Page 1

Potato Peelers

Models PE-IT-0010, 0018

Items 44184, 44185

Instruction Manual

Optional Refuse

Bin not included.

Revised - 07/04/2018

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model PE-IT-0010 / Model PE-IT-0018

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

-------------------------------------------------------------------------------------- 9 - 11

-------------------------------------------------------------------------------------- 11 - 13

--------------------------------------------------------------------------------- 13 - 15

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 9

Page

-------------------------------------------------------------------------- 9

Troubleshooting

Parts Breakdown

Electrical Schematics

Warranty Registration

----------------------------------------------------------------------------- 15 - 18

---------------------------------------------------------------------------- 19 - 21

---------------------------------------------------------------------------- 22

---------------------------------------------------------------------------- 23

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

--------------------------------------------------------------------------------------------------------------------------------------------------Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

--------------------------------------------------------------------------------------------------------------------------------------------------Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre leer y familiarizarse con todas las instrucciones de

operación y seguridad.

Omcan quisiera darles las gracias por la compra de esta máquina. Es de la máxima importancia para

guardar estas instrucciones para referencias en el futuro. También guarde la caja original y el embalaje

para envío del equipo si el mantenimiento o la devolución de la máquina es necesaria.

Safety and Warranty

The following clearly species the denitions meaning, which will be used in the present document.

DANGER

It shows the danger presence for who works on the machine and for who is the vicinity, so the indicated activity

must be performed in accordance with the actual accident prevention standards and with the indications

showed in the present manual.

4

Page 5

Safety and Warranty

PRECAUTION

It shows a warning on useful information and/or further recommendations and/or shrewdness about the actual

operation.

ATTENTION

It shows an operation to perform with attention to avoid damage to the machine.

The peeler is designed to peel potatoes using the peeler abrasive dish.

The machine is constituted from an electric motor inserted inside the STAINLESS steel hull, where the motor

shaft is connected through appropriate transmission belt to the rotation pivot where the cleaning dish is

inserted manually.

In its basic conguration the machine is constituted from:

1. STAINLESS steel hull where the feed products to treat are inserted.

The STAINLESS basin internal surface where the product to treat is introduced, is covered with a

removable abrasive length of material and washable manually.

2. Abrasive dish to insert manually in the rotation pivot, used to peel the potatoes.

3. Transparent superior lid that allows observing the working progress, this lid is equipped of handle and

safety sensor that surveys the closure position.

4. Lateral unloading door that allows the product unloading at the working end. The door is equipped with

safety sensor that surveys the closure position.

5. Drawer in STAINLESS steel sheet metal inserted manually under the bottom of the hull, on which the water

and the product dresses are unloaded. Inside the drilled drawer 1 lter in STAINLESS steel sheet metal is

placed for the dresses harvest. In the drawer inferior zone a collector for the water falling is present on well

with battery.

6. Plastic cover fastened laterally to the carcass and sealed with appropriate gasket, containing the electric

material and in its superior zone the control panel is present for the machine functioning.

All direct contact materials with the feed product are in accordance with the actual hygienic standards for

foods. The machine is provided with the rating plate on which the appropriate data is shown.

NORMAL USE, IMPROPER USE, NOT CORRECT USE OR FORBIDDEN

The machine described in the present instructions manual for the use is foreseen to be driven from an only

operator skilled and prepared on residual risks, but with the competence, in safety matter, of maintenance

employees. The operator should have at least the minimum age foreseen from the social laws about the work

and having had the necessary technical training at least from a more expert operator that had him preliminarily

trained for the correct use of the machine.

PRECAUTION

In its NORMAL USE, and reasonably foreseeable, the machine can be used only to peel potatoes with the

cover and doors closed and blocked.

5

Page 6

Safety and Warranty

ATTENTION

The machine must not be used IN IMPROPER WAY; in particular:

1. It must not be used for domestic uses.

2. It must not functioned with parameters dierent from those showed in the technical characteristics table.

3. For every use of the machine with modalities dierent from those showed in the present manual, the

manufacturer declines every responsibility.

4. The user is responsible of the damages resulting from the lacked exercise conditions observance in

accordance with the agreed technical specications and order conrmation.

5. Introduce only the listed food products.

6. Not tamper or damage intentionally nor remove or hide the labels.

ATTENTION

The machine must not be used IN NOT CORRECT WAY or FORBIDDEN so some damages or injuries could

be caused for the operator; in particular:

1. It is forbidden to move the machine when it is connected to the electric feeding.

2. It is forbidden to draw the electric feeding cable or the machine to disconnect the feeding.

3. It is forbidden to draw the electric feeding cable or the drinking water exible pipe or draw the superior

cover or the lateral handle to move the machine.

4. It is forbidden to put weights on the machine or on the electric feeding cable, on the drinking water exible

pipe or on the discharging pipe.

5. It is forbidden to put the electric feeding cable on sharp parts or with burn danger.

6. It is forbidden the machine use with the damaged and not integer electric feeding cable or with the control

devices.

7. It is forbidden the machine use with the drinking water exible pipe, with the discharging pipe or with the

superior cover packing or the lateral door damaged and not integer and however with the evident presence

of water losses from any machine component.

8. It is forbidden to leave the machine o with the electric feeding cable connected with the feeding plug or

with the drinking water exible pipe connected to the feeding plant.

9. It is forbidden to leave the machine charged unguarded switched o or in function.

10. It is forbidden to insert any type of object inside the motor ventilation cap.

11. It is forbidden the machine functioning without have closet the dresses harvest drawer with inside the lter

or without have fastened the pipe for the charge to the lateral connector (if present).

12. It is forbidden to thread any type of object under the machine base or put clothes or other between the

machine support stems and the oor.

13. It is forbidden the use of inammable substances, corrosive or harmful or high pressure water jets for the

cleaning.

