Page 1

Electrical Meat Mixers

Models MM-IT-0080, 0120

Items 37450, 37451

Instruction Manual

Revised - 06/05/2017

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model MM-IT-0080 / Model MM-IT-0120

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

-------------------------------------------------------------------------------------------- 7

----------------------------------------------------------------------------------------- 8 - 9

--------------------------------------------------------------------------------- 10 - 12

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 6

Page

-------------------------------------------------------------------------- 6

Troubleshooting

Parts Breakdown

Electrical Schematics

Warranty Registration

----------------------------------------------------------------------------------- 12

---------------------------------------------------------------------------- 13 - 16

---------------------------------------------------------------------- 17 - 18

---------------------------------------------------------------------------- 19

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information5Safety and Warranty

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

PROTECTIONS AND SAFETY FEATURES

ATTENTION

Before using the appliance make sure the safety protections are in their correct position and intact. Check they

function correctly before starting work (at the beginning of a new work shift). If there are problems contact the

maintenance team.

4

Page 5

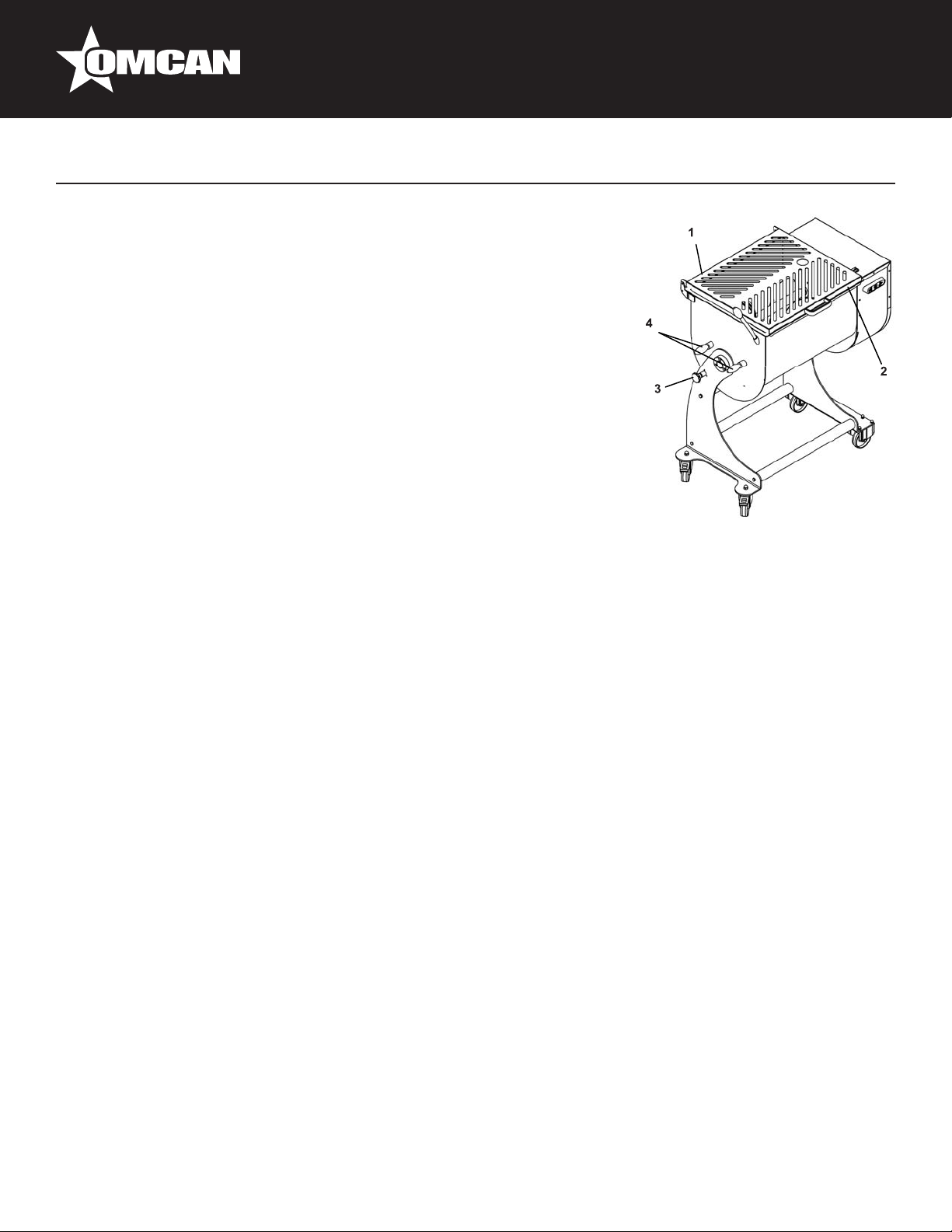

1. Rotor protection grille.

This safety feature impedes incidental contact with the rotor.

2. Micro-switch.

3. Knob to lock tank.

4. Ball grip for locking the rotor in position.

ATTENTION!

Do Not for any reason tamper with the safety features.

DANGER AND WARNING NOTICES

ATTENTION

When the appliance is connected to the electricity supply do not touch any

of the electronics. There is the risk of being electrocuted. Always respect the

information given on the warning notices. Non-observance can cause injuries

