Page 1

7 - Maintenance

7.1 - Foreward

ATTENTION!

Every maintenance and cleaning operation on the grater must only be done with the machine at a standstill, disconnected from the power supply.

The area where maintenance operations are carried out must always be

kept clean and dry.

Do not allow unauthorized personnel to work on the machine.

Any replacement of parts must be made with original spare parts at authorized work shops or directly by the manufacturer.

ATTENTION!

Disconnect the machine from the electrical supply before cleaning it.

Do not clean the machine with jets of water.

Only use non-toxic detergents, designated for cleaning components for

use with food products.

7.2 - Putting out of order

The machine is made of materials such as aluminum, steel and copper;

therefore they do not require particular operations for scrapping.

Therefore use companies specialized in trash disposal, separating the

components according to material.

8 - Problems and solutions

8.1 - Problems, causes and solutions

Problems Causes Solutions

The machine does not

start

The presser is in a high

The microswitch installed on

The start pushbutton does

The electrical motor or the

The differential switch is not

set at “0”

position

the grater inlet does not work

not work

electronic card are faulty

24

Put the switch at “I”

Lower the presser

Call technical assistance

Call technical assistance

Call technical assistance

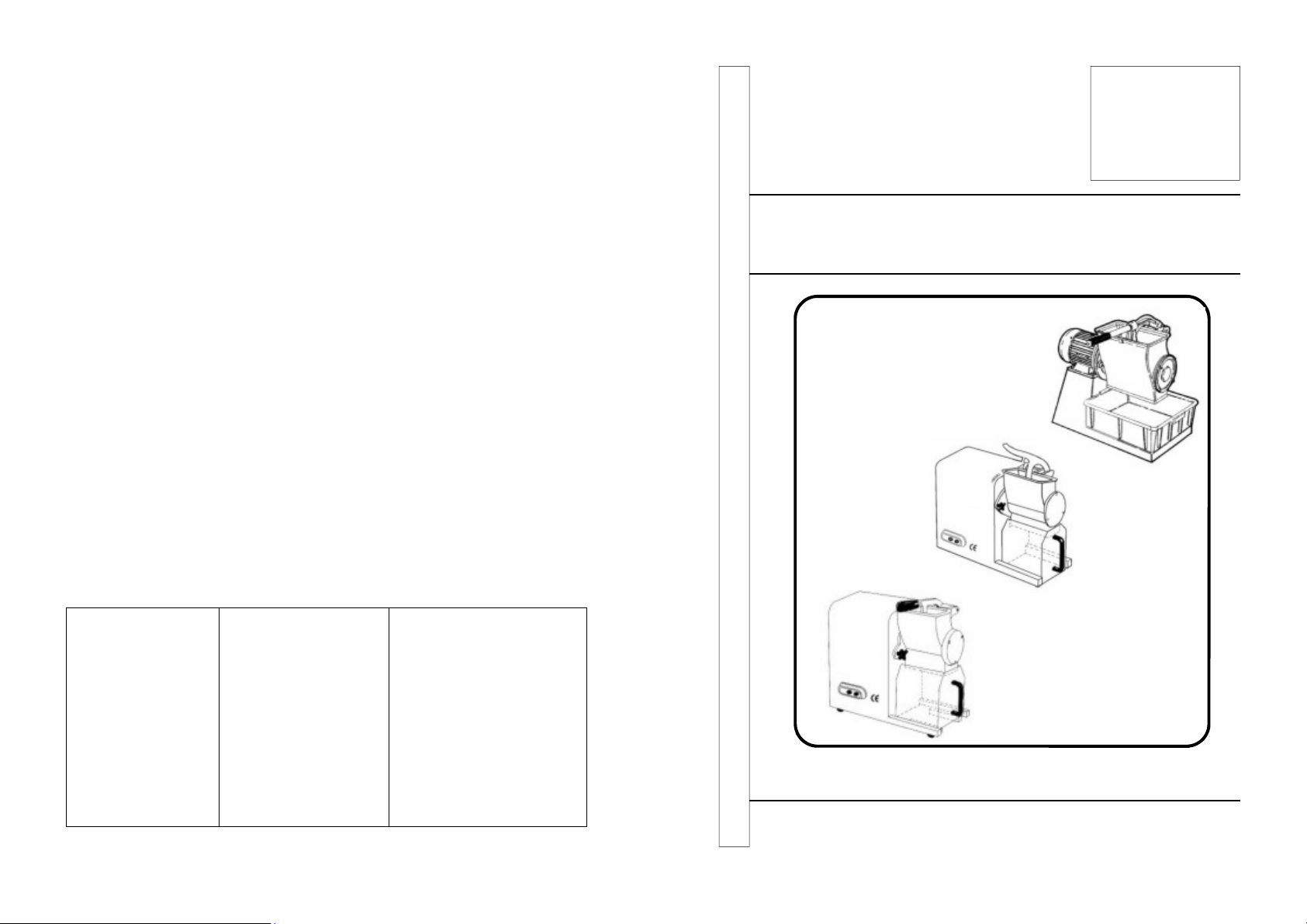

GF HP 1,5

GF HP 2

GF HP 4

GRATER

USE AND MAINTENANCE MANUAL

JULY 2003

1

Page 2

Index

1. Delivery and warranty 4

1.1 Introduction

1.2 How to keep and use this manual

1.3 Warranty

1.4 Description of the machine

1.5 Use

1.6 Prohibited uses

1.6.3 Lighting

1.7 Identification

1.7.1 Safety and warning plates

1.8 Protections and safety devices

1.9 Working positions

1.10 Vibrations

2. Technical features 12

2.1 Main parts

2.2 Technical features

2.3 Machine dimensions and weight

2.4 Noise level

2.5 Electrical diagrams

2.5.1 230-V single-phase electrical diagram

2.5.2 400-V three-phase electrical diagram

2.5.3 220-V three-phase electrical diagram

3. Testing, transport, delivery, and installation 17

3.1 Testing

3.2 Machine delivery and handling

3.3 Installation

3.3.1 Package disposal

3.3.2 Moving the machine

3.4 Connection to electrical system

3.4.1 Three-phase machine

3.4.2 Single-phase machine

4. Commands 20

4.1 List of commands

5. Start up and stop 21

5.1 Checking the correct electrical connection

5.2 Checking the presence and efficiency of protections

and safeties

6 - Using the machine

6.1 - Foreward

