Page 1

MODEL VTS-500

VACUUM TUMBLER

OPERATION MANUAL & PARTS LIST

The BIRO VTS-500 VACUUM TUMBLERS are versatile machines used for vacuum

tumbling all types of meats with marinaded blends of herbs and spices. All marinades should be FDA approved and meet F.S.I. standards. The BIRO VTS-500 produces equally impressive results with beef, pork, poultry and fish.

The unit is both easy to clean and maintain as well as sanitary in design and construction. The entire machine is built to give many years of trouble free service while

providing a unique line of marinated products for your customers.

ITEM No. VTS583-307

STARTING WITH SERIAL No. 544

ITEM No. VTS583-307

307-1-09-4

Page 2

TABLE OF CONTENTS

Page

NOTICETOOWNERSANDOPERATORS......................................... 1

SAFETYTIPS............................................................... 2

OPERATION................................................................ 3

CLEANING................................................................. 4

MAINTENANCE ............................................................. 5

PUMPFILTER.......................................................... 5-7

VACUUMPUMP......................................................... 8-9

GEARREDUCER ......................................................10-11

TOPROGRAMTIMER.....................................................12

TIMERPROGRAMNOTES..................................................13

PHOTOELECTRICEYE .................................................14-15

CONTROLPANEL–COMPONENTS.............................................16

CONTROLPANEL–REARVIEW ................................................17

DRUMASSEMBLY ...........................................................18

FRAMEASSEMBLYANDCOMPONENTS..........................................19

VACUUMHOSESANDFITTINGS.............................................20-21

COMPONENTCOVERANDREARDOOR .........................................22

OPERATORNOTES..........................................................23

WIRINGDIAGRAMS........................................................24-25

SPAREPARTSRECOMMENDATION .............................................26

OPERATOR’SSIGNATUREPAGE................................................27

LIMITEDWARRANTY.........................................................28

Page 3

BIRO’s products are designed to process food products safely and efficiently. Unless the operator is properly trained and supervised, however, there is the possibility of a serious injury. It is the

responsibility of the owner to assure that this machine is used properly and safely, strictly following

the instructions contained in this Manual and any requirements of local law.

No one should use or service this machine without proper training and supervision. All operators should read and be thoroughly familiar with the procedures contained in this Manual. Even so

BIRO cannot anticipate every circumstance or environment in which its products will be used.

You, the owner and operator, must remain alert to the hazards posed by the function of this equipment. No one under eighteen (18) years of age should operate this equipment. If you are uncertain about a particular task, ask your supervisor.

This Manual contains a number of safe practices in the SAFETY TIP section. Additional warnings are placed throughout the Manual. Warnings related to your personal safety are indicated by:

Warnings related to possible damage to equipment are indicated by:

BIRO also has provided warning labels on the equipment. If any warning label, instruction label

or Manual becomes misplaced, damaged, or illegible, please contact your nearest Distributor or

BIRO directly for a replacement.

Remember, however, this Manual or the warning labels do not replace the need to be alert and

to use your common sense when using this equipment.

1

NOTICE TO OWNERS AND OPERATORS

OR

– NOTE –

A copy of this manual is included with each MODEL VTS-500 VACUUM TUMBLER.

The descriptions and illustrations contained in this manual are not binding.

The manufacturer reserves the right to introduce any modification

without updating the manual.

Page 4

SAFETY TIPS

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

ALWAYS Read Operation and Service Manual BEFORE Operating, Cleaning or Servicing.

ALWAYS Keep Hands Clear of the Rotating Drum and Other Moving Parts.

NEVER Attempt to Remove the Drum Lid Unless Vacuum Has Been Released and the Drum is

Positioned Vertically With the Lid at the Top.

