Page 1

Refrigerated Pizza Prep Units

Models PT-CN-1270-HC, 1829-HC, 2337-HC

Items 50042, 50043, 50044

Instruction Manual

Revised - 08/28/2019

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model PT-CN-1270-HC / Model PT-CN-1829-HC / Model PT-CN-2337-HC

Section

General Information

Safety and Warranty

Technical Specications

Installation

Maintenance

Troubleshooting

--------------------------------------------------------------------------------------- 6 - 8

------------------------------------------------------------------------------------- 8 - 9

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 5

------------------------------------------------------------------------------- 9 - 10

Page

-------------------------------------------------------------------------- 6

Controller Instructions

Parts Breakdown

Electrical Schematics

Warranty Registration

---------------------------------------------------------------------------- 14 - 19

--------------------------------------------------------------------- 11 - 13

---------------------------------------------------------------------- 20 - 22

--------------------------------------------------------------------------- 23

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

Please pay close attention to the safety notices in this section. Disregarding these notices may lead to

serious injury and/or damage to the unit.

ATTENTION

• To minimize shock and re hazards, be sure not to overload outlet. Please designate one outlet for your

unit.

4

Page 5

Safety and Warranty

• Do not use extension cords.

• Do not put your hands under the unit when the unit is required to be moved.

• When the unit is not in use for a long period of time, please unplug the unit from the outlet.

• After unplugging the unit, wait at least 10 minutes before re-plugging it. Failure to do so could cause

damage to the compressor.

UNPLUG CORD

• To minimize shock and re hazards, please do not plug or unplug the cord with wet hands.

• During maintenance and cleaning, please unplug the unit.

PROPER GROUNDING REQUIRED

• To minimize shock and re hazards, make sure that the unit is properly grounded.

PROHIBITION

• Do not attempt to remove or repair any component unless instructed by factory.

• Make sure that the unit is not resting on or against the electrical cord and plug.

• To minimize personal injury, do not hang on the doors.

• Do not store any ammable and explosive gas or liquids inside the unit.

• Do not attempt to alter or tamper with the electrical cord.

