Omcan Food Machinery DI-CN-1 Installation Manual

Hot Chocolate Dispensers

Model DI-CN-1 & DI-CN-3

Instruction Manual

Version 1

3115 Pepper Mill Court, Mississauga, ON, L5L 4X5

4450 Witmer Industrial Estates, Unit 4, Niagara Falls, NY, 14305

1-800-465-0234

www.omcan.com

Table of Contents

Model DI-CN-1 / Model DI-CN-3

Section

General Information

Safety & Warranty

Technical Specications

Installation

Operation

Maintenance

---------------------------------------------------------------------------------------- 7 - 8

--------------------------------------------------------------------------------------- 8 - 10

--------------------------------------------------------------------------------- 10 - 20

-------------------------------------------------------------------------------- 3

------------------------------------------------------------------------------ 3 - 5

Page

---------------------------------------------------------------------- 5 - 6

Troubleshooting

Parts Breakdowns

Electrical Schematics

Warranty Registration

----------------------------------------------------------------------------------- 21

-------------------------------------------------------------------------- 22 - 23

---------------------------------------------------------------------------- 24

---------------------------------------------------------------------------- 25

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

Omcan provides food processing equipment, baking equipment, professional kitchen equipment, steel kitchen

ware, commercial refrigeration equipment and ice cream machine, and all kinds of products for you to choose.

They are environment-friendly with excellent designs. The units save power, complete functions, are easy to

operate and our products are more competitive than those of the same line in the international market.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damaged to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Safety & Warranty

GENERAL SAFETY RULES

Carefully read the entire instruction manual before use. The connection to the electricity main socket must

comply with the current safety standards. The machine must be connected to an electric outlet that is:

• Compatible with the plug provided with the machine.

• Of dimensions conforming to the data shown on the rating plate on the side of the machine.

• Properly grounded.

• Connected to a system provided with a differential switch and circuit breaker.

• Connected to a system that has been certied according to the current standards and regulations in the

country of use.

The power cord must not be:

• Allowed to come into contact with any kind of liquid: danger of electric shocks and/or re.

• Crushed and/or brought into with sharp surfaces.

• Used to move the machine.

• Used if it shows any damage.

• Handle with dent or wet hands.

3

Safety & Warranty

• Would into a coil when the machine is on.

• Tampered with.

Do not:

• Install the machine in a manner other than that described in installation.

• Install the machine in a place where it may be exposed to sprays of water.

• Use the machine near inammable and/or explosive substances.

• Leave plastic bags, polystyrene, nails etc. within children’s reach, since they are potential sources of

danger.

• Allow children to play or stay near the machine.

• Use spare parts other than those recommended by the manufacturer.

• Make any technical changes to the machine.

• Immerse the machine in any kind of liquid.

• Spray water to the machine to wash it.

• Use the machine other than as directed in this manual.

• Use the machine when not in full possession of your mental and physical faculties; Under the inuence of

the drugs, alcohol, etc.

• Install the machine on top of other equipment.

• Use the machine in an explosive aggressive atmosphere or in the presence of a high concentration of dust

or oily substances suspended in the air.

• Use the machine in a place where there is a risk of re.

• Use the machine to dispense substances that are not compatible with the machine’s specications.

• Clean and service the machine when the main switch is set to –ON- or with the plug inserted into the mains

outlet.

The appliance is not intended for use by persons (including children) with reduced physical, sensor or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety. Before cleaning the machine, make

sure it is unplugged; wait until the machine has cooled down sufciency. Do not clean the machine with

gasoline and/or solvents of any kind. Repair work may be performed only by a Service Center authorized

by the Manufacturer and/or specialized, trained personnel. Do not site the machine near heating equipment

(stoves or radiators). In case of re, use carbon dioxide (C02) extinguishers. Do not use water or powder

extinguishers. In the event of improper use, all warranty rights will be forfeited and the manufacturer will accept

no liability for injury or damage to persons and/or property.

The following are to be considered improper use:

• Any use other than the intended use and/or with methods other than those described herein.

• Any operation on the machine that is in contrast with the directions provided herein.

• Use of the machine after any components have been tampered with and/or safety devices have been

changed.

• Use of the machine after it has undergone repair with components not authorized by the manufacturer.

• Outdoor installation of the machine.

Stop Functions

The machine is shut down by turning off the on/off switch.