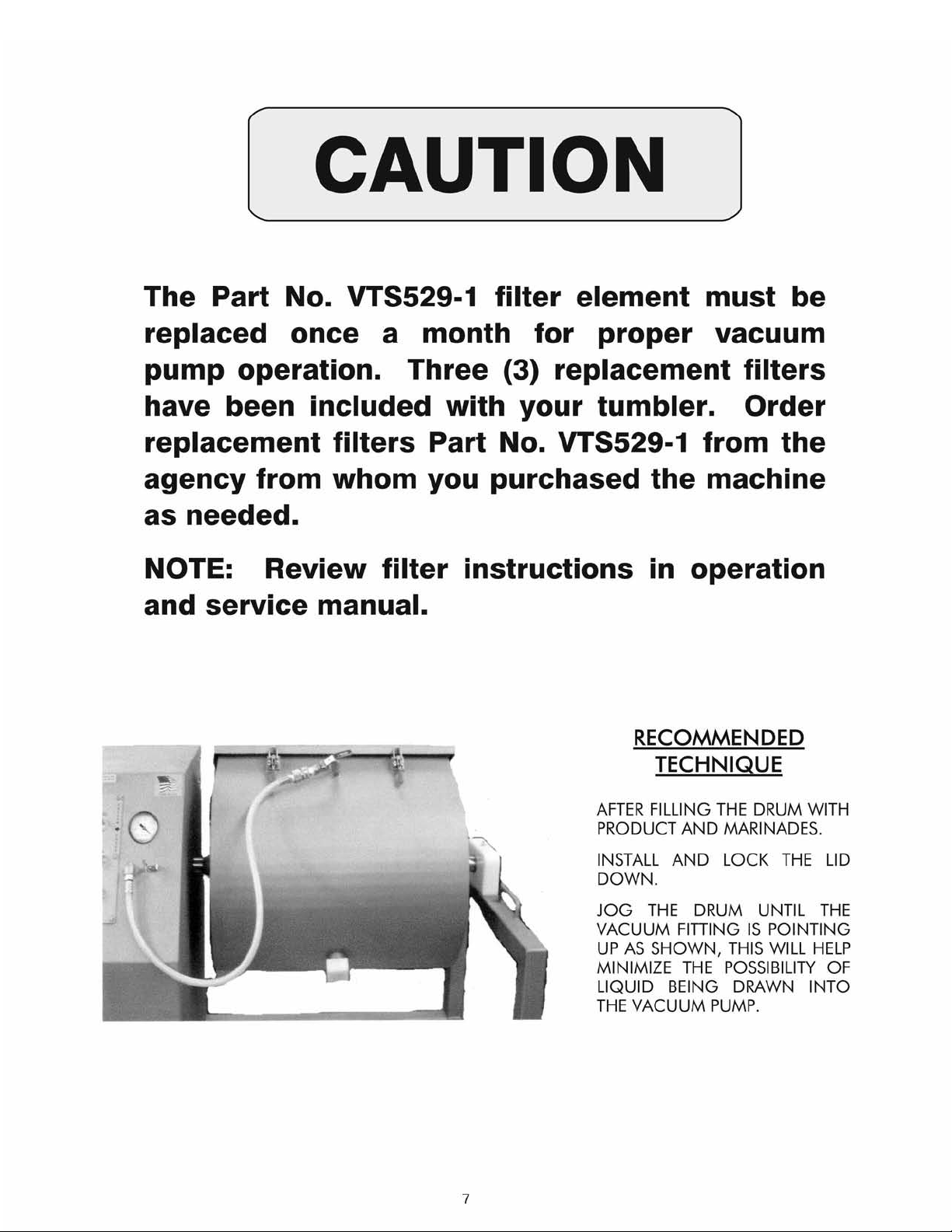

NEVER Operate Vacuum Pump Unless Properly Connected to Tumbler Drum.

ONLY Operate Vacuum Pump in Recommended Vacuum Range (15-20 Inches of Mercury)

NEVER TO EXCEED 20 INCHES Hg.

ONLY Use a Qualified Electrician to Install According to Local Building Codes: Machine MUST

Be Properly Grounded.

ONLY Install on Level, Non-Skid Surface in a Clean, Well-Lighted Work Area Away From

Children and Visitors.

DO NOT Allow Food Particles, Liquids or Any Other Foreign Material to Enter the Vacuum

Pump or Vacuum Hose.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Cleaning or Servicing.

NEVER Leave Machine Unattended While Operating.

PROMPTLY REPLACE Any Worn or Illegible Warning and/or Instruction Labels.

USE ONLY BIRO Parts and Accessories Properly Installed.

FOOD HANDLING TO PREVENT CONTAMINATION

1. ALWAYS wash hands thoroughly with warm soap and water before and after handling raw fish, poultry or

meats.

2. ALWAYS clean and sanitize all utensils and surfaces that have been in contact with raw products.

3. ALWAYS store cold foods at or below 45 deg. F (7.2 deg. C).

2

Page 5

OPERATION

ROTATING DRUM

ONLY Properly Trained Personnel Should Use This Equipment.

ALWAYS Keep Hands Clear of the Rotating Drum and Other Moving Parts.

DO NOT Tamper With, Bypass, Alter, or Modify This Equipment in Any Way From Its Original

Condition.

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Cleaning, Servicing, or When Not In Use.

NEVER Leave Unattended While Operating.

NEVER Turn Drum by Hand, Jog Machine Until Drum is in Desired Position.

ALWAYS Comply With All Regulation for Food Handling, Packaging, and Storage.

NEVER Operate Without All Warning or Instruction Labels Attached.

TO PROCESS PRODUCT AND MACHINE OPERATION

1. Weigh product to be vacuum tumbled.

2. Refer to your ingredient chart for proper amount of marinade seasoning and water.

3. Use jog switch to position drum opening upright.

4. Place product, marinade and water into tumbler drum.

5. Install gasket on drum and place cover on drum and secure with four latches.

6. Connect vacuum hose to valve on drum. Be sure valve handle is in the open position, Parallel with the valve

body.

7. Turn vacuum pump to “ON”. (Vacuum gauge will start indicating a vacuum is being pulled in the drum.) If

needle in vacuum gauge does not indicate vacuum is being pulled, turn “OFF” vacuum pump and

disconnect vacuum hose from drum. Remove drum lid and check that the lid gasket is properly installed and

seated, then repeat this procedure.

8. When vacuum gauge does indicate that a vacuum is being pulled, allow to continue running until gauge

reads between 15 and 20 inches Hg. NEVER TO EXCEED 20" Hg.

9. Close valve handle on drum, Perpendicular to valve body. Turn vacuum pump to “OFF” position. Remove

vacuum hose from valve. Drum contents are now sealed in a vacuum.

10. Program timer to desired tumble time, and press green button to start, drum will start turning.

11. Turn speed control knob to desired RPM.

12. Drum will stop when time runs out.

13. Turn off motor, jog drum until opening is in upright position. NEVER TURN DRUM BY HAND.

14. Turn valve handle to open position Parallel with valve body to release vacuum. Remove drum lid.

15. Remove product from drum.

16. Unplug machine and refer to cleaning instructions.

3

Page 6

CLEANING

ROTATING DRUM

TO AVOID PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Cleaning or Servicing.

