Omcan Food Machinery FGM111 Installation Manual

Cheese Cutters and Graters

Models FGS / FGM

Instruction Manual

Version 1

3115 Pepper Mill Court, Mississauga, ON, L5L 4X5

4450 Witmer Industrial Estates, Unit 4, Niagara Falls, NY, 14305

1-800-465-0234

www.omcan.com

Table of Contents

Model FGSM15 / Model FGSM10 / Model FGS101

Model FGS121 / Model FGM111 / Model FGM111M

Section

General Information

Safety and Warranty

Technical Specications

Installation and Operation

Maintenance

Troubleshooting

--------------------------------------------------------------------------------- 13 - 15

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 5 - 7

----------------------------------------------------------------------------- 15 - 16

Page

---------------------------------------------------------------------- 7 - 9

------------------------------------------------------------------ 9 - 13

Parts Breakdowns

Electrical Schematics

Warranty Registration

-------------------------------------------------------------------------- 17 - 28

---------------------------------------------------------------------- 29 - 33

---------------------------------------------------------------------------- 35

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

MANUAL IMPORTANCE

The present instruction manual for the use is to be considered as an integral part of the machine:

1. Must be kept for the full life of the machine.

2. Must be coupled with the machine in case of its ceasing.

3. To show all useful notices for operators and containing the electric diagrams that will be used for the

possible maintenance reparations.

SCOPE / MANUAL PURPOSE

The instructions manual has the purpose to furnish all necessary information so that the machine supplied will

be used in a proper, efcient and safe manner. Besides supplying indications and warnings, it is to identify its

principles and functioning limits. For possible doubts, call Omcan.

RECEIVERS

The instruction manual, which accompanies the machine, is an integral part of the machine and is intended

both for its operators and for skilled technicians qualied for the installation, use and maintenance of the

machine.

RESPONSIBILITY

• If the manual endures damages or is lost, request a copy from Omcan;

• The manual reects the technical state during the machine’s manufacturing; the manufacturer reserves the

right to update the product and as a consequence other manual issues, without the obligation to update

previous manuals, unless pertaining to the health and safety;

• Pay particular attention to the safety features on the machine and the prescriptions to which the following

instructions for proper use;

• The manufacturer is responsible for the machine to be in its original conguration;

• The manufacturer is not responsible for damages caused from the improper use of the machine and

damages caused by standards violation, negligence, lack of experience, imprudence and not respecting

the regulation standards on behalf of the employer, of the operator or the maintenance person and for

every possible damage caused from an irrational, improper and/or wrong use;

• The manufacturer is not responsible for consequences caused from not using original spare parts or ones

of equal characteristics;

• The manufacturer is responsible only for the information shown in the manual;

• Not fullling the requirements contained in this manual will cause the guarantee to be immediately

3

General Information5Safety and Warranty

terminated;

• Carry out the foreseen safety measures;

• Inform the operator about the specic risks to which they are exposed to and bring to their attention the

essential prevention standards;

• It is required that operators observe the safety standards and use the protection means put at their

disposal.

SYMBOLOGY MEANING

The following shows the specied symbols and their denitions which will be used in the

manual:

DANGER

This symbol shows the danger for those who work on the machine and those in the vicinity.

The indicated activity must be performed in accordance with the accident prevention standards

and with the indications showed in the manual.

PRECAUTION

The symbol is used to indicate a warning on useful information or recommendations about an

operation.

ATTENTION

The symbol is used to show that an operation should be performed with attention to avoid

damage to the machine.

The grater machine is designed to:

1. Grate tough cheese, bread and biscuits.

The machine is constituted from an electric motor inserted in a

unique fusion (basic machine body). In any versions the fusion can

be recovered from a bonnet (hulled machine body). The product is

loaded manually inside the grater mouth and placed in the top side

of the machine, always done manually. Through pressure on the

handle, the product is pushed against the grater roll. The product

load must be in a moderate quantity to avoid low pressure, due to the

safety micro switch placed in the pressure lock. The grater roll, which

can be stamped or milled, cannot be removed from the machine.

In accordance with the functioning requirements and production,

the machine can be substituted with different optional parts. The

machine is supplied with the identication plate on which the

following data is shown:

4

NORMAL USE, IMPROPER USE, OR NOT CORRECT USE

The machine describe in the present instructions manual for the use is foreseen to be drive from an only

operator skilled and prepared on residual risks with competency and in a safe manner.

