Meat Grinders

Models MG-IT-0012-C, 0022-C, 0032-C

Items 11051, 11053, *39714

Instruction Manual

Revised - 04/16/2019

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

BARE WIRE

Table of Contents

Model MG-IT-0012-C / Model MG-IT-0022-C / Model MG-IT-0032-C

Section

General Information

Safety and Warranty

Technical Specications

Installation and Operation

Maintenance

Troubleshooting

------------------------------------------------------------------------------------- 8 - 9

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 5

------------------------------------------------------------------------------- 9 - 10

Page

-------------------------------------------------------------------------- 6

-------------------------------------------------------------------- 6 - 8

Parts Breakdown

Electrical Schematics

Warranty Registration

---------------------------------------------------------------------------- 11 - 16

---------------------------------------------------------------------- 17 - 18

---------------------------------------------------------------------------- 19

2

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

WARNINGS ON THE RESIDUAL RISKS

RESIDUAL RISK DUE TO THE FIXED PROTECTIONS REMOVAL OR INTERRUPTION ON BROKEN/

WORN PARTS.

The operator must not try to open or remove a xed protection or tamper with a safety device.

4

Safety and Warranty

During operation, maintenance and cleaning, keep hands or other body parts away from the machines

dangerous areas, a residual risk remains due to:

1. Knocks with the machines manufacturing parts.

2. Grazing and/or abrasion with the machines rough parts.

3. Cuts with the sharp parts.

PROTECTION DEVICES ON THE MACHINE

The machine protections and safety devices must not be removed, never operate without attaching the hopper.

The machines transmission parts are completely isolated by means of xed protections which does not allow

access. The moving elements are not isolated from xed protections, moving protections or other safety

devices. The grinding group parts are placed away from access points so they are not reachable.

1 YEAR PARTS AND LABOUR BENCH WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule a drop off to either

an Omcan authorized service depot in the area, or to an Omcan Service warehouse to repair the