14. It is forbidden to plunge the machine in water or in other liquids.

15. It is forbidden the not authorized personnel use and with clothes dierent from that showed for the use.

16. It is forbidden to introduce in the basin or in correspondence of the service mouth, during the dish rotation,

the hands or any other part of the body or any other object (for example poles, cutlery, etc…), to remove

and to facilitate the food product charge.

17. It is forbidden to maintain the charging door completely open during the dish rotation, to facilitate the food

product charge.

18. It is forbidden the functioning with the xed and moving protection shelters not blocked correctly or

removed.

6

Page 7

Safety and Warranty

19. It is forbidden the partial removal of the protections and of the danger signals.

20. It is forbidden the functioning without that all the precautions about the residual risks elimination have been

adopted on behalf of the user.

21. It is forbidden to smoke or use free ame devices and manipulate incandescent materials, unless some

suitable safety measures aren’t adopted.

22. It is forbidden to activate or set the control and blockage devices as knobs or similar both during the

machine functioning both if you aren’t authorized.

PRECAUTION

The user is however responsible of the damages resulting from the lacked observance of the specied normal

use conditions. For possible doubts you can enquire at the Authorized Assistance Center.

PRECAUTION

The lacked standards and safety procedures applications can be danger and damage sources. The machine

means bound in the use for the respect, on behalf of the nal user, of:

1. All rules, of insertion in the environment and of people behavior, xed from the laws and/or applicable

standards; with particular reference to the xed plant upstream of the supplied machine and for its

connection / functioning.

2. All further instructions and use warnings making part of the technical / graphic documentation annexed to

the same machine.

ATTENTION

Except where dierently specied, the personnel which performs the installation interventions, connection,

maintenance, reassembly, and reuse, damages or breakdowns, demolition and dismantling must be a skilled

personnel qualied in safety matter and educated on the residual risks, with the competencies, in safety matter,

of the maintenance employees.

ENVIRONMENTS, WORKING AND PASSING PLACES

The work environment must answer to the directive 89/654/CEE requirements. In the working area foreign

object must not be present. The employer, in the directive 89/391/CEE respect, concerning the measures

realization turned to promote the safety and workers health improvement during the work, must provide to

eliminate or reduce the showed residual risks as foreseen in the present manual.

WARNINGS ON THE RESIDUAL RISKS

RESIDUAL RISK DUE TO THE FIXED AND MOVING PROTECTION FOR INTERVENTIONS WITHIN THE

BASIN

DANGER

For any occasion the operator must not try to open or remove a xed or moving protection or tamper a safety

device. In the phase of equipment, maintenance, dish change and cleaning, and during all further manual

operations that happens introducing the hands or other body parts in the machine dangerous areas, a residual

risk remains due above all to:

1. Knocks with machine manufacturing parts.

7

Page 8

Safety and Warranty

2. Grazing and/or abrasion with machine rough parts.

3. Sharp pain with the sharpened parts.

The operator and the maintenance man must be skilled for the intervention connected to the manual

operations with open protections, must be trained on the joined consequent risks and must be authorized from

a responsible person and must use adequate individual protection devices, ve ngers anti abrasion gloves.

RESIDUAL RISK DUE TO THE DISCHARGING OPERATIONS

DANGER

During the food product discharging operations, the operator must place a bowl in correspondence of the

discharge mouth before to open the door. Subsequently, with the superior cover closed and blocked, to

facilitate the products leakage with continue action on the control device the operator can activate the dish

rotation. In this phase and during the other discharge phases remains a risk due above all to:

1. Food product projection.

The operator must however always place the adequately great bowl and must maintain the lateral discharge

door handle lightly opened to convey and direct the food products in the bowl. Besides both the operator both

the other people must place laterally and not frontally to the discharge mouth.

RESIDUAL RISK DUE TO THE WATER USE

DANGER

During the functioning the machine is connected to the drinking water plant to allow the treated product

washing. The water and the treated food product dross are after fall discharged or from the machine inferior or

lateral side. In this phase and during all machine functioning remains a residual risk die above all to:

1. Flooding possibility.

2. Water splashes.

Independently from the discharge position, inferior or lateral, the machine must always be placed above a well

with drain for the water harvest. Besides if the machine is equipped with lateral discharge, it is the maintenance

man duty to foresee and insert a dress harvest lter coming from the basin and connect the pipe for the

discharge to the lateral collector.

1 YEAR PARTS AND LABOR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

8

Page 9

Safety and Warranty

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without diculty.

In any case, for suitable recycling, we suggest disposing of the products separately (dierentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

Model PE-IT-0010 PE-IT-0018

Production/H 661.4 lbs. / 300 kgs. 1102.3 lbs. / 500 kgs.

Cycle Time 90-120 seconds 120-150 seconds

Maximum Volume 22 lbs. / 10 kgs. 39.6 lbs. / 18 kgs.

RPM 320

Power 0.75 HP / 550W 1.2 HP / 900W

Electrical 115V / 60Hz / 1

Dimensions

Packaging Dimensions

Weight 98.1 lbs. / 44.5 kgs. 109.1 lbs. / 49.5 kgs.

Packaging Weight 120.2 lbs. / 54.5 kgs. 131.2 lbs. / 59.5 kgs.

Item Number 44184 44185

20.9” x 26” x 43.3”

530 x 660 x 1100mm

26.4” x 23.6” x 48”

670 x 600 x 1220mm

20.9” x 26” x 47.2”

530 x 660 x 1200mm

26.4” x 23.6” x 52”

670 x 600 x 1320mm

Installation

PREPARATION PRELIMINARY OPERATIONS

STABILITY

The machine stability is designed so that, in the foreseen functioning conditions, taking into account of the

climatic conditions is such as to allow the use without reversal risk, fall, or inopportune movement. Taking into

account of the conformation and its position, the machine results to be intrinsically steady without any fastening

needs to the trampling at. All support feet placed under the base must lay on a solid, uniform and well leveled

9

Page 10

Installation

surface.

