Page 1

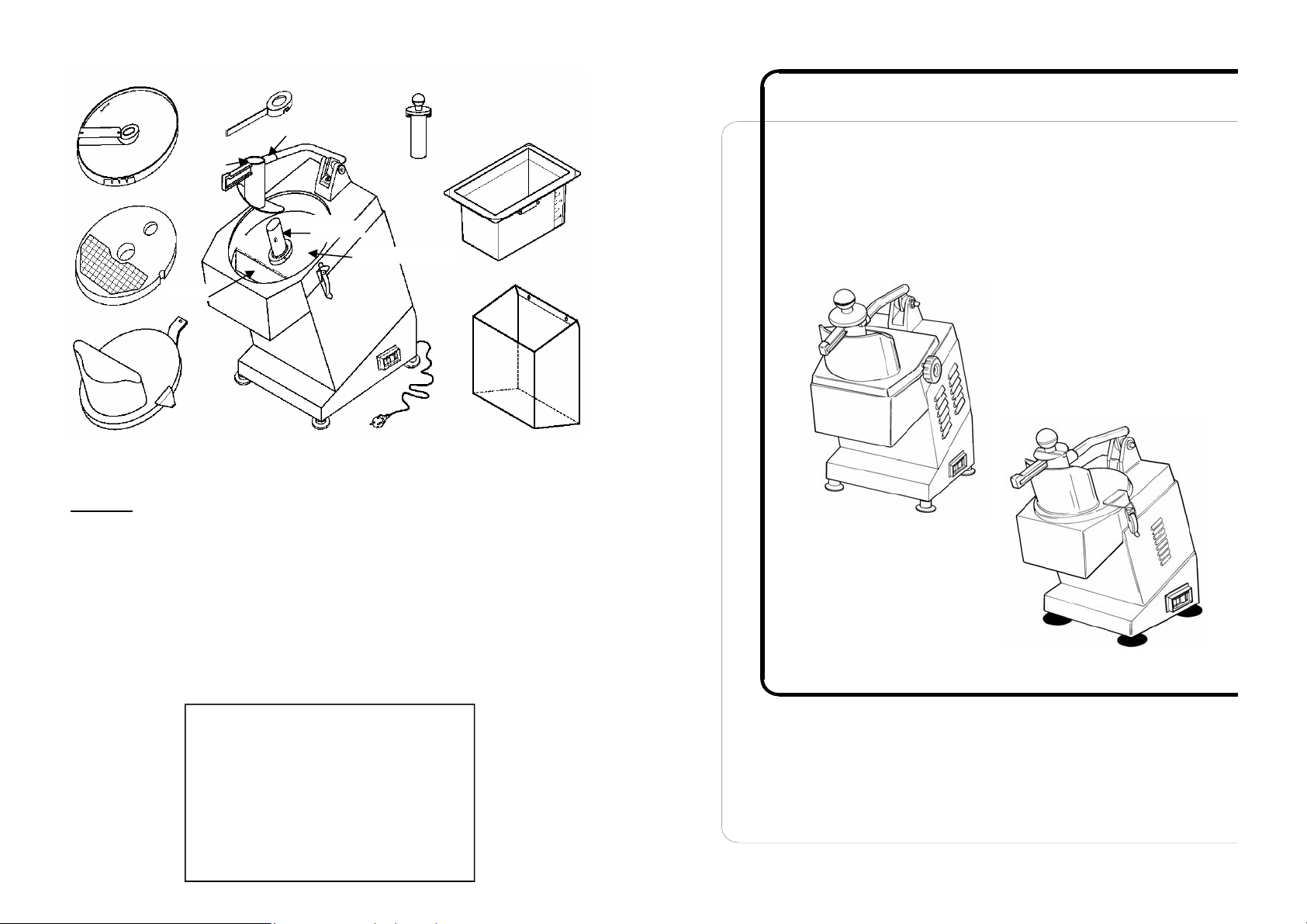

DF DISC

DISCHARGING SPATULA

PESTLE

PUSHER HANDLE

PRODUCT

INLET CYLIN-

PS DISC

LID

Fig. n°23 - View of the machine disassembled for cleaning.

