Food Processors

Models FP-ES-0015, 0015-T, 0030

Instruction Manual

Revised - 9/11/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model FP-ES-0015 / Model FP-ES-0015-T / Model FP-ES-0030

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

--------------------------------------------------------------------------------------- 5 - 6

--------------------------------------------------------------------------------------------- 7

------------------------------------------------------------------------------------ 7 - 9

-------------------------------------------------------------------------------- 3

--------------------------------------------------------------------------- 3 - 4

Page

---------------------------------------------------------------------- 4 - 5

Troubleshooting

Illustrated Diagrams

Parts Breakdowns

Electrical Schematics

Notes

Warranty Registration

------------------------------------------------------------------------------------------------- 18

----------------------------------------------------------------------------------- 10

-------------------------------------------------------------------------- 14 - 15

------------------------------------------------------------------------ 11 - 13

---------------------------------------------------------------------- 16 - 17

---------------------------------------------------------------------------- 19

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating the unit, please read this manual thoroughly. This manual should be retained for future

reference.

Safety and Warranty

This machine has moving mechanical parts and uses voltages which are potentially hazardous. Severe,

even life-threatening, personal injury could result if the instructions contained in this manual are not followed.

Before operating the unit, please read this manual thoroughly. This manual should be kept for future reference

and given to every user of the machine. The following clauses limit the liability of the manufacturer and its

representatives:

• THIS MACHINE SHOULD ONLY BE INSTALLED BY A QUALIFIED ELECTRICIAN.

• ONCE INSTALLED, DO NOT TAMPER WITH THE ELECTRICAL WIRING OF THE MACHINE.

• DO NOT USE THE MACHINE WITHOUT HAVING RECEIVED PREVIOUS INSTRUCTIONS ABOUT ITS

USE, MAINTENANCE AND SAFETY DEVICES FROM AN EXPERIENCED OPERATOR. BEFORE USING

THE MACHINE, READ THIS INSTRUCTION MANUAL CAREFULLY AND UNDERSTAND IT FULLY.

• DO NOT USE THE MACHINE WITHOUT THE PERSONAL SAFETY EQUIPMENT REQUIRED BY LAW.

• DO NOT TAMPER WITH THE MECHANICAL OR ELECTRICAL SAFETY DEVICES. ALWAYS KEEP

HANDS AT A SAFE DISTANCE FROM THE MOVING PARTS OF THE MACHINE. DO NOT LEAVE

MACHINE UNATTENDED WHILE SWITCHED ON OR IN OPERATION.

• ALWAYS DISCONNECT THE MACHINE FROM THE POWER SUPPLY BEFORE PROCEEDING WITH

CLEANING, MAINTENANCE OR REPAIRS. DO NOT OPEN THE MACHINE OR TAMPER WITH ITS

INTERNAL COMPONENTS. THERE ARE NO INTERNAL COMPONENTS THAT REQUIRE ADJUSTMENT

OR MAINTENANCE ON THE PART OF THE USER. SHOULD THE MACHINE MALFUNCTION, TURN IT

3

Safety and Warranty

OFF IMMEDIATELY AND NOTIFY THE SUPERVISOR.

Installation must be in accordance with the operating instructions and with local, provincial or state electrical

and safety codes. Compliance with codes is the responsibility of the owner and installer. Before operating the

machine, make sure that all phases are connected properly and that the machine is properly grounded and/

or connected to a circuit leakage breaker and thermal switch. Failure to do so could result in electric shock.

Make sure the safety signs and stickers are rmly afxed to the machine, that they are legible, and that they

do not become blurred or erased when the machine is cleaned. If they become damaged or lost, ask your

dealer for new ones and replace them. Keep your work area well lit and free of obstacles. When operating

the machine never wear loose clothing or jewelry which could get caught in the moving parts of the machine.

Unplug the machine when not in use. Keep children and on-lookers at a safe distance. To avoid damaging the

electrical cord, keep it out of areas where it can be stepped on. Do not alter or modify the original machine

design in any way. Should the machine need repairs, consult the ofcial distribution center where the machine

was purchased. Use only original spare parts and accessories and have them properly installed by a qualied

technician. This machine has been built exclusively for meat processing. Any other use of this machine is not in

accordance with its intended application. The manufacturer assumes no responsibility for any possible damage

or injury resulting from improper use of this machine. Additional operating instruction manuals are available

from your dealer. Your local dealer will be happy to answer any further questions you may have.

