Page 1

Pasta Machine

Model PM-IT-0004

Item 13320

Instruction Manual

Revised - 03/29/2017

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Locally QPS

Approved

Page 2

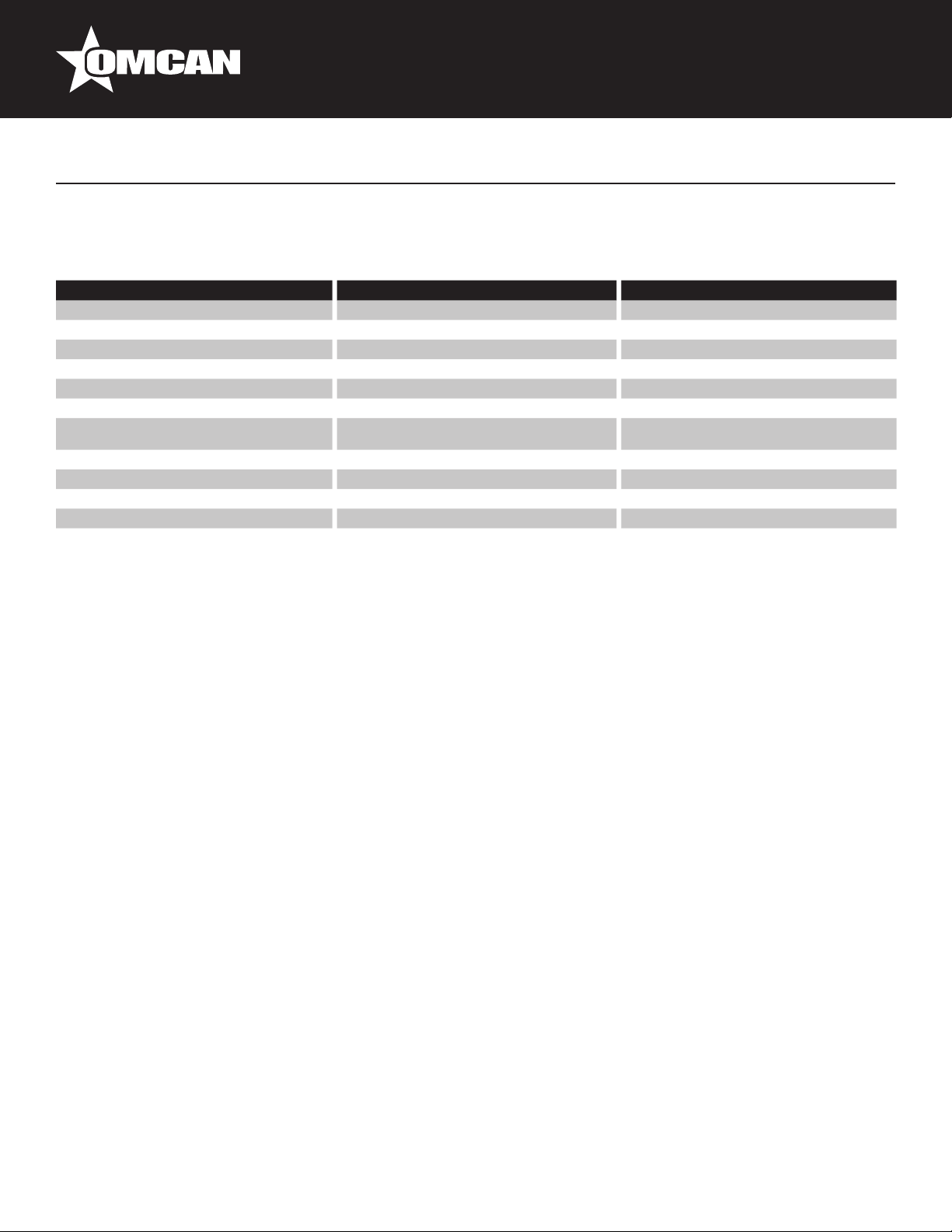

Table of Contents

Model PM-IT-0004

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

Troubleshooting

---------------------------------------------------------------------------------------------------------- 6 - 8

----------------------------------------------------------------------------------------------------------- 8 - 9

----------------------------------------------------------------------------------------------------- 9 - 11

--------------------------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------------------------- 4 - 6

----------------------------------------------------------------------------------------------------- 11

Page

-------------------------------------------------------------------------------------------- 6

Instructions Français

Instrucciones en Español

Illustrated Drawings

Parts Breakdown

Electrical Schematics

Warranty Registration

----------------------------------------------------------------------------------------- 12 - 19

------------------------------------------------------------------------------------------------ 27

---------------------------------------------------------------------------------------------- 28 - 29

---------------------------------------------------------------------------------------------- 30

---------------------------------------------------------------------------------------------- 31

----------------------------------------------------------------------------------- 19 - 26

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

--------------------------------------------------------------------------------------------------------------------------------------------------Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

--------------------------------------------------------------------------------------------------------------------------------------------------Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre leer y familiarizarse con todas las instrucciones de

operación y seguridad.

Omcan quisiera darles las gracias por la compra de esta máquina. Es de la máxima importancia para

guardar estas instrucciones para referencias en el futuro. También guarde la caja original y el embalaje

para envío del equipo si el mantenimiento o la devolución de la máquina es necesaria.

Safety and Warranty

SAFETY PRECAUTIONS

This machine has been manufactured to make your work as safe as possible. Caution is, nevertheless, the

golden rule to follow to prevent accidents. Do not put this manual away without reading it rst, regardless of

any previous personal experience. A little time spent in reading will save time and extra work. Read this manual

thoroughly before proceeding with start-up, use, maintenance and other operations. Read and rigorously follow

the herein contained instructions and recommendations:

4

Page 5

Safety and Warranty

• Read all warning labels applied to any part of the machine, and promptly replace them when they become

worn or illegible.

• Only trained and authorised personnel should operate the machine.

• If any part jams or locks up, before clearing make sure you rst switch off the motor. DO NOT clean, oil

or grease by hand any moving parts of the machine. In addition, all repair and setting operations of any

moving parts with the motor running, are prohibited, unless the necessary precautions to prevent any

accidents have been taken beforehand.

• All moving parts are tted with adequate guards and protections. Always remount them after removal for

servicing.

• Be sure to wear tight-tting clothing without any loose parts. Never wear open or unfastened jackets, shirts

or overalls.

• To prevent accidents and ensure best performance, the machine must not be modied or altered unless

authorised by the manufacturer nor must it be used in conditions or for purposes other than those for which

it has been expressly designed. Any arbitrary modication implemented in this machine will automatically

exempt the manufacturer from any liabilities for ensuing damage or injury.

• Always keep children away from the machinery.

• For reasons of hygiene, health and warranty, it is strictly prohibited to use the machine for the processing of

substances other than foods. Any other uses are contrary to the applications as originally intended by the

manufacturer, who shall consequently not be held liable for any damage to the machine itself or to other

objects, or for any injuries to persons that may arise thereof. In taking the risk of misuse, the user will be

held responsible for any consequences.

For your own personal safety, before connecting the machine to mains:

• Check that power mains leading to distribution socket is tted with an appropriate multipolar switch

protected against overloads and shortcircuits.

• Carry out all phase connections, as well as any neutral and ground connections (compulsory) with a

standard plug compatible with the above mentioned socket. The protection lead (ground) is the one

with the yellow/green insulating sheath; make sure that the power supply cable is appropriate to its use,

according to length, mains voltage and machine consumption.

• Unless adequate protections against electrical shock are tted, do not operate the machine in damp or wet

environment.

Strictly do not start up the machine without the protective panelling. This may jeopardise personnel

safety and machine serviceability.

Caution: Store this manual in a safe place, near the machine, and disclose its storage location to all involved

personnel.

