Omcan Food Machinery CD-GR-1500 Installation Manual

High Temp Dishwasher

Model CD-GR-1500

Instruction Manual

Revised - 10/2/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Table of Contents

Model CD-GR-1500

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

---------------------------------------------------------------------------------------- 4 - 5

----------------------------------------------------------------------------------------- 5 - 8

------------------------------------------------------------------------------------- 8 - 9

-------------------------------------------------------------------------------- 3

------------------------------------------------------------------------------- 3

Page

-------------------------------------------------------------------------- 4

Troubleshooting

Parts Breakdowns

Electrical Schematics

Notes

Warranty Registration

------------------------------------------------------------------------------------------- 25 - 26

------------------------------------------------------------------------------- 9 - 11

-------------------------------------------------------------------------- 12 - 23

---------------------------------------------------------------------------- 24

---------------------------------------------------------------------------- 27

2

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Safety and Warranty

A door safety switch interrupts the appliance’s operation during washing, if the door is opened in error. The

pump motor winding has integrated thermal protection which interrupts power supply to the pump, in case

of overload or overheating. A thermal safety fuse interrupts power supply in case of booster or wash tank

overheating. No technical modications are allowed in this appliance. The manufacturer is not responsible for

any resulting damages due to modications. The same applies if the appliance is used for any other purpose,

except the ones indicated.

Dishwasher Water is not potable.

Use, maintenance, and repair of dishwasher should be performed only by competent and informed persons

familiar with this machine.

1 YEAR WARRANTY

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

3

Technical Specications

Power requirements: 208/230 volts, 60 cycles, two (2) wire + Ground Single Phase 43 Amps

Water supply: 120°F / 50°C recommended, can be used on almost any water supply. Supply pressure must

be between 30 PSI (2 Bars) and 75 PSI (5 Bars).

Drain: should be vented type with connection not higher than outlet pipe of washing machine, or oor drain.

Dimensions: 28” W x 32” D x 56” H (720mm W x 815mm D x 1412mm H).

Installation

The unit should be installed by licensed and approved personnel according to all local codes.

This dishwasher is delivered with water inlet and outlet hoses.

Be sure all electrical supply specications correspond to information label on machine.

The manufacturer/ distributor is not responsible for any possible damages or risks due to improper connection

of this appliance.

INSTALLATION SUGGESTIONS

• Place the dishwasher in the desired location.

• The appliance should leveled. Adjustable feet are provided for this adjustment.

WATER SUPPLY CONNECTION

ATTENTION: Connection with the water supply should be made according to all applicable codes.

This dishwasher intended for use with a hot water supply but will also operate (at slightly reduced hourly

capacity) with a cold water supply.

• The water supply hose/pipe should be ½” or ¾” and terminate in a ¾” NPT tting (not garden hose).

• The water supply hose/pipe should be ushed before nal connection.

• Minimum ow pressure is 30 PSI (2 bars) and maximum is 75 PSI (5 bars).

• Connect hose supplied with machine to the inlet at the rear of the machine and the ¾” NPT tting on the

water supply line.

Note to plumbing installer: If local codes require a vacuum breaker, one must be locally supplied and

installed in the supply line.

DRAINAGE CONNECTION

Outow is accomplished by gravity (natural ow) in the CD-GR-1500. The outlet hose should be connected

either directly to a oor drain or drain which must not be higher than the level of the outlet at the rear of the

machine. An open drain connection or one to a vented drain pipe is recommended.

4

Installation

ELECTRICAL CONNECTION

The dishwasher operates under specic voltage as noted on the attached Technical Specications label.

Note: A licensed electrician should be used for the connection according to local codes.

A 208 or 230 volt, one (1) phase, 60hz, 50A power circuit is required as unit draws 43A using 2 wire plus

ground. No neutral (115 volt service) is required. The ground line must be connected at the junction block.

Prepare power line with about 35” ( 95 CM ) of wire with the shielding removed. Install either a ¾” connector or

½” with ½” x ¾” bushings.

Open front control panel by removing two nuts and open inside cover by removing 4 nuts holding cover.

Insert power line in appropriate ¾” hole in rear panel, or if suitable, a ½” connector with bushings can be used,

mount connector, and feed wire to front control box terminals. Mounting posts are provided to hold wires with

“Tye Wraps”. Allow sufcient slack at panel end to allow wire to move when control panel is repositioned to

closed.

