Omcan Food Machinery H15Ei Installation Manual

H15•H20•H26•H31•H42•H52

Fillers

Stuffers

Poussoirs

Version 3.5 • Revised October 2006

Kolbenfüllmaschinen

Stopmachines

Pølsestoppere

Insaccatrici

Embutidoras

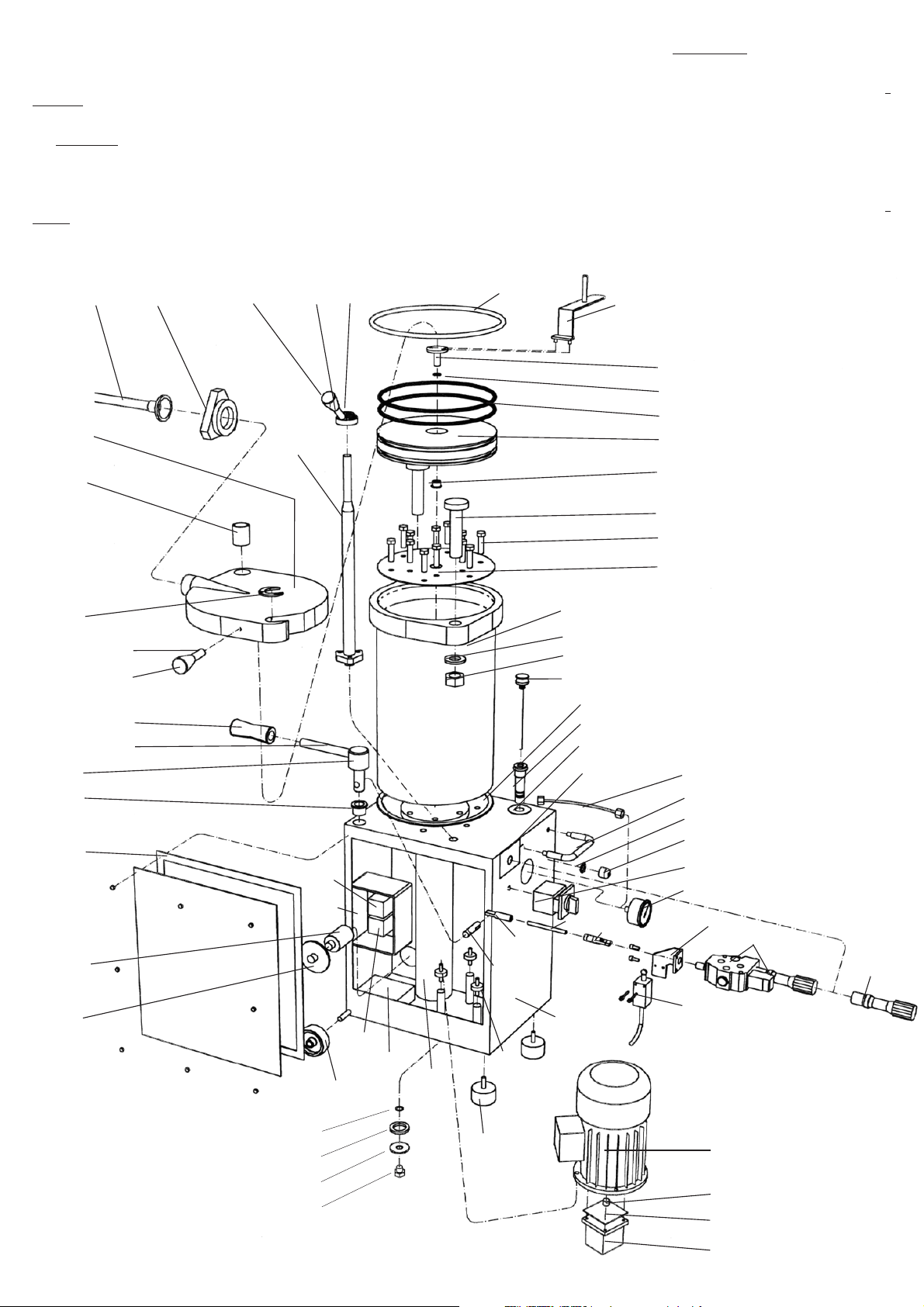

Illustration: H26p

OPERATING INSTRUCTIONS

Before operating the machine, please read this manual thoroughly.

This manual should be retained for future reference.

MODE D’EMPLOI

Avant la mise en service de cette machine, prière de lire attentivement cette

notice d’utilisation que vous conserverez pour toute référence ultérieure.

BETRIEBSANLEITUNG

Vor Inbetriebnahme der Maschine lesen Sie bitte diese Gebrauchsanleitung

gründlich durch und bewahren Sie sie für später auf.

ENGLISH

FRANÇAIS

DEUTSCH

NEDERLANDS

GEBRUIKSAANWIJZING

Lees deze gebruiksaanwijzing aandachtig door alvorens de machine

in werking te stellen. Bewaar deze handleiding als naslagwerk.

BRUGSANVISNING

Før igangsætning af maskinen bør denne håndbog læses omhyggeligt.

Gem håndbogen for fremtidige forespørgsler.

MANUALE DI ISTRUZIONI

Prima di utilizzare la macchina leggere attentamente questo

manuale e conservarlo per future informazioni.

MANUAL DE INSTRUCCIONES

Antes de utilizar la máquina lea este manual detenidamente

y consérvelo para futuras consultas.

Serial No.: __________

DANSK

ITALIANO

ESPAÑOL

THE 3-DIGIT NUMBERS SHOWN INTHIS PRINTDRAWINGARE NOT VALID FOR ORDERS. PLEASE ORDER PARTS BY USING ONLYTHE DETAILED IN THE ENCLOSED

PARTS LIST AND ONLY THROUGH THE AUTHORIZED DEALER WHO SOLD THE MACHINE. FOR SOME PARTS ADDITIONAL TECHNICAL, ELECTRICAL, DRAWING DETAILS WILL BE

NEEDED.

LES NUMÉROS DE 3 CHIFFRES INDIQUÉS DANS CET ÉCLATÉ NE SONT PAS VALIDES POUR DES COMMANDES DE PIÈCES. POUR CE FAIRE, UTILISEZ UNIQUEMENT LE CODE À

CHIFFRES

PIECES DETAILSTECHNIQUES, ELECTRIQUES,DESSINSCOMPLEMENTAIRES SERONT PRECISES.

DIE SICH IN DIESER ZEICHNUNG BEFINDLICHEN 3 STELLIGEN NUMMERN GELTEN NICHT FÜR BESTELLUNGEN. BESTELLEN SIE BITTE ERSATZTEILE AUSSCHLIEßLICH MITTELS

DES CODES, DER SICH IN DER NACHSTEHENDEN TABELLE BEFINDET. WENDEN SIE SICH DIESBEZÜGLICH BITTE IMMERAN DEN FACHHÄNDLER , BEI DEN SIE DIE

MASCHINE GEKAUFT HABEN.

DE IN DEZE TEKENING VERMELDE 3-CIJFERIGE CODES ZIJN NIET GELDIG VOOR BESTELLINGEN VAN ONDERDELEN. BESTELLINGEN KUNNENALLEEN GEDAAN WORDEN M.B.V.

DE 4-CIJFERIGE CODES VERMELD OP DE TABEL DIE TE VINDEN IS OP DE VOLGENDE PAGINA'S. WENDT U ZICH HIERVOORALTIJD AAN DE DISTRIBUTEUR WAAR U DE MACHINE

GEKOCHT HEEFT. BIJ ENKELE ONDERDELEN ZIJN COMPLETETECHNISCHEEN/OFELEKTRISCHEGEGEVENSMETEVENTUELE TEKENINGEN, ENZ. NODIG.

LOS NÚMEROS DE 3 DÍGITOS INDICADOS EN ESTE DESPIECE NO SON VALIDOS PARA PEDIDOS. LOS PEDIDOS DE REPUESTOS SOLO SE DEBEN HACER CON EL CÓDIGO DE

CIFRAS

PIEZAS SE REQUERIRÁNADEMASCOMPLETOSDETALLES TÉCNICOS, ELÉCTRICOS, DIBUJO, ETC.

COMPRIS DANS LATABLE CI-JOINTE. FAITES VOS COMMANDES EXCLUSIVEMENTÀ TRAVERS DU DISTRIBUTEUR QUI VOUSA VENDU LA MACHINE. POUR CERTAINES

4 ZIFFRIGEN

PRECISADO EN LA TABLA ADJUNTAA LAS PAGINAS SIGUIENTES Y EXCLUSIVAMENTE A TRAVÉS DEL DISTRIBUIDOR QUE LE HAYA VENDIDO LA MÁQUINA. EN ALGUNAS

4-DIGITS CODE

4

4

H-203

H-200

H-201

H-204

H-205 (7032)

H-206 (0136)

H-207 (2585)

H-251 (7316)

H-208

H-209

H-210

H-212

H-202 H-206

H-250

H-217

H-215

H-249H-260

H-242

H-247 (7060)

H-246 (7029)

H-245 (0109)

H-248

H-244

H-268

H-243

H-241

H-240

H-239

H-238

Updated

01/2006

H-237

H-236 (2589)

H-261

H-235 (2592)

H-234 (2680)

H-232 (2467)

H-259 (2403)

H-231

H-230 (0105)

H-229 (0104)

H-252 (3402)

H-258 (2278)

H-255

H-256 (7318)

H-254 (7319)

H-253 (7320)

H-267 (3435)

H-233 (2012)

H-228 (2353)

H-213

H-263 (0086)

H-264 (2683)

H-265 (2580)

H-266 (2590)

H-218

H-214

H-219

H-220

H-222 (2034)

H-221 (2033)

H-227

H-211 (2039)

H-226

H-225 (0063)

H-224 (0064)

H-223

TAPA ALUMINIO DEPOSITO

CARNE (MODELOS P)

TAPA ALUMINIO DEPOSITO

CARNE (MODELOS E)

TAPA ACERO INOX

DEPOSITO CARNE

COJINETE PLASTICO TAPA

ALUMINIO DEPOSITO MASA

E-DESMONTABLE

ALUMINIUM DEKSEL (P-

MODELLEN)

ALUMINIUM DEKSEL (E-

MODELLEN)

RVS DEKSEL

LAGERBUS PLASTIC

DEKSELAS ALUMINIUM E-

MOD AFNEEMBARE CILINDER

ALUMINIUM DECKEL (NUR P-

MODELLE)

ALUMINIUM DECKEL (NUR E-

MODELLE)

DECKEL EDELSTAHL

ROSTFREI

PLASTIK KUGELLAGER

ALUMINIUM DECKEL E-MOD

ABNEHMBARER ZYLINDER

COJINETE BRONCE TAPA

ALUMINIO DEPOSITO MASA

P-FIJO

COJINETE BRONCE TAPA

ACERO INOX DEPOSITO

MASA P-FIJO

TUERCA PORTAEMBUDOS

ALUMINIO ABIERTA

LAGERBUS BRONS

DEKSELAS ALUMINIUM P-

MODEL VASTE CILINDER

LAGERBUS BRONS

DEKSELAS RVS P-MODEL

VASTE CILINDER

AFSLUITMOER ALUMINIUM,

OPEN

BRONZE KUGELLAGER

ALUMINIUM DECKEL P-MOD

FESTSTEHENDER ZYLINDER

BRONZE KUGELLAGER

DECKEL EDROST P-

MODDELLE FESTSTEHENZYL

VERSCHLUßMUTTER

ALUMINIUM, OFFEN

TUERCA PORTAEMBUDOS

ACERO INOX, SIN RANURA

AFSLUITMOER RVS,

GESLOTEN

VERSCHLUßMUTTER

EDELSTAHL GESCHLOSSEN

HERRADURA INOX TAPA

ALUMINIO MODELO E

HERRADURA INOX TAPA

ALUMINIO MODELO P

PALANCA APERTURA TAPA

HOEFIJZERVORMIGE RVS

VERSTEVIGING E-MODEL

HOEFIJZERVORMIGE RVS

VERSTEVIGING P-MODEL

DEKSELHENDEL ZONDER

DECKELANSCHLAG FÜR

ALU.-DECKEL E-MODELLE

DECKELANSCHLAG FÜR

ALU.-DECKEL P-MODELLE

DECKELGRIFF OHNE GRÜN

SIN POMO PLASTICO VERDE

POMO ITAL PLASTICO VERDE

PALANCA TAPA

FUNDA RODILLERA GOMA

VERDE

EJE VERTICAL ACERO INOX

RODILLERA MOD. P EXCEPTO

H42/H52

RODE KNOP

DEKSELKNOP GROEN ITAL

RUBBEREN KNIEHENDEL

GROEN

VERTICALE KNIEHENDELAS

RVS MOD. P EXC H42/H52

KNOPF

GRÜN DECKELGRIFFKNOPF

AUS PLASTIK ITAL

GUMI-KNIEHEBEL GRÜN

VERTIKALER KNIEHEBEL-

SCHAFT, EDELS. ROSTFREI

MOD. P EXC H42/H52

EJE VERTICAL ACERO INOX

RODILLERA MOD. E+H42/H52

COJINETE BRONCE GIRO

RODILLERAS HP EXCEPTO

H42/H52

COJINETE BRONCE GIRO

RODILLERAS HE Y H42/H52

VERTICALE KNIEHENDELAS

RVS MOD. E+H42/H52

LAGERBUS BRONS

KNIEHENDEL VOOR HP

MODELLEN BEHALVE

H42/H52

LAGERBUS BRONS

KNIEHENDEL VOOR HE EN

H42/H52 MODELLEN

VERTIKALER KNIEHEBEL-

SCHAFT, EDELSTAHL

ROSTFREI MOD. E+H42/H52

KUGELLAGER BRONZE

KNIEHEBEL FÜR HP

MODELLEN AUSSER H42/H52

KUGELLAGER BRONZE

KNIEHEBEL FÜR HE UND

H42/H52 MODELLEN

COUVERCLE ALUMINIUM

(SEULEMENT MODELES P)

COUVERCLE ALUMINIUM

(SEULEMENT MODELES E)

PARTS LIST LISTE DE PIÈCES TEILELISTE ONDERDELENLIJST LISTA PIEZAS

ALUMINUM LID (ONLY P

MODELS)

ALUMINUM LID (ONLY E

MODELS)