1 YEAR PARTS AND LABOUR BENCH WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule a drop off to either

an Omcan authorized service depot in the area, or to an Omcan Service warehouse to repair the

equipment.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

5

Page 6

Safety and Warranty

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

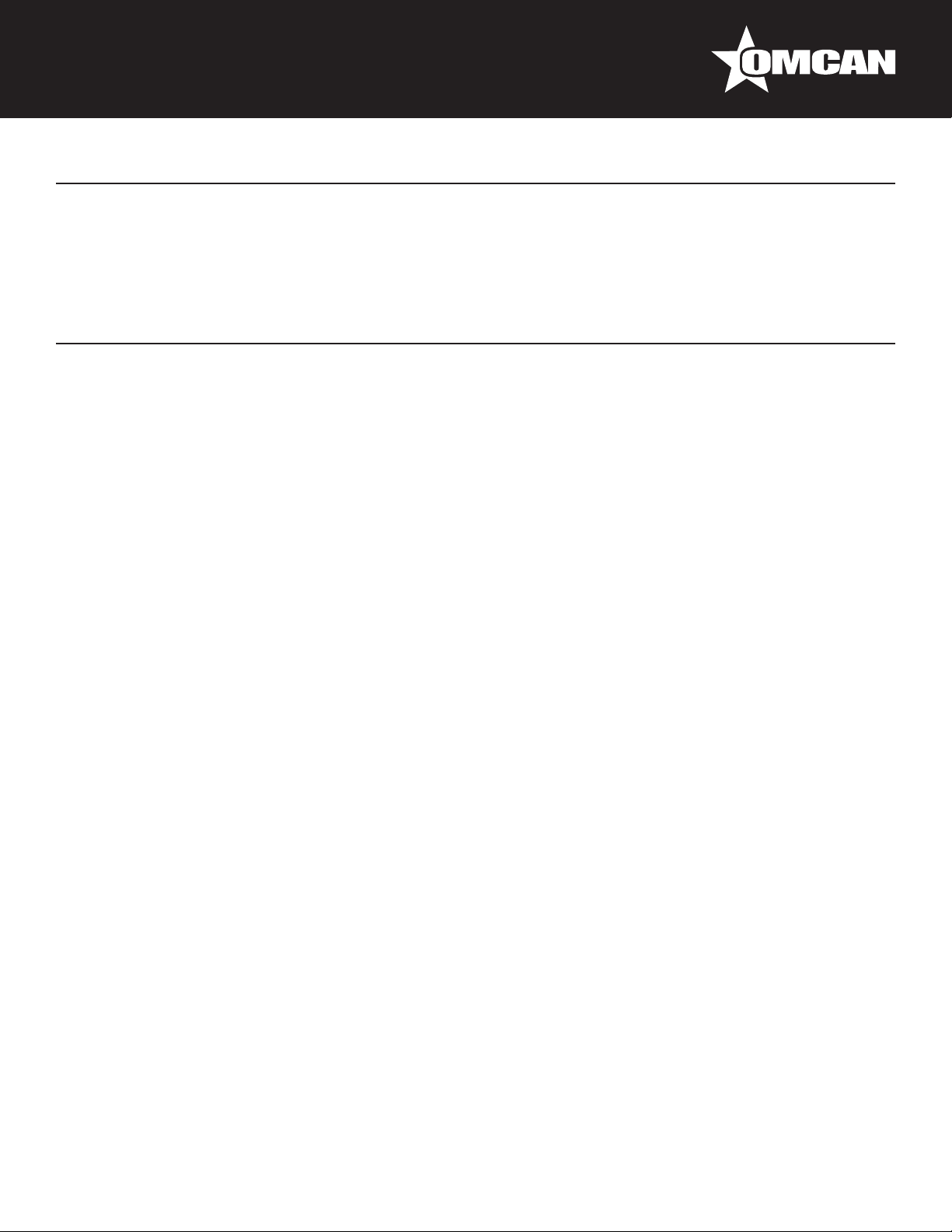

Technical Specications

Model PM-IT-0004

Tank Capacity 3.74 lbs. / 1.7 kg.

Power 0.5 HP / 0.37 kW

OUTPUT / HR 8.8 lbs. / 4 kg.

Dies Included N. 8 - Spaghetti, N. 21- Linguine, and N. 26-Fettuccine

Electrical 110 V / 60 Hz / 1 Ph

Weight 61 lbs. / 27.6 kg.

Packaging Weight 65 lbs. / 29 kg.

Dimensions (DWH) 10” x 14.5” x 16” / 254 x 368 x 406 mm

Packaging Dimension 20” x 15” x 22” / 508 x 381 x 559 mm

Item Number 13320

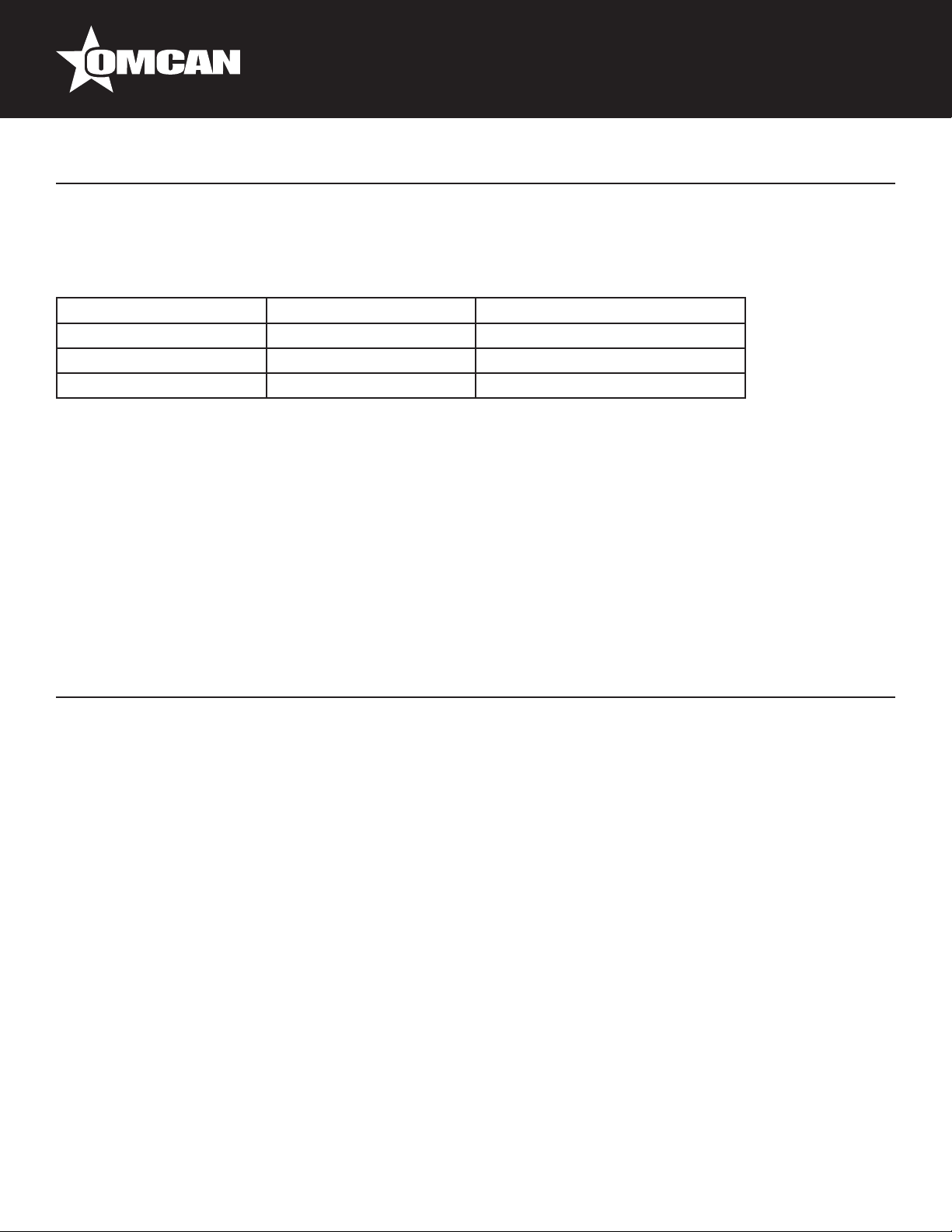

Installation

Install and use the machine in a room that can be efciently ventilated, and where the oor is smooth, compact

and easy to clean.

In order to give the necessary stability to the machine:

• Check that the footers (Fig. 8A) are securely attached to the oor; otherwise, turn them to avoid instability.

• Position the machine in the desired place with a free back space of around 50 centimeters and a side

6

Page 7

Installation

space of 70-80 centimeters in order to guarantee easy use of the machine and its cleaning (Fig. 9).

• Please check that the voltage of the machine which is written on the identication label, matches the one

foreseen by the system on your premises.

• Attach the right plug to the machine power cable in order to make the electrical connection to the system.

• After mating the plug to the mains socket, the machine is ready for use. First, however, check out proper

operation of all moving parts and components of the machine.

