Page 1

Gear-Driven Slicer

Model MS-IT-0370-H

Item 38915

Instruction Manual

Revised - 03/26/2018

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model MS-IT-0370-H

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

--------------------------------------------------------------------------------------- 6 - 7

----------------------------------------------------------------------------------------- 7 - 8

----------------------------------------------------------------------------------- 8 - 11

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 5

Page

-------------------------------------------------------------------------- 6

Troubleshooting

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

------------------------------------------------------------------------------------------- 24 - 26

----------------------------------------------------------------------------- 11 - 12

---------------------------------------------------------------------------- 12 - 22

---------------------------------------------------------------------------- 23

---------------------------------------------------------------------------- 27

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

--------------------------------------------------------------------------------------------------------------------------------------------------Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

--------------------------------------------------------------------------------------------------------------------------------------------------Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre leer y familiarizarse con todas las instrucciones de

operación y seguridad.

Omcan quisiera darles las gracias por la compra de esta máquina. Es de la máxima importancia para

guardar estas instrucciones para referencias en el futuro. También guarde la caja original y el embalaje

para envío del equipo si el mantenimiento o la devolución de la máquina es necesaria.

Safety and Warranty

MECHANICAL SAFETY DEVICES

The slicer is manufactured according to the EEC 2006/42 Machinery Directive.

The mechanical safety devices are the following:

• Product holder removable only with the slice thickness control on zero (slice thickness plate positioned to

protect the blade). After removing the product holder the slice thickness plate is mechanically clamped.

4

Page 5

Safety and Warranty

• Protection devices mounted on the product holder to prevent the operator from any accidental contact with

the blade.

• Blade guard. This xed ring protects that part of the blade which is not used for the cutting operation.

• A special mechanical safety device to sharpen the blade keeping the ngers of the operator away from the

cutting edge of the blade.

ELECTRICAL SAFETY DEVICES

The electrical safety devices in accordance with the EN 60204 standards are the following:

• Start and stop push buttons.

• Control circuit provided with electric servo-control; in any case of blade clamping the machine must be

restarted manually.

• Safety device to stop the rotation of the blade if the clamping handle of the blade guard is released.

WARNING

When the machine is not used:

• Make sure that it is off.

• Re-position the slice thickness control to zero.

Do not remove the labels placed on the machine and replace them if damaged.

