Page 1

Food Processor

Model FP-IT-0300

Item 10927

Instruction Manual

Revised - 05/30/2018

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model FP-IT-0300

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

------------------------------------------------------------------------------------------ 10

------------------------------------------------------------------------------------- 11 - 12

--------------------------------------------------------------------------------- 12 - 14

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 6

Page

---------------------------------------------------------------------- 7 - 9

Parts Breakdown

Electrical Schematics

Warranty Registration

---------------------------------------------------------------------------- 15 - 17

---------------------------------------------------------------------------- 18

---------------------------------------------------------------------------- 19

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

GENERAL PRECAUTIONS

• The vegetable cutter must be operated only by highly qualied personnel who are fully aware of the safety

measures described in this manual.

• In case of a personnel turnover, training is to be provided in advance.

• Although the machine incorporates safety devices and protections for dangerous parts, it is recommended

not to touch the moving parts.

4

Page 5

Safety and Warranty

• Before starting cleaning and maintenance operations, disconnect the plug from the electrical socket.

• To carry out cleaning and maintenance, assess the residual risks carefully (as protections are removed).

• Cleaning and maintenance require concentration.

• A regular check of the power supply cable is absolutely necessary; a worn-out or damage cord is very

dangerous.

• If the machine malfunctions, it is recommended not to use it and do not try to repair it; please call Omcan.

• Do not use the machine for processing frozen products, meat and shes with bones or non food products.

• Do not repair the machine yourself but call Omcan.

• Always use the pusher with the pestle to cut the food.

• Do not ll too much the inlet cylinder and do not press too hard to avoid any problem.

• The manufacturer shall not be liable for damage to things or injury to persons in the event:

- The machine or the safety devices and protections have been tampered with by non authorised

personnel.

- Non original spare parts and discs are installed.

- The instructions provided in this manual are not followed thoroughly.

- The machine surface is not cleaned with the right product.

SAFETY DEVICES

GENERAL SAFETY DEVICES

The mechanical, electrical and hygienic safety devices installed on the vegetable cutter described in this

manual complies with:

UL 763 and NSF Standards.

The vegetable cutter is tted with electrical and mechanical safety devices for machine operation as well as

cleaning and maintenance operations. However, there are RESIDUAL RISKS which cannot be eliminated

completely. These risks are listed in this manual under WARNINGS. These risks are cutting dangers due to the

machine handling during the disc substitution and/or cleaning.