ONLY Use Recommended Cleaning Equipment, Materials and Procedures.

NEVER Spray Water or Other Liquid Substances Directly at Motor, Power Switch or any Other

Electrical Components.

ALWAYS Thoroughly Clean Equipment at Least Daily.

DO NOT Use Harsh Chemicals, Scouring Pads or Cleansers. Ordinary Liquid Detergent for

Manual Dish Washing or Pot/Pan Washing Will Not Harm the Machine. Dish Machine

Chemicals Will Cause Brown Stains, as will Chlorine Bleach and Similar Products if Allowed

to Stand in or on the Machine for Any Length of Time.

CLEANING THE BIRO VACUUM TUMBLER:

1. Turn “OFF”, unplug machine from power source, and perform lockout/tagout procedures.

2. The drum, drum lid, and gasket can be removed and washed in utensil sink. Be sure to flush the vacuum

valve on drum with warm soapy water and rinse with clean water thoroughly. The drum, drum lid, and

gasket should be sanitized with an appropriate sanitizer approved by your local Health Dept. All parts should

be air dried before reassembly and storage.

3. The exterior of the tumbler base and drum can be pressure washed with the same type soap solution followed

by a rinse water wiping.

4. If food stains are not removed, use a product such as “Bon Ami” or “Soft Scrub”. Be sure to scrub with the

grain of the Stainless Steel with a soft cloth or sponge.

5. Streaks or water spots can usually be removed with a solution of vinegar and water.

4

Page 7

MAINTENANCE

ROTATING DRUM

TO AVOID SERIOUS PERSONAL INJURY

ALWAYS Turn Off, Unplug From Power Source and Perform Lockout/Tagout Procedure to This

Machine BEFORE Servicing.

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

NEVER Bypass, Alter, or Modify This Equipment in Any Way From Its Original Condition.

PROMPTLY REPLACE Any Worn or Illegible Labels.

USE ONLY GENUINE BIRO Parts and Accessories Properly Installed.

