Page 1

Sausage Stuffers

Models SS-ES-0026-F, 0026-FT, 0026-FS, 0048-FS, 0048-FT, 0048-F,

0065-F, 0065-FS, 0065-FT, 0095-F, 0095-FS, 0095-FT

Items 45950, 46099, 46098, 45920*, 45869*, 45959*, 45870, 46101*,

46100*, 45951, 46102, 46103*

Instruction Manual

Revised - 12/10/2018

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

*

Page 2

Table of Contents

Model SS-ES-0026-F / Model SS-ES-0026-FT / Model SS-ES-0026-FS

Model SS-ES-0048-FS / Model SS-ES-0048-FT / Model SS-ES-0048-F

Model SS-ES-0065-F / Model SS-ES-0065-FS / Model SS-ES-0065-FT

Model SS-ES-0095-F / Model SS-ES-0095-FS / Model SS-ES-0095-FT

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

-------------------------------------------------------------------------------------------------- 11 - 15

--------------------------------------------------------------------------------------------------- 15 - 17

----------------------------------------------------------------------------------------------- 18 - 23

----------------------------------------------------------------------------------------- 3 - 4

---------------------------------------------------------------------------------------- 4 - 8

------------------------------------------------------------------------------------------- 23 - 25

Page

---------------------------------------------------------------------------------- 9 - 10

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

-------------------------------------------------------------------------------------------------------- 44 - 46

----------------------------------------------------------------------------------------- 26 - 41

------------------------------------------------------------------------------------ 42 - 43

----------------------------------------------------------------------------------------- 47

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

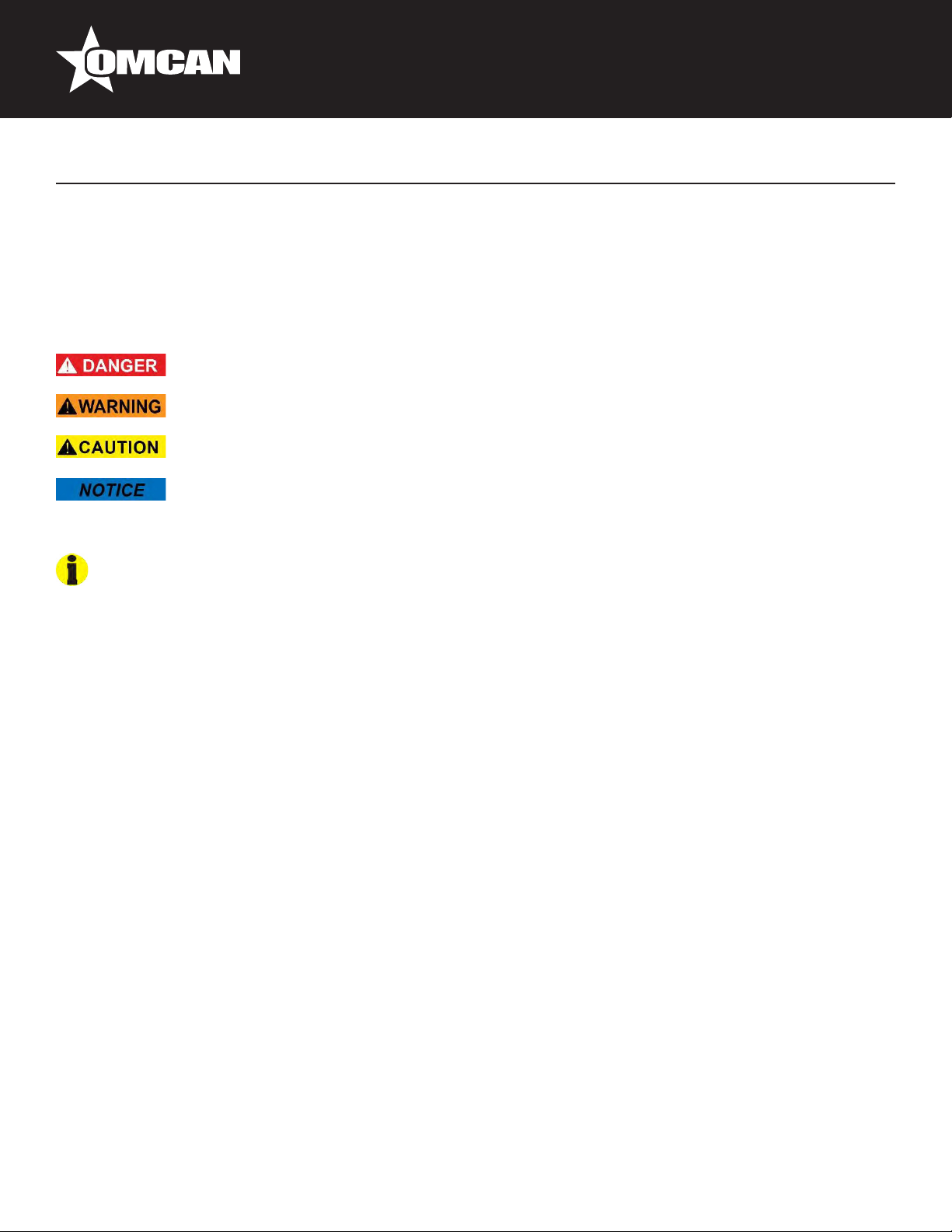

Safety and Warranty

DEFINITION OF WARNINGS AND SIGNAL WORDS

SAFETY WARNINGS AND SIGNAL WORDS USED IN THIS MANUAL

The safety instructions serve as indications and precautionary measures that must be taken into account or

adopted to avoid a dangerous situation.

This is the safety alert symbol. It is used to alert you to personal injury hazards. Obey all safety

4

Page 5

Safety and Warranty

messages that follow this symbol to avoid possible injury or death.

Warnings can be classied according to the severity of the hazardous situation. The classication is based on

an assumption of probability of being exposed to a dangerous situation and what could happen in such a case.

There are four kinds of warnings:

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

Is used to address practices not related to personal injury.

IMPORTANT INFORMATION:

NOTE: provides additional information to clarify or simplify a procedure.

SAFETY WARNINGS ATTACHED TO THE MACHINES

The safety symbols warn of special hazards and are placed in the relevant places on the machine. Check

warning symbols daily:

• Are all security symbols present?

• Are all safety symbols recognizable and readable?

Ensure that the safety plates / adhesives are rmly attached to the machine, are easily readable and are not

erased during the cleaning process. Disconnect the machine and secure the main switch against reconnection

if a warning symbol is missing or no longer recognizable. Do not reconnect the machine until they are in place

and all safety symbols are recognizable. If they become damaged or lost, contact your authorized dealer.

INTENDED USE OF THE MACHINE

In general, the hydraulic piston llers/stuffers are used to prepare sausages made of minced meat. Other

applications include dough or paste of any type that can ow through a nozzle/horn of Ø10mm. Never use

hard masses or pastes that do not ow and could cause dangerous overpressure. The temperature of the

dough to be stuffed should be higher than 2ºC (35ºF).Do not process frozen or semi-frozen doughs. Working

environment conditions: temperature +5 to + 40ºC (+40 to + 100ºF), relative humidity: 20 to 90%. The

maximum operating pressure must not exceed 120 bar.

Any other use would conict with the machine’s characteristics, the manufacturer is not liable for any damages

that may occur as a result of improper use.

5

Page 6

Safety and Warranty

MODIFICATIONS

DISCLAIMER OF LIABILITY

It is not allowed to modify the machine without the prior express authorization of Omcan, neither in its design

nor in its security systems. Omcan will not be liable for damages caused by arbitrary changes. When a user

makes essential modications to the machine, he assumes the manufacturer status. In such a case, he shall

be obliged to take all the measures incumbent on it legally as a manufacturer. The original manufacturer is

therefore released from its responsibility.

GENUINE PARTS

The machine is only allowed to be used with original Omcan accessories and spare parts. Omcan will not be

liable for damages caused by using tools, accessories or spare parts from other manufacturers.

IMPORTANT WARNINGS

Since the WARNINGS, CAUTIONS and INSTRUCTIONS in this manual cannot address all possible conditions

and situations that may arise, the operator MUST ALWAYS exercise common sense and due caution when

using this machine!

• DO NOT DISCARD THIS MANUAL; KEEP IT FOR FUTURE REFERENCE BY ALL USERS AND

MAINTENANCE PERSONNEL. PLEASE THOROUGHLY READ AND FULLY UNDERSTAND ALL THE

INSTRUCTIONS BEFORE SERVICING OR USING THE MACHINE.

• THIS MACHINE HAS MOVING PARTS AND USES VOLTAGES THAT ARE POTENTIALLY HAZARDOUS.

FAILURE TO FOLLOW THE INSTRUCTIONS CONTAINED IN THIS MANUAL COULD RESULT IN

SEVERE, POSSIBLY LIFE-THREATENING, PERSONAL INJURY.

• THIS MACHINE HAS BEEN DESIGNED EXCLUSIVELY FOR MEAT PROCESSING. USE OF THIS

MACHINE FOR ANYTHING OTHER THAN MEAT PROCESSING DOES NOT CONFORM TO ITS

INTENDED FUNCTION, IS STRICTLY PROHIBITED AND SHALL VOID Omcan’s WARRANTY. Omcan

ASSUMES NO RESPONSIBILITY FOR ANY DAMAGE OR INJURY RESULTING FROM IMPROPER USE

OF THIS MACHINE.

• DO NOT ALTER OR MODIFY THE MACHINE’S ORIGINAL DESIGN IN ANY WAY; DOING SO WILL VOID

Omcan’s WARRANTY AND MAY RESULT IN PERSONAL INJURY OR DAMAGE TO THE MACHINE.

• This machine MUST be installed ONLY by a qualied electrician in accordance with the instructions in this

manual and in compliance with all applicable national, regional and local electrical, safety and hygiene

standards and codes. Compliance with said standards and codes is the sole responsibility of the owner and

installer.

• DO NOT open the machine or tamper with its internal parts; none of the internal components requires

adjustment or maintenance by the user.

• DO NOT tamper with the machine’s mechanical or electrical safeguards.

• Use ONLY genuine Omcan parts or accessories and have them installed only by a qualied technician.

Use of unapproved parts and accessories voids Omcan’s warranty and may result in personal injury or

damage to the machine.

• NEVER attempt to repair the machine on your own. Should the machine require service, contact the

authorized dealer from whom you purchased the machine.

• Modications to the machine that raise noise emission levels above 85 dB(A) may result in hearing

6

Page 7

Safety and Warranty

damage. ALWAYS wear appropriate hearing protection.

OPERATING HAZARDS

• PLEASE READ THIS MANUAL CAREFULLY AND FULLY UNDERSTAND ALL THE INSTRUCTIONS

BEFORE USING THE MACHINE.

• DO NOT OPERATE THE MACHINE WITHOUT HAVING FIRST BEEN INSTRUCTED ON ITS USE,

MAINTENANCE AND SAFEGUARDS FROM AN EXPERIENCED OPERATOR.

• ALWAYS keep hands and hair away from moving parts when the machine is in use. There is the danger of

crushing hands, ngers, etc. when closing the lid or when the piston is raised while the lid is not completely

open.

• NEVER wear loose clothing or jewellery that could get caught on moving parts when the machine is in use.

• DO NOT use the machine without wearing the protective gear required by law.

• DO NOT leave the machine unattended while it is switched on or plugged to an electrical outlet. ALWAYS

unplug the machine when it is not in use.

• ALWAYS keep your work area well-lit and free of obstacles.

• ALWAYS keep children, visitors and bystanders away from the machine while it is in use or plugged to an

electrical outlet. NEVER allow children to operate the machine.

• SHOULD THE MACHINE MALFUNCTION, PROMPTLY TURN IT OFF AND NOTIFY THE APPROPRIATE

PERSONNEL.

• ALWAYS follow the hygiene and cleaning instructions in this manual and the local sanitary codes in order to

avoid contaminating the food mixture.

• ALWAYS rmly grip both the transport handle (located at the machine’s base) and the lid handle when

moving the machine. DO NOT tilt the machine too far while it is balanced on its wheels since it is heavy

and there is a risk of personal injury or property damage if it tips over.

ELECTRICAL HAZARDS

• DO NOT TAMPER WITH THE MACHINE’S ELECTRIC SYSTEM. THIS MACHINE MUST BE INSTALLED

ONLY BY A QUALIFIED ELECTRICIAN AND IN COMPLIANCE WITH APPLICABLE NATIONAL,

REGIONAL AND LOCAL ELECTRICAL CODES.

• ALWAYS USE CAUTION WHEN WORKING ON THE MACHINE’S ELECTRICAL SYSTEM SINCE THERE

IS A RISK OF ELECTRIC SHOCK DUE TO:

- DIRECT OR INDIRECT CONTACT WITH ELECTRIC CURRENT.