DER

PIN

OPERATING AREA

MOUTH

BOWL

CHUTE

CHAP.8 - SCRAPPING

8.1 - PUTTING THE MACHINE OUT OF SERVICE

If for some reason, you decide to put the machine out of service, make

sure nobody can use it:

⇒ disconnect it from the mains and eliminate electrical connections.

8.2 - SCRAPPING

When the machine is out of service, it can be disposed of. To scrap the

machine contact your local Specialised Waste Treatment Centre, separate

components (refer to chap.1 § 2.2).

USE AND MAINTENANCE MANUAL

SERVICE CENTRE

AUTHORIZED DEALER

20

ed. 04/2006

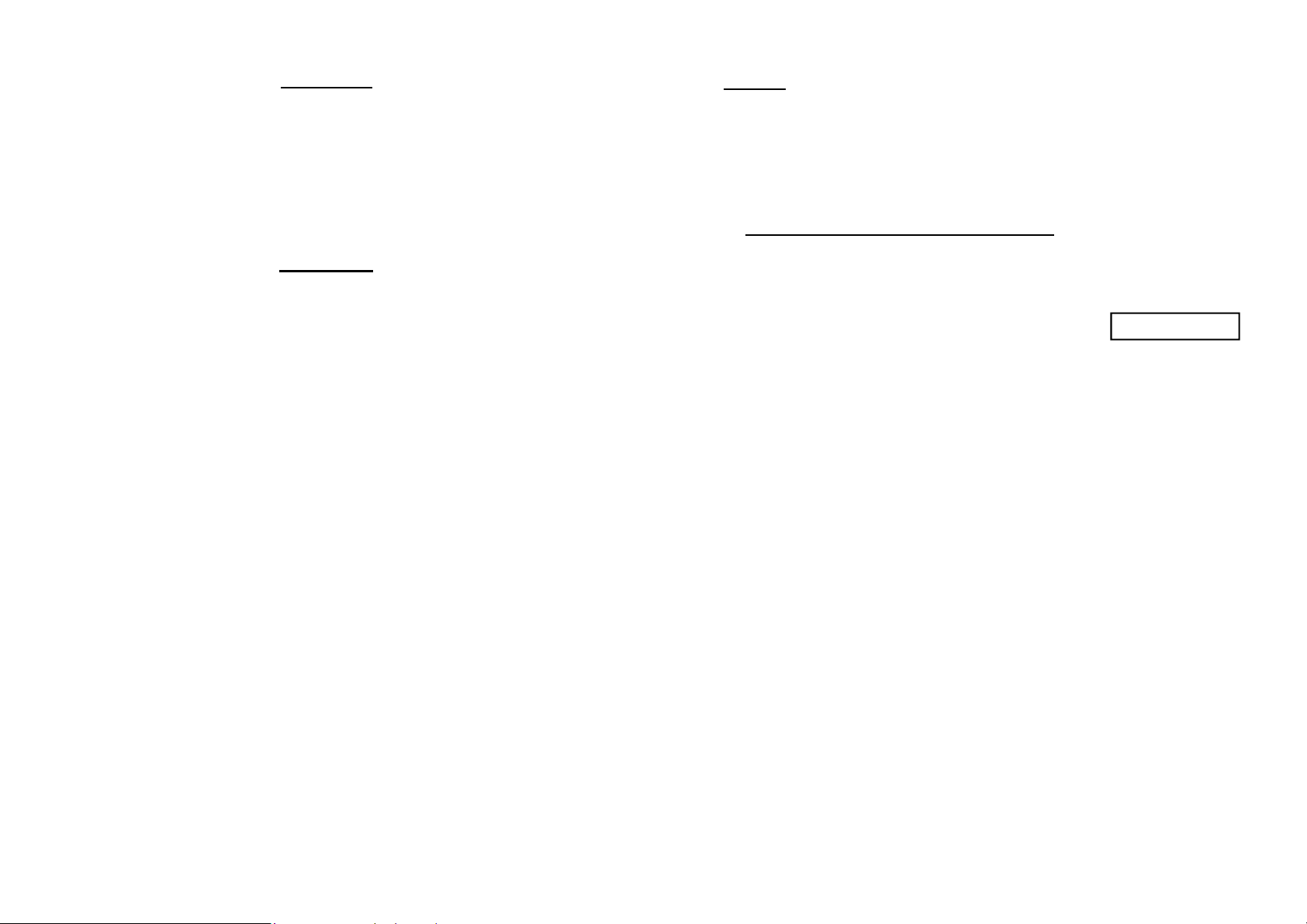

VEGETABLE CUTTER

mod. TM / TM A / TM R / TM RA

ETL

1

Page 2

FOREWORD

- This manual is meant to provide Customers with information on the

machine and its specifications and the necessary operating and

maintenance instructions in order to ensure machine performance and

longevity.