1 YEAR PARTS AND LABOR WARRANTY

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal solid urban waste

and can therefore be disposed of without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

Not only as an all-purpose cutter/chopper, but also as an emulsier to produce ne, delicate pastes. The cutter/

chopper can chop to perfection any type of meat mixture (for cold-cuts, sausages, frankfurters, pâtés, etc.) or

other industrial food products (onions, potatoes, carrots, lettuce, etc.). The presentation of the nal product

is optimal since the mixture is never crushed, bruised, or drained. The meat should be de-boned and precut

before being introduced into the bowl for chopping. Use only those prime materials adequate for alimentary

purposes. The manufacturer assumes no liability if the machine is used in any way that conicts with the

application for which the cutter/chopper was designed. The temperature of the mixture is constantly monitored

by a digital thermometer. The machine comes equipped with thermal motor protection. The cutter/chopper

has an automatic knife-stop feature which is activated by lifting the lid. The cutting head can be removed from

4

Technical Specications

the machine in one piece for replacement or cleaning. The optional six knife grouping allows for perfect and

homogeneous blending and up to 17,000 cuts per minute (20,400 in 60 Hz models). The size of the pieces

varies depending on how long the mixture is processed. Controls via the speed control knob and main safety

switch to avoid unwanted start-ups after the power has been cut. Hermetically sealed control panel and touchbutton control at 24V for single-phase machines with variable speed control. The machine’s stainless steel

construction and functional, modern design with no difcult-to-reach corners greatly facilitates the cleaning

of the cutter/chopper. The lower part of the machine is closed to prevent the entry of water or dirt and is

supported by four anti-vibration legs; this facilitates both cleaning and transportation.

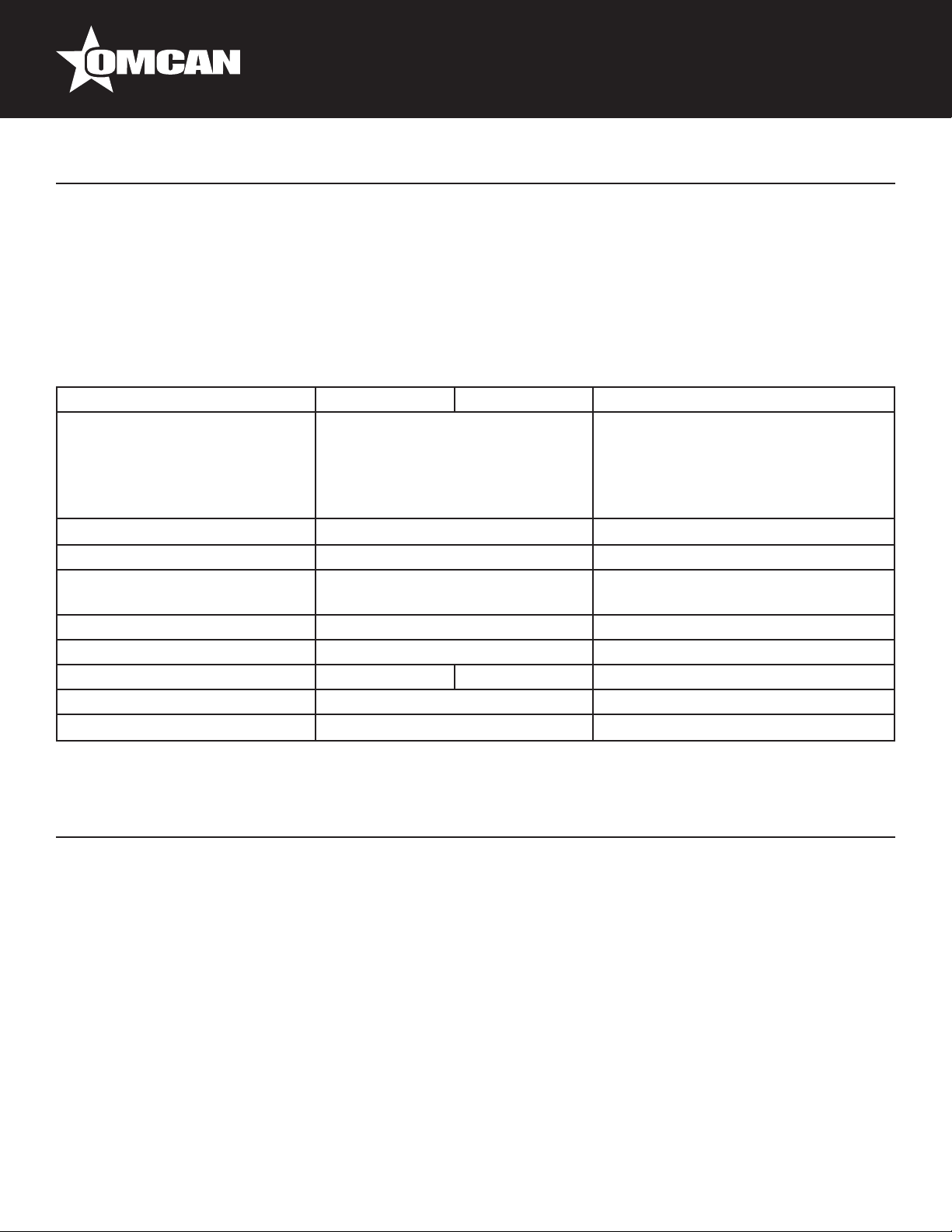

Model FP-ES-0015 FP-ES-0015-T FP-ES-0030

Features • Anti-noise lid

• 3-knife head

• Digital thermometer

• 2 speed-variable speed control

• All stainless steel

Bowl Volume 15 L / 4 gal 30 L / 8 gal

Mixture Bowl Capacity (approx.) 12 kg. / 26.4 lbs. 20 kg. / 44.1 lbs.