S/S LID COUVERCLE ACIER INOX

H52

COUSSINET PLASTIQUE

COUVERCLE ALUMINIUM

MODELE E-DÉMONTABLE

COUSSINET BRONZE

COUVERCLE ALUMINIUM

MODELE P-FIXE

COUSSINET BRONZE

PLASTIC BEARING FOR

ALUMINUM LID E-

REMOVABLE BARREL

MODEL

BRONZE BEARING FOR

ALUMINUM LID P-FIXED

BARREL MODEL

BRONZE BEARING FOR S/S

COUVERCLE ACIER INOX

MODELE P-FIXE

ÉCROU ALUMINIUM RANURE

OUVERTE PORTE-EMBOUTS

ÉCROU ACIER INOX PORTE-

EMBOUTS, FERMÉE

LID P-FIXED BARREL

MODEL

ALUMINUM HORN/NOZZLE

LOCKING NUT, OPEN SLOT

S/S HORN/NOZZLE

LOCKING NUT, W/OUT

FER COUVERCLE

SLOT

HORN/NOZZLE, ALL S/S EMBOUT, TOUT ACIER INOX FÜLLROHR, GANZ ROSTFREI WORSTHOORN RVS EMBUDO, ACERO INOX

S/S HORSESHOE FOR

ALUMINIUM MODELE E

FER COUVERCLE

ALUMINIUM MODELE P

LEVIER COUVERCLE SANS

POIGNEE PLASTIQ VERT

POIGNEE PLASTIQUE POUR

LEVIER COUVERCLE ITAL

CAOUTCHOUC VERT

ALUMINUM LID E MODEL

S/S HORSESHOE FOR

ALUMINUM LID P MODEL

LID LEVER WITHOUT

GREEN PLASTIC KNOB

GREEN PLASTIC ITAL

KNOB FOR LID LEVER

GREEN RUBBER KNEE

GENOUILLERE

AXE VERTICAL

GENOUILLERE ACIER INOX

MOD. P SAUF H42/H52

AXE VERTICAL

GENOUILLERE ACIER INOX

MOD. E+H42/H52

LEVER

VERTICAL KNEE LEVER

SHAFT P-MODEL, S/S

EXCEPT H42/H52

VERTICAL KNEE LEVER

SHAFT E+H42/H52-MODEL,

S/S

COUSSINET BRONZE AXE

GENOUILLERE POUR

MODELES HP SAUF H42/H52

COUSSINET BRONZE AXE

GENOUILLERE POUR

MODELES HE ET H42/H52

KNEE LEVER BRONZE

BEARING FOR HP MODELS

EXCEPT H42/H52

KNEE LEVER BRONZE

BEARING FOR HE AND

H42/H52 MODELS

H15 H20 H26 H31 H42

H200 7008 7008 7005 - - -

H200 7535 - 7536 - - -

H200 - - 7023 7299 7143 7568

H201 7258 - 7257 - - -

H201 0052 0052 0027 - - -

H201 - - 7259 7517 7262 7571

H202 7048 7048 7048 - - -

H202 - - 7025 7025 7025 7025

H203 Div Div Div Div Div Div

H204 7317 - 7317 - - -

H204 7101 7101 7101 - - -

H205 7032 7032 7032 7032 7032 7032

H206 0136 0136 0136 0136 0136 0136

H207 2585 2585 2585 2585 2585 2585

H208 7445 7445 7445 7445 - -

H208 7446 - 7446 - 7446 7446

H209 7454 7454 7454 7454 - -

H209 2859 - 2859 - 2859 2859

2

JUNTA COMPUERTA GOMA

VERDE

MICROINTERRUPTOR (SOLO

MODELOS A)

AFDICHTINGSRUBBER

GROEN VOOR ACHTERPLAAT

MIKRO-SCHAKELAAR

MODELLEN A

(AUTOMATISCH)

GRÜN DECKELDICHTUNG

FÜR MASCHINENGEHÄUSE

INNERER MIKROSCHALTER

CROUZET (A-MODELLE

AUTOMATISCH)

CAJA AISLANTE CUADRO

VEILIGHEIDS-ELEKTRADOOS

ELECTRICO

CONTACTOR

TELEMECANIQUE

CILINDRO HIDRAULICO

COMPLETO

PATA ANTIVIBRATORIA GOMA

KUNSTSTOF

MAGNEETSCHAKELAAR

TELEMECANIQUE

COMPLETE HYDRAULISCHE

CILINDERBUS

SCHALTGEHÄUSE

SCHÜTZ TELEMECHANISCH

KOMPLETTE

KOLBENSTANGENEINHEIT

ANTI-VIBRATIONS FUß, GRÜN

VERDE

SOPORTE ANTIVIBRATORIO

MOTOR, GOMA NEGRA

ANTIVIBRATIEPOOT

ANTIVIBRATIEBASIS MOTOR

GUMMI

ANTI-VIBRATIONS STÜTZE

MOTOR, SCHWARZ GUMMI

JUNTA BOMBA HIDRAULICA

CRUCETA ACCIONAMIENTO

ELEKTROMOTOR-POMP

VERPAKKING

ELEKTROMOTOR-POMP

VERBINDUNGSSTÜCK

MOTOR-BOMBA

KOPPELING

MOTOR- PUMPE

BANCADA INFERIOR

BASIS/VOETSTUK/

POMO Y EJE SUELTOS

REGULADOR

PRENSAESTOPAS

MANGUERA ELECTRICA

CONTRATUERCA

PRENSAESTOPAS

ONDERFRAME

KNOP EN AS VAN HET DRUK-

SNELHEIDS-REGELVENTIEL

KABELSTOP

SCHROEFDRAAD

BEVESTIGINGSMOER

KABELSTOP

NUR ROTER KNOPF +

SCHAFT FÜR

REGULIERVENTIL

ZUGENTLASTUNG

ETIQUETA REGULACION

PRESIÓN

DISTRIBUIDOR HIDRAULICO

COMPLETO

HANDVAT ASA TRANSPORTE

STICKER DRUK- SNELHEIDS-

REGELVENTIEL

COMPLEET STUURVENTIEL

TRANSPORTGRIFF

EDELSTAHL ROSTFREI

AUFKLEBER

DRUCKREGULIERVENTIEL

DRUCKREGELVENTIL

KOMPLETT

AUFKLEBER ÖL STICKER OLIE ETIQUETA TAPON ACEITE

JOINT PORTE SOCLE

CAOUTCHOUC VERT

MICRO-INTERRUPTEUR

INTERNE CROUZET

PARTS LIST LISTE DE PIÈCES TEILELISTE ONDERDELENLIJST LISTA PIEZAS

GREEN RUBBER GASKET

PANEL

INTERNAL CROUZET

MICRO-SWITCH (ONLY A-

H52

(MODELES A-AUTOMAT)

AUTOMATIC MODELS)

OIL FILTER FILTRE D’HUILE ÖLFILTER OLIEFILTER FILTRO ACEITE

COFFRET ELECTRIQUE

PLASTIQUE

OIL FILTER COVER COUVERCLE FILTRE HUILE DECKEL ÖLFILTER DEKSEL OLIEFILTER TAPA FILTRO ACEITE

GREEN PLASTIC WHEEL ROUE PLASTIQUE VERT GRÜN PLASTIKRAD WIEL PLASTIC GROEN RUEDA PLASTICO VERDE

PLASTIC ELECTRIC

SWITCHBOARD BOX

CONTACTEUR

TELEMECANIQUE

VERIN HYDRAULIQUE

COMPLET

PIED ANTI-VIBRATION

CAOUTCHOUC VERT

BASE CAOUTCHOUC NOIR

CONTACTOR

TELEMECANIQUE

AIR EXTRACTION FAN VENTILATEUR EXT RAIR VENTILATOR LUCHTVENTILATOR VENTILADOR EXTRACC AIRE

COMPLETE HYDRAULIC

CYLINDER

GREEN RUBBER ANTI-

VIBRATION FOOT

BLACK RUBBER ANTI-

ANTI-VIBRATION MOTEUR

VIBRATION MOTOR SUPP

HYDRAULIC PUMP POMPE D’HUILE ÖLPUMPE HYDRAULISCHE POMP BOMBA HIDRAULICA

ACCOUPLEMENT MOTEUR-

POMPE

MOTOR-PUMP GASKET JOINT MOTEUR-POMPE DICHTUNG MOTOR-ÖLPUMPE

MOTOR-PUMP COUPLING

ELECTRIC MOTOR MOTEUR ELECTRIQUE ELEKTROMOTOR ELEKTROMOTOR MOTOR ELECTRICO

MACHINE FRAME SOCLE MACHINE MASCHINENGEHÄUSE

SEULEMENT POIGNEE

ROUGE + AXE REGULATEUR

PRESSE-ETOUPE FIL

ALIMENTATION

RED KNOB + SHAFT ONLY

(PRESSURE CONTROL)

SUPPLY CORD GROMMET

POIGNEE TRANSPORT

GROMMET NUT ÉCROU PRESSE-ETOUPE GEGENMUTTER

ACIER INOX

AUTOCOLLANT

REGULATEUR DE PRESS

DISTRIBUTEUR

HYDRAULIQUE COMPLET

S/S TRANSPORT HANDLE

PLASTIC PRESSURE

CONTROL LABEL

COMPLETE HYDRAULIC

DIRECT CONTROL VALVE

AUTOCOLLANT ENTREE

HUILE

OIL INPUT LABEL

H15 H20 H26 H31 H42

H210 2049 3302 2017 2017 3305 3447

H211 2039 2039 2039 2039 2039 2039

H212 2035 2035 0079 0079 0079 0079

H213 7327 7327 7327 7327 7327 7327

H214 2014 2014 2014 2014 2290 2290

H215 0758 0758 0758 0758 0758 0758

H217 Div Div Div Div Div Div

H219 2019 2866 2019 2019 2019 2019

H220 0038 2610 0012 0012 0803 0803

H221 2033 2033 2033 2033 2528 2528

H222 2034 2034 2034 2034 2034 2034

H223 0037 0037 0011 0011 0855 0855

H224 0064 0064 0064 0064 0064 0064

H225 0063 0063 0063 0063 0063 0063

H226 Div Div Div Div Div Div

H227 Div 2082 Div 2009 2282 3437

H228 2353 2353 2353 2353 2353 2353

H229 0104 0104 0104 0104 0104 0104

H230 0105 0105 0105 0105 0105 0105

H231 0188 0188 0188 0188 7310 7310

H232 2467 2467 2467 2467 2467 2467

H233 2012 2012 2012 2012 2012 2012

H234 2680 2680 2680 2680 2680 2680

3

TUBO ENTRADA ACEITE

PLASTICO VERDE

TAPON PLASTICO VERDE

ACEITE CON VARILLA

TUERCA ACERO INOX

VASTAGO TAPA (MODELOS

P)

PIJP OLIETOEVOER GROEN

PLASTIC

DOP GROEN PLASTIC MET

OLIEMEETSTAAF

MOER RVS VOOR DEKSEL (P-

MODELLEN)

GRÜN ÖLROHR FÜR

ÖLEINLAß

GRÜN PLASTIK-STOPFEN MIT

ÖLMEßSTAB

MUTTER EDELSTAHL

DECKELBOLZEN (P-

MODELLE)

ARANDELA ACERO INOX

VASTAGO TAPA (MODELOS

P)

DEPOSITO CARNE P-FIJO

DEPOSITO CARNE E-

DESMONTABLE

RVS SLUITRING VAN

AANSLAGAS (P-MODELLEN)

MENGSELCILINDER P-MODEL

VASTE

MENGSELCILINDER E-MODEL

AFNEEMBAAR

UNTERLEGSCHEIBE

EDELSTAHL FÜR BOLZEN (P-

MODELLE)

BRÄTZYLINDER P-MODELLE

FESTSTEHEND

BRÄTZYLINDER E-MODELLE

ABNEHMBAR

DISCO PROTECTOR FONDO

DEPOSITO (MODELOS P)

SOMBRERETE PROTECTOR

FONDO DEPÓSITO

(MODELOS E)

RVS CILINDERBODEM

AFDEKPLAAT (P-MODELLEN)

RVS CILINDERBODEM

AFDEKPLAAT (E-MODELLEN)

ZYLINDERBODEN-

SCHUTZDECKEL (P-

MODELLE)

ZYLINDERBODEN-

SCHUTZDECKEL (E -

MODELLE)

JUNTA TAPA DEPÓSITO P

SILICONA VERDE PERFIL

RVS BOUT TORNILLO ACERO INOX

DEKSELDICHTINGSRING

VOOR P-MODELLEN

EDELSTAHLSCHRAUBEN

BEFESTIGUNG

DECKELDICHTUNG FÜR P-

MODELLE ZYLINDER (3-

REDONDO (PAQUETE DE 3)

JUNTA TAPA-DEPÓSITO E

GOMA VERDE PERFIL

RECTANGULAR (PAQUETE

DE 3)

VASTAGO ACERO INOX GIRO

TAPA HP

CILINDER (PAKKETJE VAN 3)

DEKSELDICHTINGSRING

VOOR E-MODELLEN

CILINDER (PAKKETJE VAN 3)

RVS AANSLAGAS VOOR

DEKSEL (P-MODELLEN)

PACKUNG)

DECKELDICHTUNG

RECHTECKIG GUMMI GRÜN

NUR FÜR E- MODELLE

ZYLINDER (3-PACKUNG)

EDELSTAHL BOLZEN FÜR

DECKEL (P-MODELLE)

CONJUNTO LLAVE-TORNILLO

EXTRACTOR DE PISTON

JUNTA TÓRICA PISTON

(PAQUETE DE 4/2 UD)

JUNTA TÓRICA TORNILLO

CIERRE PISTON

ZUIGERSLEUTEL

SCHRAUBE O-RING O-RING ZUIGERSCHROEF

KOLBENABZIEH-

VORRICHTUNG

TUERCA CIERRE TAPA (SOLO

ZUIGERDICHTINGSRING

(PAKKETJE VAN 4/2)

DEKSEL SLUITSCHROEF

KOLBEN O-RING ( 4/2-

PACKUNG)

DECKEL

BEFESTIGUNGSSCHRAUBE

MOD E)

(ALLEEN E-MODELLEN)

(NUR E-MODELLE)

TUBE PLASTIQUE VERT

ENTREE HUILE

PARTS LIST LISTE DE PIÈCES TEILELISTE ONDERDELENLIJST LISTA PIEZAS

GREEN PLASTIC OIL INPUT

TUBE

H52

BOUCHON PLASTIQUE

REMPLISSAGE HUILE AVEC

TIGE NIVEAU

ÉCROU ACIER INOX

BOULON COUVERCLE

(MODELES P SEULEMENT)

RONDELLE ACIER INOX

BOULON COUVERCLE

PLASTIC OIL DRAIN PLUG

WITH LEVEL BAR

S/S HEX NUT FOR LID

BOLT (P MODELS ONLY)

S/S WASHER FOR LID

BOLT (P MODELS ONLY)

(MODELES P)

CYLINDRE VIANDE E-

DEMONTABLE

DISQUE INOX PROTECTION

FIXED P MEAT BARREL CYLINDRE VIANDE P- FIXE

REMOVABLE E MEAT

BARREL

S/S BARREL BOTTOM

FOND CYLINDRE (MODÈLES

P SEULEMENT)

CHAPEAU INOX

PROTECTION FOND

CYLINDRE (MODÈLES E)

PROTECTION DISC (P

MODELS ONLY)

S/S BARREL BOTTOM

PROTECTION HAT (E

MODELS ONLY)

S/S FIXING SCREW VIS ACIER INOX FIXATION

JOINT COUVERCLE POUR

CYLINDRE MODELES P

(PAQUET DE 3 UNITÉS)

JOINT RECTANGULAIRE

CAOUTCHOUC VERT

COUVERCLE-CYLINDRE

VIANDE MODELES E

SEULEMENT (3 UNITÉS)

PIVOT ACIER INOX

COUVERCLE HP

LID GASKET FOR P

MODELS BARREL ONLY

(PACKAGE OF 3)

