mode

controlled by a temperature probe on the evaporator. When the green LED is ashing, the unit is working in

the ice making mode controlled by a xed timer.

3. Yellow LED: Ice harvest indicator light. When this LED is lit, the unit is working in the ice harvest mode

controlled by the ice-full probe. When the green LED and yellow LED is lit, it means the unit is working in

the cold preservation stage.

4. Mode button: Mainly for service. When this button is pressed, it can change from ice making mode to ice

harvest mode, or from ice harvest mode to ice making mode. You can judge the mode from the status of

the green and yellow LEDs.

5. Adjust button: Mainly for service. When this is pressed over 3 seconds, the unit will enter the Ice Size

Adjustment mode. The mode can be judged from the status of the yellow LED.

ICE SIZE ADJUSTMENT

1. Press and hold the “Adjust” button for at least 3 seconds. The unit will enter the Ice Size Adjustment mode.

The “HARVEST” LED (yellow) will be blinking continuously during the ice size adjustment.

2. While in the Ice Size Adjustment mode, press the “Clean” button or the “Mode” button for the desired ice

size.

Smaller ice setting: By pressing the “Clean” button, you can decrease the size of the ice cubes. The “ICE”

LED (green) will ash as you lower the ice size and will nally be blinking at the setting of smallest ice size.

Larger ice setting: By pressing the “Mode” button, you can increase the size of the ice cubes. The “BIN FULL”

LED (red) will ash as the larger size is set and will blink when the setting of largest ice size has been reached.

After 10 seconds without any operation, the unit will return to the previous mode.

NOTE:

• If during the ice size adjustment mode the “BIN FULL”, “ICE” and “HARVEST” LEDS blink all at once, this

7

Operation

indicates that the unit is in the regular (middle) setting of the ice size.

• When the machine is in the cleaning stage or ice full stage, the ice size adjustment mode cannot be

accessed.

During the ice-making stage, the hot gas solenoid valve is closed. The hot refrigerant gas is pumped out off

the compressor to the condenser. The hot gas is cooled by fan forced air to the warm liquid refrigerant after

passing through the condenser. The drier & lter reduces the possible dirt and humidity in the refrigerant. The

evaporator is cooled by the refrigerant. Some ice can be formed on the evaporator during the water spraying

process in the evaporator. Low pressure refrigerant gas may go back to the compressor from the evaporator.

During the ice harvest stage, the solenoid valve is opened. The hot refrigerant gas is pumped out off the

compressor to the evaporator through the hot gas valve. As the hot gas is not cooled by the condenser, the

refrigerant makes the evaporator (ice mold) slightly warm. So some ice touching the evaporator is thawed. All

of ice can slide down to the ice storage bin.

WATER SYSTEM

When the water supply pipe is connected with the main water supply, water will ll the water trough through the

oater valve until enough water inside water trough makes oater valve close. During the ice-making stage,

water is pumped from the water trough to the water distribution tube. The distributed water ows to the surface

of the evaporator. Most parts of water go back to the water trough. Some water is frozen on the evaporator

step by step. The oater valve will open and fresh water is

CIRCUIT DESCRIPTION

First time usage: As the icemaker is properly installed, switch on the water tap, let the water trough ll

(reach full on the level), then press the ON/OFF button on the front panel. The icemaker will start working

automatically In this status, the time is xed to about 3 minutes. This function is also helpful to protect the

compressor from avoiding restart within 3 minutes. At this status, the Red, Green, Yellow LEDs are lit together.

Ice-making status: The compressor, motor fan and pump are powered on. The hot gas solenoid valve is

powered off. When this green LED is lit, the unit is working in the ice making mode controlled by a temperature

probe on the evaporator. When the green LED is ashing, the unit is working in the ice making mode controlled

by a xed timer. The fan motor is also controlled by a condenser sensor. When the ambient temperature is too

low, the motor fan will stop working for good condensation to the refrigerant.