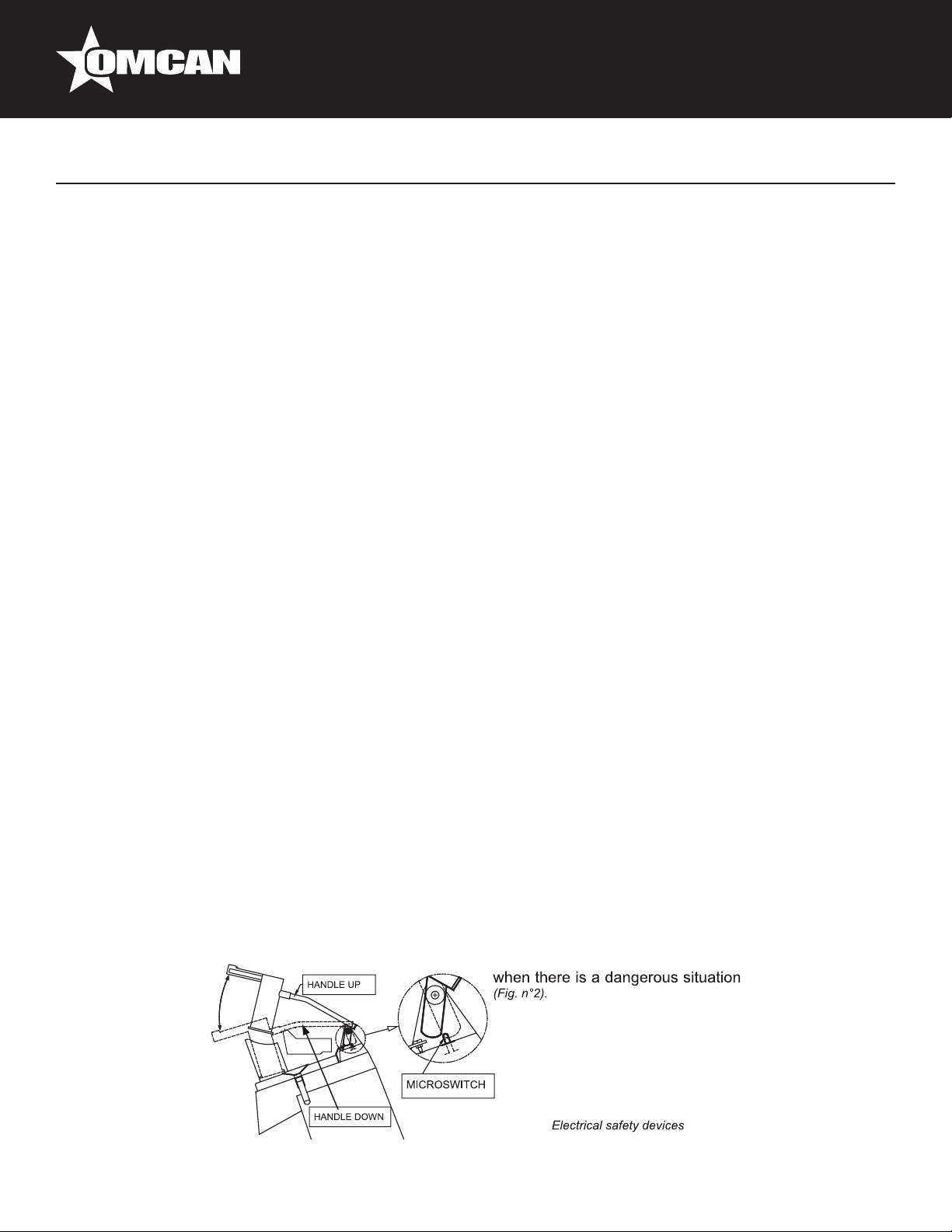

ELECTRICAL SAFETY DEVICES

The vegetable cutter is tted with microswitches:

• On the pusher lever, to stop the machine if the handle is lifted over the mouth of the lid and to enable to

turn on the machine automatically when there is a dangerous situation.