ELECTRIC FEEDING

The electric feeding connection must be in conformance with the country legislation in which is used. The

electric feeding so must be maintained in conformance with the following technical prescriptions:

1. The electric feeding must be always of type and have an intensity corresponding to the specications

indicated in the machine plate. If excessive voltages are applied, some components will be damaged

irreparably.

2. A dierential device must be foreseen coordinated with the protection circuit, respecting the legislation, the

legislative and regulation disposals in force in the installation country.

3. The electric feeding cable outside the machine cover must be made pass in the spaces prepared from You

and adequately protected.

4. If present the neutral conductor (N) before feeding the electric equipment, as for you its continuity must be

guaranteed (connected and available).

5. Before to feed the electric equipment, as for you must be guaranteed the continuity of the green yellow

conductor of the protection equipotential circuit.

DRINKING WATER FEEDING

The drinking water feeding connection must be in conformance with the country pertinent legislation where is

used. The feeding must so present the following technical prescriptions:

1. The machine must be connected to a drinking water piping.

2. The exible pipe must be connected to a tap for the water opening and closure.

3. For the protection against the over pressures, a protection device must be foreseen coordinated with the

machine drinking water system, with the aim to respect the legislative and regulation disposal using in the

installation country.

4. The connection manifold sizes of the exible pipe in endowment, the ux pressure and the water

temperature are showed in the technical data table. If the pressure is superior to the maximum agreed, a

pressure reducer valve must be assembled.

5. After having performed the connection open slowly the tap to verify that the connection is hermetic.

Eventually correct the gasket seat and the connector.

6. The drinking water exible pipe for the feeding must be made pass in the spaces prepared from You and

adequately protected.

WATER AND DROSS DISCHARGE

The machine allows alternatively to discharge the water and the product working dross in two ways:

1. With inferior fall: the machine must be simply placed above a drain well having care to verify that the dross

drawer discharge hole is aligned with the well.

2. Floor discharge: on such models the lower discharge pipe (not included in the standard supply) has to be

connected to a tube inserted into the oor draining grill.

The discharge water from the machine isn’t drinking, so it must be conveyed directly towards oor harvest

systems.

10

Page 11

Installation

ASSEMBLY / DISASSEMBLY

DANGER

The assembly / disassembly operations of any machine part are performed with the stop machine, with the

plug disconnected from the socket and with water tap closet, or with the sectioning device in OFF and with the

basin completely empty, without nor water nor food products.

LATERAL DISCHARGE COLLECTOR ASSEMBLY

In the case that the machine is equipped with inferior fall water discharge of the dross drawer, the water

and dross discharge can be foreseen through the lateral fall discharge collector. The transformation and the

intervention can be performed only from the Authorized Assistance Center.

DISH AND ABRASIVE TELO DISASSEMBLY/ASSEMBLY INSIDE THE BASIN

1. Struggle on the handle (1) of the transparent superior cover (2) and lift it up to

carry as back as possible.

2. Remove manually possible food products present within the basin (3).

3. Grasp manually and lift the dish (4) within the basin and extract it.

4. In correspondence of the discharge mouth, push manually the abrasive cloth (5)

towards inside the basin. After grasp it with both the hands and lift it completely

from the basin.

For the assembly repeat on the contrary the above described operations.

DANGER

After having inserted the at, check the correct bayonet hook in the rotating pivot.

Operation

FUNCTIONING DESCRIPTION

The control devices are designed and manufactured so as much sure and reliable and resistant to the service

normal stresses, to the foreseeable strains and to the external agents. Besides they are clearly visible,

locatable and marked from a suitable marking. Here follow the main control devices are showed:

Button Description

On/O Button for the general switching on and switching o of the controls panel.

O Button for the machine stop control.

I Button for the machine starting control with impulse.

Button for the maintained action machine starting control with the opened discharge

lateral door (if any).

11

Page 12

Operation

+

-

SWITCHING ON / SWITCHING OFF

The impulse switching on and switching o of the controls panel and the display is possible only with a

voluntary action on the control device foreseen with this aim: On/O button.

FUNCTIONING TIME

Before the machine starting the functioning time setting is possible only with a voluntary action on the control

device foreseen with this aim: + button to increase the time, or the - button to decrease the time.

STARTING

The machine impulse starting is possible, after the switching on, only with a voluntary action on the control

device foreseen for this aim: I button for the machine starting control.

STOP

For the stop control of the machine work function, without have a display complete switching o, activate the O

button.

Button for the functioning time increase (of 10 sec in 10 sec) keeping pushed it (of 1

sec in 1 sec).

Button for the functioning time decrease (of 10 sec in 10 sec) keeping pushed it (of 1

sec in 1 sec).

Red Display: Functioning time visualization.

MAINTAINED ACTION STARTING

The machine maintained action starting is possible only with a voluntary action on the control device foreseen

for this aim: button. The maintained action control is used in the 10-18 Kg versions for the product

unloading operations. During the button releasing the machine stops.

VOLTAGE LACKING

In case of electric feeding breaking or if the machine is disconnected from the electric net, this last one will be

able to be restarted only following the starting function, after the electric feeding back or the reconnection to

the electric net.

TRANSPARENT SUPERIOR COVER OPENING AND LATERAL DISCHARGE DOOR

Lifting the superior cover or the lateral discharge door (if any) the machine stops immediately for the safety

micro switch functioning. The machine can be restarted only closing and blocking the superior cover and the

lateral discharge door and following successively the starting function.

PUT IN FUNCTION

The machine operator can put in function the machine following in order the under reported indications:

1. Close and block the discharge lateral door pushing it towards the machine body and lowing the handle for

the block.

2. Introduce manually the food product with the superior transparent cover completely opened, inside the

basin. The lling must happen in accordance with the limits established in the machine technical data.

12

Page 13

Operation

3. Control positive result of the drinking water injunction nozzle, that must not be clogged.

4. Close and block the superior transparent cover pushing towards the machine body and lowing the handle

for the block.