1 YEAR PARTS AND LABOUR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

5

Page 6

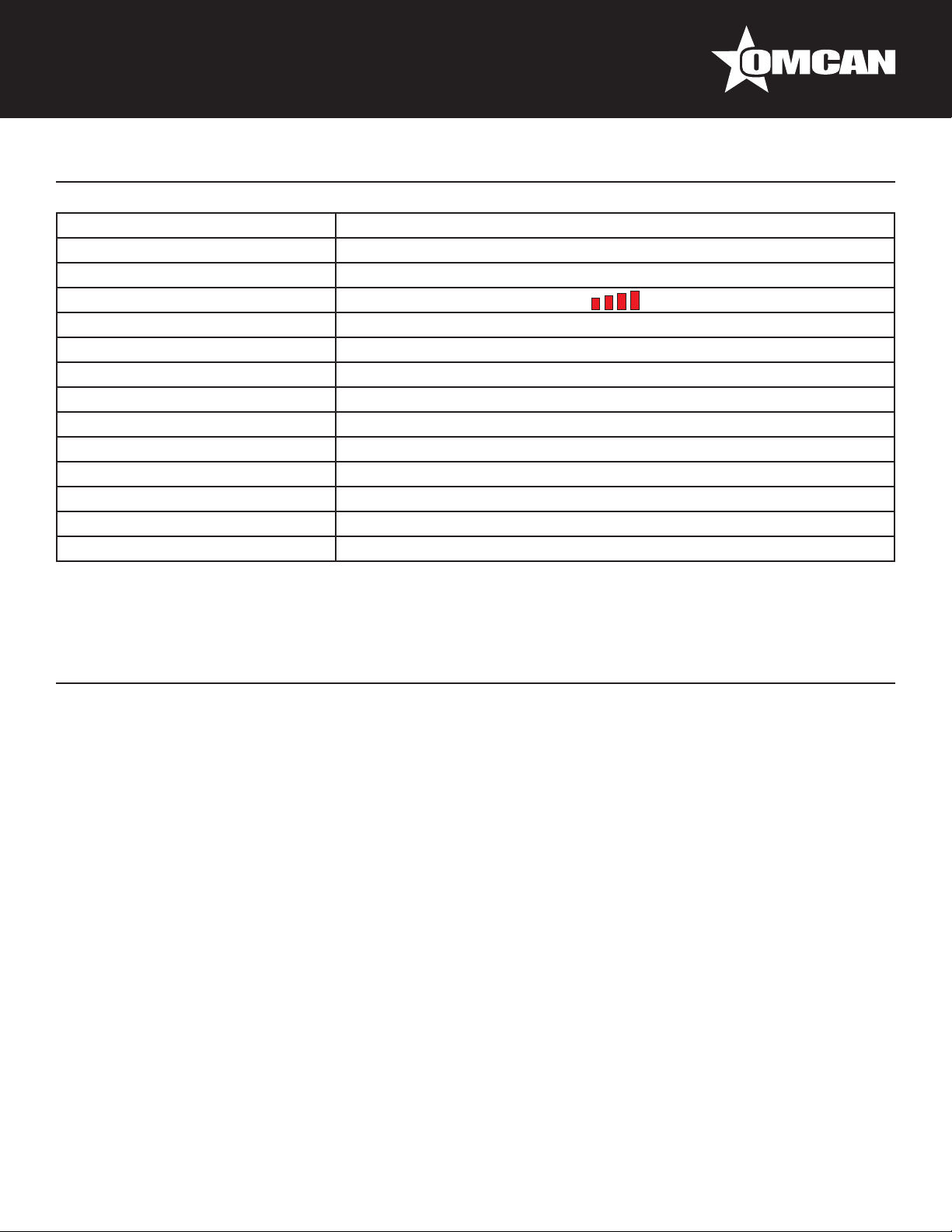

Technical Specications

Model MS-IT-0370-H

Blade Size 15” / 370mm

Power 0.4 HP / 0.3 kW

Cheese Slicing*

Slicing Volume 8 hours or more

RPM 250

Cutting Size 14.6” x 10.2” / 270 x 260mm

Cut Thickness 0”-1” / 0-25mm

Electrical 110V / 60Hz / 1

Weight 125 lbs. / 57 kgs.

Packaging Weight 140 lbs. / 63.5 kgs.

Dimensions 31.5” x 29.5” x 22.4” / 800 x 750 x 570mm

Packaging Dimensions 36” x 34” x 27” / 914 x 863 x 686mm

Item Number 38915

*Results may vary due to product consistency and temperature

Installation

The slicer must be mounted horizontally on a stable, robust and antiskid base adequate to support its weight.

The suggested height of the working table is of about 800mm. It must be checked that the product holder is not

clamped and the product to be cut can be easily loaded.

WARNING: To prevent the risk of crushing hazard, locate the machine in a manner that allows a clear space

between the moving table and any permanent structure.

PRELIMINARY CLEANING

Before connecting the plug clean off the protective oil from the machine.

WARNING

The working table must always be cleaned.

ELECTRICAL SUPPLY

The machine must be installed in the proximity of a mains socket. Check that the power supply voltage

corresponds to that described on the information label and that it is connected to an adequate earth.

1. Connect the plug.

2. Check that the blade cover fastener handle is tight screwed.

3. Check that the blade sharpener is lowered and the protective cover is closed.

6

Page 7

Installation

MANUAL FUNCTIONING

1. Press push button blade start.

AUTOMATIC FUNCTIONING

1. See manual functioning.

2. Press push button carriage start.

SLICER FUNCTIONING AND USE

The following products can be sliced: sausages, ham, cheese, bread. If large quantities of bread or cheese are

usually cut it is advisable to mount a teon coating.

WARNING

The following cannot be sliced:

• Not-eatable products.

• Foodstuffs with bones.

• Frozen products.

AUTOMATIC FUNCTIONING

Rotate the carriage release handle in a counterclockwise direction by 180°. With the automatic functioning it

is possible to change the cut stroke length to adapt it to the dimensions of the product to be cut. Rotate the

product holder stroke adjustment knob respectively in a clockwise or counterclockwise direction to lengthen

or shorten the product holder stroke. Irrespective of the selected stroke, the product holder always stops

in product load position (operator’s side) by pressing the product holder stop push button. The machine is

supplied with two self-contained motors: one for the blade and another for the product holder to better adjust its

stroke. By separating the two functions a more precise cut can be obtained.

MANUAL FUNCTIONING

Rotate the product holder release handle in a clockwise direction by 180°.