- This manual is to be used by qualified and skilled operators with

thorough knowledge of machine use and maintenance.

CONTENTS

CHAP. 1 - INFORMATION ON THE MACHINE page 4

1.1 - GENERAL PRECAUTIONS

1.2 - DESCRIPTION OF THE MACHINE

1.2.1 - General description

1.2.2 - Manufacturing features (materials used)

1.3 - SAFETY DEVICES

1.3.1 - General safety devices

1.3.2 - Electrical safety devices

1.4 - ACCESSORIES + TOOLS

1.4.1 - Accessories

1.4.1.1 - Standard accessories

1.4.2 - Tools

CHAP.2 - TECHNICAL SPECIFICATION page 11

2.1 - OVERALL DIMENSIONS, WEIGHT, FEATURES ...

CHAP.3 - RECEIVING THE MACHINE page 12

3.1 - DESPATCH OF THE MACHINE

3.2 - PACKAGE CHECK UPON RECEIPT

3.3 - PACKAGING DISPOSAL

CHAP.4 - INSTALLATION page 15

4.1 - SETTING UP OF THE MACHINE

4.1.1 - Collecting bowl

4.2 - ELECTRICAL CONNECTION

4.2.1 - Vegetable cutter TM (115 V. 60 Hz)

4.3 - VEGETABLE CUTTER WIRING DIAGRAM T.M.

4.4 - FUNCTIONAL CHECK

CHAP.7 - CLEANING OF THE MACHINE

7.1 - FOREWORD

• The machine must be cleaned at least once a day. If necessary clean

when required during the day.

• All the Vegetable cutter parts that come into contact directly or

indirectly with the food product must be cleaned thoroughly.

Before starting cleaning operations, it is necessary to:

⇒ disconnect the machine plug from the mains

power supply.

Pay attention to hazards of injury caused by cutting and/or sharp

machine components during cleaning o handling of discs.

7.2 - CLEANING PRODUCTS

The machine must be cleaned with a normal detergent at ambient

temperature, with a wet cloth.

It must never be cleaned with pressurised water, water jets, do not use

brushes or other tools or anything that could damage the machine.

N.B. DO NEVER WASH THE MACHINE PARTS IN THE

DISHWASHER.

7.3 - PROCEDURE

Disconnect the machine from the power supply.

Remove the lid and the discs, the spatula, the pestle, the bowl and/or the

chute

(Fig. n°23).

Clean accurately the inside of the mouth, the operating area and the disc

support pin.

Moreover clean all the external surfaces and the pusher handle. Dry with a

cloth and reassemble the machine.

to isolate it from the mains

CAUTION!

2

19

Page 3

cable shows signs of wear or damage call the “SERVICE CENTRE” for a

replacement.

6.1.4 - DISCS

With time the blade could worn.

For DTV, DT 2, 3, 4, 7, 9 and PS 6, 8, 10, 20 discs; it is necessary to buy

new discs.

For DF 1, 2, 3, 4, 5, 8, 10, 14 and DQ 4, 6, 8, 10 discs, it is possible to

replace the blade.

In this case, call the “SERVICE CENTRE” indicating the name of the disc.

6.2 - WHAT TO DO IF...

6.2.1 - The fixing of the discs is faulty:

Check that the discs and the disc support pin are clean.

6.2.2 - The lid does not lock:

Check that the lid is installed correctly and that it is clean .

6.2.3 - The product is not cut correctly:

Check that the blade is not worn.

6.2.4 - The product does not go out correctly or is badly cut:

Check that the discharging spatula has not been assembled with the DT

discs (the whole set); DF 1, 2, 3, 4; DQ 4; that the bowl is not full and that

the exit opening is not obstructed.