5. Put in the machine lateral zone and switch on the machine and the display, activating with impulse the On/

O button. Successively set the functioning time with impulses on the + button to increase the time, or the

- button to decrease it and start the functioning activating the I button.

6. At the end of the set time the machine stops and on the display the last working time appears. If you want

to reactivate the functioning follow the indications of the previous point or push the I button to repeat

the cycle. If on the contrary you want to stop the functioning before the end of the set time, activate with

impulse the O button.

UNLOADING

The machine operator can perform the basin discharge following in order the showed indications:

1. Put an adequate great bowl in correspondence of the discharge mouth.

2. Unblock and open the discharge lateral door pull towards up the block handle.

3. Put laterally and not frontally to the discharge mouth, open lightly the discharge lateral door to convey and

make direct the food products in the bowl.

4. Push with continue action the button, to activate the at rotation so to facilitate the food product leakage.

For the food products discharge remained in the basin bottom, it is also possible to open the superior

transparent cover and draw manually the food product from the basin superior zone.

SWITCHING OFF

In succession, the switching o must follow what here under indicated:

1. Before the switching o discharge completely the basin content.

2. Stop the machine activating the On/O button.

3. Close the drinking water tap and unscrew the feeding pipe union of the drinking water from the tap.

4. Disconnect the machine plug from the feeding socket.

5. Perform the cleaning interventions.

Maintenance

DANGER

The machine must be turned o and unplugged from the power supply before any maintenance can be

performed.

CLEANING

DANGER

It is forbidden to clean by hand the organs and the elements in motion. All cleaning interventions must be

started only and exclusively, after having unloaded the machine with the food product in working and having

13

Page 14

Maintenance

insulated from the electric feeding source and from external energy.

The machine, the electric equipment and the machine board components must not be ever washed utilizing

water, and not in any kind of jets form and quantity; so, without “bucket” nor “rubber” nor “towel”. Don’t put ever

directly the machine in the sink or under the tap. The machine hygiene level classication and the associated

equipment, for the foreseen use, are 2 (two): machine that, after a hygiene risk evaluation, is in conformance

with applicable international standards requirements, but requests a programmed disassembly for the cleaning.

All the surface and the machine parts destined to come in contact with the food product or with the food zones

((basin internal surface, transparent superior cover, discharge lateral door, the ats) and the splashes zones

(machine external surface), must be cleaned with the following modalities and order:

1. Discharge all food products inside the basin.

2. Close and block the transparent superior cover and the discharge lateral door and perform a cycle of at

least 10 seconds with the connected drinking water but without food products.

3. Unblock and open the cover and the lateral door and remove both the basin bottom at, both the coating

abrasive cloth of the basin internal surface.

4. The easy removal happens lifting the basin surface cloth before from the anterior zone in correspondence

of the discharge mouth, after from the other parts.

5. Close and block the cover and the lateral door and perform a cycle of at least 10 seconds with the

connected drinking water but without food products.

6. Unthread the steel sheet drawer from the keel bottom and empty the working dross. If the lateral discharge

is present, make the same with the lter connected with the discharge pipe.

7. Wash the at and the abrasive cloth under the drinking water jet.

8. The abrasive plate cannot be washed in the dishwasher.

9. Unblock and open the cover and the lateral door and:

● Scrape the surfaces from the possible food product residuals (for example with plastic scrapers).

● Clean all the food zone surfaces and jets zone with a morbid dampened clothes (not draining) with

detergent diluted in hot water (also common soap for dishes is good). Don’t soak them. With a towel clean

inside the grinding mouth. Use specic products for steel, which must be liquids (not in cream or pastries

however abrasive) and above all must not contain chlorine. Against the fat substances the denatured

alcohol.

● Rinse with cleaned hot water and successively dry all food zone surfaces and jets zone with soft clothes

that don’t lose coats.

● The reassembly must happen only after a working requirement, leave the pieces wrapped in a dry soft

clothes that don’t lose coats.

PERIODS OF LONG INACTIVITY

During the machine long inactivity periods provide to pass vigorously on all steel surfaces (especially if

stainless) a clothes soaked of Vaseline oil so that to spread a protective veil.

THINGS NOT TO DO BEFORE OR DURING THE CLEANING:

• Enter towards the moving elements without to be previously checked of their stop.

• Enter towards the moving elements without have stopped it in safety stop (blockage in zero position of the

electric feeding sectioning devices).

14

Page 15

Maintenance

PRODUCTS NOT TO USE:

• Compressed air with jets towards the machine.

• A high pressure cleaner or a continue water jet.

• Vapor equipment or water jets in pressure.

• Detergent that contains CHLORINE (also if diluted) or its compounds as: the bleach, the muriatic acid,

products to clear the drain, products for the marble cleaning, in general decalcifying, etc. can attack the

steel composition, staining and oxidizing it unavoidable. The only above described products fumes can

oxidize and in any case corrode the steel.

• Steel wool, brushes or abrasive discs produced with other metals or alloys (ex. Common steel, aluminum,

brass, etc…) or tools that have previously cleaned other metals or alloys, that except to scratch the

surface.

• Detergents in abrasive dust.

• Fuel, solvents or inammable and/or corrosive uids.

• Substances used to clean the silver.

Troubleshooting

TYPE POTENTIAL CAUSES Solutions

Net voltage lacking. General Black out. Contact the electric energy

distributor.

Fuses or magneto thermals

intervention place upstream of the

machine feeding line.

After having eliminated the

causes that have determined the

protection device intervention,

restore it. In case of problem

persistency contact an electrician

technician.

15

Page 16

Troubleshooting

Functioning intervention. Protection device intervention

inside the machine.

Unblock and opening of the

transparent superior cover or of the

discharge lateral door (if any).

Cause/s not identiable. Contact directly the Authorized

The machine doesn’t function: the

at doesn’t rotate.