WARNING: During the machine’s operation, in order to obtain a product with the right thickness and humidity,

avoid air currents which will cause precocious drying of the product together with its deterioration.

INSTALLATION OF THE DRAWPLATE AND START-UP OF PRODUCTION

Before performing the installation an dproduction, make sure the machine is switched off.

• Withdraw the drawplate (Fig. 5A) requested by the container lled with water where it was put after its last

use.

• Thoroughly rinse with plenty of running warm water in order to have the piece at the right temperature.

Dry it with a soft cloth.

• Unscrew the blocking ring nuts (Fig. 5B and 6A) and carefully clean the internal part including the edging.

• Take the plastic cap off (Fig. 5C and 6B).

• Disassemble the drawplate (Fig. 7A).

• Screw in the ring nuts by hand and verify that all the pieces are in their places and that they are aligned

along the axle.

• In order to start production, position the selector on the position (Fig. 3D) and push the start button (Fig.

3B).

• The initial product coming out of the machine has an unacceptable look; this is the reason why it has to be

eliminated.

• After a short time (a couple of minutes) the product coming out is acceptable, the colour goes from whitish

to yellow and it has a greater thickness. The cut of the pasta at the desired length can be made by hand or

by knife. In the rst case it is usually long length noodles (spaghetti or tagliatelle) and in the second case is

especially short noodles (macaroni, etc.).

At the end of the operation:

• Stop the machine by switching the selector to the “0” position (Fig. 3C) and then turn it on the kneading

position (Fig. 3A) for 10-15 seconds so that the pressure on the drawplate, caused by the product itself,

is eliminated.

• Switch the selector to “0” (Fig. 3C) or push the Stop button (Fig. 3E).

• Disassemble and wash the moving pieces and clean the machine.

CONTROL OF THE INSTALLATION

Verify that:

• In the “0” position (Fig. 3C), all the elements of the machine have to stop.

• In the “drawplate position” (Fig. 3D), the mixer rotates in a counterclockwise direction and the Archimedean

screw must rotate in the opposite direction.

• In the “knead” position (Fig. 3A), the parts must rotate in the opposite direction.

NOTE: Every drive is voluntarily run by the start button, when the bowl cover is closed (Fig. 10F).

7

Page 8

Installation

WARNING: If the machine or some of its parts fail, call your local authorised dealer or concessionaire for

repairs.

Operation

PREPARING THE MACHINE

Prepare the machine before every process cycle. Be sure that the machine, especially parts which come in

contact with food products (extrusion sleeve, Archimedean screw, pool, mixer and drawplate) are perfectly

clean.

OPERATING PRINCIPLE

This machine kneads the different products desired and enables you to obtain different kinds of noodles with

a different group of lengths because it draws the dough. This action is carried out to a mixer linked to an

Archimedean screw which obliges the product to assume the desired shape going through a drawplate.

USE OF THE MACHINE

After having turned the machine off:

• Position the selector on “0” (Fig. 2C) and verify the correct set-up of the Archimedean screw (Fig. 1A)

making sure that the cylinder part is sustained by the dragging shaft.

• Make sure that the plastic cap (Fig. 1B), which replaces the drawplate, is correctly positioned and the ring

nut (Fig. 1C) is tightly well-screwed on.

• Lastly lock the mixer (Fig. 1D) tightly in its seat by means of the head-knob (Fig. 1E).

• Pull up the pool cover (Fig. 4A) and always put in the pre-established ingredients in the following sequence:

our and then, after closing the cap, all the other liquid elements.

In order to obtain the right dough, you need to create the right ratio between the weight of the our and the

weight of the liquid part. Iin order to obtain a very good product, the our has to contain a humidity percentage

of no more than 15%; this allows the addition of water equal to 35% or up to 38% of the our’s weight. If you

are using ours with different humidity contents, please change the quantity of the liquid in the opposite ratio.

Moreover, in order to better use the machine, the product inside the pool has to be higher than at a minimum

level which coincides more or less with the position of the mixer axle.

8

Page 9

Operation

QUANTITIES IN ORDER TO OBTAIN GOOD DOUGH

Pour the desired quantity of our into the pool; it needs 7 eggs per kilo of our:

Flour kg. Number of Eggs Grams of Pasta Product

0.5 3 650

1 7 1.350

1, 2* 9 1.650

* This is the maximum capacity of the pool.

• Supposed weight of an egg: 50 grams.

• If you take 1 egg away you need to add 50 grams of water. Now shut the cover and put the selector in the

kneading position (Fig. 3A).

• Push the start button (Fig. 3B).

• Add the liquid part pouring it slowly, but quickly through the small hole in the cover.

• At the end of the kneading operation, which should take around 10 minutes, make sure the product has the

right thickness and should look like coffee beans (check through the small holes of the cover).

• Turn the machine off by switching the selector to “0” (Fig. 3C), or push the Stop button (Fig. 3E).

Maintenance

You have to properly clean all the elements which are in contact with the product; protection cover, pool, mixer,

Archimedean screw, drawplate, ring nut, when the product is still soft.

The moving parts have to be disassembled as follows:

• Mixer

• Make sure the external shovel is in the upper vertical position (Fig. 11A) (only this position allows the

disassembling of the piece).

• Remove the mixer, pull out the knob (Fig. 11B) until the mixer disengages.

• Take the square shaft away from its place (Fig. 11C) and at the same time turn the external end

upwards. If you want to assemble the piece follow these instructions vice versa. Line the central point

of the shaft with the peg of the moving support; then, leave the handle.

• Ring nut (Fig. 11D) and drawplate (Fig. 11E)

• Unscrew the ring nut by hand, avoiding pieces falling when the ring nut comes out of its place, in order

to avoid causing damage both to people or to the pieces themselves.

• Archimedean Screw (Fig. 11F)

• After disassembling the ring nut and the drawplate, the Archimedean screw can easily be taken off from

the machine by pushing its spiral from the internal end.

9

Page 10

Maintenance

WARNING: For healthy and hygienic processing of nutritional products, be sure to keep your machine and the

surrounding environment clean.

DANGER: Always cut off power supply before cleaning.

COVER AND POOL CLEANING

Eliminate the dough residue and make sure to thoroughly clean the most remote-access pieces: connections

of the Archimedean screw and mixer movements (Fig. 12), extrusion sleeve, cover and pool internal parts.

Use some warm water in order to eliminate the residual product and then rinse; dry the surfaces with the help

of blotting paper. To clean machine internal and external parts:

• Remove power supply plug from power mains socket.

• Clean coated surfaces with soft cloth and disinfect with alcohol.

• To clean internal parts of machine:

• Turn the machine and lay it down on a side.

• Clean the internal parts with the help of a soft cloth and blow with a compressed air jet.

WARNING: Never use non-nutritional, abrasive or corrosive chemicals to clean. Also never use coarse or

abrasive objects such as steel wool, abrasive sponges and so on. DO NOT clean the tank lid with alcohol or

other solvents.

CLEANING OF THE ARCHIMEDEAN SCREW, MIXER, RING NUT AND DRAWPLATE

• Eliminate the dough residue and wash the pieces with water; you may use a soft brush or a plastic eggslice.

• These elements can be thoroughly washed in a dishwasher. Rinse and dry the mixer, the Archimedean

screw and the ring nut and reassemble them on the machine.

• The drawplate (Fig. 5A) is to stay in a container with water when it is not in use.

• For reasons of hygiene, please change the water every day.

MAINTENANCE AND ADJUSTMENT

The points of the machine which need a certain maintenance are the following: the transmission gears, the

dragging belt and the mixer external support. Please carry out the rst maintenance after the rst 100 hours

and thereafter every 500 hours.

• Mixer support: Use registered fats for foods (USDA-H1) (in case of requirement contact your local dealer).

• Drive gears and chain: please use mineral grease SAE MR3.

BELT STRETCHING

When performing the above mentioned maintenance or when the machine is not working properly, (loss of

rounds) verify the correct stretching of the transmission belt (Fig. 13A). Put the machine on one side and make

sure that the belt is sufciently stretched. If necessary, unscrew the blocking motor screws (Fig. 13B) and push

it downwards and stretch the belt without exaggerating; then re-block the screws.

10

Page 11

Maintenance

Notes:

• Never use the machine with any missing, disassembled or open guards and shields.

• If servicing operations require repairs to electrical system and/or replacement of bearings or mechanical

components, call an expert technician or your local dealer.

Troubleshooting

PROBLEM CAUSE REMEDY

Machine Operation Failure. Disconnected plug. Connect plug.

