Page 1

Band Saw

Model BS-IT-1829-L

Instruction Manual

Revised - 10/7/2014

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: sales@omcan.com

www.omcan.com

Page 2

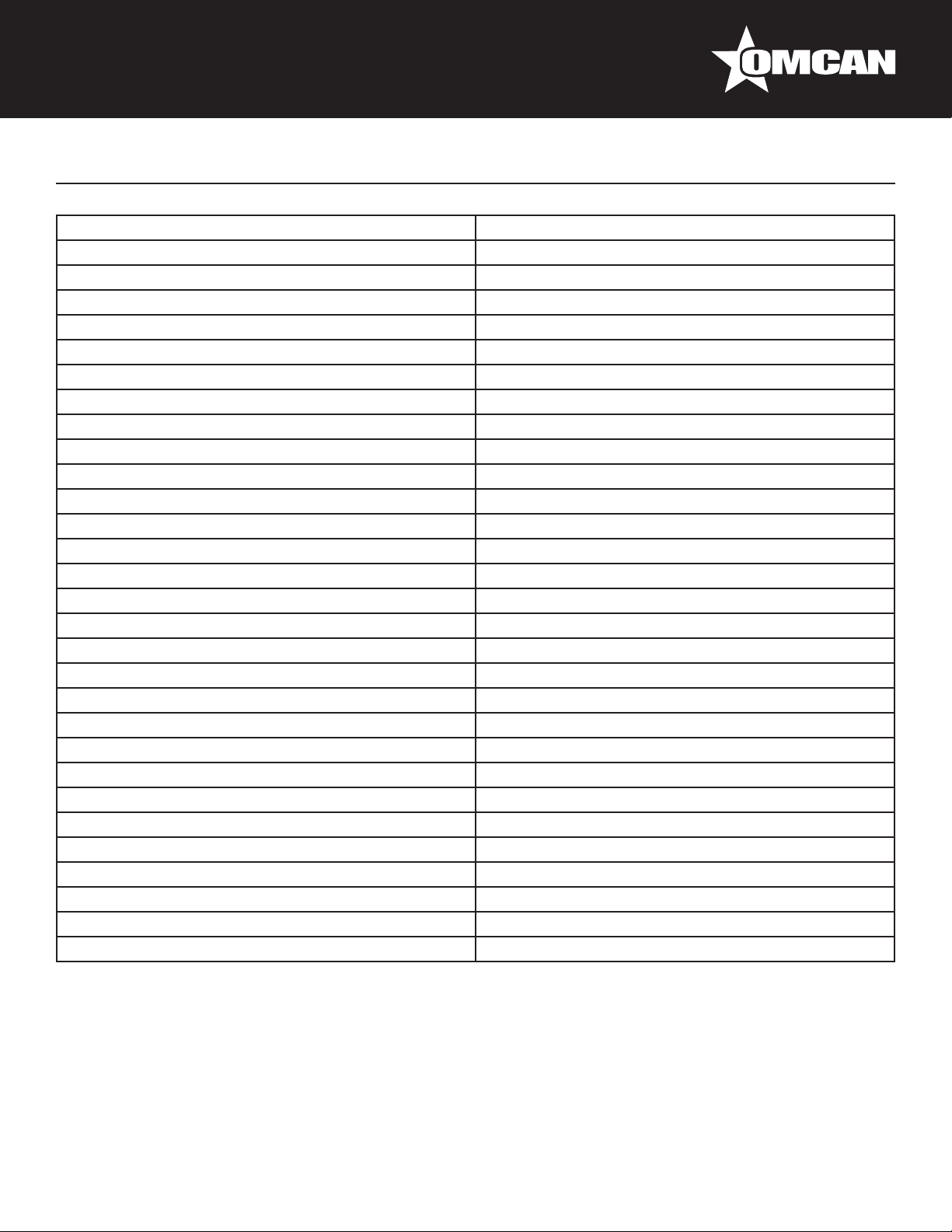

Table of Contents

Model BS-IT-1829-L

Section

General Information

Safety

Warranty

Technical Specications

Installation

Operation

--------------------------------------------------------------------------------------------- 3 - 6

------------------------------------------------------------------------------------------ 6 - 7

------------------------------------------------------------------------------------ 10 - 14

------------------------------------------------------------------------------------------- 15

