Page 1

Bowl Cutters

Models FP-ES-0050, 0080

Items 10879, 10880

Instruction Manual

Revised - 07/27/2017

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model FP-ES-0050 / Model FP-ES-0080

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

--------------------------------------------------------------------------------------- 7 - 8

--------------------------------------------------------------------------------------- 8 - 10

--------------------------------------------------------------------------------- 10 - 12

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 6

Page

---------------------------------------------------------------------- 6 - 7

Troubleshooting

Illustrated Diagrams

Parts Breakdown

Electrical Schematics

Notes

Warranty Registration

------------------------------------------------------------------------------------------------- 22

----------------------------------------------------------------------------------- 13

---------------------------------------------------------------------------- 18 - 20

------------------------------------------------------------------------ 14 - 17

---------------------------------------------------------------------------- 21

---------------------------------------------------------------------------- 23

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

This machine has moving mechanical parts and uses voltages which are potentially hazardous. Severe,

even life-threatening, personal injury could result if the instructions contained in this manual are not followed.

Before operating the unit, please read this manual thoroughly. This manual should be kept for future reference

and given to every user of the machine. The following clauses limit the liability of the manufacturer and its

representatives:

• THIS MACHINE SHOULD ONLY BE INSTALLED BY A QUALIFIED ELECTRICIAN. ONCE INSTALLED,

4

Page 5

Safety and Warranty

DO NOT TAMPER WITH THE ELECTRICAL WIRING OF THE MACHINE.

• DO NOT USE THE MACHINE WITHOUT HAVING RECEIVED PREVIOUS INSTRUCTIONS ABOUT ITS

USE, MAINTENANCE AND SAFETY DEVICES FROM AN EXPERIENCED OPERATOR.

• BEFORE USING THE MACHINE, READ THIS INSTRUCTION MANUAL CAREFULLY AND

UNDERSTAND IT FULLY.

• DO NOT USE THE MACHINE WITHOUT THE PERSONAL SAFETY EQUIPMENT REQUIRED BY LAW.

• DO NOT TAMPER WITH THE MECHANICAL OR ELECTRICAL SAFETY DEVICES.

• ALWAYS KEEP HANDS AT A SAFE DISTANCE FROM THE MOVING PARTS OF THE MACHINE.

• DO NOT LEAVE MACHINE UNATTENDED WHILE SWITCHED ON OR IN OPERATION.

• ALWAYS DISCONNECT THE MACHINE FROM THE POWER SUPPLY BEFORE PROCEEDING WITH

CLEANING, MAINTENANCE, OR REPAIRS.

• DO NOT OPEN THE MACHINE OR TAMPER WITH ITS INTERNAL COMPONENTS. THERE ARE NO

INTERNAL COMPONENTS THAT REQUIRE ADJUSTMENT ON THE PART OF THE USER.

• SHOULD THE MACHINE MALFUNCTION, TURN IT OFF IMMEDIATELY AND NOTIFY THE

SUPERVISOR.

Installation must be in accordance with the operating instructions and with local and state electrical and safety

codes. Compliance with codes is the responsibility of the owner and installer. Before operating the machine,

check that all phases are connected properly and make sure that the machine is properly grounded and/or

connected to a circuit leakage breaker and thermal switch. Failure to do so could result in electric shock. Make

sure the safety signs and stickers are rmly afxed to the machine, that they are legible, and that they do not

become blurred or erased when the machine is cleaned. If they become damaged or lost, ask your dealer for

new ones and replace them. Keep your work area well lit and free of obstacles. When operating the machine

never wear loose clothing or jewelry which could get caught in the moving parts of the machine. Unplug the

machine when not in use. Keep children and on-lookers at a safe distance. To avoid damaging the electrical

cord, keep it out of areas where it can be stepped on. Do not alter or modify the original machine design in

any way. Should the machine need repairs, consult the ofcial distribution center where the machine was

purchased. Use only original spare parts and accessories and have them properly installed by a qualied

technician. This machine has been built exclusively for meat processing. Any other use of this machine is not in

accordance with its intended application. The manufacturer assumes no responsibility for any possible damage

or injury resulting from improper use of this machine. Additional operating instruction manuals are available

from your dealer. Your local dealer will be happy to answer any further questions you may have.

1 YEAR PARTS AND LABOR WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule an Omcan authorized

service technician to repair the equipment locally.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see www.omcan.com/warranty.html for complete info.