In its NORMAL USE; the machine can be used only to:

1. Grate tough cheese, bread and biscuits.

The machine must not be used IN AN IMPROPER WAY; IN PARTICULAR:

1. It must not be used for domestic uses,

2. It must not be functioned with parameters different from those shown in the technical characteristics table,

3. When used with modalities different from those shown in the manual, the manufacturer declines every

responsibility,

4. The user is responsible for the damages resulting from the lack of observance of the conditions described

in the manual.

5. Not to tamper or damage intentionally nor remove or hide the labels.

The machine must not be used INCORRECTLY because some damages or injuries could be caused for the

operator, in particular:

1. It is dangerous to move the machine when it is connected to the electric feeding;

2. It is dangerous to pull the power cable or the machine to disconnect the feeding plug;

3. It is dangerous to put weights on the machine or on the power cable;

4. It is dangerous to put the power cable on sharp or ammable objects;

5. It is dangerous to use the machine with a damaged power cable or with the control devices;

6. It is dangerous to leave the machine off with the power cable still connected;

7. It is dangerous to leave the loaded machine unsupervised;

8. It is dangerous to insert any type of object inside the motor ventilation cap;

9. It is dangerous to use ammable substances, corrosive or harmful cleaning agents;

10. It is dangerous to put the machine on top of objects;

11. It is dangerous to insert any type of object under the machine base or place clothes or other things

between the machine feet and the working ground;

12. It is dangerous to plunge the machine in water or in other liquids;

13. It is dangerous that non-authorized personnel use the machine and with clothes different from that showed

for the use;

14. It is dangerous to introduce the grinding neck and the grater mouth with products or objects having

characteristics different from those showed in normal use, such as bones, frozen meat, non-food products

and clothing;

15. It is dangerous to introduce in the grated product exit zone any object such as knives, blades, etc.;

16. It is dangerous to function with the protection shelters and xes not blocked or correctly removed;

17. It is dangerous to partially remove the protection pieces and danger signals;

18. It is dangerous to function without all the precautions about the residual risks adopted on behalf of the user;

19. It is dangerous to smoke or use free ame devices and manipulate incandescent materials, unless some

Safety and Warranty

suitable safety measures are adopted.

However, the user is responsible for damages resulting from not observing the specied normal

use and conditions. For possible doubts you can enquire at the Authorized Assistance Center.

Failure to follow proper safety instructions can be dangerous and can cause damage or injury.

Except where differently specied, the personnel who performs the installation interventions,

connection, maintenance, reassembly and reuse, damages or breakdowns, demolition and

dismantling must be a skilled personnel qualied in safety matter and educated on the residual

risks. The personnel must be competent and perform in a safe matter with all other maintenance

employees.

ENVIRONMENTS, WORKING AND PASSING PLACES

The work environment must answer to the directive 89/654/CEE requirements. In the working area no foreign

objects can be present. The employer, in the directive of 89/391/CEE, must follow the measures promoting the

safety and health of the workers during the work. They must eliminate or reduce the residual risks as foreseen

in the manual.

WARNINGS ON THE RESIDUAL RISKS

RESIDUAL RISK DUE TO THE FIXED PROTECTIONS REMOVAL, INTERVENTIONS ON BROKEN/WORN

PARTS

The operator must not try to open or remove a protection measure or tamper a safety device.

In the phase of maintenance and cleaning, and during all further manual operations that

happens to introduce the hands or other body parts in the machine’s dangerous areas, a

residual risk remains due above all to:

1. Hitting with machine manufacturing parts,

2. Grazing and/or abrasion with machine rough parts,

3. Injury from the sharpened parts,

4. Lacerations from a tool having sharpened parts.

The operator and maintenance personnel must be skilled for the intervention connected to the manual

operations with open protections, must be trained on joined consequent risks and must be authorized from a

responsible person.

PROTECTION DEVICES ON THE MACHINE

The machine protections and safety devices must not be removed. If they must be removed for

extraordinary maintenance requirements, some measures will have to be immediately adopted.

To put in evidence and to reduce amount of danger. The reassembling aspect of the protection or safety

devices must happen as soon as the extraordinary circumstance has completed.

6

Safety and Warranty

The machine transmission parts are completely isolated by means of xed protections which do not allow

access improper objects. For all safety functions including the control and check systems, well-tested

components and safety principles have been used.