2 YEARS PARTS AND LABOUR / 5 YEARS PARTS ONLY ON COMPRESSOR

WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

5

Page 6

Technical Specications

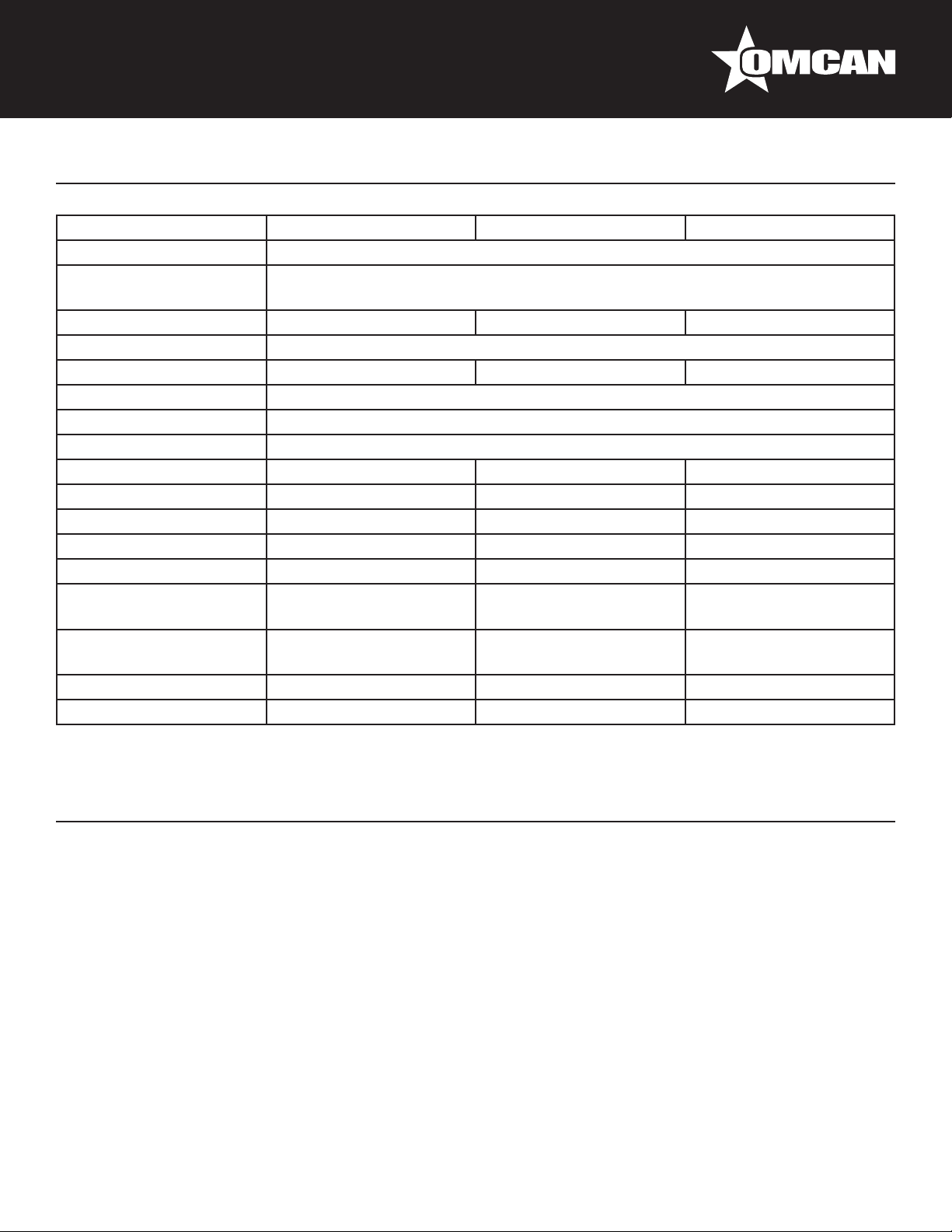

Model PT-CN-1270-HC PT-CN-1829-HC PT-CN-2337-HC

Temperature Range 0.5°C - 5°C / 33°F - 41°F

Max Ambient

Temperature Rating

Horsepower 1/6 HP 1/5 HP 1/4 HP

Electrical 110V / 60Hz / 1Ph

Amps 2.6A 3.4A 5.3A

Refrigerant R290

Isolation Material Cyclopentane

Cooling System Ventilated

Number of Inserts 6 - 1/3 pans 9 - 1/3 pans 12 - 1/3 pan

Number of Doors 1 2 3

Number of Shelves 1 2 3

Shelf Capacity 73 lbs. / 33 kgs. 64 lbs. / 29 kgs. 61.7 lbs. / 28 kgs.

Net Volume 391 L / 13.8 cu.ft. 479 L / 16.9 cu.ft. 684 L / 24.2 cu.ft.

Exterior Dimensions

Interior Dimensions

Weight 374 lbs. / 170 kgs. 431 lbs. / 195.5 kgs. 565 lbs. / 256.3 kgs.

Item Number 50042 50043 50044

49.9” x 31.5” x 42.9”

1266 x 800 x 1088mm

27.4” x 22.8” x 26.2”

696 x 580 x 665mm

32°C / 90°F

70.9” x 31.5” x 42.9”

1801 x 800 x 1088mm

48.4” x 22.8 x 26.2”

1229 x 580 x 665mm

91.9” x 31.5” x 42.9”

2334 x 800 x 1088mm

69.5” x 22.8” x 26.2”

1765 x 580 x 665mm

Installation

IMPORTANT!!!PLEASE READ BEFORE INSTALLATION

• If the unit has recently been transported. Please let unit stand still for a minimum of 24 hours before

plugging it in.

• Make sure that the unit drops down to desired temperature before loading the unit with product.

• Make sure that there is proper ventilation around the unit in the area where it will operate.

• Make sure all accessories are installed(i.e. shelves, shelf clips, casters) before plugging the unit in.

• Please read through the Operation / Owner’s Manual in its entirety.

CABINET LOCATION GUIDELINES

• Install the unit on strong and leveled surfaces.

- Unit may make unpleasant noises if surface is uneven.

- Unit may malfunction if surface is uneven.

6

Page 7

Installation

• Install the unit in an indoor, well-ventilated area.

- Unit performs more efciently in a well-ventilated area.

- For best performance, please maintain clearance of 6” on the back of the unit.