2.1 / 2.7 HP 4.8 / 6.5 HP

Total Horsepower

Knife Speed 1700 / 3400 RPM 1700 / 3400 RPM

Bowl Speed 22 / 45 RPM 22 / 45 RPM

Electrical 220V/60/1 220V/60/3 220V/60/3

Weight 441 lbs. 772 lbs.

Dimensions 40” × 31” × 30” 36.6” × 40.5” × 44.5”

• Anti-noise lid

• 3-knife head

• Digital thermometer

• 2 speed-variable speed control

• All stainless steel

Installation

STORAGE, TRANSPORT, AND DELIVERY

Always maintain the machine and its packaging in a vertical, upright position. Never pile machines one on

top of the other, nor put any weight on the machine or its packaging. The transport company assumes sole

responsibility for any damage received in transit; make sure that the machine is in proper condition upon

its delivery. If, after the proper checks have been undertaken, the condition of the machine is judged to be

satisfactory, proceed by installing it in a previously selected workspace. Because of its weight (approx. 771.6

lbs./350 kg), the unit should always be moved with a pallet mover or forklift, making sure that the blades of

the forklift are inserted properly under the lower part of the machine. Never use the knife shaft holder to lift the

machine since this could lead to serious damage of both the holder and the shaft (Pg. 13, Fig. 6). The machine

is delivered in protective packaging consisting of a wooden crate; please recycle this packaging. The total

contents of the packaging is as follows:

5

Installation

• Cutter/chopper.

• 2 wrenches for the assembly and dismantling of the knives (one double and one single).

• Instruction manual.

• If the machine comes with the option of a six-knife head, then four supplementary compensating rings will

be supplied so that the machine can additionally be used with just three knives in the head.

The machine should only be installed by a qualied technician and in compliance with local codes. The

electrical installation of the workplace should be equipped with power surge protection, which should then be

adjusted to the technical specications of your particular machine (see point 3, below).

1. Set the machine on a horizontal surface, leaving one meter’s space around the entire perimeter of the

machine in order to allow for safe and proper use, cleaning, and maintenance. The machine should be

positioned so that the plug is easily accessible. Also make sure that the work place has both sufcient

ventilation and good lighting. For the FP-ES-0015 table-model cutters/choppers, make sure that the surface

upon which the machine will be mounted is stable and solid enough to withstand the weight of the machine.

2. Make sure that the electrical data given on the machine’s specications plate (voltage, frequency, etc)

are compatible with those of the power source (there is a tolerance of ±10% for voltage and ±2% for

frequency). Except for FP-ES-0015 models with an optional single phase motor, the FP-ES-0015 - FPES-0030 cutter is a three-phase machine with a single voltage; therefore, it is not possible to change the

voltage of the motor. The electrical feed-cable/plug normally has 4 wires: 1 grounding (two-color yellow and

green), and 3 phases (either 3 black wires or 1 black wire, 1 brown wire and 1 gray wire). This color-coding

may vary depending on the norms of the country to which the machine has been shipped. It is possible to

install a lock on the main switch to eliminate the possibility of the machine being switched on accidentally

or in an unplanned fashion.

3. Before connecting the machine, use the wrenches provided to ensure that the knife grouping is properly

tightened (Pg. 13, Fig. 4). Tighten the knife grouping with the utmost care to avoid injury from accidentally

hitting the cutting head or the knives themselves.

4. With the machine completely disconnected and the main stainless steel lid open, turn the knives using a

plastic bar long enough to be able to reach the knives while remaining a safe distance from them. Make

sure the knives do not touch the bowl. To make sure that the knives do not rub against the lid, repeat the

aforementioned steps with the lid closed.

5. After verifying that the electrical specications are compatible to your power source, plug the machine in

and activate the main switch. The thermometer display on the switchboard should light up. Make sure that

the plug is appropriate for use with this type of machine. The machine is now ready to use.

IMPORTANT

Verify the proper turning direction of the knives and the bowl as follows: push the I-Start button. The machine

will begin to work and the bowl will start to turn counterclockwise. If the bowl turns in a clockwise direction, stop

the machine immediately and change 2 of the 3 phases at the power source/plug.

6

Operation

Before operating, clean the machine carefully, following the instructions in the MAINTENANCE section.