- IMPROPERLY INSTALLED DEFECTIVE OR DAMAGED ELECTRICAL PARTS.

• BEFORE operating the machine, make sure that all phases are connected properly and that the machine is

properly grounded and/or connected to a circuit leakage breaker and thermal switch. Failure to do so could

result in electric shock!

• DO NOT tamper with the machine’s electrical wiring or components after installation.

• ALWAYS disconnect the machine from the electrical outlet before proceeding with cleaning, maintenance,

or repairs.

• To avoid damaging the power cord and possible injury, keep it away from areas where it may be stepped

on or tripped over. DO NOT pull on the power cord to disconnect the plug from the electrical outlet; always

pull on the plug.

7

Page 8

Safety and Warranty

DISPOSAL

Risk of damage to people and environmental hazards. The machine is composed of different materials.

Observe local regulations on waste disposal. Instruct an authorized waste disposal company to dispose of

waste correctly.

1 YEAR PARTS AND LABOR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

8

Page 9

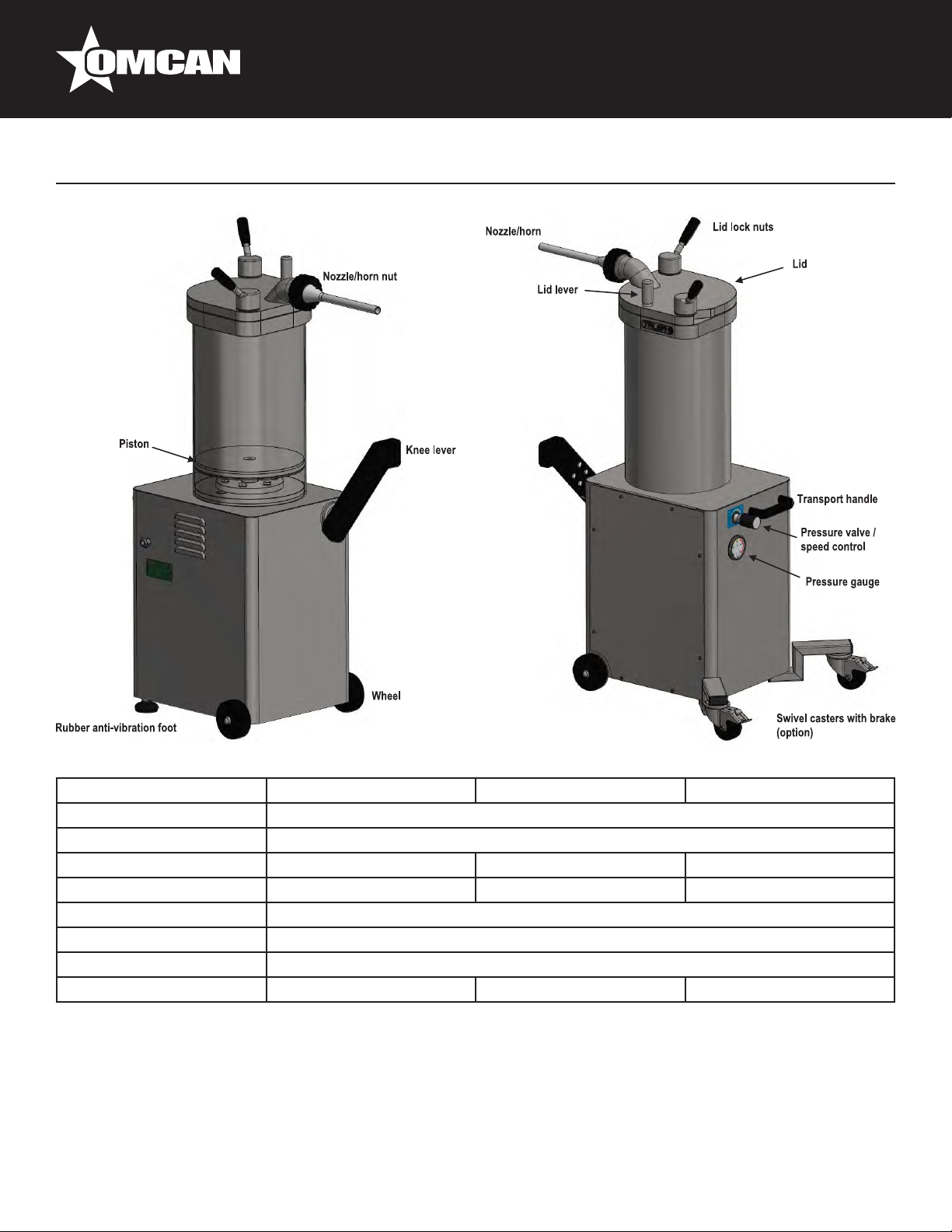

Technical Specications

14.2 L STUFFER

Model SS-ES-0026-F SS-ES-0026-FT SS-ES-0026-FS

Barrel Capacity 14.2 L / 3.7 Gal

Approx. Meat Capacity 26 lbs. / 11 kgs.

Power 1 HP / 0.75 kW 0.75 HP / 0.55 kW 1 HP / 0.75 kW

Electrical 110V / 60Hz / 1 208V / 60Hz / 3 220V / 60Hz / 1

Dimensions 19” x 21” x 49” / 483 x 533 x 1245mm

Weight 265 lbs. / 120 kgs.

Packaging Weight 310 lbs. / 140 kgs.

Item Number 45950 46099 46098

9

Page 10

Technical Specications

25.2 L STUFFER

Model SS-ES-0048-FS SS-ES-0048-FT SS-ES-0048-F

Barrel Capacity 25.2 L / 6.6 Gal

Approx. Meat Capacity 48 lbs. / 20 kgs.

Power 1.75 HP / 1.3 kW 1.5 HP / 1.1 kW 1.75 HP / 1.3 kW

Electrical 110V / 60Hz / 1 208V / 60Hz / 3 220V / 60Hz / 1

Dimensions 21” x 23” x 49” / 533 x 584 x 1245mm

Weight 310 lbs. / 140 kgs.

Packaging Weight 350 lbs. / 160 kgs.

Item Number 45920 45869 45959

35.1 L STUFFER

Model SS-ES-0065-F SS-ES-0065-FS SS-ES-0065-FT

Barrel Capacity 35.1 L / 9.2 Gal

Approx. Meat Capacity 65 lbs. / 28 kgs.

Power 1.75 HP / 1.3 kW 1.5 HP / 1.1 kW

Electrical 110V / 60Hz / 3 220V / 60Hz / 1 220V / 60Hz / 3

Dimensions 21” x 23” x 49” / 533 x 584 x 1245mm

Weight 350 lbs. / 160 kgs.

Packaging Weight 400 lbs. / 180 kgs.

Item Number 45870 46101 46100

51 L STUFFER

Model SS-ES-0095-F SS-ES-0095-FS SS-ES-0095-FT

Barrel Capacity 51 L / 13 Gal

Approx. Meat Capacity 95 lbs. / 40 kgs.

Power 2.5 HP / 1.87 kW 2.5 HP / 1.9 kW

Electrical 110V / 60Hz / 1 220V / 60Hz / 1 220V / 60Hz / 3

Dimensions 26” x 25” x 64” / 660 x 635 x 1626mm

Weight 580 lbs. / 260 kgs.

Packaging Weight 660 lbs. / 300 kgs.

Item Number 45951 46102 46103

10

Page 11

STORAGE, DELIVERY AND UNPACKING

• ALWAYS keep the machine upright, even while in its packaging.

• NEVER stack machines even if they are in their original packaging.

• NEVER place heavy objects on top of the machines or its packaging.

The machine is delivered on a pallet protected either by cardboard

packaging (F14/25/35) or wooden crate (F50). We use only recyclable

packaging and ask that you please recycle these materials.

Remove the packaging and thoroughly inspect the machine upon delivery.

Should you note any damage to the machine, retain all packing materials

and promptly notify the carrier. The transport company is solely responsible

for any damage to the machine during transit. If the machine is found to

be in satisfactory condition, follow the instructions in POSITIONING THE

MACHINE in order to safely convey it to a suitable work area. Your needs

will determine the most appropriate location for the machine.

Installation

PLACEMENT

ELECTRICAL HAZARD!

• The electrical installation of the enclosure must provide a thermal protection device (MCB) and leakage

(differential), conforming to the specications of each machine. A qualied electrician must adjust these

safety devices to the specications of your particular machine.

• Do not use the machine in wet locations.

• Do not lift the machine more than necessary, it could collapse.

• In order to move the F50 model, two people are required.

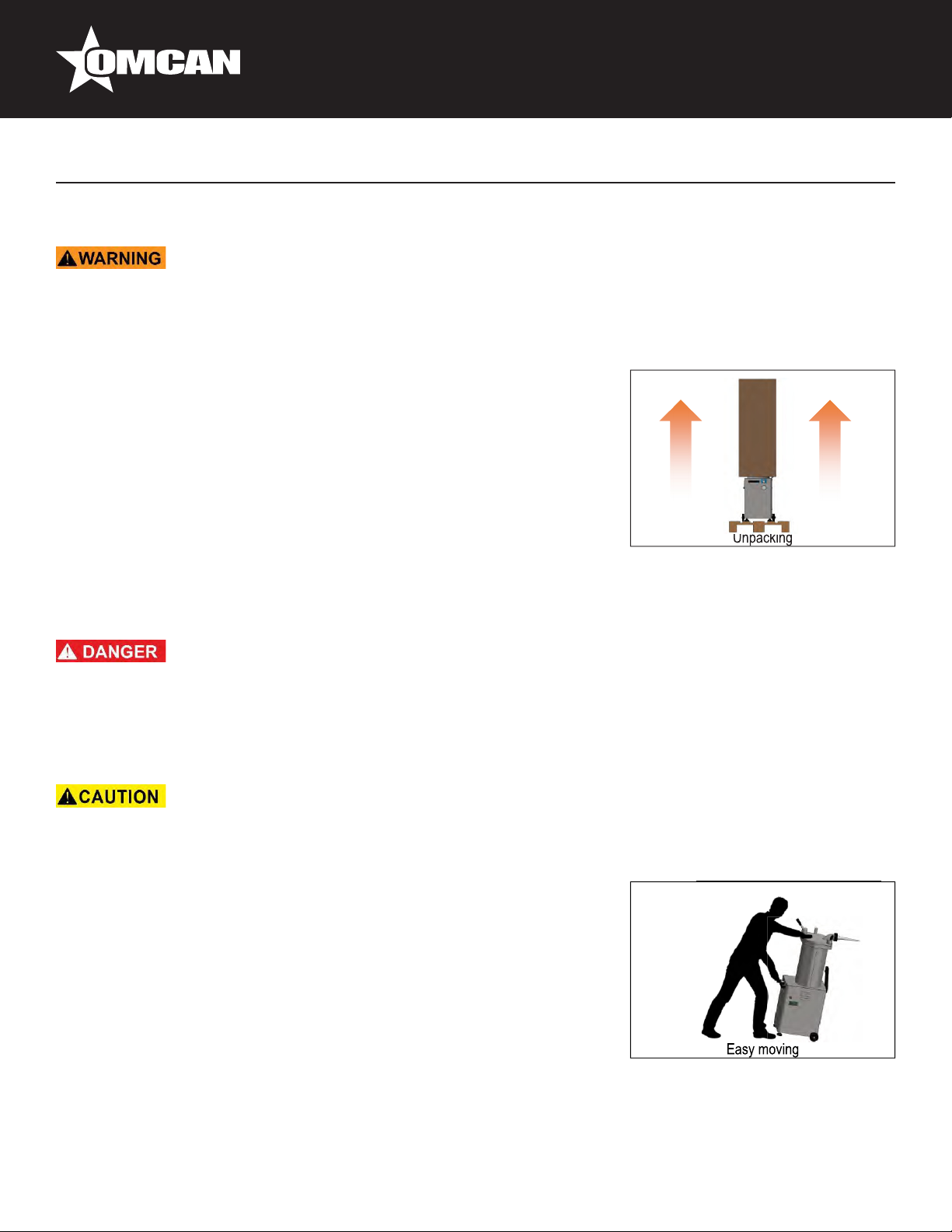

The machine should be placed in the most appropriate place, according

to the demands and needs of use. For a good, prolonged operation, the

machine should be placed in a sufciently ventilated area, avoiding lack

of air circulation. The workplace should be clean, free from obstacles and

have a horizontal and anti-slip surface. Observe a passage area around

the machine of 1 meter to proceed to use, clean and maintenance thereof.

To move the machine to the desired location:

• ALWAYS rmly hold the carrying handle and the lid handle to move the

machine. NEVER use the knee lever to move the machine!

• Tilt the machine so that it is balanced on its wheels and may be rolled

into place.