Operation

HOW TO LOAD THE PRODUCT TO BE CUT

1. Check that the slicer is off and position the slice thickness control to zero.

2. Push the product holder towards the operator.

3. Lift and rotate the product pusher: the pusher can fall back, this is normal.

4. Place the product to be cut against the wall of the product holder and the slice thickness plate.

5. Position the product pusher on the product to be cut far from the slice thickness plate. The product is fed to

the slice thickness plate by gravity making the cut easier.

6. Rotate the slice thickness control to the thickness desired.

7

Page 8

Operation

AUTOMATIC FUNCTIONING

1. Rotate the carriage release handle in a counterclockwise direction by 180°.

2. Press push button start blade.

3. Press push button start the product holder.

4. To select the most suitable carriage stroke according to the dimensions of the product to be cut, rotate the

carriage stroke adjustment knob respectively in a clockwise or counterclockwise direction to lengthen or

shorten the stroke.

DANGER

Do not touch the carriage or the product holder when the machine is working.

After completing the cutting operation, press push button stop the product holder. The blade remains in

operation whereas the product holder is fed to the stroke end where it stops towards the operator ready to start

a new cutting cycle.

By pressing push button stop the blade, the product holder stops in its working position.

MANUAL FUNCTIONING

1. Rotate the carriage release handle in a clockwise direction by 180°.

2. Press push button to start the blade.

3. With constant speed, according to the product to be sliced features, you can push the product holder tray

to its end stroke in blade direction. You can then return in the operator position and repeat this operation.

After cutting the product, reposition the product holder towards the operator. By pressing push button stop

blade the rotation of the blade stops. Re-position the slice thickness control to zero and unload the product.

Maintenance

BLADE SHARPENING

Whenever the cut is not satisfactory, sharpen the blade. The time interval between a sharpening and the

following depends on the intensity of use of the slicer and on the kind of food you cut. Replace the blade when

the diameter becomes 10mm less than the nominal diameter. For the replacement, ask the assistant service

closest to you.

WARNING

The replacement of the blade is dangerous operation. Should the sharpening quality be not

satisfactory, replace the stones by contacting Omcan.

8

Page 9

Maintenance

SHARPENING OPERATION

DANGER

The sharpening operation must be performed during the manual functioning.

For a correct sharpening of the blade follow these instructions:

1. Clean the blade removing any greasy residue.

2. Make sure that the machine is off.

3. Rotate the slice thickness control to zero to make sure that the blade is covered by the slice thickness

plate.

IMPORTANT

During the following operations the blade must always be covered by the removable protection.

4. Lift the sharpener cover.

5. Slip off completely the sharpener and spin it 180 degrees.

6. Replace the sharpener device.

7. Push the push button blade start to start the machine.

8. Sharpening: Press the sharpening wheel for about 10-15 seconds.

Then press simultaneously also the grinding stone for two seconds.

Contemporaneously loosen the two grind stones.

The sharpening and honing take place then simultaneously.

ATTENTION: for a suitable effect please execute sharpening for 10-15 seconds approx.

9. After sharpening press the blade stop push button.

10. Lift and rotate 180 degrees the sharpener and reallocate it into its initial position. Loosen the handle

rotating it clockwise to block the sharpener. Lower the sharpener cover.

CLEANING OF THE GRINDING WHEELS

To obtain an excellent sharpening the grinding wheel must always be clean. Remove dirt and grease with

alcohol and the supplied special brush. Be sure to clean and sanitize the blade after sharpening.

MAINTENANCE

All cleaning and maintenance operations must only be carried out with the machine disconnected and isolated

from the mains supply and the slice thickness control on zero.

CONTROL OF THE AIR GRATING

An air grating for the motors ventilation is placed in the lower side of the machine. Keep the section-holes free

and clean them with a brush at regular intervals.

9

Page 10

Maintenance

CHECK OF THE ELECTRIC CABLE

It is recommended to check the wear of the electric cable at regular intervals.

SPARE PARTS

In the event that replacement parts need to be tted, request only original spare parts.

CLEANING

The machine must be cleaned once a day or more frequently if necessary. Clean all the parts using a cloth

sprinkled with water and washing up liquid (do not use strong detergents) and a brush.

WARNING

Do not use water jet

DANGER

During the cleaning operations take great care: danger of accident.

COMPONENTS REMOVAL

PRODUCT HOLDER

1. Loose the product holder by rotating the product holder clamping handle in a counterclockwise direction.

2. Position to zero the slice thickness control to remove the product holder.

3. Push the product holder towards the operator until it clicks. The click will inform the operator that the

product holder is clamped.

4. Lift the last slice device from the guide bar.

5. Lift the product holder from the carriage.

IMPORTANT

The slice thickness control is clamped on zero.