- Outdoor use may cause decreased efciency and damage to the unit.

• Avoid installation in a high humidity and/or dusty area.

- Humidity could cause unit to rust and decrease efciency of the unit.

- Dust collected on condenser coil will cause unit to malfunction. Clean the condenser at least once a

month with a brush or clean cloth.

- Malfunction due to dirty condenser will void warranty.

• Select a location away from heat and moisture-generating equipment.

- High ambient temperature will cause the compressor to overwork, leading to higher energy bills and

gradual breakdown of the unit.

- Malfunction due to high ambient temperature will void warranty.

ELECTRICAL

Please ensure that the required voltage of the compressor is being supplied at all times. Low or high voltage

can detrimentally affect the refrigeration unit. All units should be plugged into a grounded and properly-sized

electrical outlet with appropriate overcurrent protection. Please refer to the electrical requirement on the

nameplate of the unit. Please make sure that your unit has its own dedicated outlet. Do not use an extension

cord.

TEMPERATURE CONTROLS

The temperature controls are factory-set to maintain an average temperature of 38°F in refrigeration. To

maintain a different temperature, adjust it on the temperature controller–see manual of temperature controller.

CAUTION

Setting the temperature control to the coldest setting may cause the evaporator coil to freeze and ice up. This

will eventually result in a warmer cabinet temperature.

LOADING PRODUCT

Shelves have been factory-installed for your convenience. Before loading shelves, please be sure that all shelf

clips are completely fastened in their correct locations. It is important that all shelves rest completely level

before stocking your cabinet with product. In order to maintain correct air ow inside the unit, please be sure

to leave two to four(2 to 4) inches of space between the back wall and stored product. Blocking the evaporator

fans will result in a warmer cabinet temperature, and ultimately compressor failure.

DEFROST SYSTEMS

Refrigerator coils are kept below the freezing point(32°F). During compressor down-time, the evaporator fan

continues to circulate air through the evaporator coil. This air circulation raises the coil temperature above the

freezing point, melting any accumulated frost. Run-off water is drained into the evaporator pan and evaporated.

Freezer coils are defrosted electrically. Automatic defrost timers are built-in to the refrigeration system and may

7

Page 8

Installation

not be adjusted. The defrost timers automatically initiate at pre-set intervals and for a pre-determined duration.

PLEASE NOTE: Excessive door opening should be avoided in order to maintain cabinet temperature and to

eliminate the possibility of coil freeze-up.

LOADING FOOD PANS

Pizza prep units and sandwich prep units are designed to function with all pans in place, even if some pans are

to be left empty. For maximum food freshness, Fill the pans only with an amount that can be used in a specic

usage period. During non-use, please close the insulated lid cover.

REVERSING THE DOORS (OPTIONAL)

Note: This only applies to the single door units.

Only perform these steps with another person present to ensure the door does not fall over.

1. Open the door.

2. Remove the screws from the top panel, then open the top panel.

3. Remove the screws of the bottom louver, then remove the louver.

4. Unscrew all of the screws from the upper hinge

5. Unscrew all of the screws from the lower hinge and remove the door and hinges.

6. Place the former upper hinge at the bottom of the unit, parallel to where the lower hinge is, do the same

with the former lower hinge except for the top. Screw the hinges into place.

7. Reassemble the door so it is facing the opposite direction.

8. Reassemble the top panel and the lower louver.

9. The door is now reversed.

Maintenance

CLEANING THE CONDENSER COIL

• For efcient operation, it is important that the condenser surface be kept free of dust, dirt, and lint.

• We recommend cleaning the condenser coil and ns at least once per month.

• Clean with a commercial condenser coil cleaner, available from any kitchen equipment retailer. Brush the

condenser ns from top to bottom, not side to side.

• After cleaning, straighten any bent condenser ns with a n comb.

CLEANING THE FAN BLADE AND MOTOR

• If necessary, clean the fan blades and motor with a soft cloth, If it is necessary to wash the fan blades,

cover the fan motor to prevent moisture damage.

8

Page 9

Maintenance

CLEANING THE INTERIOR OF UNIT

• When cleaning the cabinet interior, use a solvent of warm water and mild soap.

• Do not use steel wool, caustic soap, abrasive cleaners, or bleach that may damage the stainless steel

surface.