GREEN RUBBER

RECTANGULAR LID

GASKET FOR E MODELS

REMOVABLE BARREL

ONLY (PACKAGE OF 3)

S/S LID BOLT MODELS HP

7039 7142 7142

7021

7039

JOINT TORIQUE VIS CENTRE

PISTON

CLE ET VIS D’EXTRACTION

DU PISTON

ALUMINUM PISTON PISTON ALUMINIUM KOLBEN ALUMINIUM ZUIGER ALUMINIUM PISTON ALUMINIO

S/S PISTON PISTON ACIER INOX KOLBEN EDELSTAHL ROSTF ZUIGER RVS PISTON ACERO INOX

PISTON LOCKING BOLT O-

RING

PISTON LOCK BOLT SCRE VIS FIXATION CENTR PISTO KOLBENSCHRAUBE ZUIGERSCHROEF TORNILLO CIERRE PISTON

PISTON REMOVING

WRENCH WITH SCREW

JOINT TORIQUE PISTON

(PAQUET DE 4/2 UNITÉS)

ÉCROU FERMETURE

COUVERCLE (SEULEMENT

MODELES E)

PISTON O-RING (PACKAGE

OF 4/2 UNITS)

LID CLOSING NUT (ONLY E

MODELS)

H15 H20 H26 H31 H42

H235 2592 2592 2592 2592 2592 2592

H236 2589 2589 2589 2589 2589 2589

H237 0048 0048 0022 0022 0810 0810

H238 0049 0049 0023 0023 0811 0811

H239 7161 7265 7162 7266 7141 7567

H239 2043 - 2011 - - -

H240 2044 2044 2032 2373 0819 3446

H240 2047 - 2015 - - -

H241 2025 2025 2025 2025 0823 0823

H242 6230 6230 6231 6093 6232 6240

H242 6233 - 6234 - - -

H243 7026 7026

H244 7009 7009 7006 - - -

H244 - - 7024 7333 7144 7569

H245 0109 0109 0109 0109 0109 0109

H246 7029 7029 7029 7029 7029 7029

H247 7060 7060 7060 7060 7060 7060

H248 6235 6235 6236 6238 6237 6239

H249 7305 - 7305 - - -

4

BARRA LATERAL FIJACION

DEPOSITO (SOLO MOD E)

CILINDER

BEVESTIGINGSSTAAF

(ALLEEN E-MODELLEN)

ZYLINDER

BEFESTIGUNGSSTANGE

(NUR FÜR E-MODELLE)

HORIZONTALER

INTERRUPTOR MANUAL 0-1

CON MANETA NEGRA (SOLO

MODELOS i)

AS VAN KNIEHENDEL EJE HORIZONTAL RODILLERA

SCHAKELAAR 0-1 MET

ZWARTE KNOP (ALLEEN i-

MODELLEN)

KNIEHEBELSCHAFT,

EDELSTAHL ROSTFREI

INNERER 0-1

DREHSCHALTER MIT

SCHWARZEN KNOPF (NUR i)

VARILLA ROSCADA PALANCA

M8

ACCIONADOR RODILLERA

HORQUILLA PALANCA

ARTICULACIÓN RODILLERA

STANG KNIEHENDEL MET M8-

KNIEHEBELSCHAFT MIT M8-

DISTRIBUIDOR

SCHROEFDRAAD

ACTIVERINGSSTAAF VOOR

REGELVENTIEL

GEWINDE

AKTIVIERUNGSSCHAFT FÜR

REGELVENTIL

PALANCA TUERCA CIERRE

TAPA MODELOS E SOLO, SIN

POMO VERDE

JUNTA CIRCULAR INFERIOR

DEPOSITO, COLOR VERDE

(SOLO MOD P)

ARANDELA

METALOPLÁSTICA

HIDRÁULICA 3/8” VACIADO

STAAF MOER SLUITEN VAN

DEKSEL (ALLEEN E-MOD.),

ZONDER RODE KNOP

LAGE RONDE CYLINDER-

DICHTINGSRING, GROEN

(ALLEEN P-MOD.)

HYDRAULISCHE PLASTIC

SLUITRING 3/8”, LEDIGING

GRIFF OHNE GRÜN KNOPF

FÜR SCHLIEßMUTTER, NUR

E-MODELLE

UNTERE RUNDE ZYLINDER-

DICHTUNG, GRÜN (NUR FÜR

P-MODELLE)

HYDRAULISCHE PLASTIK-

UNTERLEGSCHEIBE 3/8”,

AUSLAUF

ARANDELA PLANA GOMA

NEGRA VACIADO

ARANDELA PLANA ESPECIAL

ACERO INOX VACIADO

SOPORTE MICROINTERRUPT

(SOLO MODELOS P)

CASQUILLO ROSCADO

PISTON ALUMINIO

VLAKKE RUBBEREN

SLUITRING ZWART, LEDIGING

VLAKKE SLUITRING

SPECIAAL RVS, LEDIGING

HOUDER MICROSCHAKEL.

(ALLEEN P MOD.)

HULS SCHROEFDRAAD

ALUMINIUM ZUIGER

FLACHE UNTERLEGSCHEIBE

SCHWARZER GUMMI,

AUSLAUF

FLACHE UNTERLEGSCHEIBE

EDELST ROSTF, AUSLAUF

HALTER MIKROSCHALTER

(NUR FÜR P MODELLE)

HÜLSE ALUMINIUM KOLBEN

BARRE LATERAL FIXATION

CYLINDRE (SEULEMENT

MODELES E)

AXE HORIZONTAL

GENOUILLERE ACIER INOX

INTERRUPTEUR MANUEL 0-1

PARTS LIST LISTE DE PIÈCES TEILELISTE ONDERDELENLIJST LISTA PIEZAS

LATERAL BARREL BAR

(ONLY E MODELS)

HORIZONTAL S/S KNEE

LEVER AXLE

MANUAL SWITCH 0-1 WITH

H52

AVEC BOUTON NOIR

(SEULEMENT MODELES i)

BLACK KNOB (ONLY i

MODELS)

FORK KNEE LEVER FOURCHE GENOUILLERE KNIEHEBELGABEL VORK VAN KNIEHENDEL

TIGE GENOUILLERE

KNEE LEVER BAR TIGE GENOUILLERE KNIEHEBEL SCHAFT KNIEHENDEL STAAF ACCIONADOR RODILLERA

FILETAGE M8

TIGE ACTIONNEMENT

DISTRIBUTEUR HYDRAULIQ

KNEE LEVER THREAD M8

HYDRAULIC CONTROL

ACTION BAR

LEVIER ÉCROU FERMETURE

SANS POIGNEE VERT,

SEULEMENT MODÈLES E

PRESSURE GAUGE P MANOMÈTRE DE PRESSION DRUCKMANOMETER MANOMETER MANÓMETRO

PRESSURE GAUGE HOSE CONDUIT MANOMÈTRE MANOMETERLEITUNG LEIDING MANOMETER LATIGUILLO MANOMETRO

LID CLOSING NUT LEVER

WITHOUT GREEN KNOB, E

MODELS ONLY

JOINT CIRCULAIRE

INFÉRIEUR CYLINDRE,

COULEUR VERT

(SEULEMENT MODÈLES P)

RONDELLE HYDRAULIQUE

METALO-PLASTIQUE 3/8”,

VIDANGE

INFERIOR CIRCULAR

BARREL RUBBER GASKET,

GREEN (ONLY FOR P

MODELS)

HYDRAULIC METAL-

PLASTIC WASHER 3/8”,

EMPTYING

RONDELLE PLATE GOMME

NOIRE, VIDANGE

RONDELLE PLATE

SPÉCIALE ACIER IN, VIDAN

SUPPORT MICROINTERR

(SEULEMENT MODÈLES P)

PLANE BLACK RUBBER

WASHER, EMPTYING

SPECIAL PLANE S/S

RUBBER, EMPTYING

OIL EMPTYING PLUG BOUCHON VIDANGE HUILE ÖLWECHSELSTOPFEN OLIE-LEDIGING DOP TAPÓN VACIADO ACEITE

MICRO SWITCH HOLDER

(ONLY FOR P MODELS)

ANNEAU FILETAGE PISTON

ALUMINIUM

RING, THREADED

ALUMINIUM PISTON

H15 H20 H26 H31 H42

H250 7251 - 7253 - - -

H251 7316 7316 7316 7316 7316 7316

H252 3402 3402 3402 3402 3402 3402

H253 7320 7320 7320 7320 7320 7320

H254 7319 7319 7319 7319 7319 7319

H255 7330 7330 7331 7331 7332 7572

H256 7318 7318 7318 7318 7318 7318

H258 2278 2278 2278 2278 2278 2278

H259 2403 2403 2403 2403 2403 2403

H260 7322 - 7322 - - -

H261 2398 2398 2399 2468 2537 3449

H263 0086 0086 0086 0086 0086 0086

H264 2683 2683 2683 2683 2683 2683

H265 2580 2580 2580 2580 2580 2580

H266 2590 2590 2590 2590 2590 2590

H267 3435 3435 3435 3435 3435 3435

H268 7065 7065 7065 - - -

5

SAMPLE OF

CE

DECLARATION OF CONFORMITY

TALSA as manufacturer, declares that the filler/stuffer model Hxx: is in conformity with the following requirements:

- European Union Machinery Directive 98/37/EC.

- European Union Low Voltage Directive 73/23/EC.

- European Union Electromagnetic Compatibility Directive 89/336/EC.

- EN 60204-1:1997: Safety of Machinery, Electrical Equipment of Machines.

- EN 292-1:4/1993 and EN292-2/A1:2/1996: Safety of Machinery; concepts, principles.

- EN 1672-2:12/1994: Basic Concepts for Food Processing Machinery; part 2: Hygiene Requirements.

- EN 50081-2:1992 and EN 50082-2:1996 Electromagnetic Compatibility EMC.

- prEN 12463:2/1999: Safety and Hygiene Requirements for Fillers/Stuffers.

EXEMPLE DE DECLARATION DE CONFORMITÉ

CE

TALSA comme fabricant, déclare que le poussoir Talsa Hxx répond aux prescriptions suivantes :

- Directive de Machines de l'Union Européenne 98/37/CEE.

- Directive de Basse Tension de l'Union Européenne 73/23/CEE.

- Directive de Compatibilité Electromagnétique de l'Union Européenne 89/366/CEE.

- EN 60204-1 : 1997 : Sécurité des Machines, Equipement Électrique des Machines.

- EN 292-1 : 4/1993 et EN292-2/A1 : 2/1996 : Sécurité des Machines; concepts, principes.

- EN 1672-2 : 12/1994 : Prescriptions relatives à l'Hygiène en Machines Alimentaires.

- EN 50081-2 : 1992 et EN 50082-2 : 1996 : Compatibilité Electromagnetique EMC.

- prEN 12463 : 2/1999 : Sécurité et Hygiène pour Poussoirs.

BEISPIEL -KONFORMITÄTSERKLÄRUNG

CE

TALSA gibt als Hersteller, die Erklärung ab, daß die Kolbenfüller Hxx entspricht den nachfolgend aufgeführten Anforderungen:

- Richtlinie über Maschinen 98/37/EG.

- Richtlinie über Niederspannung 73/23/EG.

- Richtlinie über Elektromagnetische Verträglichkeit 89/366/EG.

- EN 60204-1:1997: Sicherheit von Maschinen, Elektrische Ausrüstung von Maschinen.

- EN 292-1:4/1993 und EN292-2/A1:2/1996: Sicherheit von Maschinen; Grundbegriffen und Prinzipe.

- EN 1672-2:12/1994: Hygieneanforderungen für Nahrungsmittelmaschinen.

- EN 50081-2:1992 und EN 50082-2:1996: Elektromagnetische Verträglichkeit EMV.

- prEN 12463:02/1999: Sicherheits- und Hygieneanforderungen von Füllmaschinen.

VOORBEELD VERKLARING VAN OVEREENSTEMMING

CE

TALSA als fabrikant, verklaart hierbij dat de Stopmachine/Vulvus Hxx voldoet aan de volgende eisen:

- Richtlijn van Machines van de Europese Unie 98/37.

- Richtlijn over laagspaning van de Europese Unie 73/23/EG.

- Richtlijn over elektromagnetische compatibiliteit van de Europese Unie 89/336/EG.

- EN 60204-1:1997: Veiligheid van machines, elektrische inrichtingen van machine.

- EN 292-1:4/1993 en EN292-2/A1:2/1996: Veiligheid van machines, basisbegrippen en -principes.

- EN 1672-2:12/1994: Basisbegrippen voor voedingsverwerkingmachines; deel 2: Eisen inzake hygiëne.

- EN 50081-2:1992 een EN 50082-2:1996: elektromagnetische compatibiliteit EMC.

- prEN 12463:2/1999: Eisen inzake veiligheid en hygiëne voor Vulbussen.

EJEMPLO DE DECLARACION DE CONFORMIDAD

TALSA como fabricante, declara que la embutidora Hxx es conforme con los siguientes requisitos:

- Directiva de Máquinas de la Unión Europea 98/37/CEE.

- Directiva de Baja Tensión de la Unión Europea 73/23/CEE.

- Directiva de Compatibilidad Electromagnética de la Unión Europea 89/336/CEE.

- EN 60204-1:1997: Seguridad de las Máquinas, Equipo Eléctrico de las Máquinas.

- EN 292-1:4/1993 y EN292-2/A1:2/1996: Seguridad de las Máquinas; conceptos, principios.

- EN 1672-2:12/1994: Requisitos sobre Higiene en Maquinaria para Productos Alimentarios.

- EN 50081-2:1992 y EN 50082-2:1992: Compatibilidad electromagnética EMC.

- prEN 12463:2/1999: Requisitos sobre Seguridad e Higiene en Embutidoras.