equipment.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

5

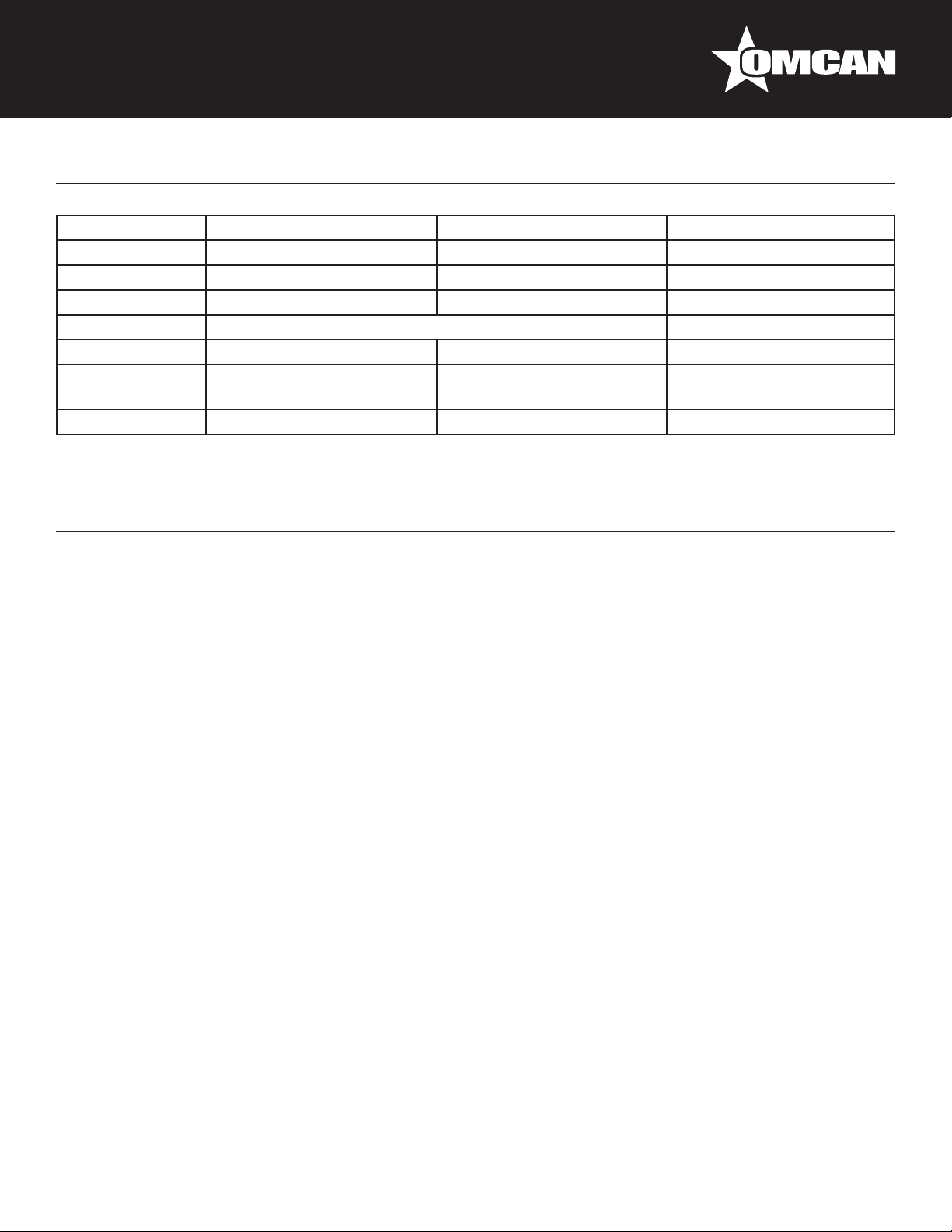

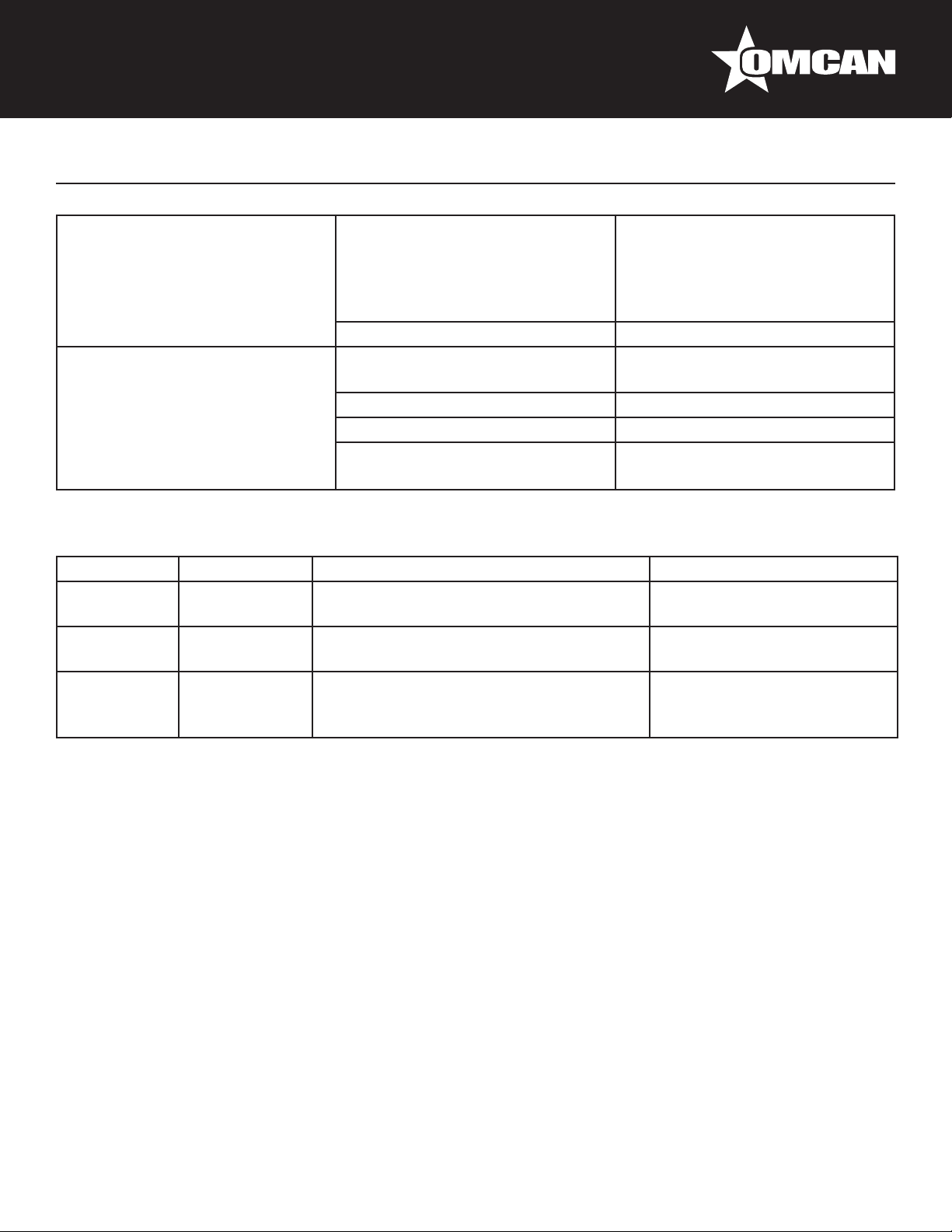

Technical Specications

Model MG-IT-0012-C MG-IT-0022-C MG-IT-0032-C

Power 745.7 W / 1 HP 1118.5 W / 1.5 HP 2237 W / 3 HP

RPM 140 90 140

Throat Opening 2” / 51mm 2.25” / 57mm 3.9” / 98mm

Electrical 110V/60/1 220V/60/1

Weight 42 lbs. / 19.1 kgs. 50 lbs. / 22.7 kgs. 114.6 lbs. / 52 kgs.