Do not overload the bowl; the mixture should not rise above the bowl’s rim. Do not rest mixture containers on

the edge of the bowl or on the safety guard as this could cause accidents or mechanical damage. Use extreme

caution when adding or removing the mixture; do not put your hands near the knives or reach into the bowl.

If necessary, use ice chips to lower the temperature of the mixture. Do not use cubes or blocks of ice as these

could damage the knife edge. Never reach into the bowl with your hands or arms while the cutter/chopper is

running. Never put your hands under the stainless steel lid. Eliminate any possibility of having your hands,

clothing or other personal effects trapped by or dragged under either of the lids or into the machine. This

machine is not designed to withstand permanent, uninterrupted use, but rather to run intermittently with pauses

to allow for the dissipation of built-up heat, the amount of which will vary depending on the consistency of the

mixture.

OPERATING INSTRUCTIONS FOR 2-SPEED ELECTRIC CUTTERS

Start with the machine totally off, that is, with both the main safety switch and the speed control knob in the

“0” (stop) position. Close the two lids one after the other (steel, then plastic). Be careful not to trap your hand

under either lid in this process. Turn the main safety switch to the “I” (on) position. The digital thermometer

display will light up. Turn the speed control knob to position “1” (low). The knives and the bowl will begin to turn.

The speed control knob has three positions: “0” (stop), “1” (slow), and “2” (fast). These can be selected as

needed at any given moment. To stop the machine completely, turn the speed control knob to the “0” (stop)

position. The knives and bowl will stop moving. Do not stop the machine using the main safety switch as this

should only be used with the speed control knob in the “0” (stop) position. Wait until the bowl and knives have

stopped completely before opening the knife lid. When nished using the machine, turn it off completely by

turning the main safety switch to the “0” position.

Maintenance

CLEANING

Always turn the machine off before proceeding with its cleaning. To do this, deactivate the auxiliary fuse board

switch and turn off the main operating switch. If possible, disconnect the machine from the power source

as well. The machine should be cleaned daily, both before and after its use. Given the easy access to all its

components, the unit is simple to clean using just warm water and a mild detergent. Never use bleach nor

any abrasive cleaners which could damage the stainless steel or other materials. Never use steam or a high

pressure jet of water to clean the cutter/chopper; avoid getting water in the interior of the machine, especially

through or around any electrical components. After every operating session, use a brush to carefully clean

the bowl, the knife shaft, and the interior part of the knife lid, as well as the plastic cover, the hinge of the lid,

and the lid holding screws if necessary. Do not put your hands near the cutting edge of the knives without

using adequate protection (gloves made of reinforced metal ber). The knife head can be removed in one

piece (Fig. 5) in order to clean it under running water; take care not to drop the knife head assemblage on the

oor or on your feet. Do not wash the knives in water hotter than 60°C or colder than 10°C. Do not wash the

7

Maintenance

knives immediately after using the machine since a brusque change in temperature could cause internal micro

ssures or deformations. It is extremely important to keep the surfaces holding the knives and separation rings

clean to avoid build-up of mixture residues. Such a build-up could create areas which bear more pressure than

others, possibly causing micro ssures that could damage or break the knife. To clean the machine manually,

always use appropriate safety equipment (latex gloves, plastic aprons, etc.). Always rinse the machine

thoroughly after using any kind of detergent or disinfectant and be sure to follow the manufacturers’ instructions

when using cleaning products. We recommend using the following products:

• Neutral detergent/degreaser pH 7. Due to its neutral pH, no special precautions are necessary. Rinse

thoroughly.

• Detergent/degreaser for manual cleaning. Use appropriate precautions and safety gear. Rinse thoroughly.

• Alkaline detergent with disinfectant and anti-corrosive components. Use appropriate precautions and safety

gear. Rinse thoroughly.

• Disinfectant based on quaternary ammonium salts. Use appropriate precautions and safety gear. Rinse

thoroughly.

Always follow the manufacturer’s recommendations carefully when using these or any other products.

Except for daily cleaning, the only maintenance required by the chopper is the changing of the transmission

belts after every 2,500 hours of operation. All mechanical or electrical repairs should be undertaken only by a

qualied specialist with proper training for the work required. After replacing the transmission belt, be sure to

position the turnbuckle roller parallel to the belt, tightening the nut which attaches the roller to its base securely.

If the electrical cord becomes damaged, have it replaced immediately with a cord of identical technical

characteristics (your local distributor can supply you with one).

DISMANTLING THE CUTTING HEAD

REMOVING THE WHOLE HEAD

In order to proceed with the cleaning or replacement of the cutting head while maintaining the settings of the

existing knives, the cutting head can be removed in one piece. Proceed as follows:

• Disconnect the machine by turning off the main switch; for added safety, turn off the isolating switch in the

main fuse board and unplug the machine.

• Never touch the knife-edge with your hands. Always use gloves made of metallic netting.