5

Page 6

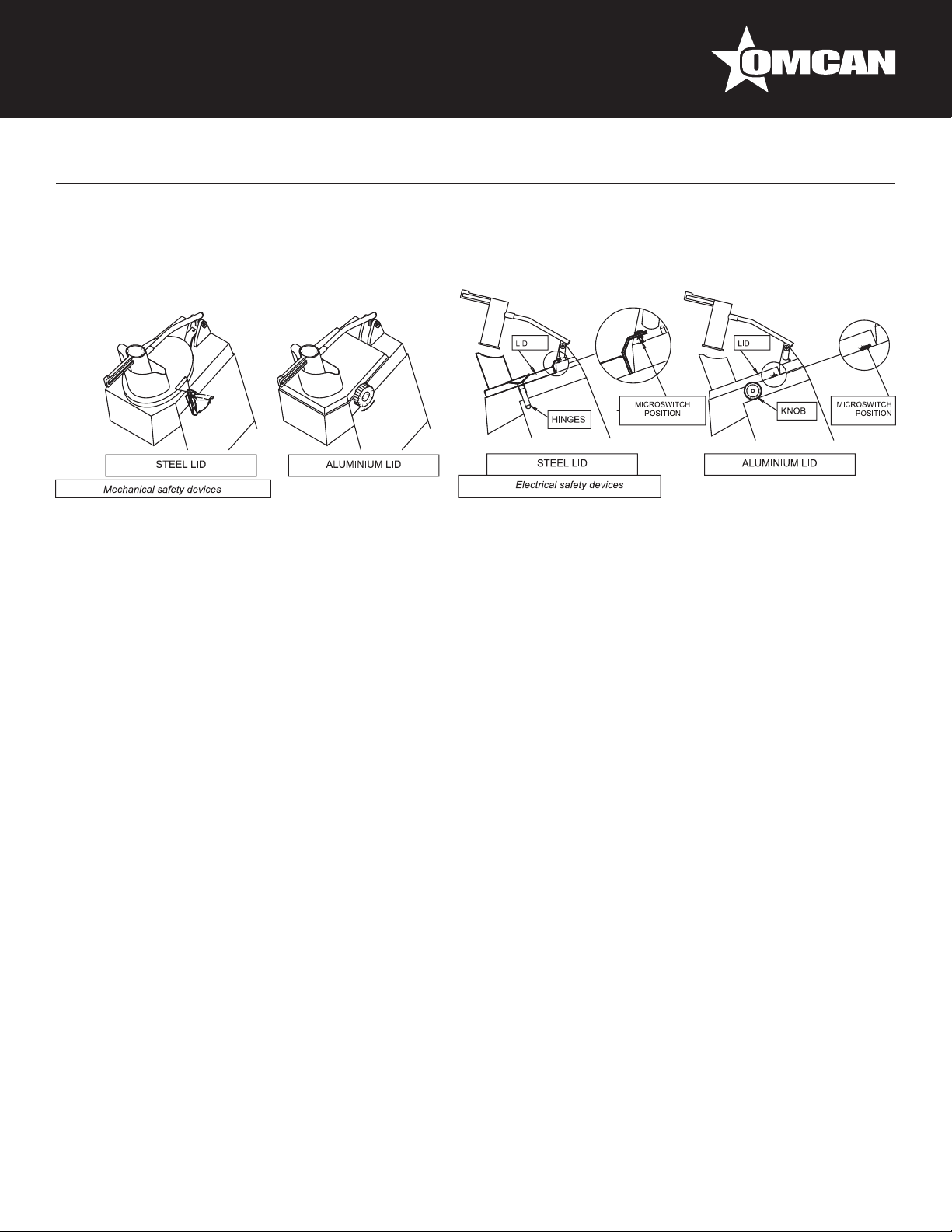

Safety and Warranty

• On the hopper, to stop the machine if the lid is removed (i.e. to replace the discs), and to permit to start the

machine voluntarily (by pressing pushbutton “I”) only when the lid is closed, correctly locked by the hinges

for the steel lid or with the knob for the aluminium lid.

1 YEAR PARTS AND LABOUR BENCH WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule a drop off to either

an Omcan authorized service depot in the area, or to an Omcan Service warehouse to repair the

equipment.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

6

Page 7

MACHINE DESCRIPTION

Technical Specications

ACCESSORIES

The vegetable cutter is provided with many accessories. Some are supplied with the cutter, other must be

requested by the Client.

STANDARD ACCESSORIES

PESTLE: Made of polyethylene for alimentary use, to facilitate the cutting of small product, it must be

introduced in the product cylinder placed on the pusher.

COLLECTING BOWL: Made of polyethylene for alimentary use, “GASTRONORM” of 1/3, h=200; equipped

with microswitch.

7

Page 8

Technical Specications

DISCHARGING SPATULA: Made of steel AISI 304 installed on the disc support pin. It makes easier to

discharge the product when cut. It can only be used with the following discs DTV, DT2 - 3 - 4 - 7 - 9, DF1 - 2 - 3

- 4.

DISCS HOLDER: Made of plasticised steel for alimentary use, it is a useful collector for discs.

TOOLS

On demand, the vegetable cutter can be supplied with different discs, suitable for many different cuts.

DISCS FOR SLICES “DF”:

They are made of aluminium and the knives are made of AISI 420. The following

discs are available:

• DF1.

• DF2.

• DF3.

• DF4.

• DF5 - specic for tomatoes and peppers.

• DF8.

• DF10.

• DF14.

DISCS FOR STRIPS “DT”:

The supporting structure is made of aluminum, and the body of the disc is made of

AISI 420. The following discs are available:

• DTV - to grate.

• DT2.

• DT3.

• DT4.

• DT7.

• DT9 - specic for mozzarella.

DISCS FOR MATCHSTICKS “DQ”:

The supporting structure is made of aluminium and the knives are made of AISI 420.

The following discs are available:

• DQ4.

• DQ6.

8

Page 9

Technical Specications

• DQ8.

• DQ10.