or even death. Make sure the warning notices are always in their correct

position and are legible. If for some reason they are missing or are illegible x them to the appliance or replace

them.

NON-PERMITTED USES

The mixer must only be used for the uses given by the manufacturer, and in particular:

• Do Not use the appliance for mixing food other than for meat.

• Do Not use the appliance if it has not been correctly installed with all the protections correctly mounted

avoiding any hazardous risk of injury.

• Do Not touch any of the electrical parts without having rst disconnected the appliance from the electricity

supply: there is risk of electrocution.

• Do Not mix quantities that cannot be contained in the mixing drum.

• Do Not wear clothing that does not conform with the accident prevention regulations. Ask your employer

regarding safety regulations and accident prevention clothing.

• Do Not turn on the appliance if faulty or out of service. Before using the appliance make sure any

hazardous working conditions have been eliminated. If there is a fault or problem with the appliance

immediately turn it off and inform the maintenance team.

• Do Not permit unauthorized staff to use the appliance. In case of an electrical accident the rst thing to do

is to pull the injured worker away from the appliance (normally in this situation the worker is unconscious).

However, be very careful as this is very dangerous. The injured worker in this situation is an electricity

conductor and touching him / her means being electrocuted. It is important to disconnect the electricity

supply by disconnecting the fuse box and if this is not possible use an insulated object or material (wooden

or PVC stick, fabric, leather, etc...) to pull the injured worker away. Immediately call the nearest casualty

department so the injured worker is admitted to hospital for treatment.

• Do Not use the appliance in environments where there is gas in the atmosphere creating a high risk of

combustion (explosion).

• Do Not repair the appliance without prior authorization.

• Always Respect the procedures for maintenance and technical assistance.