BLADE COVER

1. Rotate the slice deector and keep it away from the blade.

2. Loose the blade cover fastener handle by rotating it in a counterclockwise direction.

3. Push on the handle in the direction indicated by the arrow to lift the blade cover from the blade.

4. Lift the blade cover.

ATTENTION

Once removed the blade cover, an interlocking device stops the rotation of the blade.

DANGER

During the cleaning operations of the blade, pay attention to an accidental contact with it.

5. Press a damp cloth on the front side of the blade and move slowly from the center towards the edge in the

10

Page 11

Maintenance

direction of the arrow.

6. Follow these instructions to clean the back side of the blade.

7. With a cloth dry both sides of the blade following this procedure.

8. Insert a damp cloth between the blade and the protection ring. Pull it outwards and rotate it to clean the

internal side of the protection ring.

9. After cleaning re-position the blade cover, insert the fastener and screw in a clockwise direction to clamp

the blade cover. Lower the sharpener protective cover.

IMPORTANT

Leave all the parts to soak in warm water and washing-up liquid (do not use strong detergents) and clean them

by using a brush or a cloth. Rinse them in warm water and dry them.

To assemble the machine follow the reverse procedure as described for disassembly.

GUIDES LUBRICATION

This operation must be performed after cleaning the slicer or whenever the sliding is difcult. Use food safe oil

only.

LUBRICATION OF THE GUIDE BAR OF THE LAST SLICE DEVICE

1. Drop some food grade oil on the bar.

2. Let the last slice device slide on the guide bar.

LUBRICATION OF THE GUIDE BAR OF THE PRODUCT HOLDER CARRIAGE

1. Push the product holder towards the operator.

2. Pour the food grade lubricating oil into the special carriage bar lubricator.

3. Push the product holder to and from and repeat the operation. Re-position it towards the operator.

Troubleshooting

PROBLEM CORRECTIVE ACTION

The machine vibrates, overheats

and emits a foul smell.

The blade cannot be sharpened

any longer. The sharpening is no

regular.

On pushing the start push button

the machine does not start.

The carriage and the last slice

device run with difculty.

Stop it immediately and check that the voltage corresponds to that described on the rating label.

Clean the grinding wheels of the sharpener and check the wear of the

blade.

Check if power missing. Check the safety devices.

Lubricate the guide bars.

11

Page 12

Troubleshooting

REFERENCE

Item Number Model Number Description Manufacturer Model Number

Meat Slicer Gear Driven Horizontal

38915 MS-IT-0370-H

15” / 370mm Blade 0.4HP / 300W

110V/60/1 NSF cETL cULus

H37S

Parts Breakdown

Model MS-IT-0370-H 38915

12

Page 13

Model MS-IT-0370-H 38915

Parts Breakdown

13

Page 14

Parts Breakdown

Model MS-IT-0370-H 38915

14

Page 15

Model MS-IT-0370-H 38915

Parts Breakdown

15

Page 16

Parts Breakdown

Model MS-IT-0370-H 38915

16

Page 17

Model MS-IT-0370-H 38915

Parts Breakdown

17

Page 18

Parts Breakdown

Model MS-IT-0370-H 38915

18

Page 19

Model MS-IT-0370-H 38915

Parts Breakdown

19

Page 20

Parts Breakdown

Model MS-IT-0370-H 38915

Item No. Description Position Item No. Description Position Item No. Description Position

16900 Sharpening Assembly for H37S A1026 36569 Fixing Lever Bushing for H37S B6239 19646 Nut U5588 M16 Stainless Steel for H37S D0144X

36536

16902 Ring EL.Benzing 8 for H37S A5406 23646 Sharpener Pivot Ferrule for H37S B6256 19642 Nut M8 for H37S D0155X

17281 Ring EL.Seeger Ext.25 for H37S A5453 77552 Bushing for Plate for H37S B6332 36643 Nut U5588 M5 for H37S D0160

77585

19484 Ring 52 for H37S A5485 77553 Pusher Arm for H37S B7825 36647 Nut U5588 M8 for H37S D0165

19612 Ring 33 for H37S A5495 77554 Pusher Arm Assembly for H37S B7919 64365 Nut U5588 M8 for H37S D0165X

17283 Oil Seal 25x52x10 for H37S A5809 77518 Sharpener Cover for H37S C1616 36649 Nut U5588 M10 Stainless Steel for H37S D0167X