6

CE

Main elements Éléments principaux Hauptsteile Belangrijkste punten Essentielle deler Elementi principali Elementosprincipales••• •••

Horn/nozzle nut

Écrou porte embout

Verschlußmutter

Afsluitmoer

Omløber

Dado porta-imbuti

Tuerca portaembudos

Piston

Piston

Kolben

Zuiger

Stempel

Pistone

Piston

Knee lever

Genoullière

Kniehebel

Kniehendel

Knæpedal

Leva ginnocchio

Rodillera

Lid

Couvercle

Deckel

Deksel

Låg

Coperchio

Tapa

Lid bolt

Pivot couvercle

Deckelbolzen

Dekselbout

Lågbolt

Perno coperchio

Vástago tapa

Lid Lever

Levier du couvercle

Deckelgriff

Dekselhendel

Låghåndtag

Leva apertura coperchio

Palanca apertura tapa

Lid bolt nut

Ecrou pivot couvercle

Bolzenbefestigungsmutter

Dekselboutmoer

Møtrik for

lågbolt

Dado chiusura coperchio

Tuerca vástago tapa

Base

Socle

Gehäuse

Basis

Base

Base

Base

Horn/nozzle

Embout

Füllrohr

Worsthoorn

P

ølsehorn

Imbuto

Embudo

A utlet holes

ir o

Orifices d’aération

Öffnungen für Luft

Luchtgaatjes

Huller til udslip af luft

Fori uscita aria

Orificios aire

Valve pressure/speed control

Régulateur de pression/vitesse

Druckregulierventil

Druck/snelheid-regelventiel

Tryk/hastigheds regulator

Regolatore di pressione/velocità

Regulador de presión/velocidad

Transport handle

Poignée transport

Kunststoffgriff

Handvat

Håndtag

Maniglia

Asa transporte

Oil drain plug

Bouchon remplissage huile

Öleinfüll

Olie-invul

M

ålepind for olie

T

appo riempimento olio

apón llenado aceite

T

Wheel

Roulette

Rad

Wiel

Hjul

Ruota

Rueda

Rubber foot

Pied caoutchouc

Gummifuß

Rubber voet

Gummiben

Supporto gomma

Pata goma

7

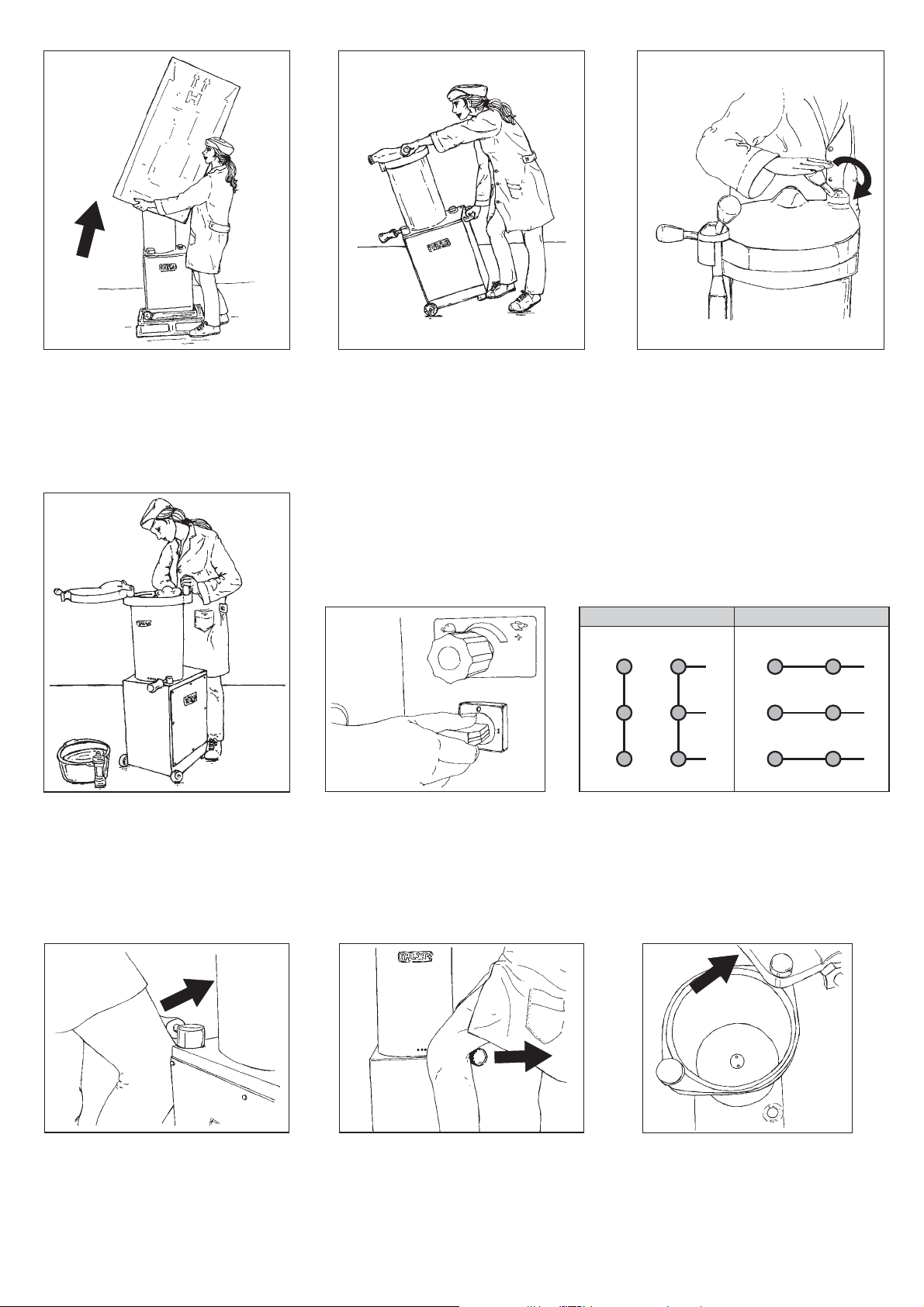

Unpacking.

Déballage.

Auspacken.

Uitpakking.

Udpakning.

Disimballo.

Desembalaje.

Proper displacement of machine.

Déplacement correct.

Richtiger Transport.

Correcte veplaatsing.

Korrekt flytning.

Spostamento corretto.

Desplazamiento correcto.

U

pper lid screws (E models).

crous couvercle (modèles E).

E

Deckelschrauben (E-modellen).

Deksel-schroeven (E-modellen).

Lågets møtrikker skrues af (modeller E).

Svitare dadi coperchio ( modelli E).

T

uercas tapa (modelos E).

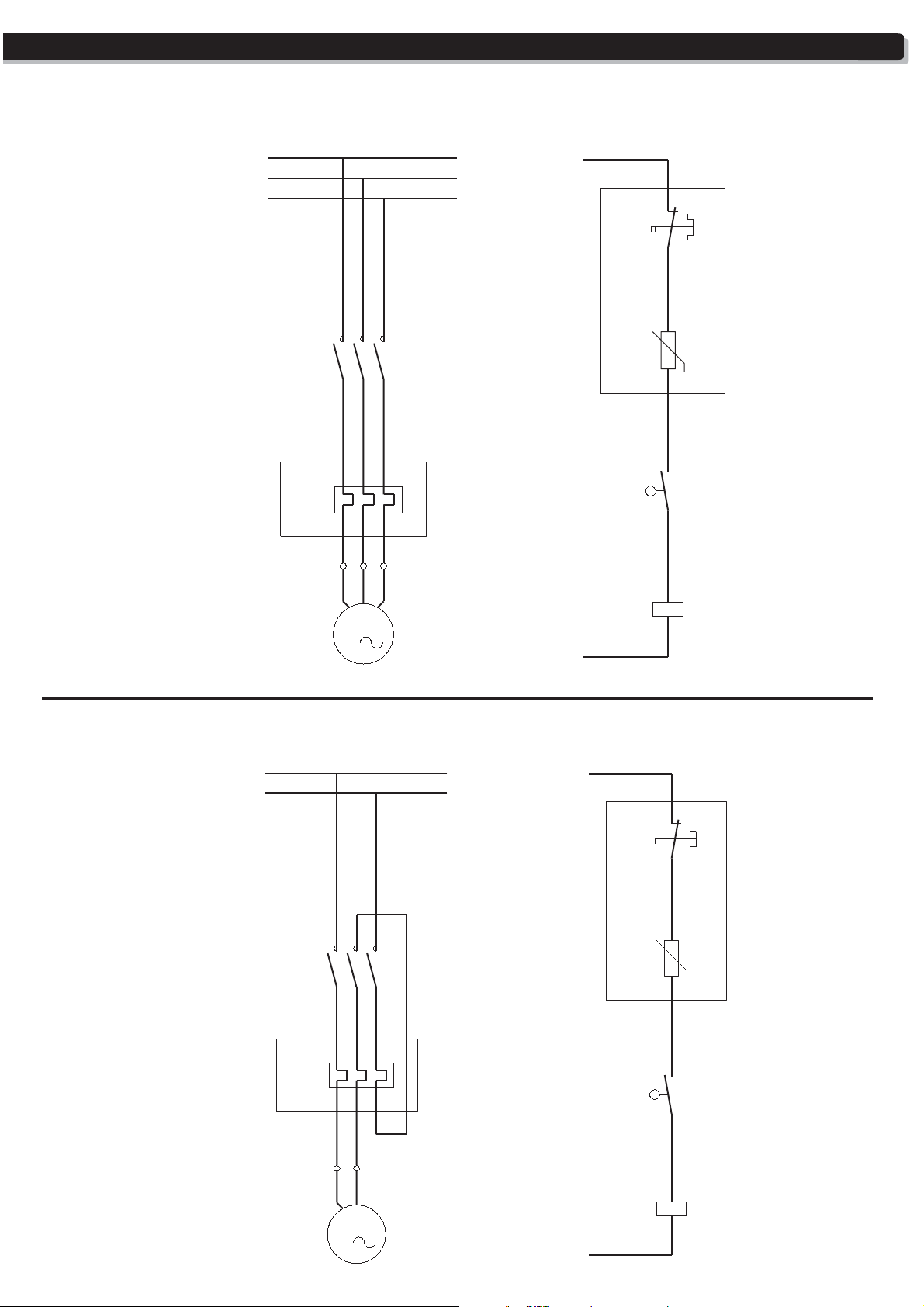

400/380 Volt. 230/220 Volt.

Clean before use.

Nettoyer avant utilisation.

Vor Gebrauch reinigen.

Wassen voor gebruik.

Maskinen bør renses før den tages i brug.

Pulizia prima dell'utilizzo.

Limpiar antes de utilizar.

Start-stop

nterrupteur marche-arrêt (modèles i).

I

switch (i models only).

Schalter (i-Modellen).

Schakelaar (i-modellen).

A

fbryderkontakten (modeller i).

Interruttore (modelli i).

I

nterruptor (sólo modelos i).

V2

U2

W2

W1

V1

U1

L3

L2

L1

V2

U2

W2

W1

V1

U1

L3

L2

L1

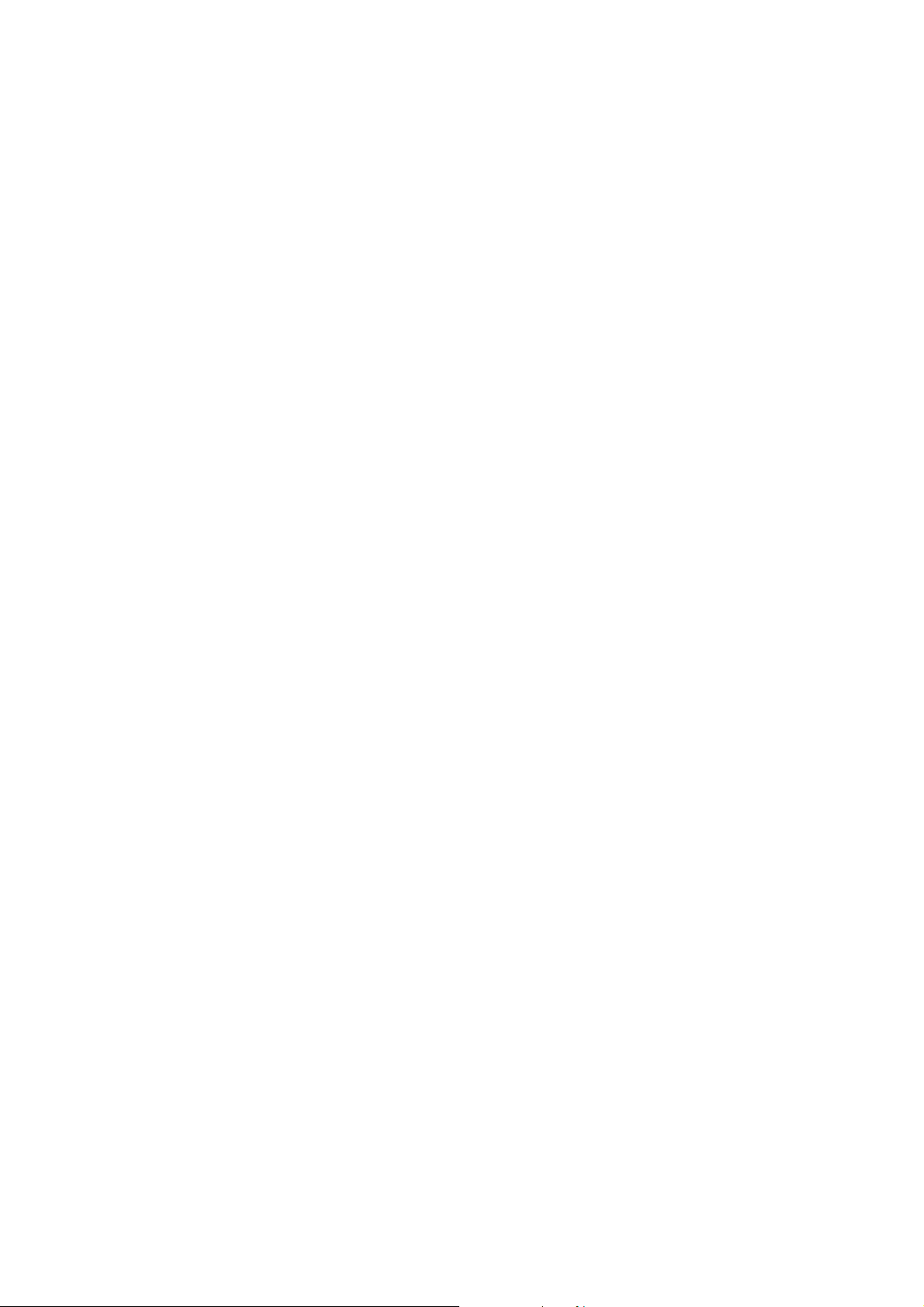

3-phase motor voltage change.

Changement voltage moteur triphasé.

Spannungswechsel 3-phasig motoren.

Veranderen van voltage 3-fasig motor.

OCmstilling af spænding.

ambio voltaggio motori 3 fase.

Posición plaquitas cambio voltaje motores trifásicos.

Raise piston.

Monter piston.

Kolben herauffahren.

Zuiger naar boven laten gaan.

Løfte stemplet.

Elevare pistone.

8

Subir pistón.

Lower piston.

Baisser piston.

Kolben herunterfahren.

Zuiger naar beneden laten gaan.

Sænke stemplet.

Abbassare pistone.

Bajar pistón.

Make room for mixture.

Laisser place pour mélange.

Raum für Füllgut.

Plaats laten voor de mengsel.

Ifyldning af farsen

.

Mettere l'impasto.

Dar cabida masa.

on lid

Insert green gasket.

Placer joint couvercle.

Deckeldichtung einlegen.

Grüne

Groene

dekseldichtingsring plaatsen.

vert

Placering af pakningen.

Mettere guarnizione verde.

Colocación

junta verde de tapa.

Installing locking nozzle/horn nut.

Placer écrou porte-embout.

Füllrohrverschlußmutter andrehen.

Wartel aandraaien.

Skru oml

øberen på.

Mettere dado porta-imbuto.

Colocar tuerca porta embudo.

Putting on nozzle/

horn.

Placer embout.

Füllrohr anbringen.

Worsthoorn plaatsen.

Pølsehornet sættes på.

Mettere imbuto.

Instalar

embudo.

Unscrew piston locking bolt.

Desserrer vis fixation piston.

Kolbenschraube lösen.

Zuigerschroef losdraaien.

Stempelbolten løsnes.

Allentare chiusura pistone.

Desenroscar

P

iston seals cleaning.

cierre pistón.

Nettoyage joints piston.