Plug leads not correctly connected. Check lead connections.

Product gets stuck when being

poured out.

The product looks unacceptable

even after the initial minutes; it

breaks and loses our.

The product does not come out

from the drawplate.

Trip switch adjusted for insufcient

values.

Unsuitable trip switch. Replace trip switch.

The security hook on the pool

cover is not inserted properly.

Dough too humid is used. Reduce the quantity of water used

Too short kneading time. Increase the kneading time.

Too reduced water percentage. Increase the quantity of

The blocking of the drawplate

because of dried dough.

Adjust trip switch accordingly.

Position the hook at the end of the

run.

for the dough respecting the above

mentioned percentage.

water in order to respect the

aforementioned percentage.

Disassemble and clean the

drawplate.

REFERENCE

Item Number Model Number Description Manufacturer Model Number

13320 PM-IT-0004

Pasta Machine 9 LB / 4 KG per Hour

0.5 HP / 373 W 110V/60/1

TR70

11

Page 12

Instructions Français

LA SÉCURITÉ ET LA GARANTIE

Lorsque nous avons réalisé cette machine, nous avons tout fait pour rendre votre travail plus sûr. La prudence

est de toute manière irremplaçable et il n’y a pas de meilleure règle en matière de prévention des accidents.

Ne pas mettre cette notice de côté sans l’avoir lue, indépendamment d’expériences précédentes. Quelques

minutes consacrées à la lecture peuvent successivement faire économiser du temps et de la fatigue. Lire

attentivement cette notice avant de procéder au démarrage, à l’utilisation, à la maintenance et à d’autres

interventions sur la machine, et suivre scrupuleusement les instructions et les consignes indiquées ci-dessous:

• Observez les plaquettes appliquées sur la machine et remplacez immédiatement celles qui ont été égarées

ou qui sont illisibles.

• La machine ne doit être utilisée que par des personnes compétentes et qui connnaissent le fonctionnement

de cette dernière.

• En cas de bourrage ou de blocage de n’importe quel organe, éteindre le moteur avant toute intervention. Il

est interdit de nettoyer, de huiler ou de graisser à la main les éléments en mouvement de la machine. Il est

également interdit de réparer ou de régler les différents organes lorsque le moteur est en marche, si on n’a

pas pris toutes les précautions nécessaires an d’éviter des accidents éventuels.

• Tous les organes en mouvement sont équipés des protections qui s’imposent. Remonter soigneusement

celles qui auraient pu être enlevées pour des exigences de service.

• Les vêtements portés par l’opérateur doivent être prêts du corps et sans parties ottantes. Ne jamais porter

de vestes ou de chemises déboutonnées.

• An d’éviter des accidents et assurer des performances optimales, la machine ne doit être ni modiée ni

transformée sans l’approbation du constructeur, elle ne doit pas être utilisée dans des conditions ou à des

ns pour lesquelles elle n’est pas prévue. Toute modication arbitraire apportée à cette machine dégage le

fabricant de toute responsabilité dérivant de dommages ou de lésions consécutifs.

• Ne pas laisser les enfants s’approcher de la machine.

• Pour des raisons d’hygiène, de santé et de garantie, il est absolument interdit d’utiliser la machine pour

travailler des produits non alimentaires. Toute autre utilisation sera considérée contraire à l’utilisation

prévue par le fabricant, qui ne pourra, par conséquent, être tenu pour responsable des dommages aux

choses et à la machine elle-même ou bien des lésions aux personnes qui en dériveront éventuellement.

Il faut considérer que si vous prenez le risque d’un usage non approprié, vous vous assumerez la

responsabilité qui en découlera.

Pour votre sécurité, avant de brancher la machine sur le réseau:

• S’assurer qu’un disjoncteur omnipolaire adéquat, équipé des protections contre les surcharges et les

courts-circuits est branché en amont de la prise de distribution.

• Effectuer la connexion des phases, du neutre éventuel et de la terre (obligatoire) à l’aide d’une che

normalisée compatible avec la prise indiquée ci-dessus. Le conducteur de protection (terre) est indiqué par

la couleur jaune/verte de l’enveloppe isolante; vérier le bon état du câble d’alimentation en fonction de sa

longueur, de la tension du réseau et de la puissance absorbée par la machine.

• Éviter d’opérer si le milieu est humide ou mouillé à moins d’avoir les protections appropriées contre les

chocs électriques.

Eviter absolument de mettre la machine en marche sans panneaux de protection. Cela peut nuire à

12

Page 13

Instructions Français

votre sécurité personnelle et à la machine elle-même.

Attention: Conserver scrupuleusement la présente notice dans un lieu approprié, à côté de la machine et

connu de toutes les personnes concernées.

1 AN PIÈCES ET TRAVAIL BANC GARANTIE

Dans la période de garantie, contacter Omcan Inc. au 1-800-465-0234 pour planier une chute hors

soit un dépôt Omcan de service autorisé dans la zone ou à un entrepôt Omcan service pour réparer

l’équipement.

Entretien non autorisée annulera la garantie. La garantie couvre les pannes électriques et une partie

pas une mauvaise utilisation.

S’il vous plaît voir www.omcan.com/warranty.html pour info complète.

AVERTISSEMENT:

Les matériaux d’emballage sont considérés comme des déchets solides urbains normale et peuvent donc être

éliminés sans difculté.

En tout cas, pour le recyclage approprié, nous suggérons tranchent des produits séparément

(différenciée des déchets) selon les normes en vigueur.

NE PAS JETER LES EMBALLAGES DANS L’ENVIRONNEMENT!

SPÉCIFICATIONS TECHNIQUES

Modèle PM-IT-0004

Capacité du réservoir 3.74 lbs. / 1.7 kg.

Power 0.5 HP / 0.37 kW

SORTIE / HR 8.8 lbs. / 4 kg.

Dies Inclus N. 8 - Spaghetti, N. 21- Linguine, and N. 26-Fettuccine

Tension nominale 110 V / 60 Hz / 1 Ph

Poids 61 lbs. / 27.6 kg.

Poids de l’emballage 65 lbs. / 29 kg.

Dimensions (DWH) 10” x 14.5” x 16” / 254 x 368 x 406 mm

Dimensions de l’emballage 20” x 15” x 22” / 508 x 381 x 559 mm

Numéro d’article 13320

13

Page 14

Instructions Français

INSTALLATION

Pour positionner et utiliser la machine, prévoir une pièce bien aérée, ayant un plan d’appui nivelé et compact,

facile à entretenir.

Pour assurer la stabilité nécessaire à la machine:

• S’assurer que les patins (Fig. 8A) sont bien appuyés au sol; sinon, les faire tourner jusqu’à ce que

l’instabilité soit éliminée.

• Positionner la machine à l’endroit désiré, en prenant soin de laisser un espace libre de 50 cm. environ à

l’arrière, et de 70 à 80 cm. sur les côtés, an de permettre une utilisation facile et aisée de la machine,

ainsi qu’une maintenance et un nettoyage efcaces (Fig. 9).

• S’assurer que le voltage de la machine, indiqué sur l’étiquette d’identication est celui qui est prévu par

l’installation électrique de l’établissement.

• Monter sur le câble d’alimentation la che compatible avec le branchement électrique sur l’installation.

• Après qu’on a enfoncé la che dans la prise de courant, la machine est prête à être utilisée, mais contrôler

préalablement que tous les organes et les composants de la machine fonctionnent correctement.

AVERTISSEMENT: En phase de travail, an d’obtenir un produit ayant une consistance et un taux d’humidité

corrects, il faut au contraire éviter les courants d’air qui provoqueraient le séchage précoce du produit et sa

détérioration.

MONTAGE DE LA FILIERE ET DEBUT DE LA PRODUCTION

Avant d’effectuer l’installation et la production, assurez-vous que la machine est hors tension.

• Prélever la lière (Fig. 5A) désirée du récipient rempli d’eau où elle avait été placée après la dernière

utilisation.

• Bien la rincer sous l’eau chaude courante, de manière à ce qu’elle soit à la bonne température. L’essuyer à

l’aide d’un chiffon doux.

• Dévisser la douille de blocage (g. 5B et 6A) et nettoyer soigneusement la partie interne, y compris le let

• Enlever le bouchon en plastique (Fig. 5c et 6B).

• Monter la lière (Fig. 7A).

• Serrer la douille à la main et vérier que les différentes pièces sont à leur place, c’est-àdire qu’elles n’ont

pas été déplacées axialement à cause d’épaisseurs créées par du produit qui s’est glissé à l’intérieur.