• ALWAYS place the machine on a at, level surface. Should the machine wobble, adjust the anti-vibration

legs until it is perfectly level and stable.

11

Page 12

Installation

• The machine should be positioned so that the power plug is easily accessible to the operator.

Do not store the machine in cold places (i.e. refrigerated storage house). Persistent low temperatures

can cause damages in the machine.

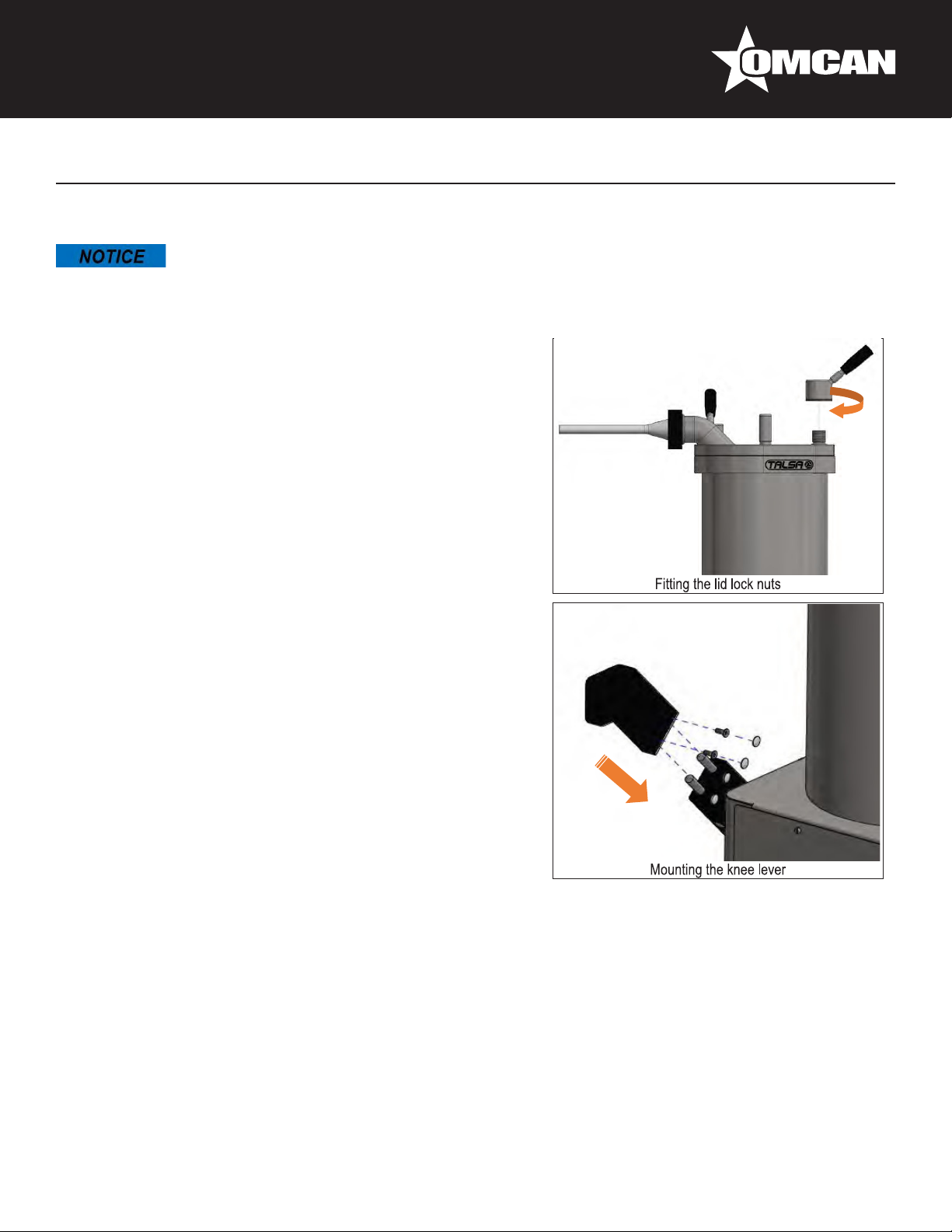

INSTALLATION OF THE LID LOCK NUTS AND

KNEE LEVER

Before using the stuffer it is necessary to assemble the lid lock

nuts and knee lever delivered with the machine.

• Screw the lid lock nuts on the threads projecting from the

lid. Do not overtighten, as this would hinder the opening and

closing of the lid.

• Place the knee lever at the anchor point.

• Attach the two screws with Allen wrench supplied with the

machine. Check the operation of the knee lever. It should

move with little effort and return to the center position when

released (in the lifting drive the piston).

• Place the two gray caps on the heads of the screws.

Knee lever position and action of the piston:

• When you push the toggle to the left, the piston must rise.

The knee lever automatically returns to the center position

when no pressure is applied thereon.

• When pushing the lever rightward the piston must descend.

In this position, the lever is automatically locked until

the piston reaches the lower position. The piston can be

stopped at any time by pushing the lever to the center

position.

It is possible to reverse the direction of drive knee lever / piston.

Consult your dealer where you purchased the stuffer.

12

Page 13

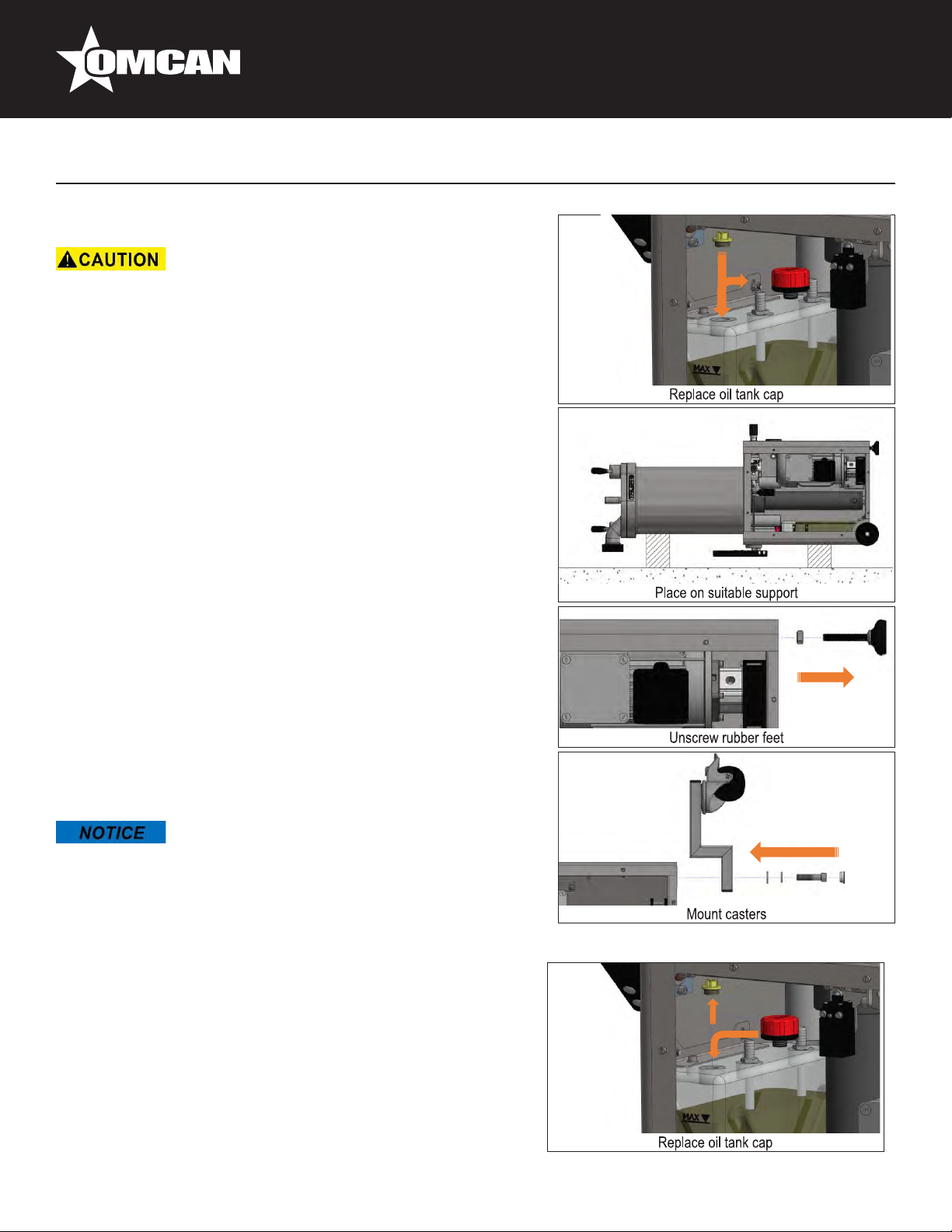

INSTALLING CASTERS (OPTIONAL)

• To lay down and lift the machine at least two people are

needed.

• ALWAYS secure the position of the machine setting the brakes

on the castors (optional).

Optionally the stuffer is provided with two pivoting wheels with

brakes that facilitate the movement of the stuffer. To install these

wheels follow the instructions below:

• Unscrew and remove the screws that hold the panel to the

machine base, then withdraw it.

• Remove the evaporator cap (red) and replace it with the

transport cap (yellow). This cap closes the oil reservoir

hermetically, avoiding leakage of hydraulic oil for the following

steps.

• Lay the machine to the side of the knee lever, on a suitable

support to prevent damaging the lever. To lay down and lift the

machine at least two people are needed.

• Remove the anti-vibratory rubber feet unscrewing them from

the machine body.

• Attach the extensions and casters with the screw and washers

provided.

• Lift the machine (at least two people are required).

• Very important! Before operating the machine, replace the

evaporator cap (red) in the oil tank.

• Check the operation of the machine and close machine body

cover.

Installation

Before putting the machine into operation, make sure to

replace the transport cap (yellow) with the cap of the oil tank

(red). Operating the machine with the yellow transport cap

will damage the hydraulic system!

TRANSPORT CAP OF THE OIL TANK (MACHINES

SENT LYING)

Machines sent lying on a pallet (air shipment), have a transport

oil cap (yellow) closing the oil tank hermetically, to prevent

oil leakage during transport. Before operating the machine,

replace the transport oil cap by the depressurized oil cap (red)

delivered with the machine.

• Unscrew and remove the screws that hold the panel to the

13

Page 14

Installation

machine base, then withdraw it.

• On the oil reservoir, replace the transport oil cap (yellow) by the depressurized oil cap (red).

• Check the oil level in the tank. It must be between the MAX and MIN marks on the tank. If necessary, add

enough oil to bring the level up to the maximum mark. Do not ll the tank completely, as a certain volume of

air for expansion of the oil is necessary.

• Replace the panel at the end of operations.

• Before putting the machine into operation, make sure to replace the transport cap (yellow) with the cap of

the oil tank (red). Operating the machine with the yellow transport cap will damage the hydraulic system!

• The llers are supplied from factory with the appropriate hydraulic oil level. Therefore, it is usually not

necessary to rell it. In the exceptional event that the new machine is delivered with a lack of hydraulic oil,

DO NOT connect it. Proceed to ll it before operation.

CONNECTING TO THE POWER SOURCE

ELECTRICAL HAZARD!

• This machine must be installed only by a qualied technician and in compliance with applicable national,

regional and local electrical codes.

• The machine MUST remain disconnected from the power supply throughout this procedure.

CHECK THE WIRING BEFORE CONNECTING THE MACHINE! Call a qualied electrician if the electrical

specications do not correspond with your power source: the wiring in the electrical cord is normally assigned

as follows: PHASE(S): Black, Brown or Gray. NEUTRAL: Blue (or White in some non CE/CEN/UE countries).

GROUND: Bi-coloured Yellow / Green (or Green in some non CE/CEN/UE countries).

• Ensure that the electrical characteristics of the stuffer, detailed in the plate xed to the machine (voltage,

frequency, Hz, phases), coincide with those of the mains. A tolerance of ± 10% in voltage and frequency ±

2% is accepted.

• If they match those of the network, have a qualied electrician connect a plug to the power cord.

• If the voltage of the machine does not match the network, and if dual voltage three-phase motor, it

appropriate to adjust the voltage thereof, as described in Voltage change and then have a qualied

electrician connect a plug to the power cord.

• It is mandatory the use of a standard plug for connecting the machine.

Once connected machine check the proper operation of the stuffer: push the brace rmly to the left (rising

piston).

• If the phases are correctly connected, the piston will rise and lower correctly when operating the knee lever.

• If the phases are not well connected, the pump will operate in reverse, the motor will make noise but

the piston will not move. Stop the machine immediately and switch it from the mains. Have a qualied

technician permute two of the three phases in the plug; NEVER inside the machine.