• Wash door gaskets on a regular basis, preferably weekly. Simply remove door gasket from the frame of the

door, soak in warm water and soap for thirty (30) minutes, dry with soft cloth, and replace.

• Check door gaskets for proper seal after they are replaced.

• Periodically remove the shelves and pilasters from the unit and clean them with mild soap and warm water.

To remove the pilasters, rst remove the shelves and shelf brackets. Then, simply lift the pilaster up and

out.

WARNING

Disconnect power cord before cleaning any parts of the unit.

Troubleshooting

Before requesting any service on your unit, please check the following points. Please note that this

guide serve only as a reference for solutions to common problems.

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Compressor not running. Fuse blown or circuit breaker

tripped.

Power cord unplugged. Plug in power cord.

Thermostat set too high. Set thermostat to lower

Cabinet in defrost cycle. Wait for defrost cycle to nish.

Replace fuse or reset circuit

breaker.

Temperature.

9

Page 10

Troubleshooting

Condensing unit runs for long

periods of time.

Cabinet is noisy. Loose part(s). Locate and tighten loose part(s).

Cabinet Temperature Is too warm. Thermostat set too warm. Set thermostat to lower

Excessive amount of warm product

Placed in cabinet.

Prolonged door opening or door

ajar.

Door gasket(s) not sealing

properly.

Dirty condenser coil. Clean the condenser coil.

Evaporator coil iced over. Unplug unit and allow coil to

Tubing vibration. Ensure tubing is free from contact

Blocking air ow. Re-arrange product to allow for

Excessive amount of warm product

Placed in cabinet.

Fuse blown or circuit breaker

tripped.

Dirty condenser coil. Clean the condenser coil.

Prolonged door opening or door

ajar.

Evaporator coil iced over. (see above)

Allow adequate time for Product to

cool down.

Ensure doors are closed when not

in use. Avoid opening doors for

long periods of time.

Ensure gaskets are snapped in

Completely. Remove gasket and

Wash with soap and water. Check

condition of gasket and Replace if

necessary.

Defrost. Make sure thermostat is

not set too cold. Ensure that door

gasket(s) are sealing properly.

with other tubing or components.

Temperature.

Proper air ow. Make sure there

Is at least four inches of clearance

from evaporator.

Allow adequate time for product to

cool down.

Replace fuse or reset circuit

breaker.

Ensure doors are closed when not

in use. Avoid opening doors for

long periods of time.

For service call 1-800-465-0234.

10

Page 11

Controller Instructions

Digital controller model: PJEZ for cooler

Display and functions

During normal operation, the controller displays the value of the probe set using parameter/4(=1 ambient

probe, default, = 2 second probe, = 3 third probe).In addition, the display has LEDs that indicate the activation

of the control functions (see Table 1), while the 3 buttons can be used to activate/deactivate some of the

functions(see Table 2).

LED’s and Associated Functions (Table 1)

Icon Function Normal Operation Start Up

ON OFF Blink

Compressor On Off Request ON

Fan On Off Request ON

Defrost On Off Request ON

Aux Output On Output Off - ON

Alarm All No Alarm - ON

Clock RTC tted and enabled, at

least 1 time band set

RTC not tted or disabled, not

even 1 time band set

- ON if RTC

tted

11

Page 12

Controller Instructions

Table of Functions activated by the buttons - Models S, X, Y, C (Table 2)

Button Normal Operation Start Up

Pressing the Button Alone Pressed Together

Up

ON/OFF

Down

Defrost

Set Mute - 1 sec.: display/set the set

Setting the set point (desired temperature)

More than 3 sec: toggle ON/

OFF

More than 3 sec: start/stop

defrost

point.

- more than 3 secs.: access

parameter setting menu

(enter password )

- mute audible alarm

(buzzer)

Start/Stop

continuous cycle

- For 1 sec.

-

Pressed

together

Start parameter

reset procedure

For 1 sec.

display

rmware

vers. code

RESET current EZY set

• press SET for 1 sec, the set value will start ashing after a few moments;

• increase or decrease the value using UP or DOWN;

• press SET to conrm the new value.

Switching the device ON/OFF

Press UP for more than 3 sec. The control and defrost algorithms are now disabled and the Instrument

displays the message “OFF” alternating with the temperature read by the set probe

Manual defrost

Press for DOWN more than 3 sec (the defrost starts only the temperature conditions are valid).