Connect power line to junction block. Be sure connections are tight.

Close control panel cover with the 4 nuts, and close the front panel with the two acorn nuts.

After installation, the dishwasher should be cleaned thoroughly before putting into operation.

Operation

INSTRUCTIONS FOR REGULAR OPERATION

The appliance is intended to clean dishes, cups, glasses, silver, etc. Be sure the items placed to be washed

are suitable for dishwashing. Silver should be cleaned of heavy food residues, if not washed right after use.

This machine is not intended for use with items which were used with acids, mineral oil, grease, gasoline or

colors.

PREPARATION OF DISHES FOR WASHING.

For best results avoid allowing food residues to dry. Remove bulk food residues, olive pips, lemon peels, tooth

picks, etc., before placing the dishes in the basket.

If washing is delayed, we recommend that you soak dishes and/or glasses which have food residues.

5

Operation

LOADING BASKETS

Place glasses and cups, with the opening facing down and not piled one on top of the other, in the appropriate

baskets. Glasses should not touch each other (damage to glass or stains due to contact may occur).

Plates should be stacked vertically in appropriate baskets and not touching each other.

Place tableware in the supplied plastic basket, with handles downwards or placed freely in a level plastic

basket.

In any case, avoid overloading.

AUTOMATIC FILLING OF DETERGENT

This model has an automatic detergent pump for use with a container of non foaming liquid detergent. The

detergent pump is a peristaltic regulated (looks exactly like the rinse-aid pump) and can be regulated by a

screw above and on the right of the glass cover. The regulation can be from 0 lt/hour to 3,0 lt/hr.

both pumps are mounting vertically on an inox bracket in front of the washing pump and are marked with two

yellow stickers.

MANUAL FILLING OF DETERGENT

Use only non-foaming detergent suitable for commercial dishwashers. In the event of non use or malfunction

of the automatic detergent injection system, put the detergent suppliers recommended amount directly into the

wash compartment tank after the machine has reached its operating temperature.

The correct dosage depends on the water hardness and the amount of dirt on the dishes.

Follow the detergent manufacturer’s recommendations. Less detergent deters good washing results and more

detergent usually does not provide better results, but rather more unnecessary consumption and environment

pollution.

Do not use granular detergent. Poor results usually occur.

Do not use caustic products. This will void the guarantee.

RINSE-AID “DOZER”

Before you perform these adjustments, turn off the power supply.

This model has an automatic rinse-aid pump for use with a container of liquid rinse-aid. The rinse-aid pump is

a peristaltic regulated (looks exactly like the detergent pump) and can be regulated by a screw above and on

the right of the glass cover. The regulation can be from 0 lt/hour to 0,7 lt/hr.

6

Operation

The dozer is adjusted from the manufacturer’s premises at its maximum value for easy initial priming

and must be adjusted accordingly (depending on water hardness, water pressure, how dirty the dishes

are, and the detergent used).

For initial priming of dozer, during the initial lling of the wash tank, start by switching on machine normally.

While the wash tank is lling, during the initialization only, open and close the door in 5 second intervals. Be

careful of spraying water. Do this for about 10 times, and the rinse system will be primed. Empty wash tank and

ll normally. Operate 2 or 3 wash cycles and machine is now ready to be calibrated or ready for normal use.

To reduce (-) the amount of rinse aid, turn the center screw clockwise. To increase (+), turn counterclockwise.

Note: this is a 15 revolution adjusting screw to provide ne adjustments as required.

Hint to installing personnel: After priming system by operating machine through several cycles, rotate

adjusting screw gently to full closed position (clockwise) and adjust (counter-clockwise) about 7 full revolutions.

Empty wash tank and rell with fresh water. Operate for two or three cycles and verify concentration level.

Adjust dozer to achieve nal desired results.

OPERATION

1. Check that the pump inlet lter has been placed in the correct position if it was removed for cleaning.

2. Check that the overow stand pipe is inserted correctly in its outlet.

3. Close door.

4. Turn power switch to “ON” (switches should now illuminate.)

5. The dishwasher will ll automatically.

6. The booster indicator should come on to indicate that the inlet water to the rinse and ll system is being

heated to the required rinse temperature (usually 185°F / 84°C.)