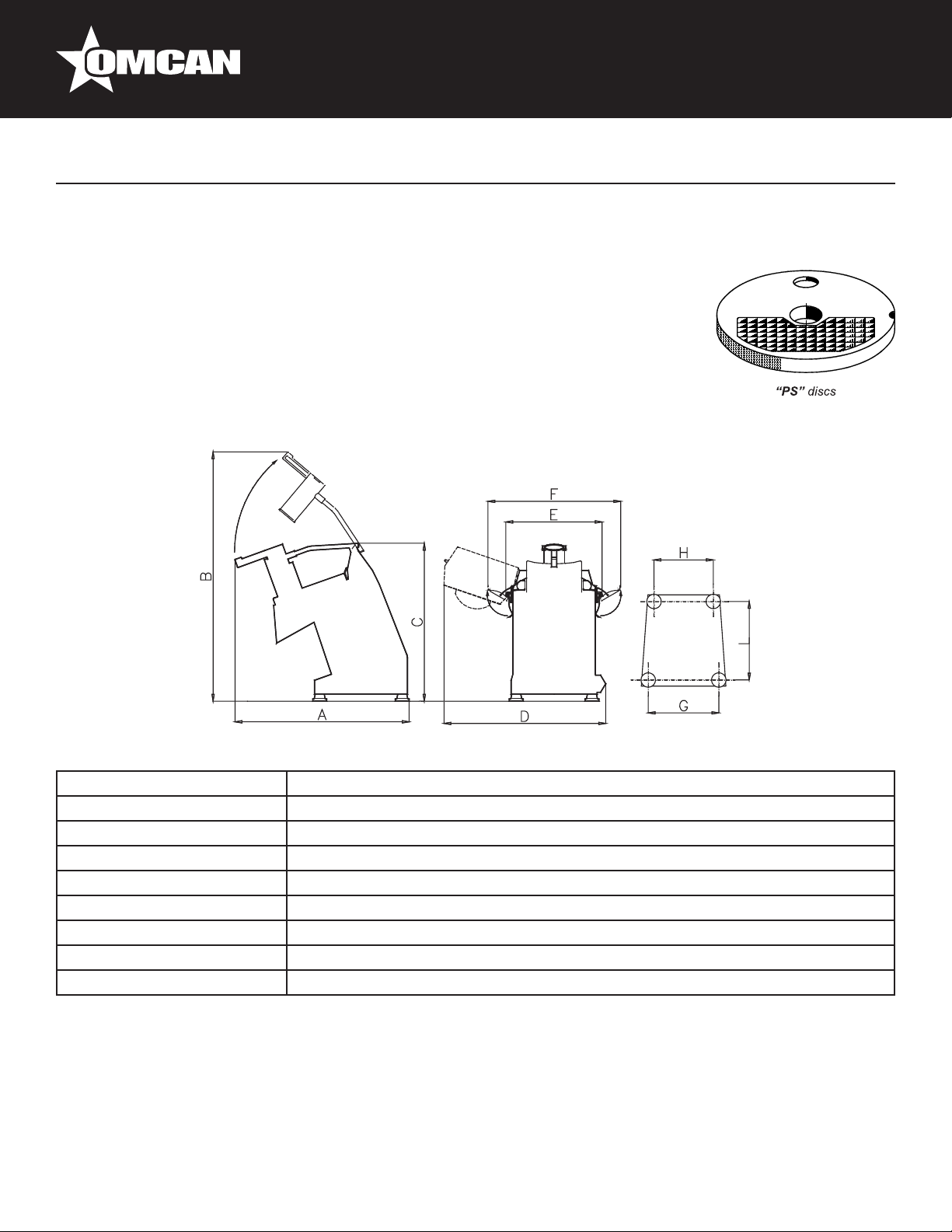

DISCS FOR CUBES “PS”:

The supporting structure is made of aluminium and the knives are made of AISI 420.

The following discs are available:

• PS8 coupled with DF8.

• PS10 coupled with DF10.

• PS20 coupled with DF14.

OVERALL DIMENSIONS, WEIGHT, FEATURES

Model FP-IT-0300

Power 0.7 HP / 0.52 kW

Disc Speed 300 RPM

Mouth Opening 3 1/16” x 6 1/4” / 78 x 159mm

Electrical 110V / 60Hz / 1

Food Collection Bin/Tray 1/3-size, 7QT / 6.5L, Clear | 12.75” x 7” x 8” / 324 x 178 x 203mm

Weight 54 lbs. / 24.5 kgs.

Dimensions 20” x 11” x 19” / 508 x 279 x 483mm

Item Number 10927

Machine electrical specications are indicated on the rating plate afxed to the side of the grater; before

connecting to power supply, please see Rating Plate.