• Pour commencer la production, placer le sélecteur en position (Fig. 3D) et appuyer sur le bouton-

poussoir de démarrage (Fig. 3B).

• Normalement, le premier produit se présente à la sortie de la machine sous un aspect non acceptable.

C’est pour cela qu’il doit être éliminé.

• Peu de temps après (2 mn. environ) le produit sortant devient acceptable, sa couleur varie du blanchâtre

au jaune et il a plus de consistance. On peut couper la pâte à la longueur désirée à la main ou à l’aide d’un

couteau. On découpe normalement les pâtes à long format (type spaghettis, tagliatelles, etc.) à la main,

tandis-que les pâtes à petit format (type macaronis, etc.) sont coupées au couteau.

A la n du travail:

• Arrêter la machine en mettant le sélecteur sur la position “0” (Fig. 3C) puis le tourner sur la position de

pétrissage (Fig. 3A) pendant 10 à 15 secondes de manière à éliminer la pression sur la lière, due au

14

Page 15

Instructions Français

produit.

• Remettre enn le sélecteur sur le “0” (Fig. 3C).

• Procéder ensuite au démontage et au lavage des pièces mobiles, ainsi qu’au nettoyage de la machine.

VERIFICATION DE L’INSTALLATION

Vérier donc:

• Qu’en position “0” (Fig. 3C) tous les organes de la machine sont immobiles.

• En position “lière” (Fig. 3D) le malaxeur tourne dans le sens inverse des aiguilles d’une montre et la vis de

sélection doit tourner dans le sens inverse.

• En position “malaxeur” (Fig. 3A)les organes doivent tourner dans le sens inverse.

N.B.: Tout actionnement est commandé volontairement par l’intermédiaire du bouton-poussoir de démarrage,

quand le capot de protection de la cuve est renfermé (Fig. 10F).

AVERTISSEMENT: En cas de non-fonctionnement de la machine ou d’une de ses parties, s’adresser au

revendeur ou au concessionnaire agréé pour toute intervention

OPÉRATION

DE LA MACHINE

A faire avant le début de chaque cycle de travail. S’assurer que la machine est parfaitement propre, surtout les

petites pièces au contact du produit: manchon d’extrusion, vis de sélection, cuve, malaxeur et lière

PRINCIPE DE FONCTIONNEMENT

Lorsqu’elle travaille les produits alimentaires voulus, cette machine permet d’obtenir différents types de pâtes

de longueur différente, en étirant la pâte à travers des disques différents. L’action se déroule au moyen d’un

organe malaxeur couplé à une vis de sélection qui oblige le produit à prendre la forme voulue en passant par

une lière.

UTILISATION DE LA MACHINE

Assurez-vous d’avoir éteint la machine, puis:

• Positionner le sélecteur sur “0” (Fig. 2C), s’assurer que la vis de sélection est correctement montée

(Fig. 1A), la partie cylindrique devant être appuyée contre l’arbre d’entraînement.

• S’assurer également que le bouchon en plastique (Fig. 1B) qui remplace la lière est bien positionné, et

que la douille (Fig. 1 C) est bien vissée.

• Enn bloquer de manière sure le malaxeur (Fig. 1D) dans son logement au moyen du pommeau qui se

trouve sur le devant de la machine (Fig. 1E).

• Soulever le capot de la cuve (Fig. 4A), et verser les ingrédients établis toujours dans l’ordre suivant: la

farine, puis successivement, après avoir fermé le capot, la partie liquide.

15

Page 16

Instructions Français

Pour obtenir une pâte ayant une consistance correcte, il faut qu’il existe un rapport précis entre le poids de

la farine et celui de la partie liquide; pour obtenir un produit excellent, la farine doit avoir un pourcentage

d’humidité non supérieur à 15% et cela permet d’ajouter une quantité d’eau pesant 35 à 38% du poids

de la farine. Si on utilise de la farine ayant un pourcentage d’humidité différent, modier la quantité de

liquide selon un rapport inversement proportionnel. De plus, pour une meilleure utilisation de la machine,

il faut que le produit travaillé à l’intérieur de la cuve soit supérieur à un niveau minimum, qui peut coïncider

approximativement avec la position de l’axe du malaxeur.

DOSES POUR OBTENIR UNE BONNE PATE

Verser dans la cuve la quantité de farine désirée en tenant compte du fait que pour chaque kg. de farine il faut

7 oeufs:

Farine en kg. Number of Eggs Pâte produite en g.

0.5 3 650

1 7 1.350

1, 2* 9 1.650

* Contenance maximum de la cuve.

• Poids supposé d’un oeuf: 50 g.

• Pour chaque oeuf en moins ajouter 50 g. d’eau.

• Fermer le capot et mettre le sélecteur en position (Fig. 3A).

• Appuyer sur le bouton-poussoir de démarrage (Fig. 3B).

• Ajouter la partie liquide en la versant progressivement, mais rapidement, par la fente du capot.

• A la n de l’opération de pétrissage, qui dure environ 10 minutes, s’assurer que le produit a une consistance correcte, c’est-à-dire qu’il devra se présenter sous la forme de grains de café (contrôle à effectuer

par les fentes du capot).

• Eteindre la machine en mettant le sélecteur sur le “0” (Fig. 3C), ou bien appuyer sur le bouton-poussoir

d’arrêt (Fig. 3E).

ENTRETIEN

Il est donc vivement conseillé de nettoyer soigneusement toutes les pièces au contact du produit: capot de

protection, cuve, malaxeur, vis de sélection, lière, douille, tant que le produit est encore mou.

Les parties mobiles devront être démontées de la manière suivante:

• Malaxeur

• S’assurer que la pale extérieure est en position verticale haute (Fig. 11A) (on ne peut démonter la pièce

que dans cette position).

• Démonter le malaxeur, tirer le pommeau (Fig. 11B) jusqu’à dégager le malaxeur.

• Désengager l’arbre carré de son logement (Fig. 11C) et tourner simultanémentl’extrémité externe vers

le haut. Pour le montage de la pièce, opérer dans le sens inverse en faisant attention à aligner le siège

central de l’arbre avec le centreur du support mobile; puis relâcher le pommeau.

• Douille (Fig. 11D) et lière (Fig. 11E)

16

Page 17

Instructions Français

• Dévisser la douille à la main, en faisant attention dès que la douille sort de son logement à ne pas faire

tomber les pièces (il ne faut pas se faire mal, ni endommager les pièces).

• Vis de sélection (Fig. 11F)

• Une fois que la douille est démontée avec la lière, on peut extraire la vis de sélection facilement en la

prenant par l’extrémité interne et en la poussant en-dehors de la spirale.

IMPORTANT: Étant donné qu’on utilise la machine avec des produits alimentaires le nettoyage de celle-ci et

du milieu environnant est une chose fondamentale pour la santé et l’hygiène du produit ni.

DANGER: Se rappeler de débrancher l’alimentation électrique avant d’exécuter toute opération de nettoyage.

NETTOYAGE DE LA CUVE ET DU CAPOT

Enlever les résidus de pâte, en faisant attention à réaliser un nettoyage soigné au niveau des parties les plus

difciles d’accès: raccords du mouvement de la vis de sélection et du malaxeur (Fig. 12), manchon d’extrusion,

angles internes de la cuve et capot. Utiliser de l’eau chaude pour éliminer le produit résidu et pour le rinçage;

essuyer les surfaces avec du papier buvard alimentaire.

En ce qui concerne le nettoyage de la partie externe et interne de la machine:

• Débrancher la che d’alimentation du réseau d’énergie.

• Nettoyer les surfaces laquées à l’aide d’un chiffon humide puis les désinfecter à l’alcool.

• Pour les parties internes de la machine:

• Renverser la machine sur le côté droit ou gauche.

• Nettoyer les parties internes à l’aide d’un chiffon doux et soufer un jet d’air sous pression.

IMPORTANT: Pour le nettoyage, n’utiliser en aucun cas de produits chimiques non alimentaires, abrasifs

ou corrosifs. Eviter absolument d’utiliser des moyens rugueux ou abrasifs tels la paille d’acier, les éponges

abrasives, etc. Ne pas nettoyer le couvercle de la cuve avec de l’alcool ou avec d’autres solvants.