Dimension

Item Number 11051 11053 39714

16.25” x 8” x 17.5”

413 x 203 x 445mm

17” x 9” x 20”

432 x 229 x 508mm

18.7” x 11.8” x 22”

475 x 300 x 560mm

Installation and Operation

TRANSPORTATION, HANDLING AND STORAGE

All transportation and handling operations must be performed from trained personnel and must have read and

understood the safety precautions mentioned in this manual.

1. Perform the machine handling and transportation only when unplugged.

2. Verify that the lifting means are able to support the loading weight and overall dimensions in safe

conditions.

3. Avoid dropping or shaking the unit during transportation.

PREPARATION PRELIMINARY OPERATIONS

STABILITY

The machines stability is designed so that it can be used without the risk of falling or unwanted movement.

ELECTRICAL SUPPLY

The electrical supply connection must be in conformance with the country legislation in which it is being used.

1. The electrical supply must match the required specications indicated on the rating plate. If excessive

voltages are applied, some components will be damaged beyond repair.

2. The device must be grounded in conformance to the local standards.

3. The electrical supply cable outside the machine cover must be adequately protected.

GRINDING GROUP ASSEMBLY / DISASSEMBLY

The assembly / disassembly operations of any machine part are performed with the machine in the OFF

position, and the plug disconnected from the socket.

6

Installation and Operation

To assemble the grinder, do the following steps in this order:

1. Insert into the shaft (1) in order: the worm (2), the cutting knife oriented

as shown in the gure (3), and the plate (4).

2. Screw down and tighten the screw (5).

To disassemble, do the above in reverse order.

FUNCTIONING DESCRIPTION

STARTING THE MACHINE

To start the machine, the switch has to be placed on the “I” position.

STOPPING THE MACHINE

To stop the machine, the switch has to be placed on the “O” position.

FUNCTIONING SAFETY

If the machine is under stress, operated for a long period of time or overloaded, stop immediately for the

thermal protection functioning. In this case wait for the unit to cool completely before using again.

OPERATION

The machine operator can begin operation of the machine when:

1. The machine is installed properly.

2. The machine is connected to the electrical supply.

3. The hopper is inserted in the correct position.

4. The grinding group assembly is installed correctly.

5. The worm rotates in the correct direction.

6. Tests the switch.

7. Checks that all safety conditions are being met.

8. Checks that the plug is in the correct socket.

9. Place a collecting tray below the shaft to collect the nal product.

10. Start the machine by placing the switch to the “I” position.

11. Manually introduce the chopped meat into the machine neck and use the supplied stomper to push the

meat into the shaft.

12. Once the operation is completed, or when the product no longer comes out of the plate, place the switch to

the “O” position to stop the machine.

It is recommended to only operate the machine when there is product in the unit.

AFTER EACH USE

Once the machine has been operated and is no longer needed for use, please do the following:

1. Before turning off the unit, wait until the food product has nished going through the plate.

2. Turn off the machine by placing the switch to the “O” position.

3. Unplug the unit from the electrical socket.

4. Perform the cleaning and maintenance steps detailed in the “Maintenance” section.

7

Installation and Operation

UNBLOCK IN CASE OF OBSTRUCTION

During operation, or during the worm rotation, due to the food products being introduced with incompatible

parts (ie: bones), the machine could become blocked and cause a malfunction.

To be able to resume normal operation, the grinding group must be disassembled, and the blockage must be

removed.

Maintenance

PROTECTIVE SAFETY DEVICES

For any procedures described in this section, it is necessary to remove some of the xed protections from

their positions. The removal can only be performed by an authorized Omcan technician. At the end of the

maintenance procedures, these protections must be replaced and fastened in their original positions.

The machine must be switched off and unplugged prior to any maintenance and cleaning.

EXTRAORDINARY MAINTENANCE

In the event of any extraordinary maintenance, it can only be completed by an authorized Omcan service

technician.

CLEANING

All cleaning procedures must be started only when the machine is no longer in operation and is unplugged

from the electrical socket.

The machine, the electrical equipment and electrical components must never be submerged, sprayed, or

washed with water. Use a dry cloth to wipe these components.