Ice harvest status: The pump is powered off. The hot gas solenoid valve, compressor and motor fan is

powered on. The fan motor is also controlled by a condenser sensor. When the ambient temperature is too

low, the motor fan will stop working for good condensation to the refrigerant. The Yellow LED indicates the ice

harvest status.

Ice full status: If the ice bin is lled with ice or the full sensor is covered, the machine stops making ice

automatically. In this status, the compressor stops working. The RED LED indicates the ice full status.

8

Maintenance

ADJUSTMENT AND REPLACEMENT

All maintenance to be performed by a certied technician only (call omcan at 1-800-465-0234)

Replace Controller, fuse and the sensor of temperature

ELECTRICAL SHOCK HAZARD

Disconnect electrical power before

beginning removal of parts

• Remove the rear cover, front panel,

• Locate the Electronic controller,

• Pull out the temperature sensors (one at the evaporator, another at the condenser).

• Loosen the screws connecting the Electronic controller, replace a new one. Reverse the above step to

replace.

• If you need to replace the fuse, open the front panel of the control box, you will nd the fuse.

• Take out the fuse, replace a new one. Reverse the above step to reassemble.

9

Maintenance

• If you need replace the temperature sensors, pull out the temperature sensors, open the panel of the

controller box, pull out the other side, replace a new one. Reverse the above steps to reassemble.

The cube size has been adjusted before leaving

the factory. Adjust accordingly.

Replace the water system components

Please see the water system drawing. The water leakage should be checked after this kind of operation.

Before replacing the water system components, it is necessary

to drain the system rst.

Replacing the water pump

• Disconnect electrical power.

• Remove the rear cover.

• Unplug the lines connector with the water pump, the water outlet tube of pump and the water inlet tube of

pump.

• Loosen the screws, replace a new one.

• Reverse the above steps to reassemble.

Replace the cooling system components

• Replace the condensing components, See the cooling system diagram.

• Replace the compressor and the compressor kit (includes relay, thermal protect).

10

Maintenance

• If you only need to replace the compressor kit, remove the rear panel, locate the compressor, take the clip,

open the cover, replace the old compressor,

• Reverse the above steps to reassemble.

• If you need to replace the compressor, remove the rear cover, and cabinet, locate the compressor.

• Unplug the lines and take out the grounded line, add the low side access valve, open the Process/Suction,

evacuate refrigerant, take out the compressor, replace a new one, joint together, then recover refrigerant,

weigh in the nameplate charge.

• Reverse the above steps to reassemble.

11

Maintenance

Replace the fan motor and fan blade

• Remove the front panel, rear and cabinet.

• Locate the fan motor, unplug the lines connected to the fan motor, loosen the screws of the bracket that

holds the fan motor.

• Replace a new one, If you only need to replace the fan blade, loosen the screws holding the fan blade,

take out the damaged fan blade, replace with a new one.

• Reverse the above steps to reassemble.

Replace the hot gas valve, drier and evaporator

• Remove the rear cover.

• Locate the drier and hot gas valve, add low side access valve, recover refrigerant, replace the drier and hot

gas valve, evacuate and weigh in the nameplate charge.

• Reverse the above steps to reassemble.

• If you need to replace the evaporator.

• Remove the rear, locate the evaporator, add the low side access valve, open the process/suction, weld

open the two welds, replace a new one. Recover refrigerant, evacuate and weigh in the nameplate charge.

• Reverse the above steps to reassemble.

Troubleshooting

ELECTRICAL SHOCK HAZARD

Turn the unit off and unplug it before

beginning to remove any parts.

BEFORE MAINTENANCE

• Make sure the user uses a 115 VAC, 60Hz. only 15amp electrical supply, and make sure that it is properly

grounded to protect the maintainer against electrical shock.

• Check out if the leads loose? Turn off? Short circuit? If you have such problems, foreclose in turn.

12

Troubleshooting

BASIC CHECKING

If the icemaker has some trouble through the basic checking. The service technician must then check it

thoroughly, then maintain accordingly.