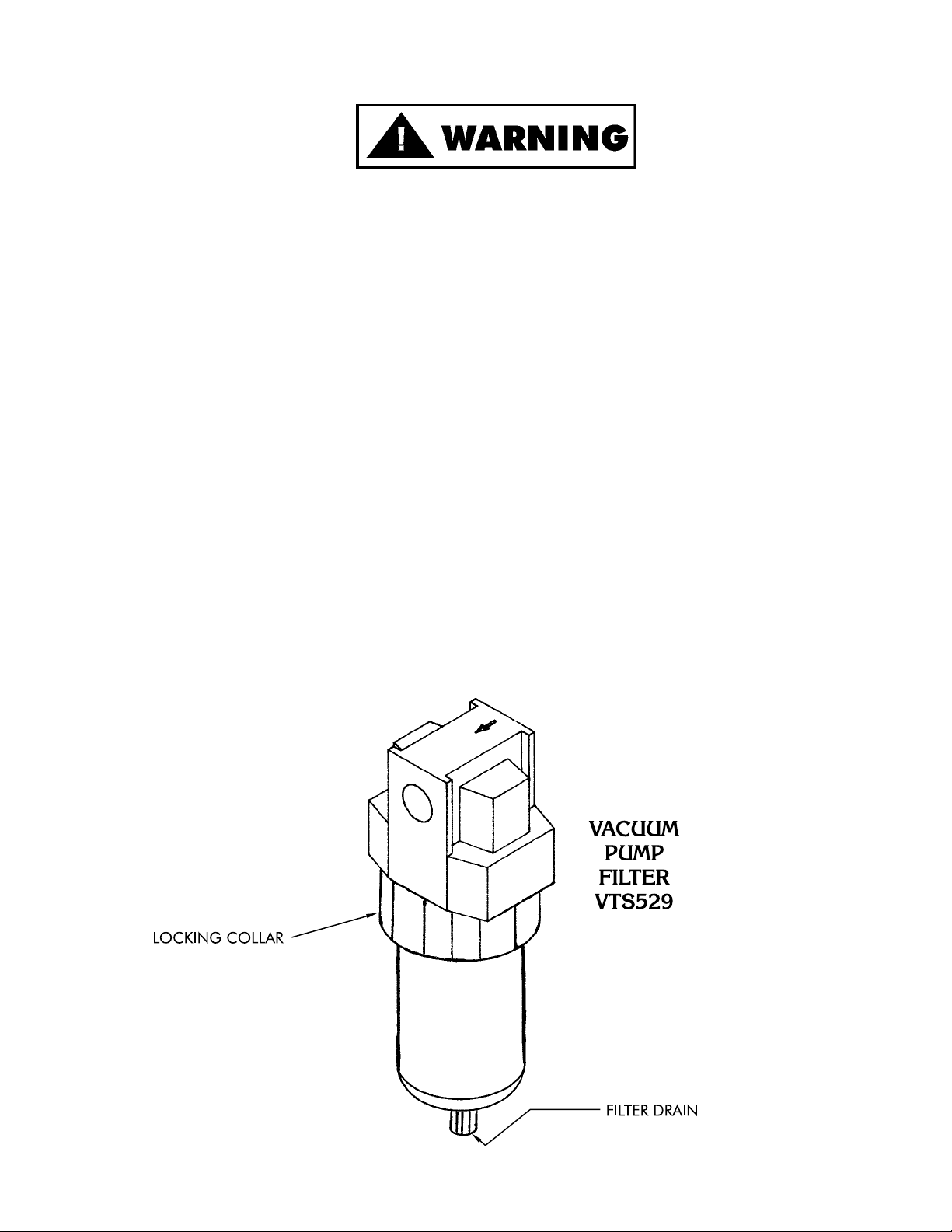

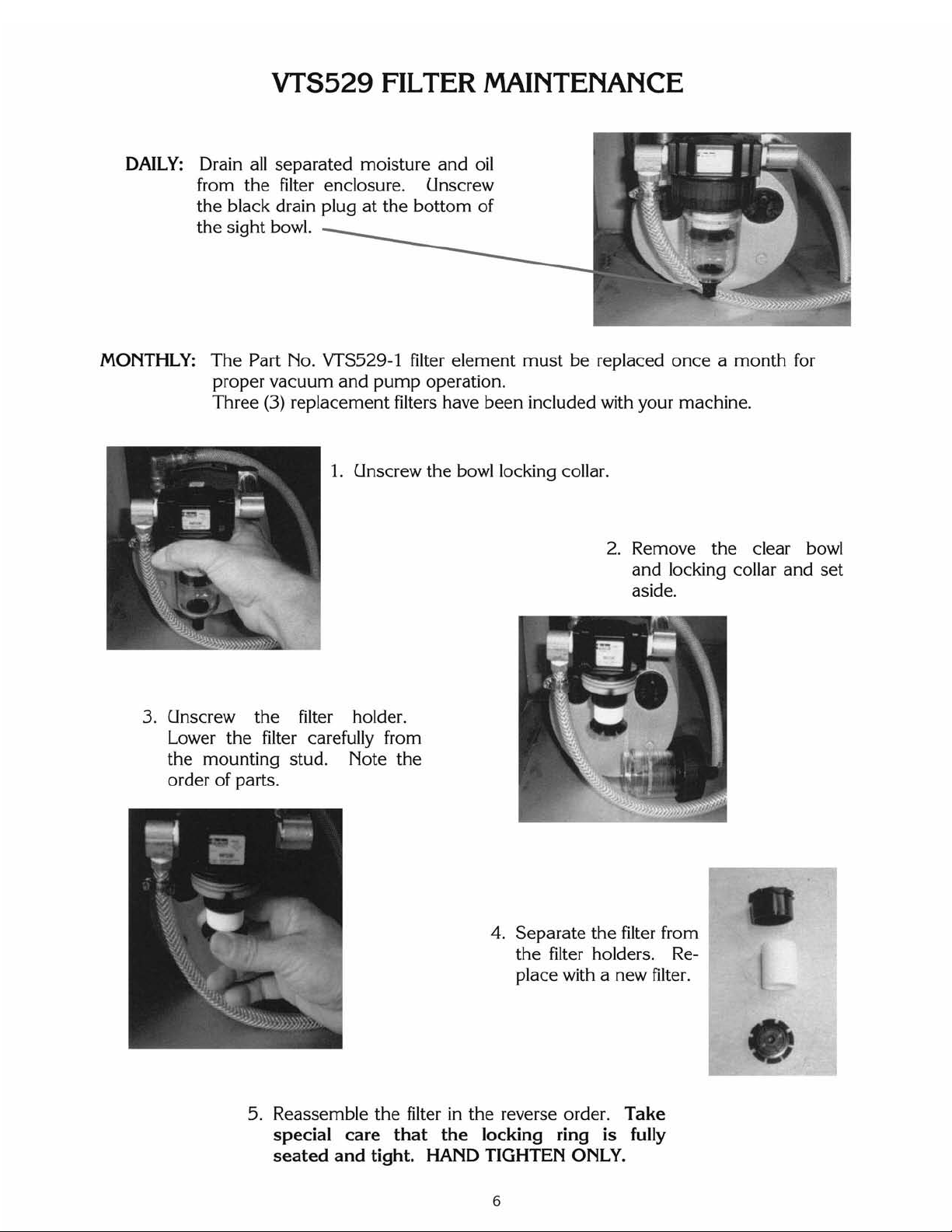

A. PUMP FILTER No. VTS529

1. Check filter daily. Filter must be drained before the separated moisture and oil reaches the bottom of the

lower black baffle. Drain by unscrewing the black drain plug in bottom of sight bowl.

2. The filter element No. VTS529-1 should be removed and cleaned monthly.

a. Unscrew the black locking collar.

b. Remove bowl and locking collar.

c. Unscrew the black baffle at the bottom of the filter.

d. Clean bowl and filter element. Reinstall the filter element. Clean bowl with mild soap and water only. Do

not use detergents, cleansing agents, such as acetone, alcohol, benzene or gasoline, which are damaging

to plastic.

e. Lubricate bowl lip to assist initial sealing. Use only mineral based oils or grease. Do not use synthetic oils

or silicones.

5

Page 8

Page 9

Page 10

VACUUM PUMP MAINTENANCE

WARNING: MAKE SURE THE ELECTRIC MOTOR IS PROPERLY GROUNDED AND THE WIRING IS DONE BY

A QUALIFIED ELECTRICIAN FAMILIAR WITH NEMA MG2 SAFETY STANDARDS, NATIONAL ELECTRICAL

CODE AND ALL LOCAL SAFETY CODES.