The potatoes don’t peel correctly. Worn at surface. Contact directly the Authorized

Feeding voltage lacking. Check and restore the electric

Sectioning devices on “O”. Turn the sectioning devices in the

Lacked working time setting. Set the timer in the controls panel.

Intervened fuses or not functioning

magneto thermals.

Lacked buttons functioning. Check the buttons eciency and

Damaged micro switches. Contact directly the Authorized

Slow drive belt determines also

noise or creaking emission.

Abrasive cloth surface inside the

worn basin.

Contact an electrician technician:

after having eliminated the

causes that have determined the

protection device intervention,

restore it.

In case of fuses intervention,

change them with types of the

same model, calibration and

intervention curve.

Unblocking and opening the cover

or the door, the machine stops

immediately for the safety micro

switches functioning. Close and

block the cover and the door

handles.

Assistance Center.

energy.

position “ON ”

Change the intervened fuses,

check the magneto thermal

switches condition.

eventually contact directly the

Authorized Assistance Centre.

Assistance Centre.

Contact directly the Authorized

Assistance Centre.

Assistance Centre for the change.

Contact directly the Authorized

Assistance Centre for the change.

16

Page 17

Troubleshooting

Drinking water absence inside the

basin during the functioning.

Excessive water presence inside

the basin that doesn’t discharge

or splash in the machine inferior

zone.

Presence of evident water drops

or wire drawings in the machine

superior and/or inferior surface.

Drinking water exible pipe not

connected.

Tap closed. Rotate the superior part in

Water emission nozzle inside the

obstructed basin.

Damage in the plant inside the

machine.

Dross separation lter obstructed. Clean it.

Drawer in steel in the body inferior

zone mal inserted.

Presence of losses from the lateral

discharge pipe union

Drinking water exible pipe unions

not screwed correctly to the tap or

to the machine.

Worn transparent superior cover

gasket.

Worn discharge inferior door

gasket.

Water losses presence in the

plastic wrapping perimeter zone.

Water splashes coming from the

exible pipe or wire drawings.

Connect the drinking water exible

pipe, screwing the piping union to

the tap male joint.

clockwise for the drinking water

ow.

Perform the nozzle holes cleaning

as showed, with the switched o

machine and insulated from the

external feeding sources.

Contact directly the Authorized

Assistance Centre

Insert on the drawer bottom so

that the basin discharge happens

completely inside the drawer.

Discharge pipe not inserted

correctly or not blocked with strip.

Switch o the machine, insulate it

from the external feeding sources

and tighten the pipe unions to the

relative male joints. In the case

the pipe union thread is stripped

or the gaskets are absent, contact

directly the Authorized Assistance

Centre.

Contact directly the Authorized

Assistance Centre for the change.

Contact directly the Authorized

Assistance Centre for the change.

Contact directly the Authorized

Assistance Centre.

Flexible pipe with holes or cracks,

contact directly the Authorized

Assistance Centre for the change.

Change the pipe at least every 3

years.