ATTENTION!

Only authorized personnel can use the machine.

Before beginning work the operator must make sure that all the protections are in place and that the safety devices are fitted and working properly. If not, switch off the machine and contact the head of maintenance.

6.2 - Using the sieve

Fig. 6.2.1

The extractable sieve “1” in stainless steel enables obtaining a uniformly

grated product, avoiding sieving.

It must be requested upon ordering the machine.

2

23

Page 3

5.2 - Checking the presence and efficiency of protections and

safeties

1. Microswitch on the lever

While the machine is running lift the presser until the microswitch

intervenes and stops the machine.

Keep the presser still in the point in which the microswitch interve

nes and check that the space between the loading inlet and the

presser is such to block fingers from entering.

If this is not the case contact an authorized reseller or the manufac

turer.

2. Microswitch on the lever

While the machine is running extract the plexiglass container and

make sure that the machine stops.

5.3 - Checking the efficiency of the stop pushbutton (fig. 4.1.1)

While the machine is connected to the power supply and the utensil is moving press the pushbutton “2” fig. 4.1.1

5.4 - Start up

- Set the differential switch fitted upstream at "I". The light indicator “3”

fig.4.1.1 will light up, indicating that the machine is powered

- Press the start pushbutton “2” (fig. 4.1.1) to start the machine.

Note

If the presser is in an “open” position the machine will not run, therefore it

will have to be lowered.

5.5 - Stop

- Press the stop pushbutton "1" fig 4.1.1 to stop the running of the machine; the light indicator “3” fig. 4.1.1 will remain on to indicate that the

machine is powered.

- Then set the differential switch installed upstream at "0", in this way

disconnecting the machine.

Note

Each time a work shift finishes or the machine is left to rest, the differential

switch must be left set at “0”.

5.3 Checking the efficiency of the stop button

5.4 Start up

5.5 Stop

6. Using the machine 23

6.1 Foreward

6.2 Using the sieve

7. Maintenance 24

7.1 Foreward

7.2 Putting out of order

8. Problems and solutions 24

8.1 Problems, causes and solutions

22

3

Page 4

1 - Delivery and warranty

1.1 - Introduction

ATTENTION!

The purpose of the symbols used in this manual is to draw the reader’s

attention to points and operations that can endanger the personal safety of

the operators or risk damaging the machine.

Do not use the machine unless you are certain that you have correctly

understood these warnings.

ATTENTION!