9

Page 10

Installation

PACKAGING OF THE MACHINE

The vegetable cutter is accurately packed and then

despatched from our warehouses. The package

includes:

1. A solid cardboard box.

2. The machine.

3. Some elements to keep the machine stable.

4. The bowl.

5. The pestle.

6. This manual.

7. CE conformity declaration.

SETTING UP OF THE MACHINE

The vegetable cutter must be installed on a suitable

and adequate size work table, the machine must be

solid, stable and xed at a height of 80 cm from the

ground. Moreover the machine must be installed

in a room with max. 75% non saline humidity at a

temperature between +5°C and +35°C (41°F and

95°F); in a location and environment that does not

provoke malfunctions or faults in the machine.

COLLECTING BOWL

If the Vegetable cutter is provided with a collecting bowl, place it under the

mouth of the machine, so as to cover the product exit.

ELECTRICAL CONNECTION

The Vegetable cutter is equipped with a power supply cable with a SJT 16

AWG mm2 section; length 1,5 m and a NEMA 5 plug. Connect the Vegetable

cutter to 115 Volt 60 Hz, by interposing a differential thermomagnetic switch

10 A DI = 0,03 A. Check correct machine grounding. Moreover check that the

specications on the rating plate-serial number correspond to the specications

provided in the consignment and delivery note.

10

Page 11

Operation

FUNCTIONAL CHECK

To check the correct machine operation, proceed as follows:

1. Turn ON push button “I” and stop push button “0” and check that the corresponding pilot lights turn on and

off.

2. Check that the motor stops and then turns on when you lift or lower the pusher handle.

3. Check that the machine stops when your remove the lid and that it turns on by pressing push button

START “I” only if the lid is correctly installed.

USE OF THE MACHINE

DISCS ASSEMBLY - CAUTION!

1. Choose one of the following discs DF 1-2-3-4-5-8-10-14, DTV, DT 2-3-4-7-9, or DQ 4-6-8-10; remove the

steel or aluminium lid, and place the disc on the shaft. Rotate the disc until it is xed. Replace the stainless

steel lid fastening it with the specic hinges or the aluminium lid fastening it with the knob.

2. TO CUT CUBES: Choose the couple of discs among PS8-DF8, PS10-DF10, PS20-DF14. Place the rst

disc PS. with the cavity turned on the right side placing yourself in front of the machine. Then install the DF

disc.

NOTE: NEVER USE THE DISCHARGING SPATULA WITH COUPLED DISCS PS-DF.

3. If the machine is supplied with a discharging spatula, we advise to use it with the following discs DF 1-23-5, DTV, DT 2-3-7-9, DQ4. The spatula must be assembled on the disc support pin before any other disc.

After having assembled the spatula, proceed as in point “1”.

LOADING AND CUTTING THE PRODUCT - CAUTION!

When the machine is working, it is necessary to stand correctly to avoid accidents.

The body must always be perpendicular to the working table. Pay the maximum

attention that no members of your body enter in contact with the machine.

11

Page 12

Operation

NOTE: The product has to be loaded in the Vegetable Cutter when it is OFF.

Proceed as follows:

1. Load the product in the mouth of the lid. If the product is small (i.e. carrots,

baby marrows, etc.) put it in the inlet cylinder placed on the handle. Turn on the

machine and help the cutting by pressing slightly on the pusher handle or with the

pestle if you use the inlet cylinder.

2. When the product is cut, lift the pusher handle, a safety device will stop the

machine. Load another product and lower the handle, the machine will start

automatically.

3. To replace the disc and change the type of cutting, proceed as described in Disc

Assembly. After this operation, an electronic device will lock the automatic restart

of the machine; to restart the machine, it will be necessary to press push button

“I”.

4. If you use the bowl, after 2-3 cutting cycles, empty it. The use of the machine

with a full bowl, could block the discharge of the product in the working area, and

cause a faulty cut, the machine lock or the motor failure.

Maintenance

IMPORTANT

Before performing any maintenance operation, it is necessary to disconnect the plug from the mains to isolate

it from the mains power supply.

BELT

The drive belt does not require adjustment. In general after 3-4 years, it must be replaced, in this case call

Omcan.

FEET

Feet may deteriorate or lose elasticity, reducing machine stability. If support feet show signs of wear or

damage, replace.

POWER SUPPLY CABLE

Periodically check for wear in the power supply cable. If the power supply cable shows signs of wear or

damage call Omcan for a replacement.

12

Page 13

Maintenance

DISCS

With time the blade could wear:

• For DTV, DT 2, 3, 4, 7, 9 and PS 6, 8, 10, 20 discs; it is necessary to buy new discs.

• For DF 1, 2, 3, 4, 5, 8, 10, 14 and DQ 4, 6, 8, 10 discs, it is possible to replace the blade.