Continuous cycle

Press UP and DOWN together for more than 3 sec

Access and setting type F (frequent) and type C (conguration) parameters

1. press SET for 3 sec (the display will show “PS”);

2. • to access the type F and C parameter menu, enter the password “22” using UP/DOWN, press SET to

conrm;

• to access the F parameter menu only, press SET (without entering the password);

3. scroll inside the parameter menu using UP/DOWN;

12

Page 13

Controller Instructions

• to display/set the values of the parameter displayed, press SET, then UP/DOWN and nally SET to

conrm the changes (returning to the parameter menu).

To save all the new values and exit the parameter menu, press SET for 3 s;

To exit the menu without saving the changed values (exit by timeout) do not press any button for at least 60 s.

REFERENCE

Item Number Model Number Description Manufacturer Model Number

50042 PT-CN-1270-HC

50043 PT-CN-1829-HC

50044 PT-CN-2337-HC

Refrigerated Prep Table Pizza

50” / 1270mm 110V/60/1 ETL cETLus

Refrigerated Prep Table Pizza

72” / 1829mm 110V/60/1 ETL cETLus

Refrigerated Prep Table Pizza

92” / 2337mm 110V/60/1 ETL cETLus

PICL1-HC

PICL2-HC

PICL3-HC

13

Page 14

Parts Breakdown

Model PT-CN-1270-HC 50042

14

Page 15

Parts Breakdown

Model PT-CN-1270-HC 50042

Item No. Description Position Item No. Description Position Item No. Description Position

AB462 Cabinet for PICL1-HC 1 AB476 Evaporator for PICL1-HC 20 AB159 Condenser for PICL1-HC 39

AB463 Top Rail for PICL1-HC 2 AB477

AB464 Control Panel for PICL1-HC 3 AB478

AB465 Door for PICL1-HC 4 AB479

AB466 Gasket for PICL1-HC 5 AB480

AA388 Axis Cover for PICL1-HC 6 68809 Evaporator Fan Motor for PICL1-HC 25 AA371 Filter for PICL1-HC 44

AA955 Spring Hinge Board for PICL1-HC 7 AA962

AA360 Bottom Right Hinge for PICL1-HC 8 AA971 Evaporator Fan Cover for PICL1-HC 27 AB493 Air Shield Board for PICL1-HC 46

AA359 Upper Right Hinge for PICL1-HC 9 AB481 Evaporator Cover for PICL1-HC 28 64172 Compressor for PICL1-HC 47

AB467 Stand Off Bracket for PICL1-HC 10 AB482 Air Guide Sheet for PICL1-HC 29 AB494 Starter Kit for PICL1-HC 48 - 51

AB468 Fixer for Cutting Board for PICL1-HC 11 AB483 Pan Bracket-25 for PICL1-HC 30 AA584 4" Castor with Brake for PICL1-HC 52

AB469 Cutting Board for PICL1-HC 12 AB484 K Strip-3 Holes for PICL1-HC 31 AA743 4" Castor for PICL1-HC 53

AB470 Inner Drain Pan for PICL1-HC 13 AB485 K Strip-4 Holes for PICL1-HC 32 AB495 Back Grill for PICL1-HC 54

AA124 Power Switch for PICL1-HC 14 AB486 K Clip for PICL1-HC 33 AB169 Foaming Hole Cover for PICL1-HC 55

AB471 Thermostat for PICL1-HC 15 AB487 Shelf for PICL1-HC 34 AA133 Drain Hose for PICL1-HC 56

AB472 Left Lid Hinge for PICL1-HC 16 AB488 Castor Support for PICL1-HC 35 AA135 Power Cord for PICL1-HC 57

AB473 Right Lid Hinge for PICL1-HC 17 AB489 Left Compressor Unit Track for PICL1-HC 36 AA379