For greater clarity some illustrations in this manual show the machine or

parts of it with the panels or carters removed.

Do not use the machine in such conditions; all protections must be correctly fitted and in perfect working order.

This manual cannot be reproduced, even partially, and its contents cannot

be used for purposes other than those permitted by the manufacturer.

Any violations of the above will lead to punishment according to law.

1.2 - How to keep and use this manual

The purpose of this manual is to instruct the user, through texts and figures, on transport, handling, use, and maintenance of the machine; the manual must therefore be carefully read before using the machine. Carefully

keep this manual near the machine in an easily and quickly accessible

place for future reference.

If the manual is misplaced or damaged, ask your dealer or manufacturer

for a copy.

If the machine is sold, inform the manufacturer of the name and address of

the new owner.

The manual reflects the state of technology at the moment the machine is

sold and cannot be considered inadequate if it is subsequently updated

due to newly gained knowledge.

In this regard the manufacturer reserves the right to update its products

and manuals without being obliged to update previous products or manuals apart from exceptional cases.

If in doublt consult the nearest servicing center or the manufacturer.

The manufacturer aims to continuously optimize its product.

For this reason any comments or suggestions on how to improve the product and/or manual are welcome.

The machine has been delivered to the user under the warranty conditions

5 - Start up and stop

5.1 - Checking the correct electrical connection

ATTENTION!

Check that the feeding line corresponds to the value reported on the identification plate of the machine and that it is outfitted with an efficient floor

plug.

1. Put the plug into the electrical outlet.

2. Set the differential switch in position "I". The lit indicator “3” fig. 4.1.1,

indicating that the machine is powered, must be illuminated.

3. Press the pushbutton “2” fig. 4.1.1 to start and immediately afterwards

press the stop one “1” fig. 4.1.1, checking the rotation direction of the

roller.

Note

The presser must be in a low position.