WARNING: THE MOTOR IS THERMALLY PROTECTED AND CAN AUTOMATICALLY RESTART WHEN THE

OVERLOAD RESETS. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING. PERSONAL

INJURY COULD BE THE RESULT.

WARNING: DO NOT USE KEROSENE OR OTHER COMBUSTIBLE SOLVENTS TO FLUSH UNIT. USE ONLY

GAST BRAND AH255 FLUSHING SOLVENT OR EQUIVALENT.

1. CONSTRUCTION: The end plate, body, rotor and all mounting brackets are cast iron. Any moisture that

accumulates in the pump will tend to corrode the interior, especially if it stands idle. The muffler box, on the

front of the unit, is made of aluminum. The vanes are made of hard carbon and are precision ground. They

should last many thousand hours depending on degree of vacuum at which the pump is run.

2. STARTING: CAUTION: NEVER LUBRICATE THIS OILLESS AIR PUMP. The carbon vanes and grease

packed motor bearings require no oil. If the motor fails to start or slows down when under load, shut the unit

off and unplug. Check that the supply voltage agrees with the motor post terminals and motor data name

plate. If the pump is extremely cold, allow it to warm to room temperature before starting.

3. FLUSHING: Should excessive dirt, foreign particles, moisture, or oil are permitted to enter the pump the

vanes will act sluggish or even break. Flushing the pump should remove these materials. There are two

options for performing this operation. Option 1: You will need two pipe nipples at least 4" long with

3

8

" NPT

on one end. 1) Remove the filter elements from the front of the muffler box and screw the nipples in through

the same holes. 2) With the pump running allow about 2 tbsp. of flushing solvent to be ingested into the

vacuum side of the unit. CAUTION: WEAR EYE PROTECTION AND FLUSH IN A WELL VENTILATED

AREA. Repeat the flushing procedure. If it does not remedy the situation, remove the end plate for further

examination. Option 2: Remove the filter elements from the front of the muffler box and carefully remove

the five bolts that hold the muffler box in place (be careful not to damage the gaskets and it may be

necessary to replace them). Tap the box with a small hammer to break it loose. DO NOT PRY WITH A

SCREWDRIVER as the gasket will be damaged. This will allow access to the intake and exhaust ports.

4. DISASSEMBLY: If flushing does not eliminate the problem, remove the six bolts holding the end plate to the

body. Now remove the end plate and the four vanes (do not remove the rotor or loosen any electric motor

through bolts). The vanes could be worn or could require further cleaning. The top clearance (between the

rotor and body) may be adjusted by: 1) loosen body bolts, 2) lightly tap on the pump body and turn the rotor

while setting this clearance to assure all points on the rotor clear the body.

REASONS FOR PROBLEM

LOW HIGH PUMP MOTOR

VAC. PRESS. VAC. PRESS. OVERHEATING OVERLOAD

Filter dirty X X at pump X X

Muffler dirty at pump X X

Vacuum line collapsed X at pump X X

Relief valve set too high X X X X

Relief valve set too low X X

Plugged vacuum line X X at pump at pump X X

Vanes sticking X X

Running at too high RPM X X X X

Vanes worn (replace) X X

Shaft seal worn (replace) X X

Dust or offset powder in pump X X X X

Motor not wired correctly X X X

8

Page 11

VTS1034-1

3

4

HP VACUUM PUMP

9

1 VTS-AK518 Pump body 1 req’d.

+2 VTS-AK513 Vane 4 req’d.

3 VTS-AK511 Pump shroud 1 req’d.

4 VTS-AK514 Pump end plate 1 req’d.

+5 VTS-AK522 Gasket 1 req’d.

6 VTS-AK520 Muffler box 1 req’d.

+7 VTS-AK473 O-ring 2 req’d.

+8 VTS-AK524 Felt 2 req’d.

+9 VTS-AK510 End cap 2 req’d.

10 VTS-AK526 End cap assembly, 8 & 9 2 req’d.

11 VTS-AK512 Rotor 1 req’d.

12 VTS-AD126 Tolerance ring 1 req'd.

NOT SHOWN

+ VTS1034-1K Service kit (consists of 2, 5, 7, 8, 9) –

K479

11 & 12 Should not be replaced in field

Page 12

LUBRICATION FOR GROVE GEAR REDUCER

1. Factory Filling

The speed reducers are oil filled at the factory to the proper level for the standard mounting position. The oil

level should be checked and adjusted (if necessary) prior to operation, using the oil level plug provided and

while the unit is oriented in its operating position.

2. Oil Changing

WHEN CHANGING OIL FOR ANY REASON,

DO NOT MIX DIFFERENT OILS IN THE REDUCER.

OILS SHOULD BE COMPATIBLE WITH

VITON®SEAL MATERIAL.

Therefore, when changing to a different oil, it is recommended that the housing be completely drained and

thoroughly flushed with a light flushing oil prior to refilling with the appropriate lubricant. The oil level should

be rechecked after a short period of operation and adjusted, if necessary.

OIL SHOULD BE CHANGED MORE OFTEN IF THE

REDUCER IS USED IN A SEVERE ENVIRONMENT

(i.e., DUSTY, HUMID)

A. Initial Oil Change

The oil in a new speed reducer should be changed at the end of 250 hours of operation. (30 days for 8

hour per day service, 15 days for 16 hour service, 10 days for 24 hour service.)