-------------------------------------------------------------------------------- 3

Page

---------------------------------------------------------------------- 8 - 9

Maintenance

Troubleshooting

Parts Breakdowns

Electrical Schematics

Warranty Registration

--------------------------------------------------------------------------------- 16 - 17

----------------------------------------------------------------------------- 17 - 19

-------------------------------------------------------------------------- 20 - 21

---------------------------------------------------------------------------- 22

---------------------------------------------------------------------------- 23

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

WARNING! THIS HANDBOOK HAS TO BE READ CAREFULLY AND UNDERSTOOD CORRECTLY

BEFORE USING THE MACHINE; KEEP IT ALWAYS AVAILABLE FOR AN EASY CONSULTATION. FOR

ANY DOUBT, CONTACT THE MANUFACTURER IMMEDIATELY.

WARNING! ANY OPERATION NOT EXPLICITLY DESCRIBED OR NOT EXPLICITLY ENVISAGED IN THIS

HANDBOOK IS ABSOLUTELY FORBIDDEN.

WARNING! Any operators or receiver of the machine, explicitly and irrevocably acknowledges that the Omcan

Inc. cannot be held liable (from civil, criminal or any other type of liability) in the case of an accident resulting

from (and not necessarily “as a consequence of”) a breach of one or more (no exclusions admitted) of the rules

envisaged in this handbook. The above has to be explicitly and irrevocably accepted with the startup and use

of the machine.

The design of this machine features many safety measures to safeguard the operator, however there are

hazards which cannot be fully reduced through design and protection techniques; these hazards are called

“non-eliminable residual hazards” and are dangerous for the operator. Therefore, carefully read this handbook

and all the attached documents is mandatory as is paying the utmost attention to all the rules.

CHECK PACKAGE UPON ARRIVAL

If no external damage is evident on the package upon its arrival, open it and check that all the components are

inside. If the package has suffered rough handling, bumps or damage (visible or concealed), the carrier must

be informed within 24 hours about any damage. A detailed report on the extent of the damage caused to the

machine must be lled within three days from the delivery date shown in the shipping documents.

Safety

READING AND UNDERSTANDING THIS HANDBOOK

WARNING! Do not use the machine before you have read and understood this handbook, the warnings and/or

all diagrams for the machine. Read and fully understand any additions, corrections and any other information,

instruction, explanation which Omcan Inc. and/or their technical and commercial network will give you in any

way (e-mail, fax, website, letter).

3

Page 4

Safety

WARNING! Do not use the machine for purposes other than what is stated in this handbook and/or in the

warnings and/or in diagrams on the machine. Using the machine for purposes other than those stated in the

manual may cause injury or damage to the machine.

• Omcan Inc. and the dealer cannot be held responsible for the consequences stemming from behaviors

which do not conform with those listed in this manual and/or warnings and/or diagrams of the machine.

• Not complying with the instructions indicated in this manual and/or warnings and/or diagrams for the

machine ends any warranty and can also have legal repercussions in case of accident.

WARNING! Do not alter the machine and its assembly system in any way.

WARNING! Never damage or alter any component of the machine, both general and specic safety

components, are directly or indirectly necessary for your safety.

WARNING! Any use not explicitly allowed by Omcan Inc. is absolutely forbidden and may cause injury or

damage; therefore, it is in breach of safety rules and transfers liability to both the person who gives the

instruction and the person who carries it out.

WARNING! Although several safety measures are in place, there are dangers which cannot be totally reduced

through the design and the safeguarding techniques. Such dangers are called “non-eliminable residual

hazards” and are dangerous to the operator: therefore, carefully read and understand this handbook and all the

warnings and the diagrams for the machine. It is mandatory and recommended to follow all instructions, with

no exceptions.