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal solid urban waste

5

Page 6

Safety and Warranty

and can therefore be disposed of without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

APPLICATIONS, FEATURES, AND DESCRIPTION

Not only is the unit an all-purpose cutter/chopper, but also as an emulsier to produce ne, delicate pastes.

The cutter/chopper can chop and mix (bidirectional mixing is an optional feature) to perfection any type of meat

mixture (for cold-cuts, sausages, frankfurters, pâtés, etc.) or industrial food products (onions, potatoes, carrots,

lettuce, etc.). The presentation of the nal product is optimal since the mixture is never crushed, bruised, or

drained. The meat should be de boned and precut before being introduced into the bowl for chopping. Use

only those prime materials adequate for alimentary purposes. The manufacturer assumes no liability if the

machine is used in any way that conicts with the application for which the cutter/chopper was designed.

The temperature of the mixture is constantly monitored by a digital thermometer (Fig. 1 No. 2). The cutter’s/

chopper’s two (three in the case of machines with the mixing option) high-powered, self-ventilating motors

guarantee perfect functioning - whatever the temperature or consistency of the mixture - since the motors’

two speeds can be selected to produce four different cutting combinations. The possibility of operating the

motors individually helps adapt the cutting/chopping process to each user’s specic needs. Equipped with

thermal motor protection through thermal relays. The cutter/chopper has an automatic knife-stop feature

which is activated by lifting the lid. The cutting head can be removed from the machine in one piece for

replacement or cleaning. The six-knife grouping allows for perfect and homogeneous blending and up to 21600

cuts per minute (25800 in 60 Hz models). The size of the pieces varies depending on how long the mixture

is processed. The digital bowl-turn counter allows for perfect control over the appearance and quality of the

nal product. Hermetically sealed control panel and touch-button control at 24V (low voltage for safety). The

machine’s stainless steel construction and functional, modern design with no difcult-to-reach corners greatly

facilitates the cleaning of the cutter/chopper. The lower part of the machine is closed to prevent the entry

of water or dirt and is held by four anti-vibration legs; this facilitates both cleaning and transportation. The

bowl, made in solid all-stainless steel, is protected by a frontal safety guard. The knife cover, with its assisted

opening mechanism, can be lifted and lowered without excessive effort. The anti-noise bowl lid, made in a

single piece of transparent plastic, allows for ample visibility of the product. This lid is equipped with a device

which automatically lowers the knife speed when the lid is opened in order to avoid high noise levels which

could be harmful to the user. The 80L can be supplied with an optional motorized extracting arm to permit easy

and fast emptying of the bowl.