4

Safety & Warranty

Plates

None of the plates or labels applied on the machine must be removed, covered or damaged, especially those

relating to safety. In the event of damage to any of the rating plates on the machine, contact the manufacturer

for a replacement.

EMERGENCY SITUATIONS

Warning: to stop the machine in any emergency situation, rmly press the main switch so that it sets to OFF.

In the event of re, it is necessary to clear the area in order to allow trained staff, with the proper protective

equipment to intervene. Always use approved extinguishers and never use water or substances of an uncertain

nature.

1 YEAR PARTS AND LABOR WARRANTY

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal solid urban waste

and can therefore be disposed of without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

MACHINE DESCRIPTION

Use of the Machine

The machine for professional use you have purchased is intended to produce hot chocolate drinks.

5

Technical Specications

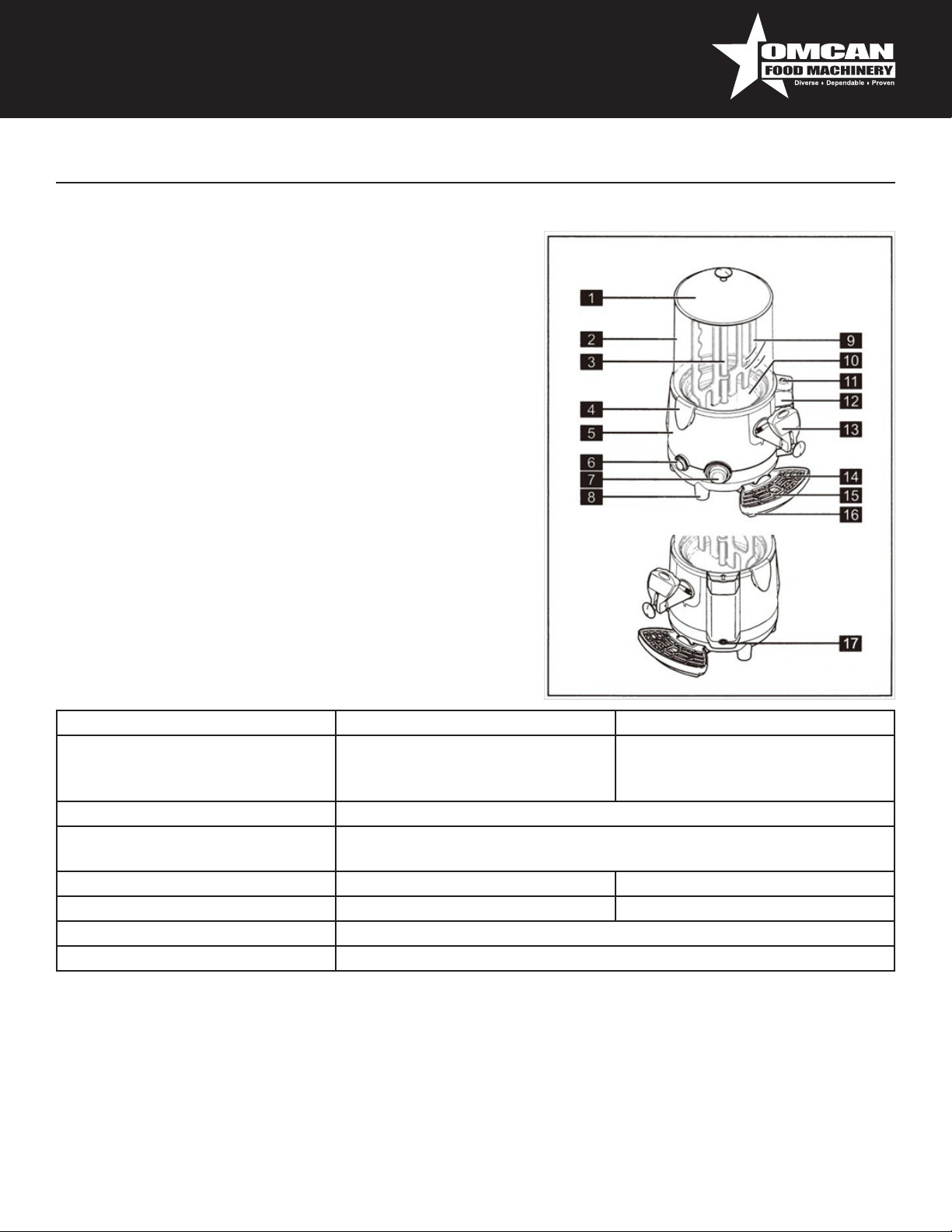

MAIN COMPONENTS

The main components making up the machine are:

1. Bowl lid.

2. Bowl (5 or 10 liters [1.32 or 2.64 US gals]).

3. Mixing auger.

4. Bowl hook-on handles.

5. Machine body.

6. Main switch.

7. Chocolate temperature adjustment thermostat (°C - °F).

8. Lower body.

9. Mixer.

10. Pan.

11. Lid for boiler tank water level indicator tray.

12. Boiler tank water level indicator tray.

13. Product dispenser unit (tap).

14. Drip tray maximum level indicator.

15. Drip tray grid.

16. Drip tray.

17. Boiler tank drainage cap.

TECHNICAL DATA

The technical data and features are listed below:

Model DI-CN-1 DI-CN-3

Machine dimensions L=41 cm (16.14”)

W=28 cm (11.02”)

H=46.50 cm (18.31”)

Operating voltage (V) See rating plate on side of machine

Ambient operating temperature Min. 10°C(50°F)

Max. 320°C(89.6°F)

Number of bowls 1 1

Capacity of each bowl 5 Liters (1.32 Gal US) 10 Liters (2.64 Gal US)

Sound pressure level << 70 dB.

Class N

Note: The manufacturer reserves the right to make changes to the machine without notice.

Important: Any changes and/or additions of accessories must be explicitly approved and implemented by the

manufacturer.

L=41 cm (16.14”)

W=28 cm (11.02”)

H=58 cm (22.83”)

6

Installation

The machine must be installed indoors in a well-lit and well-ventilated room with a rm, solid, level oor

(slope less than 20°); during installation, place the machine well out of the reach of children and unauthorized

persons.

The machine may only operate in places with an ambient temperature ranging between 10°C (50°F) and 32°C.

(89,6°F).

Accessories Supplied

Pipe cleaner: for correct cleaning of the hot chocolate dispensing channel.

POSITIONING

It is necessary to check the following:

• The site has been duly prepared for machine

installation.

• That the premises are suitably well lit, aired, clean

and hygienic, and that the power socket is within

easy reach.

• The surface the machine will be installed on is rm,

at and solid.

• That the machine is placed at least 20 cm {7.8

inches) from the edge of the top used.

