Omcan Food Machinery F350-2 Installation Manual

14” Impulse Sealers

Item 14432 & 14433

Instruction Manual

Version 1.1

3115 Pepper Mill Court, Mississauga, ON, L5L 4X5

4450 Witmer Industrial Estates, Unit 4, Niagara Falls, NY, 14305

1-800-465-0234

www.omcan.com

Table of Contents

Item # 14432 / Item # 14433

Section

General Information

Safety & Warranty

Technical Specications

Operation

Maintenance

Troubleshooting

--------------------------------------------------------------------------------------------- 4

------------------------------------------------------------------------------------- 4 - 5

-------------------------------------------------------------------------------- 3

---------------------------------------------------------------------------------- 3

------------------------------------------------------------------------------------- 6

Page

-------------------------------------------------------------------------- 4

Parts Breakdowns

Electrical Schematics

Warranty Registration

------------------------------------------------------------------------------ 7 - 8

------------------------------------------------------------------------------ 9

---------------------------------------------------------------------------- 11

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

The impulse sealer is suitable for sealing polyvinyl chloride, polyethylene bags. The temperature is

electronically controlled and is easy to be adjust. The temperature is stably controlled. The machines are used

in the area of food, medicine, daily cosmetics, local specialities, aquatic products, seeds, chemical products,

garments etc. They are the best sealers for factories, stores and other users.

CHECK PACKAGE UPON ARRIVAL

If no external damage is evident on the package upon its arrival, open it and check that all the components are

inside. If the package has suffered rough handling, bumps or damage (visible or concealed), the carrier must

be informed within 24 hours about any damage. A detailed report on the extent of the damage caused to the

machine must be lled within three days from the delivery date shown in the shipping documents.

Safety & Warranty

• This machine should only be installed and operated by trained personnel. Do not change the electrical

wiring of the machine.

• Read all instructions carefully and do not operate the machine until the operator has fully read this manual.

• Do not use the machine without the personal safety equipment.

• Keep hands, long hair, foreign objects, clothes and jewelry away from any moving parts.

• Do not leave the machine unattended while the unit is on or in operation.

• Always turn off and unplug the unit before performing any maintenance.

1 YEAR PARTS AND LABOR WARRANTY

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal solid urban waste

and can therefore be disposed of without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

3

Technical Specications

Item # 14432 14433

Description 14” seal bar, 2 mm width 14” seal bar, 5 mm width

Electrical 110V/60/1 110V/60/1

Weight 42 lbs. 42 lbs.

Dimensions (DWH) 20.75” × 16.5” × 33.5” 20.75” × 16.5” × 33.5”

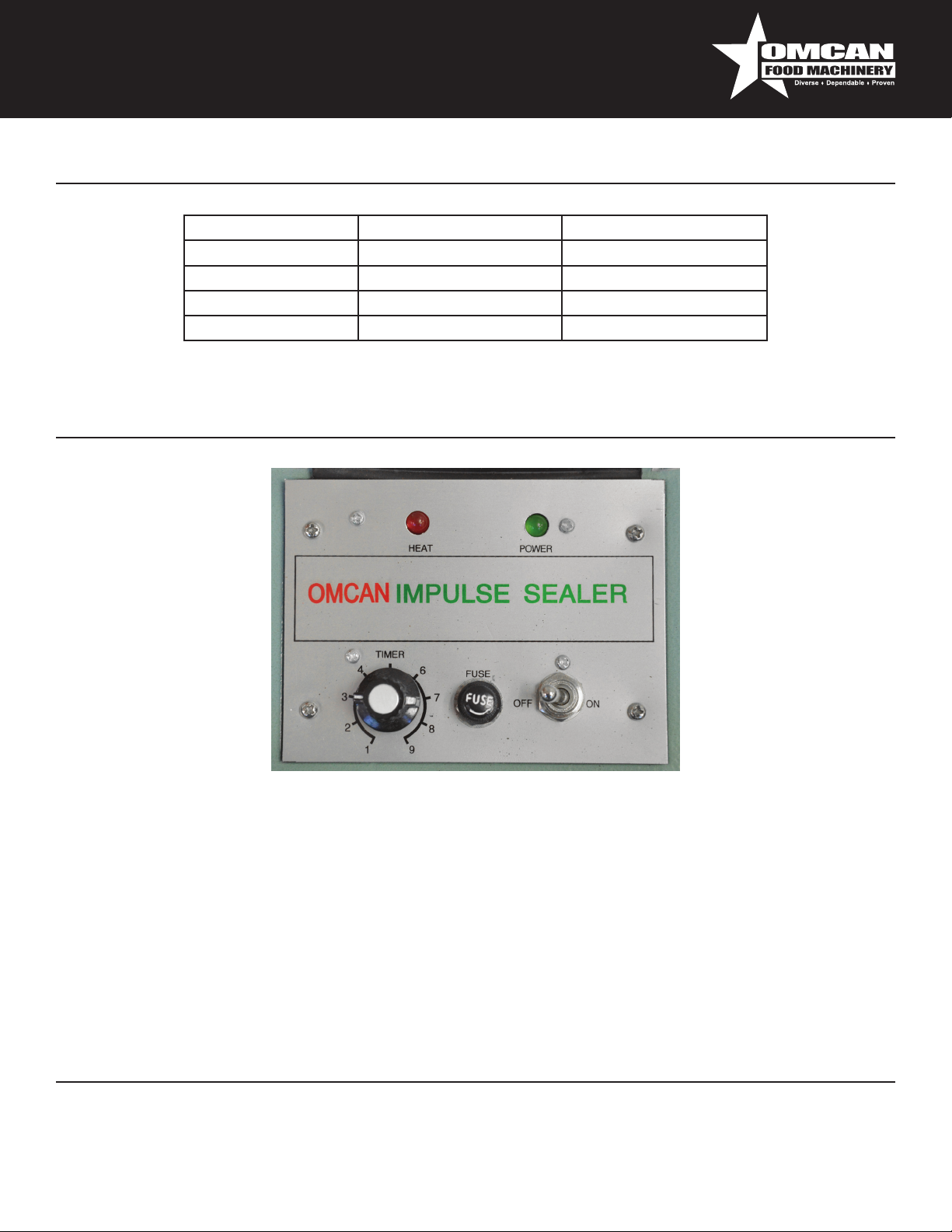

Operation

Fig. 1 - Diagram

of the control

panel for the

impulse sealer

ADJUSTMENT AND USAGE OF IMPULSE SEALER

Connect to 110V power source according to the indication label on the machine. Switch on the power, the red

light will turn on. Adjust the sealing time according to the materials and the thickness of the bags to be sealed.

The sealing time should be adjusted to around grade 1 before sealing. Put the opening of the bag between

the heat sealers, step down on the pedal and the yellow lamp lights. Take out the sealed bag after the yellow

lamp is off. If the seal is not tight enough, lengthen the sealing time. Try sealing the bag several times until it is

sealed well with clearness and no wrinkles. Seal the bag at this measured time and temperature. The cooling

time should not be too short, otherwise wrinkles will be the result. The longer the sealing time, the longer the

cooling time.

Maintenance

Never try to seal without bags. Don’t set the sealing time to the high grade without trial of the sealing bag.

4

Loading...

Loading...