The machine must not be used by persons under age of 18 (eighteen). The use of the machine is forbidden

to people with physical or mental disabilities as the machine is designed to be exclusively used by people

who are fully capable to use the machine. People with stress or physical/mental weakening, should not use

the machine for the safety all persons around the machine. People under the effect of alcohol, psychotrope

drugs, narcotics (soft and heavy drugs) must not use or be in the vicinity of the machine. The machine has to

be used by one (1) operator who is well-acquainted with its functioning. Operation of the machine is to carried

out by only one person. The machine is not designed to be used by persons who are not qualied or trained,

therefore all activities have to be performed only by professional staff properly trained and qualied: use and

maintenance for butchers; repairs carried out by technicians; dismissal by relevant operators. If the machine

is not being used for extended period of time (examples: end of shift; weekend; holidays, bank holidays and

permissions; absence for any reason), never leave it switched on and connected to the power line though

the drive is not running, to avoid the useless consumption of power and for safety reasons. Omcan Inc. is

not responsible for the actions mentioned above and the person in charge of the machine must take care of

them. At the end of each shift, the machine has to be switched off and put in the emergency state by pushing

the red push button. If the control board is equipped with a safety key for the startup (optional component),

the operator must remove this key. The machine must never be used by persons who have not been trained

and who are not formally authorized to operate this machine. If the operator is not trained, the supervision of

a qualied operator is necessary. Remind anyone using the machine that they must use the machine safely

and carefully to avoid accidents and increase working safety. The machine is supplied with guards and safety

devices which must not be removed or modied; the person in charge of safety and the machine operator must

supervise so that the machine is always equipped with original guard.

4

Page 5

Safety

PERSONAL PROTECTIVE EQUIPMENT

PERSONAL PROTECTIVE EQUIPMENT IN CONFORMITY WITH CURRENT RULES: all of the following

personal protective equipment (PPE) has to be in conformity with relevant technical rules in force (Directive no.

89/656/CEE and following amendments and updates) and therefore has to be EC-marked and have relevant

declaration of conformity which usually refers to specic European (EN) technical rules of the harmonized

type. The operators must always inform the employer, manager and/or representative of the anomalies in the

operation or characteristics of the use of their personal protective equipment.

HEAD: The use of a cap to keep the hair gathered is mandatory in order to avoid entanglement with the

moving elements; for hygienic reasons, the cap must always be clean and must be able to retain the hair of the

operators. The hair might get entangled and cause serious accidents.

EYES: To protect the eyes from bone splinters and/or accidental blade breaking, wear safety glasses.

NOSE, MOUTH: To protect the respiratory tract from toxic or dangerous emissions of meat and similar

substances, it is mandatory to wear ltering masks; they have to be replaced with signs of dirt or partial

clogging; they have to be replaced after 2 (two) working days.

EARS: The machine does not produce a loud noise and it produces a continuous level of acoustic pressure

equivalent weighted “A” of 82 dB(A) ± 1 dB(A) vacuum and of 88 dB(A) ± 1 dB(A) when dry cutting large

and strong bones; thus ear protectors (protective headset) are strongly recommended and workers must be

instructed on their correct use. The use of new blades or very sharp blades and water-lubrication of the cutting

area of bones contribute to reducing the noise. The length of exposure to the noise is also a hazard. Submit

workers to regular health checks.

LIMBS AND BODY (what not to do): Never wear rings, wrist watches, bracelets, jewelry, torn clothing or

those with loose parts, scarves, ties, loose belts as they might get entangled and cause serious injury.

LIMBS AND BODY (what to do): For the protection of body parts, always wear overalls or coats with elastic

cuffs; both have to be wore well tight, without leaving them open, only partially tightened or with loose parts;

tighten the sleeves around the cuffs and always keep your hair gathered in a cap.

FEET: it is mandatory to wear safety shoes with steel tips to protect the feet from the fall of heavy objects (the

5

Page 6

Safety

machine itself or its spare parts or large pieces of food).

HANDS: to protect your hands, wear marked protective gloves in conformity with the rules for protective gloves

against mechanical hazards, since they must suitably protect hands against abrasion, cuts and tears and

perforations.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Warranty

The warranty can be exerted through the retailer (therefore it is exerted by Omcan Inc.) and:

• It always starts from the date when the machine is delivery by Omcan Inc.’s authorized retailers and lasts

for a maximum period of 12 (twelve) months;

• It guarantees the free replacement of the pieces which might break or abnormally wear due to assessed

faults of design, supply, construction, or assembly which can be attributed to Omcan Inc.;

• The request for a free repair has to be directly addressed to Omcan Inc. or the dealer where the machine

has been purchased;

• As for the repair (both free of charge and not), the machine has to be put in safe conditions (in the original

packing or one similar to the original packaging), fully at the cost of the person requiring such repair. It must

be sent to Omcan Inc. or those who have been authorized by the Manufacturer to perform the repair (both

free of charge and not);