Page 6

Safety and Warranty

1 YEAR PARTS AND LABOUR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

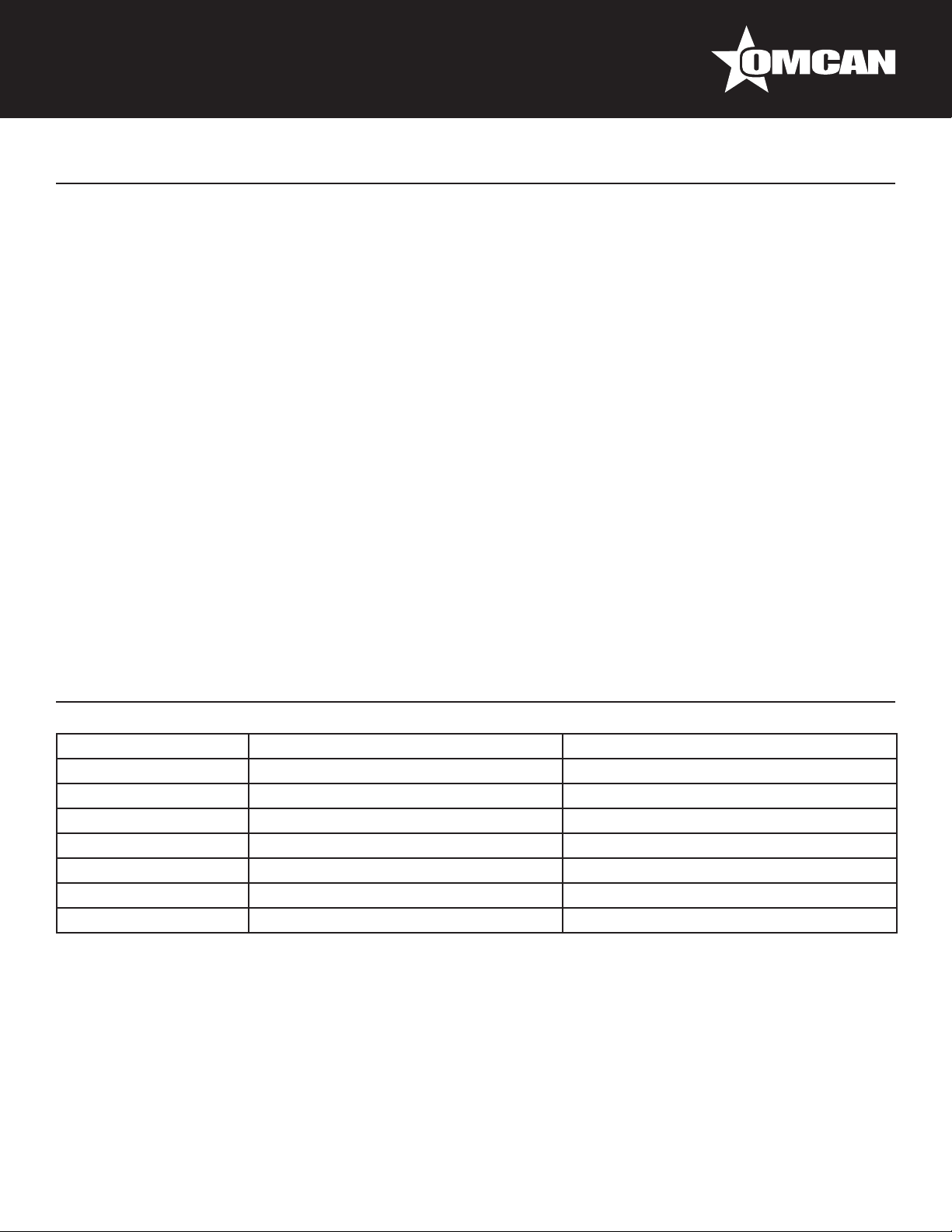

Model MM-IT-0080 MM-IT-0120

Power 559 W / 0.5 HP (x2) 735 W / 1 HP (x2)

Electrical 220 V / 60 / 1 220 V / 60 / 3

Tank Dimensions 24” x 20” / 620 x 500mm 26” x 21.7” / 660 x 550mm

Capacity 110 L / 80 kgs. 163 L / 120 kgs.

Dimensions 25” x 39” x 41” / 635 x 990 x 1400mm 27.6” x 43” x 40.5” / 700 x 1090 x 1030mm

Weight 198 lbs. / 90 kgs. 304.2 lbs. / 138 kgs.

Item Number 37450 37451

6

Page 7

Installation

ATTENTION!

The work surface or area where the appliance is to be installed must be horizontal and solid guaranteeing

stability and safety. When installing the appliance bear in mind that amp space must be left around the

appliance. This space allows you to work freely with the appliance and allows easy access when servicing or

repairing it. Provide suitable lighting around the appliance for the worker using the meat mixer.