6.2.5 - The machine locks:

Check that the product is not frozen or too hard and that the power supply

is the one indicated on the rating plate (Fig. n°15).

6.2.6 - The micro on the pusher handle and on the lid do not work:

Check that they are not dirty.

6.2.7 - The machine does not start:

Check that all the safety devices are correctly installed (See Chapter

about safety devices 1.3); that the plug and the switches are correctly

connected.

CHAP. 5 - USE OF THE MACHINE page 15

5.1 - DISCS ASSEMBLY

5.2 - LOADING AND CUTTING THE PRODUCT

CHAP.6 - MAINTENANCE AND ADVICE page 17

6.1 - FOREWORD

6.1.1 - Belt

6.1.2 - Feet

6.1.3 - Power supply cord

6.1.4 - Discs

6.2 - What to do if...

6.2.1 - The locking of the discs is faulty

6.2.2 - The lid does not close correctly

6.2.3 - The product is not cut correctly

6.2.4 - The product does not go out correctly or is badly cut

6.2.5 - The machine locks

6.2.6 - The micro on the pusher handle and on the lid do not work

6.2.7 - The machine does not start

CHAP.7 - CLEANING OF THE MACHINE page 19

7.1 - FOREWORD

7.2 - PRODUCTS

7.3 - HOW TO CLEAN THE MACHINE

CHAP.8 - SCRAPPING page 20

8.1 - PUTTING THE MACHINE OUT OF SERVICE

8.2 - SCRAPPING

18

3

Page 4

CHAP.1 - INFORMATION ON THE MACHINE

1.1 - GENERAL PRECAUTIONS

- The vegetable cutter must be operated only by highly qualified

personnel who are fully aware of the safety measures described in this

manual.

- In case of a personnel turnover, training is to be provided in advance.

- Although the machine incorporates safety devices and protections for

dangerous parts, it is recommended not to touch the moving parts.

- Before starting cleaning and maintenance operations, disconnect the

plug from the supply socket.

- To carry out cleaning and maintenance, assess the residual risks

carefully (as protections are removed).

- Cleaning and maintenance require concentration.

- A regular check of the power supply cable is absolutely necessary; a

worn-out or damage cord is very dangerous.

- If the machine malfunctions, it is recommended not to use it and do not

try to repair it; please call the “Service Centre”, contact details are

provided at the end of this manual.

- Do not use the machine for processing frozen products, meat and

fishes with bones or non food products.

- Do not repair the machine yourself but call the “Authorised Service

Centre”.

- Always use the pusher with the pestle to cut the food

- Do not fill too much the inlet cylinder and do not press too hard to avoid

any problem .

- The manufacturer shall not be liable for damage to things or injury to

persons in the event:

⇒ The machine or the safety devices and protections have been

tampered with by non authorised personnel;

⇒ Non original

spare parts and discs are installed;

⇒ The instructions provided in this manual are not followed

scrupulously;

⇒ The machine surface is not cleaned with the right product .

B When the product is cut, lift the pusher handle, a safety device will

stop the machine. Load another product and lower the handle, the

machine will start automatically.

Fig. n°21 - Loading the product directly

in the mouth

Fig. n°22 - loading the product

through the product inlet cylinder.

C To replace the disc and change the type of cutting, proceed as

described in point 5.1 “A”. After this operation, an electronic device will

lock the automatic restart of the machine; to restart the machine, it will

be necessary to press pushbutton “I”.

D If you use the bowl, after 2-3 cutting cycles, empty it. The use of the

machine with a full bowl, could block the discharge of the product in the

working area, and cause a faulty cut, the machine lock or the motor

failure.

CHAP.6 - MAINTENANCE AND ADVICE

6.1– FOREWORD

Before performing any maintenance operation, it is necessary to:

Disconnect the plug from the mains to isolate it from the mains power

supply.

6.1.1 - BELT

The drive belt does not require adjustment. In general after 3-4 years, it

must be replaced, in this case call the “SERVICE CENTRE”.

6.1.2 - FEET

Feet may deteriorate or lose elasticity, reducing machine stability. If

support feet show signs of wear or damage, replace.