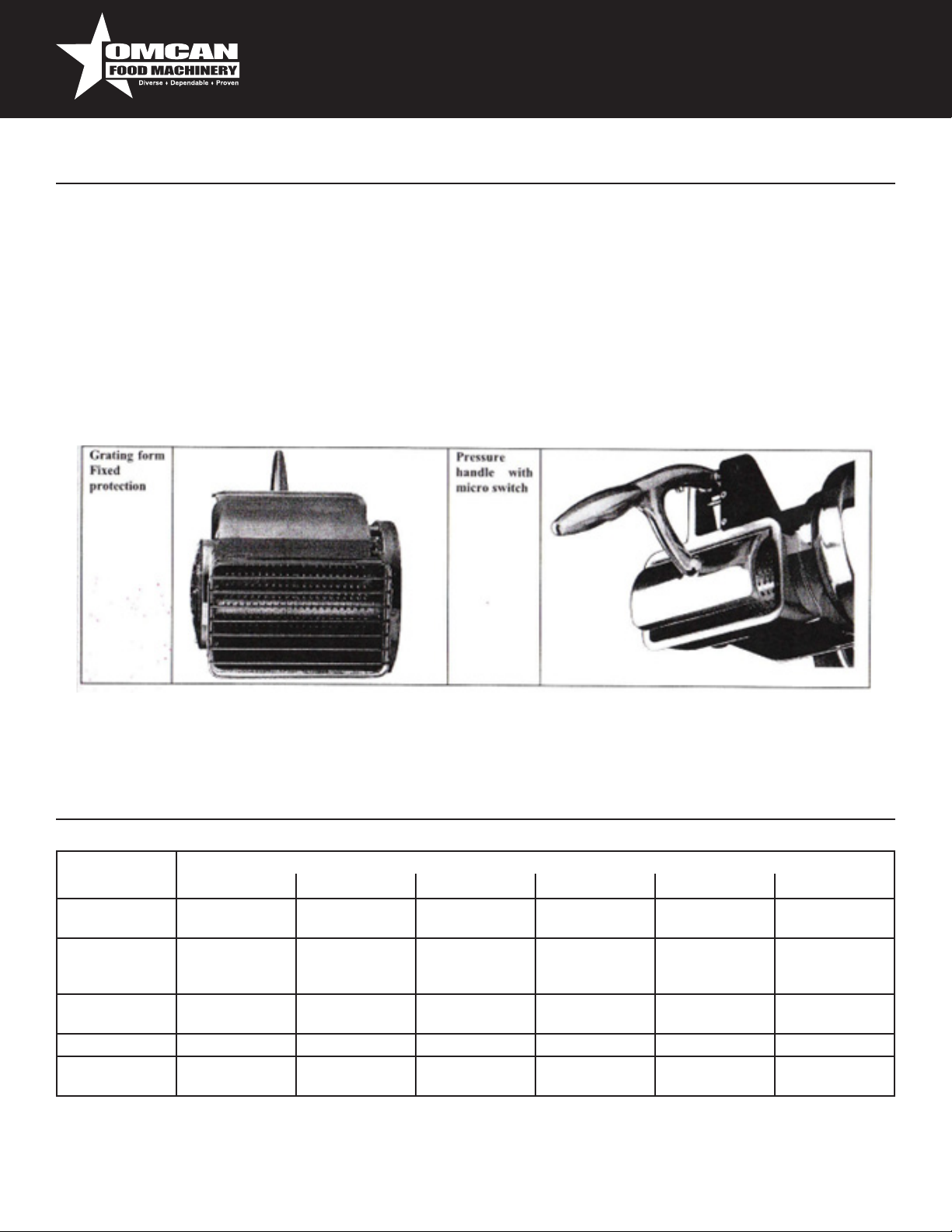

Grater group:

1. Taking into account the machine’s modality and use, the moving elements are not isolated from the

protections and safety devices,

2. On the handle and pressure group, a micro switch is placed, which stops the grater roll rotation so it is

possible to access the grater mouth,

3. Fingers are prevented from accessing the grater roll as there is a xed protection piece to stop this.

ONE YEAR WARRANTY

Technical Specications

TECHNICAL

DATA

Motor Power

(kW / HP)

Grater Mouth

Internal Size

(mm)

Grater Timetable

production (kg/h)