INSTALLING

To move the package use a fork-lift truck or similar means. The appliance is in a carton box and packed on a

pallet.

• Remove the two plastic straps that hold the carton box to the pallet.

• Remove the carton box.

• Remove the cellophane wrapping and any other packaging materials.

DISPOSING OF PACKAGING

Packaging materials such as carton, nylon and wood are all products considered normal urban waste. These

materials can be disposed of as per normal procedures. If the appliance is destined to countries where there

are specic waste laws, dispose of packaging conforming with the local laws in force.

HANDLING APPLIANCE

As the following models 50 - 120 M/B 50 - 120 - 80 - 180 BA have wheels they can be manually moved by

pulling

CONNECTING TO ELECTRICITY SUPPLY

ATTENTION!

Check the electricity supply corresponds to the value given on the appliance ID plate. Electrical works can

only be carried out by specialised and authorized staff with prior authorisation by the person in charge of the

appliance. Connect the appliance to a circuit provided with an efcient earth socket. If necessary use suitable

extension leads guaranteeing safety. The section (thickness) of the extension lead must be greater than the

appliance power supply cable. This avoids any hazardous overheating. Avoid pulling or twisting the power

cable as this can damage the internal wires.

7

Page 8

Operation

LIST OF CONTROLS AND INDICATORS

CONTROL PANEL

1. Stop button.

- Black.

- Press to stop rotor motor.

2. Light indicator for tension.

- Green.

- Indicates power supply. On the stop button marked with “1” it is green and remains lit when the appliance

has power.

3. Start button.

- Grey.

- Press for starting the rotor.

4. Push button for inverting rotation.

- Grey.

- Press to invert rotation in the opposite direction to push button “3”.

5. Light indicators rotor in movement.

- Red / yellow-colored.

- Indicates that the rotor is in movement. This indicator is located near start push button “3”, and near push

button for inverting rotation “4”. It is red and lights up when the rotor command is given.

STAINLESS STEEL CONTROLS

1. Drive push-button (continuous).

- In stainless steel.

- Press to start the blade.

2. Stop push-button.

- Press to stop the propeller transmission motor.

3. Reverse drive push-button.

- In stainless steel.

- Press to start the blade in opposite direction to pus-button “1”.

4. Network presence indicator light.

8

Page 9

Operation

- Signals that the machine is connected to the electrical network.

5. Drive indicator light.

- Signals that the tool of the machine is in movement.

- Located close to the start push-button “3” and close to the reverse drive push-button “3”.

- Visible only when the control is operating.

TURNING THE APPLIANCE ON AND OFF

CHECKING CONNECTION TO ELECTRICITY SUPPLY

Switch the on/off switch on the appliance to position “I”. The green light “2”

should come on, indicating power on. Press push button “3” for starting, the

red indicator light “5” should come on, and then immediately press push button

“1” for stopping. This is to check that the appliance works correctly. Press push

button “4” for starting, the red indicator light “6” should come on, and then

immediately press push button “1” for stopping. This is to check that the rotor

rotates in an opposite direction to push button “3”.

CHECKING PROTECTIONS AND SAFETY FEATURES AND THEIR EFFICIENCY

1. Rotor Protection grille.

Visually check that the protection grille is intact.

2. Micro-switch.

With the appliance running, check that it automatically stops when the protection grille is raised. If this is

not the case contact you local authorised dealer or the manufacturer.

ATTENTION!

If the previously mentioned safety protections and casing are not intact, are damaged, missing or work

incorrectly, turn the appliance off and contact the aftersales assistance to repair the appliance.

TURNING ON THE APPLIANCE

Switch the power on/off switch from position “0” to “1”. Indicator “2” should light up indicating power on. Press

push button “3” for starting the rotor.

TURNING OFF THE APPLIANCE

To stop the appliance press push button “1” (stops the electric motor), the red indicator light “5” will go out.