• With the wrenches provided unscrew the cap nut at the end of the knife shaft in a CLOCKWISE direction

(Pg. 13, Fig. 4 - step 1). Pull the entire assembly towards the left until you have separated it from the shaft

(Pg. 13, Fig. 5). If necessary, hit the base of the knife holder several times with a plastic mallet to remove it;

never hit the knives themselves with any instrument or tool.

To reassemble the cutting head, repeat the dismantling operations in reverse order, taking into account the

assembly recommendations listed in the section below.

DISMANTLING THE KNIVES SEPARATELY

In order to remove the knives separately while leaving the knife-head assembly attached to the shaft, proceed

as follows:

8

Maintenance

• Disconnect the machine by turning off the main switch; for added safety, turn off the isolating switch in the

main fuse board and unplug the machine.

• Never touch the knife-edge with your hands. Always use gloves made of metallic netting. With the

wrenches provided unscrew the cap nut at the end of the knife shaft in a CLOCKWISE direction (Pg. 13,

Fig. 4). With the same wrenches, but using two sides of the same width, unscrew (also in a CLOCKWISE

direction) and remove the knife xing nut ring.

• Remove the knives and the compensating rings separately, remembering rst to make a note of their order

and position (Pg. 12, Fig. 2).

To reassemble the knife head, repeat the dismantling operations in reverse order, making sure of the following:

• The xing nut for the knife grouping is not tightened completely until the knives have been turned (with the

help of a bar made of a pliant material) to ensure that the knives do not touch or rub against the bowl or the

lid.

• Adjust each knife so that there is a 2-3 mm space between each knife and the bowl (Pg. 12, Fig. 3). For

this adjustment we recommend using a space gauge made of a pliant material (cardboard, cork, etc.) to

follow the path marked by the end of each knife and a plastic mallet to adjust the knives accordingly.

• For safety reasons, do not try to leave a space of 0 mm between the knives and the bow. This is not

recommendable because the strong vibrations which result under certain operating conditions could cause

one or more of the knives to make contact with the bowl.

• The knives are equipped with a ange which functions as a knife stop. During installation, this ange

should stay in contact with the knife holder.

• Once the knife-head has been reassembled correctly, tighten both the head and the xing nut for the knife

assembly with the wrenches provided.

SHARPENING THE KNIVES

If the quality of the cutting/chopping should noticeably diminish, the knives should be sharpened by a qualied

professional, paying special attention to maintaining the length and weight of each of the knives in a given

group or head. The knives should only be sharpened by an expert specialized in the sharpening of tempered

knives. Before sharpening the knives, consider whether the resulting reduction in size will be substantial

enough to warrant the installation of completely new knives. In principle, the external knife-edge should not

be reduced more than 1 cm from its original size. Once the knives have been sharpened, before reinstalling

them in the machine, a small space should be led from the stop ange located in the hexagonal area (Fig. 3)

to compensate for any possible shortening of the knives. To clean the knife surfaces, use a product with anticorrosive properties. Always store the knives in their packaging; this will help maintain the cutting edge and it

will protect them from any accidental bumps or friction. Always transport the knives in their packaging when

possible. To adjust or move the knives always use adequate safety measures and equipment.