6.1.3 - POWER SUPPLY CABLE

Periodically check for wear in the power supply cable. If the power supply

4

17

Page 5

In this case the discharging spatula must not be installed

Fig. n°18 Fig. n°19

Fig. n°18 - Assembly of the discharging spatula

Fig. n°19 - Assembly of the coupled discs PS- DF

5.2 - LOADING AND CUTTING THE PRODUCT

CAUTION!

When the machine is working, it is

necessary to stand correctly to avoid

accidents. The body must always be

perpendicular to the working table (

Fig. n°20)

. Pay the maximum attention

that no members of your body enter

in contact with the machine.

N.B. The product has to be loaded in

the Vegetable cutter TM when it is

OFF.

Fig. n°20 - Correct position.

Proceed as follows:

A Load the product in the mouth of the lid

(see Fig. n°21). If the product is

small (i.e. carrots, baby marrows, etc.) put it in the inlet cylinder placed

on the handle

(see Fig. n°22). Turn on the machine and help the cutting

by pressing slightly on the pusher handle or with the pestle if you use

the inlet cylinder.

see

1.2 - MACHINE DESCRIPTION

PUSHER

PESTLE

PUSHER HANDLE

HOPPER

BODY

BASE

HINGE

POWER SUPPLY CORD

CONTROLS

KNOB TO FIX THE LID

Fig. n°1 - General view of the vegetable cutter mod. “TM”

FEET

1.2.1 - GENERAL DESCRIPTION

The vegetable cutter TM has been designed and manufactured by our firm

with the aim of ensuring:

- the highest degree of safety during use, cleaning and maintenance;

- the highest standard of hygiene due to a careful selection of materials

which come into contact with food products, elimination of sharp edges

in the machine structure that come into contact with the food product,

facilitating and ensuring perfect cleaning, as well as facilitating machine

disassembly and part removal;

- robust and stable components;

16

5

Page 6

a) reduced noise emission generated by the drive belt;

b) practical and easy to move.

1.2.2 - MANUFACTURING FEATURES (Materials used)

The vegetable cutter TM has been manufactured using materials with high

resistance to mechanical worn and to corrosive agents present in the

product.

More specifically:

- The hopper and the base are made of anodised aluminium to ensure

the contact with food products (hygiene) and to ensure resistance to

acids, salts and rust.

- The body, the lid, the pusher handle and the discs support are made of

steel AISI 304 or 430.

- The pestle, the pusher, the bowl and the control panel are made of

high resistant plastic, appropriate to enter into contact with food

products.

- The cutting discs:

a) The Disc set DF, DQ and PS have the main structure made of

aluminium and the knives made of AISI 420.

b) The Disc set DT have the main structure made of plastic and the

knives made of AISI 420.

1.3 - SAFETY DEVICES

1.3.1 - GENERAL SAFETY DEVICES

The mechanical, electrical and hygienic safety devices installed on the

vegetable cutter T.M. described in this manual complies with:

UL 763 and NSF Standards

** The vegetable cutter is fitted with electrical and mechanical safety

devices for machine operation as well as cleaning and maintenance

operations.

However, there are RESIDUAL RISKS which cannot be eliminated

completely. These risks are listed in this manual under WARNINGS.

These risks are cutting dangers due to the machine handling during the

disc substitution and/or cleaning.

1.3.2 - ELECTRICAL SAFETY DEVICES

The vegetable cutter T.M. is fitted with microswithes:

A On the pusher lever, to stop the machine if the handle is lifted over the

mouth of the lid and to enable to turn on the machine automatically

4.4 - FUNCTIONAL CHECK

To check the correct machine operation, proceed as follows:

a) Turn ON pushbutton “I” and stop pushbutton “0” and check that the

corresponding pilot lights turn on and off

(Fig. n°17).

b) Check that the motor stops and then turns on when you lift or lower the

pusher handle.

c) Check that the machine stops when your remove the lid and that it

turns on by pressing pushbutton START “I” only if the lid is correctly

installed.

Fig. n°17 - Control panel.

CHAP.5

5.1 - DISCS ASSEMBLY

A Choose one of the following discs DF 1-2-3-4-5-8-10-14, DTV, DT 2-3-

B (TO CUT CUBES)

Choose the couple of discs among PS8-DF8, PS10-DF10, PS20-DF14.