All standard reducers ordered from the factory are filled with lubricant to operate within a 30° to 100°F

ambient temperature range.

B. Subsequent Oil Changes

Under normal conditions, after the initial oil change, the oil should be changed after every 2500 hours of

operation, or every six months, whichever occurs first. Under severe conditions (rapid temperature

changes, moist, dirty or corrosive environment) it may be necessary to change oil at intervals of one to

three months. Periodic examination of oil samples taken from the unit will help establish the appropriate

interval.

C. Synthetic Oils

Synthetic lubricants can be advantageous over mineral oils in that they generally are more stable, have a

longer life, and operate over a wider temperature range. These oils are appropriate for any application but

are especially useful when units are subjected to low start-up temperatures or high operating

temperatures. Use of synthetics can cause problems if they are not compatible with the seals or the

conventional lubricants they replace. For continuous duty at normal ambient temperatures (-10°F to

105°F) we recommend the use of Mobile SHC 634

which is compatible with the standard compounded oil

shipped in our product and the Viton® seal material used through size 252.

3. Overfilling or Underfilling

If a speed reducer is overfilled with oil, the energy used in churning the excessive oil can result in overheating.

If this occurs, shut down the drive, remove the oil level plug and allow oil to drain until oil ceases to drain

from the level hole, reinstall the oil level plug and restart the drive. if the speed reducer is underfilled, the

resultant friction can cause overheating and possible damage. If this occurs, fill the speed reducer to the oil

level plug hole and check the gearing for excessive wear. NOTE: Oil capacity is 1¾ pints

.

4. Oil Seals

Although the speed reducer uses high quality oil seals and precision ground shafts to provide a superior seal

contact surface, it is possible that circumstances beyond the speed reducer's control can cause oil seal

leakage (damage during shipment or installation, etc.). When replacing a shaft oil seal, using the following

suggestions will help to insure leak-free operation and long seal life.

A. When installing a new seal, cover the keyway and any other surface discontinuity with smooth tape to

protect the seal lip from being damaged.

B. A sealant should be used between the O.D. of the seal and the I.D. of the bore into which the seal is

installed. The seal bore should also be free of any burrs, nicks, or scratches.

C. Be sure that the seal is not cocked in the seal bore. The outer face of the seal should be flush with the

surface into which it is mounted.

10

Page 13

VTS512-1 GROVE GEAR REDUCER

LUBRICATION AND MAINTENANCE

AFTER SERIAL No. VT3

VIEW IS FROM OPPOSITE END OF DRUM

LUBRICANTS FOR VTS512-1 GROVE GEAR WORM REDUCER

The precision-made gears and bearings in Grove Gear Speed Reducers require high-grade lubricants of the proper viscosity to maintain trouble-free performance. For best results, use lubricants

on the following chart for worm gear reducers.

Manufacturer 30° to 100°F Ambient Temperature

AGMA Compounded No. 7

50° to 125°F Ambient Temperature

AGMA Compounded No. 8

Amoco Oil Co. Worm Gear Oil Cylinder Oil #680

Chevron USA, Inc. Cylinder Oil #460X Cylinder Oil #680X

Exxon Co. USA Cylesstic TK-460 Cylesstic TK-680

Gulf Oil Co. Senate 460 Senate 680D

Mobile Oil Corp. 600 W Super Cylinder Extra Hecla Super

Shell Oil Co. Valvata Oil J460 Valvata Oil J680

Sun Oil Co. Gear Oil 7C Gear Oil 8C

Texaco Honor Cylinder Oil 650T Cylinder Oil

Union Oil Co. of CA Steaval A Worm Gear Lube 140

Standard factory-installed lubricant is Mobile Oil Corp. 600 W Super Cylinder Oil (AGMA7).

Some gear lubricants contain E.P. additives that can be corrosive to gear bronze material. Avoid

lubricants that are compounded with sulfur and/or chlorine.

11

Page 14

TO PROGRAM TIMER

Part No. VTS511

Key Sequence Display

Press SET Key SEt1 prompt is displayed

Press SET Key Setpoint 1 (tumble time) is displayed with

flashing digit indicating that setpoint can be

changed.

Change using Arrow Keys New setpoint value is displayed.

Press ENT Key New setpoint entered into memory.

Press SET Key SEt2 prompt is displayed.

Press SET Key Setpoint 2 (relax time) is displayed with

flashing digit indicating that setpoint can be

changed.

Change using Arrow Keys New setpoint value is displayed.

Press ENT Key New setpoint entered into memory.

Press SET Key rEPT prompt is displayed.

Press SET Key Cycle repeat is displayed with flashing digit

indicating that setpoint can be changed.

Change using Arrow Keys New setpoint value is displayed

Press ENT Key New setpoint entered into memory.

Press ENT Key Press RST key

Timing cycle is entered into memory

NOTE: The ENT must be pressed after any variable data has been entered.

EXAMPLES SETTINGS:

Tumble for 15 minutes

Relax for 10 minutes

Repeat 3 times

SEt1 = 15.00

SEt2 = 10.00

REPt = 0003

Total tumble time 45.00 minutes

Total relax time 30.00 minutes

Tumble for 45 minutes

No relax time

Repeat 1 time

SEt1 = 45.00

SEt2 = 00.00

REPt = 0001

Total tumble time 45.00 minutes

12

Page 15

TIMER PROGRAM NOTES

13

Page 16

VTS1053

PHOTOELECTRIC EYE

OPERATING INSTRUCTIONS

Starting Operation

1. Open the cover and guard of the sensor; make sure that no dirt enters the device.

2. Select switching function:

L.ON: Light-switching if light received, output (Q) switches.