HEARING CHECK

• Listen for the user’s depiction about the icemaker during a test run. Try to understand what is the defect

and how did the user operate the icemaker before calling for service.

• Is the running sound is normal?

VISUAL CHECK

• Check the pipe of cooling system, especially the welding points. If there is some oil, the gas is leaking out

so that no ice making or less ice is produced.

• If the cycle of the ice making and harvest is normal?

• Check the water system, especially the connections. If there is some water leaking?

• Check if the water lter needs to be replaced.

• Check if the icemaker is installed according to the user manual.

• Check if the icemaker needs to be cleaned.

PHYSICAL CHECK

• Touch the hot gas pipe (with the evaporation weld), feeling the temperature. At the ice making stage it

should feel cool. At the ice harvest stage it should feel hot.

• Touch the capillary tube (the drier nearby), does it feel lukewarm?

13

Troubleshooting

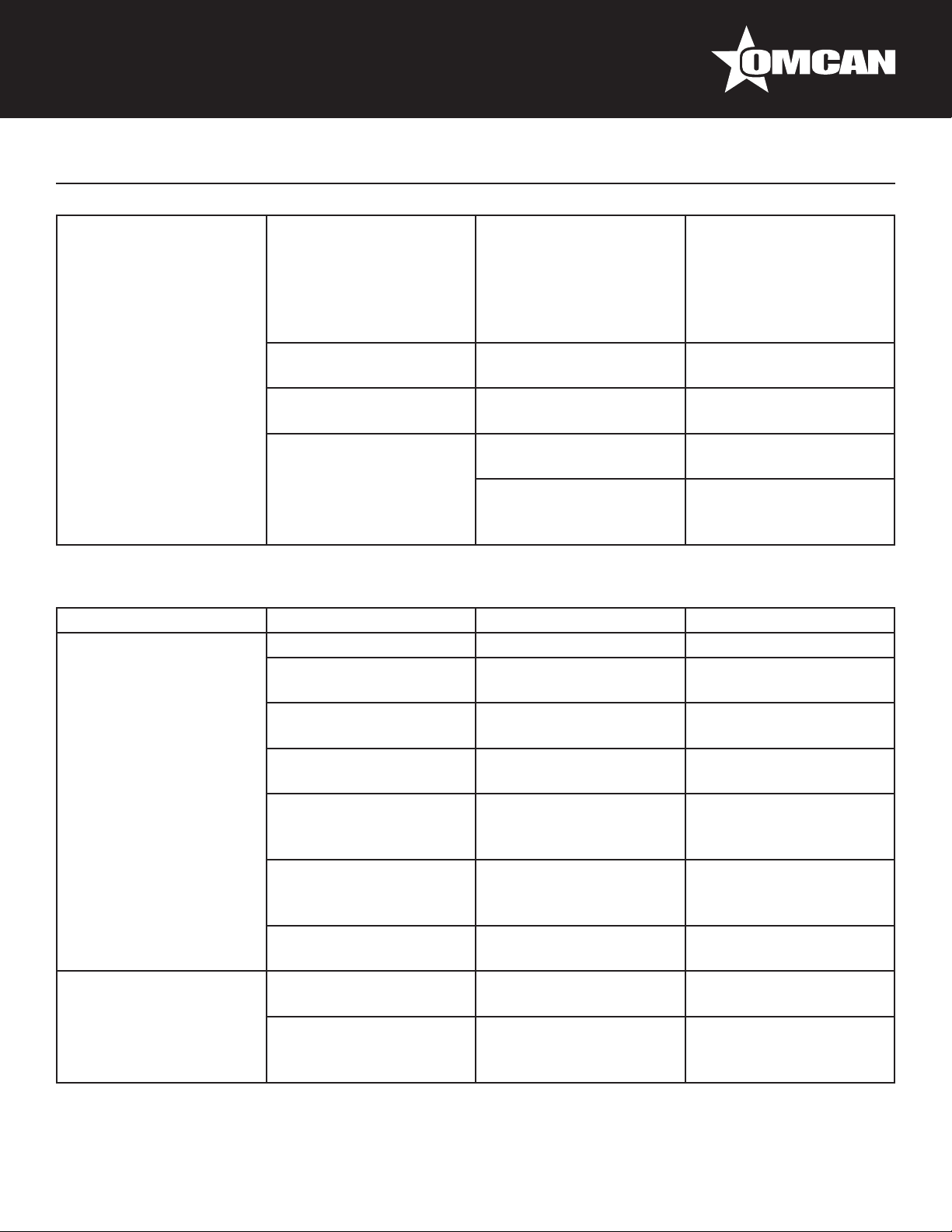

TROUBLESHOOTING GUIDE

This troubleshooting guide in the user manual should be read before attempting any service. Be sure to turn to

this guide only when the trouble shooting in user manual can’t help you solve the problem.

THE MACHINE DOES NOT MAKE ICE

Problem Check part or point Possible Cause Probable Correction

The machine doesn’t

operate

Water System Water supply tap The water supply tap is

Plug The icemaker is

unplugged.

Socket Socket is damaged Check and replace.

Power switch The icemaker power

button is set at OFF.

Fuse The fuse is blown. Replace fuse.

Wiring connection Some wiring connection

is incorrect or loose.

Voltage The voltage of the power

supply is low.

Ice full probe The ice full probe is not

working.

Ice full probe The ice full probe is

covered by something.

Wiring Some wiring is damaged. Replace with a new one.

Electric component Some electrical

component has failed.

Controller The controller has failed. Replace with a new one.

turned off.

Water supply pipe The water supply pipe is

not properly connected or

may be kinked.

Plug the icemaker in.

Switch the icemaker

power button to ON.

Check and re-connect.

Add manostat.

Replace with a new one.

Clear the probe and