17

Page 18

Troubleshooting

REFERENCE

Item Number Model Number Description

Potato Peeler 22 lb./10 kg. with

44184 PE-IT-0010

44185 PE-IT-0018

Microswitch and Floor Water Discharge

0.75 HP/550 W 115V/60/1 QPS

Potato Peeler 39.6 lb./18 kg. with

Microswitch and Floor Water Discharge

1.2 HP/900 W 115V/60/1 QPS

Manufacturer Model

Number

FP100

FP102

18

Page 19

Model PE-IT-0010 44184

Model PE-IT-0018 44185

Parts Breakdown

19

Page 20

Parts Breakdown

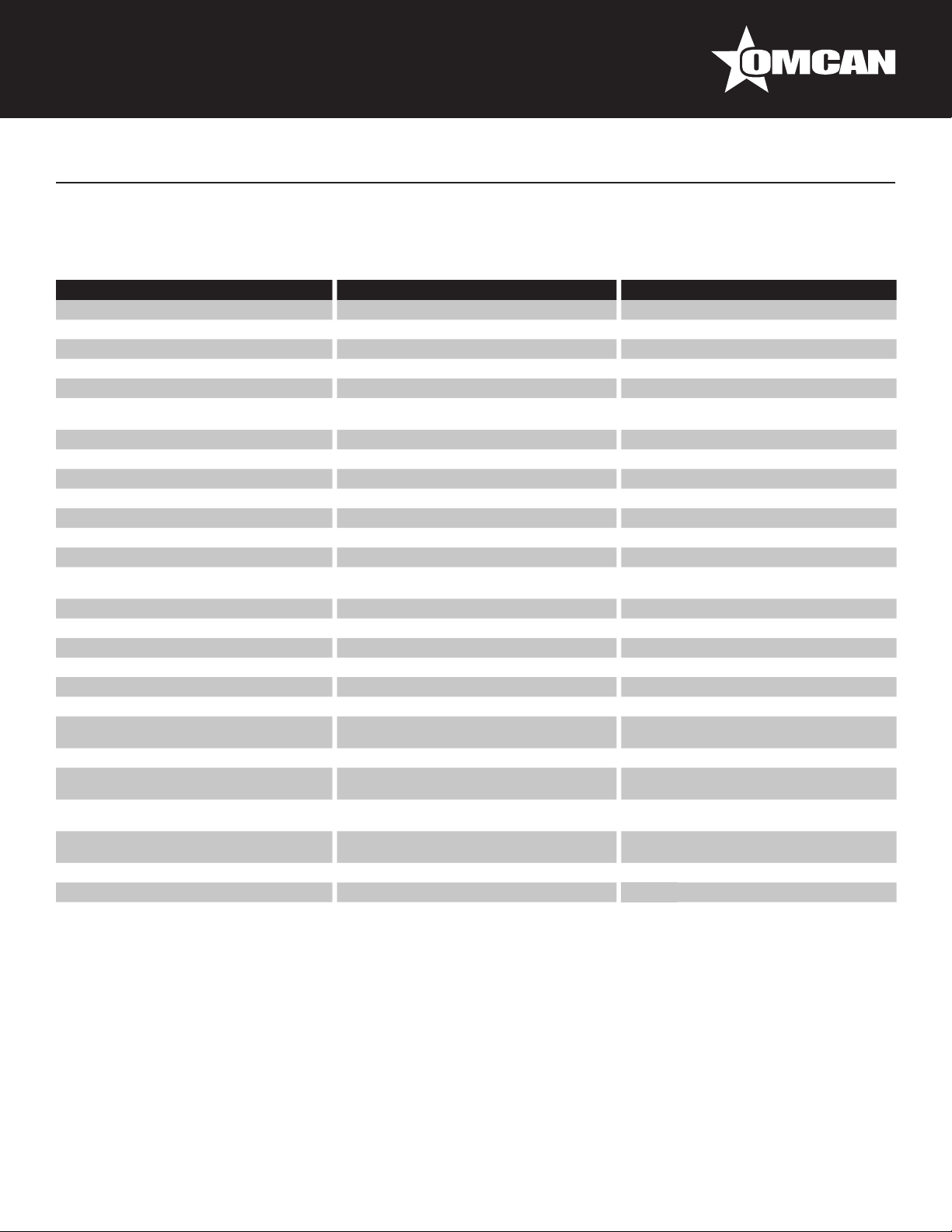

Model PE-IT-0010 44184

Item No. Description Position Item No. Description Position Item No. Description Position

64598 Pin for FP100 1 64625 INOX Screw Cover (2 pcs.) for FP100 29 64651 Drawer Handle for FP100 57

64599 5x5x15 Key for FP100 2 64626 Magnet 6x20 Cover for FP100 30 64652 Waste Drawer for FP100 59

64600 Mechanical Seal D.25 for FP100 3 64627 Cover Gasket for FP100 31 64653 Waste Filter for FP100 60

64601 Bearing 6004 2RS for FP100 4,11 64628 Nozzle of Water for FP100 32 64654 Left Arm Handle for FP100 61

64602 Seeger from 42 for FP100 5,10 64629 Resca for Water Jet Nozzle for FP100 33 64656 Handle Grip for FP100 62

64603 Ring OR 6225 for FP100 6 64630 Strap 13/15 for FP100 34 64657

64604 M8x16 Flanged Screw (6 pcs.) for FP100 7 64631 Water Tube 8x22 for FP100 35 64658 Right Arm Handle for FP100 64

64605 Flange Seal Gasket (6 pcs.) for FP100 8 64632 Strap 15/18 for FP100 36 64659 Door Sticker for FP100 65

64606 Motor Flange for FP100 9 64633 Solenoid Valve for FP100 37 64660 Door Gasket for FP100 68

64607 Conduit Pulley for FP100 12 64634 80/50 Discharge Reduction for FP100 38 64661 Magnet 6x15 Door for FP100 69

64608 Belt J12 for FP100 13 64635 Water Load Tube for FP100 39 64662 Door for FP100 70

15364 Washer 8x32x2 for FP100 14 64636 Keyboard Cover for FP100 40 64663 Micro Magnetic Door for FP100 73

15440 Screw 8x25 for FP100 15 64637 Digital Keypad for FP100 41 64664 Stainless Steel Bush (2 pcs.) for FP100 74

70181 Washer 8x16x1,5 (4 pcs.) for FP100 16 64638 Micro Magnetic Cover for FP100 42 64665

64610 Stainless Grain M8x40 (2 pcs.) for FP100 17 64639 Electronic Control Board for FP100 43 64666 Cover Handle Bar for FP100 76

64611 Nut M8 (2 pcs.) for FP100 18 64640 Rubber Handle 20mm for FP100 44 64667 Screw 5x8 INOX (2 pcs.) for FP100 77

64612 20 uF Capacitor for FP100 19 64641 Cable Gland PG13.5 for FP100 45 64668 Stainless Steel for FP100 78

64614 Complete Motor V.110/60Hz for FP100 20 15372 Screw 5x25 (4pcs.) for FP100 46 64670 Abrasive Canvas for FP100 79

64616 Motor Pulley for FP100 21 64642 Electric Box for FP100 47 64672 Pelapated Abrasive Plate for FP100 80

64617 Washer 10x20x2 for FP100 22 64643 Electric Box Gasket for FP100 48 64673 Transparent Cover Complete for FP100 81

64618 Nut M10 for FP100 23 64644 Power Board B.T. V.110/60Hz for FP100 49 64674

64619 Upper Cover Handle for FP100 24 64645 Cable Tie 80/100 for FP100 50 64675 Complete Door for FP100 82

64620

64621

64622 Transparent Cover for FP100 27 64648 Screw 8x18 INOX (4 pcs.) for FP100 53 64678

64623 Stainless Steel Cover for FP100 27 64649 Bottom C / Gambe INOX for FP100 54

64624 Screw 6x8 INOX T.E. (2 pcs.) for FP100 28,58 64650 Foot (4 pcs.) for FP100 56

Special Stainless Nut M6 (2 pcs.) for

FP100

Stainless Steel Screw M6x14 (2 pcs.)