Indicator light “2” will remain on indicating power on. Switch the power on/off switch to position “0” turning off

the power supply.

INVERSION

To invert rotor rotation press push button “4”.

Note: When a work shift is over always switch the on/off power switch to position “0”.

9

Page 10

Maintenance

EMPTYING AND CLEANING

EMPTYING THE MIXING BOWL

Turn off the mixer, the on/off switch is in position “0” unplug from main power

supply. The mixing bowl is designed to rotate to facilitate emptying.

• With the bowl in a horizontal position grip the handle on the bowl titling bar.

• Pull the tank locking knob.

• Once having released the mixing bowl rotate by pulling the tilting bar.

• Open the protection grille and empty the bowl.

CLEANING THE MIXING BOWL

With the machine off and switch in position “0” and with the plug removed from

the socket proceed with cleaning the bowl. Thanks to the possibility of rotating

the bowl cleaning operations are facilitated.

• With the bowl in a horizontal position grip the handle on the bowl titling bar

(1).

• Unhook and remove the pins which lock the mixing blades (2) in position.

• Unscrew the bowl locking knob (3) anti-clockwise.

• Once having released the mixing bowl rotate by pulling the tilting bar (1).

• Open the grille (4) and proceed with removing the mixing blades.

• Make sure the mixing blades are positioned to allow for enough space to

remove them.

• Grip the mixing blades one at a time (5) and pull outwards to remove.

• The surface is now smooth and easy to clean, clean the mixer thoroughly

and if necessary disinfect.

• With a sponge soaked with water and a neutral (pH 7) and non-toxic

degreaser (food grade) clean and remove any food product left on the mixer

and on the mixing blades. Do not use petrol, solvents or other ammable

liquids as detergents; only used authorised non-toxic and non-ammable

solvents. Take all the necessary precautions adopting also appropriate

protections required for the cleaning product being used when cleaning

and disinfecting the mixer. Always follow the instructions provided for the

cleaning product being used.

• To mount the mixing blades after cleaning, simply reverse the above steps.

CLEANING THE APPLIANCE

At the end of the work shift the appliance must be carefully cleaned and

disinfected.

• Stop the appliance and switch the on/off switch to “0” and remove the power

plug.

• With a sponge soaked with water and suitable neutral degreasers (non-toxic) remove and clean any traces

of food.

Do not use petrol, solvents or other inammable liquids such as detergents. Use authorised non-toxic and noninammable solvents.

Take suitable precautions when cleaning considering the products being used. Always follow the instructions

10

Page 11

Maintenance

for use given.

ATTENTION!

The mixer must always be off and the power plug removed from the power socket when servicing and

cleaning. The maintenance area must always be clean, dry and well illuminated. Do not allow unauthorized

staff to service the appliance. Do not put parts of your body, hands or arms into the mixer or openings not

protected where there is the risk of being injured. Always use protective clothing (suitable gloves, glasses etc.)

Do not use petrol, solvents or other inammable liquids such as detergents. Use authorised non-toxic and

non-inammable solvents. Do not compressed air to clean the appliance. If it is considered necessary to use

compressed air, use eye protection (glasses) with side protections and limit pressure to a max of 2 atm. (1,9

bar). Do not use a naked ame as lighting when servicing and repairing the appliance.

MAINTENANCE CHECKS

CHECKS AND TESTS TO BE CARRIED OUT WHEN INSTALLING

To make sure the appliance has not been damaged when delivered or when being installed, carry out the

following tests;

BEFORE SETTING TO WORK:

• Check that the power supply tension corresponds to the value given on the ID plate.

• Check that there are all the warning and ID plates and that they are not damaged.

• Check that the power supply cable is not damaged and is intact.

• Check that the safety features such as the magnetic sensors are intact and not damaged.

FUNCTIONAL CHECKS WITH THE APPLIANCE RUNNING:

• Check the efciency of the protections and safety features. There is the possibility that during transport

these have been damaged or are out of adjustment.