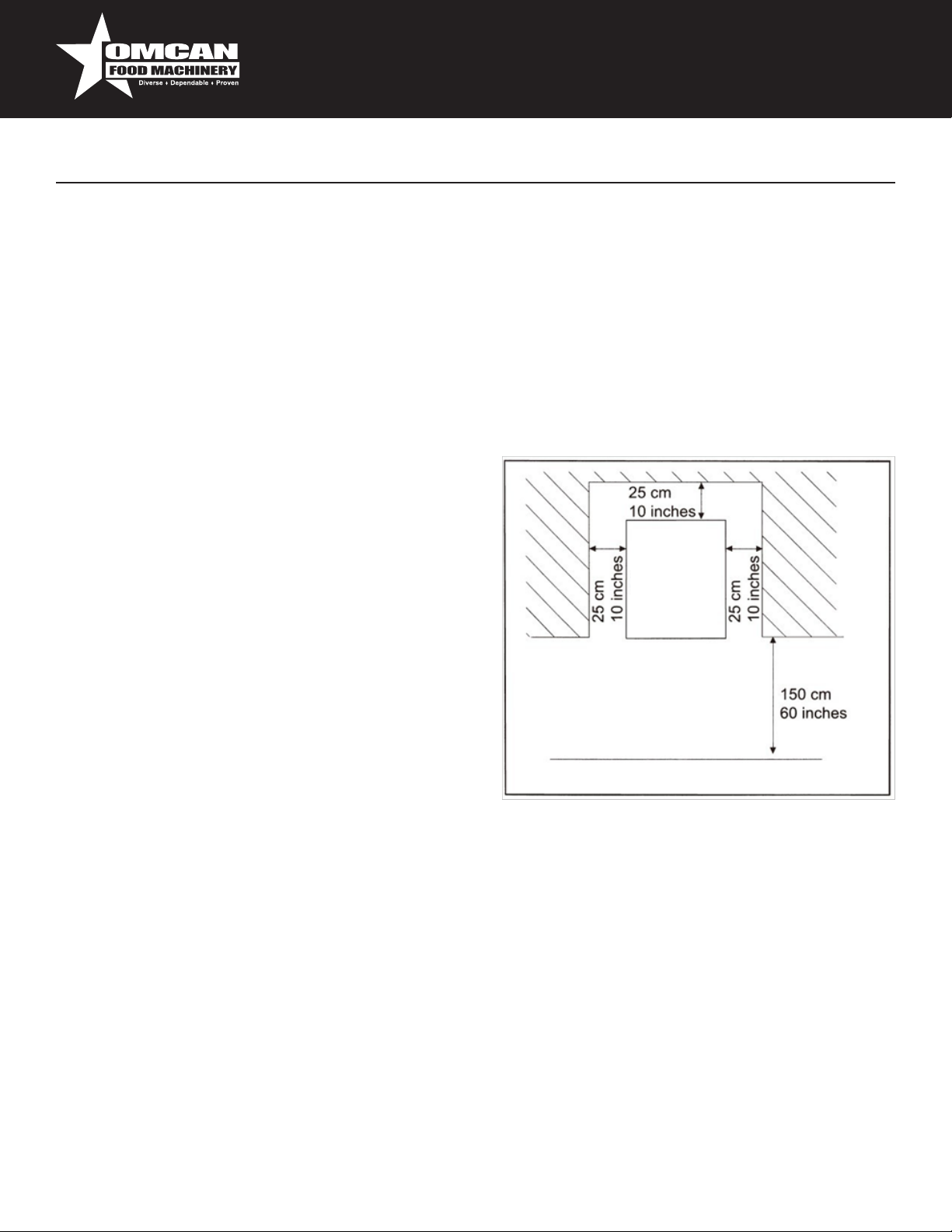

Adequate clearance must be left around the machine

to enable personnel to work without any constraints

and also to leave the work area immediately in case

of need. The image to the right shows the minimum

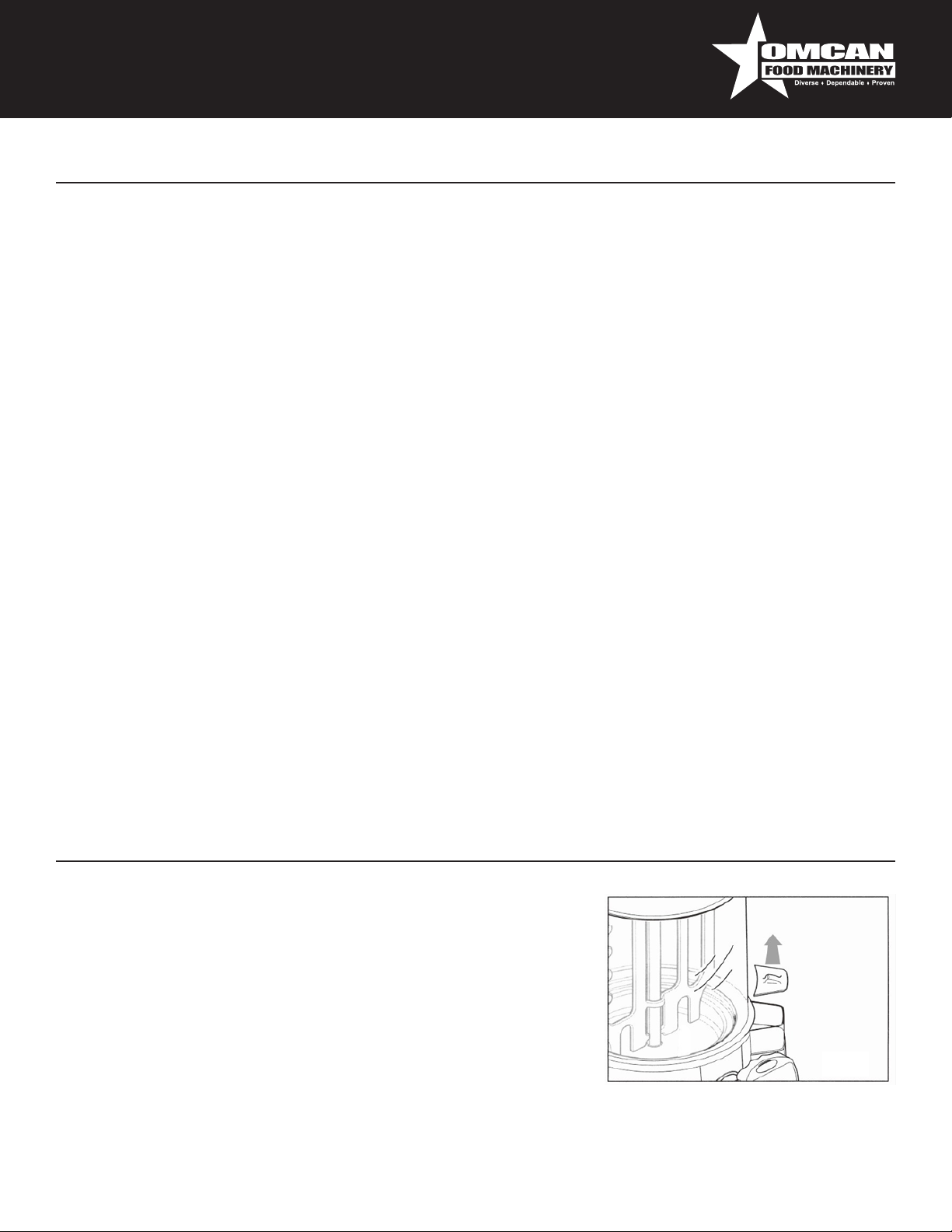

clearances for installation.

The image shows the clearances required for accessing:

• The controls situated on the left side.

• Machine parts so that they may be serviced in the event of a fault.

Important note: when lifting the machine, do not use the product dispenser unit (tap), drainage pipe, water

level indicator tray, bowl hook on handles or the bowl itself; grip the bottom machine body. Any damage to the

machine deriving from failure to follow these rules will not be covered by the warranty.

After positioning the packing container in the vicinity of the installation site, proceed as follows:

• Open the front pad of the packing container.

• Lift the machine and remove it from its packing.

• Then position it on the prepared site.

Before the machine is operated the rst time, its components must be thoroughly cleaned; for further details

see the relevant section herein.

7

Installation

DISPOSAL OF PACKING MATERIALS

After opening the box, make sure to separate the packing materials according to type and dispose of them

in accordance with the current regulations in the user’s country. We recommend keeping the box for future

conveyance or transport.

ELECTRICAL CONNECTION

This job may be performed only by specialized technical personnel. Before inserting the plug into the mains

power socket, make sure that:

• The line voltage used is the same as the value indicated on the manufacturer’s rating plate.

• The main switch is set to OFF.

If the machine is being connected to the electricity mains for the rst time, this operation must be performed by

a specialized technician, while the Customer will be responsible for and have to take care of any subsequent

connections. The machine must be connected to the electricity main socket by means of the plug tted on the

power cord. Be sure to comply with:

• The technical regulations and standards in force at the time of installation.

• The data shown on the rating plate on the side of the machine.

Warning: the electric outlet must be situated in a place easily within reach of the user, so that no effort is

required in order to disconnect the machine from the power supply when necessary. If the power cord is

damaged, you must have it replaced either by the manufacturer or a specialized technician.

It is forbidden:

• To use extension cords of any type.

• To replace the original plug.

• To use adaptors.

Operation

Before the machine may be started up for the rst time, specialized

technical personnel must check that it functions properly.

STARTING UP

To start up the machine carry out the following steps:

• Make sure that the switch is set to off.

• Take off the lid.