14

Page 15

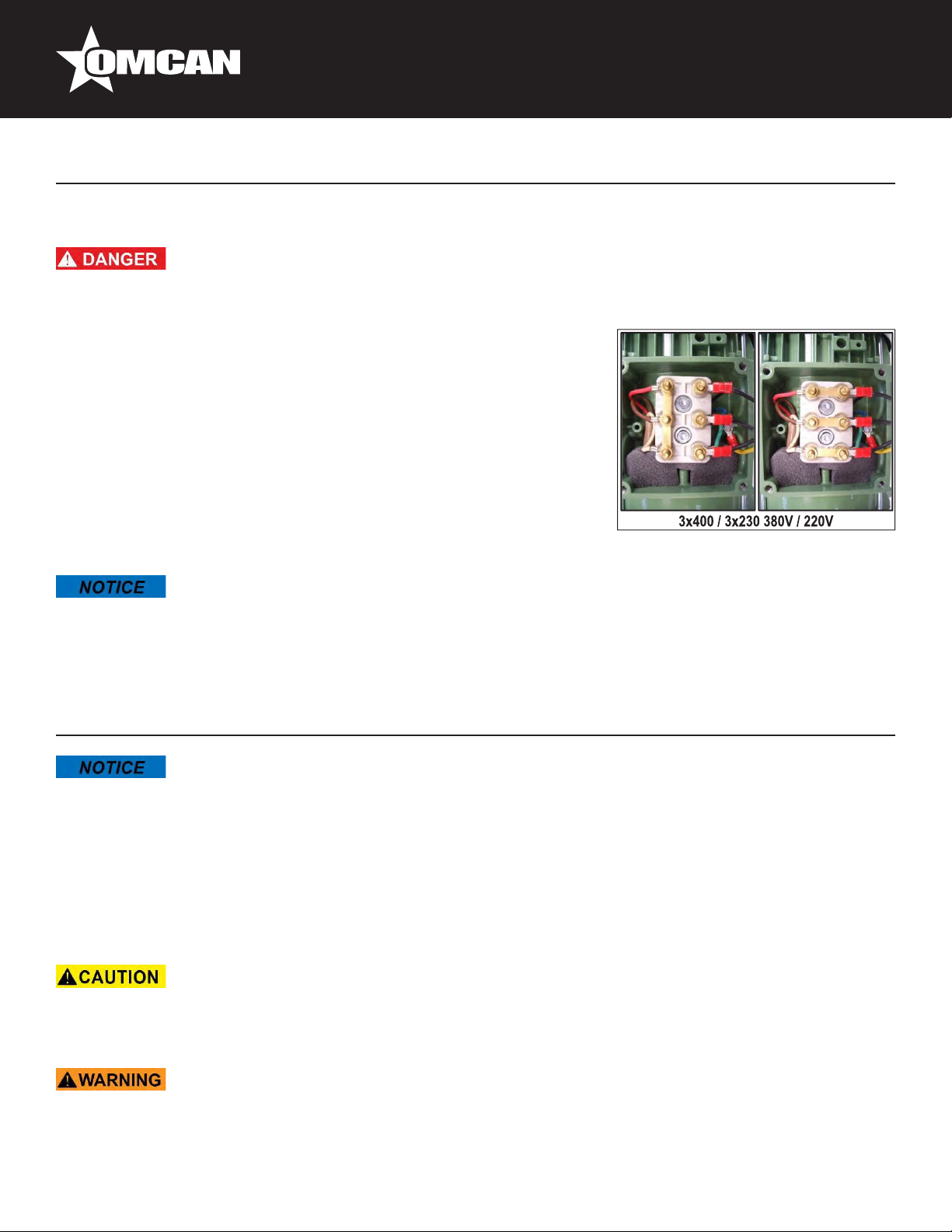

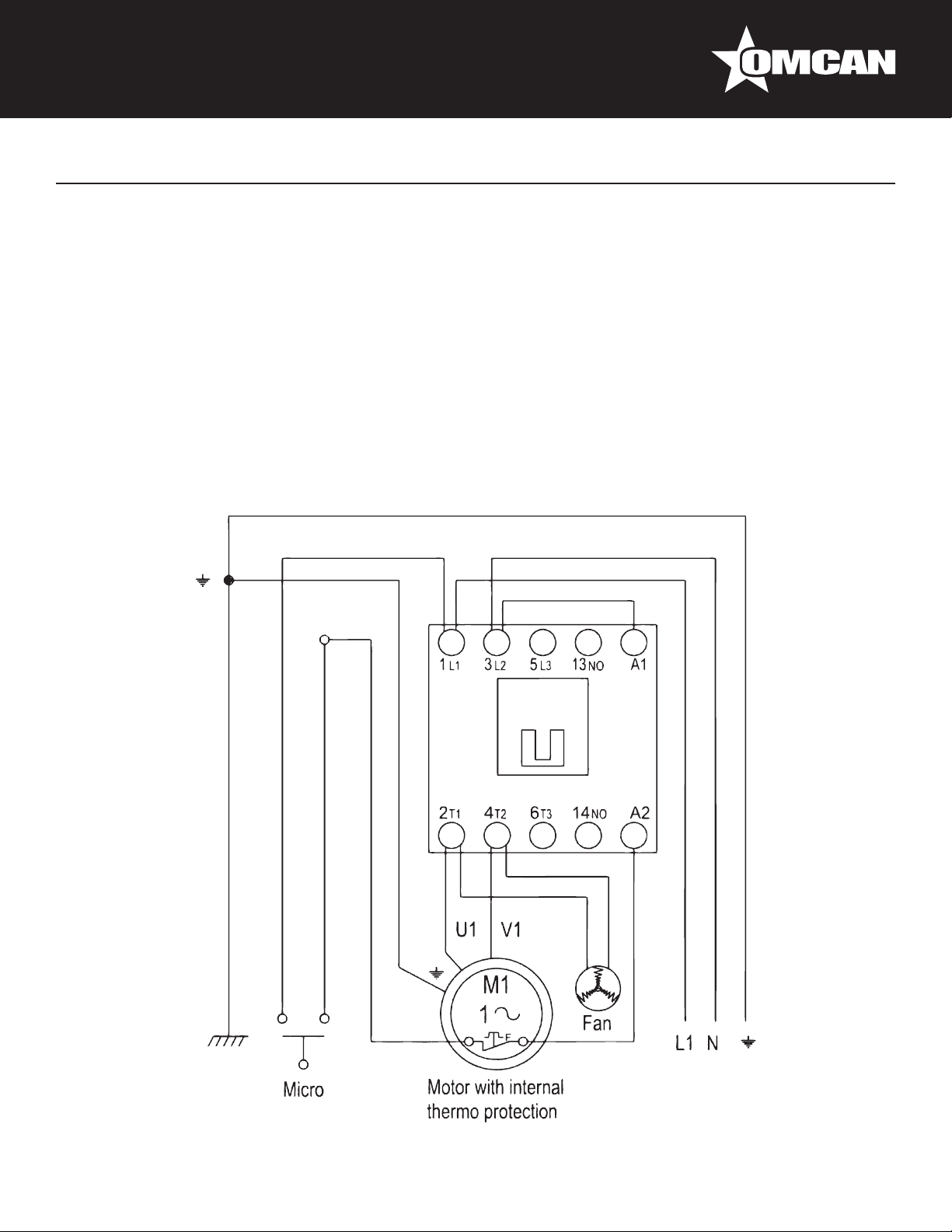

VOLTAGE CHANGE

ELECTRICAL HAZARD!

• This operation must only be carried out by a qualied electrician!

• The machine MUST remain disconnected from the power supply

throughout this procedure.

Only dual voltage three-phase machines powered 380 / 220V (400 /

230V EU) Unscrew and remove the screws that hold the panel to the

machine base, then withdraw it. Make the following changes in the

components:

• Open the terminal box by removing the screws 4 thereof.

• Release 6 locknuts small terminals.

• Put the plates in the correct position.

• Reseal the motor terminal box.

• Replace the panel at the end of operations.

Installation

The Qualied electrician in charge of changing the voltage of the machine should refer to the corresponding

wiring diagrams in this manual.

Operation

• BEFORE STARTING WORK, PLEASE READ AND UNDERSTAND THIS ENTIRE MANUAL AND SAFETY.

• DO NOT use the machine without having been instructed by an advanced user.

• Practice using the machine in vacuum before contacting mass.

• This machine is not designed to run in continuous operation uninterrupted at high pressures, but

intermittent operation stops dissipating the heat generated varies depending on the consistency of the

product.

STEPS TO FOLLOW

• If the phases are not well connected, power up the pump will operate in reverse, the engine make noise but

will not move the piston. In this case stop immediately and disconnect the machine from the mains.

• Have a qualied electrician permute two of the three phases in the plug.

• Observe all hygiene measures in food processing, using the necessary protection material (washing,

gloves, hat, apron, etc.)

15

Page 16

Operation

1. Fully open the lid. Reduce friction by unscrewing the lid locking nuts.

2. Before the rst use, and regularly thereafter, wash the tank, lid and

nozzles/horns with hot water.

3. Decrease working pressure of the machine to minimum, by turning

the pressure valve knob to the left (counter-clockwise).

4. Plug the machine to the mains.

5. Lower the piston pushing the knee lever to the right up to the

required volume to accommodate the desired meat mass.

6. Place meat dough in the tank while pressing each load to prevent

the presence of air pockets that can break the casing in the working

process.

7. Place the lid seal in its housing with the lip upwards. The lid seal has

a unique position with the protruding lip upwards.

Remember: Do not close the lid without the gasket or mounted

backwards, because doing so would harm the gasket or lid.

8. Raise the piston using the knee lever until the mass reaches the top

of the tank.

9. Lubricate with edible fat, or other USDA approved for food, the top of

the lid seal and the bottom of the lid.

10. Close the lid gently. Be careful not to pinch your hand in the closing

process.

Important: Do not use the nozzle/horn to close the cover, as

it could be twisted; exclusively use the lever for opening and

closing lid.

Tighten the lid lock nuts close enough so the pressure cannot raise

the lid.

11. Attach the appropriate nozzle/horn (as wide and short as possible) to

the nozzle/horn holder on the lid, securing it with the nozzle/horn nut.

12. Prepare enough casings.

13. Press the leg against the knee lever up to its limit. It is not

recommended to use the knee lever only halfway as an accelerator,

always push it until its limit.

14. Cautiously increase the working pressure by slowly rotating pressure

valve knob clockwise (in the direction of clock). Avoid high pressure,

as it may be excessive and the meat would practically spurt out of the

nozzle/horn.

15. When meat mass starts to gush out of the nozzle/horn, reduce the

pressure and place the casings. Adjust the pressure to the ideal

speed.

Remember: The air trapped between the meat mass and the lid

will be expelled rst through the nozzle/horn before the mass begins to ow.

16. Once the work is nished, push the knee lever to the right. It is not necessary to keep pushing the lever,

since the machine has an automatic lock until the piston reaches the lower position. To stop the hydraulic

unit at any time, leave the knee lever at the center position.

16

Page 17

Operation

17. When nished using the machine, proceed to clean it thoroughly.

Always turn down the piston to the bottom of the tank, disconnect the

electric plug from the base and make sure the machine’s brakes are

tightened, thus avoiding any involuntary displacement in your absence.

Remember: clean the ller according to the instructions on the

cleaning section when nished using the machine at the end of

the day.

• DO NOT leave the machine unattended while it is powered on or in operation.

• ALWAYS rmly grip both the transport handle (located at the machine’s base) and the lid handle when

moving the machine. DO NOT tilt the machine too far while it is balanced on its wheels since it is heavy

and there is a risk of personal injury or property damage if it tips over).

• ALWAYS keep hands away from any moving parts while the machine is in operation. There is the danger of

crushing hands, ngers, etc. when closing the lid or when the piston is raised while the lid is not completely

open.

• To prevent mechanical hazards and personal injury, do not open or close the cover if the machine is

operating.

• Be careful when removing the lid. Because of its weight it could fall and cause injury.

USEFUL TIPS

• The minimum operating temperature for the ller is 5°C. Therefore never store the machine in cold rooms,

freezers, etc.

• This machine is not designed to operate in continuous uninterrupted service, but to work on an intermittent

regime with stops to dissipate the heat generated which varies depending on product consistency.

• Given the pressure transmitted to pump hydraulic oil, it is normal that the temperature can raise above

60°C and the machine body is hot after a prolonged operating period.

• For a better presentation of the sausage lling process, smoother and less effort and heating of the

machine the following is recommend:

- Select nozzle/horn with the largest diameter and shortest length possible.

- Meat mass should be minced/chopped as ne as possible and as warm as possible.

• During operation of the machine with dough, you cannot open the lid until lowering the piston a bit, since

the compressed meat mass would prevent it.