Mass (kg) 17 17 20 17 20 40

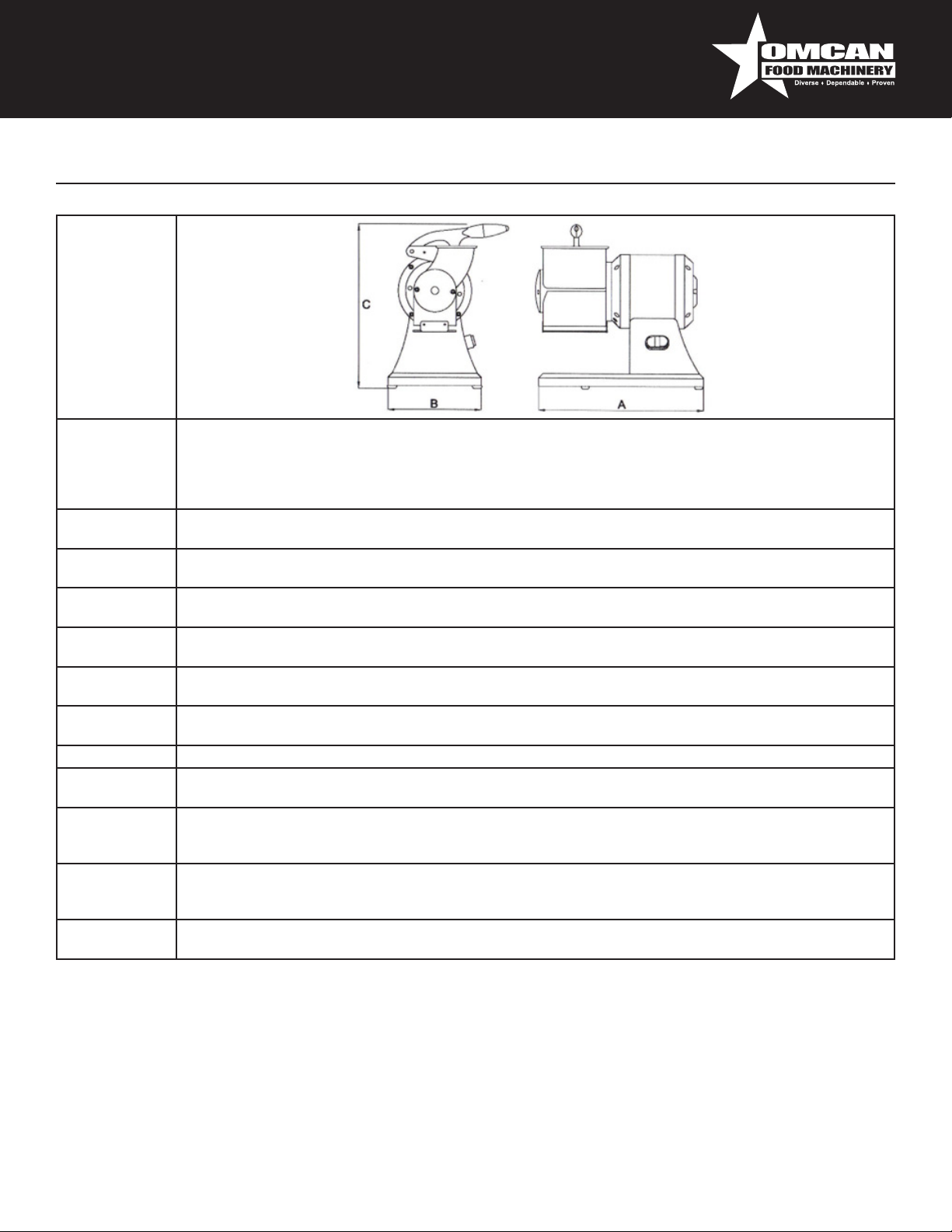

Maximum Size: A

x B x C (mm)

GS G8D GSM G1 GD GG

0.75 / 1 0.75 / 1 1.1 / 1.5 0.75 / 1 0.75 / 1 3 / 4

140 x 75 140 x 75 140 x 75 140 x 75 140 x 75 x 2 285 x 150

50 50 50 50 50 100

380 x 220 x 380 380 x 220 x 380 420 x 220 x 380 410 x 220 x 350 540 x 220 x 380 700 x 400 x 600

MODEL

7

Technical Specications

Continue

Acoustic

Power Level

Considered

Equal to A

Current Nature -

Frequency

Full Charge

Current

Use Nominal

Voltage

Auxilary Circuits

Voltage

Mass and

Neutral

Protection

Degree

Use Place Inside

Machine

Positioning

Max

Environment Air

Temperature

Requested

Minimum

Illumination

Product Directive

Conformance

Working ground used in the food eld of height included between 900/1100mm from the trampling level of

adequate capacity, with a free circulation space of at least 800mm

98/37/CE, 73/32/CEE and successive modications and integrations, Reg. 1935/2004

Minor of 70dBA

Cfr. Machine Plate

Cfr. Machine Plate

Cfr. Machine Plate

AC 24V - DC 24V

TT e TN

IP X3

+40°C

500 lux

8

Technical Specications

GROUP

GS G8D GSM G1 GD GG

Basic machine body, grater on the left ● ● ● ●

Basic machine body, grater on the right ● ● ●

Increased motor ●

Motor from 3 kW ●

Hulled machine body (I) ●

Stamped grater roll ● ● ● ● ● ●

Milled grater roll ● ● ● ● ●

GROUP EXAMPLE

1. Machine Body

2. Control Switch ON/OFF

3. Pressure Handle

4. Grater Mouth

5. Collect Container

MODEL

Installation and Operation

The machine management is allowed only by authorized personnel and those of a sufcient

technical experience.