for FP100

25,66,72 64646 80mm Exhaust Pipe for FP100 51 64676 Drawer Complete for FP100 83

26,67 64647

8x16x1,5 INOX Washer (4 pcs.) for

FP100

52 64677 Electrovalve Kit Complete for FP100 84

M6x25 Stainless Steel Screw Head (2

pcs.) for FP100

Screw 6x8 INOX Button (2 pcs.) for

FP100

Stainless Steel Cover Complete for

FP100

Bracket and Electrical Panel and No. 2

Bushings for FP100

63

75

81

85

20

Page 21

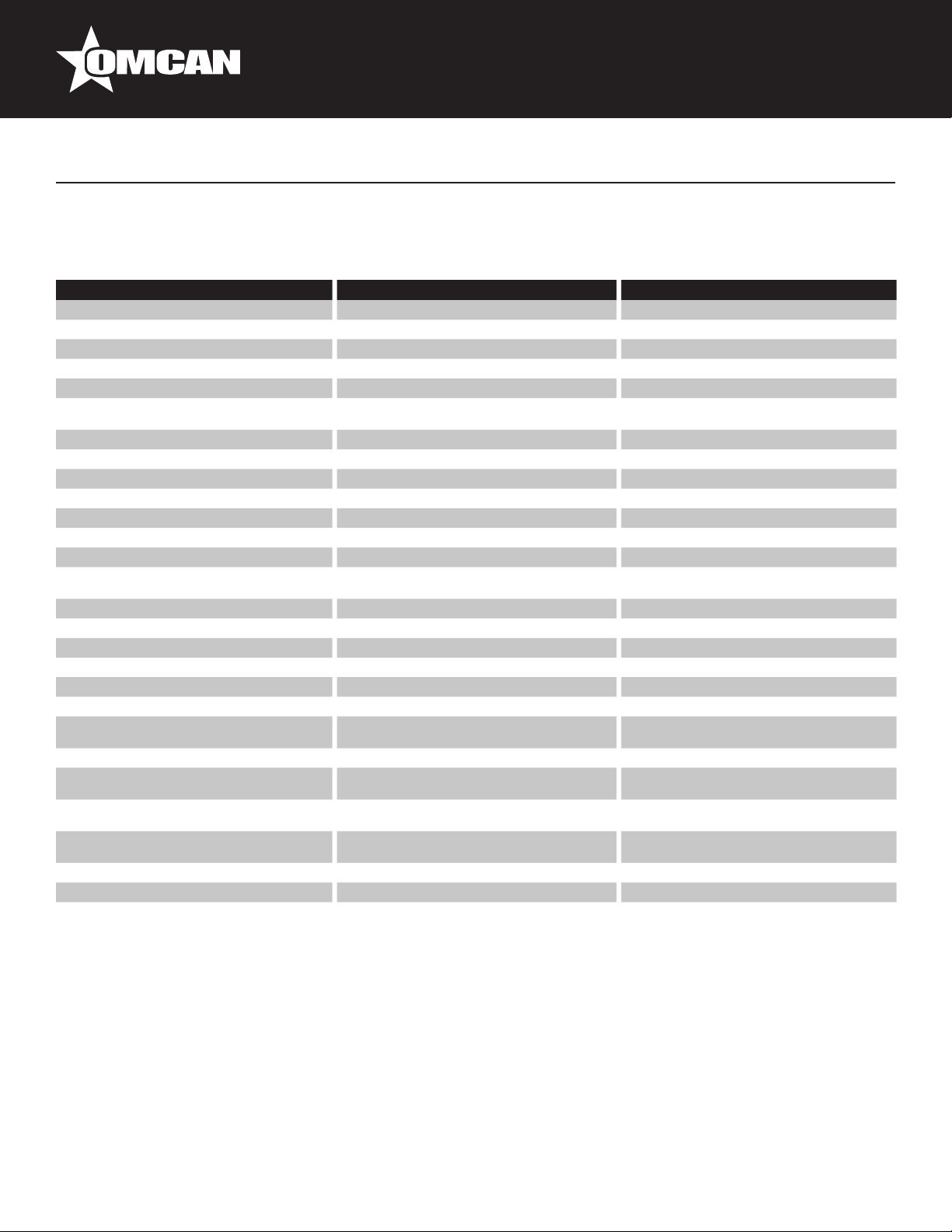

Parts Breakdown

Model PE-IT-0018 44185

Item No. Description Position Item No. Description Position Item No. Description Position

64598 Pin for FP102 1 64625 INOX Screw Cover (2 pcs.) for FP102 29 64651 Drawer Handle for FP102 57

64599 5x5x15 Key for FP102 2 64626 Magnet 6x20 Cover for FP102 30 64652 Waste Drawer for FP102 59

64600 Mechanical Seal D.25 for FP102 3 64627 Cover Gasket for FP102 31 64653 Waste Filter for FP102 60

64601 Bearing 6004 2RS for FP102 4/11 64628 Nozzle of Water for FP102 32 64654 Left Arm Handle for FP102 61

64602 Seeger from 42 for FP102 5/10 64629 Resca for Water Jet Nozzle for FP102 33 64656 Handle Grip for FP102 62

64603 Ring OR 6225 for FP102 6 64630 Strap 13/15 for FP102 34 64657

64604 M8x16 Flanged Screw (6 pcs.) for FP102 7 64631 Water Tube 8x22 for FP102 35 64658 Right Arm Handle for FP102 64

64605 Flange Seal Gasket (6 pcs.) for FP102 8 64632 Strap 15/18 for FP102 36 64659 Door Sticker for FP102 65

64606 Motor Flange for FP102 9 64633 Solenoid Valve for FP102 37 64660 Door Gasket for FP102 68

64607 Conduit Pulley for FP102 12 64634 80/50 Discharge Reduction for FP102 38 64661 Magnet 6x15 Door for FP102 69

64608 Belt J12 for FP102 13 64635 Water Load Tube for FP102 39 64662 Door for FP102 70

15364 Washer 8x32x2 for FP102 14 64636 Keyboard Cover for FP102 40 64663 Micro Magnetic Door for FP102 73

15440 Screw 8x25 for FP102 15 64637 Digital Keypad for FP102 41 64664 Stainless Steel Bush (2 pcs.) for FP102 74

70181 Washer 8x16x1,5 (4 pcs.) for FP102 16 64638 Micro Magnetic Cover for FP102 42 64665

64609 Stainless Grain M8x35 (2 pcs.) for FP102 17 64639 Electronic Control Board for FP102 43 64666 Cover Handle Bar for FP102 76