77601 Oil Seal OR 2010 for H37S A5848 36591 Carriage Support for H37S C185404 36651 Sharpener Support Nut for H37S D0183

17287 O-Ring 123 17.86x2.62 for H37S A5852 65141 Flat Cart for H37S C1885 79264 Blade Support Screw for H37S D5454

77602 O-Ring OR 4500 for H37S A5857 77534 Cart Assembly for H37S C1904 77506 Spacer Ø22x22 for H37S D5465

77547 Pin Stop Ring for H37S A5921 77605

77502 Shaft Sealing Ring Ø98x42 for H37S A5946 79263 Contact Pin for H37S C3352 77556 Right Spacer INT90 for H37S D5624

36546 Carriage Rod for H37S B1024 36601

77548 Tray Rod for H37S B1038 36607 Blade Cover Bolt Keeper 14x14 for H37S C5007 17341 Spacer D.10.5x14 H.9 for H37S D5643

77533 Quandra Bar for H37S B1081 36609 Capacitor 20µF 250V for H37S C5814 36661

36548 Shock Absorber Bar 12x170 for H37S B1251 65148 Condenser 20mf 250V for H37S C5815 36665 Locknut Spacer for H37S D577018

77549 Plate Rod for H37S B1258 74403 Connector Faston 2 Poles Male for H37S C6010 77519 Spacer Eccentrico for H37S D577141

19508 Carriage Rod for H37S B1376 77611 P.C.B. Cover Box for H37S C644680 77557 Spacer Supp.Bar Post. for H37S D5834

79260 Body for H37S B1808 36614 Cover Anter.Motor H (Diam.135) for H37S C6464 65168 Eccentric Cusc. Cart lg.43 for H37S E145801

16904 Bushing Sharpener for H37S B6048 36615 Back Motor Cover for H37S C6466 36677 Cam Pin for H37S E1460

64357 Bushing DU 16x18x15 for H37S B6053 65149 Cover Fan Mot.ESTR.Diam 135 for H37S C6573 77590 Cam for Sharpener for H37S E1461

17304 Bushing for H37S B6056 19534 Housing Sharpener H for H37S C6807 77558 Eccentric for H37S E1471

17305 Bushing DU 18x20x15 for H37S B6057 19536 Rack for H37S C7244 19564 Cam 25mm for H37S E1474

19514 Bushing Guard A310 for H37S B6061 65156 Bearing 2Z-6205 25x52x15 for H37S C8011 36680 Carriage Felt for H37S F1606

16906 Bush Sharpening for H37S B6075 16925 Bearing 2RS-6204 20x47x14 for H37S C8024 77614 Nylon Cable Tie (Diam.45x200) for H37S F2815

16907 Bush Sharpening for H37S B6076 36630 Bearing 5x16x6.5 for H37S C8035 36682 Unhook Friction Clasp 12x22x8 for H37S F3015

17307 Bushing Sharp for H37S B6083 36631 Bearing 2RS-6205 25x52x15 for H37S C8056 77591 Support Blade Flange for H37S F6039

19630 Bushing Fastener for H37S

78265 Bushing Funnel for H37S B6110 60423 Touch Pad Gasket for H37S C8242 17351 Locknut for H37S G5018

77550 Bushing DU 10x12x10 for H37S B6 111 19637 Nut M3 for H37S D0101 36689 Stainless Steel Locknut M8 for H37S G5027

77588

17312 Bushing 22x25x20 for H37S B6211 77612 Self-Locking Nut M3 UNI7473 for H37S D0110 65173 Ring for Eccentric for H37S G5054

36563 Carriage Bushing for H37S B6213 77535 Special Nut M10 for H37S D0116 36695 Ring Support Cap for H37S G5055

36564

36566

36567 Bushing DU 12x14x25 for H37S B6222 36638 Nut U5589 M10 Stainless Steel for H37S D0137X 77507 Locknut M22 P.1 for H37S G5106

77551 Bushing for Plate Ø16x19 for H37S B6231 77505 Stainless Steel Nut U5588 M12 for H37S D014215 19580 Handle TS8 for H37S I1907

Ring EL.Benzing 6 Stainless Steel for

H37S

Ring EL.Seeger Est.25 Ser.Heavy for

H37S

Bushing Fastener Guard Knife A310A

for H37S

Bushing for Carriage Support lg.23mm

for H37S

Bushing to Hold Carriage Springs for

H37S

A5404X 17313 Bushing DU 14x15x16 for H37S B6244 77555

A5454 77503 Bushing DU 12x14x30 INOX for H37S B6336 36646 Nut U5588 M6 Stainless Steel for H37S D0163X