6

Page 7

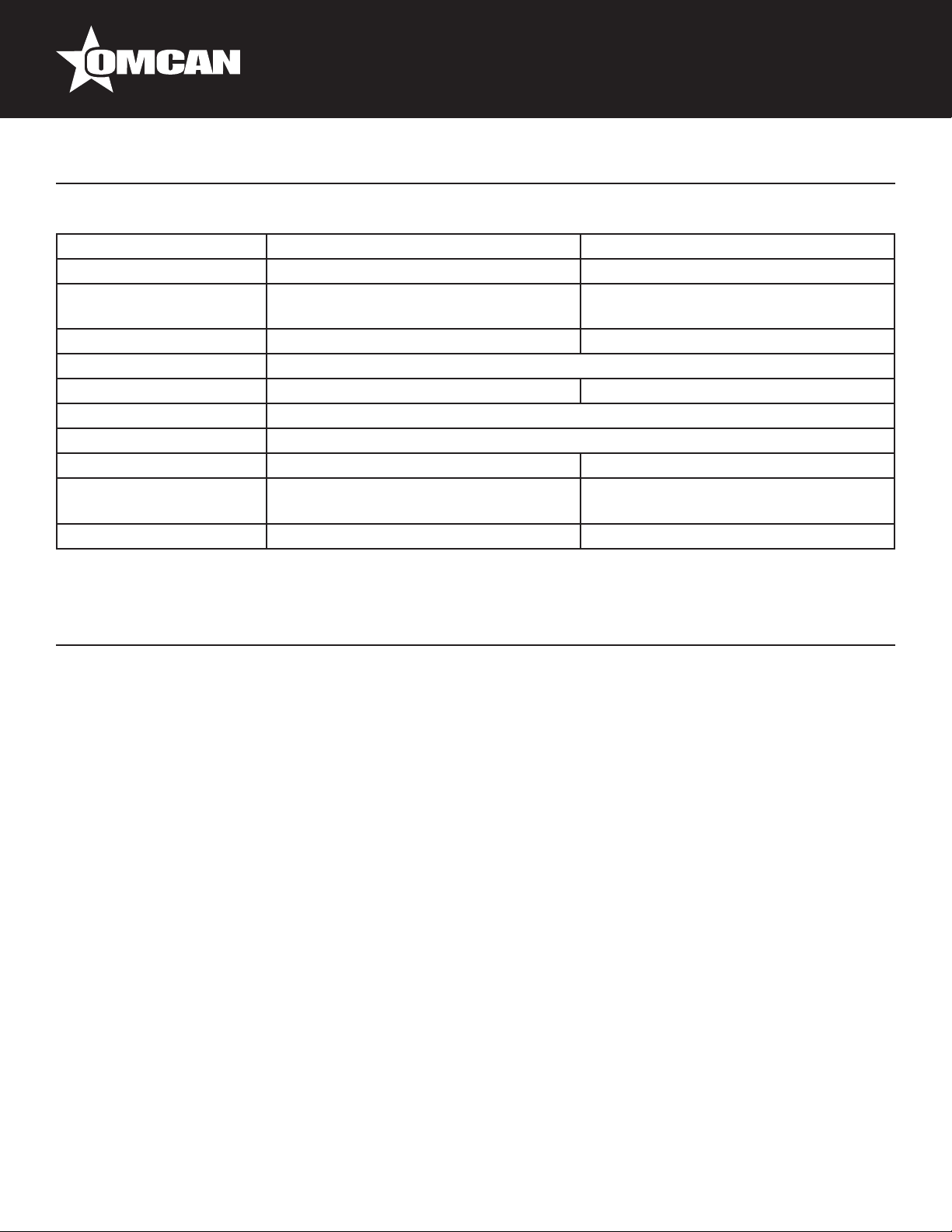

Technical Specications

Model FP-ES-0050 FP-ES-0080

Bowl Volume 50 L / 13 Gal 80 L / 21 Gal

Approx. Mixture Bowl

Capacity

Knife Horsepower 12 / 15 HP 14.3 / 20.4 HP

Knife Speed 2200 / 4300 RPM

Bowl Horsepower 0.7 / 1.5 HP 2 / 3.4 HP

Bowl Speed 11 / 21 RPM

Electrical 220V/60/3

Weight 1322.75 lbs. / 600 kgs. 2425 lbs. / 1100 kgs.

Dimensions

Item Number 10879 10880

81.5 lbs. / 37 kgs. 143.3 lbs. / 65 kgs.

46.4” x 49.2” x 47.2”

1179 x 1250 x 1199mm

57” x 82.3” x 50”

1448 x 2090 x 1270mm

Installation

STORAGE, TRANSPORT, AND DELIVERY

Always maintain the machine and its packaging in a vertical, upright position. Never pile machines one on

top of the other, nor put any weight on the machine or its packaging. Since the units are voluminous, if more

than one machine is to be stored or transported, make sure there is enough free space for proper storage

and/or transport. The transport company assumes sole responsibility for any damage received in transit;

make sure that the machine is in proper condition upon its delivery. If, after the proper checks have been

undertaken, the condition of the machine is judged to be satisfactory, proceed by installing it in a previously

selected workspace. Because of its weight (approx. 600 kg/50L, 1087 kg/80L), the machine should always be

moved with a pallet mover or forklift, making sure that the blades of the forklift are inserted properly under the

lower part of the machine. Never use the knife shaft holder to lift the machine since this could lead to serious

damage of both the holder and the shaft (Fig. 6). The machine is delivered in protective packaging consisting

of a wooden crate; please recycle this packaging. The total contents of the packaging is as follows:

• The cutter/chopper with 6-knife head installed.

• 2 wrenches for the assembly and dismantling of the knives (one double and one single).

• 4 supplementary rings to allow for use of the machine with just 3 knives.

• Instruction manual.

• Document of CE-conformity for units sent to countries within the EU and those belonging to the CEN.

The machine should only be installed by a qualied technician and in compliance with local codes. The

electrical installation of the workplace should be equipped with power surge protection, which should then be

adjusted to the technical specications of your particular machine (see number 3, below).