NETTOYAGE DU MALAXEUR, DE LA VIS DE SELECTION, DE LA DOUILLE ET DE LA

FILIERE

• Enlever les résidus de pâte en nettoyant les pièces sous un jet d’eau, et utiliser éventuellement une petite

brosse humide ou une palette en plastique.

• Ces pièces peuvent lavées plus énergiquement dans un lavevaisselle. Rincer le malaxeur puis l’essuyer, et

de même pour la vis de sélection et la douille. Les remonter ensuite sur la machine.

• La lière (Fig. 5A) doit être immergée dans un récipient rempli d’eau pendant tout le temps où elle reste

inutilisée.

• Pour des raisons d’hygiène, changer l’eau de ce récipient tous les jours.

MAINTENANCE ET REGLAGE

Les points de la machine qui ont besoin de maintenance sont: les engrenages de transmission, la courroie

17

Page 18

Instructions Français

d’entraînement et le support externe du malaxeur. Effectuer la première maintenance au bout de 100 heures

de fonctionnement, et successivement toutes les 500 heures.

• Support du malaxeur: Utiliser de la graisse pour aliments de type homologué suivant les spécications

USDA-H1 (si nécessaire, s’adresser au revendeur de la zone).

• Engrenages de transmission et chaîne: Utiliser de la graisse minérale de type SAE MR3.

TENSION DE LA COURROIE

A l’occasion de la maintenance prévue ou en cas de fonctionnement irrégulier de la machine (perte de tours),

s’assurer que la courroie de transmission est correctement tendue (Fig. 13A). Pour cela, renverser la machine

sur un côté. Si la courroie n’est pas sufsamment tendue, desserrer les vis de blocage du moteur (Fig. 13B),

le déplaçer vers le bas puis tendre la courroie sans exagérer. Terminer l’opération en reserrant les vis.

Notes:

• Ne jamais utiliser la machine lorsque les protections et les protecteurs sont démontés, manquants ou

ouverts.

• Si les interventions de maintenance concernent des réparations de parties qui ont un rapport avec l’installation électrique et/ou si on doit procéder au remplacement de paliers ou de composants mécaniques, faire

exécuter ces opérations par du personnel spécialisé ou par le revendeur.

DÉPANNAGE

PROBLÈME CAUSE REMEDES

La machine ne fonctionne pas. Fiche débranchée. Enfoncer la che.

Fils de la che non xés

correctement.

Disjoncteur de sûreté étalonné sur

des valeurs insufsantes.

Disjoncteur de sûreté inadéquat. Changer le disjoncteur de sûreté.

Le levier de sécurité sur le capot

de la cuve n’est pas inséré

correctement.

Il se colle à la sortie. La pâte utilisée est trop humide. Réduire la quantité d’eau utilisée

Le produit a un aspect non

acceptable même après les

premières minutes; il se coupe, il

se pulvérise.

Le produit ne sort pas de la lière. La lière est bouchée car la pâte

Le temps de pétrissage est trop

bref.

Le pourcentage en eau est trop

faible.

est trop sèche.

S’assurer que les ls sont xés

correctement.

Étalonner le disjoncteur de sûreté

d’une manière adéquate.

Positionner le levier en n de

course.

pour le pétrissage, en respectant

le pourcentage prévu.

Augmenter le temps de pétrissage.

Augmenter la quantité d’eau

de manière à respecter le

pourcentage prévu.

Démonter et nettoyer la lière.

18

Page 19

RÉFÉRENCE

Instructions Français

Numéro

d’article

13320 PM-IT-0004

Numéro de

modèle

La description Numéro du fabricant Modèle

Machine à pâtes 9 LB / 4 KG par heure

0.5 HP / 373 W 110V/60/1

TR70

Instrucciones en Español

SEGURIDAD Y GARANTÍA

PRECAUCIONES DE SEGURIDAD

En realizando esta máquina todo fue cumplido para que el trabajo de Ustedes se volviera más seguro. En todo

caso la prudencia es insostituibile y no hay regla mejor para prevenir los accidentes. Este manual no ha de ser

puesto de lado sin haberlo leido, independientemente de precedentes experiancias. Unos minutos dedicados a

su lectura harán ahorrar, en lo sucesivo, tiempo y trabajo. Lean atentamente este opúscolo antes de proceder

al arranque, empleo, manutención y otras intervenciones sobre la máquina, y sigan escrupulosamente las

instrucciones y advertencias explicada a continuación:

• Observar las chapitas aplicadas sobre la máquina y sustituir inmediatamente las que se hayan extraviado

o se hayan vuelto ilegibles.

• La máquina debe ser utilizada solamente por personas responsables, instruidas sobre el funcionamiento

de la misma.

• En caso de atascamiento o bloqueo de cualquier órgano, antes de soltarlo, apáguese el motor. Está

vedado limpiar, aceitar o engrasar a mano los elementos en movimiento de la máquina. También está

prohibido efectuar todas las operaciones de reparación y ajuste de los varios órganos, con el motor en

movimiento, si no se han tomado todas las precauciones necesarias para evitar posibles accidentes;

• Todos los órganos en movimiento deben estar dotados de las oportunas protecciones. Montar de nuevo

las que eventualmente hayan sido removidas por exigencias de servicio.

• La ropa endosada por el operador debe ser adherente y libre de partes en revoloteo. No endosar sacos o

camisas desliadas.

• Para evitar accidentes y asegurar las máximas prestaciones, la máquina no debe ser modicada o

alterada en modos no aprobados por el constructor, ni tampoco debe ser empleada bajo condiciones o

para nes a los que no está prevista. Toda modicación arbitraria que se aporte a esta máquina, libra al

constructor de toda responsabilidad que se origine de consiguientes daños o lesiones.

• Mantener a los niños siempre alejados de la máquina.

• Por razones de higiene, salud y garantia, queda absolutamente prohibido el uso de la máquina para la

elaboración de productos no alimenticios. Cualquier otro empleo será considerado contrario a la utilización

prevista por el fabricante, el cual, por lo tanto, no podrá resultar responsable de los daños a cosas y a la

máquina misma, ni tampoco de las lesiones a personas que de ello eventualmente se originen. Es preciso

19

Page 20

Instrucciones en Español

considerar que al tomarse el riesgo en el uso improprio se asume también la responsabilidad consiguiente.

Para vuestra seguridad, antes de conectar la máquina a la red, hay que:

• Controlar que en el punto inicial de la toma de distribución esté insertado un adecuado interruptor

omnipolar provisto de protecciones contra sobrecargas y cortos circuitos.

• Efectuar la conéxion de las fases, del eventual neutro y de tierra (obligatoria) con un enchufe normalizado

compatible con la toma arriba indicada. El conductor de protección (tierra) está indicado por la coloración

amarillo/verde de la envoltura de aislamiento; vericar la idoneidad del cable de alimentación; en función

de su longitud, de la tensión de red y de la potencia absorbida por la máquina.

• Evitar de operar cuando el ambiente sea húmedo o mojado, a menos que no se usen las protecciónes

adecuadas contra los shocks eléctricos.

Evitar de la manera más absoluta poner en función la máquina si no tiene paneles de protección. Eso

es perjudicial a los nes de la seguridad personal y de la máquina misma.

Atención: Conservar escrupolosamente el presente manual en lugar idóneo, cerca de la máquina y al

conocimiento de todos los interesados.

1 AÑO EN PIEZAS Y TRABAJO BANCO DE GARANTÍA

Dentro del período de garantía, póngase en contacto Omcan Inc. al 1-800-465-0234 para programar

una caída ya sea a un depósito autorizado Omcan servicio en la zona, o para un almacén de servicio

Omcan para reparar el equipo.

Mantenimiento no autorizada anulará la garantía. La garantía cubre no fallas eléctricas y piezas de uso

indebido.

Por favor, vea www.omcan.com/warranty.html para obtener información completa.

ADVERTENCIA:

Las piezas de embalaje se clasican como residuos sólidos urbanos y por lo tanto se pueden eliminar sin

dicultades.

En cualquier caso, para el reciclaje adecuado, le sugerimos comercialización de esos productos por

separado (residuos diferenciada) de acuerdo con las normas vigentes.

NO TIRAR LOS PRODUCTOS ENVASADO EN EL MEDIO AMBIENTE!

20

Page 21

Instrucciones en Español

ESPECIFICACIONES TÉCNICAS

Modelo PM-IT-0004

Capacidad del depósito 3.74 lbs. / 1.7 kg.

Power 0.5 HP / 0.37 kW

SALIDA / HR 8.8 lbs. / 4 kg.