make the ice-full probe is

free of obstructions.

Find the controller,

press the mode button

to change the mode. It

is helpful to judge which

part is out of function.

Turn on the water supply

tap.

Reconnect the water

supply pipe.

14

The compressor doesn’t

start

The compressor runs but

makes no ice

Troubleshooting

Water line The water line leaks. Plug in again.

The water line is blocked. Clean it, see user manual

“ice making system

cleaning”

Water supply pressure is

low.

Water inlet The water inlet is blocked. Check and clear it

Water pump Water pump damaged. Replace water pump.

The room temperature is

out of the stated range,

the water pump stops

automatically.

The lines of the water

pump are loose.

The housing of water

pump leaks.

Drainage tray on top of

the compressor

Wiring connects It’s loose. Plug tightly, or replace.

The start relay/thermal

protect

The startup coil / running

coil

Condenser The condenser may be

Fan The fan may be dirty or

The Electronic controller The controller is damaged Replace the Electronic

Refrigerant Refrigerant leaks

Drainage tray on top of

the compressor is full.

It’s damaged. Replace the start relay/

It’s turned off. Replace the compressor.

The motor of the

compressor has short

circuited.

dirty.

damaged

completely.

Adjust the water supply

pressure within the stated

range.

Make the temperature

return within the stated

range.

Plug in again.

Replace water pump.

Drain off water by

unscrewing lower

drainage nut.

thermal protect of the

compressor.

Replace the compressor.

Clean the condenser.

Clean or Replace the fan.

controller.

Add low side access

valve, locate leak, recover

refrigerant, replace drier,

evacuate and weigh in

the data plate charge.

15

Troubleshooting

Capillary tube Capillary tube is blocked. Add low side access

Vent The vent is obstructed

Hot gas valve Hot gas valve is

The Electronic controller The mode of making ice

LOW PRODUCTION

around the ice machine.

damaged.

doesn’t turn to harvest.

The unit is working in the

cold preservation stage

mode.

valve, recover refrigerant,

replace hot gas valve,

replace drier, evacuate

and weigh in the

nameplate charge.

Clean the vent.

Replace.