• Approach the ller to the worktable as much as possible to avoid meat falling to the ground or on the

operator.

• Try to work at a reasonable speed and pressure, thus avoiding constant starts and stops the hydraulic unit.

17

Page 18

Maintenance

CLEANING INSTRUCTIONS

• If using detergents, disinfectants or oils maintenance, observe the special instructions of the

manufacturers.

• NEVER use water pressure jet to clean or rinse any part of the machine.

• NO use abrasive products, especially those erasable plates or safety adhesives.

• NO open or close the lid without the red seal, because doing so will scratch the cover and ange.

• To prevent mechanical hazards during cleaning operations and removing the piston, always open the lid

completely before making up the piston.

Electrical Hazard!

• The machine MUST remain disconnected from the power supply throughout the entire cleaning procedure.

• NEVER wet or dampen the machine’s electrical components (switches, cables, etc.)

• To proceed with the manual cleaning using suitable protection (latex gloves, plastic apron, etc.) is required.

• ALWAYS necessary intensive rinsing machine after application of detergents or disinfectants to prevent

contamination of the mass.

Cleaning the ller is essential not only for health reasons but also for efcient operation. NEGLIGENCE IN

CLEANING MAY VOID THE WARRANTY. Stuffer should be cleaned after and, where appropriate, before each

use. To facilitate this, Omcan has designed these machines so that all components are easily accessible.

EXTERIOR CLEANING

• To clean the exterior of the machine use hot water and a mild

detergent.

• After each day the bottom of the lid (mass outlet hole), the nozzle/horn

holder nut and the nozzles/horns must be thoroughly cleaned, inside

with a tubular round brush.

• Use plenty of hot water to clarify the axis of rotation of the lid in order to

remove residual salt and spices that might crystallize and swell after a

few hours / days of inactivity and prevent the lid is opened and closed

easily.

• The top of the piston silicone gasket should also be cleaned daily by

following these steps:

- Fully open the lid and remove the lid gasket.

- Press the knee lever until the piston reaches the top of its travel. A

portion of the piston silicone gasket will hover at the top of the tank.

- Clean with a soft brush and / or damp cloth.

• The lid and piston of the ller are heavy as they are made of solid stainless steel. Be careful when

removing them.

18

Page 19

Maintenance

• Due to their heavy weight, it is recommended to remove the lid and piston of the F50s between two people.

INTERIOR CLEANING

It is recommended to periodically clean the inside of piston and tank. The

frequency depends on the product (dough consistency), working pressure,

etc. We recommend starting with a daily inspection, lengthening intervals

depending on their needs.

• Fully open the lid and remove the gasket.

• Press the knee until the piston reaches the top of its travel.

• The piston being at the top and simultaneously pushing the knee lever,

unscrew the screw located in the center of the piston with the aid of the

extractor key supplied with the machine.

• Press the knee lever so that the piston goes down a little.

• Screw the extractor key into the thread of the piston, then press the knee

lever to raise the piston.

• Pull up the key to take the piston out of the machine.

• Disconnect the machine.

• Proceed to clean the tank, perfectly drying the bottom in order to avoid

the formation of water pockets and subsequent oxidation of the top

of the machine body. The hole at the bottom of the tank is a for water

drainage.

• Clean the piston and silicone gasket.

• To prevent noise on the rise or lowering of the piston, lubricate the piston

silicone gasket before inserting it into the reservoir, with edible fat or

other authorized USDA food.

• To mount the piston:

- Perfectly dry the bottom of the tank.

- Place the piston in the reservoir and fully tighten the piston screw,

taking care that the small seal is installed correctly.

- Then raise and lower the piston and then tighten the screw to ensure

that it is secure. Otherwise it could bend when pushed against the lid.

- Lubricate the piston screw and thread before placing it. This will make

disassembly easier.

• When the machine is not in use, keep the piston at the bottom of the tank. Being immersed in the hydraulic

oil will prolong the life of the rod and seals.

GENERAL CLEANING RECOMMENDATIONS

Steps Products Tools Observations

Supercial cleaning & residue

removal.

Extensive cleaning. Mild

detergent.

Spatula. Promptly after use.

Brush,

bucket.

19

Allow the product to work approximately 15

minutes.

Page 20

Maintenance

Rinsing. Warm water. Sponge,

bucket.

Inspection. Visually examine all critical components,

Disinfecting. Disinfectants;

NEVER use

bleach.

Rinsing. Potable

water.

Drying. Cleaning

Conservation. Lubricating

oil.

Sponge,

cleaning

cloth.

Sponge,

bucket.

cloth.

Cleaning

cloth.

The water should be 40 to 50°C (100 to

120°F).

especially those subject to stress and wear.

Disinfect after completing all other cleaning

operations.

ALWAYS rinse the machine thoroughly after

using detergents and disinfectants.

Be sure to completely dry all cleaned

components.

Only external machine parts.

RECOMMENDED CLEANING INTERVALS

Interval Area to be cleaned Product Tools Observations

Daily. Daily Lid, lid gasket,

tank and piston

screw.

Weekly. Piston, piston seals

and piston screw

gasket

Every two

weeks.

NOTE: The above cleaning intervals are suggested for companies with just one work shift. The

machine should be cleaned more frequently if it is used for multiple shifts each day.

Machine body, bottom

of the machine.

Mild detergent, warm

water.

Mild detergent, warm

water.

Mild detergent, warm

water.

Sponge,

cleaning

cloth.

Sponge,

cleaning

cloth.

Sponge,

cleaning

cloth.

Mild detergent, warm water

Sponge, cleaning cloth

Remove contamination from

the piston center screw

using, if necessary, a brush to

prevent the accumulation of

waste.

To remove the piston follow

the instructions detailed

above.

STAINLESS STEEL CARE

Never use aggressive cleaners with stainless steel such as bleach or similar chlorine derivatives products. If

you have used it, never leave acting, rinse immediately with plenty of water and dry thoroughly.

It is uncommon, but possible, that small traces of rust or oxidation points may be observed on the machine.

This may be due to:

• Welding impurities.

• Food fragments adhering to the surface.

20

Page 21

Maintenance

• Pits resulting from use of aggressive cleaners such as bleach or similar chlorine derivatives products.

• Moisture that remains after cleaning with water. ALWAYS wipe dry all components that have been cleaned.

To remove these rust spots simply use a liquid stripper with a cloth, or clean with Scotch Brite.

MAINTENANCE

• ALWAYS unplug the machine before proceeding with maintenance and inspection.

• ALWAYS follow the safety instructions in this manual during maintenance and inspection operations.

Breakdowns resulting from infrequent or improper maintenance can lead to expensive repairs, lost productivity

due to down time and could void our warranty; therefore, regular and adequate maintenance is indispensable.

The safety and life of the machine depend on many factors, including proper maintenance. Although it is

difcult to give specic advice regarding inspection, maintenance or parts replacement schedules since these

depend on many variables related to the machine’s use, we can make some recommendations. The user,

however, is solely responsible for formulating and following an inspection and maintenance schedules that

reect the machine’s actual use. Our local distributor will be delighted to provide you with further information.

MAINTENANCE AND INSPECTION INTERVALS

Inspection interval Critical component Maintenance information

Daily. Lid gasket. Check it and replace it if necessary.

Piston silicone seal. Check it and replace it if necessary.

Monthly. Knee lever. Performance review and grease if necessary.

Lid opening. Performance review and grease if necessary.

Annually. Hydraulic oil. Check the level and ll the reservoir if neces-

sary.

Every 2,500 to 5,000 hours. Hydraulic oil. Change the hydraulic oil.

The above maintenance and inspection intervals are suggested for a machine under normal use. The ller

should be inspected and maintained more frequently if it is used heavily.

MAINTENANCE AND INSPECTION TIPS

Electrical Hazard!

• If the electric cord becomes damaged, immediately have a qualied electrician replace it with a cord of

identical specications. Contact your dealer’s service department to obtain the replacement cord.

• Lid gasket:

- Replace in case of leakage of meat dough, in case of wear or breakage.

- To reduce friction between the gasket and the bottom of the lid, lubricate both with animal or authorized

21

Page 22

Maintenance

fat.

- It is manufactured of non-toxic material suitable for food use.

• Piston seal:

- Replace if leakage or breakage.

- To avoid noise when raising or lowering the piston, lubricate before inserting the piston into the tank with

edible fat or other food authorized USDA

• Hydraulic: to avoid premature wear of the rod of the hydraulic reservoir, keep the piston at the bottom of the

tank when nished using the machine. This way the rod will remain submerged in hydraulic oil.

• Lid closing: the lid can be closed more or less tightening the lid locking nuts, depending on the degree of

sealing to be obtained. If you normally work with dry meat masses you can tighten the nuts with less force;

for liquid masses you may close the lid more tightly and thus avoid the possibility of leakage.

• Spare parts: if you need a spare, contact your dealer who sold the unit, indicating all identication details

(model, serial number, year of manufacture, power, voltage, frequency, etc.) you’ll nd on the nameplate of

the machine.

HYDRAULIC OIL

• Hydraulic oil level:

- Check the oil level on the marks of the tank. Unscrew and remove

the screws that hold the panel to the machine base, then withdraw it.

- On the tank, check that the oil level is between the MAX and MIN

marks.

- Fill the tank to the maximum level (not over), since the greater

amount of cooling oil will improve dissipation of heat from the

hydraulic unit, increasing its useful life.

- The lack of oil for operation can be noticed if the piston rises

“leapfrog” to allow air to enter the circuit.

• Oil temperature: given the pressure transmitted to pump hydraulic oil,

it is normal that the temperature can rise up to 60° C and the machine

body becomes hot after prolonged operating period. This machine

is not designed to run in continuous, uninterrupted operation at high

pressures, but to work in an intermittent regime with stops to dissipate generated heat.

• Hydraulic oil life: Omcan cannot provide accurate data on the life of the oil, because it depends on several

variable factors: temperature, operating pressure, presence of moisture or traces of water, etc. It can be

estimated at 5,000 hours, depending on conditions. If the oil thins, is dirty and shows presence of impurities

or after using the machine has a whitish color due to the presence of water, replace it by rst emptying the

oil deposit. Fill in oil following the instructions. Normally the hydraulic oil level will be maintained for years.

• Replacing the hydraulic oil:

- It is recommended to remove used oil with a suction pump oil.

- Unscrew and remove the screws that hold the panel to the machine base, then withdraw it.

- Remove the depressurized oil cap (red) and enter the suction pipe of the pump through the same hole.

Ensure that the tubing reaches the bottom of the tank to suck any impurities. Empty the tank by pumping

the oil in a suitable container. Please recycle used oil.

- Using a funnel or lling gun, enter the amount of hydraulic oil indicated in the table, through the lling

hole. Do not ll the tank completely, as a certain volume of air is required for expansion of the warm oil.

22

Page 23

Maintenance

- Move the piston up and down two or three times in order to purge and remove air pockets circuit. The lack

of enough oil for operation can be seen that the piston rises “leapfrog” to allow air to enter the circuit.

- If an oil suction pump is not available, the oil reservoir can be disassembled by releasing the oil reservoir

tubes and screws. Remove the tank and pour the oil through the lling hole into a suitable container.

Model Oil reservoir capacity

F14 6 liters / 1.6 US Gal

F25 & F35 7 liters / 1.9 US Gal

F50 13 liters / 3.4 US Gal

Use high pressure hydraulic oil (200 bar) ISO VG 46 viscosity and quality level equivalent to ISO 67434: 2015 DIN 51524-2 or HM: 2006-04 HLP.

Troubleshooting

• ALWAYS power off and unplug the machine from the electrical outlet before proceeding with cleaning,

maintenance, or repairs.

• If you are unable to resolve the difculty, DO NOT CONTINUE TO USE THE MACHINE and contact your

authorized Omcan dealer for service.

Problems Possible Causes Solutions

The machine is not working. The machine is switched off. Connect the machine.

The sound of the motor rotation is

heard, but the piston does not go

up or down when pushing the knee

lever.

The machine is connected to a

lower voltage.

Without tension in one or more

stages.

The internal micro switch on / off

the knee lever is defective or not

properly adjusted.

The pressure valve is at the

minimum.

The motor turns in the opposite

direction to the correct.

Change the voltage of the machine

to the right.

Check fuses, plugs and switches.

Contact an electrician to replace or

readjusted.

Increase pressure by turning knob

clockwise.

Permute two of the three phases in

the plug.

23

Page 24

Troubleshooting

The piston moves up and down

but the machine seems to lack

strength.

The air passage hole located at the

base of the tank is clogged.

The piston and the piston seal are

dirty.

The mains voltage is not

compatible with the selected for

the engine.

The three-phase motor (if

applicable) is only running two

phases.

There is little hydraulic oil. Fill the oil reservoir up to “MAX”

There is an oil leak in the ttings or

pipes.