9

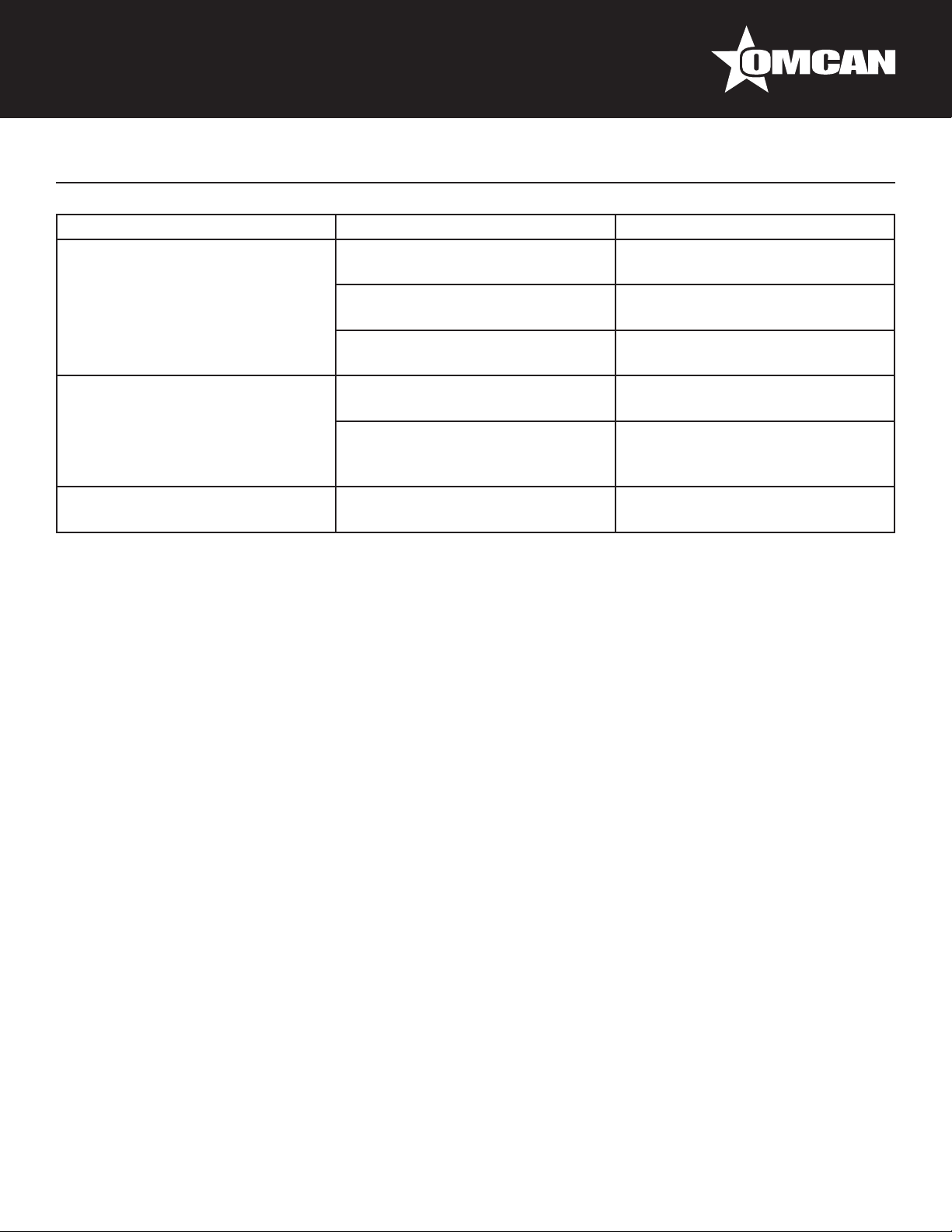

Troubleshooting

Problem Possible Causes Solution

Machine does not work. Machine is not connected to the

power source.

The main switch is in the 0-Stop

position.

No voltage in one or more phases. Check the fuses, plug and

Machine is connected to power

source but knives do not turn.

Bowl turns in the wrong direction. The phases are reversed. Switch 2 of the 3 phases in the

The stainless steel lid is not

closed.

The thermal protective clixon has

blown.

Connect the machine to the power

source.

Move the switch to the I (on)

position.

switches.

Close the stainless steel lid.

Let the machine cool down for a

few minutes, then switch it back

on.

power source connection.