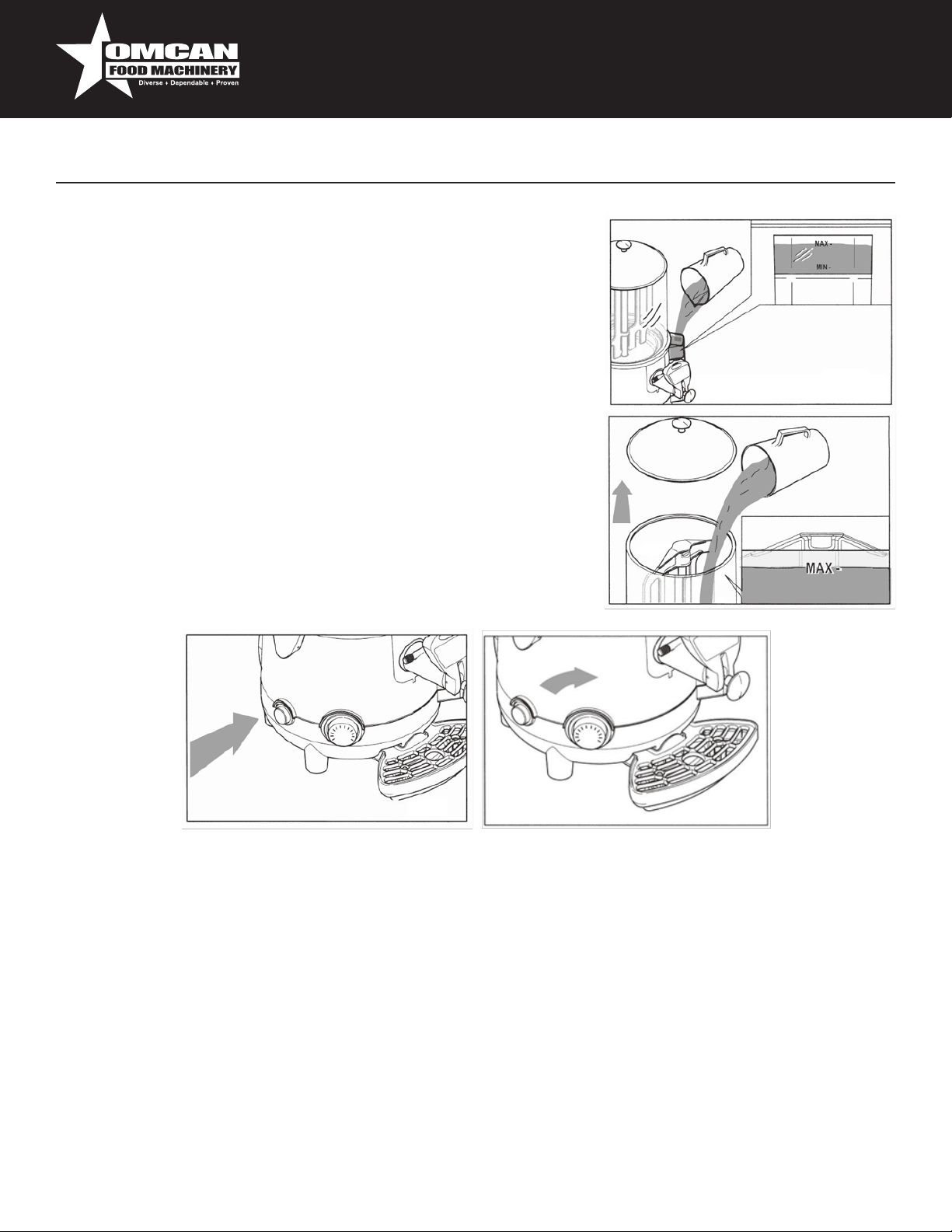

• Fill the boiler tank with water using the boiler tank level indicator

tray, until it reaches the maximum value indicated on the tray itself,

which is marked MAX.

8

Warning: ll the boiler tank by pouring in water slowly and check for a

few seconds to make sure that the water level has reached the MAX

level and that it is stable.

When lling an empty boiler rank for the rst time, the amount of water

needed to completely ll the tank is approximately 3.25 liters(0.86

GAL US).

• Remove the lid and pour the beverage prepared according to the

manufacturer’s instructions into the bowl.

• Never exceed the maximum level, which is marked MAX on the

tray itself.

• After pouring the product into the bowl,t the lid back in place.

• Make sure that the plug has been inserted into the mains socket.

• Press the main switch to start the machine; the product inside the

bowl will start to be mixed.

Operation

LIT LED: MACHINE ON.

LED OFF: MACHINE OFF.

• Set the thermostat to the required temperature to heat the product inside the bowl.

• The machines with LCD offer the opportunity to make a visual check to see when the product has reached

the required temperature inside the bowl.

Warning: during bowl and/or boiler switch off the machine using the main switch (LED off). There is a

temperature sensor, if the water is boiled up and the heating element is over heated. The temperature sensor

will shut down the machine. Then you need to press the reset button to restart the machine.

DISPENSING THE PRODUCT

Warning: The products dispensed from the machine has a very high temperature; risk of scalding.

9

Loading...

Loading...