NB: NEVER USE THE DISCHARGING SPATULA WITH COUPLED

C If the machine is supplied with a discharging spatula

- USE OF THE MACHINE

CAUTION!

4-7-9, or DQ 4-6-8-10; remove the steel or aluminium lid, and place the

disc on the shaft. Rotate the disc until it is fixed. Replace the stainless

steel lid fastening it with the specific hinges or the aluminium lid

fastening it with the knob.

Place the first disc PS. with the cavity turned on the right side placing

yourself in front of the machine. Then install the DF disc, proceeding as

described in point “A”

DISCS PS-DF.

to use it with the following discs DF 1-2-3-5, DTV, DT 2-3-7-9, DQ4.

The spatula must be assembled on the disc support pin before any

other disc (

see Fig. n°18). After having assembled the spatula, proceed

as in point “A”.

(see Fig. n°24).

(Fig. n°6), we advise

6

15

Page 7

4.2 - ELECTRICAL CONNECTION

4.2.1 - VEGETABLE CUTTER T.M. (115 Volt, 60 Hz)

The Vegetable cutter T.M. is equipped with a power supply cable with a

SJT 16 AWG mm

Connect the Vegetable cutter to 115 Volt 60 Hz, by interposing a

differential thermomagnetic switch 10 A DI = 0,03 A.

Check correct machine earthing.

Moreover check that the specifications on the rating plate-serial number

(Fig. n°15) correspond to the specifications provided in the consignment and

delivery note.

4.3 - WIRING DIAGRAMS OF THE VEGETABLE CUTTER T.M.

2

section; length 1,5 m and a NEMA 5 plug.

Fig. n°15 - Rating plate - serial number

HANDLE UP

when there is a dangerous situation

(Fig. n°2).

MICROSWITCH

HANDLE DOWN

Fig. n°2 - Electrical safety devices

B On the hopper, to stop the machine if the lid is removed (

discs

) (Fig. n°3A), and to permit to start the machine voluntarily (by

pressing pushbutton “I”

) only when the lid is closed, correctly locked by the

hinges for the steel lid or with the knob for the aluminium lid

i.e. to replace the

(Fig. n°3).

Fig. n°16 - Wiring diagram

14

STEEL LID ALUMINIUM LID

Fig. n°3 - Mechanical safety devices

LID LID

HINGES

STEEL LID ALUMINIUM LID

Fig. n°3A - Electrical safety devices

MICROSWITCH

POSITION

7

KNOB

MICROSWITCH

POSITION

Page 8

1.4 - ACCESSORIES + TOOLS

1.4.1 - ACCESSORIES

The vegetable cutter T.M. is provided with many accessories. Some are

supplied with the cutter, other must be requested by the Client.

1.4.1.1 - STANDARD ACCESSORIES

Pestle: made of polyethylene for alimentary use, to facilitate the cutting of

small product, it must be introduced in the product cylinder placed on the

pusher

Collecting bowl

“GASTRONORM” of 1/3, h=200; equipped with microswitch (Fig. n°5).

Fig. n°4 - Pressing pestle for

vegetables

Discharging spatula: made of steel AISI 304 installed on the disc suppo rt

pin. It makes easier to discharge the product when cut. It can only be used

with the following discs DTV, DT2 - 3 - 4 - 7 - 9, DF1 - 2 - 3 - 4

(Fig. n°6)

Discs holder

collector for discs. (Fig.n°7).

(Fig. n°4).

: made of polyethylene for alimentary use,

Fig. n°5 - Bowl fitted with microswitch

Fig. n°6 - Discharging spatula

: made of plasticised steel for alimentary use, it is a useful

Fig. n°7 - Discs holder

3.2 - PACKAGE CHECK UPON RECEIPT

Upon receipt of the package containing the Vegetable cutter T.M., check

accurately that the package has not been damaged during transport.

If the package shows signs of damage caused during transport, the carrier

must be informed immediately; moreover a detailed report on the extent of

the damage caused to the machine must be notified to the carrier within

three days from the delivery date on the shipping documents. DO NOT

OVERTURN THE PACKAGE!! When the package is transported, make

sure the box is lifted by the 4 corners (parallel to the ground).