AB474 Lid for PICL1-HC 18 AB490

AB475 Lid Hinge Axis for PICL1-HC 19 AB491

Left Support of Evaporator Cover for

PICL1-HC

Right Support of Evaporator Cover for

PICL1-HC

Upper Support of Evaporator Cover for

PICL1-HC

Evaporator Fan Motor Holder for

PICL1-HC

Blade of Evaporator Fan Motor for

PICL1-HC

Right Compressor Unit Track for

PICL1-HC

Compressor Unit Installation Board for

PICL1-HC

21 AA607 Condenser Fan Motor for PICL1-HC 40

22 AA208

23 AA207 Condenser Fan Cover for PICL1-HC 42

24 AA129 Filter Fixer for PICL1-HC 43

26 AB492 Outer Drain Pan for PICL1-HC 45

37

38

Blade of Condenser Fan Motor for

PICL1-HC

Temperature Sensor of Cabinet Inside

for PICL1-HC

41

58

15

Page 16

Parts Breakdown

Model PT-CN-1829-HC 50043

16

Page 17

Parts Breakdown

Model PT-CN-1829-HC 50043

Item No. Description Position Item No. Description Position Item No. Description Position

AB496 Cabinet for PICL2-HC 1 AB508 Right Lid Hinge for PICL2-HC 21 AB524

AB497 Top Rail for PICL2-HC 2 AB509 Lid for PICL2-HC 22 AB525

AB498 Control Panel for PICL2-HC 3 AB475 Lid Hinge Axis for PICL2-HC 23 AB526

AB499 Right Door for PICL2-HC 4 AB510 Lid for PICL2-HC 24 AB527 Condenser for PICL2-HC 44

AB500 Gasket for PICL2-HC 5 AB511 Evaporator for PICL2-HC 25 AA984 Condenser Fan Motor for PICL2-HC 45

AA388 Axis Cover for PICL2-HC 6 AB512

AA955 Spring Hinge Board for PICL2-HC 7 AB513

AA360 Bottom Right Hinge for PICL2-HC 8 AB514

AA359 Upper Right Hinge for PICL2-HC 9 AB515

AB501 Left Door for PICL2-HC 10 68809 Evaporator Fan Motor for PICL2-HC 30 AB528 Outer Drain Pan for PICL2-HC 50

AB500 Gasket for PICL2-HC 11 AA962

61468 Bottom Left Hinge for PICL2-HC 12 AA971 Evaporator Fan Cover for PICL2-HC 32 64167 Compressor for PICL2-HC 52

AB200 Upper Left Hinge for PICL2-HC 13 AB516 Evaporator Cover for PICL2-HC 33 AB530 Starter Kit for PICL2-HC 53 - 56

AB502 Stand Off Bracket for PICL2-HC 14 AB517 Air Guide Sheet for PICL2-HC 34 AA584 4" Castor with Brake for PICL2-HC 57

AB503 Fixer for Cutting Board for PICL2-HC 15 AB518 Pan Bracket-25 for PICL2-HC 35 AA743 4" Castor for PICL2-HC 58

AB504 Cutting Board for PICL2-HC 16 AB519 K Strip-3 Holes for PICL2-HC 36 AB531 Back Grill for PICL2-HC 59

AB505 Inner Drain Pan for PICL2-HC 17 AB520 K Strip-4 Holes for PICL2-HC 37 AB169 Foaming Hole Cover for PICL2-HC 60

AA124 Power Switch for PICL2-HC 18 AB521 K Clip for PICL2-HC 38 AA133 Drain Hose for PICL2-HC 61

AB506 Thermostat for PICL2-HC 19 AB522 Shelf for PICL2-HC 39 AA135 Power Cord for PICL2-HC 62

AB507 Left Lid Hinge for PICL2-HC 20 AB523 Castor Support for PICL2-HC 40 AA379

Left Support of Evaporator Cover for

PICL2-HC

Right Support of Evaporator Cover for

PICL2-HC

Upper Support of Evaporator Cover for

PICL2-HC

Evaporator Fan Motor Holder for

PICL2-HC

Blade of Evaporator Fan Motor for

PICL2-HC

26 AA248

27 AA249 Condenser Fan Cover for PICL2-HC 47

28 AA129 Filter Fixer for PICL2-HC 48

29 AA371 Filter for PICL2-HC 49

31 AB529 Air Shield Board for PICL2-HC 51

Left Compressor Unit Track for

PICL2-HC

Right Compressor Unit Track for

PICL2-HC

Compressor Unit Installation Board for

PICL2-HC

Blade of Condenser Fan Motor for

PICL2-HC

Temperature Sensor of Cabinet Inside

for PICL2-HC

41

42

43

46

63

17

Page 18

Parts Breakdown

Model PT-CN-2337-HC 50044

18

Page 19

Parts Breakdown

Model PT-CN-2337-HC 50044

Item No. Description Position Item No. Description Position Item No. Description Position