7

Page 8

Installation

1. Set the machine on a horizontal surface, leaving one meter’s space around the entire perimeter of the

machine in order to allow for safe and proper use, cleaning, and maintenance. The machine should be

positioned so that the plug is easily accessible. Also make sure that the work place has both sufcient

ventilation and good lighting.

2. Make sure that the electrical data given on the machine’s specications plate (voltage, frequency, etc.

are compatible with those of the power source (there is a tolerance of ±10% for voltage and ±2% for

frequency). The 50L/80L cutter is a three-phase machine with a single voltage only; therefore, it is not

possible to change the voltage of the motors. The machine’s electrical feed cable/plug normally has

4 wires: 1 grounding (two-color yellow and green), and 3 phases (either 3 black wires or 1 black wire,

1 brown wire and 1 gray wire). This color-coding may vary depending on the norms of the country to

which the machine has been shipped. The 50L/80L cutters/choppers are machines with elevated energy

consumption; therefore, it is necessary to install an auxiliary fuse board equipped with a magnetometer and

a differential. It is advisable to make monthly checks to ensure that the differential is functioning properly;

this can be done by pushing the test button. It is possible to install a lock on the main switch to eliminate

the possibility of machine being switched on accidentally or in an unplanned fashion.

3. Before connecting the machine, use the wrenches provided to ensure that the knife grouping is properly

tightened (Fig. 4). Tighten the knife grouping with the utmost care to avoid injury from accidentally hitting

the cutting head or the knives themselves.

4. After verifying that the electrical specications are compatible with your power source, plug the machine in

and activate the main switch, making sure that the switchboard indicators (thermometer and turn counter)

light up. Remember that the plug must be appropriate for use with this type of machine.

5. With the cover open, press rst the red mushroom-shaped stop button, and then the brake release button

(see Fig. 1 No. 1), which will release the knife block. With the brake release button depressed, turn the

knives using a plastic bar long enough to be able to reach the knives while remaining a safe distance from

them. Make sure the knives do not touch the bowl as they turn. To make sure that the knives do not rub

against the lid, repeat the aforementioned steps with the lid closed. The machine is now ready to use.

IMPORTANT

Verify the proper turning direction of the knives and the bowl as follows: disengage the red mushroom-shaped

emergency stop button by turning it a few degrees to the right and then pushing the “I-Start” button. The

machine will begin to work and the bowl will start to turn counterclockwise. If the bowl turns in a clockwise

direction, stop the machine immediately and switch 2 of the 3 phases at the power source.

Operation

Before operating the cutter, clean the machine carefully, following the instructions found below in

MAINTENANCE section.

Close the two lids one after the other (steel, then plastic). Be careful not to trap your hand under either lid

in this process. Disengage the red emergency stop button by turning it a few degrees to the right. Push the

“I-Start” button (low knife speed) located on the right of the control panel. The knives and the bowl will begin

8

Page 9

Operation

to turn. The knives and the bowl each have two buttons to select either the rst (low) or second (high) speed.

Please note the following:

• Always start the machine at the rst (low) knife speed.

• The knives and bowl turn in a synchronized fashion; it is not possible for them to turn independently from

one another.

From the rst (low) knife speed it is possible to select the second (high) speed and then return to the rst (low)

speed again (1st-2nd-1st speed sequence). Do not overload the bowl; the mixture should not rise above the

bowl’s rim. Do not rest mixture containers on the edge of the bowl or on the safety guard as this could cause

accidents or mechanical damage. Use extreme caution when adding or removing the mixture; do not put

your hands near the knives or reach into the bowl. If necessary, use ice chips to lower the temperature of the

mixture. Do not use cubes or blocks of ice as these could damage the knife edge. Never reach into the bowl

with your hands or arms while the cutter/chopper is running. Never put your hands under the stainless steel lid.