• Possible faults in planning, supply, construction, assembly, appearance, functioning, training which can be

attributed to Omcan Inc. have to notify Omcan Inc. by letter with return receipt and sent to the registered

ofce. Omcan Inc. must be informed even by fax and/or e-mail in order to avoid further damage and/or

accidents;

• The non-fulllment of these rules releases Omcan Inc from the consequences of further damage and/or

accidents subsequent to delayed or omitted communications;

WARRANTY EXCLUSIONS

WARNING! The warranty of Omcan Inc. NEVER INCLUDES:

• The replacement of the machine after a service required for a failure;

• The reimbursement for the working hours used by staff not directly entrusted by Omcan Inc. to carry out

services and/or repairs;

6

Page 7

Warranty

• The reimbursement for consumption, rent of equipment or purchase of equipment to carry out services and

repairs by staff not directly entrusted by Omcan Inc.;

• The transportation of the machine to and from the authorized service center are fully at the cost of the

person requiring repair.;

• The necessary packaging to transport the repaired machine if it has been delivered without the original

packing.

• The reimbursement for damaged or destroyed possessions or goods;

• The reimbursement for loss of prot, service interruption, expenses of any kind, penalties, or corporate

image damage;

• The reimbursement for loss from other equipment, machines or manufacturing lines working together with

this machine, subsequent to damage or destruction of things or goods in these equipment or machines or

lines;

• Damage caused by the unsuitability of the environment where the machine is located (humidity,

temperature, electromagnetic elds or dirt which exceed the limits established by this handbook and those

established by law);

• Phenomena which do not depend on the normal functioning of the machine (atmospheric electric

discharge, power stress, re, ooding, etc.);

• Defects or failures caused by use not listed in this manual;

• Defects depending upon the wrong use of the machine by anyone and those defects which appear after

changes carried out on the machine without the written authorization of Omcan Inc.;

• Defects and/or failures in case of non-original spare parts not having equivalent manufacturing

characteristics.

WARRANTY EXPIRATION

WARNING! The warranty of Omcan Inc. COMPLETELY EXPIRES:

• If any rule, instruction, recommendation, warning, prohibition listed by Omcan Inc. or their commercial

network in any form (oral, written, by phone, fax or e-mail, on paper, electronic, magnetic, optical,

audiovisual supports, etc.); or any rule in this handbook is infringed;

• With the improper or unreasonable use of the machine;

• If the machine is modied in any way, even slightly;

• If non-original spare parts or accessories of Omcan Inc. are assembled;

• If the machine is modied, without the written approval of Omcan Inc., even if this would occur after

recommendations or orders of public or private authorities for control and prevention;

• If the machine is repaired by staff who is not directly authorized by Omcan Inc.; inexperienced staff and

unauthorized staff must not perform any repair or extraordinary maintenance;

• If the damage to the machine is attributable to carelessness and negligence;

• If the machine has not been regularly purchased and paid according to contractual agreements existing

with Omcan Inc.or with the authorized retailers;

• If there is no invoice or receipt proving the purchase;

• Any missed or delayed payment implies the expiry of the validity of the warranty granted by Omcan Inc. for

the whole period of the missed or delayed payment;

• The periods relevant to the missed or delayed payment cannot be recovered after the settlement of the

debt; the warranty of Omcan Inc. expires at this date;

7

Page 8

Technical Specications

Single-Phase 110V/1/60Hz

Dimensions (± 1 cm) (L× W × H) 54 cm × 47 cm × 89 cm

Weight 36 kg

Working table (L × W) Fixed, 39 cm × 37.5 cm

Max cutting height 26 cm

Max cutting width 21 cm

Blade guide and Blade protection Manual Setting

Portion device Manual setting

Saw Blade material Steel for food

Saw Blade length 1830 mm

Saw Blade width 16 - 20 mm

Pulley engine diameter / channel Ø 22 cm / Ø 22 cm

Interaxle pulleys Manual setting

Electrical feeding Single-Phase 110V ~ 60 Hz

Electrical capacity installed 1.1 kW = 1.5 HP

Motor rotation speed 1.680 ± 50 rpm

Grounding Yes (class | device)