• Carry out several functional tests using pieces of food that are the same size that will be used in normal

working conditions.

PERIODICAL CONTROLS

To maintain reliability and performance in time, as well as proceeding as indicated, it is necessary to carry out

regular tests and checks as follows:

BEFORE EACH WORK SHIFT:

• Every day check safety features and protections work correctly.

• Check the power cable is intact.

THE END OF THE WORK SHIFT:

• Carefully clean the appliance removing any traces of food.

• Remove, clean and mount rotor and blades.

11

Page 12

Maintenance

LUBRICATION

Periodically grease gears (2).

• Unplug the machine from its power source.

• Take off the protective casing (1).

• Grease the gears using a brush.

• Reassemble the casing and fasten the screws.

The oil in the transmission reduction gears is long-life and does not need to be ever replaced.

Troubleshooting

Problem Cause Remedy

The appliance does not start. The on/off switch is in position “0”. Switch the switch to position “1”.

The grill is raised. Lower the grill.

The microswitch mounted on the

mixing drum does not work.

Either the electric motor or the

command circuit board is faulty.

The controls do not work or the

blades do not change direction.

Contact Omcan.

Contact Omcan.

Contact Omcan.

REFERENCE

Item Number Model Number Description

37450 MM-IT-0080

37451 MM-IT-0120

Meat Mixer 176 lbs. / 80 kgs.

2 x 0.5 HP / 2 x 559 W 220V/60/1

Meat Mixer 265 lbs. / 120 kgs.

2 x 1 HP / 2 x 735 W 220V/60/3 CE

12

Manufacturer Model

Number

IP80BA

IP120BA

Page 13

Model MM-IT-0080 37450

Parts Breakdown

13

Page 14

Parts Breakdown

Model MM-IT-0080 37450

Item No. Description Position Item No. Description Position Item No. Description Position

62601 Cavo + Spina CEE 2P + T for IP80BA 01 62623

62602 Power Lead, Motor TF/1,5 for IP80BA 02 78634 Knob P02 M10 for IP80BA 30 62645 Sher Din 125 D 10 for IP80BA 57

62603 Strain Relief + Nut for IP80BA 04 62624

62604 Dado Ott.Nich.PG 11 for IP80BA 05 62625

62605 Essacavo Plastica PG7 for IP80BA 06 62626 Door Support for Microswitch for IP80BA 33 62648 Ind Nut Din 1587 M5 for IP80BA 60

62606 Essacavo Plastica PG 11 for IP80BA 07 61569 Canotto Ferma Culla IP for IP80BA 34 62649 P Nut Din 1587 M6 for IP80BA 61