Eliminate any possibility of having your hands, clothing or other personal effects trapped by or dragged under

either of the lids or into the machine. The anti-noise lid is equipped with a device which automatically lowers

the knife speed from high to low when the lid is opened in order to minimize noise levels which might otherwise

be harmful to the user. To stop the machine completely, press the red stop button. The knives and bowl will

stop moving. The red emergency stop button should only be used either to stop the machine in emergencies

or disengage the knife brake; it should never be used to stop the machine under normal conditions. Wait until

the bowl and knives have stopped completely before opening the knife lid. To disengage the knife brake for

adjustment or cleaning, rst press the red emergency button and then the black brake release button. With

the black button pressed down, the knives can be turned with the help of a bar made of a pliant material. In

the case of a sudden drop in electrical current, the knife brake will engage automatically, instantly stopping the

knives from turning. This machine is not designed to withstand permanent, uninterrupted use, but rather to run

intermittently with pauses to allow for the dissipation of built-up heat, the amount of which will vary depending

on the consistency of the mixture. When nished using the machine, turn it off completely by turning the main

switch to the “0” position.

SLOW SPEED MIXING OPTION

Starting in the “Stop” position with the machine completely stopped, proceed as follows:

• Press either of the two mixing buttons located on the lower part of the control panel (Fig. 1 No. 7-8). The

knives will begin to turn slowly.

• Each mixing button changes the turning direction of the knives.

• To stop the mixing function, press the red mixing-stop button located on the lower left of the control panel

(Fig. 1 No. 9).

MOTORIZED EMPTYING ARM OPTION

Before removing the mixture from the bowl using the motorized arm, you should rst make sure that there are

adequate receptacles for the mixture at the ready near the emptying pan outlet. Then open the plastic anti-

noise cover. The cutter must be running to use the emptying arm. If possible, select one of the slow speeds

from the mixing option (Fig. 1 No. 7-8); if your machine does not have mixing capability, run the cutter at knife

9

Page 10

Operation

speed 1 (slow). In addition, select bowl speed 1 (slow). Lower the emptying arm by pulling down on its front

handle; the motorized disk will automatically start to function. When lowering the arm, take care not to crush

anything with the arm or its hinge. Grasping the arm rmly, insert the turning disk slowly into the mixture,

adjusting it to obtain the appropriate emptying ow. Make sure to periodically check the receptacle being lled

to avoid overow. To stop, raise the emptying arm to its initial vertical position; the motorized disk will stop

turning. To facilitate cleaning, the emptying pan can be dismantled easily by loosening the 2 knobs located on

its lower side and pulling the pan up. Similarly, to clean the area between the side plate and the extracting disk,

remove the side plate by loosening the knob on its upper surface.

Maintenance

CLEANING

Always turn the machine off before cleaning it. To do this, deactivate the auxiliary fuse-board switch and turn

off the machine’s main operating switch. If possible, disconnect the machine from the power source as well.

The machine should be cleaned daily, both before and after its use. Given the easy access to all its

components, the TALSA cutter/chopper is simple to clean using just warm water and a mild detergent. Never

use bleach nor any abrasive cleaners which could damage the stainless steel or other materials. Never use

steam or a high pressure jet of water to clean the cutter/chopper; avoid getting water in the interior of the

machine, especially through or around any electrical components. After every operating session, use a brush

to carefully clean the knife-head assembly, the bowl, the safety guard, the knife shaft and bushing gasket, the

interior part of the knife cover, the plastic lid, the hinge of the lid, and if necessary the lid holding screws.

IMPORTANT: THE KNIFE HEAD MUST BE REMOVED IN ONE PIECE (Fig. 5) AFTER EVER WORK DAY so

that it can be cleaned thoroughly under running water. Be extremely careful not cut yourself or drop the knife

assembly to the oor or on your feet. The area of the knife-bushing gasket must also be thoroughly cleaned.

Do not put your hands near the cutting edge of the knives without using adequate protection (gloves made of

reinforced metal ber). Do not wash the knives in water hotter than 60°C or colder than 10°C. Do not wash the

knives immediately after using the machine since a brusque change in temperature could cause internal micro

ssures or deformations. It is extremely important to keep the surfaces holding the knives and separation rings

clean to avoid build-up of mixture residue. Such a build-up could create areas which support more pressure

than others, possibly causing micro ssures that could damage or break the knife. To clean the machine

manually, always use appropriate safety equipment (latex gloves, plastic aprons, etc.). Always rinse the

machine thoroughly after using any kind of detergent or disinfectant and be sure to follow the manufacturers’

instructions when using such cleaning products.