The chambers of the hydraulic

cylinder are communicated.

REFERENCE

Item Number Model Number Description

45950 SS-ES-0026-F

46099 SS-ES-0026-FT

46098 SS-ES-0026-FS

45920 SS-ES-0048-FS

45869 SS-ES-0048-FT

45959 SS-ES-0048-F

45870 SS-ES-0065-F

46101 SS-ES-0065-FS

Sausage Stuffer 26 LB/12 KG Capacity Stainless

Steel Hydraulic Piston 1HP/0.75kW 110V/60/1

Sausage Stuffer 26 LB/12 KG Capacity Stainless

Steel Hydraulic Piston 0.75HP/0.55kW 208V/60/3

Sausage Stuffer 26 LB/12 KG Capacity Stainless

Steel Hydraulic Piston 1HP/0.75kW 220V/60/1

Sausage Stuffer 48 LB/22 KG Stainless Steel

Hydraulic Piston 1.75HP/1.3kW 110V/60/1

cQPSus

Sausage Stuffer 48 LB/22 KG Capacity

Stainless Steel Hydraulic Piston 1.5 HP/1.1kW

208V/60HZ/3PH cQPSus

Sausage Stuffer 48 LB/22 KG Capacity Stainless

Steel Hydraulic Piston 1.75 HP/1.3kW 220V/60/1

cQPSus

Sausage Stuffer 65 LB/29 KG Capacity Stainless

Steel Hydraulic Piston 1.75HP/1.3kW 110V/60/1

Sausage Stuffer 65 LB/29 KG Capacity Stainless

Steel Hydraulic Piston 1.75HP/1.3kW 220V/60/1

cQPSus

Clean it.

Clean them.

Contact an electrician to change

the voltage of the machine.

Contact an electrician to check

electric grid.

Call your local dealer.

Call your local dealer.

Manufacturer Model

Number

F14s/26 110/60/1

F14s/26 208/60/3

F14s/26 220/60/1

F25s/48 110/60/1

F25s/48 208/60/3

F25s/48 220/60/1

F35s/65 110/60/1

F35s/65 220/60/1

24

Page 25

46100 SS-ES-0065-FT

45951 SS-ES-0095-F

46102 SS-ES-0095-FS

46103 SS-ES-0095-FT

Troubleshooting

Sausage Stuffer 65 LB/29 KG Capacity Stainless

Steel Hydraulic Piston 1.5HP/1.1kW 208-

220V/60/3 cQPSus

Sausage Stuffer 95 LB/43 KG Capacity Stainless

Steel Hydraulic Piston 2.5HP/1.87kW 110V/60/1

Sausage Stuffer 95 LB/43 KG Capacity Stainless

Steel Hydraulic Piston 2.5HP/1.87kW 220V/60/1

Sausage Stuffer 95 LB/43 KG Capacity Stainless

Steel Hydraulic Piston 2.5HP/1.87kW 208-

220V/60/3 cQPSus

F35s/65 220/60/3

F50s/95 110/60/1

F50s/95 220/60/1

F50s/95 220/60/3

25

Page 26

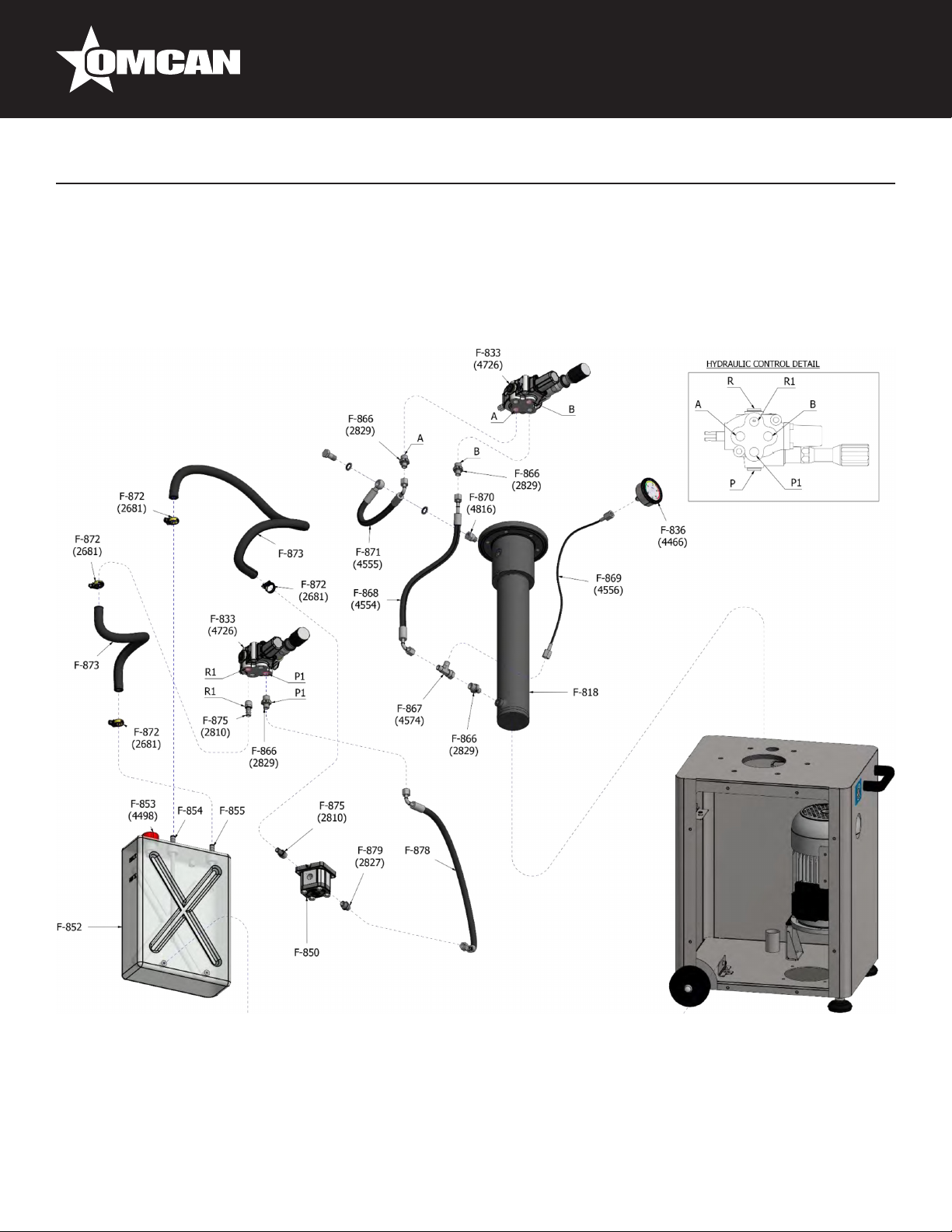

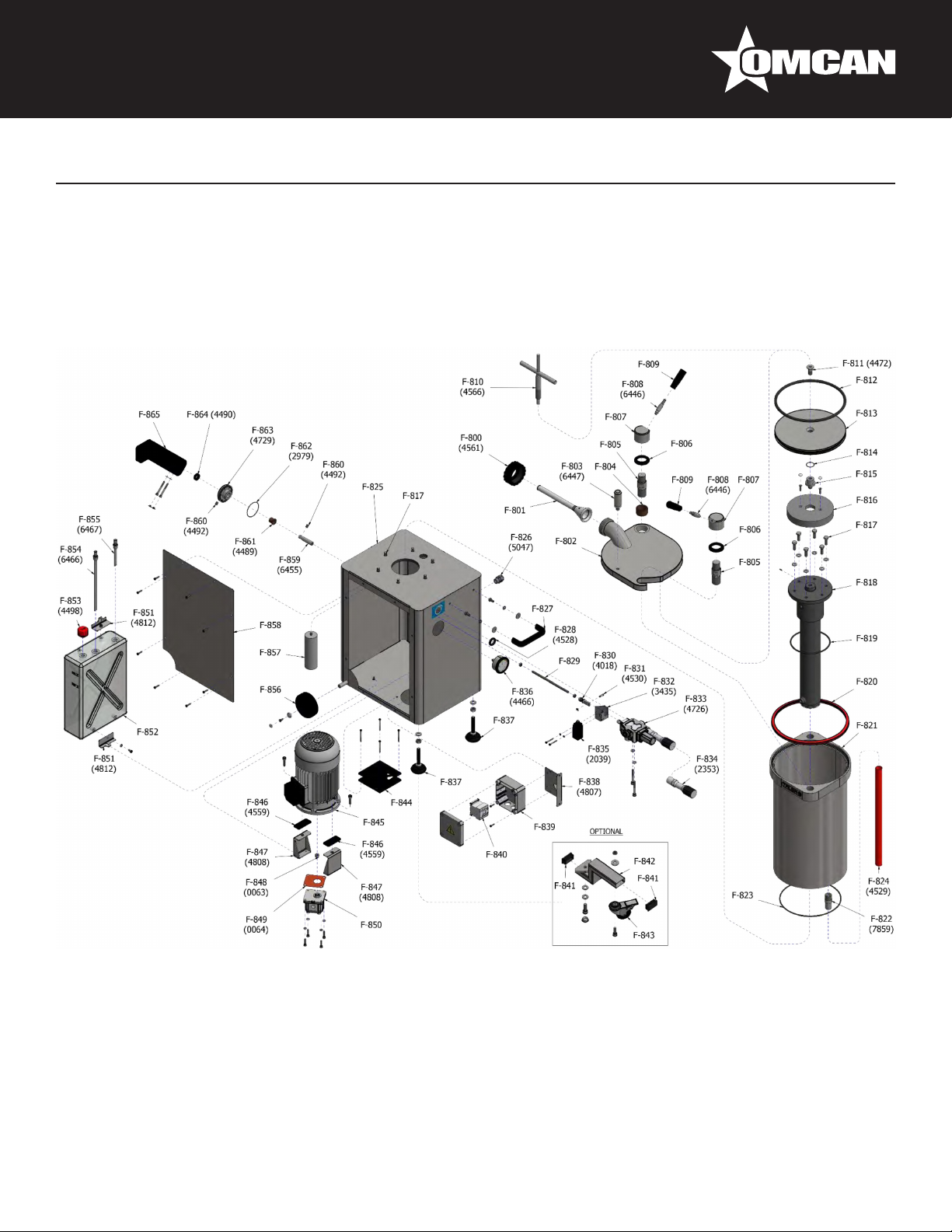

Parts Breakdown

Model SS-ES-0026-F 45950

Model SS-ES-0026-FT 46099

Model SS-ES-0026-FS 46098

26

Page 27

Model SS-ES-0026-F 45950

Model SS-ES-0026-FT 46099

Model SS-ES-0026-FS 46098

Parts Breakdown

27

Page 28

Parts Breakdown

Model SS-ES-0026-F 45950

Model SS-ES-0026-FT 46099

Model SS-ES-0026-FS 46098

Item No. Description Position Item No. Description Position Item No. Description Position

66842

66843

66844

66845

66846

66847

66848

66849

66850

66851 Nut for Lid Lock AISI303 for F14S F-807 66874

66852

66853 Knob Black Thread M10 80mm for F14S F-809 66876

66854

66855

66856

66857

66858

66859

66860

66861

66862

66863

66864

Nozzle/Horn Retention Nut Black for

F14S

Nozzle/Horn Poliet. HD Translucent

D.Ext.14 Int.10L.Use 160mm (6") for

F14S

Nozzle/Horn Poliet. HD Translucent

D.Ext.20 Int.16L.Use 196mm (8") for

F14S

Nozzle/Horn Poliet. HD Translucent

D.Ext.30 Int.26L.Use 196mm (8") for

F14S

Stainless Steel Lid, without Accessories

for F14S

Lid Opening Lever AISI303 (All Stuffers/

Fillers FS) for F14S

Bras Bushing B11 A-42-54-30 Lid for

F14S

Stainless Steel Bolt, M39/M36 Lid for

F14S

Bushing for Lid Lock Nut, Plastic APM500

Black for F14S

Lever for Lid Lock Nut AISI303, without

Black Knob for F14S

Spanner/Wrench, Piston Extractor for

F14S

CSK Allen Screw, Stainless Steel

M16x35 DIN7991 for F14S

O-Ring, Int. Diam. 345x10 Red Silicone

(1*Piston) for F14S

Piston, Stainless Steel, without O-Ring

for F14S

O-Ring, Int. Diam. 34x2mm Threaded Tip

Piston for F14S

Threaded Tip Hydraulic Cylinder Bolt

AISI303 for F14S

Hood Clamp, Hydraulic Cylinder,

D.198mm NBR70 for F14S

Stainless Steel Hexagonal Screw,

M12x35 DIN933 for F14S

Hydraulic Cylinder, DE0450800449G01

Filler/Stuffer for F14S

O-Ring, Int. Diam. 165x5mm, Hydraulic

Cylinder for F14S

Lid Seal Polyurethane Red, Diam.Ext.