Kolbendichtungen reinigen.

Zuigerdichtingsringen schoonmaken.

Stempelpakningerne enses.

r

Pulire guarnizioni pistone.

Limpieza juntas pistón.

Remove piston.

Enlever piston.

Kolben herausziehen.

Zuiger uithalen.

Udtræk stemplet.

Allentare chiusura pistone.

Extraer pistón.

P

iston cleaning.

Nettoyage piston.

Kolben reinigen.

Zuiger schoonmaken.

Rens stemplet.

Pulire pistone.

Limpieza pistón.

9

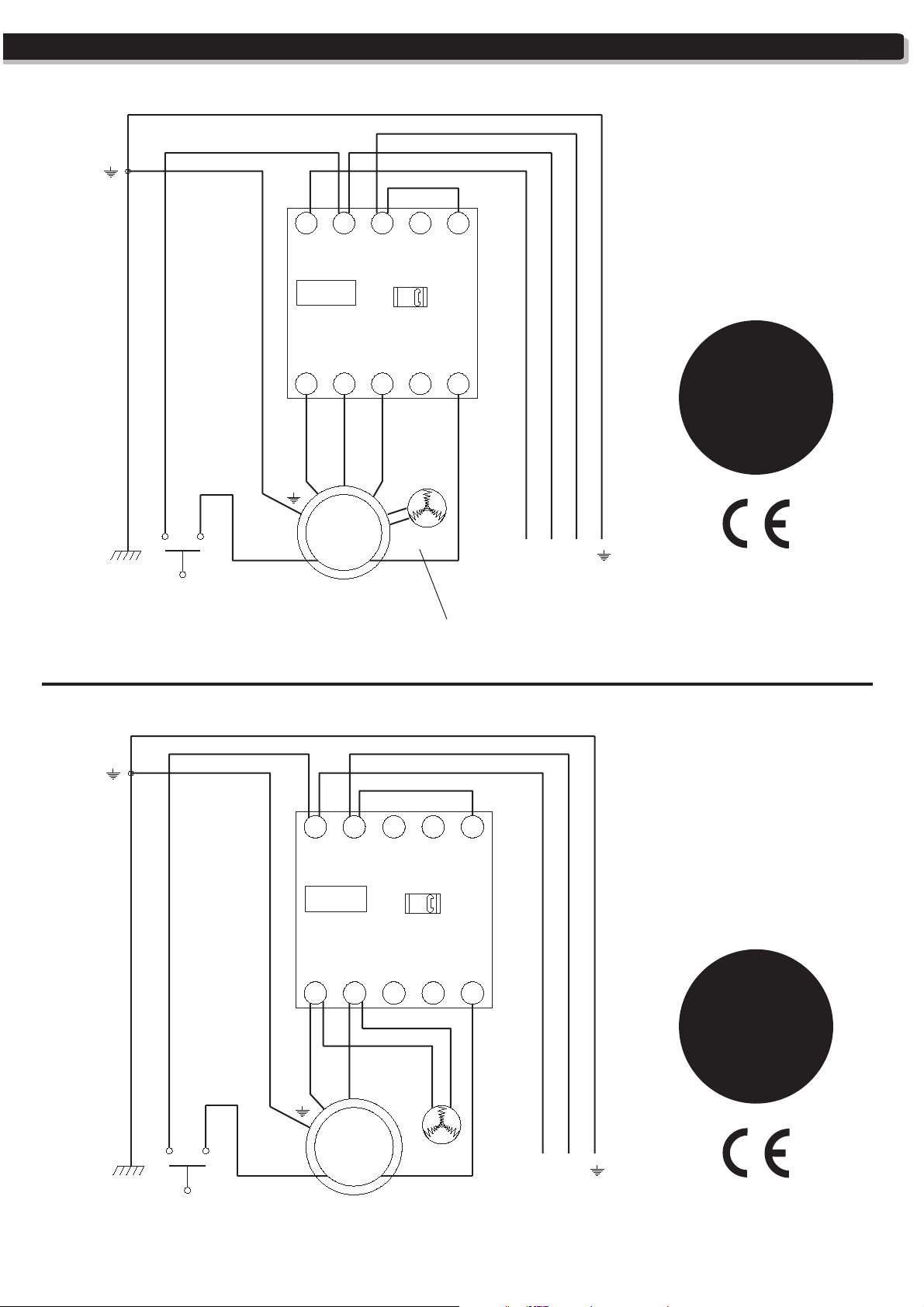

ELECTRIC SCHEMAS • SCHÉMAS ÉLECTRIQUES • ELEKTROSCHEMA • EL-SKEMAER • SCHEMI ELETTRICI • ESQUEMAS ELÉCTRICOS

H31.a

H42.a

Micro

31 L1

LC1K

4T12

T2 T36

V1U1

M

3~

Motor with internal

thermo protection

13L3 NO5L2 A1

14 A2

W1

Fan

NO

Fan on H42/H52 only

L1

L2

H52.a

automatic

3-phase

3-ph

400V

230V

L3

Micro

31 L1

LC1K

4T12

T2 T36

V1U1

M

1~

Motor with internal

thermo protection

13L3 NO5L2 A1

NO

14 A2

Fan

L1

H31.am

H42.am

H52.am

automatic

1-phase

1-ph

230V

220V

N

10

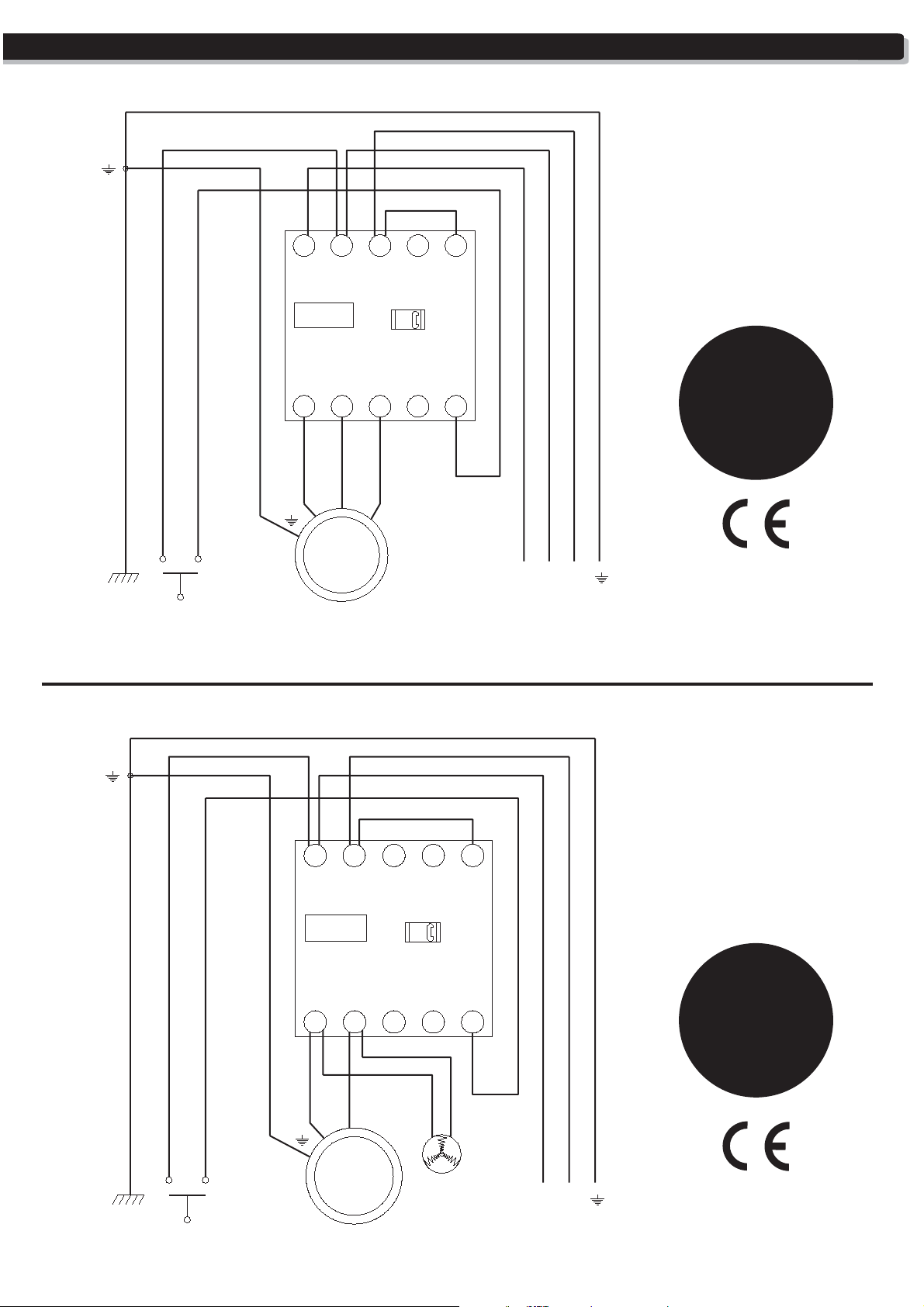

ELECTRIC SCHEMAS • SCHÉMAS ÉLECTRIQUES • ELEKTROSCHEMA • EL-SKEMAER • SCHEMI ELETTRICI • ESQUEMAS ELÉCTRICOS

H15.a

H20.a

H26.a

31 L1

13L3 NO5L2 A1

automatic

3-phase

LC1K

3-ph

4T12

T2 T36

NO

14 A2

400V

230V

V1U1

W1

Micro

3~

LC1K

M

31 L1

4T12

T2 T36

13L3 NO5L2 A1

NO

14 A2

L1

L2

L3

H15.am

H20.am

H26.am

automatic

1-phase

1-ph

230V

Micro

M

1~

220V

V1U1

Fan

L1

N

11

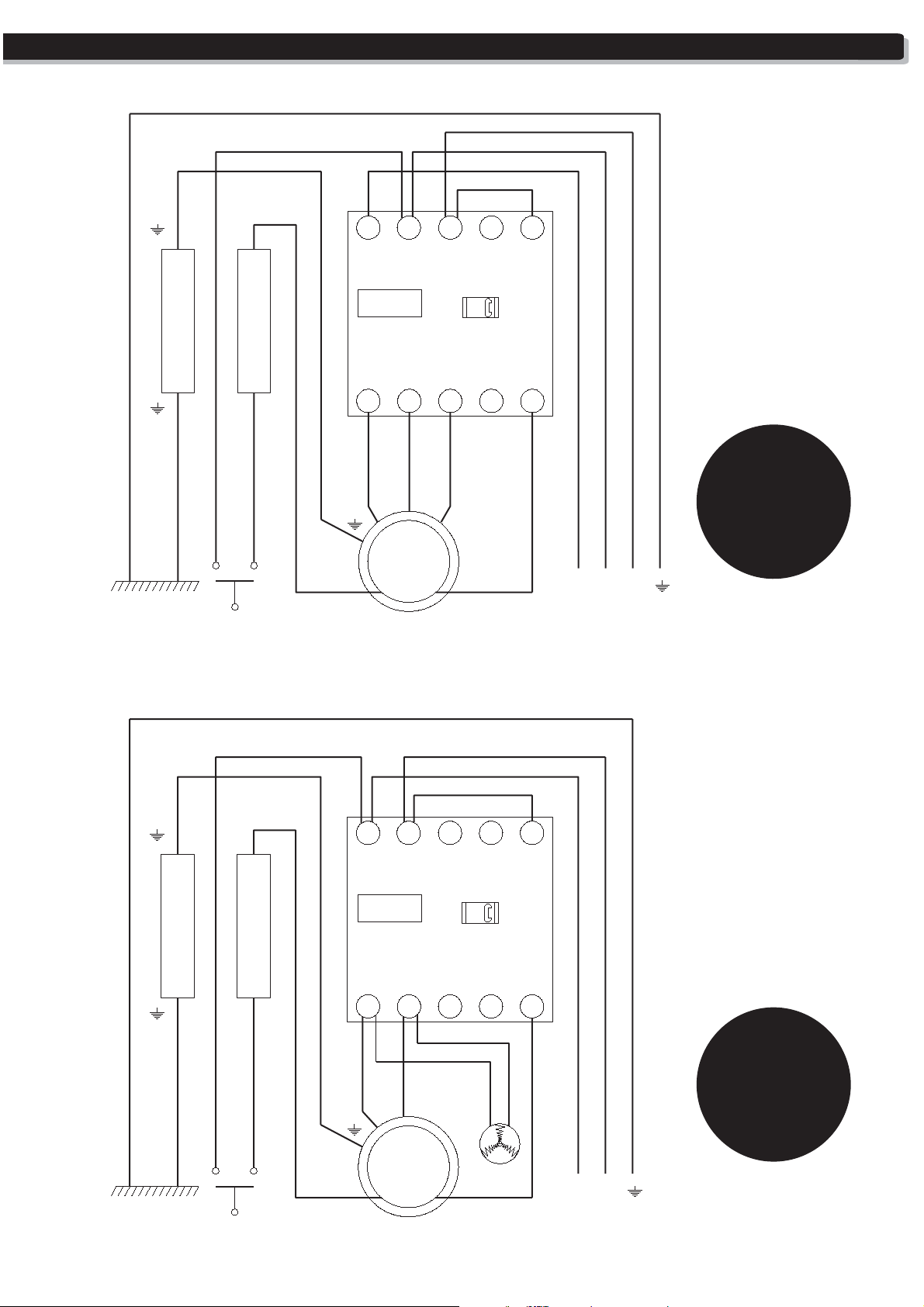

USA/CANADA ELECTRIC SCHEMAS • SCHÉMAS ÉLECTRIQUES USA/CANADA • ESQUEMAS ELÉCTRICOS USA/CANADA

USA/Canada only:

H26pa-UL/CSA

Terminal block

Micro

Terminal block

31 L1

LC1K

4T12

T2 T36

V1 W1U1

M

3~

Motor with internal

thermo protection

13L3 NO5L2 A1

NO

14 A2

L1

H15pa/H20pa

H31pa/H42pa

H52pa

automatic

3-phase

60Hz

3-ph

208V

220V

L3L2

12

Terminal block

Micro

Terminal block

31 L1

LC1K

4

2

T1

6

T2 T3

V1U1

M

1~

Motor with internal

thermo protection

13L3 NO5L2 A1

NO

14 A2

Fan

L1

USA/Canada only:

H15pam/H20pam

H26pam/H31pam

H42pam/H52pam

automatic

1-phase

60Hz

1-ph

•

220V

N

ELECTRIC SCHEMAS • SCHÉMAS ÉLECTRIQUES • ELEKTROSCHEMA • EL-SKEMAER • SCHEMI ELETTRICI • ESQUEMAS ELÉCTRICOS

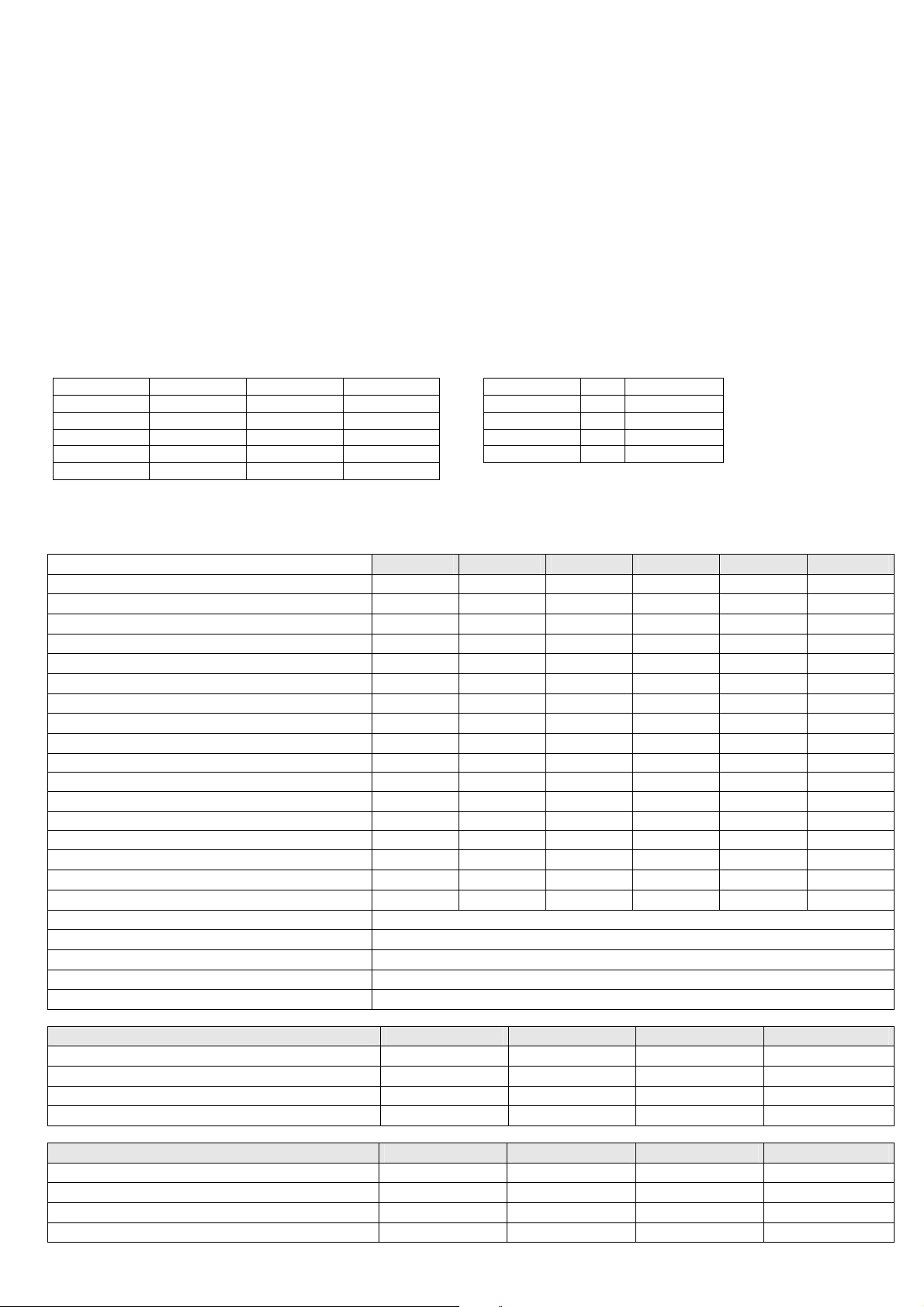

• ELECTRIC SCHEMA model A-automatic, 3-phase. • SCHEMA ELECTRIQUE Modèle A-automatique, triphas’e.

• ELEKTRISCHE SCHEMA Modelle A-automatisch, 3-phasig. • ESQUEMA ELÉCTRICO modelo A-automático, trifásica.

1/L1

3/L2

5/L3

-KM2

-F1

1

2

1

2

U1

L1

95

-F1

96

5

3

-S1

-KM1

-R1

T

13

14

A1

A2

H15/H20/H26:

OPTIONAL THERMAL RELAY.

RELAIS THERMIQUE OPTIONNEL.

THERMORELAIS AUF WUNSCH.

RELE TERMICO OPCIONAL.

6

4

5

3

6

4

H15/H20/H26:

OPTIONAL THERMAL RELAY.

RELAIS THERMIQUE OPTIONNEL.

THERMORELAIS AUF WUNSCH.

V1

W1

RELE TERMICO OPCIONAL.

M

3

L2

• ELECTRIC SCHEMA model A-automatic, 1-phase. • SCHEMA ELECTRIQUE Modèle A-automatique, monophasé.

• ELEKTRISCHE SCHEMA Modelle A-automatisch, 1-phasig. • ESQUEMA ELÉCTRICO modelo A-automático, monofásica.

1/L1

5/N

-KM2

-F1

1

2

1

2

U1

5

3

6

4

5

3

6

4

H15/H20/H26:

OPTIONAL THERMAL RELAY.

RELAIS THERMIQUE OPTIONNEL.

THERMORELAIS AUF WUNSCH.

RELE TERMICO OPCIONAL.

V1

M

1

L1

H15/H20/H26:

OPTIONAL THERMAL RELAY.

RELAIS THERMIQUE OPTIONNEL.

THERMORELAIS AUF WUNSCH.

RELE TERMICO OPCIONAL.

N

-F1

-S1

-KM1

-R1

95

96

T

13

14

A1

A2

13

NOTICE: This cap is for transport purposes only!. Before operating the

machine, replace it with the enclosed depressurized oil cap/dipstick.

ATTENTION: avant l’installation de la machine, veuillez rémplacer ce bouchon

d`étancheité transport par le bouchon-tige niveau huile dépressurisé livré.

ACHTUNG: Dieser Verschluß ist nur für Transportzwecke: Entfernen Sie ihn

unbedingt vor den Inbetriebnahme der Maschine und ersetzen Sie ihn durch den

beigefügten Öleinfüllverschluß mit Druckausgleich und Ölmeßstab.

LET OP: Deze dop is alleen voor transportdoeleinden! Verwijder deze vóór het in

gebruik nemen van de machine en vervang deze door de bijgevoegde

sluitdop/oliemeetstaaf met ontluchtingsgat.

ATENCION: este tapón sólo es válido para las tareas de transporte!. Antes de

conectar la máquina, reemplácelo por el tapón-varilla despresurizador entregado.

NO

OK

]

ALWAYS LEAVE

YOU HAVE FINISHED USING THE MACHINE.

LAISSEZ TOUJOURS

VOUS AVEZ FINI D'UTILISER LA MACHINE.

WENN DIE ARBEIT

ZYLINDER IMMER GANZ NACH UNTEN GEFAHREN WERDEN.

WANNEER U KLAAR

DE CILINDER STAAN.

SITÚE SIEMPRE

ACABE DE UTILIZAR LA MÁQUINA.

To remove the meat barrel do not use the hydraulic system; do it by removing the piston

with the supplied wrench.

N'utilisez pas le groupe hydraulique pour démonter le cylindre à viande; faite le en

démontant le piston à l'aide de la clé d’extraction fournie.

Gebrauchen Sie nicht das Hydrauliksystem, um den Fleischzylinder zu zerlegen; machen

Sie dies indem Sie den Kolben anhand der beigefügten Ausziehvorrichtung

herausnehmen.

Gebruik nooit het hydraulische systeem om de vlees-cylinder te demonteren; doe dit

met het uitnemen van de zuiger met behulp van de bijgevoegde sleutel.

Para desmontar el depósito carne no utilice el grupo hidráulico; hágalo desmontando el

pistón con la llave suministrada.

THE PISTON IN THE BOTTOM OF THE MEAT CYLINDER ONCE

LE PISTON AU FOND DU CYLINDRE À VIANDE QUAND

MIT DER MASCHINE BEENDET IST, SOLLTE DER KOLBEN IM

BENT MET HET WERK, LAAT U DAN DE ZUIGER ONDERIN

EL PISTÓN EN EL FONDO DEL DEPÓSITO DE MASA CUANDO

14

PRES.

T - 2467

WARNING • ATTENTION • ACHTUNG • LET OP

ADVASRSEL•FIGYELEM•ATTENZIONE•ATENCIÓN

400/230 V dual-voltage machine factory preset to:

Machine bi-tension 400/230 V, branchée à l'usine à :

400/230 V Maschine wurde in unserer Fabrik auf folgende Spannung eingestellt:

400/230 V machine is standaard aangesloten op:

400/230 V maskine er fra fabrikken koblet til:

A gép kettös müködésü 400/230 V, gyártóüzemi beállítás:

Macchina a doppio voltaggio 400/230 V, collegata alla fabbrica a:

Máquina bi-tensión 400/230 V, conectada en fábrica a:

3x400 V • 50 Hz

Machine must be properly grounded and/or connected to a circuit leakage breaker.

ENGLISH

TABLE OF CONTENTS -- INSTRUCTION MANUAL FOR FILLERS/STUFFERS:

ILLUSTRATIONS:

LABELED DIAGRAM

SPARE PARTS LIST

ESSENTIAL ELEMENTS

DRAWINGS

ELECTRIC DIAGRAMS FOR "A" MODELS (AUTOMATIC WITH CONTACTOR)

1 SAFETY INSTRUCTIONS

2 LIST OF POSSIBLE OPERATING HAZARDS

2.1 MECHANICAL HAZARDS

2.2 ELECTRICAL HAZARDS

2.3 NOISE HAZARDS

2.4 PERSONAL HEALTH HAZARDS

3 TECHNICAL FEATURES

3.1 GENERAL INFORMATION

3.2 DENOMINATION

3.3 MODELS

3.4 TECHNICAL SPECIFICATIONS

4 DELIVERY

5 INSTALLATION

5.1 UNPACKING AND POSITIONING

5.2 CONNECTING THE MACHINE

5.3 HYDRAULIC OIL FILLING

5.4 CHANGING THE VOLTAGE

5.4.1 CHANGING THE VOLTAGE ON “A” MODELS (AUTOMATIC-CONTACTOR)

5.4.2 CHANGING THE VOLTAGE ON “I” MODELS (SWITCH)

6 OPERATING INSTRUCTIONS

6.1 HANDLING STEPS

6.2 USEFUL TIPS

7 CLEANING

7.1 CLEANING INSTRUCTIONS

7.2 CLEANING PRECAUTIONS

7.3 CLEANING CHECKLIST

8 MAINTENANCE

8.1 MAINTENANCE AND INSPECTION SCHEDULES

8.2 MAINTENANCE AND INSPECTION TIPS

9 TROUBLESHOOTING GUIDE

1. SAFETY INSTRUCTIONS

This machine has moving mechanical parts and uses voltages that are potentially ha zardous. Severe, even life-threatening, personal

injury could result if the instructions contained in this manual are not followed. Before operating the unit, please read this manual

thoroughly. This manual should be kept for future reference an d given to every user of the mac hine. The following clauses limit the

liability of the manufacturer and its representatives :

• T HIS MACHINE SHOULD ONLY BE INSTALLED BY A QUALIFIED ELECTRICIAN. ONCE INSTALLED, DO NOT TAMPER WITH

THE ELECTRICAL WIRING OR COMPONENTS OF THE MACHINE.

• DO NOT USE THE MACHINE WITHOUT HAVING RECEIVED PREVIOUS INSTRUCTIONS ABOUT ITS USE, MAINTENANCE

AND SAFETY DEVICES FROM AN EXPERIENCED OPERATOR.

• READ THE INSTRUCTION MANUAL CAREFULLY BEFORE USING THE MACHINE.

• DO NOT USE THE MACHINE WITHOUT THE PERSONAL SAFETY EQUIPMENT REQUIRED BY LAW.

• DO NOT TAMPER WITH THE FIXED GUARDS, THE SAFETY INTERLOCK ELECTRICAL SWITCHES OR ANY OTHER SAFETY

DEVICES.

• ALWAYS KEEP HANDS AT A SAFE DISTANCE FROM THE MOVING PARTS OF THE MACHINE.

• DO NOT LEAVE MACHINE UNATTENDED WHILE SWITCHED ON OR IN OPERATION.

• ALWAYS DISCONNECT THE POWER SUPPLY BEFORE REMOVING SHROUDS, REMOVABLE GUARDS, COVERS, DOORS,

FENCES, PANELS, ETC. FOR SERVICING, CLEANING, OR REPAIRS.

15

• DO NOT OPEN THE MACHINE OR TAMPER WITH ITS INTERNAL PARTS. THERE ARE NO INTERNAL COMPONENTS THAT

REQUIRE ADJUSTMENT OR MAINTENANCE ON THE PART OF THE USER.

• SHOULD THE MACHINE MALFUNCTION, TURN IT OFF IMMEDIATELY AND NOTIFY THE SUPERVISOR.

• Installation must be in accordance with the operating instructions and with local and state hygiene standards and safety codes.

Compliance with codes is the responsibility of the Owner and Installer.

• Before operating the machine, make sure that it is properly grounded and/or connected to a circuit l eakage breaker and thermal

switch. Failure to do so could result in electric shock.

• Make sure the safety signs and stickers are firmly affixed to the machine, that they are legible, and that they have not been blurred or

erased after the machine is cleaned. If they become damaged or lost, ask your dealer for new ones and replace them.

• Keep your work area well lit and free of obstacles.

• When operating the machine never wear loose clothi ng or jewelry that could get caught in the moving parts.

• Unplug the machine when not in use.

• Keep children and on-lookers at a safe distance.

• Do not pull on the cord to remove the electrical plug from the socket.

• To avoid damaging the electrical cord, keep it out of areas where it can be stepped on.

• Do not alter or modify the machine’s original design in any way.

• Should the machine need repairs, consult the official dealer where the machine was purchased.

• Use only genuine TALSA parts and accessories and have them properly installed by a qualified technician.

• This machine has been designed exclusively for meat processing. Any other use of this machine is not in accordance with its

intended application. The manufacturer assumes no responsibilit y for any possible damage or injury resulting from im proper use of

this machine.

Additional operating instruction manuals are available from your dealer.

Your local dealer will be happy to answer any further questions you may have.

2. LIST OF POSSIBLE OPERATING HAZARDS

Read and review thoroughly the following operating hazards.

2.1 MECHANICAL HAZARDS

• Crushing hands, fingers etc. on the barrel when closing the lid.

• Crushing hands, fingers etc. between the lid and the pist on while the latter is being raised, especially when the lid is not c ompletely

open.

• Crushing hands, fingers etc. between the piston and the u pper part of the base during the dismantling of the removable barrel on E

models.

• Personal injury should the machine tip over if it is raised too high while being moved (since the fillers are on wheels, this is an

important hazard).

• Foot injuries should the piston fall during dismantling or cleaning.

2.2 ELECTRICAL HAZARDS

• Electric shock due to direct or indirect contact with electrical current.

• Electric shock due to defective electrical parts.

2.3 NOISE HAZARDS

Hearing damage should any modification of the machine’s or iginal design raise noise emission levels above 85 dB(A).

2.4 PERSONAL HEALTH HAZARDS

Changes in the nature of the food mixture if hygiene and cleaning instructions have not been followed.

3. TECHNICAL FEATURES

3.1 GENERAL INFORMATION

The H hydraulic piston fillers/stuffers combine technology, superior materials, and high engineering standards along with practical

applications to provide quick and simple operation, as well as ease of maintenance.