In this case, call Omcan indicating the name of the disc.

TROUBLESHOOTING

The xing of the discs is faulty: Check that the discs and the disc support pin are clean.

The lid does not lock: Check that the lid is installed correctly and that it is clean.

The product is not cut correctly: Check that the blade is not worn.

The product does not go out correctly or is badly cut: Check that the discharging spatula has not been

assembled with the DT discs (the whole set); DF 1, 2, 3, 4; DQ 4; that the bowl is not full and that the exit

opening is not obstructed.

The machine locks: Check that the product is not frozen or too hard and that the power supply is the one

indicated on the rating plate.

The micro on the pusher handle and on the lid do not work: Check that they are not dirty.

The machine does not start: Check that all the safety devices are correctly installed and that the plug and the

switches are correctly connected.

CLEANING OF THE MACHINE

IMPORTANT

• The machine must be cleaned at least once a day. If necessary clean when required during the day.

• All the Vegetable cutter parts that come into contact directly or indirectly with the food product must be

cleaned thoroughly.

Before starting cleaning operations, it is necessary to:

• Disconnect the machine plug from the mains to isolate it from the mains power supply.

Pay attention to hazards of injury caused by cutting and/or sharp machine components during

cleaning or handling of discs.

CLEANING PRODUCTS - CAUTION!

The machine must be cleaned with a normal detergent at ambient temperature, with a wet cloth. It must never

be cleaned with pressurised water, or water jets, do not use brushes or other tools or anything that could

damage the machine.

NOTE: NEVER WASH THE MACHINE PARTS IN THE DISHWASHER.

IMPORTANT: Disconnect the machine from the power supply. Remove the lid and the discs, the

spatula, the pestle, the bowl and/or the chute. Clean accurately the inside of the mouth, the operating

area and the disc support pin. Moreover clean all the external surfaces and the pusher handle. Dry with

a cloth and reassemble the machine.

13

Page 14

Maintenance

SCRAPPING

PUTTING THE MACHINE OUT OF SERVICE

If for some reason, you decide to put the machine out of service, make sure nobody can use it:

• Disconnect it from the mains and eliminate electrical connections.

SCRAPPING

When the machine is out of service,

it can be disposed of. To scrap the

machine contact your local Specialised

Waste Treatment Centre, separate

components.