Wiring Assembly 6 Poles LG.400 for

H37S

Rivet 1.9x5 for H37S C4640 36656 Motor Spacer for H37S D5640

B6104B 16926 Bearing 2RS-6000 (10x26x8) for H37S C8067 65172 Flange for Impugn. Graduated for H37S F609076

B6140 77504 Stainless Steel Nut U5587 M4 for H37S D0102X 36691 Ring for Bushing for H37S G5053

B6214 16928 Nut U5589 M6 for H37S D0133 77559 Plate Bar Supp. Ring 250/273 for H37S G5056

B6221 65158 Low Nut U5589 M8 6S for H37S D0135 36697 Logging Locknut for H37S G5064

C3236 19648 Knife Spacer for H37S D5602

Domed Nut DIN 917 M8 Stainless Steel

for H37S

Carriage Shock Absorber Spacer for

H37S

D014515

D5762

20

Page 21

Parts Breakdown

Model MS-IT-0370-H 38915

Item No. Description Position Item No. Description Position Item No. Description Position

17356 Fastener Handle for H37S I1926 16955 Shock Absorber for H37S P1059 19655 Meat Grip Stud for H37S P7420

19587 Sharpener Knob for H37S I1957A 77563 Shock Absorber for H37S P1065 60424 Touch Pad Screw for H37S P7447

36705 Adjustment Knob for H37S I1970A 17395 Shock Absorber for H37S P1081 77539 Stud Plate M8x25x35 for H37S P7474

36708 Assembly Index Knob for H37S I1990A 77509 Deector for H37S P115501 19850 Protection for H37S P7856

65177 Handle 25x70 M10 for H37S I203576 77510 Slice Deector for H37S P1371 77525 Mobile Protection for H37S P7919

17363 End Grip Handle for H37S I2040 77521 Ext. Blade Cover for H37S P1599 78282 Lock Washer for H37S P8620

36714 Blade Cover Handling for H37S I2058 77522 Blade Cover for H37S P1677 24030 Sharpener Operating Handle for H37S P8625

36717 Knob Assembly for H37S I2098 77616 Strain Relief for H37S P2004 78284 Bracket for H37S P8626

17364 Nylon Gear DP 56, 80, Z29 for H37S I2404 60421 Electrical Conduit for H37S P2011 19657 Washer 4 for H37S R6003

65194 370mm Blade ØINT.326.5 for H37S L0637 36778 Wire-Press for H37S P2014 19661 Washer 8 for H37S R6030

79268 Nut for H37S M0816 36779 Core-Hitch+Nut for H37S P2015 19665 Washer for H37S R6260

77520 Magnet Ø8x25 for H37S M0819 17416 Pin Sharpener for H37S P3207 19666 Washer for H37S R6280

14787 Grinding Stone C for H37S M6602 16959 Pin Grinding for H37S P3225 19667 Washer 12x17x2 for H37S R6281

21644 Honing-Finishing Stone for H37S M6621 17419 Pin Truing for H37S P322601 36880 Washer U6592 3 for H37S

36741 Spring 2.9x4x12 Stainless Steel for H37S M7001 64371 Grinding Stone Pin Assembly for H37S P3381 17455 Washer U6592 4 for H37S R6505

17377

17379

17380

19776 Spring 14x1.5x60 for H37S M7032 23645 Sharpener Pivot for H37S P3528 77512 Washer 8.5x18x2 for H37S R652215

19782 Spring 19.5x1.5x16.7 for H37S M7050 77564 Pin Support Meat Grip Arm H for H37S P3636 19668 Washer 10 for H37S R6530

17381 Spring 22.5x1.8x18 for H37S M7052 79272 Knife Shaft for H37S P3648 36885

19250 Spring 24.8x1.8x15 for H37S M7071 77511 Pin Deector for H37S P3653 77513

36746 Spring 7x0.8x23 Cam for H37S M7076 77565 Pivot Pusher for H37S P3654 17458 Contact Washer for H37S R6806

65201 Spring 15.6x20x2.2 Cart Parac. for H37S M7120 77523 Knife Cover Support Pin for H37S P3655 36889 Washer 10.5x16x1 for H37S R6816

36749 Carriage Bar Spring 25-28-1.5 for H37S M7121 77524 Pin for Protec.Support for H37S P3656 16969 Washer 18.2x25x0.5 for H37S R6840

78283 Screw for H37S M7132 77566 Pivot Pusher for H37S P3663 17460 Washer 34.2x46x0.5 for H37S R6846

17383 Motor (New Style) for H37S M8256 77594 Driving Pivot Assembly of T8093 for H37S P3697 19674 Washer 44.5x51.5x0.2 for H37S R6848