The roller rotation direction must be the same as the one indicated

by the arrow fig. 5.1.1

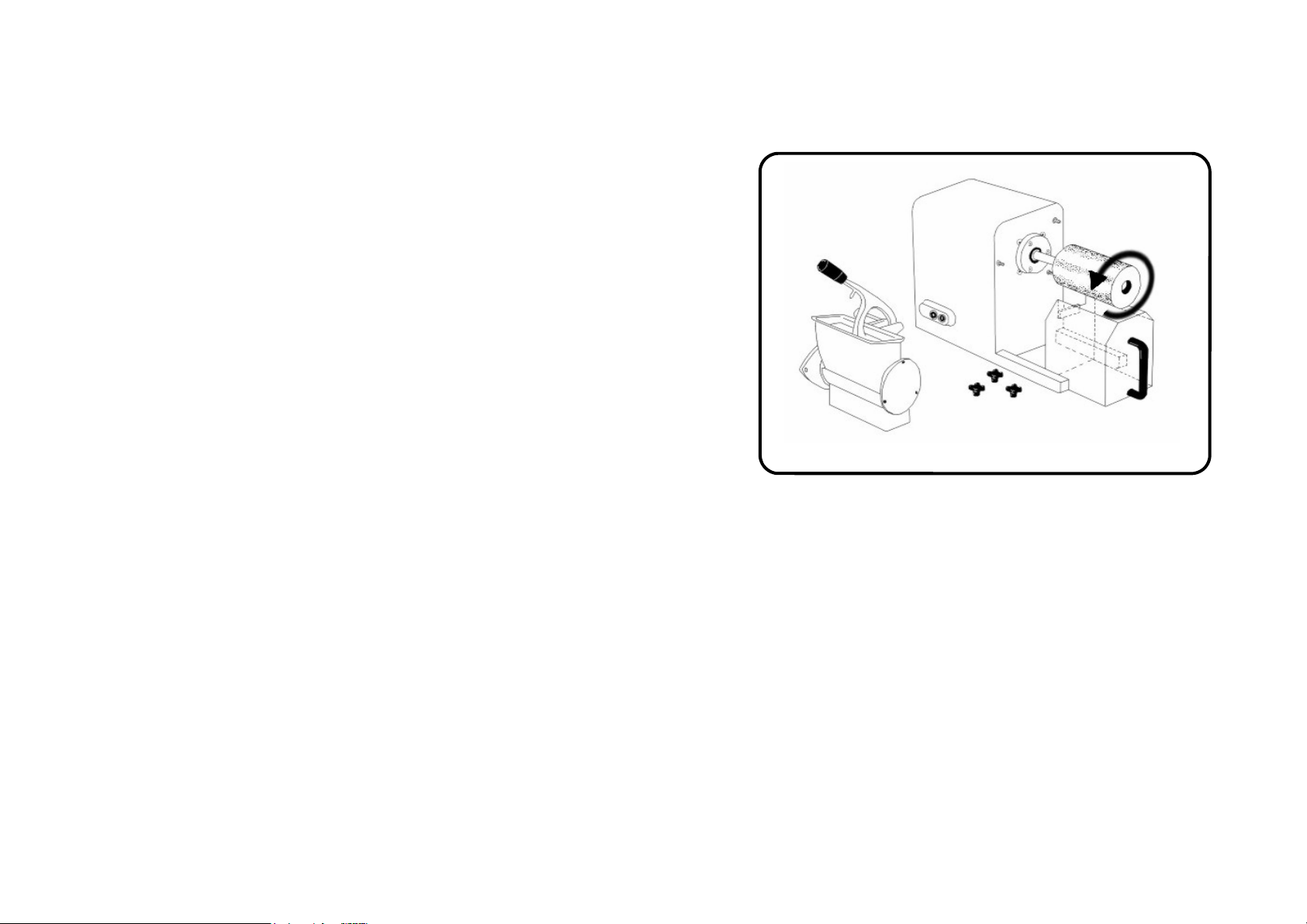

Fig. 5.1.1

4

21

Page 5

4 - Commands

4.1 - List of commands

1 - Stop pushbutton

- Stop pushbutton: black color

- Press to stop the machine

- The led on the pushbutton lights up only when the stop pushbutton is

pressed (4 fig. 4.1.1)

2 - Start pushbutton

- Start pushbutton: gray color

- Press to start the machine

3 - Lit indicator of connection to the mains

- White color

- It indicates the connection of the machine to the network.

4

3

2 1

Fig. 4.1.1

in force at the time of purchase.

Contact your supplier for any clarifications needed.

1.3 - Warranty

The user is not authorized to tamper with the machine for any reason. If

there is a fault contact the manufacturer. Any attempts at dismantling or

tampering with any component of the machine in general by the user or

unauthorized personnel will cause the lapse of the declaration of conformity according to the EEC Directive 89/392, will render the warranty null

and void and the manufacturer will be exempt from any responsibility for

damage to people or things due to such tampering.

The manufacturer is also exempt from all responsibility in the following

cases:

- Incorrect installation;

- Improper use of the machine by inadequately trained personnel;

- Failure to comply with the regulations in force in the country in which

the machine is used;

- Lack of or insufficient maintenance;

- Use of unoriginal spare parts or spare parts not specifically designed

for the model;

- Total or partial failure to follow the instructions.

1.4 - Description of the machine

The grater you have purchased is a simple, compact and powerful machine, with a high yield.

- Since it must be used to grate food products the components that can

come into contact with the product have been carefully chosen to guarantee maximum hygiene.

- The base is made of micro shot-peened stainless steel.

- The inlets have been treated with a buffering procedure to facilitate clea

ning.

- The roller is made of stainless steel to guarantee maximum hygiene

and make it last longer.

- The motor is self-ventilated to keep yield constant during the prolonged

use of the machine.

- The stainless steel extractable sieve (provided upon request) is used to

grate the bread uniformly.

The models represented in this manual have been manufactured in compliance with the EEC Directive 89/392 and modifications thereafter.

In case of an accident the manufacturer cannot be held responsibile if the

machine has been modified or tampered with, if the safety protections ha-

20

5

Page 6

ve been removed, or if the machine has been used for purposes prohibited

by the manufacturer.

1.5 - Use

The machine has been designed and built to grate cheese, bread or similar products.

It must be used in professional environments and by skilled personnel who

are trained to operate in the sector and have read this manual.

Use the grater only when it is securely placed on a solid work table. The

dimensions of the product must enable it to fit in the loading inlet.

1.6 - Forbidden uses

The machine must only be used for the purposes expressly intended by

the manufacturer. In particular:

- Do not use the machine to grate food products other than cheese, bread and the like.

- Do not use the machine if it has not been correctly installed with all the

protections intact and correctly assembled to avoid the risk of severe

injury.

- Do not access electrical components without having previously disconnected the machine: risk of electrocution.

- Do not work products that are bigger than what can be totally contained

in the feeding inlet.