REFERENCE

Item Number Model Number Description Manufacturer Model Number

10927 FP-IT-0300

0.7 HP / 522 W 110V/60/1 ETL cETLus

Food Processor 300 RPM

TM

14

Page 15

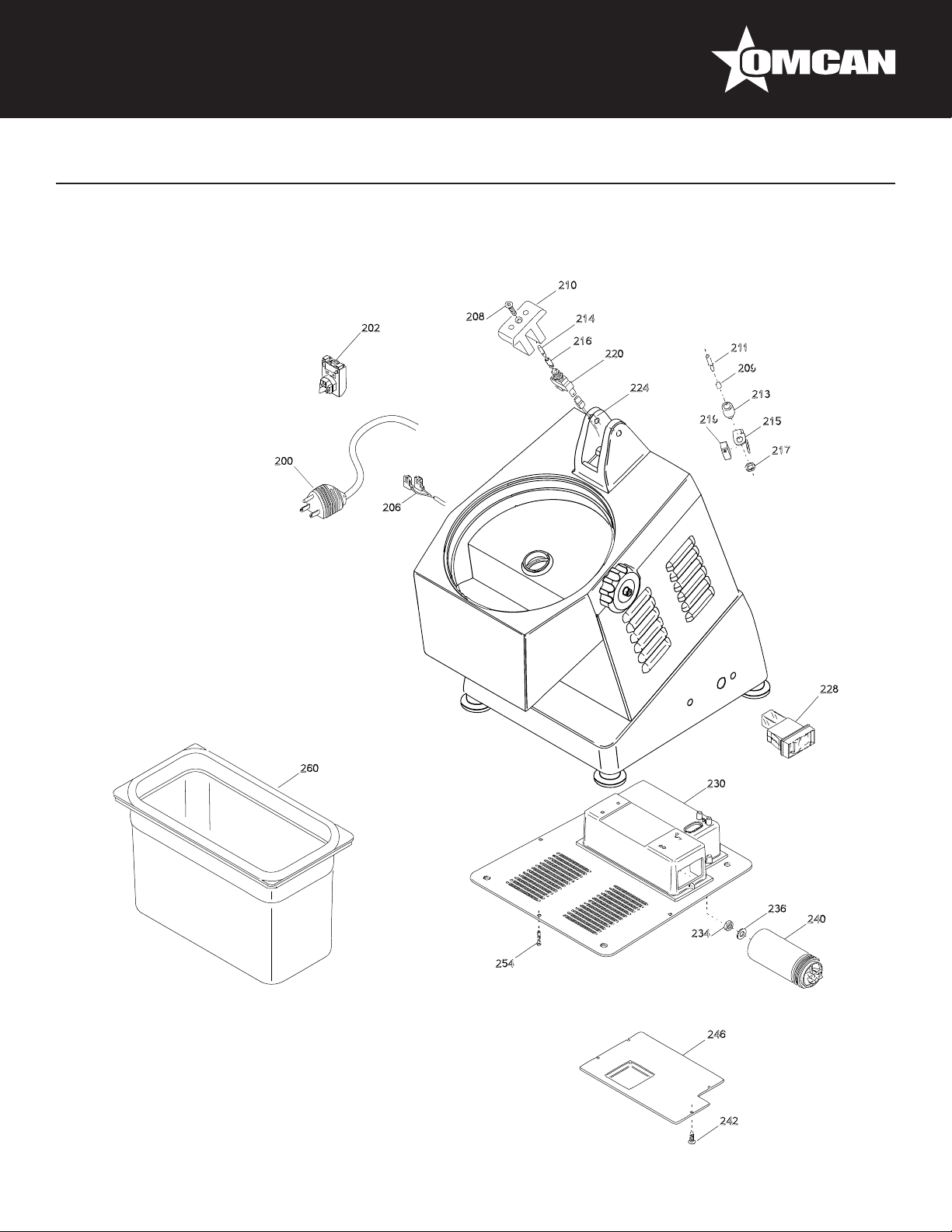

Model FP-IT-0300 10927

Parts Breakdown

15

Page 16

Parts Breakdown

Model FP-IT-0300 10927

16

Page 17

Parts Breakdown

Model FP-IT-0300 10927

Item No. Description Position Item No. Description Position Item No. Description Position