Replace the Electronic

controller.

Work in normal mode.

Problem Check part or point Possible Cause Probable Correction

Cooling System Refrigerant Refrigerant leaks partially. Recharge.

Condenser The condenser may be

dirty.

The ambient temperature The ambient temperature

is too high or too low.

Fan The fan is dirty or

damaged.

Hot gas valve Hot gas valve

performance is poor, little

ice is produced.

Electronic controller The setting temperature

of Electronic controller is

low.

Sensor The sensor of

temperature is damaged

Water System Water distribution tube The water distribution

tube is blocked.

Water line The water quality is too

poor. The water line is

blocked.

Clean the condenser.

Check the ambient and

air ow.

Clean or replace.

Replace the hot gas

valve.

See the service manual

"adjust the size of ice

cubes".

Replace the temperature

sensor.

Clean the water

distribution tube.

Use a lter apparatus

installed in front of the

water inlet valve.

16

Troubleshooting

Silica gel tubes The silica gel tubes

are distorted, leads to

blocking.

Floater valve The oater valve

leaks. Leads to low ice

production.

Wheel The icemaker is not

properly leveled.

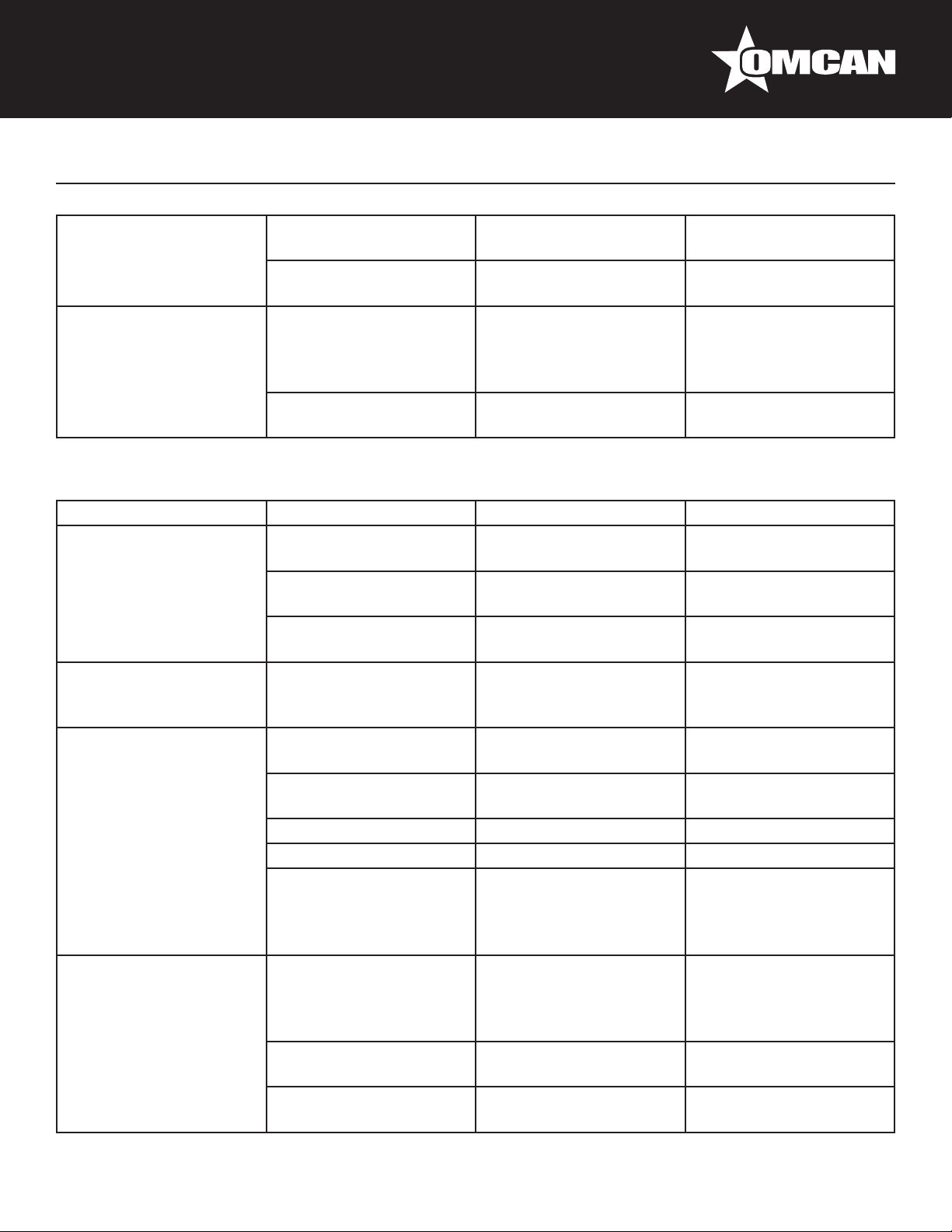

ICE CUBES ARE NOT SATISFACTORY

Problem Check part or point Possible Cause Probable Correction

Cubes are too small Condenser The condenser is dirty or

the air grills are covered.

The ambient temperature The ambient temperature

is too high.

Electronic controller The setting temperature

is high.

Refrigerant Refrigerant leaks. Recharge.

Cubes are too big Electronic controller The setting temperature

of Electronic controller is

low.

Sensor Temperature sensor

of the evaporator is

damaged.

The cubes are partially

formed--have ragged

sides

The ambient and water

temperature

Water quality The water quality is poor. Use a water-soften / lter

Evaporator Ice machine is dirty. Clean and sanitize the ice

Water distribution tube The water distribution

The room temperature The room temperature is

The ambient temperature

and water temperature

are too low.

tube is partially blocked.

out of the stated range,

the water pump stops.

Make the silica gel tubes

resile.

Repair or replace.

See installation.

Clean the condenser.

Leave space around the

machine.