62607 Essacavo + Dado Plastica PG for IP80BA 08 61571 Spring for IP80BA 35 62650 P Nut Din 1587 M8 for IP80BA 62

61549 X GW 44207 for IP80BA 09 61570 Pin for IP80BA 36 62651 Dado Cieco Din 1587 M12 for IP80BA 63

62608

37258 Microswitch_SO Inox for IP80BA 11 62627 Female Blade for IP80BA 38 62653 Nguette Din 6885/A 8x7x28 for IP80BA 65

37260 Magnet M634 for IP80BA 12 62628 Male Blade for IP80BA 39 62654

62609

62610

62611 Stainless Steel Off Button for IP80BA 15 62630

62612 Circuit Board R3+Autom EQ for IP80BA 16 62631

62613 Cuscinetto 6205 ZZ for IP80BA 17 62632

62614

62615

62616 Gasket 40-62-7 for Mincer for IP80BA 20 62635

62617 Rondella Zinc. M8x30 H4 for IP80BA 21 62636

62618

62619

62620

62621

62622

79656 Knob for Fixing Container for IP80BA 27 62642

61556

Morsetto A Pettine X Equipotenz. BZ

for IP80BA

Frame for 3 Buttons Stainless Steel

Panel for IP80BA

Stainless Steel On Button with Lamp

Omega 24V for IP80BA

Cuscinetto Reg. SP 7205 ME 80 Evo

for IP80BA

Cap 40/7/C Pulley 1C SO1650 for

IP80BA

Dist. Rid-Corona Dent. ME 80 Evo for

IP80BA

Dist. Rid-Corona Dent. SP=20 ME Evo

for IP80BA

Dist. Plast. Cop. 10x6x4 ME BA Evo

for IP80BA

Cola Flang. JFM-1622-12 TCM-ME for

IP80BA

Handle 236-148 M6_Collection Tray for

IP80BA

Stainless Steel Non-Swivel.Caster D.100

for IP80BA

10 61564

13 61563 Blade Rod for IP80BA 40 62655 Vite Tbei Iso 7380 M6x25 for IP80BA 67

14 62629 Culla Inox ME 80 Evo Bialb for IP80BA 41 62656

18 62633

19 62634 Base SX ME 80 Evo Bialb for IP80BA 46 62661

22 62637 Corona Dentata ME 80 Evo for IP80BA 49 62664 TE Din 933 M10x20 T.F for IP80BA 76

23 62638

24 62639

25 62640

26 62641

28 62643 Flat Washer Din 125 D 6 for IP80BA 55 62670 B Overload Protection EQ for IP80BA 82

Ruota Mobile Con Fren D 100 C/Perno

for IP80BA

Mot. Pam 71 B 14 4 Poli Mono ME Evo

for IP80BA

Washer for Bone Saw SO 1650 Inox for

IP80BA

Lever Rod for Container Overturning

for IP80BA

Coperchio Vasca ME 80 Evo Bialb for

IP80BA

Carter Motore ME 80 Evo Bialb for

IP80BA

Fascia Carter Mot. ME 80 Evo Bialb for

IP80BA

Base DX Rid. ME 80 Evo Bialb for

IP80BA

Tubo Unione Basi ME 80 Evo Bialb for

IP80BA

Flangia Supp. Rid ME 80 Evo Bialb for

IP80BA

Staffa Blocco Riduttori ME 80 Evo for

IP80BA

Ridut. CM50 71 B14 I50 80 Evo Bialb

for IP80BA

Supp. Cusc. Rib. Lato SX Evo Bialb for

IP80BA

Perno Trasc.Femm L=220 ME 120 Evo

for IP80BA

Perno Trasc.Masc L=220 ME 120 Evo

for IP80BA

29 62644 AT Washer Din 125 D 8 for IP80BA 56

31 62646 Ina Elastica Din 1481 3x18 for IP80BA 58

32 62647 Ina Elastica Din 1481 5x20 for IP80BA 59

37 62652 T ES. Din 439 M10 Basso for IP80BA 64

Linguette Din 6885/AB 8x7x16 for

IP80BA

TE Autof.TC + Din 7981 D 3, 5x16 for

IP80BA

42 62657 Rew Tspei Din 7991 M8x20 for IP80BA 69

43 62658 TE Tspei Din 7991 M8x30 for IP80BA 70

44 62659

45 62660 Sher Large Din 9021 D 6x18 for IP80BA 72

47 62662 TE Din 933 M8x16 T.F. for IP80BA 74

48 62663 X.Screw Din 933 M8x20 for IP80BA 75

50 62665 TE Din 933 M12x30 T.F for IP80BA 77

51 62666 X.Nut Din 934 M8 for IP80BA 78

52 62667

53 62668 Cknut ES Din 982 M6 Alto for IP80BA 80

54 62669 TE Poeliers M4x10 for IP80BA 81

TE Tsp Torx Din 7991 M6x16 TX30 for

IP80BA

X.Socket Head Cap Screw M6x20 for

IP80BA

Athead CSK Screw Din 963 M5x25 for

IP80BA

66

68

71

73

79

14

Page 15

Model MM-IT-0120 37451

Parts Breakdown

15

Page 16

Parts Breakdown17Electrical Schematics

Model MM-IT-0120 37451

Item No. Description Position Item No. Description Position Item No. Description Position