65205 Oiler Bar Cart for H37S O4040 36809 Tray for H37S P4422 77540 Washer 6.2x14x0.6 for H37S R6854

36759

17390 Rubber Shock ABS. 16x22x2.5 for H37S P1019 19832 Flat Bar for H37S P4651 36892 Washer 17x30x4 for H37S R6874

36760 Pin Tray Shock-Absorber for H37S P1025 77537 Ecc. Locking Plate for H37S P486081 16972 Washer 5.5x19x2.5 for H37S R6884

17392 PL.Shock Absorb.8.5x20 for H37S P1034 60469 Motor Straight Bracket for H37S P4869 36893

36761 Shock Absorber for H37S P103401 16961 Foot for H37S P5008 36897 Special Washer 5.5x22x1.5 for H37S R6932

19797 Nylon Shock 8.5x8 for H37S P1042 77538 Sliding Bearing Flat 19x490x3 for H37S P5116 78261 Rotor (A3109 P2521) Stator for H37S R8021

19798 Plastic Shock for H37S P1045 79273 Body Plate for H37S P5305 65242 Wheel Ø25x9,5 for Plate for H37S R8520

77561 Shock Absorber D12 H18 for H37S P1052 77567 Meat Tray Assembly for H37S P5343 77619 P.C.B. Protection Box for H37S S100480

36762 Rubber Plug for H37S P1053 65227 Removable Pressing Machine for H37S P6761 19680 Ball 3.17 for H37S S3005

77562 Shock Absorber for H37S P1054 77568 Pusher Assembly for H37S P7040 17465 Ball 4.76 for H37S S3015

Spring 8.5x1.0x25 Stainless Steel for

H37S

Spring 11.9x0.7x27 Stainless Steel for

H37S

Spring 13.4x1.3x30 Stainless Steel for

H37S

Rubber Shock Absorber 12x19x2 for

H37S

M7013 36793 Pin.Handle for H37S P3430 16967 Washer U65926 for H37S R6512

M7029 62428 Lock Plate Pivot H for H37S P344016 17457

M7030 65210 Pin Ass.Mola Sbavatrice A1026 for H37S P3458 36884

P1012 36812 Tray for H37S P4443 77596 Switch Washer A310 for H37S R6864

Washer U6592 6 Stainless Steel for

H37S

Washer U6592 8 Stainless Steel for

H37S

Washer U6592 10 Stainless Steel for

H37S

Stainless Steel Washer U6592 12 for

H37S

Stainless Steel Special Washer 8.5x24x2

for H37S

R6504

R6512X

R6520X

R6530X

R654015

R6897X

21

Page 22

Parts Breakdown

Model MS-IT-0370-H 38915

Item No. Description Position Item No. Description Position Item No. Description Position

41350 Circuit Board 110V/60 for H37S S3265 77543 Bracket for H37S T8545 37058 Stainless Steel Screw M4x8 for H37S V6370

77541 Index Arm for H37S S3802 62439 Blade Support Shaft for H37S T9699 37059 Stainless Steel Screw M4x14 for H37S V6371

79277 Housing for H37S S5226 79283 Shaft Pin for H37S T9742 77546

77542

36920 Pin 4x25 for H37S S7526 37013 Motor Fan MEC80 148x16 for H37S V4014 37070

36924 Pin M.E.U6875 6x30 for H37S S7546 37018 Screw STTC U6113 M6x6 for H37S V6010 77578

36926 Pin U7586 3x18 for H37S S7557 37021 Screw for H37S V6030 37072

77569 Pin U7586 6x30 for H37S S7570 77577 Screw STEI U5923 M10x40 for H37S V6047 37073

17476 Foot Support Pin D.10 M8 for H37S S7595 77529

77526 Pin Ø8x23 for H37S S7608 37023 Screw STEI U5929 M5x5 for H37S V6065 37078

77570

77571 Lock Pin Pusher Arm for H37S S7623 37024 Screw STEI U5929 M6x6 for H37S V6066X 17498 Screw TSPEI U5933 M4x10 for H37S V7043