7. When the booster water has reached the correct temperature, the corresponding light switches off and the

wash tank light comes on if the wash water temperature is not sufciently hot (usually 140°F / 60°C.)

8. At initial daily start, allow about 10 to 20 minutes for machine to stabilize water temperatures to their proper

temperatures.

Note: After warm-up, one initial wash cycle should be performed to thoroughly mix soap and water

and be sure unit is fully warmed up and ready to wash properly.

9. After initial warm-up, when all heater lights are off, the dishwasher is ready to wash.

Note: If door is opened during operation, the safety control will turn off the timer. Washing or

rinsing will restart from beginning of wash cycle.

10. Open the door, insert the basket with the items (dishes, glasses, etc.) noting that heavy food residue

has been removed. (If the automatic soap injection system is not used, pour the proper amount of liquid

detergent manually into the wash tank.) Close the door.

11. To start the washing program, select the program desired and close the door. The automatic program

commences, with the green program indicator light in the program selector switch changing from ashing to

steady.

Note: This unit is equipped with a “positive rinse temperature control and will not advance from

wash to rinse unless the rinse water is at the preset temperature (usually about 185°F / 85°C.)

12. When the program is nished, the green program light returns to ashing.

13. Promptly open the door and remove the basket with the clean items. Use caution with hot items.

7

Operation

14. Allow to dry.

If, after washing, there are stains from dirt or water spots, the cause may be one of the following:

• Wrong ratio of detergent to water.

• Rinsing water with very high mineral content.

• Improper quantity of rinse-aid.

• Wrong arrangement of items in the basket.

• Low water pressure during rinsing.

• Low water temperature during washing.

• Clogged or miss-positioned lters.

• Clogged jets.

Maintenance

DAILY MAINTENANCE OPERATION.

• Turn the power switch off.

• Empty the wash tank by removing the overow standpipe.

• Remove and clean the pump inlet lter and the four sediment lters.

• Rinse the washing compartment to remove any dirt residues.

• Reassemble the parts in reverse order.

The appliance should never operate without the pump lter in place.

MAINTENANCE / CARE / REPAIR

Proper operation and safe use may be ensured only through the correct use of the appliance, as well as

the compliance with the operation instructions, the corresponding specications and the care and cleaning

indications.

Notice: Before cleaning or performing any maintenance, other than daily interior cleaning, power and water

supply must be turned off. The appliance should never be sprayed with water or high pressure cleaning

solution, because any water or solution which may get into the electrical components will affect operation of the

appliance as well as present a potential for electrical shock. No safety systems should be disabled.

REGULAR MAINTENANCE AND CLEANING WORKS

Depending on local water hardness, the nozzles on the rinse arms should be cleaned regularly. Caution must

be exercised to not damage the nozzles.

8

Maintenance

PAY ATTENTION TO THE CORRECT POSITION OF FILTERS AND WASH ARM INSTALLATIONS AND BE

SURE NON-STICK BUSHINGS ARE NOT WORN.

Clean the appliance with warm water and conventional cleaning aids.

Stainless steel parts should never be cleaned them with “steel wool”, wire brush, etc, since even the lightest

contacts on the surfaces with steel may contaminate the stainless steel and cause rust formation. Use brushes

made of polymer plastic, natural bristles, or thin brass wire. Always keep brush movements in line with grain in

the Stainless Steel so that you will not affect the appearance. Finally, rinse with clean water and dry thoroughly.

We remind you that corrosion (rust formation) on stainless steel surfaces is not created by itself, but

rather due to the use of improper cleaning products (e.g. whitening or particularly caustic cleaning

products based on chlorine). Occasionally calcium sediments will form on the internal walls of the

dishwasher (due to mineral particles in the water), which may affect the correct operation of the

appliance and requiring regular removal.

SPARE PARTS, ACCESSORIES AND COMPONENTS

Spare parts and components are usually available at the authorized local service agency, or directly from

Omcan, In case of claims or complaints, you must supply the model and serial number of the appliance /

machine found on the specication label of the appliance.