16491 Aluminum Lid for TM 2 19260 Closing Knob for TM 42 19258 Retaining C-Clip Ext.Seeger D20 for TM 108

37314 Pin 5x30 for TM 4 37325

16490 Magnet 6x12 for TM 6 37326

37315 Pin for Aluminum Lid for TM 7 37327 Motor 110/60 UL for TM 52 37340 Terminal Box for TM 202

16503 Product Pusher Knob for TM 8 37328 Screw for TM 54 37341 Power Connection Cable for TM 206

16493 Pusher Complete for TM 10 37329 Base / Frame for TM 60 16492 Microswitch Spring for TM 209, 216

37316 Nylon Spacer for TM 12 37348 Nut M08 for TM 62, 234 16487 Supporto Micro 1 UL for TM 210

37317 Stainless Steel Lever for TM 14 37330 Washer 6x18 for TM 66 16485 Micro Plunger-Long UL for TM 211, 214

37318 Plug for TM 16 16496 Foot M8 for TM 70 37342 Cylinder X Pin Micro UL for TM 213

16486 Pusher Housing UL for TM 20 37331 Belt Pulley for TM 80 37343 Square Support Micro ETL UL for TM 215

66090

37319 Acorn Nut M08 for TM 26 19259 Bearing 6004 2RS for TM 84, 112 37344 Microswitch Wiring for TM 224

37320 Washer 08x24 INOX for TM 28 37332 Bearing Block for TM 90 16452 On/Off Switch Weber 120 V for TM 228

24107 Stud Bolt M8 for TM 30 37333 Washer 06x24 for TM 94 37345 Bottom Enclosure Panel for TM 230

16455 Ejector for TM 32 37334 Motor Pulley for TM 96 16498 Capacitor 35 MF for TM 240

37321 Nylon Pivot Stop-Block for TM 33 37335 Main Shaft Assembly D.20 for TM 100 37346 Protection Cover for TM 246

37322 Screw T.E. INC 4x16 for TM 34 37336 Set Pin 6x6x20 for TM 102 37347 Product Container 1/3 H.200 for TM 260

37323 Screw TEI 4x10 for TM 35 37337 Set Screw M04x05 for TM 103

37324 Square Hopper for TM 40 37338 Insert for TM 104

Screw T.Poelier CACC. M4x35 for Press

for TM

22 16481 Belt J 483x8 for TM 82 24106 Microswitch UL for TM 219, 220

Stainless Steel Prong Shoulder Screw

for TM

Stainless Steel Cabinet with Louvers

for TM

46 19257 Retaining C-Clip Seeger D42 for TM 110

50 37339 US Power Cord 110V for TM 200

17

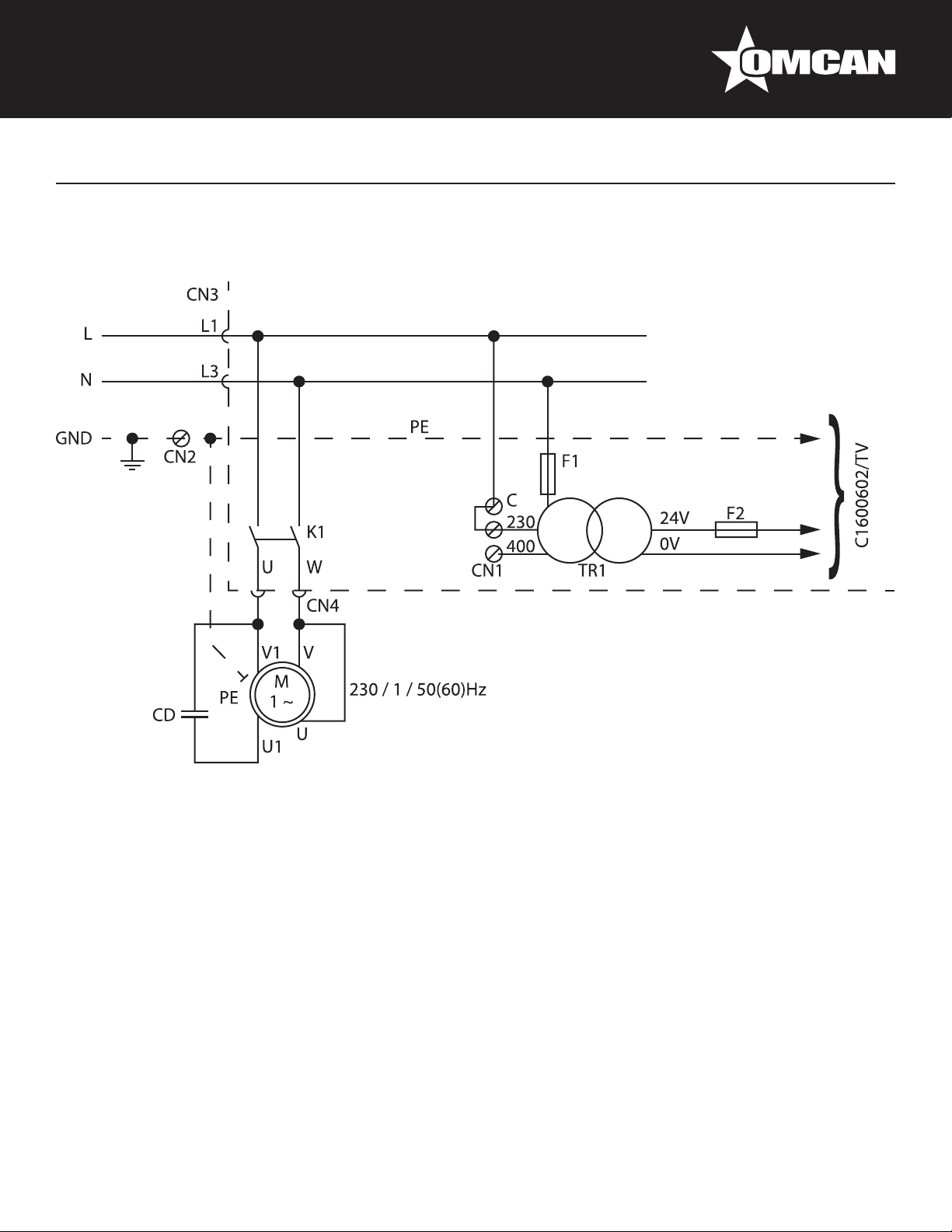

Page 18

Electrical Schematics

Model FP-IT-0300 10927

18

Page 19

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

19

Page 20

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...