• Totally enclosed hydr aulic oil reservoir. Equipped with two plastic anti-vibr ation legs, as well as t wo non-castor wheels and a handle

to make moving the machine easier.

• TALSA Fillers are noted for having a totally rectified barrel (P models with fixed barrel) and allo wing for simple dismantling and

cleaning (E models with removable barrel).

• Start and stop of the motor either manually by s witch (i models) or automatically via contactor (A models). In the latter, the machine

uses electricity only when the knee lever is pressed. T his results in savings on electricity and less wear and tear on the machine’s

components. It also allows for quieter operation, since the motor-pump is not in constant use.

• Release of the knee lever causes pisto n decompression and instantly stops the product flow, regardle ss of nozzle size or product

density.

• The specially reinforced pressure system allo ws for easy processing of even the densest and coldest sausage m ixtures; machine

equipped with pressure gauge (P models).

• Speed control knob situated near the operator for quick and precise adjustment.

16

• Operation via ergonomically positioned kne e lever allows the operator to keep both hands free. The piston is lowered b y reversing

the knee lever control.

• Automatic lid lock with adjustable pressure closing (P models) precludes the need for flywheels.

• T he piston, which can b e removed eas ily, has t wo gaskets to pr event the mixtur e from escaping bet ween the joints (exce pt H42/H52

models). The machines have been designed to allow for quick access to all components, thus enabling easy cleaning and

maintenance.

• Appropriate for all kinds of natural or artificial casings.

• Made to CE and USDA standards.

• Waterproof internal electric box (models A).

ACCESSORIES included: Three nozzles ø12, 20, 30 mm. Spanner and piston extraction screw. Spare lid gasket. Horn holding nut. Oil.

Instruction manual.

OPTIONS: H26 stainless steel lid, piston and nut (H26S model). Single phase. Portio ning device PH5 00. Curved nozzle valve. Speci al

diameter or length nozzles (table 6.2 below).

3.2 DENOMINATION

• Filler/Stuffer H15/20/26/31/42 with fixed barrel P. • Filler/Stuffer H15/26 with removable barrel E.

3.3 MODELS

H15Pi H15PA H15Ei H15EA

H20Pi H20PA

H26Pi H26PA H26Ei H26EA

H31PiS H31PAS

USDA UL

H26S

H31S

H42S

H26PA

H26PAS

H42PiS H42PAS H52S

H52PiS H52PAS

• P = fixed barrel. • E = removable barrel. • A = start and stop of the motor automatically via contactor.

• i = start and stop of the motor by switch. • S = stainless steel lid, piston and nut

3.4 TECHNICAL SPECIFICATIONS

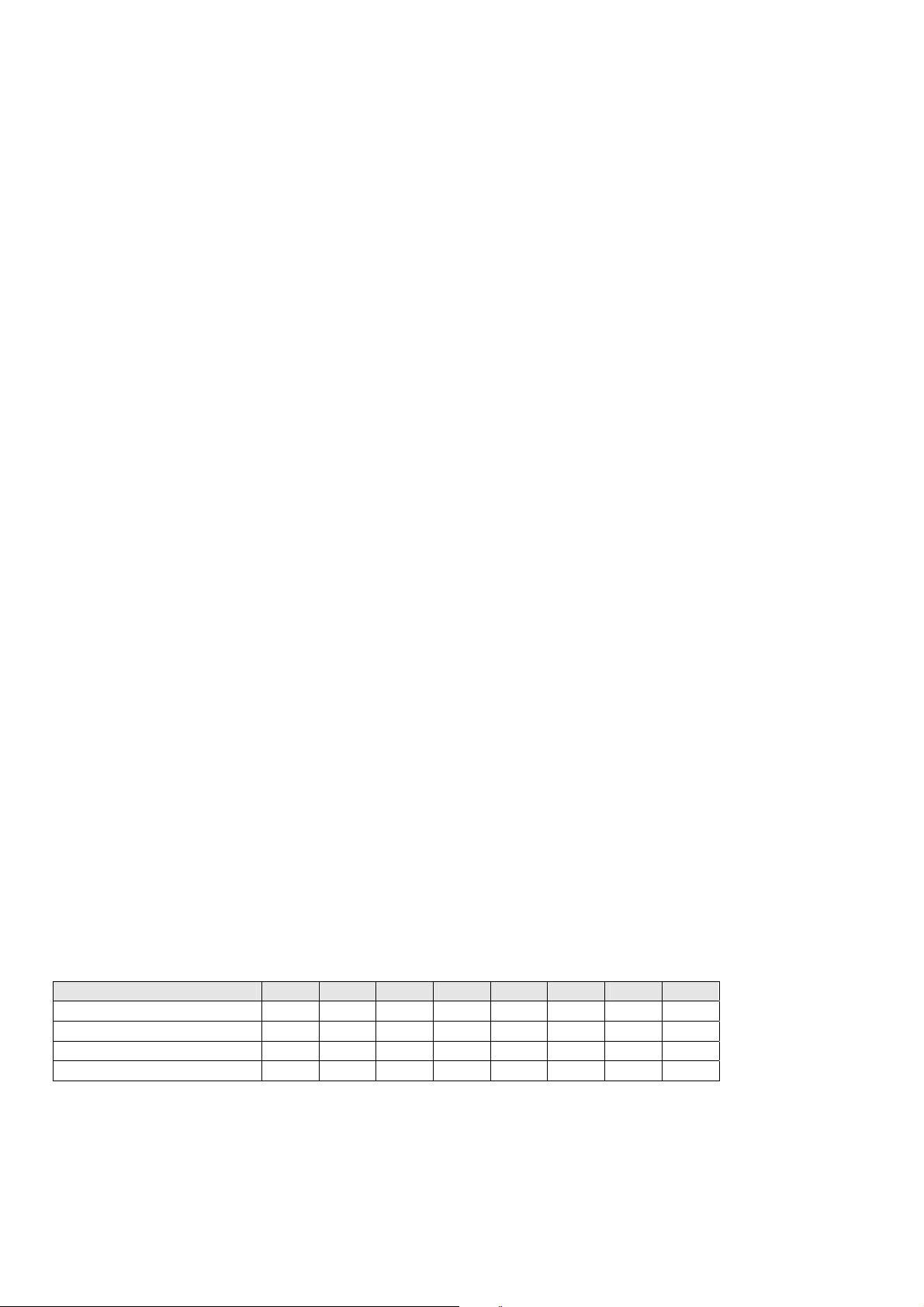

H15 H20 H26 H31 H42 H52

Mixture barrel capacity in liters 14.9 19.9 25.6 30.8 41.5 51,6

Mixture barrel capacity in kg of meat (approx) ±12 ±16 ±22 ±28 ±36 ±44

Barrel capacity in pounds of meat (approximate) ±26 ±35 ±48 ±62 ±79 ±96

Hydraulic oil tank capacity (liters) 10 10 15 15 25 25

Hydraulic oil tank capacity (US gallons) 2.6 2.6 4 4 6.6 6.6

Mach measurements (width x depth x height), cm 42x67x100 42x67x120 46x72x112 47x73x112 55x78x120 59x80x120

Mach measurements (width x depth x height), in. 17"x26"x39" 17"x26"x47" 18"x28"x44" 18"x29"x44" 22"x31"x47" 23"x32"x47"

Cardboard packaging measurements, cm 55x60x116 55 x60x139 55x60x139 55x60x139 -- -Cardboard packaging measurements, inches 22”x24”x46” 22”x24”x55” 22”x24”x55” 22”x24”x55” -- -Cardboard packaging volume, m³/cbm 0.38 0.46 0.46 0.46 -- -Wooden crate packaging measurements, cm -- -- -- -- 67x72x147 67x72x147

Wooden crate packaging measurements, inches -- -- -- -- 26"x28"x58" 26”x28”x58”

Wooden crate packaging volume, m³/cbm -- -- -- -- 0.70 0.70

Net/gross weight of 3-phase machine with oil, kg ±100 / ±115 ±117 / ±135 ±135 / ±155 ±180 / ±200 ±260 / ±290 ±330 / ±360

Net/gross weight 3-phase of mach with oil, pounds ±220 / ±253 ±258 / ±298 ±298 / ±342 ±397 / ±441 ±573 / ±683 ±777 / ±848

3-phase motor noise level dB(A) LEQ at 1 m ±58 ±58 ±61 ±61 ±64 ±64

1-phase motor noise level dB(A) LEQ at 1 m ±61 ±61 ±64 ±64 ±67 ±67

Max./min. environmental relative humidity, % 20 to 90%

Recommended hydraulic oil viscosity 5º Engler 50ºC (equiv. ISO3498: cat HL VG46, DIN8659: HL-46)

Max./min. environmental temperature ºC / ºF +5 to +40ºC (+40 to +110ºF)

Stainless steel grade AISI304 (equiv. DIN 1.4301, AFNOR Z6CN 18.09)

Aluminum grade AFNOR AG6T-Y (equiv. ASTM G8A - UNE L2331)

Three-phase motor data 50/60 Hz

Motor power HP 0.75 1.25 2 2.5

Motor power kW 0.55 0.94 1.5 1.87

Motor consumption Amp 380/400 Volt 1.9 2.5 3.7 4.5

Motor consumption Amp 220/230 Volt 3.3 4.3 6.4 7.8

Single-phase motor data 50/60 Hz

Motor power HP 1.25 1.75 2.25 2.5

Motor power kW 0.94 1.31 1.68 1.87

Motor consumption Amp 220/230 Volt 6.9 9 10.5 12.5

Capacitor µF 25 µF / 450 V. 40 µF / 450 V. 55 µF / 450 V. 55 µF / 450 V.

17

4. DELIVERY

The machine is delivered on a pallet and comes protected by cardboard packagi ng (H42/H52 models co me in a wooden crate, optiona l

for all other models). Besides the machine, this packaging includes an instruction manual, a p ack of 3 nozzles (12, 20 and 30mm in

diameter), a spanner, a piston extraction screw, and a spare lid gasket. We use only recyclable packaging (please recycle). The

transport company assumes sole responsibility for damage received in transit, check condition upon receipt.

5. INSTALLATION

(Estimated time: 45 minutes. Machine should only be installed by a qualified technician and in compliance with local codes).

The electrical installation of the workplace should be equipped with power surge full protection, which should then be adjusted to the

technical specifications of your particular unit (see number 3 below).

5.1 UNPACKING AND POSITIONING

Always keep the machine in a vertical position. Take the machine out of its box. Remove the knee lever (and the u pper lid scre ws for E

models) from the inside of the barrel and set them in their proper positions.

Do not use the knee lever to move the machine. T he machine comes with two fixed (non-castor) wheels in the front and two plastic

anti-vibration legs in the back; lift the back part of the machine using the transport handle and mov e the machine to the desir ed location

(two people are necessary for moving the heavier H42 and H5 2 models). Do not raise the filler/stuffer too high when moving it since it

could tip over, causing personal injury. Pl ace the m achine on a lev el surface. Sho uld the machi ne wobble, adjust the a nti-vibration legs

until it is perfectly stable and level. The machine should be placed so that the plug is easily accessible.

IMPORTANT: Remove the protective transport cap on the oil inlet ( marked OIL) and replace it with the depressuri zed oil cap/dipstick

enclosed with the machine. Also make sure that the air hole s located at the base of the b arrel are totally clear; if not, the piston will no t

function properly.

5.2 CONNECTING THE MACHINE

Make sure the electrical characteristics of the machine (connection, voltage, an d frequency) are suited to your power source. (These

specifications are given in detail on the technical sp ecifications sticker affixed to the machine itself; there is a tolerance of ±10% for

voltage and of ±2% for frequency). If the specifications are compatible with your power source, refer to the 6.OPERATING

INSTRUCTIONS section below.

If the electrical features of the machine are not compatible with your power source an d your machine is a dual voltage, three-phase

unit, adjust the voltage as described below in the 5.4.CHANGING VOLTAGE section.

Once the machine has been installed and the oil level i nside the reservoir has been c hecked using the dipstick attached to the oil inlet

screw, check the turning direction of the three-phase motor. If the phases are correctl y adjusted, the piston will rise and fall when the

knee pedal is pushed. If the phases are incorrect, the pump will not work properly; the motor will make noise, but the piston will not

move. Stop immediately and interchange two of the three phases in the plug. Make sure that the plug and outlet are appropriate for the

machine.

IMPORTANT, the wiring in the electrical cord is normally assigne d as follows: Phase(s): • Black, Brown, Gray • Ground wire: Twocolored Yellow/Green or Green. Check the wiring before connecting; call a qualified electrician if the electrical specifications do not

correspond with your power source.

5.3 HYDRAULIC OIL FILLING

The H filler/stuffer is delivered with hydraulic oil already in the internal reservoir; therefore, the initial addition of oil to the hydraulic

system is usually unnecessary.

In the exceptional case that a machine is delivered without hydraulic oil in the reservoir, do not turn it on. Fill the reservoir as follows:

• Remove the oil reservoir screw (marked OIL) located in the upper part of the base.

• Check that the correct level of oil is inside the reservoir by using the dipstick (with max./min. marks) attached to the oil reservoir cap.

• Using a funnel, po ur the hydraulic oil into the tank. Do not fill the reservoir t o the top since a certain amount of air m ust

reservoir to allow for expansion. Use oils for medium pressure hydraulic assemblages (approx. 100 bar), and of a viscosity of

approximately 5º Engler (equivalent to IS03498: cat HL VG46 or DIN8 659: HL-46). After filling the reservoir, raise and lower the

piston several times to purge any remaining air from the hydraulic circuit.

Always fill the reservoir to the maximum level without exceeding it since the more oil there is in the reservoir, the mor e effectively the

heat given off by the hydraulic assemblage will be cooled. This helps lengthen the life of the oil.

Because there should be no loss of oil or oil vapors, an adequate level of hydraulic oil should last several years (between 2500 and

5000 hours of use), making it unnecessary t o check the oil level as long as the machine is functi oning well. For more information, see

the 8.MAINTENANCE section below.

5.4 CHANGING THE VOLTAGE

IMPORTANT: Only for three-phase machines with dual voltage motor 3 80/220 Volt (400/230 Volt for EU), etc. This operation should

only be carried out by a qualified electrician.

Do not connect the machine to the power source. If already plugged in, unplug it and leave it disconnect ed for the entire process.

Remove the screws from the steel lid on the base. Remove the lid.

5.4.1 CHANGING THE VOLTAGE ON A MODELS (AUTOMATIC-CONTACTOR)

MOTOR: Open the connection terminal box of the motor by unscre wing the four screws. Loosen the six small nuts on the connection

terminals and place the plates in the correct position.

CONTACTOR: will need to be replaced by a qualified technician to a n ew one of same voltage than power supply.

remain in the

5.4.2 CHANGING THE VOLTAGE ON “I” MODELS (SWITCH)

MOTOR: Open the connection terminal box of the motor by unscre wing the four screws. Loosen the six small nuts on the connection

terminals and place the plates in the correct position.

18

6. OPERATING INSTRUCTIONS

IMPORTANT: Before operating the unit, read this manual thoroughly. Test the machine when it is empty before using it on food.