3.3 - PACKAGING DISPOSAL

The components of the packaging (cardboard, pallet, plastic straps and

polyurethane foam) are urban solid waste; therefore they can be easily

disposed of.

If the machine has to be installed in countries where specific regulations

are in force, packaging must be disposed of in compliance with such

regulations.

CHAP.4 - INSTALLATION

4.1 - SETTING UP OF THE MACHINE

The vegetable cutter must be installed on a suitable and adequate size

work table refer to Fig.n°12, (and therefore sufficiently large); the machine

must be solid, stable and fixed at a height of 80 cm from the ground.

Moreover the machine must be installed in a room with max. 75% non

saline humidity at a temperature between +5°C e +35°C; in a location and

environment that does not provoke malfunctions or faults in the machine.

4.1.1 - COLLECTING BOWL

If the Vegetable cutter T.M. is provided with a collecting bowl, place it

under the mouth of the machine, so as to cover the product exit (Fig. n°14).

Fig. n°14 - Collecting bowl

8

13

Page 9

CHAP. 3 - RECEIVING THE MACHINE

3.1 - DESPATCH OF THE MACHINE (see Fig. n°13)

The vegetable cutter TM is accurately packed and then despatched from

our warehouses. The package includes:

a) a solid cardboard box;

b) the machine;

c) some elements to keep the machine stable;

d) the bowl;

e) the pestle;

f ) this manual;

h) EC conformity declaration.

a)

c)

Fig. n°13 - Package description

b)

d)

e)

f)

g)

1.4.2 - TOOLS

On demand, the vegetable cutter TM, can be supplied with different discs,

suitable for many different cuts.

DISCS FOR SLICES “DF”

:

They are made of aluminium and the knives are made of AISI 420.

The following discs are available:

DF1

DF2

DF3

DF4

DF5

specific for tomatoes and peppers

DF8

DF10

DF14

Fig. n°8 - “DF” tools

- DISCS FOR STRIPS “DT”:

The supporting structure is made of plastic ,

and the body of the disc is made of AISI 420.

The following discs are available:

DTV

to grate

DT2

DT3

DT4

DT7

DT9 specific for mozzarella

Fig. n°9 - “DT” tool

- DISCS FOR MATCHSTICKS “DQ”

:

The supporting structure is made of aluminium

and the knives are made of AISI 420.

The following discs are available:

DQ4

DQ6

DQ8

DQ10

Fig. n°10 - “DQ” tool

12

9

Page 10

- DISCS FOR CUBES “PS”:

The supporting structure is made of aluminium

and the knives are made of AISI 420.

The following discs are available:

PS8

coupled with DF8

PS10 DF10

PS20 DF14

CHAP.2 - TECHNICAL SPECIFICATIONS

2.1. - OVERALL DIMENSIONS, WEIGHT, FEATURES ...

Fig. n°12 - Overall and maximum dimensions

Fig. n°11 - “PS” tool

10

Power supply

Power

Turns

Distance between

feet G x H x I

Dimensions

A x E x C

Max Dim.

A x F x B

Package Dim.

Net weight

Gross weight

Noise level

u.m. TM steel TM aluminium

115V / 60Hz 115V / 60Hz

watt / Hp 550 / 0.75 550 / 0.75

R.P.M. 300 300

mm

in.

mm

in.

mm

in.

mm

In.

225 x 180 x 255

7

8-

/8 x 7 x 10

510 x 280 x 460

1

20-

/8 x 11 x 18-1/8

510 x 400 x 790

1

20-

/8 x 15-3/4 x 31-7/8

720 x 350 x 500

3

28-

/8 x 13-3/4 x 19-3/4

225 x 180 x 255

7

8-

/8 x 7 x 10

510 x 280 x 460

1

20-

/8 x 11 x 18-1/8

510 x 535 x 790

1

20-

/8 x 15-3/4 x 31-7/8

720 x 350 x 500

3

28-

/8 x 13-3/4 x 19-3/4

Kg / lbs. 22 / 48,4 23 / 50,6

Kg / lbs. 24 / 52,8 26 / 57,2

dB

≤70 ≤70

Machine electrical specifications are indicated on the rating plate affixed to the

side of the grater; before connecting to power supply, please read § 4.2 Wiring

.

11

Loading...

Loading...