10

Illustrated Diagrams

11

Fig. 1

Illustrated Diagrams

Fig. 2 - Different Knives

Assembly Systems

12

Fig. 3 - Knives Adjustment

Illustrated Diagrams

Step 1 Step 2

Fig. 4 - Knives

loosening procedure

13

Fig. 5 - Knives Head

Disassembly or

Assembly

Fig. 6 - How to

move the machine

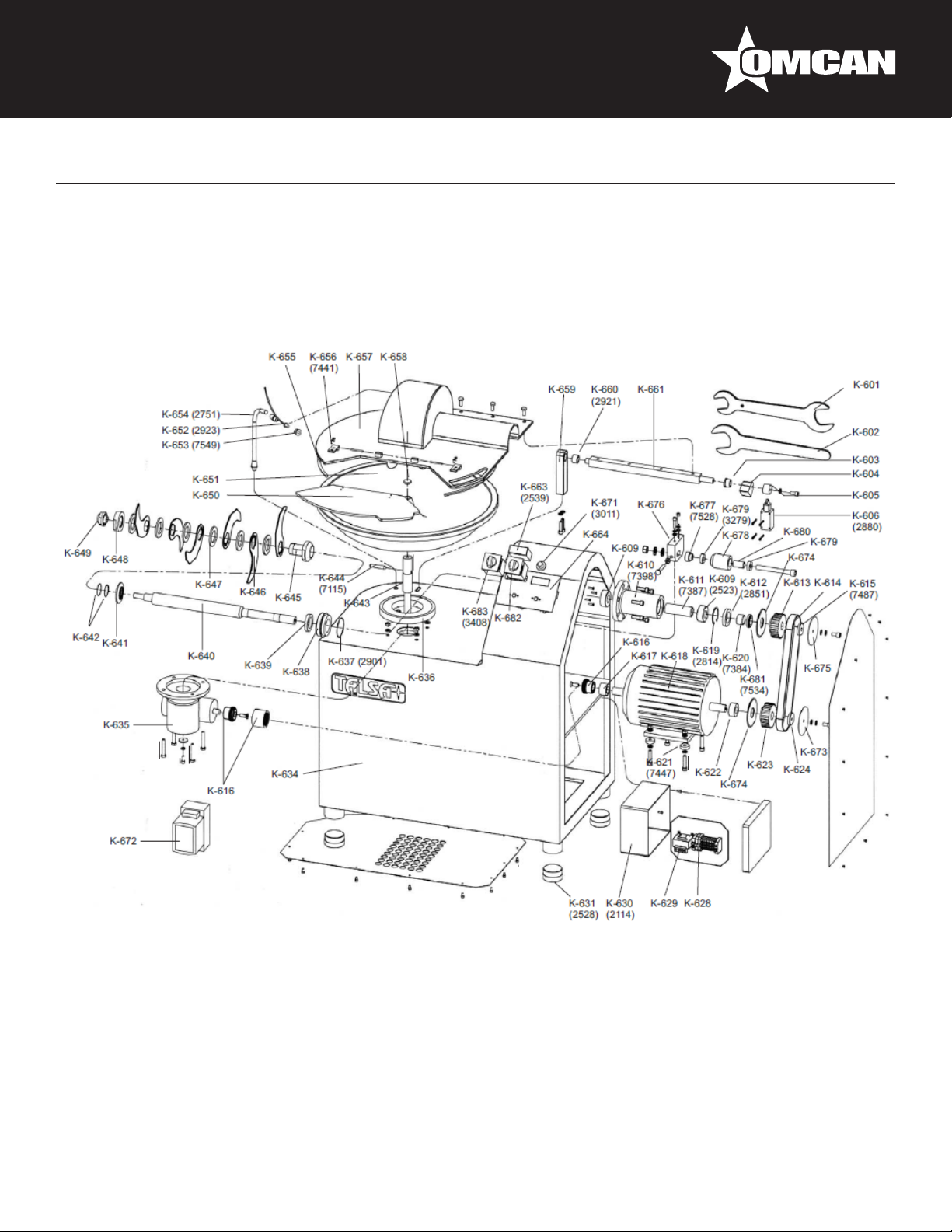

Parts Breakdown

Model FP-ES-0015 10875

Model FP-ES-0015-T 19256

Model FP-ES-0030 10878

14

Parts Breakdown

Model FP-ES-0015 10875

Model FP-ES-0015-T 19256

Model FP-ES-0030 10878

Description Position Description Position Description Position

Double Key Knife Disassembling K601 Isolating Electric Box K630 Tube Thermometer Sensor K654

Single Key Knife Disassembling K602 Anti-vibrating Foot K631 Lid/Bowl Friction Bar K655

Bronze Bearing K603 Machine Frame K634 Plastic Body Hinge Lid K656

Lid Lever K604 Bowl Gear Reducer K635 Stainless Steel Lid K657

Lid Lever for Microswitch K605 Plastic Bowl Ring K636 Bowl Screw Cap K658

Lid Safety Microswitch K606 Knives Shaft O-Ring K637 Lid Column Holder K659

Knives Shaft Bearing K609 Knives Shaft Dressing K638 Bronze Bearing K660

Knives Shaft Holder K610 Knives Shaft Bushing Gasket K639 Squared Shaft Lid Folding K661

Ring Bearing Separation K611 Knives Shaft Bushing Gasket K639 Digital Thermometer Display K663

Knives Bushing Gasket K612 Knives Shaft K640 Front Panel Board K664

Knives Shaft Pulley K613 Separator Ring K641 Speed Control Knob (Optional) K671

Belt K614 O-Ring Separator K642 Speed Controller (Optional) K672

Knives Shaft Pulley Washer K615 Bowl Shaft Reducer K642 External Washer K673

Elastic Coupling K616 Bowl Shaft Reducer Pin K644 Internal Washer K674

Safety Ring Pin K617

Motor K618 4 Cuts Knife K646 Holder Turnbuckle K676

Knives Shaft Locking Ring K619

Knives Shaft Ring K620

Motor Holder K621

Separator Motor Pulley K622

Motor Pulley K623 Locking Knives Nut K648

Motor Pulley Washer K624

Fuse K628 Transparent Anti-noise Lid K650

Transformer K629 Bowl K651

Transformer K629 Thermometer Sensor K652 2 Speeds Switch Selector K683

Hexagonal Knives Holder, Counterclockwise thread

Knives Spacer Ring 4 mm (FPES-0015 only)

Knives Spacer Ring 7 mm (FPES-0015 only)

Knives Spacer Ring 5 mm (FPES-0030 only)

Knives Spacer Ring 9 mm (FPES-0030 only)