Muere Incluido N. 8 - Spaghetti, N. 21- Linguine, and N. 26-Fettuccine

Electrico 110 V / 60 Hz / 1 Ph

Peso 61 lbs. / 27.6 kg.

Peso del embalaje 65 lbs. / 29 kg.

Dimensiones (DWH) 10” x 14.5” x 16” / 254 x 368 x 406 mm

Dimensiones de embalaje 20” x 15” x 22” / 508 x 381 x 559 mm

Número de artículo 13320

INSTALACIÓN

Para el posicionamiento y utilización de la máquina, debe ser previsto un local con piso plano y compacto, con

posibilidad de asegurar una limpieza esmerada y buena aireación.

Para asegurar la estabilidad necesaria a la máquina:

• Verifíquese que los pies (Fig. 8A) estén bien apoyados en el piso; en caso contrario, hay que girarlos hasta

eliminar la inestabilidad.

• Colocar la máquina en el lugar deseado, con la advertencia de dejar un espacio libre en la parte posterior

de cerca de 50 cm. y en los lados de al menos 70-80 cm., para permitir una fácil utilización y una

manutención y limpieza ecaz (Fig. 9).

• Vericar que el voltaje de la máquina, marcado en la etiqueta de identicación, sea el previsto por la

instalación eléctrica del edicio.

• Montar en el cable de alimentación de la máquina, el enchufe idóneo para la conexión eléctrica a la

instalación.

• Después de haber insertado el enchufe a la toma de corriente, la máquina está lista para el uso, previa

una prueba del correcto funcionamiento de todos los órganos y componentes de la máquina.

ADVERTENCIA: Durante el periodo de trabajo, en cambio, para obtener un producto con la justa consistencia

y humedad, hay que evitar las corrientes de aire que causarían el secamiento precoz del producto y su

deterioración.

MONTAJE DE LA HILERA E INICIO PRODUCCION

Antes de realizar la instalación y la producción, asegúrese de que la máquina está apagada.

• Retirar la hilera (Fig. 5A), requerida por el contenedor llenado de agua, de donde fue colocada después de

su última utilización.

• Enjuagar bien con agua corriente caliente de modo que la pieza alcance la justa temperatura.

21

Page 22

Instrucciones en Español

• Secarla con paño mórbido. Desenroscar la abrazadera de bloqueo (Fig. 5B - 6A) y limpiar cuidadosamente

la parte interior, inclusive la rosca.

• Quitar el tapón de plástico (Fig. 5C - 6B). Montar la hilera (Fig. 7A).

• Atornille las tuercas anulares a mano y verique que todas las piezas estén en su sitio y que estén

alineadas a lo largo del eje.

• Cerrar la abrazadera a mano y vericar que las varias piezas estén en su asiento y no desplazadas

axialmente a causa de producto que haga de espesor. Para iniciar la producción, colocar el selector sobre

la posición (Fig. 3D) presionar el pulsador START (Fig. 3B).

• El primer producto que sale de la máquina se presenta normalmente con un aspecto no aceptable; por eso

debe ser eliminado.

• Después de breve tiempo (cerca de 2 minutos) el producto que sale llega a ser aceptable, varia su color

de blanquecino a amarillo y presenta una mayor consistencia. El corte de la pasta al largo deseado puede

efectuarse a mano o con la ayuda de un cuchillo. En el primer caso se cortan, normalmente, pastas de

formato largo (como spaghetti, tallarines, etc.), mientras que se cortan con el cuchillo las pastas cortas

(tipo macarrones, etc.).

Al terminar el trabajo:

• Parar la máquina poniendo el selector en la posición “0” (Fig. 3C) y girarlo después sobre la posición de

mezcla (Fig. 3A) por 10-15 segundos de manera que sea eliminada la presión sobre la hilera debida al

producto.

• Reponer en n el selector sobre “0” (Fig. 3C).

• Proceder entonces al desmontaje y lavado de las piezas móviles y a la limpieza de la máquina.

VERIFICACION DE LA INSTALACION

Vericar por tanto:

• En la posición “0” (Fig. 3C), todos los órganos de la máquina deben estar parados.

• En posición “hilera” (Fig. 3D), el mezclador gira en sentido contrario a las agujas del reloj, y la cóclea

deberá girar en sentido contrario.

• En la posición “mezclar” (Fig. 3A), los órganos girarán en sentido contrario.

NOTA: Todo accionamiento es gobernado volontariamente a través del pulsador de arranque, cuando la

tapadera de protección del recipiente está cerrada (Fig. 10F).

ADVERTENCIA: En caso de faltado funcionamiento de la máquina o de cualquier parte de ella, para

cualquiera intervención hay que dirigirse al revendedor o concesionario autorizado.

OPERACIÓN

FASE PREPARATORIA DE LA MAQUINA

Debe ser ejecutada antes del inicio de cada ciclo de trabajo. Cerciorarse de la perfecta limpieza de la máquina

y especialmente de todas las piezas a contacto con el producto: manguito de extrusión, cóclea, recipiente,

mezclador e hilera.

22

Page 23

Instrucciones en Español

PRINCIPIO DE FUNCIONAMIENTO

La máquina, elaborando productos alimenticios deseados, permite obtener varios tipos de pasta y de variado

largo, trelando el amasijo a través de discos diferentes. La acción se desarrolla por medio de un órgano

mezclador acoplado a una cóclea que fuerza el producto a tomar la forma deseada pasando por una hilera.

UTILIZACION DE LA MAQUINA

Después de haber con certeza apagado la máquina:

• Posicionar el seleccionador sobre “0” (Fig. 2C), verifíquese el correcto montaje de la cóclea (Fig. 1A),

observando que la parte cilíndrica quede apoyada al árbol de arrastre.

• Asegurarse también que el tapón de plástico (Fig. 1B), sustitutivo de la hilera esté bien posicionado y la

abrazadera (Fig. 1C) bien cerrada.

• Por último, bloquear el mezclador (Fig. 1D) en su alojamiento con el pomo (Fig. 1E).

• Levantar la tapadera del recipiente, (Fig. 4A) y verter siempre los ingredientes preestablecidos en el

siguiente orden: la harina, y sucesivamente, después de cerrar la tapadera, la parte líquida. Para lograr

un amasijo correcto es necesario que exista una relación exacta entre el peso de la harina y el de la parte

líquida.

Para obtener un producto óptimo la harina debe tener un porcentaje de humedad no superior al 15%, y eso

permite añadir una cantidad de agua del 35% al 38% del peso de la harina. En caso se utilizaren harinas con

porcentaje de humedad diferente, hay que modicar la cantidad del líquido en la relación inversa. Además

para una mejor utilización de la máquina es necesario que el producto elaborado en el interior del recipiente

sea superior a un nivel mínimo, que aproximadamente puede coincidir con la posición del eje del mezclador.

DOSIS PARA OBTENER UN BUEN AMASIJO

Verter en el recipiente la cantidad de harina deseada teniendo en cuenta que por cada kg. de harina sirven 7

huevos:

Harina kg. Huevos n° Producto pasta gr.

0.5 3 650

1 7 1.350

1, 2* 9 1.650

* Contenido máximo del recipiente.

• Peso supuesto de n° 1 huevo: gr. 50.

• Por cada huevo en menos, añadir gr. 50 de agua.

• Cerrar la tapadera y poner el selector en la posición (Fig. 3A).

• Presionar el pulsador START (Fig. 3B).

• Añadir la parte líquida vertiéndola gradualmente pero en breve tiempo a través de la rendija de la

tapadera.

• A nal de la operación de amasijo, de una duración aproximada de 10 minutos, asegurarse que el producto

tenga la justa consistencia, debiendo el mismo presentarse a la vista bajo forma de granos de café (control

23

Page 24

Instrucciones en Español

que se efectua a través de las ranuras de la tapadera).

• Apagar la máquina poniendo el selector sobre “0” (Fig. 3C), o presionar el pulsador STOP (Fig. 3E).

MANTENIMIENTO

Se recomienda por tanto ejecutar una cuidadosa limpieza de todas las piezas particulares a contacto con el

producto: tapadera de protección, recipiente, mezclador, cóclea, hilera, abrazadera, mientras tanto que el

producto se encuentra aún blando.

Las partes móviles deben ser desmontadas en la manera siguiente:

• Mezclador

• Asegurarse que la paleta externa esté en la posición vertical superior (Fig. 11A) (solamente esta

posición permite el desarme de la pieza).