8

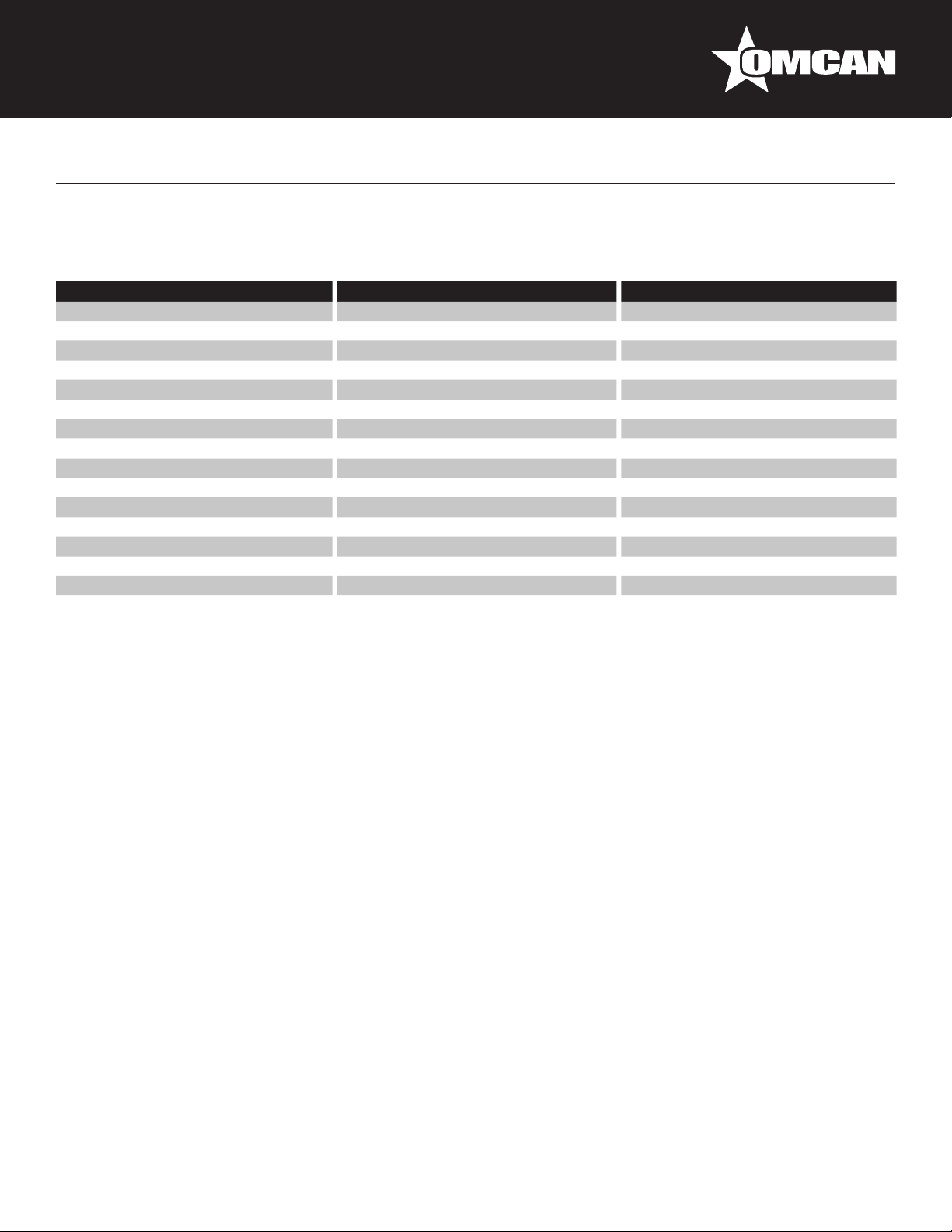

Maintenance

Follow the steps as listed:

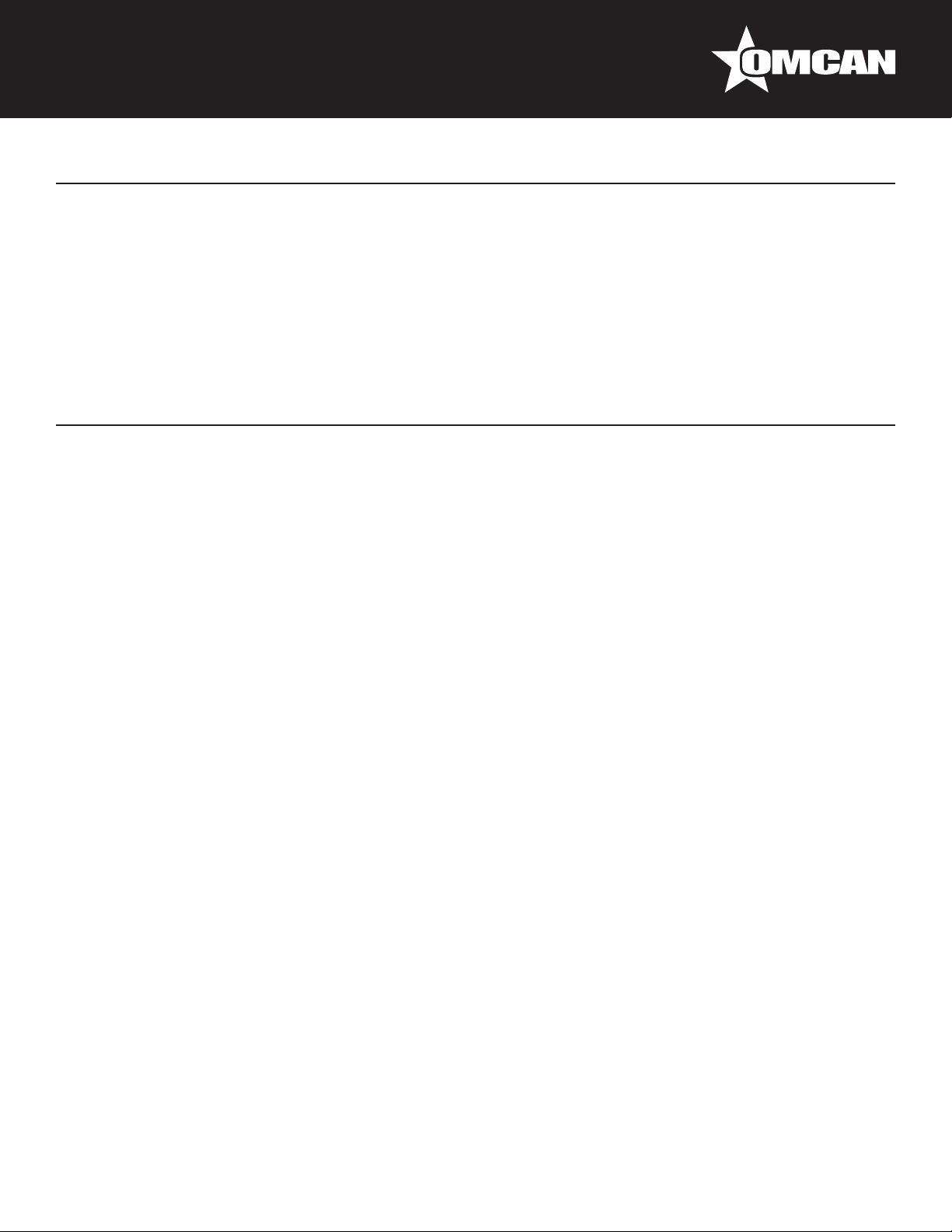

FREQUENCY PERSONNEL CATEGORY SOLUTIONS

At the end of

every use and

before daily use.

Operator DISINFECTION Use PH neutral detergents.

Use demineralized water if temperatures exceed

60°C/140°F.

If any other products are used, they must be

adequate to the materials being disinfected.

PERIODS

OF LONG

INACTIVITY

PRODUCTS NOT

TO USE

If the machine has been inactive for a long period

of time, vigorously wipe the machine with a cloth

soaked in Vaseline to create a protective barrier.

Compressed or pressurized air jets.

Vapor equipment.

Detergent that contains any of the following

compounds:

- Bleach.

- Hydrochloric acid.

- Products that are used to clear drains.

- Caustic soda products for cleaning marble.

- Etc.

Steel wool, brushes or abrasive discs produced with

other metals or alloys, or tools that have previously

cleaned other metals or alloys.

Detergents in abrasive dust.

Fuel, solvents or inammable and/or corrosive

uids.

Substances used to clean silver.

The following indicated problems that may occur:

TYPE POTENTIAL CAUSES SOLUTIONS

The electrical supply is not

adequate.

General blackout. Contact an electrician.

Blown fuse. Replace the fuse, if the problem

Troubleshooting

continues, contact an electrician.

9

Troubleshooting

The machine stops. The protection device stops the

machine.

The cause could not be identied. Contact Omcan directly.

The machine doesn’t function: the

worm will not rotate.

The electrical supply is not

adequate.

The switch is on the “O” position. Place the switch to the “I” position.

Blown fuse. Replace the fuse.

The unit is overheated. Wait for the unit to cool completely

Contact an electrician to eliminate

the causes, once the cause has

been determined, restore the

machine to the recommended

function.

Check and restore the electrical

supply.

before starting.