404mm for F14S

F-800 66865 Fixed Dough Barrel for F14S F-821 66881

F-801 66866

F-801 66867

F-801 66868

F-802 66869 Cabinet with Accessories for F14S F-825 39059 Air Extraction Fan 220V 1PH for F14S F-844

F-803 66870

F-804 66871 Handle M8 for F14S F-827 36045

F-805 66872

F-806 66873

F-808 66875

F-810 66877

F-811 31219

F-812 16524

F-813 66878

F-814 66879 Foot, Stainless Steel for F14S F-837 66892 Oil Return Pipe D.10 L.120mm for F14S F-854

F-815 66880 Holder Isolating Box for F14S F-838 66893 Oil Suction Pipe D.10 L.270mm for F14S F-855

F-816 36042

F-817 66048

F-818 79579

F-819 44094 Contactor 6A 220V/60Hz/1 for F14S F-840 66896 Brass Bushing, B11 A-6-9-12 for F14S F-860

F-820 44093 Contactor 6A 208V/60Hz/3 for F14S F-840 66897

Deposit Drainage Pipe D.27 L.62 Gas

3/4" AISI304 for F14S

O-Ring, Int. Diam. 340x4, Flange Dough

Barrel for F14S

Transparent Fabric Hose PVC D.32x25,

Deposit Drain for F14S

Grommet, S-Tec 5308959 M20x1,5/13

Poliamyde, Grey for F14S

Wall Pass-Through D.34/21,8x6mm

EPDM Black 70 SH for F14S

Threaded Rod Hydraulic Control M8

L=268mm AISI304 for F14S

Internal Fork, Hydraulic Control Activator,

Stainless Steel for F14S

Cylindrical Pin, D.6x19,5 Stainless Steel

for F14S

Holder, Microswitch Distributor, Stainless

Steel for F14S

Hydraulic Control 102N8SA23X-340 with

Pressure Knob for F14S

External Pressure Valve Control Assembly M1670/861, Black Knob for F14S

Micro Position Deterctor, Comepi Metal

Wheel for F14S

Pressure Gauge D.63, WIKA 213.53,

0-200 Bar, Thread 1-4" for F14S

Isolating Box, Legrand 100x100x55mm

Code 92138 for F14S

Isolating Box, IDE 162x116x76, Polycarbonate (H UL-CSA +110V) for F14S

Contactor, LS MC-22B AC 110V/60&50Hz

1A1B EXP A.C. 22 AMP for F14S

F-822 66882

F-823 66883

F-824 66884 Fan, 110V-60HZ-1 for F14S F-844

F-826 66885 Motor, 110V-60HZ-1 for F14S F-845

F-828 36048

F-829 66886

F-830 66887 Support Motor Cabinet for F14S F-847

F-831 31222

F-832 31221

F-833 66888 Gear Pump 1L05IB01 R for F14S F-850

F-834 66889 Support Oil Reservoir/Cabinet for F14S F-851

F-835 66890

F-836 66891 Oil Cap, Depressurized, Red for F14S F-853

F-839 36110 Wheel, D.125mm Nylon for F14S F-856

F-839 66894 Panel Access Cabinet for F14S F-858

F-840 66895

Cap, Kapsto, GPN270 REF. R6030 3

for F14S

Extension Swivel Castor AISI304 for

F14S

Swivel Caster Black/Stainless Steel with

Brake for F14S

Motor 1-Phase 1/220V-60HZ-

1.25HP/0.9KW-1700 RPM Capacitor

30 for F14S

Motor 3-Phase H 3/208/220V-60HZ-

0.75HP-0.55KW 1700 RPM for F14S

Silent Block Single Phase Motor

70x30x5mm EPDM Black for F14S

Motor-Pump Coupling for Fillers/Stuffers

for F14S

Seal, Vellumoid 1625-1 for Pump Type

L for F14S

Internal Oil Reservoir, Poliprop. White

for F14S

Activator Knee Lever D.15 L.70mm

AISI303 for F14S

Brass Bushing, B11 B-15-20-20/25-3

with Collar for F14S

F-841

F-842

F-843

F-845

F-845

F-846

F-848

F-849

F-852

F-859

F-861

28

Page 29

Parts Breakdown

Model SS-ES-0026-F 45950

Model SS-ES-0026-FT 46099

Model SS-ES-0026-FS 46098

Item No. Description Position Item No. Description Position Item No. Description Position

66898 O-Ring, Int. Diam. 61x2 for F14S F-862 66903

66899 Support Knee Lever AISI304 for F14S F-863 66904

66900 Gasket, Knee Lever for F14S F-864 66905

66901

66902

Knee Lever, Plastic APM1000 Black

for F14S

Hydraulic Union, Simple, GE8LR 3/8"

BSP for F14S

F-865 66906

F-866 66907

T Joint EVL-08 (Outlet Control to Hydraulic Cylinder + Gauge) for F14S

Hose, 460mm R1T1/4 TL90HG8LTL45HG8L, Bottom Cylin-Hydr Control

for F14S

Hose, Pressure Gauge 1/4", Length

500mm for F14S

Hydraulic Union, Simple MF 1/4 BSPP

HF 1/4 BSPP for F14S

Hose, 290mm R1T1/4 ESF1/4TL90HG8L, Top Cylin-Hydraulic Control

for F14S

F-867 66908

F-868 66909

F-869 61763

F-870 66910

F-871 65038

Hose Clamp, MIKALOR D.12-20/9 for

HYDR. Oil Drain Tube NH for F14S

Rubber Hose KLEMINE-20 Bar D.12x20

for F14S

Nozzle Cover, Rubber 12 Male Thread

3/8" (Draining Hose) for F14S

Hose, 720mm R1T1/4 TL90HG8LTL45HG8L (Hydraulic Pump Control)

for F14S

Hydraulic Union, Simple, GE8LR 1/4"

BSP for F14S

F-872

F-873

F-875

F-878

F-879

29

Page 30

Parts Breakdown

Model SS-ES-0048-F 45959

Model SS-ES-0048-FT 45869

Model SS-ES-0048-FS 45920

30

Page 31

Model SS-ES-0048-F 45959

Model SS-ES-0048-FT 45869

Model SS-ES-0048-FS 45920

Parts Breakdown

31

Page 32

Parts Breakdown

Model SS-ES-0048-F 45959

Model SS-ES-0048-FT 45869

Model SS-ES-0048-FS 45920

Item No. Description Position Item No. Description Position Item No. Description Position

66842

66843

66844

66845

66911

66847

66848

66849

66850

66851 Nut for Lid Lock AISI303 for F25S F-807 66874

66852

66853 Knob Black Thread M10 80mm for F25S F-809 66876

66854

66855

66912

66913

66914

66915

66916

66861

66917

66918

66919

Nozzle/Horn Retention Nut Black for

F25S

Nozzle/Horn Poliet. HD Translucent

D.Ext.14 Int.10L.Use 160mm (6") for

F25S

Nozzle/Horn Poliet. HD Translucent

D.Ext.20 Int.16L.Use 196mm (8") for

F25S

Nozzle/Horn Poliet. HD Translucent

D.Ext.30 Int.26L.Use 196mm (8") for

F25S

Stainless Steel Lid, without Accessories

for F25S

Lid Opening Lever AISI303 (All Stuffers/

Fillers FS) for F25S

Bras Bushing B11 A-42-54-30 Lid for

F25S

Stainless Steel Bolt, M39/M36 Lid for

F25S

Bushing for Lid Lock Nut, Plastic APM500

Black for F25S

Lever for Lid Lock Nut AISI303, without

Black Knob for F25S

Spanner/Wrench, Piston Extractor for

F25S

CSK Allen Screw, Stainless Steel

M16x35 DIN7991 for F25S

O-Ring, Int. Diam. 345x10 Red Silicone

(1*Piston) for F25S

Piston, Stainless Steel, Without O-Ring

for F25S

O-Ring, Int. Diam. 34x2mm Threaded Tip

Piston for F25S

Threaded Tip Hydraulic Cylinder Bolt

AISI303 for F25S

Hood Clamp, Hydraulic Cylinder,

D.198mm NBR70 for F25S

Stainless Steel Hexagonal Screw,

M12x35 DIN933 for F25S

Hydraulic Cylinder, DE0450800449G01

Filler/Stuffer for F25S

O-Ring, Int. Diam. 165x5mm, Hydraulic

Cylinder for F25S

Lid Seal Polyurethane Red, Diam.Ext.

404mm for F25S

F-800 66920 Fixed Dough Barrel for F25S F-821 66881

F-801 66866

F-801 66921

F-801 66868

F-802 66922 Cabinet with Accessories for F25S F-825 66884 Fan, 110V-60HZ-1 for F25S F-844

F-803 66870

F-804 66923 Handle M8 for F25S F-827 36046

F-805 66872

F-806 66924

F-808 66875

F-810 66877

F-811 31219

F-812 16524

F-813 66878

F-814 66879 Foot, Stainless Steel for F25S F-837 66892 Oil Return Pipe D.10 L.120mm for F25S F-854

F-815 66880 Holder Isolating Box for F25S F-838 66893 Oil Suction Pipe D.10 L.270mm for F25S F-855

F-816 36042

F-817 66048

F-818 44093 Contactor, 208V/60Hz 3 for F25S F-840 66895

F-819 44094 Contactor, 220V/60Hz 1 for F25S F-840 66896 Brass Bushing, B11 A-6-9-12 for F25S F-860

F-820 79579

Deposit Drainage Pipe D.27 L.62 Gas

3/4" AISI304 for F25S

O-Ring, Int. Diam. 340x4, Flange Dough

Barrel for F25S

Transparent Fabric Hose PVC D.32x25,

Deposit Drain for F25S

Grommet, S-TEC 5308959 M20x1,5/13

Poliamyde, Grey for F25S

Wall Pass-Through D.34/21,8x6mm

EPDM Black 70 SH for F25S

Threaded Rod Hydraulic Control M8

L=268mm AISI304 for F25S

Internal Fork, Hydraulic Control Activator,

Stainless Steel for F25S

Cylindrical Pin, D.6x19,5 Stainless Steel

for F25S

Holder, Microswitch Distributor, Stainless

Steel for F25S

Hydraulic Control 102N8SA23X-340 with

Pressure Knob for F25S

External Pressure Valve Control Assembly M1670/861, Black Knob for F25S

Micro Position Detector, Comepi Metal

Wheel for F25S

Pressure Gauge D.63, Wika 213.53,

0-200 Bar, Thread 1-4" for F25S

Isolating Box, Legrand 100x100x55mm

Code 92138 for F25S

Isolating Box, IDE 162x116x76, Polycarbonate (H UL-CSA +110V) for F25S

Contactor, LS MC-22B AC 110V/60&50Hz

1A1B EXP A.C. 22 AMP for F25S

F-822 66882

F-823 66883

F-824 39059 Air Extraction Fan 220V 1PH for F25S F-844

F-826 19410

F-828 66925 Motor, 110V-60HZ-1 for F25S F-845

F-829 66886

F-830 66887 Support Motor Cabinet for F25S F-847

F-831 31222

F-832 31221

F-833 64313 Gear Pump 1L05IB01 R for F25S F-850

F-834 66889 Support Oil Reservoir/Cabinet for F25S F-851

F-835 66890

F-836 66891 Oil Cap, Depressurized, Red for F25S F-853

F-839 36110 Wheel, D.125mm Nylon for F25S F-856

F-839 66926 Panel Access Cabinet for F25S F-858

F-840 66897

Cap, Kapsto, GPN270 REF. R6030 3

for F25S

Extension Swivel Castor AISI304 for

F25S

Swivel Caster Black/Stainless Steel with

Brake for F25S

Motor H26 3-Phase H 3/208/220V-60HZ-

1.5HP-1.1KW 1700 RPM for F25S

Motor 1-Phase 1/220V-60HZ-1.75HP-1

3KW-1700 Clockwise Rotation for F25S

Silent Block Single Phase Motor

70x30x5mm EPDM Black for F25S

Motor-Pump Coupling for Fillers/Stuffers

for F25S

Seal, Vellumoid 1625-1 for Pump Type

L for F25S

Internal Oil Reservoir, Poliprop. White

for F25S

Activator Knee Lever D.15 L.70mm

AISI303 for F25S

Brass Bushing, B11 B-15-20-20/25-3

with Collar for F25S

F-841

F-842

F-843

F-845

F-845

F-846

F-848

F-849

F-852

F-859

F-861

32

Page 33

Parts Breakdown

Model SS-ES-0048-F 45959

Model SS-ES-0048-FT 45869

Model SS-ES-0048-FS 45920

Item No. Description Position Item No. Description Position Item No. Description Position