19870 Stator 120/60 for H37S S8562 19692 Screw M6x8 for H37S V6067 37083

77597 Washer Bracket A310 for H37S S9009 19694 Screw M8x10 for H37S V6075 37085 Screw 8x25 for H37S V705616

77527 Protec. Support for H37S S9185 37029 Screw STEI U5929 M8x20 for H37S V6079 19713 Screw Sharpener for H37S V7710

77572 Bracket for Plate Rod for H37S S9188 77544 Vite STEI U5923 M10x35 for H37S V6088 37091 Screw H for H37S V7730

19181 Bracket Support for H37S S9192 19697 Screw M5x16 for H37S V6211 17503 Screw M5x13 for H37S V7908

60422 Touch Pad Back Casing for H37S S9236 19699 Screw M4x25 for H37S V6231 19715 Screw Sharpener for H37S V7910

77573 Hand Grip Arm Support for H37S S9425 77515 Screw TC U6107 M4x25 INOX for H37S V623115 17504 Screw for H37S V7915

77574 Hand Grip Support for H37S S9434 19700 Screw M6x16 for H37S V6240 19717 Screw M6x50 for H37S V7917

77575 Plate Support for H37S S9457 77598

77576 Sharpener Support for H37S S9468 19702 Screw M6x25 for H37S V6246 37095 Screw for Rod 6x13 for H37S V7993A

77528 Ext.Knife Protect.Support for H37S S9489 37042 Screw TCEI U5931 M8x25 for H37S V6254 19724 Screw H for H37S V8001

19877 Rubber Cap for H37S T1001 19704 Screw M10x16 for H37S V6262 16987 Special Screw M6x15 for H37S V8020

36981 Rubber Cap for H37S T1004 77516 Screw TCEI U5931 M12x35 for H37S V626315 37102 Screw M6x20 for H37S V8035

19879 Label for H37S T1603 77530 Screw TCEI U5931 M10x30 for H37S V6264 19920 Screw M8x30 for H37S V8036

36985 Label Plate for H37S T1617A 19706 Screw for H37S V6278 77580 Stainless Steel Screw M8x16 for H37S V8051

19883 Label Oil for H37S T1690 37050 Screw TC AUT.D7971 4.2x9 for H37S

77628 Switch Overlay for H37S T1760 77531

62438 Blade Cover Fastener for H37S T5071 77629 Screw TBTC AUT.U6954 4,2x13 for H37S V6296 77582 Special Screw Ø8x15 for H37S V8104

42974 Tie Rod for H37S T5191 77545

79280 Knife Shaft Assembly for H37S T8093 77517

Cylindrical Pin U1707 8x35 Stainless

Steel for H37S

Lock Pin for Carriage Plate Rotation

for H37S

S7432 77514 Slice Thickness Plate for H37S V313305 37067 Screw TE U5739 M5x20 for H37S V6423

Stainless Steel Screw STEI U5923

M8x55 for H37S

S7618 19691 Grub Screw M6x6 for H37S V6066 17497

Stainless Steel Screw TCEI U5931

M6x20 for H37S

Screw TCEI U5931 M6x14 INOX for

H37S

Stainless Steel Screw TCEI U5931

M8x45 for H37S

Screw TCEI U5931 M12x45 Inox for

H37S

V605115 37077 Screw TSP U6109 M4x6 Inox for H37S V700615

V6245X 19720 Screw M6 for H37S V7934

V6285 37113 Screw for Carr. Index M8x25 for H37S V8099

V628915 77581 Special Screw M10x18 for H37S V8103

V633115 77532 Special Screw M8x40 for H37S V8121

V634915

Screw TE U5737 M6x15 Stainless Steel

for H37S

Screw TE U5739 M6x20 Stainless Steel

for H37S

Stainless Steel Screw TE U5739 M8x14

for H37S

Screw TE U5739 M8x20 Stainless Steel

for H37S

Screw TE U5739 M8x25 Stainless Steel

for H37S

Stainless Steel Screw TSP U6109

M5x12 for H37S

Screw TSP U6109 M5x15 Stainless

Steel for H37S

Locking Screw-Support for H37S V705016

V6421X

V6449X

V645715

V6460X

V6461X

V7013X

V7014X

22

Page 23

Model MS-IT-0370-H 38915

Electrical Schematics

Position Description Position Description Position Description

X1 Spina C1 Capacitor 220uF K1 Power Relay

T1 Transformer C2 Capacitor 100uF K2 Power Relay

F1 Fuse 500mA C3 Capacitor 20uF K3 Command Relay

D1 Straightener 1A R1 Resistance 1k K4 Command Relay

D2 Protective Diode R2 Resistance 1k S1 Stop Button

L1 LED Orange Line R3 Resistance 10k S2 Start Button

L2 LED Green March R4 Resistance 47 Hom S3 Blade Guard Disc Protection

23

Page 24

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

24

Page 25

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

25

Page 26

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

26

Page 27

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

27

Page 28

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...