Adjust the ambient

temperature.

See the service manual

"adjust the size of ice

cubes".

See the service manual

"adjust the size of ice

cubes".

Replace the temperature

sensor.

Adjust the temperature.

apparatus installed in

front of the water inlet

valve.

machine.

Clean the water

distribution tube.

Make the temperature

return within the stated

range.

17

Troubleshooting

The ice cubes have

shape deformities

Cubes are partially

formed—are white at the

bottom

OTHER PROBLEMS

Problem Check part or point Possible Cause Probable Correction

The body is electried Ground line The ground line isn't in

Scales occur frequently

inside the machine

Loud noise during

operation

Water is leaking out of the

unit

Filter Water ltration element

needs to be changed.

Water trough Water trough level is too

low.

The room temperature The room temperature

is out the stated range,

the water pump stops

automatically.

Water trough Water trough level is too

low.

the socket.

Lines The lines are not

insulated.

Electric component The electric component is

not insulated.

The water quality The rigidity of the water

quality is too high.

Spring of the internal

compressor

Water pump The noise of the water

Pipeline system Pipeline system resonate Clear pipeline system

Feet The feet are not leveled Level and lock the feet.

Fan motor The fan motor is loose,

The operation Some water drops to the

Water supply connection Water supply connection

Drainage tray on top of

the compressor

The spring of the internal

compressor drops.

pump

the clearance of the rotor

is bigger, the fan blade

turns back

oor when you open the

door to take out ice from

ice storage bin.

is leaking.

Water full probe is out of

function

Replace the lter.

Adjust the water oater.

Make the temperature

return within the stated

range.

Adjust the water oater.

Please use the socket

meeting the standard.

Adjust, reconnect /

replace lines

Replace this electric

component.

Use a water-soften

apparatus installed in

front of the water inlet.

Replace the compressor.

Replace the water pump.

Relocate the fan motor /

replace

Normal condensation on

the door or some water

from the ice. Take care

when you take out ice.

Tighten the tting.

Replace with a new one.

18

Loading...

Loading...