D.ON; Dark-switching if light interrupted, output (Q) switches.

WT 260-R and -S only: Light-switching: Relay 1x u, separated galvanically.

3. With following connectors only:

Connect and secure cable receptacle tension-free

Only in versions with terminal clamp area:

Loosen ½" PF screwed connection, remove sealing plugs.

Cable outlets downward or to the back. Pass the dead power supply line through and connect the sensor

according to connection diagram.

4. Close the protective cap.

Mount the sensor using the mounting holes and align it roughly.

Connect the operating voltage to the sensor (see Type imprint).

Check scanning distance, and compare with characteristic in diagram (x = scanning distance, y = operating

reserve).

Reflectance: 6% = black, 18% = gray, 90% = white (based on standard white to DIN 5033).

Aligning light reception:

Position the object. Align the WT 260 with the object. Turn the knob >SENS, <to max. When the light

reception is optimal, the switching output switches into the state set in.

If no or too little light is received, realign the photoelectric proximity switch with the object and check the

application conditions.

5. Setting the sensitivity (SENS):

Remove the object. The switching output switches (Pos. A = Max).

When there is interference from the background:

Turn the knob (turning range 270º) in the direction of min. (e.g. position A). Set the rotary knob to min.

Position the object. Turn the knob in the direction of max. until the switching output switches (e.g.

position B).

If position B < position A:

Select the middle setting (e.g. position C). Check overall operation. If operation is OK, setting is

completed. IF operation is not OK, check the application conditions and realign.

If position A < position B:

Background influence is excessive. Check the application conditions and realign. Check sealing faces,

seals, and screwed joints, then replace and screw down cover.

Maintenance

SICK photoelectric switches do not require any maintenance.

We recommend that you clean the optical interfaces and check the screw connections and plug-in

connections at regular intervals.

14

See #5, Page 15.

See #1, Page 15.

Page 17

VTS1053

Photoelectric Eye Operating Instructions

15

This tumbler contains a photo sensor

light beam as a safety barrier. If a

person or object blocks the beam, the

machine will STOP.

Clear the photo sensor beam & press

the start button to resume operation.

Page 18

Page 19

17

Page 20

DRUM ASSEMBLY

18

Item

No. Description

HHS025S Hex head screw ¼-20´½SS

ST97 Drain cap wrench

VTS1081-1 Drum cover handle

VTS1083-8 Lid latch

VTS1083-9 Latch keeper plate

VTS361 Drain tube

VTS363-1 Drain cap

VTS364 Drive shaft key

VTS562-3 Drum weldment

VTS566-5 Drum cover

VTS568-1 Drum cover gasket

VTS569-1 Mounting block

VTS7152 Ball valve S.S.

VTS7194 Quick coupling S.S.

Page 21

Page 22

20

Item

No. Description

VTS1034-1 Vacuum pump – ¾ HP

VTS1103 Reducer bushing ½

´

3

8

– S.S.

VTS1112 Shim washer .125 Thk

´

.875 ID

´

1.375 OD

VTS1113 Shim washer .093 Thk

´

.875 ID

´

1.375 OD

VTS1114 Male hose barb

3

8

hose

´

½ NPT

VTS529 Filter (06F21BC)

VTS529-1 Filter element

VTS585 Elbow, 90 degree street,

3

8

", brass

VTS586 Nipple, 3 inch,

3

8

pipe, brass

VTS587 Nipple, 2 inch,

3

8

pipe, brass

VTS591 Nipple 1

3

8

´

3

8

pipe – brass

VTS592 Elbo – 90º

´

3

8

pipe – brass

Item

No. Description

VTS7002 Vacuum gauge

VTS7117 Tee barb – plastic

3

8

´

3

8

´

3

8

VTS7118 Straight barb – brass ¼ FPT

´

3

8

VTS7132 Washer – a luminum 1

3

16

O.D.

´

11

16

I.D.

VTS7155-9 Vacuum hose – 9 inch

VTS7155-10 Vacuum hose – 10 inch

VTS7155-15 Vacuum hose – 15 inch – Nylobrade

VTS7155-19 Vacuum hose – 19 inch

VTS7156 Hose clamp

VTS7159 90 degree elbow – S.S.,

3

8

FPT

´

3

8

FPT

VTS7214 Hose barb – brass

3

8

MPT

´

3

8

Page 23

21

Item

No. Description

VTS1036-2 Drum Weldment

VTS1049 Control Box Cover

VTS7002 Vacuum gauge – glycerin filled

VTS7116 90º elbow

3

8

MPT

´

3

8

FPT – SS

VTS7118 Straight barb ¼ FPT

´

3

8

– brass

VTS7132 Washer – aluminum

1

3

16

O.D.

´

11

16

I.D.