10

Page 11

Maintenance

Interval Cleaning Area Method Product Tools Observations

Daily Bowl, safety guard,

knife shaft, interior

of main lid, plastic

lid, knives and knife

head

Fortnightly Bowl holder and

surrounding area

Except for daily cleaning, the only maintenance required by the 50L-80L chopper is the changing of the

transmission belts after every 2,500 hours of operation. The belts used are as follows:

• 50L: 3 units of type SPAX-1832 (for all models) and additionally 2 units of the type SPAX-900 (models with

mixing option only).

• 80L: 3 units of type B-1900-MC (for all models) and additionally 2 units of the type B-1060-MC (models with

mixing option only).

If the electrical cord becomes damaged, have it replaced immediately with a cord of identical technical

characteristics (your local distributor can supply you with one). Before undertaking any maintenance or repair

work in the machine’s interior, be sure to open the knife lid to release the pressure on the pneumatic springs.

All mechanical or electrical repairs should be undertaken only by a qualied specialist with proper training for

the work required.

Manual Mild detergent,

hot water

Manual Mild detergent,

hot water

Sponge, cloth IMPORTANT: Remove

the knife head to facilitate

cleaning. Clean lid hinge

completely and, if necessary,

clean lid holding screws with

a brush.

Sponge, cloth

DISMANTLING THE CUTTING HEAD

REMOVING THE WHOLE HEAD

In order to proceed with the cleaning or replacement of the cutting head while maintaining the settings of the

existing knives, the cutting head can be removed in one piece. Proceed as follows: Disconnect the machine by

turning off the main switch; for added safety, turn off the isolating switch in the main fuse board and, if possible,

unplug the machine. Never touch the knife-edge with your hands. Always use gloves made of metallic netting.

With the wrenches provided, unscrew the cap nut at the end of the knife shaft in a CLOCKWISE direction

(Fig. 4 - step 1). Pull the entire assembly towards the left until you have separated it from the shaft (Fig. 5). If

necessary, hit the base of the knife holder several times with a plastic mallet to remove it; never hit the knives

themselves with any instrument or tool. To reassemble the cutting head, repeat the dismantling operations in

reverse order, taking into account the assembly recommendations listed in section below.

DISMANTLING THE KNIVES SEPARATELY

In order to remove the knives separately while leaving the knife-head assembly attached to the shaft, proceed

as follows:

• Disconnect the machine by turning off the main switch; for added safety, turn off the isolating switch in the

11

Page 12

Maintenance

main fuse board and, if possible, unplug the machine.

• Never touch the knife-edge with your hands. Always use gloves made of metallic netting.

• With the wrenches provided unscrew the cap nut at the end of the knife shaft in a CLOCKWISE direction

(Fig. 4).

• With the same wrenches, but using two sides of the same width, unscrew (also in a CLOCKWISE direction)

and remove the knife xing nut ring.

• Remove the knives and the compensating rings separately, remembering rst to make a note of their

proper order and position (Fig. 2).

• To reassemble the knife head, repeat the dismantling operations in reverse order, making sure of the

following: The xing nut for the knife grouping is not tightened completely until the knives have been turned

(with the help of a bar made of a pliant material) to ensure that the knives do not touch or rub against the

bowl or the lid.

• Adjust each knife so that there is a 2-3 mm space between it and the bowl (Fig. 3). For this adjustment

we recommend using a space gauge made of a pliant material (cardboard, cork, etc.) to follow the path

marked by the end of each knife and a plastic mallet to adjust the knives accordingly.

• For safety reasons, do not try to leave a space of 0 mm between the knives and the bowl since the strong

vibrations which result under certain operating conditions could cause one or more of the knives to make

contact with the bowl.

• The knives are equipped with a ange which functions as a knife stop. During installation, this ange

should stay in contact with the knife holder.

SHARPENING THE KNIVES

If the quality of the cutting/chopping should noticeably diminish, the knives should be sharpened by a qualied

professional, paying special attention to maintaining the length and weight of each of the knives in a given

group or head. The knives should only be sharpened by an expert specialized in the sharpening of tempered

knives. Before sharpening the knives, consider whether the resulting reduction in size will be substantial

enough to warrant the installation of completely new knives. In principle, the knife-edge should not be reduced

more than 1 cm from its original size. Once the knives have been sharpened, before reinstalling them in

the machine, a small space should be led from the stop ange located in the hexagonal area (Fig. 3) to

compensate for any possible shortening of the knives. To clean the knife surfaces, use a product with anticorrosive properties. Always store the knives in their packaging; this will help maintain the cutting edge and it

will protect them from any accidental bumps or friction. Always transport the knives in their packaging when

possible. To adjust or move the knives always use adequate safety precautions and equipment.