6.1 HANDLING STEPS

• Loosen the screws on the upper lid (only for E models) and open the lid with a slight upward motion to reduce friction.

• Wash the meat barrel, the underside of the lid, and the appropriate nozzle with hot water.

• Lower the pressure of the machine to the minimum by turning the red knob that regulates the filling speed counter-clockwise.

• Plug the machine in.

• Turn the gray switch located on the right of the machine to the “I” (start) position (I models only).

• Turn the machine on by pushing the knee lever.

• Push the knee lever all the way back to lower the piston enough to make room for the desired amount of mixture.

• Place the m ixture in th e meat barrel, pres sin g each ne w load of mixture down to avo id the formation of air pockets which could break

the casing during the filling process.

• Put the green lid gasket in place.

• Using the knee pedal, raise the piston until the mixture reaches the top of the barrel.

• Using food fat or another USDA approved shortening, grease the upper part of the lid gasket and the underside of the lid.

• Carefully clos e the lid with a light lifting m ovement to avoid friction, takin g care not to pinch or crimp the cover gask et in the process.

To close the lid, use only the lever incorpor ated in the lid itself; do not use the nozzle. Take extrem e care not to trap or pinch your

hands while closing the lid.

• After putting the screws back on the upper lid (E models onl y), place the optimum-size nozzle (largest diameter and shortest length

possible) on the lid, locking it in place by turning the triangular nozzle nut. Prepare the proper amount of casing.

• Push the knee lever all the way for ward to the piston raising position. Always push the knee lever firmly; do not use it as a speed

control regulator.

• Carefully raise the pressure by slowly turnin g the pressure control k nob clockwise. Do not raise the pr essure suddenly, as this could

cause the mixture to come out of the nozzle too quickly.

• Note how the piston will begin to rise and air will come out of the nozzle.

• Once the mi xtu re begins to come out of the n ozzle, releas e t he pressur e and pl ace the casing on the n ozzle. Adj ust the red pre ssure

control knob to select the optimum speed.

• Once the casing has been filled, push the knee l ever back to the piston lowering position until th e piston is at its lowest level in the

barrel.

• To stop the hydraulic assemblage, bring the knee pedal to the central position.

• Turn the gray switch located on the right of the machine to the “O” (stop) position (I models only).

• When finished using the machine, clean it, lo wer the piston to its lowest position in the barrel, unplug the machine and make sure

that the machine cannot roll.

6.2 USEFUL TIPS

• Do not use the machine without having received previous instructions from an exper ienced operator.

• This instruction manual should be read carefully and fully understood before using the machine.

• Test the machine when it is empty before using it on food.

Observe all the appropriate hygiene measures when handling food products; use adequate protective equipment and procedures

(washing, gloves, cap, apron, etc.).

To produce sausage with a better appearance and less smearing, as well as for more uniform mi xture and less wear and tear on t he

machine, we recommend the use of:

• Horn with the largest diameter and shortest length possible.

• Finely chopped mixtures at the least coldest temperature possible.

Consequently we recommend avoiding very long nozzl es or nozzles with small diameters when using roughly chopped or very cold

mixtures.

If nozzles of special dimensions are needed, order them from your dealer. There is a wide range of sizes available:

Model: B C D E F G H I

External diameter, mm Ø 12 15 18 20 25 30 38 43

Internal diameter, mm Ø 10 12 15 17 22 27 35 40

Tube length, mm 160 195 195 195 195 195 220 235

Total nozzle length, mm 210 245 245 233 220 220 245 260

Never use the nozzle to close the lid since the rim could break. Close the lid with the lid lever only.

Do not open or close the lid without the green gasket in place since this could lead to scratches on the lid and clamp.

The barrel lid cannot be opened without first slightl y lowering the piston by placing the knee ped al in the down position. This will stop

the mixture from blocking the opening.

Place the machine as close to the work surface as possible. The locations of the nozzl e and knee lever allow the nozz le to be located

completely over the work surface, thus guaranteeing that no liquid falls onto the floor or the operator.

In order to prevent overheating in i models, turn the machine off after use. Turn the motor on only when in use.

19

Work at a reasonable pace, thus avoiding c onstant stopping and restarting of the hydraulic assemblage. This machine is not designed

to withstand permanent, uninterrupted use at high pressure, but rather to run intermittently with pauses to allo w for the dissipation of

the heat generated, the amount of which depends on the consistency of the mixture. Because of the pressure transmitted by the pump,

after prolonged periods of use the hydraulic oil may reach temper atures of up to 60ºC (140ºF) and the base side panel ma y become

warm to the touch.

7. CLEANING

IMPORTANT: In order to avoid mechanical hazards durin g cleaning oper ations and p iston dismantlin g, always open the l id completely

when raising the piston.

7.1 CLEANING INSTRUCTIONS

To clean the outside of the machine use hot water and a mild cleanser.

Do not use any abrasive products, especially those that could scratch warning stickers and labels.

Never wet or dampen the electrical elements of the machine (switches, cables, etc.). Never use a jet of water to clean any part of the

machine, especially the air holes on the side of the oil tank cap.

At the end of each workday, the underside of the lid (the mixture exit hole), as well as the nozzle(s) and the nozzle nut should be

cleaned thoroughly. If necessary, clean the inside of the nozzles with a round brush. Do not op en or close the lid without the green

gasket in place since this could scratch the lid and clamp.

Using hot water only, rinse the lid bolt and bearing to eliminate any resid ue that could crystallize (salts, spices, etc.) and thus impede

the proper functioning of the lid.

The upper part of the black piston gasket should also be cleaned daily, following these steps:

• Open the lid completely and remove the green lid gasket.

• Press the knee lever until the piston rises to its uppermost position. P art of the black piston gasket will now be accessible via the

upper part of the barrel. Clean it with a damp cloth.

We recommend that you periodically clean the piston and barrel interior thoro ughly:

• Loosen the screws on the upper lid (E models only), open the lid completely and remove the green lid gasket.

• Press the knee lever until the piston rises to its uppermost position.

• With the piston at its highest position, simultaneousl y push the knee lever and, with the aid of the two pivots of the wrench supplied,

unscrew the piston-locking bolt (two turns) located in the center of the piston.

• Screw the wrench completely into the piston hole. The piston will rise above the rim of the barrel.

• Pull the wrench up to remove the piston from the barrel.

• Unplug the machine.

• Clean the inside of the cylinder. Make sure that the bottom of the cylind er is comp letely DRY to av oi d the formatio n of water droplets,

which could eventually lead to the formation of rust on the upper part of the base.

IMPORTANT: Piston and barrel cleaning can also be done by dismantling the removable barrel (E models only); however, to avoid

mechanical hazards as well as damage to the piston gaskets, we advise removal of the piston only.

7.2 CLEANING PRECAUTIONS

Because of the weight of the piston, use caution when moving it.

Clean the piston and the black piston gaskets (1 or 2, dependi ng on the model). To avoid damaging the gaskets, never use sharp or

pointed tools (knives, screwdrivers) to remove them. To reduce the noise caused by the movement of the piston, grease the piston

gaskets with food fat or another USDA approved shortening before putting them back into the barrel.

Never introduce water inside the barrel since it c ould filter down to the base of the machine and affect the electrical and mechanical

components. The holes in the bottom of the barrel are vents for air only.

To reassemble the piston, make sure that the bottom of the barrel is completely dry, then place the piston in the barrel an d screw the

piston-locking bolt tight, making sure that the smaller gasket is prop erly placed. Raise and lower the piston, and tighten the piston

locking bolt again, making sure it does not bend against the pressure of the lid. Grease the thread of the piston-locking bolt before

replacing it; this will make future dismantling easier.

When the machine is not in use, leave the piston hea d at the bottom of cylinder, where it will be subm erged in hydraulic oil. T

lengthen the life of the ram and the gaskets.

For correct hygienic control, see the 7.2.CLEANING CHECKLIST section below.

7.3 CLEANING CHECKLIST

IMPORTANT: Never use a jet of water to clean any part of this machine!. When using detergents, disinfectants or maintena nce oils,

follow the manufacturers’ special instructions.

We recommend the use of cleaning or disinfecting products mentioned herewith. To clean the machine manually, always use

appropriate safety equipment (latex gloves, plastic aprons, etc.). Always rinse the machine thoroughly after using any kind of detergent

of disinfectant. Always follow the instruction provided by the manufacturer of the product.

Product Manuf Name Notes

Neutral detergent pH7 Henkel TOPAX 10

Due to its neutral pH, no special precautions are necessary. Rinse

thoroughly.

Detergent for manual cleaning Henkel RIK Use appropriate precautions and protective gear. Rinse thoroughly.

Alkaline detergent with disinfectant

incorporated

Henkel TOPAX 68 Use appropriate precautions and protective gear. Rinse thoroughly

Disinfectant with ammonium salts Henkel TOPAX 91 Use appropriate precautions and protective gear. Rinse thoroughly.

his will

20

GENERAL CLEANING ADVICE:

Cleaning steps Products Method Tools Notes

Superficial cleaning Manual Spatula

Extensive cleaning Mild detergent Manual Brush, bucket Leave product to work ± 15 minutes.

Rinsing Warm water Manual Sponge, bucket Warm water 40/50 º C - 100/120 º F.

Inspection Check critical points and problematic parts.

Disinfecting Disinfectant products Manual Sponge, cleaning cloth After completing all other cleaning operations.

Rinsing Drinking water Manual Sponge, bucket

Drying Cleaning cloth

Maintenance Lubricating oil Manual Cleaning cloth External machine parts.

SPECIFIC CLEANING ADVICE:

Interval Cleaning area Method Products Tools Notes

Underside of the lid, lid gasket,

Daily

Fortnightly

These cleaning instructions have been elaborated for companies with just one shift; shorter intervals should be observed in companies

with many work groups.

IMPORTANT: Among the parts which should be cleaned daily (see “SPECIFIC CLEAN ADVICE” above), the piston bolt retaining

screw must be cleaned thoroughly by dismantling it. In E models, the following parts should als o be dismantled for better cleaning: lid

closing nuts, lid, barrel.

Piston removal: See section 7.1 above.

inside of the barrel and piston

bolt retaining screw

Piston, piston gaskets and gasket

of piston bolt retaining screw

Manual

Manual

Mild detergent,

warm water

Mild detergent,

warm water

Remove all residue directly after use, removing

smaller machine parts if necessary.

Sponge,

cleaning cloth

Sponge,

cleaning cloth

Eliminate dirt from retaining screw

using a brush if necessary. Avoid

build up of residues.

To remove the piston, follow the

instructions above.

8. MAINTENANCE

IMPORTANT: Unplug the machine before proceeding with maintenance and inspection.

During maintenance and inspection operations always follow the safety instructions in this manual.

Mechanical breakdowns caused by inadequate or improper maintena nce can lead to high repair costs as well as work stoppages;

therefore, regular and adequate maintenance is indispensable.

The safety and life of the machine depend on many factors, including proper maintenance.

Because different companies have different shift schedules, it is impossible to prescribe in advance h ow often you should proce ed with

inspections, maintenance or replacement. Adjust your inspection routine to the number of work groups you have in your company.

Our local dealer will be delighted to give you further information.

The table below contains information about mainte nance and inspection (control intervals, critical points, etc.) for a machine under

normal use.

8.1 MAINTENANCE AND INSPECTION SCHEDULES

After reading the following, consult the MAINTENANCE AND INSPECTION TIPS section for more details.

Control interval Critical points / Maintenance information

• Check green lid gasket and replace it if necessary.

Daily

Monthly

Yearly

Every 2500-5000 service hours

8.2 MAINTENANCE AND INSPECTION TIPS

Green lid gasket

spare gasket comes with the machine. The gasket is made from a non-toxic material that is safe for alimentary use. Place the glued

joint of the gasket under the lid bolt. To reduce lid friction and e xtend lid g asket life, befor e closing al ways greas e the gre en gasket and

the lower part of the lid with animal fat or another USDA approved.

Black piston gasket

gasket with animal fat or another USDA approved shortening before placing it in the barrel.

Hydraulic oil level

level marked without exceeding it since the more oil ther e is in the reservoir, the more effectively the heat given off b y the hydraulic

assemblage will be cooled. This helps lengthen the life of the oil.

: Replace if damaged or if leaks are observed. This gasket is reversible, i. e. it can be us ed with either side facing up. A

: Replace if damaged or if leaks are observed. To reduce noise caused b y the movement of the piston, grease th is

: The oil level can be tested with the dipstick provided on the oil inlet screw. Always fill the reservoir to the maximum

• Check the two black piston gaskets and replace them if necessary.

• Check the air holes located at the base of the barrel and clear them of any obstruction.

• Check the lid closure and tighten if necessary by regulating the lid fixing bolts (P models only).

• Check hydraulic oil level and refill the reservoir if necessary.

• Change hydraulic oil.

• Check oil filter and replace it if necessary.

21

Hydraulic oil duration: The life of hydraulic oil varies depending on m any factors, e.g. temperature and pressure at which the machine is

run, the presence of humidity or residual water, etc. Normally it can la st between 2.500 and 5.000 hours of service. If the oil loses

viscosity, becomes impure, or turns a whitish color from having had water pumped into it, drain the oil by empt ying the housing via the

plug located at the bottom of the machine. Refill the oil following the instructions found i n the INSTALLATION section above. Because

there is no natural loss of oil or oil v apors, an adequate l evel of hydraulic oil should last several years, making it unnecessar y to c heck

the oil level regularly. If the oil level is insufficient, the piston will not move smoothly, since air will be entering the circuit.

Changing the hydraulic oil

: Remove the oil outlet plug located at the bottom of the bas e an d drain the r es ervoir, em pt yin g the oi l i nto an

appropriate recipient (please recycle used oil). Replac e the plu g an d sea l the oil outl et site hermetic ally. Using a funnel, fill the reservoir

with 10 liters (for H15/H20 models), 15 liters (for H26/H31 models) or 25 liters (for H42/H52 models) of hydraulic oil via the tank

opening. Do not fill the reservoir to the top since a certain amount of air must be present to allow for expansion. Use oils for medium

pressure hydraulic assemblages (approx. 100 bar), and of a viscosit y of approximately 5º Engler (equiv alent to IS03498: cat HL VG46

or DIN8659: HL-46). After filling the reservoir, raise and lower the piston several times to eliminate air pockets from the hydraulic circuit.

Oil filter

: Located inside the oil reservoir, the oil filter is not accessible to the user and should only be repl aced by a qua lified tec hnician.

To remove the oil filter remove the two screws that attach the closing clamp to the filter and pull the filter outward. Normally, th e filter

should not become dirty or present any abnormalit y. If the filter must be changed, use a similar filter with a thread of 3/8” BSP and a

filtering capacity of 10 liters per minute, (5 liters per minute for H15/H20). After reassembling the unit, the closin g clamp must be seal ed

hermetically.

Oil temperature

: Because of the pressure transmitted by the pump, after prolonged periods of use the hydraulic oil may reach

temperatures of up to 60ºC (140ºF) and the base side panel may become warm to the touch. This machine is not designed to withstand

permanent, uninterrupted use at high pressure, but rather to run intermittently with pauses to allow for the dissipation of the heat

generated, the amount of which depends on the consistency of the mixture.