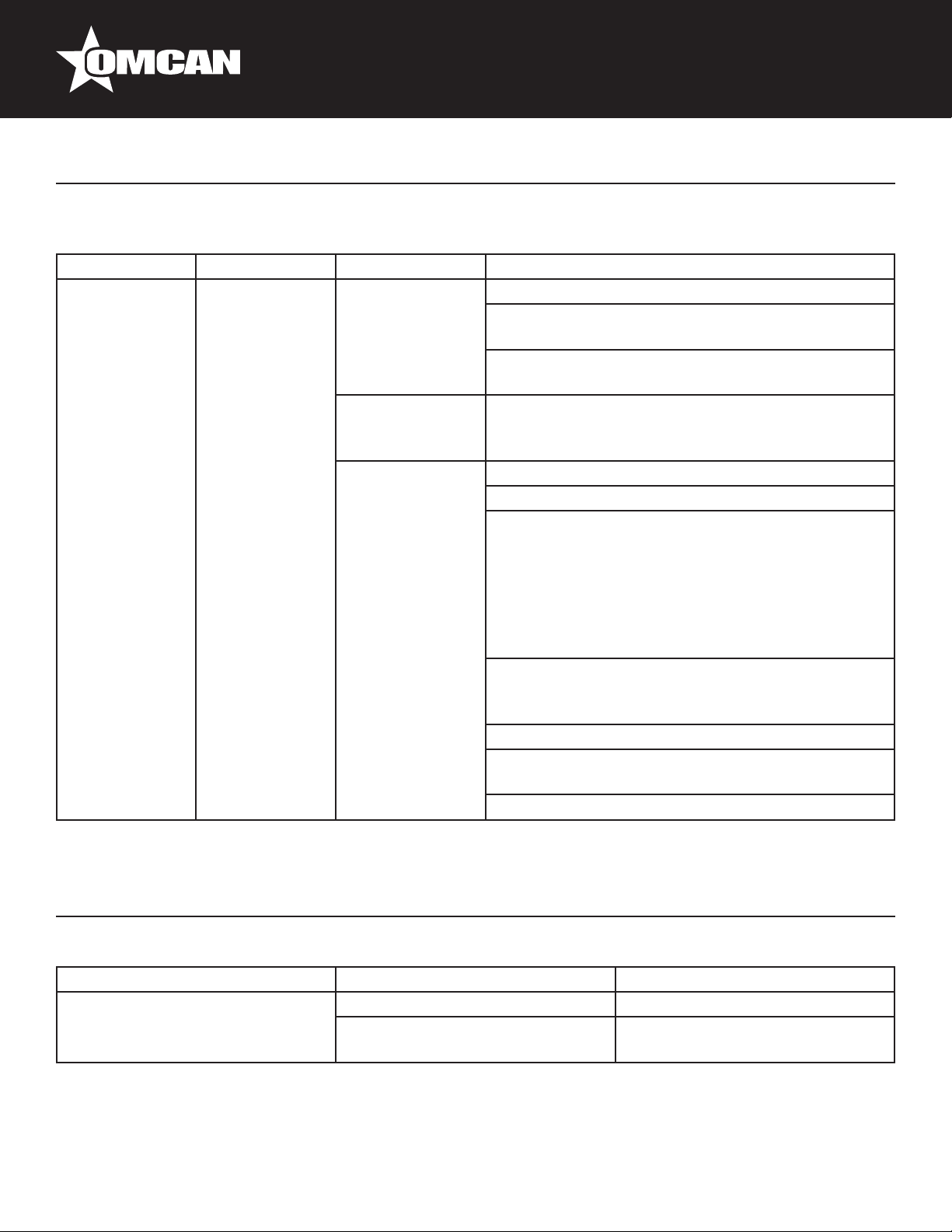

REFERENCE

Item Number Model Number Description Manufacturer Model Number

11051 MG-IT-0012-C

11053 MG-IT-0022-C

39714 MG-IT-0032-C

Meat Grinder #12 Aluminum

1 HP / 746 W 110V/60/1

Meat Grinder #22 Aluminum

1.5 HP / 1119 W 110V/60/1

Meat Grinder #32 Stainless Steel

3 HP / 2200 W 220V/60/1

with 34cm x 50cm Pans

FTS12

FTS22

TI32R

10

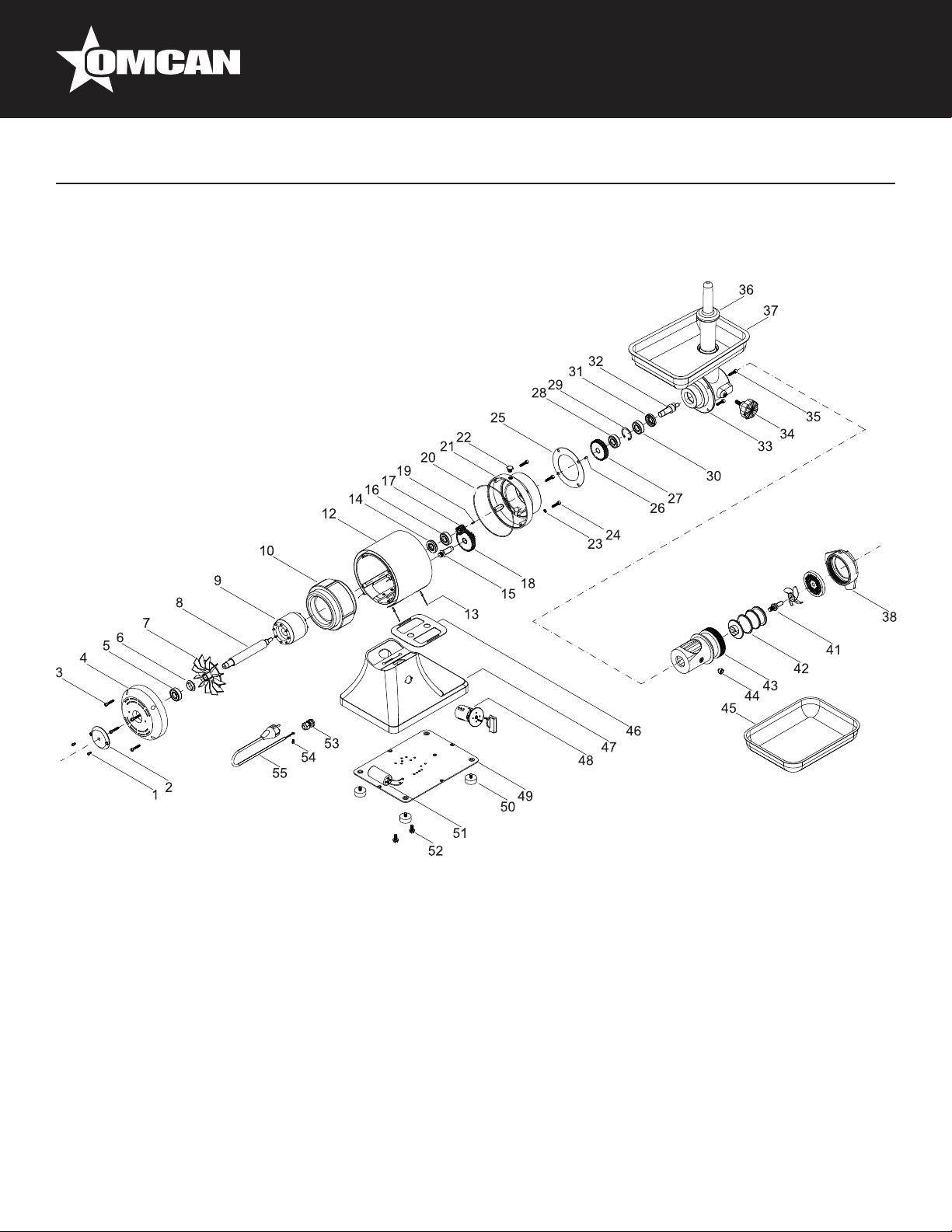

Model MG-IT-0012-C 11051

Parts Breakdown

11

Parts Breakdown

Model MG-IT-0012-C 11051

Item No. Description Position Item No. Description Position Item No. Description Position

15351 Screw 4x8 for FTS12 1 / 48 15391 Key 3mm for FTS12 17 / 18 15402 Grub Screw for FTS12 39

15352 Disc Locking ABS DA 80mm. for FTS12 2 15393 Gear Big Easy for FTS12 19 15362 Container MIS.250x180 for FTS12 40

15353 Screw 5x30 for FTS12 3 15394 Seeger of 40 for FTS12 21 15460 Base Guard for FTS12 41

15380 Back Motor Cover for FTS12 4 15395 Transmission Pin for FTS12 24 19378 Bipolar Switch for FTS12 42

15381 Bearing 6203 ZZ for FTS12 5 / 20 15396 Jacket Holder for FTS12 25 15410 Screw 8x22 for FTS12 43