12

Page 13

Troubleshooting

Problem Possible Causes Solution

Machine does not work. Machine is not connected to the

power source.

The main switch is in the 0-Stop

position.

No voltage in one or more phases. Check the fuses, plugs and

Machine is connected to power

source but knives do not turn.

Bowl turns in the wrong direction. The phases are reversed. Switch 2 of the 3 phases in the

2nd knife speed (fast) does not

work.

The stainless steel lid is not

closed.

The red emergency stop button is

pressed down.

One of thermal relays has blown. Let the machine cool down for a few

The plastic anti-noise lid is open. Close the plastic lid and press the

Connect the machine to the power

source.

Turn the switch to the I-On position.

switches.

Close the stainless steel lid.

Disengage the emergency stop

button.

minutes, then switch it back on.

power source connection.

2nd life speed (fast) button.

REFERENCE

Item Number Model Number Description Manufacturer Model Number

Bowl Cutter 50L / 52QT 2200-4300RPM

10879 FP-ES-0050

10880 FP-ES-0080

12-15HP / 8948-11185W Knife (0.7-1.5HP

/ 522-1119W Bowl) 220V/60/3

Bowl Cutter 80L / 84QT 2200-4300RPM

14.3-20.4HP / 10664-15212W Knife (2-

3.4HP / 1491-2535W Bowl) 220V/60/3

K50

K80V

13

Page 14

Illustrated Diagrams

Main Components

Knives

Lid

Anti-noise

Cover

Frontal Bowl

Protector

Control

Board

Motor Access

Panel

Lid Lever

Electric Switchboard Access

Panel

Electric Main

Cord

Anti-vibration

Legs

Main Switch

Bowl

Base

14

Page 15

Fig. 1

Illustrated Diagrams

No. Description No. Description No. Description No. Description

1 Emergency Stop

Button.

2 Display. 5 Bowl Speed 2. 8 Mixing Rotation

3 Knife Speed 1. 6 Bowl Speed 1. 9 Mixer Stop Button.

4 Knife Speed 2. 7 Mixing Rotation

Clockwise.

Counter

Clockwise.

10 Knife Brake

Release.

11 Stop Button.

15

Page 16

Illustrated Diagrams17Illustrated Diagrams

16

Page 17

• Knives loosening

procedure

Page 18

Parts Breakdown

Model FP-ES-0050 10879

Model FP-ES-0080 10880

18

Page 19

Model FP-ES-0050 10879

Model FP-ES-0080 10880

Parts Breakdown

19

Page 20

Parts Breakdown

Model FP-ES-0050 10879

Model FP-ES-0080 10880

Item No. Description Position Item No. Description Position Item No. Description Position

36222

36223

76731

62500 Internal Auxiliary Timer for K50, K80V K405 36255 Mixing Motor for K50, K80V K438 36286 Lower Hinge Plate for K50, K80V K470

76732 Thermal Relay for K50, K80V K406 62506 Machine Frame for K50, K80V K439 36287 Lower Hinge Nut for K50, K80V K471

76733 Bowl Motor Contactor for K50, K80V K407 36256 Main Switch for K50, K80V K440 36288 Body Hinge Lid Plastic for K50, K80V K472

76734 Auxiliary Contact Block for K50, K80V K408 36257 Main Switch for K50, K80V K440 36289 Shaft Hinge Lid Plastic for K50, K80V K473

76735 Fuse for K50, K80V K409 62507 Lower Cover for K50, K80V K441 36290 Stainless Steel Main Lid for K50, K80V K474

76736 Auxiliary Relay for K50, K80V K411 36258 Anti-Vibrating Foot for K50, K80V K442 36291 Lid-Bowl Friction Bar for K50, K80V K475

73737 Transformer for K50, K80V K412 36259 Bowl Motor for K50, K80V K443 62510 Emergency Button for K50, K80V K477

73738 Transformer for K50, K80V K412 36263 Bowl Gear Reducer for K50, K80V K447 76748

36236

36237 Shaft Knives Belt for K50, K80V K414 62365

36238 Shaft Knives Pulley for K50, K80V K415 36266 Knives Shaft Locking Ring for K50, K80V K450 62511

36239 Shaft Knives Ring for K50, K80V K416 36267 Knives Bearing for K50, K80V K451 36296

36240 Isolating Electric Box for K50, K80V K417 36268 Knives Shaft for K50, K80V K452 36297 Anti-Noise Lid for K50, K80V K486