- Do not wear clothes that do not comply with safety regulations. Consult

your employer for safety regulations and the safety devices required.

- Do not use the machine if it is not working correctly.

Before starting the machine make sure that any dangerous condition

has been appropriately eliminated. If a fault occurs, stop the machine

and notify persons in charge of maintenance.

- Do not allow unauthorized personnel to carry out work on the machine.

In the event of emergency treatment due to an accident caused by electrical shock, first remove the victim from the conductor (as he will be

unconscious).

This operation is dangerous as the victim is a conductor in this case

and touching him could cause electrocution.

Therefore disconnect the contact directly from the power supply valve

or, if this is not possible, distance the victim using insulating material

(wooden or pvc sticks, fabric, leather, etc.).

A doctor should be promptly called and the patient should be taken to

the hospital.

3.4 - Connection to the electrical system

ATTENTION!

Make sure the electrical source corresponds to the value reported on the

identification plate of the machine. Each operation should be carried out

only by specialized personnel authorized by the appropriate supervisor.

Connect the machine to a network with an efficient floor plug.

3.4.1 - Three-phase machines at 400 Volt-50 Hz and threephase machines at 230 Volt - 50 Hz

In these set ups the machine is outfitted with a feeding cable with a section of 4 x 1.5 and a length of about 1.5 meters. Connect the cable to the

three-phase electrical supply network, inserting a 16-Amp magnetothermic

differential switch.

N.B.: usually it is BLUE or it is indicated by N° 4

3.4.2 - Single-phase machine at 230 Volt-50 Hz

In this set up the machine is outfitted with a feeding cable with a section of

3 x 1.5 and a length of about 1.5 meters.

N.B.: usually it is BLUE or it is indicated by N° 4

Connect the cable to the 230 V/50 Hz single-phase electrical supply

network, inserting a 16-Amp magnetothermic differential switch.

For machines with voltages different from those mentioned consult the

manufacturer.

If the feeding cable needs to be extended, use a cable with the same section as the one supplied by the manufacturer.

6

19

Page 7

3.3 - Installation

The area where you intend to install the machine must be flat and solid.

Furthermore, the machine must be positioned with ample space around it.

This enables greater maneuverability during working phases and guarantees access for periodic maintenance.

Ensure sufficient lighting around the machine to guarantee correct visibility

for the machine operator.

ATTENTION!

3.3.1 - Package disposal

The components of the packaging such as cardboard, nylon and wood can

be freely disposed of as they are compatible with solid urban waste.

Nylon is a pollutant if it is burned because it produces toxic fumes. Do not

burn and do not throw away but dispose of it according to the laws in

force.

If the machine is delivered in countries in which there are particular laws,

dispose of the packaging according to the presciptions of these laws in

force.

3.3.2 - Moving the machine

ATTENTION!

Lift the machine with a forklift of suitable capacity.

Check the stability and positioning of the weight on the forks, especially

along uneven, slippery or inclined paths. When moving the machine keep

the load as low as possible to guarantee greater stability and visibility.

Stabilize the grip by widening the forks of the forklift.

1.6.3 - Lighting

Sufficient natural and artificial lighting must be provided around the machine. Lighting must be disposed of in compliance with the laws in force of

the country the machine is installed in.

In any case, lighting must be uniform and guarantee operator visibility in

every point of the machine and it must not create dangerous reflections.

The lighting must enable a clear reading of the control panels and the individuation of emergency pushbuttons.

18

7

Page 8

1.7 - Identification

An exact description of the "Model", the "Serial number" and the '"Year of

Construction" of the machine will enable our servicing department to provide rapid, efficient responses. Always indicate the above information whenever you contact the servicing department.

Use the data on the plate shown in fig. 1.7.1.

As a memorandum we suggest filling in your machine data in the following

box.

Grater model…....…………

Serial N°………………….

Year of construction…………….

Type……………………………...

A

_______Watt

_______ Volt

G

C

E

Fig. 1.7.1

Matr. __________

A. ______ Hz.

F

_____ Kg.

B

D

LA FELSINEA SRL via L. Einaudi

35016 Piazzola sul Brenta PD ITALY

A = Grater model

B = Serial number

C = Electrical motor power

expressed in Watts

D = Amperes

E = Motor frequency expressed in Volts

F = Machine weight in Kg

G = Manufacturer

ATTENTION!

Do not, for any reason, alter the data given on the plate.