66898 O-Ring, Int. Diam. 61x2 for F25S F-862 66903

66899 Support Knee Lever AISI304 for F25S F-863 66904

66900 Gasket, Knee Lever for F25S F-864 66905

66901

66902

Knee Lever, Plastic APM1000 Black

for F25S

Hydraulic Union, Simple, GE8LR 3/8"

BSP for F25S

F-865 66906

F-866 66907

T Joint EVL-08 (Outlet Control to Hydraulic Cylinder + Gauge) for F25S

Hose, 460mm R1T1/4 TL90HG8LTL45HG8L, Bottom Cylin-Hydr Control

for F25S

Hose, Pressure Gauge 1/4", Length

500mm for F25S

Hydraulic Union, Simple MF 1/4 BSPP

HF 1/4 BSPP for F25S

Hose, 290mm R1T1/4 ESF1/4TL90HG8L, Top Cylin-Hydraulic Control

for F25S

F-867 66908

F-868 66909

F-869 61763

F-870 66910

F-871 65038

Hose Clamp, MIKALOR D.12-20/9 for

HYDR. Oil Drain Tube NH for F25S

Rubber Hose KLEMINE-20 Bar D.12x20

for F25S

Nozzle Cover, Rubber 12 Male Thread

3/8" (Draining Hose) for F25S

Hose, 720mm R1T1/4 TL90HG8LTL45HG8L (Hydraulic Pump Control)

for F25S

Hydraulic Union, Simple, GE8LR 1/4"

BSP for F25S

F-872

F-873

F-875

F-878

F-879

33

Page 34

Parts Breakdown

Model SS-ES-0065-F 45870

Model SS-ES-0065-FS 46101

Model SS-ES-0065-FT 46100

34

Page 35

Model SS-ES-0065-F 45870

Model SS-ES-0065-FS 46101

Model SS-ES-0065-FT 46100

Parts Breakdown

35

Page 36

Parts Breakdown

Model SS-ES-0065-F 45870

Model SS-ES-0065-FS 46101

Model SS-ES-0065-FT 46100

Item No. Description Position Item No. Description Position Item No. Description Position

66842

66843

66844

66845

66927

66847

66848

66849

66850

66851 Nut for Lid Lock AISI303 for F35S F-807 66874

66852

66853 Knob Black Thread M10 80mm for F35S F-809 66876

66854

66855

66928

66929

66914

66915

66916

66861

66917

66918

66930

Nozzle/Horn Retention Nut Black for

F35S

Nozzle/Horn Poliet. HD Translucent

D.Ext.14 Int.10L.Use 160mm (6") for

F35S

Nozzle/Horn Poliet. HD Translucent

D.Ext.20 Int.16L.Use 196mm (8") for

F35S

Nozzle/Horn Poliet. HD Translucent

D.Ext.30 Int.26L.Use 196mm (8") for

F35S

Stainless Steel Lid, without Accessories

for F35S

Lid Opening Lever AISI303 (All Stuffers/

Fillers FS) for F35S

Bras Bushing B11 A-42-54-30 Lid for

F35S

Stainless Steel Bolt, M39/M36 Lid for

F35S

Bushing for Lid Lock Nut, Plastic APM500

Black for F35S

Lever for Lid Lock Nut AISI303, without

Black Knob for F35S

Spanner/Wrench, Piston Extractor for

F35S

CSK Allen Screw, Stainless Steel

M16x35 DIN7991 for F35S

O-Ring, Int. Diam. 345x10 Red Silicone

(1*Piston) for F35S

Piston, Stainless Steel, without O-Ring

for F35S

O-Ring, Int. Diam. 34x2mm Threaded Tip

Piston for F35S

Threaded Tip Hydraulic Cylinder Bolt

AISI303 for F35S

Hood Clamp, Hydraulic Cylinder,

D.198mm NBR70 for F35S

Stainless Steel Hexagonal Screw,

M12x35 DIN933 for F35S

Hydraulic Cylinder, DE0450800449G01

Filler/Stuffer for F35S

O-Ring, Int. Diam. 165x5mm, Hydraulic

Cylinder for F35S

Lid Seal Polyurethane Red, Diam.Ext.

404mm for F35S

F-800 66931 Fixed Dough Barrel for F35S F-821 66881

F-801 66866

F-801 66932

F-801 66868

F-802 66922 Cabinet with Accessories for F35S F-825 39059 Air Extraction Fan 220V 1PH for F35S F-844

F-803 66870

F-804 66923 Handle M8 for F35S F-827 36046

F-805 66872

F-806 66924

F-808 66875

F-810 66877

F-811 31219

F-812 16524

F-813 66878

F-814 66879 Foot, Stainless Steel for F35S F-837 66892 Oil Return Pipe D.10 L.120mm for F35S F-854

F-815 66880 Holder Isolating Box for F35S F-838 66893 Oil Suction Pipe D.10 L.270mm for F35S F-855

F-816 36042

F-817 66048

F-818 79579

F-819 44094 Contactor 6A 220V/60HZ/1 for F35S F-840 66896 Brass Bushing, B11 A-6-9-12 for F35S F-860

F-820 44093 Contactor 6A 208V/60HZ/3 for F35S F-840 66897

Deposit Drainage Pipe D.27 L.62 Gas

3/4" AISI304 for F35S

O-Ring, Int. Diam. 340x4, Flange Dough

Barrel for F35S

Transparent Fabric Hose PVC D.32x25,

Deposit Drain for F35S

Grommet, S-TEC 5308959 M20x1,5/13

Poliamyde, Grey for F35S

Wall Pass-Through D.34/21,8x6mm

EPDM Black 70 SH for F35S

Threaded Rod Hydraulic Control M8

L=268mm AISI304 for F35S

Internal Fork, Hydraulic Control Activator,

Stainless Steel for F35S

Cylindrical Pin, D.6x19,5 Stainless Steel

for F35S

Holder, Microswitch Distributor, Stainless

Steel for F35S

Hydraulic Control 102N8SA23X-340 with

Pressure Knob for F35S

External Pressure Valve Control Assembly M1670/861, Black Knob for F35S

Micro Position Detector, Comepi Metal

Wheel for F35S

Pressure Gauge D.63, WIKA 213.53,

0-200 Bar, Thread 1-4" for F35S

Isolating Box, Legrand 100x100x55mm

Code 92138 for F35S

Isolating Box, IDE 162x116x76, Polycarbonate (H UL-CSA +110V) for F35S

Contactor, LS MC-22B AC 110V/60&50Hz

1A1B EXP A.C. 22 AMP for F35S

F-822 66882

F-823 66883

F-824 66884 Fan, 110V-60HZ-1 for F35S F-844

F-826 66925 Motor, 110V-60HZ-1 for F35S F-845

F-828 19410

F-829 66886

F-830 66887 Support Motor Cabinet for F35S F-847

F-831 31222

F-832 31221

F-833 64313 Gear Pump 1L05IB01 R for F35S F-850

F-834 66889 Support Oil Reservoir/Cabinet for F35S F-851

F-835 66890

F-836 66891 Oil Cap, Depressurized, Red for F35S F-853

F-839 36110 Wheel, D.125mm Nylon for F35S F-856

F-839 66926 Panel Access Cabinet for F35S F-858

F-840 66895

Cap, Kapsto, GPN270 REF. R6030 3

for F35S

Extension Swivel Castor AISI304 for

F35S

Swivel Castor Black Stainless Steel with

Brake for F35S

Motor 1-Phase 1/220V-60HZ-1.75HP-1

3KW-1700 Clockwise Rotation for F35S

Motor H26 3-Phase H 3/208/220V-60HZ-

1.5HP-1.1KW 1700 RPM for F35S

Silent Block Single Phase Motor

70x30x5mm EPDM Black for F35S

Motor-Pump Coupling for Fillers/Stuffers

for F35S

Seal, Vellumoid 1625-1 for Pump Type

L for F35S

Internal Oil Reservoir, Poliprop. White

for F35S

Activator Knee Lever D.15 L.70mm

AISI303 for F35S

Brass Bushing, B11 B-15-20-20/25-3

with Collar for F35S

F-841

F-842

F-843

F-845

F-845

F-846

F-848

F-849

F-852

F-859

F-861

36

Page 37

Parts Breakdown

Model SS-ES-0065-F 45870

Model SS-ES-0065-FS 46101

Model SS-ES-0065-FT 46100

Item No. Description Position Item No. Description Position Item No. Description Position

66898 O-Ring, Int. Diam. 61x2 for F35S F-862 66903

66899 Support Knee Lever AISI304 for F35S F-863 66904

66900 Gasket, Knee Lever for F35S F-864 66905

66901

66902

Knee Lever, Plastic APM1000 Black

for F35S

Hydraulic Union, Simple, GE8LR 3/8"

BSP for F35S

F-865 66906

F-866 66907

T Joint EVL-08 (Outlet Control to Hydraulic Cylinder + Gauge) for F35S

Hose, 460mm R1T1/4 TL90HG8LTL45HG8L, Bottom Cylin-Hydr Control

for F35S

Hose, Pressure Gauge 1/4", Length

500mm for F35S

Hydraulic Union, Simple MF 1/4 BSPP

HF 1/4 BSPP for F35S

Hose, 290mm R1T1/4 ESF1/4TL90HG8L, Top Cylin-Hydraulic Control

for F35S

F-867 66908

F-868 66909

F-869 61763

F-870 66910

F-871 65038

Hose Clamp, MIKALOR D.12-20/9 for

Hydr. Oil Drain Tube NH for F35S

Rubber Hose KLEMINE-20 Bar D.12x20

for F35S

Nozzle Cover, Rubber 12 Male Thread

3/8" (Draining Hose) for F35S

Hose, 720mm R1T1/4 TL90HG8LTL45HG8L (Hydraulic Pump Control)

for F35S

Hydraulic Union, Simple, GE8LR 1/4"

BSP for F35S

F-872

F-873

F-875

F-878

F-879

37

Page 38

Parts Breakdown

Model SS-ES-0095-F 45951

Model SS-ES-0095-FS 46102

Model SS-ES-0095-FT 46103

38

Page 39

Model SS-ES-0095-F 45951

Model SS-ES-0095-FS 46102

Model SS-ES-0095-FT 46103

Parts Breakdown

39

Page 40

Parts Breakdown

Model SS-ES-0095-F 45951

Model SS-ES-0095-FS 46102

Model SS-ES-0095-FT 46103

Item No. Description Position Item No. Description Position Item No. Description Position

66842

66843

66844

66845

66933

66847

66934

66935

66936

66937 Nut for Lid Lock AISI303 for F50S F-807 66874

66852

66938 Knob Black Thread M10 80mm for F50S F-809 66876

66854

66855

66939

66940

66941

66942

66943

66944

66945

66946

66947

Nozzle/Horn Retention Nut Black for

F50S

Nozzle/Horn Poliet. HD Translucent

D.Ext.14 Int.10L.Use 160mm (6") for

F50S

Nozzle/Horn Poliet. HD Translucent

D.Ext.20 Int.16L.Use 196mm (8") for

F50S

Nozzle/Horn Poliet. HD Translucent

D.Ext.30 Int.26L.Use 196mm (8") for

F50S

Stainless Steel Lid, without Accessories

for F50S

Lid Opening Lever AISI303 (All Stuffers/

Fillers FS) for F50S

Bras Bushing B11 A-42-54-30 Lid for

F50S

Stainless Steel Bolt, M39/M36 Lid for

F50S

Bushing for Lid Lock Nut, Plastic APM500

Black for F50S

Lever for Lid Lock Nut AISI303, without

Black Knob for F50S

Spanner/Wrench, Piston Extractor for

F50S

CSK Allen Screw, Stainless Steel

M16x35 DIN7991 for F50S

O-Ring, Int. Diam. 345x10 Red Silicone

(1*Piston) for F50S

Piston, Stainless Steel, without O-Ring

for F50S

O-Ring, Int. Diam. 34x2mm Threaded Tip

Piston for F50S

Threaded Tip Hydraulic Cylinder Bolt

AISI303 for F50S

Hood Clamp, Hydraulic Cylinder,

D.198mm NBR70 for F50S

Stainless Steel Hexagonal Screw,

M12x35 DIN933 for F50S

Hydraulic Cylinder, DE0450800449G01

Filler/Stuffer for F50S

O-Ring, Int. Diam. 165x5mm, Hydraulic

Cylinder for F50S

Lid Seal Polyurethane Red, Diam.Ext.

404mm for F50S

F-800 66948 Fixed Dough Barrel for F50S F-821 66954

F-801 66866

F-801 66949

F-801 66868

F-802 66950 Cabinet with Accessories for F50S F-825 39059 Air Extraction Fan 220V 1PH for F50S F-844

F-803 66870