• Desmontar el mezclador y tirar del pomo (Fig. 11B) hasta liberarlo.

• Desensartar el árbol cuadrado de su asiento (Fig. 11C) y contemporaneamnete girar la extremidad

externa hacia arriba. Para el montaje del particular obrar en sentido inverso con la advertencia de

alinear el alojamiento central del árbol con la espiga del soporte móvil; luego soltar la perilla.

• Abrazadera (Fig. 11D) e hilera (Fig. 11E)

• Desenroscar la abrazadera a mano, poniendo cuidado a que no caigan las piezas, en el momento en

que la abrazadera sale de su asiento, para no causar daños a sí mismo o las piezas mismas.

• Cóclea (Fig. 11F)

• Desmontada la abrazadera con hilera, la cóclea se puede extraer facilmente de la máquina empujádola

desde la espiral por la extremidad interna.

IMPORTANTE: Dado que la máquina se emplea con productos alimentarios, la limpieza de la misma y del

ambiente circunstante es asunto fundamental para la salud y el higiene del producto acabado.

PELIGRO: Hay que acordarse de desconectar la alimentación eléctrica antes de ejecutar cualquier operación

de limpieza.

LIMPIEZA DEL RECIPIENTE Y DE LA TAPADERA

Quitar los residuos de pasta, con el cuidado de ejecutar una limpieza esmerada en las partes de más dicil

acceso: conexiones del movimiento de la cóclea y del mezclador (Fig. 12), manguito de extrusión, ángulos

interiores del recipiente y tapadera. Utilizar agua caliente para la eliminación del producto residual y enjuague;

secar las supercies con panel absorbente de uso alimentario.

Por lo que respecta la limpieza de la parte externa e interna de la máquina:

• Desconectar el enchufe de alimentación de la red de energía.

• Limpiar con paño mórbido las supercies barnizadas y desinfectarlas con alcohol.

• Para las partes internas de la máquina:

• Inclinar la máquina y ponerla sobre un lado.

• Limpiar con un paño mórbido las partes internas y soplar con un chorro de aire en presión.

24

Page 25

Instrucciones en Español

IMPORTANTE: En ningún caso se puede utilizar para la limpieza productos químicos no alimentares,

abrasivos o corrosivos. Evítese de la manera más absoluta usar elementos ásperos o abrasivos como viruta

de acero, esponjas abrasivas etc. No limpiar la tapa de la cuba con alcohol ni disolventes de ningún tipo.

LIMPIEZA DE: MEZCLADOR, COCLEA, ABRAZADERA E HILERA (Fig. 5)

• Quitar los residuos de pasta, poniendo las piezas bajo un chorro de agua, ayudándose eventualmente con

un cepillito mórbido o una paleta de plástico.

• Estos particulares pueden ser lavados más energicamente en un lavaplatos. Enjuagar y secar el

mezclador, la cóclea y la abrazadera y luego montarlos de nuevo en la máquina.

• La hilera (Fig. 5A) debe mantenerse en un recipiente sumergida en agua durante todo el tiempo en que

queda sin utilizar.

• Por razones de higiene hay que cambiar diariamente el agua del recipiente.

MANUTENCION Y REGULACION

Los puntos de la máquina que necesitan manutención son: los engranajes de transmisión, la correa de

arrastre y el soporte exterior del mezclador. Ejecutar la primera manutención después de las primeras 100

horas de funcionamiento, y sucesivamente cada 500 horas.

• Soporte del mezclador: Utilizar grasa para alimentos de tipo homologado según especicaciones

USDA-H1; (en caso de necesidad acudir al revendedor de zona).

• Engranajes de transmisión y cadena: Utilizar grasa mineral tipo SAE MR3.

TENSION DE LA CORREA

En ocasión de la manutención prevista o en caso de irregular funcionamiento de la máquina (pérdidas de

revoluciones), vericar la correcta tensión de la correa de transmisión (Fig. 13A). Para eso hay que colocar la

máquina sobre un lado y cerciorarse que la correa quede sucientemente tensa. En caso de necesidad, aojar

los tornillos de bloqueo motor (Fig. 13B), desplazarlo hacia abajo y luego tensar la correa sin exagerar; en n

cerrar de nuevo los tornillos.

Notas:

• Jamás utilizar la máquina con las protecciones y resguardos sea faltantes sea abiertos.

• En caso que las intervenciones de manutención se reeran a reparaciones de partes relacionadas con la

instalación eléctrica y/o la sustitución de cojinetes o componentes mecánicos, hay que hacer ejecutar las

operaciones por personal especializado o por el revendedor.

25

Page 26

Instrucciones en Español

SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSAS REMEDIOS

Faltado funcionamiento de la

máquina.

Producto es pegajoso en la salida. Amasijo empleado demasiado

Producto de aspecto no aceptable

aún después de los minutos

iniciales: se quiebra, se pulveriza.

El producto no sale de la hilera. Obstrucción de la hilera debida a

Enchufe desconectado. Conectar el enchufe.

Alambres del enchufe no

correctamente jados.

Interruptor diferencial automático

calibrado para valores

insucientes.

Interruptor diferencial automático

no adecuado.

Gancho de seguridad sobre

tapadera recipiente no

correctamente insertado.

húmedo.

Tiempo de amasijo demasiado

breve.

Porcentaje de agua demasiado

reducido.

amasijo secado.

Controlar la correcta jación de los

alambres.

Calibrar en forma adecuada el

interruptor diferencial automático.

Cambiar interruptor diferencial

automático no adecuado.

Posicionar el gancho a n de

carrera.

Reducir la cantidad de agua

utilizada para el amasijo,

respetando el % previsto.

Aumentar el tiempo de amasijo.

Aumentar la cantidad de agua de

modo tal que sea respetado el %

previsto.

Desmontar y limpiar la hilera.

REFERENCIA

Número de

artículo

13320 PM-IT-0004

Número de

modelo

Descripción

Máquina de las pastas 9 LB / 4 KG por

hora 0.5 HP / 373 W 110V/60/1

26

Número de modelo del

fabricante

TR70

Page 27

Illustrated Drawings

Fig. 1

Fig. 5

D

E

C

A

Fig. 2

B

A

C

A

Fig. 3

C

A

A

B

B

Fig. 6

D

C

B

E

Fig. 4

A

Fig. 7

50 cm

A

F

Fig. 8

Fig. 11

A

70-80

cm

70-80

cm

Fig. 10

Fig. 9

A

C

F

B

E

A

D

B

Fig. 12

Fig. 13

27

Page 28

Parts Breakdown

Model PM-IT-0004 13320

28

Page 29

Parts Breakdown

Model PM-IT-0004 13320

Item No. Description Position Item No. Description Position Item No. Description Position

74564 Tub for TR701PH 1 74576 Gasket for TR701PH 13 74588 Handle on the Lid for TR701PH 24A

74565 Sleeve for TR701PH 2 74577 Sprocket Z=70 M=1.5 for TR701PH 14 74589 Cam for Microswitch for TR701PH 25

74566 Fixing Ring for TR701PH 3 74578 Sprocket Z=50 M=1.5 for TR701PH 15 74590 Leg for TR701PH 26

74567 Worm for TR701PH 4 74579 Bearing 7204 for TR701PH 16 74591 Microswitch Pizzato FR515 for TR701PH 27

74568 Mixer for TR701PH 5 74580 Bearing 6204 for TR701PH 17 74592 Start Button Stop for TR701PH 28

74569 Spherical Grip for TR701PH 6 74581 Lower Shaft for TR701PH 18 74593 Reversing Direction for TR701PH 29

74570 Spring Pin for TR701PH 7 74582 Tree Top for TR701PH 19 74594

74571 Tree Stand Mixer for TR701PH 8 74583 Support Plate for TR701PH 20 41411 Sealing Ring for TR701PH 31

74572 Motor MM63 for TR701PH 9 74584 Reduction for TR701PH 21 74595 Cork for TR701PH 32

74573 Pulley Engine for TR701PH 10 74585 Cater Back for TR701PH 22 74596 Key Fixing Ring for TR701PH 33

74574 Belt Z19 1/2 for TR701PH 11 74586 Rod Cover for TR701PH 23 78631 Control Panel for TR701PH

74575 Pulley Diameter 100 SPZ1 for TR701PH 12 74587 Cover for TR701PH 24

Complete Electrical System for

TR701PH

30

29

Page 30

Electrical Schematics

Model PM-IT-0004 13320

30

Page 31

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

31

Page 32

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...