3 - Testing, transport, delivery, and installation

3.1 - Testing

The machine in your possession has been tested in our facotry to ensure it

runs properly and is correctly regulated.

3.2 - Machine delivery and handling

All the forwarded material has been accurately checked prior to delivery to

the shipping agent.

Overall dimensions (mm)

GT HP 1.5 GT HP 2

A

660 800

C

B

C

470 600

610 520

A

Gross weight (Kg)

GT HP

1.5

30 39

GT HP 2

Note

The measurements are expressed in millimeters and the weight in kg

Unless otherwise stipulated by the client or hindered by particularly burdensome transport, the machine is wrapped with nylon and carboard.

The packaging dimensions are shown in fig. 3.2.1

When the machine is received check that the packaging is intact.

Should the packaging be damaged sign the transport documents, noting

that:

" I accept, but ..." and the reason.

Once the package has been opened, if machine components are found to

have been genuinely damaged, declare such damage to the shipping agent within three days of the date indicated on the transport documents.

GT HP 2

620

1200

800

GT HP 4

75

Fig. 3.2.1

8

17

Page 9

2.5.3 - 220 three-phase electrical diagram

L 1

L 2

L 3

1.7.1 - Safety and warning plates (fig. 1.7.2)

ATTENION!

Do not intervene on electrical parts while the machine is connected to the

power supply.

Risk of electrocution.

Observe the warnings on the plates. Failure to observe them can

cause serious injury.

Make sure the plates are always fitted and readable. If not, fit or replace

them.

M

A

A

B

C

A

D

B

C

KEY

A = motor command card

M = motor

L1, L2, L3 = three-phase line

16

Fig. 2.5.3

VOLT 230 VOLT 400

D

9

Fig. 1.7.2

Page 10

1.8 - Protections and safety devices

ATTENTION!

Before using the machine make sure that the devices are correctly positioned and in perfect working order.

At the beginning of each work shift check that they are fitted and working

properly; if not, notify the head of maintenance.

1

2.5.2 - 400-V three-phase electrical diagram

L 1

2

Fig. 1.8.1

1. Microswitch on the lever

The machine is outfitted with a microswitch on the lever of the inlet.

This works by blocking the machine when the lever remains lifted or

the inlet is completely disassembled.

2. Microswitch on the container

The machine is outfitted with a microswitch on the plexiglass container.

When the container is extracted the machine stops fig..1.8.1.

ATTENTION!

Do not tamper with the safety devices in any way.

L 2

L 3

A

KEY

A = motor command card

M = motor

L1, L2, L3 = three-phase line

M

Fig. 2.5.2

10

15

Page 11

2.4 - Noise level

Testing of the level of noise emitted from the machine indicates that the

level is lower than 70 dBA.

The manufacturer can supply a copy of the noise test upon request.

2.5 - Electrical diagrams

2.5.1 - 230 V - 50 Hz single-phase electrical diagram

L 1

L 2

A

KEY

A = motor command card

M = motor

L1, L2 = single-phase line

M

Fig. 2.5.1

1.9 - Working positions

The correct working position for the operator to optimize the running of the

grater is indicated in fig. 1.9.1.

Fig. 1.9.1

1.10 - Vibrations

The vibrations that the machine transmits to the table are not important.

14

11

Page 12

2 - Technical features

2.1 - Main parts

To facilitate the understanding of the manual the main machine components are listed below and shown in fig. 2.1.1.

1. Machine body

2. Grater roller

3. Plexiglass container

4. Grater inlet

5. Inlet lever

6. Pushbutton panel

7. Feeding cable

5

6

4

1

7

3

Fig. 2.1.1

2

2.2 - Technical features

MODEL GF HP 1,5 GF HP 2 GF HP 4

Motor

Feed

Roller revs

Inlet dimensions

Hp 1.5 2 4

V 230-400V/50Hz 230-400V/50Hz 230-400V/50Hz

R.P.M. 1,400 1,400 1,400

mm 140 x 80 190 x 95 300 x 160

2.3 - Machine dimensions and weight

Overall dimensions mm

C

A B

GF HP 1,5 GF HP 2

A

260 360

B

460 620

C

400 720

GF HP 4

C

A

B

Net weight Kg

GF HP 1,5 GF HP 2

27 34,5

GF HP 4

Note

All the measurements are expressed in millimeters and the weight in kg

Fig. 2.3.1

610

740

660

65

12

13

Loading...

Loading...