61577

61578

61579

61556

61580

61581

18961

61564

78634

61569 Canotto Ferma Culla IP for IP120BA 11 61590

79656

61571 Spring for IP120BA 14 61592

61570 Pin for IP120BA 15 61593

37260 Magnet M634 for IP120BA 16 61594

61582

61583 Nut DIN 1587 M 6 for IP120BA 18 61596 Gasket 40-62-7 for Mincer for IP120BA 39 61610 Zinc Washer M8x30 H4 for IP120BA 100

Cradle INOX ME 120 EVO BIALB for

IP120BA

Tank Cover ME 120 EVO BIALB for

IP120BA

Mobile Wheel with Brake D 100 C/Perno

for IP120BA

Stainless Steel Non-Swivel Caster D.100

for IP120BA

Paddle Female IX ME 120 KG Bialbero

for IP120BA

Paddle Male IX ME 120 KG Bialbero for

IP120BA

Handle 236-148 M6 Collection Tray for

IP120BA

Lever Rod for Container Overturning for

IP120BA

Knob P02 M10 IP 80BA/G3S/SA for

IP120BA

Knob for Fixing Container IP 50-100 for

IP120BA

Screw TSP TORX DIN 7991 M 6x12

TX30 for IP120BA

1 61584

2 61585

3 61586 Bearing 6205 ZZ for IP120BA 21 61599

4 61549 Box GW 44207 for IP120BA 22 61600

5 41224

6 61587 Door Support for Microswitch for IP120BA 25 61561 Switch for PCB Taglioretti for IP120BA 48

8 37258

9 61588

10 61589

12 61591

17 61595

Carter Band MOT. ME 120 EVO BIALB

for IP120BA

Shaft Support SX EVO BIALB for

IP120BA

Circuit Board R3+AUTOM EQ_IP BA XP

for IP120BA

Microswitch SO INOX/IP BA/TC32F/GF

for IP120BA

Motor Cover ME 120 EVO BIALB for

IP120BA

Cap 40/7/C Pulley 1C SO1650 for

IP120BA

Washer for Bone Saw SO 1650 INOX

for IP120BA

Paddle Rod IX ME 120 KG Bialbero for

IP120BA

Flange Support ME 80 EVO BIALB for

IP120BA

RIDUT. CM63 80 B14 I50 120 EVO BA

for IP120BA

MOT. PAM 80 B 14 4 POLI TRIF ME EVO

for IP120BA

PERNO TRASC.FEMM L=220 ME 120

EVO for IP120BA

19 61597

20 61598

23 61601

26 37179

27 61602 Cable and Plug CEE 3P + T. for IP120BA 50

28 61604 Strain Relief + Nut for IP120BA 51

29 61603 Fuse OTT.NICH.PG 11 for IP120BA 51 A

31 61605 Ring Gear ME 80 EVO for IP120BA 53

33 61606

35 61607 Bushing ME 80 EVO for IP120BA 57

36 61608 Terminal Comb BZ for IP120BA 58

37 61609

Bearing Reg. SP 7205 ME 80 EVO for

IP120BA

PERNO TRASC.MASC L=220 ME 120

EVO for IP120BA

Base SX ME 120 EVO BIALB for

IP120BA

Base DX RID. ME 120 EVO BIALB for

IP120BA

Tube Union Bases ME 120 EVO BIALB

for IP120BA

Gaskey for Round Control Panel for

IP120BA

Bracket Lock Gear ME 120 EVO for

IP120BA

Door Screw 10x6x4 ME BA EVO for

IP120B

40

42

43

44

45

49

55

59

16

Page 17

Model MM-IT-0080 37450

Page 18

Electrical Schematics

Model MM-IT-0120 37451

18

Page 19

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

19

Page 20

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...