Before switching on the machine perform the following operations:

• Read with attention the technical documentation.

• Know what protections and emergency devices are available on the machine, their

location and functioning.

The non-authorized use of commercial parts and accessories altering the protections and safety devices can

cause some malfunctions and danger for the operators. The operator must have received adequate training.

WORKING POSITIONS AND OPERATORS TASKS

As described in the instructions manual, the machine is designed to be drive by an operator skilled and

informed on the residual risks with competency and in a safe manner.

9

Installation and Operation

The normal working zone of the operator is:

1. The machine’s frontal zone near the grater mouth (dened loading zone) in normal conditions of functioning

is the loading operations of the food product, with the xed covers closed and blocked;

2. The machine’s front, the product dispenser in normal conditions of functioning is the location for withdrawal

operations of the food product stored in the collect container, with the xed covers in closed and blocked

position.

TRANSPORTATION, HANDLING AND STORING

All transportation and handling operations must be performed by informed and trained personnel and must

have read and understood the safety instructions shown in this manual.

1. Perform the machine handling and transportation always when it is off;

2. Verify that lifting means are use, it is able to support the loading weight and overall

dimensions in safety conditions and that are approved and subjected to a regular

maintenance,

3. Adopt all necessary measures to assure the maximum stability in relation to their mass,

4. Avoid making the machine suffer shaking or accidental collisions during the moving and

the loading,

5. Perform the handling with continual movements, without pulls or repeated impulses.

PACKING REMOVAL – OPENING MODALITY

PACKING DESCRIPTION – HOW TO GET RID OF THE PACKING MATERIAL

The machines are package so that the liquids inside and organic matters are not present. There is a

polyethylene cover around the machine which is then inserted in a cardboard box of adequate size. The empty

spaces within the box are occupied with ll material.

Do not waste the packaging, but store it for possible transportation or locate a recycling agency for disposal.

It is an employer’s obligation to be acquainted of the laws in its own country and observe these legislations. It

is forbidden and liable to nes to leave the machine and electric equipment in the environment.

PREPARATION PRELIMINARY OPERATIONS

STABILITY

The machine stability is designed so that in normal functioning conditions, taking into account the climatic

conditions, the machine can be used without reversal risk, fall or inopportune movement. Taking into account

the conformation and the position of the machine, it will function without fastening it to the working ground.

GRATER ROLL ROTATION

The operations indicated must be performed by the maintenance person (skilled personnel

in the electric maintenance eld of industrial machinery). For machines fed with three phase

voltage (3 PE AC 400V 50Hz), slacken lightly the blockage wheel to not have a strong

10

Installation and Operation

pressure on the drilled plate for the cutting knife. When turning on, verify the Archimedean screw / grater

roll rotates counterclockwise. If there is clockwise rotation, switch off the machine, disconnect the plug,

disassemble it, disconnects the two phase conductions and invert their position.

FUNCTIONING DESCRIPTION

The control devices are designed and manufactured to handle normal service stresses and strains. The control

devices are clearly visible, locatable and marked distinctly. The main control devices are shown:

TYPE / COLOUR REFERENCE / DESCRIPTION

Button / Black “0” / button for the machine stop control

Button / White “1” / button for the machine start control

STARTING

The machine only starts with a voluntary action on the control device: white button “1” for the starting control.

STOP

For the stop control push the black button “0”. In case of momentary or extended stop, all food products must

be removed to get the machine to function again.

FUNCTIONING SAFETY

If the machine is under stress or is exposed to long functioning times or overload, the thermal protection

function will stop the machine. In this case, wait until it is completely cooled before proceeding to the starting

function.

VOLTAGE LACKING

In the case of the electric feeding breaking off of the machine and being disconnected, the machine will only

restarted after the electric feeding is back or there is re-connection to the power source.

STARTING

The machine only starts with a voluntary action on the control device: white button “1” for the starting control.

STOP

For the stop control push the black button “0”. In case of momentary or extended stop, all food products must

be removed to get the machine to function again.

FUNCTIONING SAFETY

If the machine is under stress or is exposed to long functioning times or overload, the thermal protection

function will stop the machine. In this case, wait until it is completely cooled before proceeding to the starting

function.

VOLTAGE LACKING

In the case of the electric feeding breaking of if the machine is disconnected, the machine will only be restarted

after the electric feeding is back or there is re-connection to the power source.

11

Loading...

Loading...