Nut Blocked Final Knives Shaft

Counter-clockwise Thread

K645 External Washer K675

K647 Turnbuckle Pulley Washer K677

K647 Tension Wheel K678

K647 Turnbuckle Pulley Bearing K679

K647 Separation Ring Tensor Bearings K680

Separation Ring Knives Shaft

Pulley

K649 3-phase Switch with Disconnector K682

3/1-phase Switch with

Disconnector

3/1-phase Switch with

Disconnector

K681

K682

K682

15

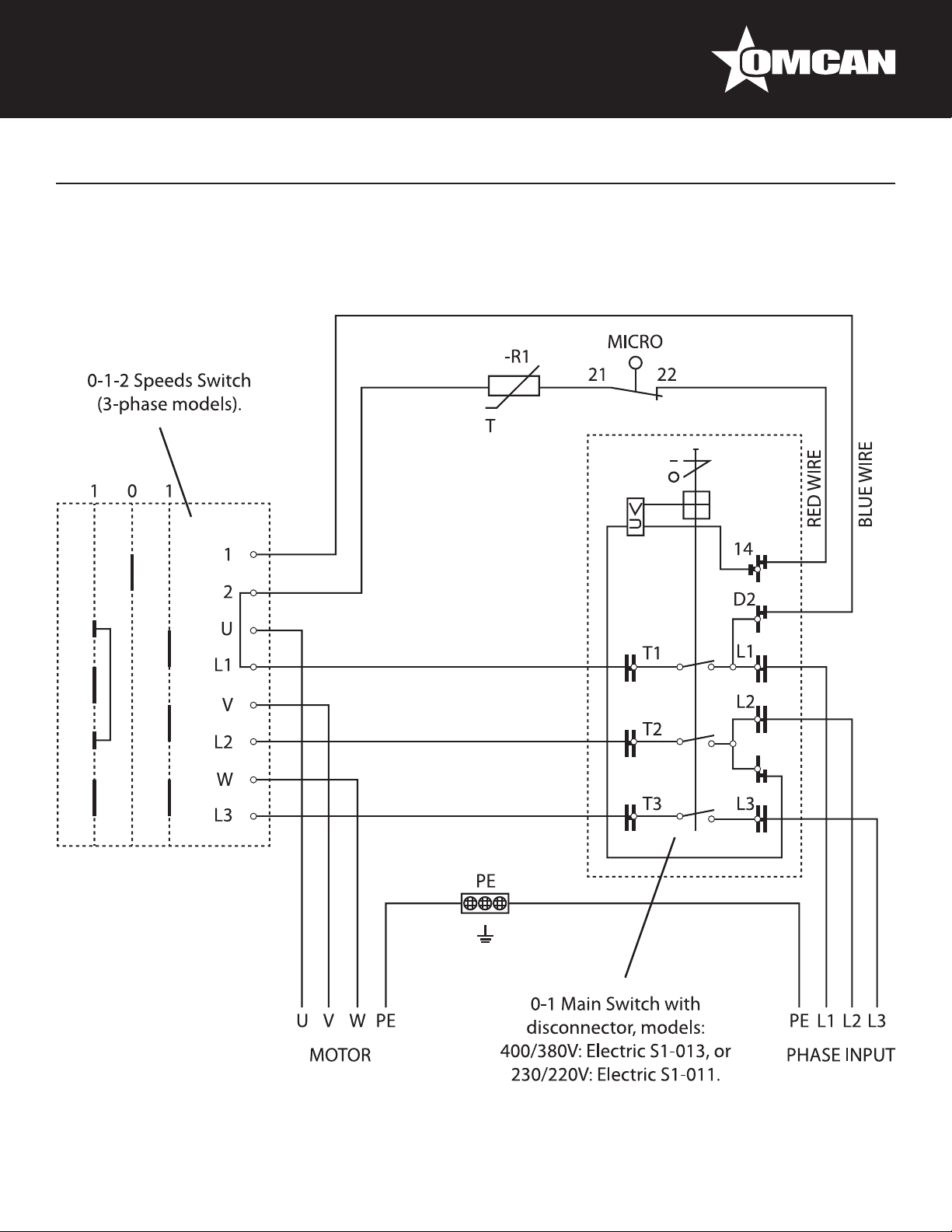

Electrical Schematics

Model FP-ES-0015-T 19256

Model FP-ES-0030 10878

16

Model FP-ES-0015 10875

Electrical Schematics

17

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

18

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

www.omcan.com/warrantyregistration.html

For mailing in Canada For mailing in the US

OMCAN INC.

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

Niagara Falls, New York

OMCAN

USA, 14305

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Thank you for choosing Omcan

19

Over the last 65 years, Omcan has grown to become a leading supplier to the food

service industry in Canada and the USA. Our success over these many years is

directly attributed to our established relationships with all of our valued customers

and through providing them with Diverse, Dependable and Proven products.

Omcan continues to help our customers remain competitive.

With associates in North America, Europe, Asia, and South America, our global

footprint continues to expand as we hold to the principle that clients benet from

the accessibility and familiarity of our sales team. In 2013 as our geography and

brand recognition continued to grow, we changed to one name Omcan Food

Machinery.

In over 200,000 sq ft of warehouse space we stock over 2,500 quality food

equipment and supplies for the food preparation market.

Loading...

Loading...