15445 Motor Shaft for FTS12 6 15458 Ring 164.5x2 for FTS12 26 15411 Rubber Base Cover for FTS12 44

15383 Rotor for FTS12 7 15459 Washer for FTS12 27 15413 Capacitor 40 uF for FTS12 45

15469 Stator for FTS12 8 15398 Rubber Plug for FTS12 28 15412 Screw 4.8x12 for FTS12 46

15384 Motor Cover - Open for FTS12 9 15397 Screw 6x25 for FTS12 29 42930 Cordset Mod. Schuko V.230 for FTS12 47

15385 Stainless Cover for FTS12 10 15401 Knob for FTS12 30 15407 Grand PG11 for FTS12 49

15370 Rivets for FTS12 11 15400 Plunger for FTS12 31 15360 Rubber Feet for FTS12 50

15387 Oil Seal 40x25x7 for FTS12 12 / 23 42929 Hopper for FTS12 32 15408 Base for FTS12 51

15447 Gear Pin for FTS12 13 15406 Aluminum Ring for FTS12 33 42932 Ring Mounting Fan for FTS12 52

15389 Bearing 6203 2RS for FTS12 14 / 22 15454 Worm Pin for FTS12 36 78144 Fan for FTS12

15392 Double Gear for FTS12 15 15404 Worm and Pin for FTS12 37 78145 Crankshaft Fan for FTS12 54

15390 Propeller Gear for FTS12 16 17233 Jacket for FTS12 38 78146 Long Fan Housing for FTS12 55

53

12

Model MG-IT-0022-C 11053

Parts Breakdown

13

Parts Breakdown

Model MG-IT-0022-C 11053

Item No. Description Position Item No. Description Position Item No. Description Position