Insulation class IP 54

Environment at T Temperature 5°C < T < 45°C

Environment at relative humidity Ur 5% < Ur < 90%

Environment under pressure 1 bar ± 10%

Environment with atmosphere Non-explosive

Working table material Stainless Steel

Portion device material Stainless Steel

Door material Painted aluminium

Base frame material Painted aluminium

Tension 110V

Phases 1

Frequency 60 Hz

Weight 32 kg

8

Page 9

Technical Specications

C) MACHINE BODY 1) DRIVING PULLEY Q) DOOR LOCKING KNOB

SCREWS

D) DOOR 2) PULLEY PATH P) PORTION DEVICE

L) WORKING TABLE F) EXIT WASTE OPENING V) BLADE GUIDE SCREWS

N) SAW BLADE G) BLADE GUIDE T) BLADE TENSION KNOB

Z) BLADE PROTECTOR R) METALLIC GRID

PROTECTION AGAINST ACCESS

TO BLADE AND PULLEY FROM

EXIT WASTE OPENING

J) BLADE GUIDE Y) SLIDING BLOCKS FOR SAW

BLADE CLEANING

B) BLADE GUIDE BLOCK KNOB H) SAW BLADE THRUST

BEARING

M) MICROSWITCH

K) OPTIONAL ONLY FALLING

MEAT PUSHER

9

Page 10

Installation

A space of at least 100 cm (39.37”) has to be left around each side of the machine to avoid hazards, falling

of the machine, to easily perform cleaning and maintenance and to avoid difculty when using with pieces of

meat. The oor must be a non-slip surface and has to be always kept clean.

The machine has to be assembled on a at, level surface (or onto a very stable pedestal) having a height

ranging from at least 45 cm (17.72”) and not exceeding 69 cm (27.17”) from ground so that the working

table upper surface is at a height from the ground ranging from 80 cm (31.50”) to 105 cm (41.34”). Then, the

electrical assembly has to be carried out.

After the installation, make sure that no one touches the machine and connect the feeding plug to a socket

(110 V ~ 60 Hz for single-phase motor machines).

• To switch the machine on, turn clockwise the rotational device towards “I” = ON =

switched ON.

• To switch the machine off, turn counterclockwise the rotational device towards “O”

= OFF = switched OFF.

Check the correct rotation of the motor and blade running direction, which always goes from upwards to

downwards. Check that (both when the motor is running and when it is idle, but the machine is powered)

the efciency of the connection and protection of the electrical switchboard have been performed. If such

checks are passed, the machine is electrically installed; if they are not, contact Omcan Inc. or the dealer for

maintenance.

10

Page 11

Installation

BLADE GUIDE SLIDING BLOCKS ADJUSTMENT

1. Make sure that the machine is switched off (rotational device positioned “O” = OFF);

2. Make sure that the machine is not working (blade has stopped);

3. Unscrew any of the two black (M) small knobs while paying attention not to unscrew it completely from its

seat (S);

4. Bring the white sliding block (P) close to the blade (L) until they are very close;

5. Evaluate the thickness of the sliding block (the sliding blocks of the blade guide are open to continuous

wear; therefore they have to be replaced when their thickness is below 1.5 cm) and, if necessary, replace it

with a new sliding block;

6. Re-screw the small knob (M) to lock the sliding block (P);

7. Repeat the operations from 1 to 6 for the other sliding block;

[K] OPTIONAL ONLY falling meat pusher.

11

Page 12

Installation

BLADE GUIDE HEIGHT ADJUSTMENT

1. Make sure that the machine is switched off (rotational device positioned “O” = OFF);

2. Make sure that the machine is not working (blade has stopped);

3. Unscrew the black knob (N) (located opposite to the working table of the operator) which, through its

integral screw, blocks the rod (A) of the blade guide (G) coming out from machine upper part and the

working table; in this way, the rod (A) of the blade guide (G) can run vertically;

4. Adjust the height of the blade guide (G) according to the height of the material to cut (max. 1 cm above it);

5. Screw the small knob (N) to block the rod (A) of the blade guide (G), the blade guide (G) and the protection

(R) necessary to them, at the desired height;

[K] OPTIONAL ONLY falling meat pusher.