´

1

16

TK

VTS7152 Ball valve – SS

VTS7155-1 Hose w/

3

8

crimped fitting – 38" long

Item

No. Description

VTS7155-9 Vacuum hose – 9 inch

VTS7158 Hose barb

3

8

MPT

´

3

8

´

1

3

8

barb lg

VTS7159 90 degree elbow – S.S.,

3

8

FPT

´

3

8

FPT

VTS7160 90º street ¼ MPT

´

¼ FPT – brass

VTS7172 Vacuum gauge label

VTS7193-B Quick coupler BST-3

VTS7194-B Nipple – quick coupler BST-N3m

VTS7214 Hose barb

3

8

MPT

´

1 barb – brass

Page 24

COMPONENT COVER AND REAR DOOR

22

Item

No. Description

42MC-Y25B7 Pop rivet – aluminum

1

8

´

¼

HHS035S Hex head screw ¼-20

´

5

8

S.S.

PC159 Strain relief fitting – ½ dia.

PC161 Strain relief fitting

7

8

dia

VTS1048 Rear door

Item

No. Description

VTS1053 Photoelectric eye w/bracket

VTS1075 Sight window – 2" dia.

VT460S Model and S/N plate

VT464S Filter label

VTS580 Component cover (NSS)

VTS1053 Photoelectric eye w/bracket only

VTS1053-1 Photoelectric eye assembly complete - 4 wires

VTS1053-2 Photoelectric eye assembly complete - 5 wires

used w/

used w/VTS511 timer

VT492S timer

VTS1075 Sight window - 2” dia.

VT460S Model and S/N plate

VT464S Filter label

VTS580 Component cover (NSS)

Page 25

— NOTES —

23

Page 26

120 VAC WIRING DIAGRAM

24

Page 27

220 VAC WIRING DIAGRAM

25

Page 28

RECOMMENDED

VTS-500 SPARE PARTS

– NOTES –

26

VTS568 Drum cover gasket

VTS363-1 Drain cap

VTS529 Vacuum pump filter

VTS7112 Locking knob

VTS511 Timer

VTS1053 Photoelectric eye

VTS529-1 Filter elements

Page 29

OPERATOR’S SIGNATURE PAGE

WARNING

READ AND UNDERSTAND THIS ENTIRE

MANUAL BEFORE SIGNING BELOW

MY SIGNATURE ATTESTS THAT I HAVE COMPLETELY READ AND UNDERSTAND THIS MANUAL.

I REALIZE THAT THIS MACHINE, IF OPERATED CARELESSLY, CAN CAUSE SERIOUS INJURY TO

MYSELF AND OTHERS.

NAME (PRINT) SIGNATURE

SUPERVISOR’S

INITIALS

DATE

27

Page 30

LIMITED WARRANTY:

WARRANTY: The Biro Manufacturing Company warrants that the BIRO Vacuum Tumbler will be

free from defects in material and workmanship under normal use and with recommended service.

BIRO will replace defective parts, which are covered by this limited warranty, provided that the defective parts are authorized for return, shipping charges prepaid, to a designated factory for inspection and/or testing.

DURATION OF WARRANTY: The warranty period for all parts covered by this limited warranty is

one (1) year from installation/demonstration as advised on the returned warranty registration card,

or eighteen (18) months starting from original factory shipping date, whichever occurs first, except

as noted below.

PARTS NOT COVERED BY WARRANTY: The following are not covered by this limited warranty:

VTS529 vacuum pump inlet filter, VTS568 drum lid gasket. This limited warranty does not apply

to machines sold as used, rebuilt, modified, or altered from the original construction in which the

machine was shipped from the factory. Water contaminated electrical systems and VTS1034-1

Vacuum Pump are not covered under this limited warranty. BIRO is not responsible for electrical

connection of equipment, adjustments to switch components or any other electrical requirements,

which must be performed only by a certified electrician. BIRO is not responsible for service

charges or labor required to replace any part covered by this limited warranty or for any damages

resulting from misuse, abuse, lack of proper or recommended service. Failure to follow drum

loading procedure will result in liquid collecting inside the vacuum pump which voids this warranty.

EXCLUSION OF WARRANTIES AND LIMITATION OF REMEDIES: BIRO gives no warranties

other than those expressly stated in this limited warranty. THE IMPLIED WARRANTY OF MERCHANTABILITY, THE IMPLIED WARRANTY OF FITNESS FOR PROCESSING OF FOOD PRODUCTS, AND ALL OTHER IMPLIED WARRANTIES ARE SPECIFICALLY EXCLUDED. BIRO IS NOT

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, EXPENSES, OR LOSSES. THE

REMEDIES PROVIDED IN THIS BIRO LIMITED WARRANTY ARE PURCHASER’S SOLE AND EXCLUSIVE REMEDIES AGAINST BIRO.

REGISTRATION CARDS: You must sign, date and complete warranty registration card supplied

with each machine. The warranty registration card must be returned to The Biro Manufacturing

Company for proper registration. If no warranty card is returned to BIRO, the warranty period will

begin from the date the machine was originally shipped from the factory.

HOW TO GET SERVICE:

1. Contact the agency from whom you purchased the machine.

2. Consult the yellow pages of the phone directory for the nearest authorized dealer.

3. Or call BIRO Service Department (419) 798-4451, who will put you in contact with the

nearest service agency.

THE BIRO MANUFACTURING COMPANY

1114 Main Street

Marblehead, Ohio 43440-2099

Ph. 419-798-4451

Fax 419-798-9106

E-mail: service@birosaw.com

Web: http://www.birosaw.com

28

ITEM NO.: VTS583-307

Form No. VTS500-3-06-3 COMM

ITEM NO.: VTS583-307

Form No. VTS500-1-09-4 PPD

Loading...

Loading...