64611 Nut M8 (2 pcs.) for FP102 18 64640 Rubber Handle 20mm for FP102 44 64667 Screw 5x8 INOX (2 pcs.) for FP102 77

64613 50 uF Capacitor for FP102 19 64641 Cable Gland PG13.5 for FP102 45 64669 Stainless Steel for FP102 78

64615 Complete Motor V.110/60Hz for FP102 20 15372 Screw 5x25 (4 pcs.) for FP102 46 64671 Abrasive Canvas for FP102 79

64616 Motor Pulley for FP102 21 64642 Electric Box for FP102 47 64672 Pelapated Abrasive Plate for FP102 80

64617 Washer 10x20x2 for FP102 22 64643 Electric Box Gasket for FP102 48 64673 Transparent Cover Complete for FP102 81

64618 Nut M10 for FP102 23 64644 Power Board B.T. V.110/60Hz for FP102 49 64674

64619 Upper Cover Handle for FP102 24 64645 Cable Tie 80/100 for FP102 50 64675 Complete Door for FP102 82

64620

64621

64622 Transparent Cover for FP102 27 64648 Screw 8x18 INOX (4 pcs.) for FP102 53 64678

64623 Stainless Steel Cover for FP102 27 64649 Bottom C / Gambe INOX for FP102 54

64624 Screw 6x8 INOX T.E. (2 pcs.) for FP102 28/58 64650 Foot (4 pcs.) for FP102 56

Special Stainless Nut M6 (2 pcs.) for

FP102

Stainless Steel Screw M6x14 (2 pcs.)

for FP102

25,66,72 64646 80mm Exhaust Pipe for FP102 51 64676 Drawer Complete for FP102 83

26/67 64647

8x16x1,5 INOX Washer (4 pcs.) for

FP102

52 64677 Electrovalve Kit Complete for FP102 84

M6x25 Stainless Steel Screw Head (2

pcs.) for FP102

Screw 6x8 INOX Button (2 pcs.) for

FP102

Stainless Steel Cover Complete for

FP102

Bracket and Electrical Panel and No. 2

Bushings for FP102

63

75

81

85

21

Page 22

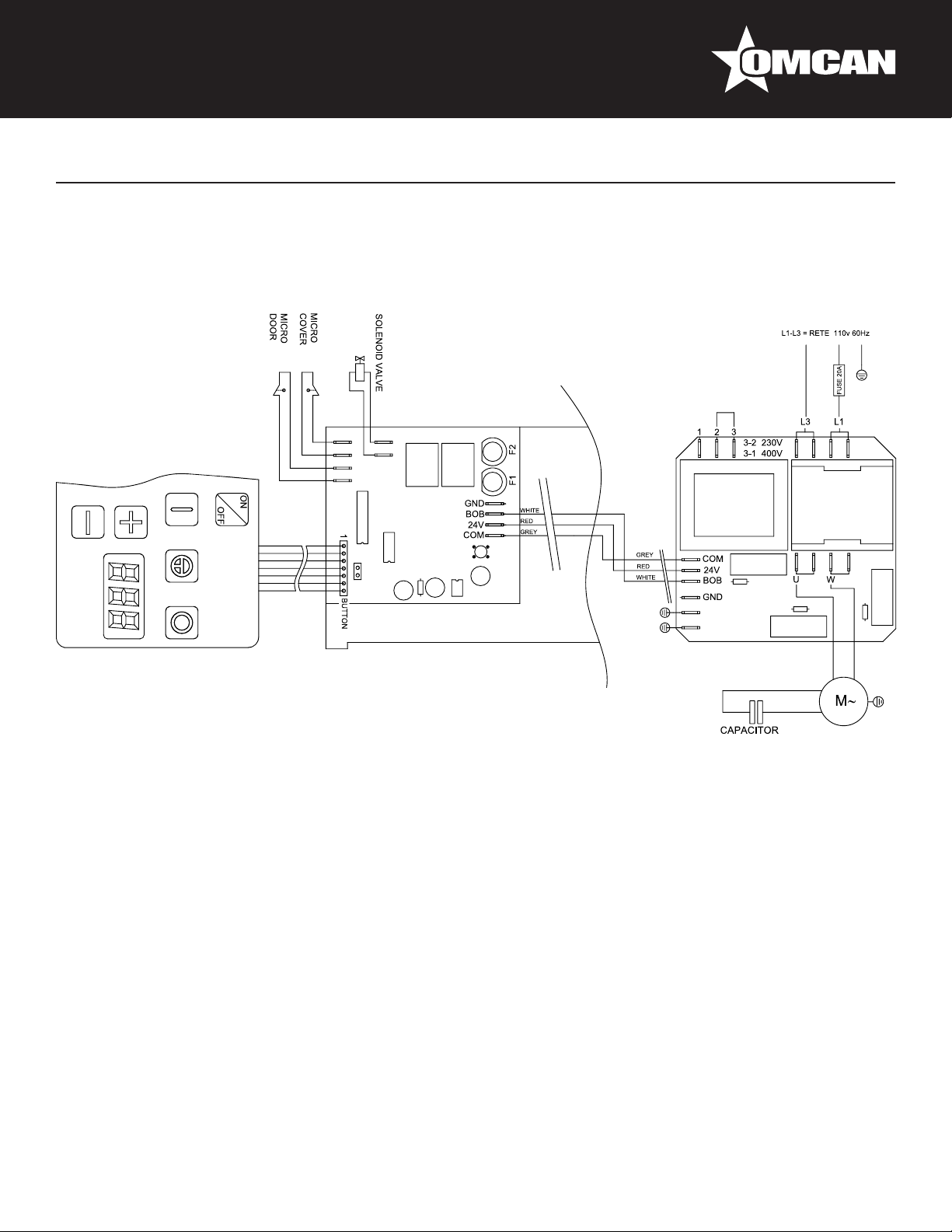

Electrical Schematics

Model PE-IT-0010 44184

Model PE-IT-0018 44185

22

Page 23

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear o the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

23

Page 24

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...