12

Page 13

Installation

BLADE TENSION ADJUSTMENT

1. Make sure that the machine is switched off (rotational device positioned “O” = OFF);

2. Make sure that the machine is not working (blade has stopped);

3. Screw the black knob (T) located on top to increase the blade tension and unscrew to decrease the blade

tension; it is not necessary to open the door or unscrew the pulley to perform such adjustment;

4. Screw the black knob (T) so that the white line on the neck of the button is very close to the frame of the

bone band saw (as per photo of the back side of the bone band saw);

5. Always check the blade tension when the machine is not working before restarting it (before restarting the

motor);

(K) OPTIONAL ONLY falling meat pusher.

BLADE REPLACEMENT

1. Make sure that the machine is switched off (rotational device positioned “O” = OFF);

2. Make sure that the machine is not working (blade has stopped);

3. Open the door (H) at least 90°;

4. Disassemble the protection device (R) from the blade necessary to the blade guide (G);

5. Unscrew the black knob (T) located on the top to decrease the interaxle between the two pulleys and

reduce the tension of the blade until it easily and manually comes out from pulleys;

6. Extract the blade from the pulleys making sure not to hurt yourself (do not work with bare hands, use the

prescribed protective gloves) and put it in a safe place not accessible to children or non-trained personnel;

7. Insert a new blade in the pulleys making sure not to hurt yourself (do not work with bare hands, use the

prescribed protective gloves) inserting it in the pulleys by shifting it as opposed to those performed to draw

it out;

13

Page 14

Installation

8. Check the correct positioning of the new blade on the two pulleys;

9. Screw the black knob located on the top to increase the interaxle between the two pulleys and increasing

the tension of the blade up to the desired value. It should be tight enough so that the blade cannot be

extracted from the pulleys from pulling on it;

10. Re-assemble and adjust the protection device (R) of the blade necessary to the blade guide;

11. Close the door (H) towards the framework body (C);

14

Page 15

Operation

1. Make sure that the machine is switched off (rotational device positioned “O” = OFF);

2. Make sure that the machine is not working (blade has stopped);

3. Put the material to cut on the working table;

4. Adjust the height of the blade guide according to the height of the material to cut;

5. Adjust the lateral position and leave a space similar to the thickness of the product between it and the saw

blade;

6. Bring the material to cut in contact with the portioning device;

7. NOTE: It is forbidden to cut materials such as wood, plastic, paving tiles, bricks, stones, glass, metals,

leather, cardboard, fabrics, etc. even though a specic blade for this aim is available;

8. Wear the safety gloves and start the machine after having checked that nobody is close to it by turning

clockwise the rotational device towards “I” = ON;

9. To cut other slices having the same thickness, go back to 6;

10. To cut other slices having a different thickness, go back to 5;

11. If the height of the material to cut varies of more than 1 cm when cutting more slices, go back to 1.

15

Page 16

Maintenance

WARNING! Before any cleaning and/or maintenance and/or check, switch the machine off (rotational device

positioned “O” = OFF) and then disconnect the power cord from the socket. Cleaning, maintenance or checks

must be performed when the machine is not connected to the power source.

Before restarting the machine, make sure that no one is touching it. The use and the regular cleaning of the

machine reduce the need for extraordinary maintenance and repair; the daily cleaning of the machine is an

important factor to promptly detect possible defects or damages. At least once a week, clean the machine with

a soft and dry cloth which does not lose its fabric. Avoid using petrol, solvents or any other type of detergent on

the non-metallic parts which can be exclusively cleaned with a neutral and non-foamy water-based detergent.

Never use abrasive products, chlorate substances, wire wools, brushes of any type, scrapers, etc., only use

small brushes having rigid bristles and cloths which do not lose fabrics, bers or fragments.

WARNING! The machine must never be washed with water jets (without buckets, rubber hoses or sponges).

WARNING! The machine does not need lubrication or greasing since it is equipped with self-lubricating

bearings.

WARNING! After a thorough visual check at the beginning of each shift, make sure:

• The inside of the machine is clean while playing close attention to the pulleys; if necessary, clean and

sanitize them;

• The cleanness of the lower container gathering the processed waste; if necessary, clean and sanitize it;

• The condition of the power cable and its plug;

• The condition of the switchboard and the control buttons (check whether there are cracks, splintering,

scratches, distortions, cuts, etc.);

• The working of all safety devices: the rotational device positioned “O” = OFF and door interblock

microswitch; then all the remaining safety devices already listed;

If damaged or bad working components are detected, do not allow anyone to use the machine and put a

warning about such prohibition; then contact the dealer or Omcan Inc. for maintenance.