36241 Lid Lever for Microswitch for K50, K80V K418 76746 Screw with Hole for K50, K80V K453 36298 Bowl Screw Cap for K50, K80V K487

62501 Bronze Bearing for K50, K80V K419 76746 Knives Shaft Holder for K50, K80V K454 36299 Bowl Central Screw for K50, K80V K488

62502 Threaded Rod for K50, K80V K420 36270 Knives Limit Ring for K50, K80V K455 36300 Bowl for K50, K80V K489

36242 Lid Gas Piston for K50, K80V K421 36271 Sensor Protector for K50, K80V K4556 36301 Bowl Guard Spacer for K50, K80V K490

36323 Lid Safety Microswitch for K50, K80V K422 36273 Small Ring Bowl for K50, K80V K457 36302 Bowl Frontal Guard for K50, K80V K491

36243 Pulley Shaft Motor for K50, K80V K424 36275 Bronze Bearing for K50, K80V K458 36303

62503 Motor Access Panel for K50, K80V K426 36276 Bowl Shaft Reducer for K50, K80V K459 62512 80L Bowl Bushing Gasket for K50, K80V K493

62504 Motor Access Panel Seal for K50, K80V K427 62508 Bowl Shaft Reducer Pin for K50, K80V K460 62513 80L Bowl Bearing for K50, K80V K494

36245

62505 Clutch Washer for K50, K80V K429 36278 Bronze Bearing for K50, K80V K462 62515 Ring Thermometer Probe for K50, K80V K533

36247 Anti-Folding Clutch Holder for K50, K80V K430 36279 Lid Column Holder for K50, K80V K463 62516

36248 Electromagnetic Clutch for K50, K80V K431 36280 Hexagonal Knives Holder for K50, K80V K464 62517 Cable Gland for K50, K80V K535

36249 Mixing Belt for K50, K80V K432 36281 Knives Spacer Ring for K50, K80V K465 62518 Anchorage Shaft Covers for K50, K80V K536

36250

36251 Belt Tension Lever for K50, K80V K434 36283 4 Cuts Knife for K50, K80V K466 62519 Bowl Shaft Washer for K50, K80V K538

Double Wrench Knife Disassembly for

K50, K80V

Single Wrench Knife Disassembly for

K50, K80V

Main Motor Knives Contactor for K50,

K80V

Shaft Knives Pulley Washer for K50,

K80V

Motor Knives Pulley Washer for K50,

K80V

Mixing Gear Reducer Pulley for K50,

K80V

K401 76742 Motor Platform for K50, K80V K435 36284 Locking Knives Nut for K50, K80V K467

K402 36252 Mixing Gear Reducer for K50, K80V K436 36285

K404 76743 Main Knives Motor for K50, K80V K437 62509 Thermometer Sensor for K50, K80V K469

K413 36264 Plastic Lid Safety Sensor for K50, K80V K448 36293 Emergency Button Body for K50, K80V K479

Knives Front Bushing Gasket for K50,

K80V

K428 36277 Squared Shaft Lid Folding for K50, K80V K461 62514

K433 36282 Knives Spacer Ring for K50, K80V K465 76749 Ring for Knife Motor for K50, K80V K537

K449 36295 Front Panel Board for K50, K80V K481

Nut Blocked Final Shaft Knives Counterclockwise Thread for K50, K80V

Digital Thermometer Display for K50,

K80V

Electric Switchboard Access Panel for

K50, K80V

Metal Detector Fixed On Lid for K50,

K80V

Pulley Front Bushing Gasket for K50,

K80V

80L Bowl Lower Bushing Gasket for

K50, K80V

Protection Tube Thermometer Sensor

for K50, K80V

K468

K478

K483

K485

K492

K495

K534

20

Page 21

Model FP-ES-0050 10879

Model FP-ES-0080 10880

Electrical Schematics

21

Page 22

Notes

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

22

Page 23

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

www.omcan.com/warrantyregistration.html

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

23

Page 24

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 3,500 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 3500

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 3,500 productos con origen a nivel mundial.

Loading...

Loading...