Troubleshooting

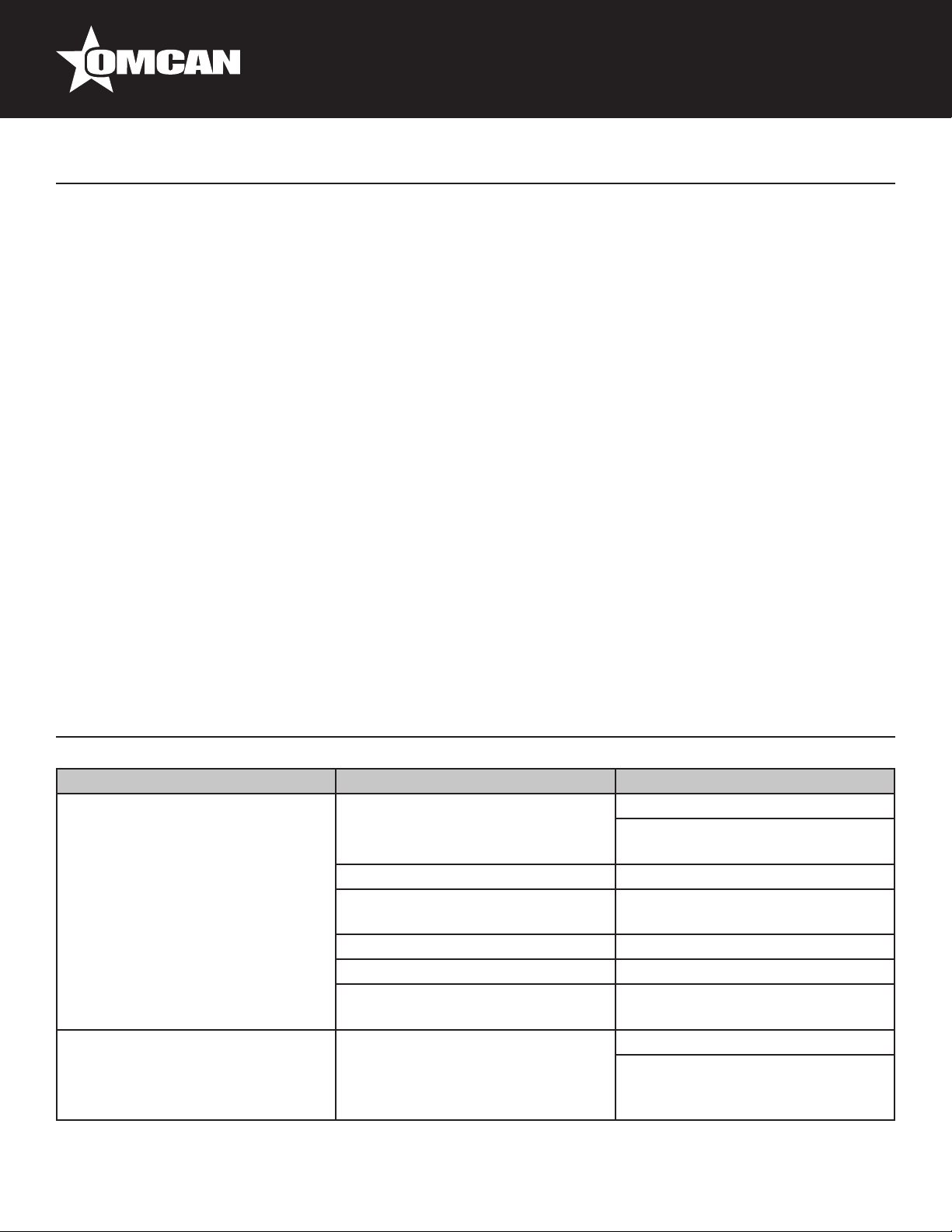

PROBLEM CAUSE SOLUTION

The dishwasher does not operate. No power to the machine. Check the connection.

Breaker or fuse has not been

activated or is faulty.

Control switch S1 not activated. Turn switch S1 on.

Switch S1 is faulty. Refer to the authorized service

agency, local dealer, or Omcan.

Water supply not turned on. Turn the supply on.

Door is not closed. Close the door.

Water inlet valve is faulty. Refer to the authorized service

agency, local dealer, or Omcan.

Fill water runs continuously. Overow drain stand pipe not

installed properly.

Install overow drain stand pipe.

Verify that overow drain stand

pipe is installed properly with

overow slots upwards.

9

Loading...

Loading...