STORAGE AND DISPOSAL

In order to preserve the machine (which is off) for a very long period the following rules must be abided by:

• Disconnect the power cable from the socket;

• Do not lay on the machine any other object and make sure that the place of storage is dry, not humid, dust

free, clean and free from insects or other animals and protected against bad weather conditions or other

agents (for example, atmospheric agents, drops of water or other liquids, pollution) which might damage it;

the place must not be subject to considerable temperature ranges;

• Abide by all technical specications indicated earlier in this operating handbook;

• If the original packing is still available, put the machine into it or cover it with a piece of cloth of nylon,

cellophane, polyethylene or other material of suitable size and if possible package it rmly to avoid the

machine being damaged due to falls or damage by other materials which might enter into contact with it.

16

Page 17

Maintenance

It is also forbidden to leave or dispose the machine or any of its parts in the environment. It is also forbidden to

dispose there is still solid urban waste; if the machine is no longer used, deliver it to qualied disposal facilities

or authorized dealers.

Troubleshooting

PROBLEM POSSIBLE CAUSES SOLUTIONS

Machine does not start. Lack of power from the electrical

network.

Electrical network’s ON/OFF is in

“O” position, OFF.

Machine’s ON/OFF switch in “O”

position.

Damaged ON/OFF switch. Contact the manufacturer to have

Machine does not stop. Machine ON/OFF switch in “I”

position.

Damaged ON/OFF switch. Turn the ON/OFF switch to

Restore the supply of power from

the electrical network.

Turn the ON/OFF switch of the

electrical network to “I” position,

ON.

Turn the ON/OFF switch to “I”

position.

the ON/OFF switch replaced and

check the electrical parameters (V,

A, cos φ).

Turn the ON/OFF switch to “O”

position.

“O” position and contact the

manufacturer or dealer to have the

ON/OFF switch repaired.

17

Page 18

Troubleshooting

Door is open but the machine does

not stop.

The machine is noisy (vibration,

creaking, whistling, etc.).

Damaged door safety microswitch. Contact Omcan or the dealer to

have the door safety microswitch

replaced.

The working table or one of the

supports which do not touch the

ground.

One or two supports of the

machine do not lay properly on the

working table.

Saw blade is too slow or too tight. Check the pulleys and the tension

One or both pulleys are damaged

or out of their axis.

The door is not properly closed. Check door hinges and relevant

The safety microswitch is not

properly xed.

The sliding blocks of the blade

guide are too tight on saw blade.

Saw blade has damaged toothing. Replace the saw blade with a new

Saw blade with toothing unsuitable

for the material to cut.

Material to cut is too hard. Avoid trying to cut such material

Material to cut is not included

among those envisaged by Omcan

Inc.

Add some shims under the working

table or adjust the supports so that

they are all at.

Adjust the machine supports so

that all lay at.

of the feeding band and adjust it

through the upper black knobs.

Check the condition of the pulleys

and if they are out of axis or not

properly xed, contact Omcan

Inc. or the dealer to have them

repaired.

locking screws and, if necessary,

screw them in.

Check the safety microswitch

locking screws and, if necessary,

screw them.

Adjust the sliding blocks slightly

taking them away from the blade.

See above on how to adjust the

sliding blocks.

one. Ensure it is an original spare

part.

If the material to cut is among

those envisaged for the machine,

contact Omcan Inc. or the dealer

to have a saw blade suitable for

the material to cut, otherwise read

below.

since it is not included in the list

supplied by Omcan Inc.

Avoid trying to cut such material

since it is not included in the list

supplied by Omcan Inc.

18

Page 19

Troubleshooting

The saw blade coming out from

the pulleys.

Considerable heating of the saw

blade.

Cutting is not perfect. Saw blade is too slow or too tight. Check the pulleys and the tension

Saw blade is too slow or too tight. Check the pulleys and the tension

of the feeding band and adjust it

through the upper black knobs.

One or both pulleys are damaged

or out from their axis.

Bad quality of blade. Replace the saw blade with a new

Loss of sharpening of the saw

blade.