AB532 Cabinet for PICL3-HC 1 AB544 Right Lid Hinge for PICL3-HC 21 AB560

AB533 Top Rail for PICL3-HC 2 AB545 Lid for PICL3-HC 22 AB561

AB534 Control Panel for PICL3-HC 3 AB475 Lid Hinge Axis for PICL3-HC 23 AB527 Condenser for PICL3-HC 43

AB535 Right Door for PICL3-HC 4 AB546 Evaporator for PICL3-HC 24 AA984 Condenser Fan Motor for PICL3-HC 44

AB536 Gasket for PICL3-HC 5 AB547

AA388 Axis Cover for PICL3-HC 6 AB548

AA955 Spring Hinge Board for PICL3-HC 7 AB549

AA360 Bottom Right Hinge for PICL3-HC 8 AB550

AA359 Upper Right Hinge for PICL3-HC 9 68809 Evaporator Fan Motor for PICL3-HC 29 AB562 Outer Drain Pan for PICL3-HC 49

AB537 Left Door for PICL3-HC 10 AA962

AB536 Gasket for PICL3-HC 11 AA971 Evaporator Fan Cover for PICL3-HC 31 64168 Compressor for PICL3-HC 51

61468 Bottom Left Hinge for PICL3-HC 12 AB551 Evaporator Cover for PICL3-HC 32 AB564 Starter Kit for PICL3-HC 52 - 55

AB200 Upper Left Hinge for PICL3-HC 13 AB552 Air Guide Sheet for PICL3-HC 33 AA584 4" Castor with Brake for PICL3-HC 56

AB538 Stand Off Bracket for PICL3-HC 14 AB553 Pan Bracket-25 for PICL3-HC 34 AA743 4" Castor for PICL3-HC 57

AB539 Fixer for Cutting Board for PICL3-HC 15 AB554 K Strip-3 Holes for PICL3-HC 35 AB565 Back Grill for PICL3-HC 58

AB540 Cutting Board for PICL3-HC 16 AB555 K Strip-4 Holes for PICL3-HC 36 AB169 Foaming Hole Cover for PICL3-HC 59

AB541 Inner Drain Pan for PICL3-HC 17 AB556 K Clip for PICL3-HC 37 AA133 Drain Hose for PICL3-HC 60

AA124 Power Switch for PICL3-HC 18 AB557 Shelf for PICL3-HC 38 AA135 Power Cord for PICL3-HC 61

AB542 Thermostat for PICL3-HC 19 AB558 Castor Support for PICL3-HC 39 AA379

AB543 Left Lid Hinge for PICL3-HC 20 AB559 Left Compressor Unit Track for PICL3-HC 40

Left Support of Evaporator Cover for

PICL3-HC

Right Support of Evaporator Cover for

PICL3-HC

Upper Support of Evaporator Cover for

PICL3-HC

Evaporator Fan Motor Holder for

PICL3-HC

Blade of Evaporator Fan Motor for

PICL3-HC

25 AA248

26 AA249 Condenser Fan Cover for PICL3-HC 46

27 AA129 Filter Fixer for PICL3-HC 47

28 AA371 Filter for PICL3-HC 48

30 AB563 Air Shield Board for PICL3-HC 50

Right Compressor Unit Track for

PICL3-HC

Compressor Unit Installation Board for

PICL3-HC

Blade of Condenser Fan Motor for

PICL3-HC

Temperature Sensor of Cabinet Inside

for PICL3-HC

41

42

45

62

19

Page 20

Electrical Schematics

Model PT-CN-1270-HC 50042

20

Page 21

Model PT-CN-1829-HC 50043

Electrical Schematics

21

Page 22

Electrical Schematics

Model PT-CN-2337-HC 50044

22

Page 23

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

https://omcan.com/warranty-registration/

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

23

Page 24

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 5,000 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 5000

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 5,000 productos con origen a nivel mundial.

Loading...

Loading...