15351 Screw 4x8 for FTS22 1 / 54 15392 Double Gear for FTS22 18 15455 Ring for FTS22 38

15352 Disc Locking Abs DA 80mm. for FTS22 2 15391 Key 3mm for FTS22 19 / 26 15454 Worm Pin for FTS22 41

15353 Screw 5x30 for FTS22 3 15458 Ring 164.5x2 for FTS22 20 15453 Aluminum Worm and Pin for FTS22 42

15380 Back Motor Cover for FTS22 4 15441 Motor Cover - Front for FTS22 21 15451 Jacket for FTS22 43

15381 Bearing 6203 ZZ for FTS22 5 / 28 15444 Brass Oil Cap for FTS22 22 15452 Grub Screw for FTS22 44

15414 Ring for FTS22 6 15459 Washer for FTS22 23 15456 Container MIS.300x220 for FTS22 45

15415 Fan for FTS22 7 15442 Screw 6x20 for FTS22 24 42927 Base Gasket for FTS22 46

15445 Motor Shaft for FTS22 8 15448 Seal for FTS22 25 18658 Base for FTS22 47

15446 Rotor for FTS22 9 15393 Gear for FTS22 27 19378 Bipolar Switch for FTS22 48

20178 Stator for FTS22 10 15394 Seeger of 40 for FTS22 29 42928 Bottom Base Closure for FTS22 49

15386 Stainless Motor Cover for FTS22 12 15395 Transmission Pin for FTS22 32 15360 Rubber Foot for FTS22 50

15370 Rivets for FTS22 13 15450 Jacket Holder for FTS22 33 18657 Capacitor 40 uF for FTS22 51

15387 Oil Seal 40x25x7 for FTS22 14 / 31 15401

15447 Gear Pin for FTS22 15 15443 Screw 6x18 for FTS22 35 15407 Grand PG11 for FTS22 53

15389 Bearing 6203 2RS for FTS22 16 / 30 15400 Plunger for FTS22 36 42926 Cordset Mod.Schuko V.230 for FTS22 55

15390 Propeller Gear for FTS22 17 15449 Hopper for FTS22 37

Knob for FTS22 34 15410 Screw 8x22 for FTS22 52

14

Model MG-IT-0032-C 39714

Parts Breakdown

15

Parts Breakdown

Model MG-IT-0032-C 39714

Item No. Description Position Item No. Description Position Item No. Description Position

70162 Pestle for TI32R 1 15363 Screw 8x20 for TI32R 20 70202 Wheel Steel Round for TI32R 40

70163

70164 Steel Screw 5x12 for TI32R 3 70184 Flange Front Inox for TI32R 22 70204 Circuit Board with Reversal for TI32R 42

70165 Upper Flange Inox D76 for TI32R 4 70185 Steel Screw 6x16 for TI32R 23 70205 Electrical Box + PG for TI32R 43

70166 Casing Steel for TI32R 5 70186 Thrust Bearing 51305 for TI32R 24 70206 Tapping Screw 4.6x10 for TI32R 44

70167 Steel Screw 8x16 for TI32R 6 70187 Bearing 6006 2RS for TI32R 25 70207 Condenser 55 uF for TI32R 45

70168

15407 Gland PG11 for TI32R 8 70189 Key 6x6x30 for TI32R 27 70209 Foot Rubber Thread for TI32R 47

70170 Filter only Three Phase for TI32R 9 70190 Pin Driver Helix for TI32R 28 70210 Screw M6x20 for TI32R 48

70171 4x45 Screw for Fan for TI32R 10 70191 Wheat Inox 6x20 for TI32R 29 70211 Washer 6x18x1.5 for TI32R 49

70172 Fan 230V only Single Phase for TI32R 11 70192 Mouth Stopping Pin for TI32R 30 70212 Screw 5x12 for TI32R 50

70173 Switch Triple 24V. Reverse for TI32R 12 70193 Ring 3075 for TI32R 31 70213 Fund Closure for TI32R 51

70174 Bracket Door Micro for TI32R 13 70194 Stud Stainless Steel Lever for TI32R 32 70214 Rubber Anti for TI32R 52

70175 Screw 8x12 for TI32R 14 70195 Steel Screw 5x12 for TI32R 33

70176 Micro Switch for TI32R 15 70196 Lever Stop for Mouth Reels for TI32R 34 70216

70177 Screw + Nut for Micro 5x35 for TI32R 15a 70197 Mouth Meat Inox for TI32R 35 70189 Key 6x6x30 for TI32R 55

70178 Self-Locking Nut M24x1.5 for TI32R 16 70198 Steel Screw for TI32R 36 70218 Funnel Mod.32 Hole 15 for TI32R 56

70179 Washer 25x40x2 for TI32R 17 70199 Pin Knifeholder for TI32R 37 70219 Funnel Mod.32 Hole 20 for TI32R 57

70180 Gear for TI32R 18 11079 #32 Knife Inox for TI32R 38 70220 Funnel Mod.32 Hole 25 for TI32R 58

70181 Washer 8x16x1,5 for TI32R 19 11210

Hopper D76 Big Prot.Mano + Fork for

TI32R

Cable with Plug Mod.Schuko V.230 for

TI32R

2 70183 Internal Aluminum for TI32R 21 15456 Container Mis.300x220 for TI32R 41

7 70188 Oil Seal 30x55x7 for TI32R 26 70208 Self-Locking Nut M8 for TI32R 46

70215 Vibration Motor for TI32R 53

Complete Motor V.230 / 60Hz Hp.3 for

TI32R

#32 Stainless Steel Plate 10mm with Hub

for TI32R

39 70221 Kit Electrical V.230 / 50-60Hz for TI32R 59

54

16

Model MG-IT-0012-C 11051

Electrical Schematics

Model MG-IT-0022-C 11053

17

Electrical Schematics

Model MG-IT-0032-C 39714

18

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

https://omcan.com/warranty-registration/

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

19

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 5,000 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 5000

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 5,000 productos con origen a nivel mundial.

Loading...

Loading...