Waste clogged between blade and

blade guide.

Bearings of one or both pulleys are

damaged or blocked.

Loss of sharpening of the saw

blade.

Check the pulleys and contact

Omcan Inc. or the dealer to have

them repaired if they are out of

their axis.

one. Ensure it is an original spare

part.

Replace the saw blade with a new

and original one.

Disassembly and thoroughly

clean the blade guide and then

reassemble it.

Contact Omcan Inc. or the dealer

to replace the bearings.

of the feeding band and adjust it

through the upper black knob if it

differs from the relevant values.

Replace the saw blade with a new

one. Ensure it is an original spare

part.

19

Page 20

Parts Breakdown

Model BS-IT-1829-L 10254

20

Page 21

Model BS-IT-1829-L 10254

Parts Breakdown

Item

No.

34916 Knob to close the opening 2 34938

34917 Rubber Washer 3 34939 Transporter guide plug (n° 1) 27 34962 Nut 51

34918 Brass closing screw 4 34940 Transporter guide in aluminium 28 34963 Pivot meat pusher 52

34919 Nut 5 34941 Transporter guide pole 29 34964 Meat pusher 53

34920 Lower protection 6 34942 Washer 30 34965 Washer 54

34921 Upper y-wheel screw 7 34943 Nut 31 34966 Screw 55

34922 Screw to protect from dust 8 19953 Blade protection 32 34967

34923 Bearing 6203 2RS 9 34944 Upper y-wheel pivot 33 34968 Knob meat pusher 57

34924 Lower y-wheel screw 10 34945 Nut 34 34969 Carter motor 58

34925 Screw 11 34946 Adjustment y-wheel screw 35 34970 Motor 59

19950 Upper y-wheel 12 34947 Lamination 36 34971 Support to close cables 60

19951 Lower y-wheel 13 34948 Coulisse 37 34972 Micro support to close cables 61

10328 Band Saw Blade for 1829-L 14 34949 Washer 38 34973 Motor support 62

34927 Hinge 15 34950 Nut 39 34974 Screw 63

34928 Screw 16 34951 Tension grip bearing 40 34975 Working surface 64

34929 Washer 17 34952 Tension grip spring 41 19952 Bakelite plate 65

34930 Shavehook (n° 1) 18 34953 Tension grip knob 42 19954 Microswitch 66

34931 Shavehook pivot (n° 1 ) 19 34954 Opening 43 34976 Cable closer PG 11 67

34932 Rubber washer 20 34955 Screw 44 34977 Cable closer PG 9 68

34933

34934 Bearing pivot 22 34957 Knob to support guide 46 34979 Carcass (not interchangeable) 70

34935 Bearing to control the push 23 34958 Cutting guide support 47 34980 Switch ON-OFF + Plastic box 71

34936 Nut 24 34959 Cutting guide pole 48 34981 Power Cord 72

Description Position

Opening (not interchangeable) 1 34937 Knob transporter guide (n° 1) 25 34960

Screw to face the working

surface

21 34956 Screw to support cutting guide 45 34978 Screw 69

Item

No.

Description Position

Transporter guide ring nut in

aluminium (n° 1)

26 34961

Item

No.

Description Position

Cutting guide to subdivide to

pieces

Knob of the transporter guide

pole

Connection of knob meat

pusher

49

50

56

21

Page 22

Electrical Schematics

Model BS-IT-1829-L 10254

22

Page 23

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

www.omcan.com/warrantyregistration.html

For mailing in Canada For mailing in the US

OMCAN INC.

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

Niagara Falls, New York

OMCAN

USA, 14305

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Thank you for choosing Omcan

23

Page 24

Over the last 65 years, Omcan has grown to become a leading supplier to the food

service industry in Canada and the USA. Our success over these many years is

directly attributed to our established relationships with all of our valued customers

and through providing them with Diverse, Dependable and Proven products.

Omcan continues to help our customers remain competitive.

With associates in North America, Europe, Asia, and South America, our global

footprint continues to expand as we hold to the principle that clients benet from

the accessibility and familiarity of our sales team. In 2013 as our geography and

brand recognition continued to grow, we changed to one name Omcan Food

Machinery.

In over 200,000 sq ft of warehouse space we stock over 2,500 quality food

equipment and supplies for the food preparation market.

Loading...

Loading...